Page 1

GB

I

nstruction & Owners Manual

F

Manuel d’instructions et du propriétaire

D

Anleitungs- & Betriebshandbuch

N

Veiledning og Brukerhåndbok

S

B

ruksanvisning

Gebruiks- en bezittershandleiding

NL

5"Chipper/

Shredders

Models

70554s

71014s

Crary Company

Box 849

West Fargo, ND 58078

(701) 282-5520 (800) 247-7335

FAX: (701) 282-9522

71020s

Cat. No. 12261

Manual No. 498

Page 2

B

EARCAT

Dear Bear Cat Customer,

Thank you for purchasing a Crary Bear Cat Chipper/Shredder. The Bear

Cat Chipper/Shredder is designed, tested, and manufactured to give years

of dependable performance. To keep your chipper operating at peak

efficiency, it is necessary to adjust it correctly and make regular

inspections. The following pages will assist you in the operation and

maintenance of your machine. Please read and understand this manual

before operating the chipper.

If you have any questions or comments about this manual, please call us

toll-free at 1-800-247-7335.

If you have any questions or problems with your chipper, please call or

write your local factory-authorized Bear Cat dealer.

Please Send Us Your Warranty Card

A warranty card is included in your owner's kit packaged with your

chipper. Please take the time to fill in the information requested on the

card. When you send your completed card to us, we will register your

machine and start your coverage under our limited warranty.

How to

Contact

Bear Cat

A

DDRESS

Crary Bear Cat

237 NW 12th Street

PO Box 849

West Fargo, ND 58078

P

HONE

800-247-7335

701-282-5520

Fax: 701-282-9522

H

OURS

M-F, 8 a.m. to 5 p.m.

Central Time

Owner's Record

Please take a moment to record the following

information about your chipper. If you need to

call for assistance, please be ready to provide

your model and serial numbers. This

information will allow us (or your dealer) to

help you more quickly when you call.

Model Number

Serial Number

Serial Number Decal Location

Serial Number Decal

Page 3

W

ARRANTY

Chipper Limited Warranty

Crary Bearcat Chipper models 70554s, 71014s and 71020s are warranted for two years from date of

sale for consumers and 90 days from the date of sale for Commercial or Rental operations..

Within the above stated period, Crary Co. will replace any part(s) found to be defective in material and/

or workmanship, after the receipt of the part in our plant. Labor costs to replace these defective parts

will be paid at a Crary established labor rate and time allowed (flat rate) for repair. All transportation

charges incurred in shipping part(s) are the responsibility of the purchaser.

This warranty is void in the case of accidents, failure to perform normal maintenance, or failure to

follow those instructions listed in the service manual. This warranty is also in lieu of all other

expressed warranties and voids any implied warranty as to the merchantability or fitness of the product

for a particular purpose and of any other obligation on the part of Crary Co. Some states do not allow

limitations on how long the implied warranty lasts, so the above limitation may not apply to you.

This warranty applies only to parts or components which are defective, and does not cover necessary

repair due to normal wear, misuse, accidents, or lack of proper maintenance. This includes belts,

pulleys, and chipper blades. Regular routine maintenance of the unit to keep it in proper operating

condition is the responsibility of the owner.

All warranty repair reimbursable under the Crary Co. warranty must be performed by an authorized

Bearcat service dealer using Bearcat approved replacement parts. Repair or attempted repair by anyone

other than an authorized Bearcat service dealer is not reimbursable under the Crary Co. warranty. In

addition, these unauthorized repair attempts may result in additional malfunction, the correction of

which is not covered by warranty.

Crary Co. is not liable for indirect, incidental, or consequential damages in connection with the use of

this product including any cost or expense or providing substitute equipment or service during periods

of malfunction or non-use.

Some states do not allow the exclusion of incidental or consequential damages, so the above exclusion

may not apply to you. This warranty gives you specific legal rights. You may also have other rights

which vary from state to state.

Be sure to note the Chipper serial number in any correspondence with Crary Co. or any authorized

Bearcat dealer. The serial number is located on the rotor assembly cover.

Warranty

Page 4

Contents

Section 1: Safety Instructions.................................2

1.2 Safety Decals................................................................................. 4

Section 2: Assembly, Controls, and Operation.....6

2.1 Assembly....................................................................................... 6

2.1.1 Towable Models .............................................................................. 6

2.1.2 PTO Models .....................................................................................6

2.2 Controls ......................................................................................... 7

2.2.1 Engine Models ................................................................................ 7

2.2.2 PTO Models .....................................................................................7

2.3 Operation ....................................................................................... 8

2.3.1 Starting Towable Models ................................................................ 8

2.3.2 Setup: PTO Models .........................................................................8

2.3.3 Chipping and Shredding (All Models) ...........................................9

2.3.4 Stopping Engine Models ................................................................9

2.3.5 Stopping PTO Model....................................................................... 9

Maintenance Chart ...............................................................................10

Section 3: Service and Maintenance ....................11

3.1 Sharpening Chipper Blades ............................................................11

3.1.1 Removing Chipping Blades .........................................................11

3.1.2 Chipping Blade Sharpening Tips ................................................11

3.1.3 Setting Chipping Blade Clearance ..............................................11

3.2 Replacing Shredder Knives ............................................................12

3.3 Clearing Plugged Rotor ..................................................................12

3.4 Replacing Drive Belts.....................................................................13

3.4.1 Engine Models .............................................................................. 13

3.4.2 PTO Models ...................................................................................13

3.5 Changing Discharge Screens .........................................................14

3.6 Trailer Service Tips ........................................................................14

3.7 Other Service Tips .........................................................................14

3.7.1 Engine Models .............................................................................. 14

3.7.2 PTO Models ...................................................................................14

C

ONTENTS

Troubleshooting.......................................................15

Service Accessories ................................................16

Section 4: Diagrams & Photographs ............... 17-20

Warranty ...................................................................21

1

Page 5

S

ECTION

1

Safety

Instructions

Your safety and the safety of others is very important.

We have provided important safety messages in this

manual and on the machine. Please read these

messages carefully.

A safety message alerts you to potential hazards that

could hurt you or others. Each safety message is

preceded by one of three words: DANGER,

WARNING, or CAUTION.

You WILL be KILLED or

DANGER

WARNING

CAUTION

SERIOUSLY HURT if you don't

follow instructions

You CAN be KILLED or

SERIOUSLY HURT if you don't

follow instructions.

You CAN be HURT if you don't

follow instructions.

2. Avoid wearing loose-fitting clothing. Never

operate this machine wearing loose clothing

particularly if it has drawstrings which could

wrap around or get caught in the machine.

3. Operate the machine only on a level surface. Do

not operate the machine on a paved, concrete, or

hard gravel surface. Operating on a hard surface

may cause discharged material to rebound and

kickback. It will also cause increased machine

vibration. Increased vibration may cause the

machine to move and will promote premature

wear of parts or loosening of fasteners.

4. Before starting the machine, visually check that

all screws, nuts, bolts, and other fasteners are

properly secured. Check all screws, nuts, bolts,

and other fasteners every 10 hours of operation

for proper tightness to insure everything is in

proper working condition.

Operation

1. Before starting the machine, make certain that

the cutting chamber is empty.

Before Operating

1. Become familiar with the owner's manual before

attempting to operate this equipment. See engine

owner's manual for additional safety information.

2. Do not allow children to operate this equipment.

3. Do not operate this equipment in the vicinity of

bystanders.

4. Carbon monoxide can be extremely dangerous in

enclosed areas; do not run the machine in an

enclosed area. The exhaust from the engine

contains carbon monoxide, which is colorless,

odorless, and tasteless.

5. Do not allow hands (or any part of body or clothing)

inside the feeding chamber, discharge chute, or near

any moving part.

6. Before inspecting or servicing any part of the

machine, shut off the engine, and make sure all

moving parts have come to a complete stop.

Preparation

1. Wear safety glasses at all times while operating

the machine. One pair of safety glasses is

provided with each chipper.

2. When feeding chipable material into the machine, be extremely careful to exclude pieces of

metal, rocks, bottles, cans, and other foreign

objects.

3. The shredder will aggressively pull material into

it. Once material is grabbed during feeding, let

go immediately and move away.

4. If the cutting mechanism strikes any foreign object

or if the machine should start making an unusual

noise or vibration, immediately shut off the engine,

and allow the machine to come to a complete stop.

After machine stops:

a) Inspect for damage.

b) Replace or repair any damaged parts.

c) Check for and tighten any loose parts.

5. Every 10 hours of operation, check the bolts on the

following for correct torque (75 ft. lbs.):

• Chipper rotor bearing

• Chipper blades (use 5/16" bolts. Tighten to 20 ft. lbs.)

Failure to maintain proper fastening torque (75 ft.

lbs.) on bolts for the components listed above may

result in severe damage to the chipper and/or

personal injury!

2

Page 6

S

ECTION

1

6. Do not allow processed material to build up in

the discharge area; this may prevent proper

discharge and can result in kickback of material

through the feed opening.

7. Do not attempt to operate the chipper with any of

the guards, deflectors, or shrouds removed. Keep

away from moving parts.

8. Keep all guards, deflectors, and shrouds in good

working condition.

9. Always stand clear of the discharge area when

operating this machine.

10. Keep your face and body back from the feed opening.

11. Do not overreach. Keep proper balance and footing

at all times.

12. Do not transport or move machine while the machine is running.

13. If the machine becomes clogged, shut off engine.

Allow machine to come to a complete stop before

clearing debris.

14. On electric start models, disconnect cables from

battery before doing any inspection or service.

15. Do not tamper with the engine governor settings on

engine models; the governor controls the maximum

safe operating speed and protects the engine and all

moving parts from damage caused by over-speed.

Additional Safety Rules for

Towable Models

1. Always connect hitch safety chains. Make sure

trailer hitch bolts are tight and secure. Do not

attempt to tow the trailer if vehicle is not equipped

with a 2" ball.

2. Maximum towing speed should not exceed 55

M.P.H. Inflate tires to manufacturer's specifications

as stated on the tire sidewall. Check wheel lug bolts

periodically to be sure they are tight and secure.

3. Make sure that the jack stand on trailer is in the UP

position to clear the ground during towing. Place

the jack stand on a level surface and secure it in the

DOWN position before use.

4. Shut off fuel supply to engine when towing.

5. Disconnect spark plug wire when towing.

Maintenance and Storage

(Towable Models)

1. When this equipment is stopped for servicing,

inspection, storage, or to change an accessory, make

sure that the spark plug is disconnected.

2. Store the machine out of the reach of children and

where fuel vapors will not reach an open flame or

spark. For storage periods of three months or more,

drain the fuel and dispose of it in a safe manner.

Always allow the machine to cool before storing.

Additional Safety Rules for PTO

Models

1. Connect 3 pt. hitch pins and snap pins, connect

P.T.O. shaft and have leg stands secured in DOWN

position when in use.

2. To move unit: Shut off P.T.O., lift 3 pt. hitch, and

adjust leg stands if needed.

3. Keep guards and shields in place at all times while

operating. Always disengage the tractor P.T.O and

shut off the engine before removing guards or shields.

4. Keep hands, feet, and clothing away from all P.T.O.

drive parts.

5. Never clean, lubricate, or adjust the chipper/shredder when it is running.

6. Clothing worn by operator must be fairly tight.

Never wear loose clothing or clothing with draw

strings when working around P.T.O.

7. Before starting the tractor, always make sure the transmission is in neutral or park and P.T.O is disengaged.

Note: This machine is designed to operate with

P.T.O. ratings from 15 to 30 H.P. Use of P.T.O

ratings above 30 H.P. may cause belt and machine

damage in overload conditions.

Maintenance and Storage (PTO

Models)

1. When this equipment is stopped for servicing,

inspection, storage, or to change an accessory, make

sure to disengage the P.T.O. and shut off the tractor

engine.

2. Store the machine out of the reach of children. For

storage periods of three months or more, clean the

machine thoroughly and store in a dry area.

3

Page 7

S

ECTION

1

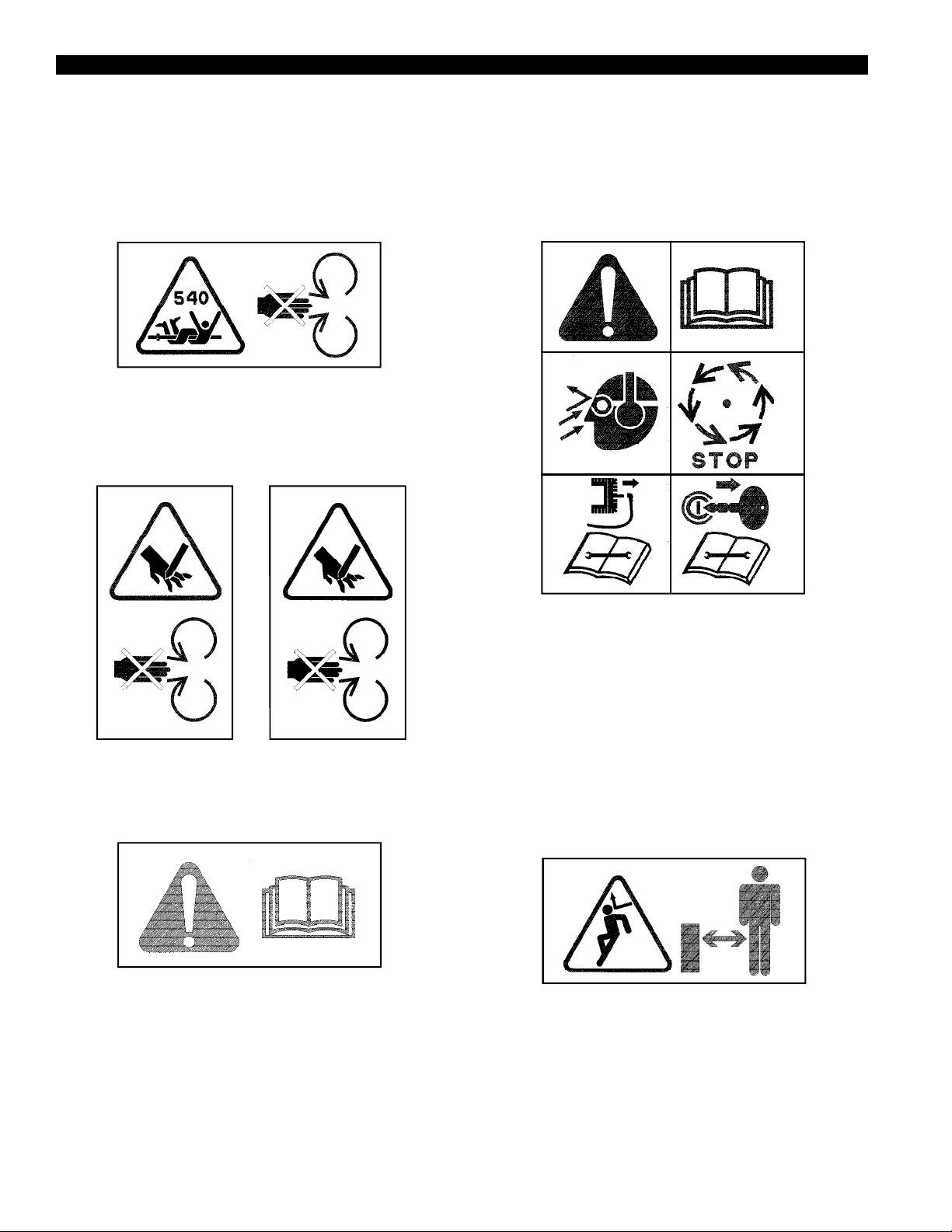

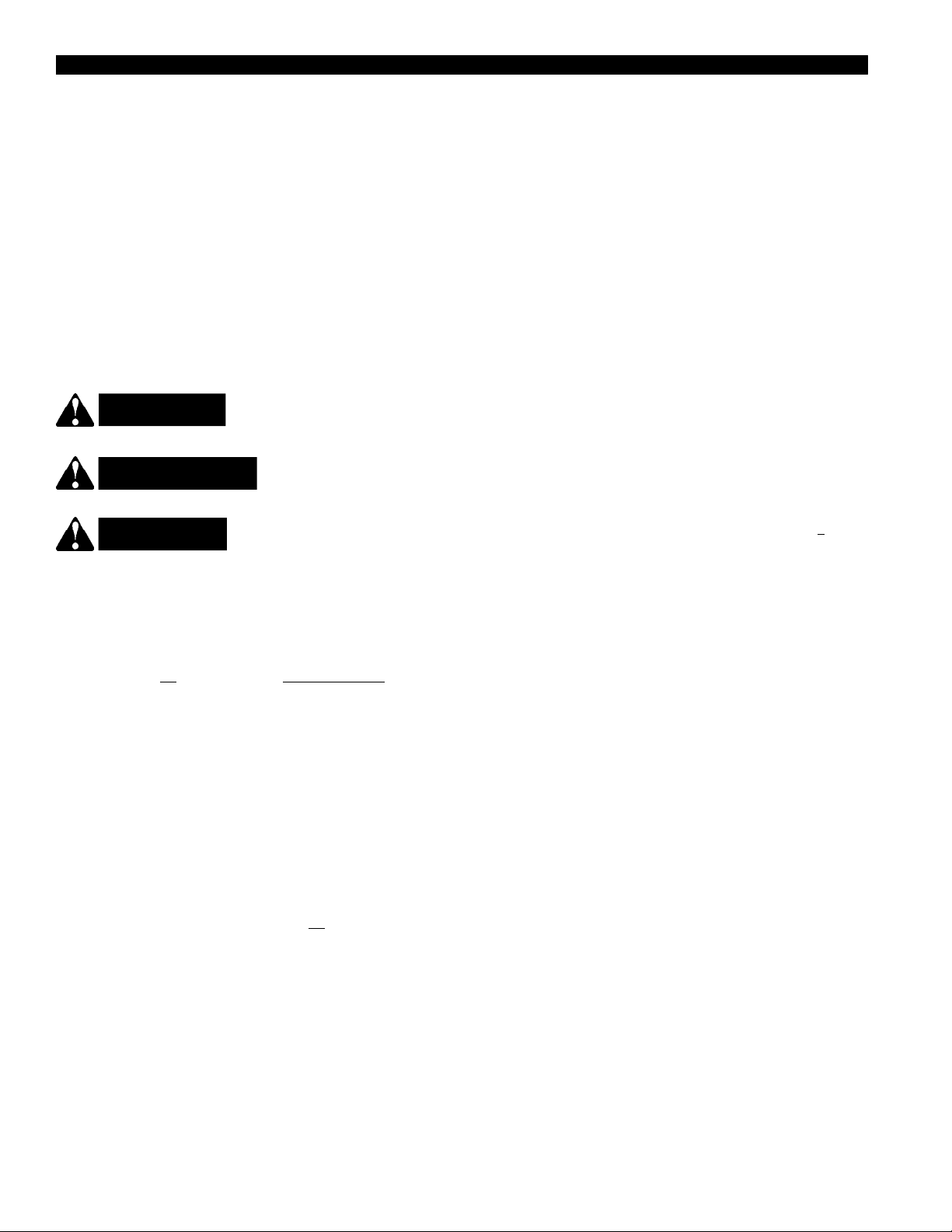

1.2 Safety Decals

Safety and instruction decals are located on the chipper frame and engine. Replace any decal that is damaged or

unreadable. For location of safety decals on the chipper frame, see parts drawings and lists in section 4.

Note: For engine safety and instruction decals, see engine owner's manual or contact the engine manufacturer.

12168

Keep hands, feet and body away from driveshaft while

machine is operating to avoid entanglement. Operate

machine at a 540 PRM input speed.

12169

12171

Keep hands and feet out of inlet and discharge openings

while machine is operating to avoid injury.

12172

1

3

5 6

2

4

Panel 1 - Attention

Panel 2 - Read and become familiar with the Owner's

manual before operating this machine.

Panel 3 - Wear proper eye and ear protection while

operating this machine.

Panel 4 -Stop machine and allow all parts to come to a

complete stop before cleaning, making

adjustments or servicing machine.

Panel 5 and 6 - Stop engine and remove spark plug wire

or key before cleaning, making adjustments or

servicing machine.

12170

Read and become familiar with the Owner's manual

before operating this machine.

4

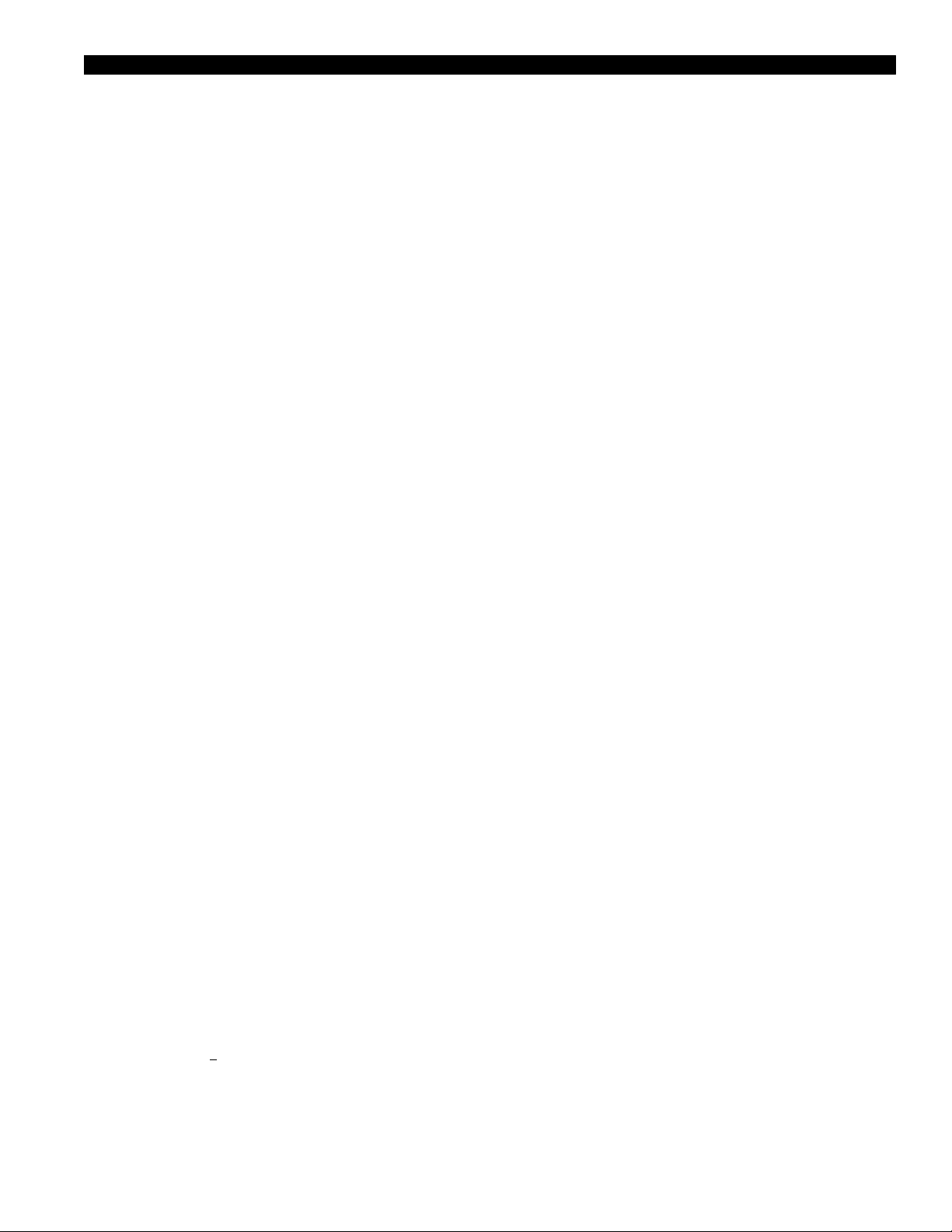

12173

Keep away from discharge opening while machine is

operating. Point discharge away from bystanders or

anything that could be damaged by flying debris.

Page 8

S

ECTION

1

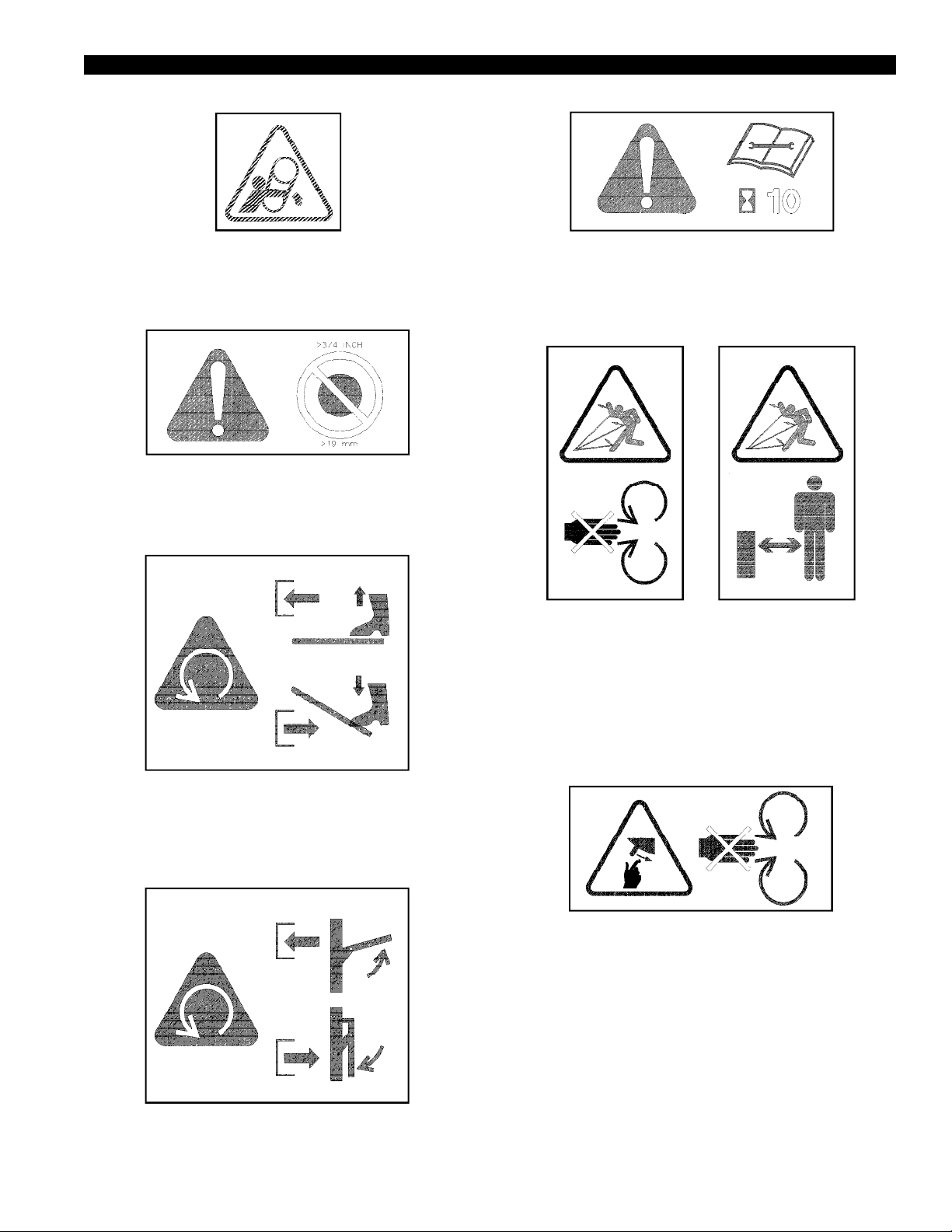

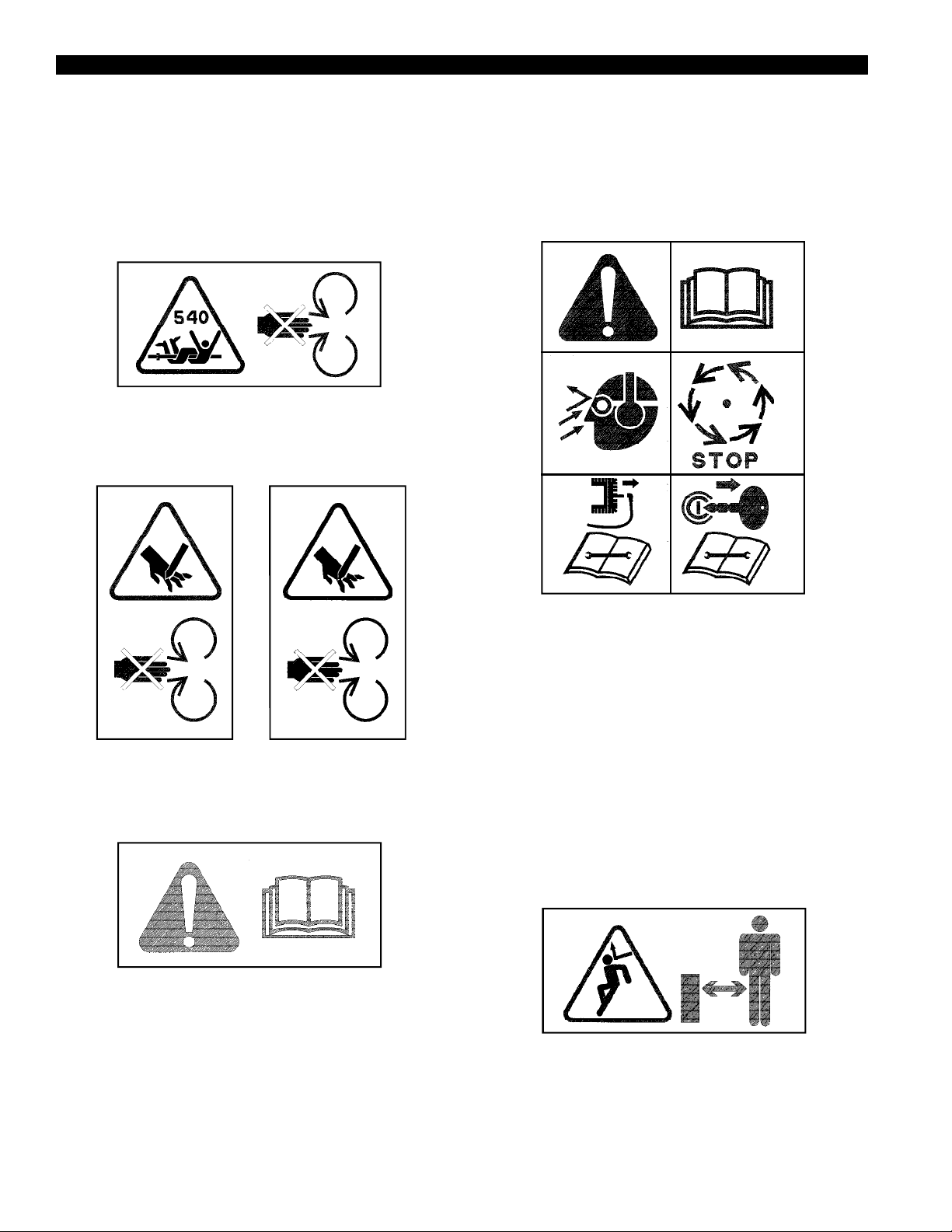

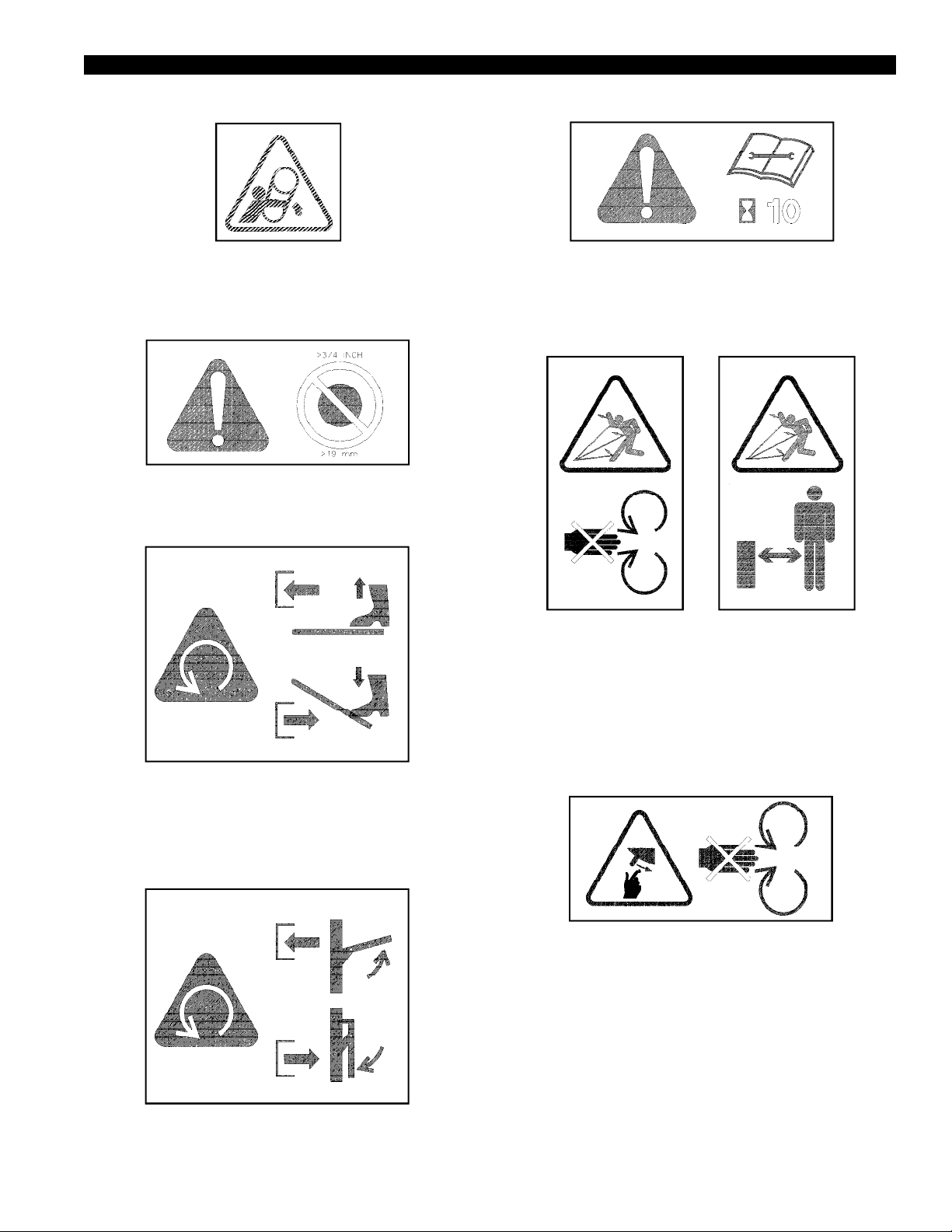

12174

Keep hands and other body parts from rotating parts.

Replace shields before operating machine.

12176

Do not put material larger than 3/4 inch (19mm) in

diameter into machine shredder.

12183

12250

Check chipper blade, anvil and feed roller bolt for proper

torque after every 10 hours of operation. Refer to Owner's

Manual for instructions.

12251 12252

Press clutch pedal down with foot to disengage clutch

while starting engine. Slowly release foot to engage

chipper clutch after engine is running.

12184

Keep away from

uncovered discharge

opening while machine is

operating. Do not operate

Keep bystanders away

from front of machine

while operating. Avoid

injury from flying debris.

machine without

discharge bag or

container in place.

12254

Keep hands, feet and all body parts away from cutters

while operating to avoid serious injury.

Raise lever slowly to engage chipper/shredder clutch after

engine is running. Push lever down to disengage clutch.

5

Page 9

S

ECTION

2

Assembly,

Controls, and

Operation

2.1 Assembly

2.1.1 Towable Models

1. Remove from crate.

2. Install the bolt-on hopper assembly using (11) 5/16"

x 3/4" bolts, washers, and locknuts. Insert the bolts

and washers from the outside of the hopper to the

inside. Secure the bolts with washers and locknuts.

3. Attach the rims and tires to the trailer frame, using

the wheel bolts supplied.

4. Using three 5/16" x 1" bolts, six 5/16" washers, and

three 5/16" nylock nuts, attach the chipper chuteside fender to the existing fender bracket mounted

on the trailer. Use washers under the bolt heads and

above the nuts. Torque the bolts to 20 ft. lbs.

2.1.2 PTO Models

1. Remove from crate.

2. Install the bolt-on hopper assembly using (11)

5/16" x 3/4" bolts, washers, and locknuts. Insert

the bolts and washers from outside the hopper.

Secure the bolts with washers and locknuts.

3. Connect the P.T.O shaft female end to male end

already attached to the chipper/shredder.

4. Mount the chipper/shredder to the tractor 3 pt. hitch

and connect the P.T.O shaft.

WARNING! Use extreme care when

operating the P.T.O. Stay clear from all

moving drive shafts. Always disengage the

P.T.O. and shut the tractor engine off when working

on the machine.

5. Adjust the leg stands so that the P.T.O drive shaft

runs as straight as possible (see figure 4-1, pg

18). The P.T.O shaft angle should not exceed 7

degrees (plus or minus). The maximum distance

between the chipper/shredder and the tractor

should not exceed 22-1/2 inches (see figure 4-2,

pg 17).

5. Using three 5/16" washers and three 5/16" nylock

nuts, attach the left side fender to the large belt

guard. There are three weld stubs on the belt guard

to attach the fender. Torque the nuts to 20 ft. lbs.

6. Install the trailer hitch under the trailer frame with

three 3/8" bolts, washers, and nuts. Tighten to 25 ft.

lbs.

7. Add oil to the engine. See engine manual for engine

oil specs and amount.

8. Place the 12 volt battery (not supplied) on the tray

attached to the hitch assembly.

Note: Use group U1, 12 volt, 32 amp battery with 250

cold cranking amps.

9. Attach the black cable to the negative battery

terminal and the red cable to the positive battery

terminal. Secure the battery with the angle and bolts

supplied.

10. Connect the spark plug wire to the spark plug.

Torque Chart

Standard minimum tightening

torque for normal assembly

applications.

Bolts (SAE GR5)

Size Ft. Lbs.

5/16" 20

3/8" 35

Screws

Size Ft. Lbs.

5/16" Set 15

#10-24 Set 3

6

Page 10

S

ECTION

2

2.2 Controls

2.2.1. Engine Models (See figure 4-3,

pg. 17)

1. Engine Throttle (20 hp Kohler): Changes

engine speed. Turn knob clockwise for full

throttle operation. Turn knob counter clockwise

for idle on warm up. Turn knob fully counter

clockwise to shut engine off. Refer to engine

manual for further engine operating instructions.

Engine Throttle (14 hp Kohler): Changes

engine speed. Pull lever up for full throttle

operation. Push lever down for idle on warm up.

Push lever fully downward to shut engine off.

Refer to engine manual for further engine operating instructions.

2. Engine Choke: Use when starting cold engine.

Pull to "On" position when starting. Push lever to

"Off" position when engine is running. Refer to

manual for further engine operating instructions.

3. Key Switch: Located above recoil starter on

engine case. Activate starter switch and release as

soon as engine is running. Do not engage starter for

more than 10 seconds or damage could result.

4. Engine Fuel Tank: Use unleaded fuel. Do not

mix fuel with oil.

5. Trailer Hitch: Always use 2" ball and safety

chains.

12. Rotor Shaft End Cover: Covers rotor shaft end

bearing.

13. Foot Pedal: Use to engage rotor assembly drive

belt.

2.2.2. PTO Models (See figure 4-4,

pg. 18)

1. 3 Pt. Hitch Connections: Mounts chipper/

shredder to tractor 3 pt. hitch. Connect direct for

category 0 and 1. A bushing kit must be installed

on 3 pt. mount connections for category 2.

2. P.T.O Shaft: Connects chipper/shredder to

tractor P.T.O. shaft. Avoid drive line angles over

7 degrees (plus or minus) when unit is in use.

3. Drive Belt Shield: Never remove shield while

machine is running.

4. Shredder Hopper: Feed materials to be shredded through the hopper to the shredder.

5. Chipper Chute: Feed materials to be chipped

through the chute to the chipper blades.

6. Leg Stands: Adjust to allow proper drive shaft

angle. Never move machine unless legs clear the

ground.

7. Jack shaft: Used to adjust for correct belt

tension.

8. Rotor Access Cover: Used to remove chipper

blades and service rotor assembly.

6. Jack Stand: Always have in UP position and

clear from ground when moving. Place in

DOWN position on level surface. Lock jack in

place with snap pin before use.

7. Engine Drive Belt and Shield: Never remove

shield when machine is in use.

8. Shredder Hopper: Feed materials to be shredded through the hopper.

9. Chipper Chute: Feed materials to be chipped

through the chipper chute.

10. Discharge Opening Screen: Chips and shredded

material exit through the screen and opening.

11. Engine Battery: Not included. Use group U1,

12 volt, 32 amp battery with 250 cold cranking

amps.

Note: This machine is designed to operate with

P.T.O. horsepowers ranging from 15 to 30 H.P. Use

of P.T.O. horsepowers above 30 H.P. may cause belt

and machine damage in overload conditions.

7

Page 11

S

ECTION

2

2.3 Operation

Caution: The chipper/shredder rotor may

continue to rotate even with the engine

stopped. Do not attempt any repair or

adjustment until the entire machine has come to a

complete stop. Remove spark plug wire before

servicing. Never operate this machine without the

discharge screen in place.

2.3.1 Starting Towable Models

Caution: Move machine to a clear, level

area outdoors before starting. Do not

operate machine on a paved, concrete, or

gravel surface. Do not operate in the vicinity of

bystanders. Make sure cutting chamber is empty

before starting.

1. Fill engine oil to correct level before starting engine.

See engine manual for operation and maintenance

instructions.

Note: Some oil usage is normal. Check level with each use.

WARNING! Handle gasoline with care. It is

highly flammable. Always use an

approved container and fill tank outdoors.

Never add fuel to a running or hot engine.

2. Before starting, full fuel tank with fresh, clean,

regular unleaded gasoline. DO NOT MIX OIL

WITH GASOLINE.

6. Move choke lever to "Run" position. After a

short shut down, it may not be necessary to use

full choke. If engine fails to start, move lever to

"Run" or partial choke.

7. Once engine is running and no choke is needed,

slowly let foot clutch pedal up. This will engage

drive belt and the rotor will turn.

8. If engine kills when engaging foot clutch pedal,

either use more choke or increase engine RPM.

9. When clutch is engaged, the foot pedal may vibrate

or shake until the engine and rotor have increased to

full running RPM.

Note: When restarting a warm engine after a short shut

down, it may not be necessary to use full choke. If

engine fails to start, move lever to "Run" or partial

choke.

Caution: Wear safety glasses at all times

when operating the machine. Avoid

wearing loose fitting clothing. Wear gloves

and heavy clothing to protect yourself. Use common

sense and follow all safety instructions to protect

yourself from branches, sharp objects, and other

harmful objects.

2.3.2 Setup: PTO Model

Note: The P.T.O. shaft will telescope from 18 to 26

inches. This will leave 4 inches overlap at maximum

telescoping distance.

3. Place the throttle control midway between slow and

fast positions. Place the choke control to the "On"

position.

Caution: See operation/start-up decal by

foot clutch pedal on machine before

starting.

4. Depress foot clutch pedal. This will disengage drive

belt and enable engine to start.

5. Activate the starter switch. Release the switch as

soon as the engine starts. Do not engage starter for

more than 10 seconds.

Note: If battery is not charged, the engine can be

started by pulling the recoil starter with key in "On"

position.

8

1. Place tractor transmission in park or neutral and set

parking brake. Connect 3 pt. mounts on chipper/

shredder and tractor (a special bushing kit is required for category 2 or 3 pt. hitches). Secure

connections with snap pins.

2. Connect P.T.O shaft to tractor. Do not operate

machine at speeds different than specified on shield.

3. Adjust leg stands so that the drive shaft runs as

straight as possible. Avoid joint angles greater than 7

degrees. Make sure both stands are adjusted evenly.

WARNING! Never inspect or work on P.T.O.

drive area before disengaging P.T.O and

shutting off tractor engine.

Page 12

S

ECTION

2

4. Start tractor engine and engage P.T.O. drive

clutch (see tractor owner's manual). Increase

engine speed to rated P.T.O. RPM position.

Note: Do not operate machine if the distance

between the back of the tractor P.T.O. shaft to the

shoulder on the chipper/shredder rotor shaft is

greater than 22-1/2 inches. Readjust hitch or pins, or

consult your dealer for proper fit.

2.3.3 Chipping and Shredding (All

Models)

Caution: Keep face and body away from the

feed opening. Do not overreach. Keep

proper balance.

Shredding (See figure 4-5, pg. 18)

Caution: The shredder will aggressively

pull material into it. Once material is

grabbed by machine during feeding, let go

immediately and move away.

1. Place material to be shredded (grass, leaves, garden

refuse, sticks, and branches up to 1-1/2 inches in

diameter and 24" long) into the hopper. If necessary,

use a leaf tamper, branch, or other similar object to

push the material through the inlet guards.

2. Feed the material evenly into the shredder so that

the engine or tractor does not lug down or shredder

becomes clogged. If the machine becomes plugged,

refer to the Service and Maintenance Section,

"Clearing Plugged Rotor," for instructions. Branches

or items that plug or cause the machine to stall

should be fed more slowly and carefully, or put into

the chipper.

the limb or insert it continuously at a rate that

will not kill the engine or stall the tractor. Rotating the branch as you feed it will improve cutting

action.

Note: the chipping blades will become dull with use

and require periodic sharpening. Refer to Service

and Maintenance, "Sharpening Chipper Blades," for

instructions.

2.3.4 Stopping Engine Models

WARNING! Do not leave machine

unattended, or attempt any inspection or

service unless the engine is stopped and

spark plug wire is removed from spark plug.

1. Move throttle to "Slow" Position.

2. Depress foot clutch pedal.

3. Move throttle to "Stop" position or shut off key

switch.

4. Remove spark plug wire from spark plug.

Note: the rotor will continue to turn for some time after

the engine has been shut off. You can tell that the rotor

has stopped when there is no noise or machine vibration.

The stopping time can be shortened by inserting a

branch in the chipper chute to contact the blades and

slow the rotor.

2.3.5 Stopping PTO Model

WARNING! Do not leave machine

unattended. Do not attempt any inspection

or service unless P.T.O. is disengaged and

tractor engine is shut off. Allow machine to come to

a complete stop.

Chipping (See figure 4-6, pg. 18)

1. Select limbs that are up to 5 inches in diameter.

Trim side branches off that cannot be bent over

enough to feed into the chipper chute. Hold

small diameter branches together in a bundle and

feed simultaneously.

2. Place limb (butt end first) into the chipper chute

until it contacts the chipper blades. The actual

feed rate of the limb into the chipper will depend

on the type of material fed, and the sharpness of

the cutting blades. Alternately insert and retract

1. Move tractor throttle to "Slow" position.

2. Disengage P.T.O lever and shut off tractor

engine.

3. Allow machine to come to a complete stop.

Note: the rotor will continue to turn for some time

after the P.T.O has been disengaged. You can tell that

the rotor has stopped when there is no noise or

machine vibration. The stopping time can be

shortened by inserting a branch in the chipper chute

to contact the blades and slow the rotor.

9

Page 13

S

ECTION

3

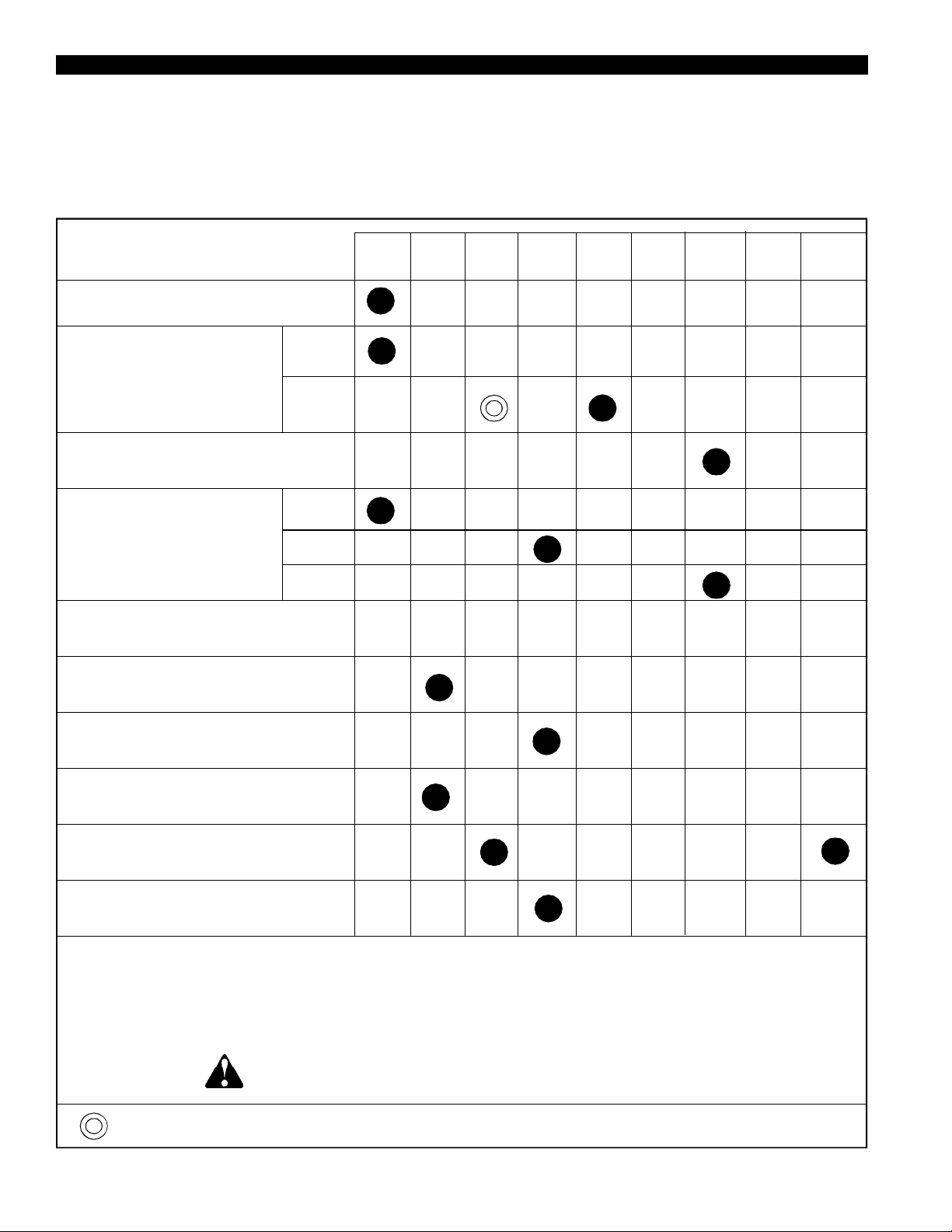

Maintenance Chart

Inspection Items

Check Nuts & Bolts (Including Wheels &

Tire Pressure)

Check

Engine Oil (Engine Models)

Replace

Replace Spark Plug (Engine Models)

Check

Air Filter Element (Engine

Models)

Replace Fuel Filter (Engine Models)

Clean

Replace

Before

Each Use

Every

10

Hours

Every

25

Hours

Every

50

Hours

Interval

*

Every

100

Hours

Every

200

Hours

Every

300

Hours

**

Every

800

Hours

Every

1

years

Check Sharpness of Chipper Blades

Grease Bearings and Pivots

Check Bolts: Chipper Blades

Check Drive Belt

Clean Machine

Note: (*) Service more frequently when used in dusty conditions

(**) Replace Paper element type only

Before inspecting or repairing any part of the machine, shut off the engine and make sure all

moving parts have come to a complete stop.

Indicates first hours of use.

10

Page 14

S

ECTION

3

Service and

Maintenance

Caution: Before inspecting or servicing any

part of the machine, shut off the engine,

and make sure all moving parts have come

to a complete stop. The chipping blades are sharp!

Use care when working on machine to avoid injury.

Engine Models: Check the engine oil, and change

the oil and filter as recommended in the manual.

Service and replace the air cleaner as recommended.

3.1 Sharpening Chipper

Blades

The chipper blades will eventually become dull,

making chipping difficult. It is recommended that

the chipper blades are sharpened every 5-15 hours

of chipper operation.

3.1.1 Removing the Chipping Blades

1. Remove the discharge screen by removing the

5/16 inch retaining bolt and pulling the screen

outward.

2. Rotate the rotor so that the bolts holding the

chipper blade are most accessible.

3. Remove the two hex head bolts holding the

blade itself. Repeat for the second blade.

Grind the angled edge of the chipping blade to 45

degrees (see figure 4-7, pg. 18): Grind the blades on

a slow-speed wet grinder if possible, or have them

sharpened by a professional.

If you use a bench grinder, be careful when grinding

so that the blade material does not get too hot and

change color–this will remove the blade's special

heat treated properties. Use short grinding times and

cool with water.

Try to remove an equal amount off each blade to

maintain balance. After sharpening, replace the

chipping blades and tighten bolts to 20 ft. lbs.

NOTE: Never sharpen or grind on the back side of the

chipper blade. This will cause the edge to roll and

the chipping blade will be damaged, causing poor

chipping and feeding of material. Small

imperfections, nicks, burrs, etc. on the flat side of the

blade will not affect the performance of the machine.

3.1.2 Chipping Blade Sharpening

Tips

Poor chipping performance is usually a result of dull

chipping blades. If your chipper's performance has

decreased, check for the following symptoms:

• Severe vibration when feeding material into the

chipper.

• Small diameter branches do not self-feed.

• Chips discharge unevenly or have stringy tails–

especially when chipping green branches.

Before you sharpen the chipping blades, check for

permanent damage. Replace the blade if:

• The blade is cracked (especially around the bolt

holes) or the edges are too deeply chipped to be

ground smooth.

• The base of the cutting edge is worn or has been resharpened so that it is too close to the rotor chipping

slot.

3.1.3 Setting Chipping Blade

Clearance

The chipping blades should clear the chipper block

located directly under the chipper chute by 1/16 inch to

1/8 inch. To adjust the blade clearance, proceed as

follows:

1. Remove the lower belt guard and the discharge

screen. Remove plastic cover from the rear rotor

bearing.

2. Loosen the set screws holding the lock collar on the

front and rear bearings.

3. Use a punch and hammer to tap the lock collars in a

direction opposite of normal rotation so that they

rotate and can be removed.

4. Using a rubber mallet, tap the end of the rotor shaft

to obtain 1/16 to 1/8 of an inch clearance (See

figure 4-8, pg. 19). The blade clearance can be

viewed through the discharge opening. Rotate

the rotor and check the clearance on both chipping blades.

11

Page 15

S

ECTION

3

5. Once clearance has been set, the lock collars

must be replaced to retain setting. Slip the lock

collars over the eccentric hub on the bearings.

Using a punch and a hammer, rotate the lock

collars in the direction of shaft rotation (i.e.

clockwise on the rear bearing and counterclockwise on the front bearing) and "set" them with a

positive hammer tap. Tighten the lock collar set

screws.

6. Loosen the set screws that hold the belt pulley on

the rotor shaft. Move the pulley on the shaft so it

is aligned directly below the similar pulley on the

engine shaft (the pulley should be moved the

equal but opposite amount that the rotor was

moved).

7. Insure the pulley drive key is completely seated

under the pulley and tighten the set screws.

8. Replace the lower belt guard, discharge screen,

and plastic bearing cap.

3.2 Replacing Shredder

Knives (Figure 4-9, pg. 20)

shafts in the correct order. If the spacers are not

installed properly, the rotor will be out of balance

and also will not have proper shredding action.

7. Repeat steps #5 & #6 for shafts 2, 3, and 4.

Make sure to install knives and spacers in the

proper order as shown on the drawing.

8. Reattach chipper chute to frame and tighten

bolts.

9. Reinstall discharge screen and discharge cover

and test machine.

On later model serial number machines (#11010

and above) the shredder kit can be installed

without removing the chipper chute. Follow

instructions below:

1. Remove belt guards from under the engine

frame. Remove discharge cover and screen.

2. Remove #10-24 nuts and bolts from the knife

shafts.

3. Align shaft with 5/8 inch hole in rear of frame

and small hole in front of machine (the small

hole is located by the chipper chute).

Caution: The shredder will aggressively

pull material into it-- especially after

installing new, sharp knives. Once material

is grabbed by machine during feeding, let go

immediately and move away.

Care must be taken to insure knives and spacers are

installed properly to maintain rotor balance.

1. Remove discharge cover, screen, and rotor end

cap.

2. Loosen the set screws holding the lock collar on

the chipper chute side rotor bearing.

3. Using a punch and hammer, tap the lock collar in

the direction opposite of normal rotation until

loose and remove.

4. Remove chipper chute cover bolts and remove

the chute.

5. Remove #10-24 bolt and nut from knife shaft

#1, slide knife shaft off of rotor assembly, and

discard the used shaft, spacers, bolt, and knives.

6. Insert new shaft, knives, spacers, bolt, and nut in

shaft #1 location (note order of assembly on

drawing). Be sure to install the spacers on the

4. Using a small punch or rod, drive the shaft

toward and out the rear 5/8 inch hole.

5. To assemble, insert shaft through 5/8 inch hole in

rear of the frame and slide knives and spacers in

their proper order onto the shaft. Install a new

#10-24 nut and bolt.

6. Repeat steps #3 through #5 to assemble the other

three shafts.

Note: Never reuse rotor shafts, bolts, and nuts if they

show signs of wear or abuse. Install new ones.

3.3 Cleaning Plugged Rotor

WARNING! If the machine becomes

plugged, shut off the engine, disconnect

the spark plug wire (or disengage P.T.O.),

and allow the machine to come to a complete stop

before clearing debris. Do not operate machine

without proper guards and screens in place.

1. Engine models: Stop engine, disengage rotor

clutch and allow machine to come to a complete

stop. Remove the spark plug wire.

12

Page 16

S

ECTION

3

P.T.O. models: Disengage P.T.O. Shut off tractor

engine.

2. Remove 5/16 inch bolt holding the discharge

screen in place. Pull the screen out of the machine.

3. Clean the debris out of the shredding rotor. Turn

the rotor by hand to be sure it is free to rotate.

4. Replace discharge screen by inserting top lip of

screen into slot inside machine and rotate screen

downward until bolt hole in screen bottom aligns

with hole in machine.

5. Replace spark plug wire (engine models), restart

engine and resume operation.

3.4 Replacing Drive Belts

Check the condition of the drive belt(s) annually or

every 30 hours of operation, whichever comes first. If a

belt is cracked, frayed or worn, it should be replaced. To

replace a belt, proceed as follows:

10. Check pulley alignment. Place a straightedge

across the face of both pulleys to inspect. If

necessary, loosen the set screws on both pulleys

and adjust them so that they are directly in line.

11. Replace belt guards. Allow 1/8 inch clearance

between top of belt and inside of lower belt guard.

Make sure all bolts, nuts, and fasteners are properly

torqued to 20 ft. lbs.

3.4.2 P.T.O. Models

1. Disengage P.T.O. Shut off tractor engine.

2. Disconnect P.T.O. shaft from tractor and remove

machine from 3 pt. hitch.

3. Remove round shield (connected to belt guard that

covers P.T.O shaft) by removing two 5/16" nuts.

4. Remove P.T.O. shaft from chipper/shredder by

removing two set screws and pulling shaft off.

5. Remove belt guard end and belt guard that covers

pulleys.

3.4.1 Engine models:

1. Stop engine, disengage rotor clutch, and allow

machine to come to a complete stop. Remove the

spark plug wire.

2. Remove large belt guard (four 5/16" bolts).

3. Remove inner belt guard from under drive belt.

4. Disconnect and plug fuel line from fuel tank.

5. Remove fuel tank from frame assembly.

6. Slip the drive belt off the pulleys. If necessary,

loosen the engine bolts and tip the engine forward to

allow the belt to slip off the pulley.

7. Inspect pulleys for wear. Replace the pulleys if they

are cracked or worn. The belt contact area should

be smooth and flat.

8. Place new belt over pulleys. Do not force or pry the

belt over the pulleys as this may cause cord breakage. If necessary, loosen engine mounting bolts and

tip the engine forward to allow the belt to be easily

placed over the pulley.

9. Align the engine so the crankshaft is parallel to the

rotor shaft. Tighten engine mounting bolts to 20 ft.

lbs. torque.

6. Loosen bolts that attach the jack shaft pillow block

and move shaft toward frame. Slip belts off pulleys.

7. Inspect pulleys for wear. Replace the pulleys if they

are cracked or worn. The belt contact area should

be smooth and flat.

8. Place new belts over pulleys. Do not force or pry

the belt over the pulleys as this may cause cord

breakage.

9. Check pulley alignment. Place a straightedge across

the face of both pulleys to inspect. If necessary,

loosen the set screws on both pulleys and move

them so that they are directly in line. Retighten the

pulley set screws. Make sure jack shaft is aligned

parallel to rotor shaft before tightening pillow block

bolts.

10. Install belt shields and guards. Allow 1/8 inch

clearance between top of belt and inside of lower

belt guard. Make sure all bolts, nuts, and fasteners

are properly torqued to 20 ft. lbs.

11. Install P.T.O shaft and tighten set screws. Install

P.T.O. shield. Never run P.T.O without all shields in

place.

13

Page 17

S

ECTION

3

3.5 Changing Discharge Screens

Optional discharge screens with different hole sizes

can be purchased and used in your chipper/shredder.

To change the screen proceed as follows:

1. Stop engine, disengage rotor, and allow machine to

come to a complete stop. Remove spark plug wire

from spark plug (engine models).

2. Remove the 5/16 inch bolt in the bottom center that

holds the discharge screen in place. Pull the screen

out of the machine and set aside.

3. Clean any trash or debris out of the screen area.

4. Place optional screen in machine. Hook top lip of

screen into slot and rotate screen downward to align

hole in screen with hole in machine. Place bolt

through machine and screen, attach nut and tighten.

3.6 Trailer Service Tips

(Engine Models)

1. Check wheel bolt torque every 10 hours of towing

use.

3.7.2 PTO Models

1. Remove discharge screen after using machine

and clean out any material in screen area. This

will help avoid material build up under screen

mounting surface.

2. Once a year, grease the two bearings on the rotor

shaft and the two bearings (under small belt guard)

on the main shaft. Be careful not to blow seals on

the bearing by over greasing.

3. The P.T.O. shaft has 4 grease zerks. Grease these

lightly every 50 hours of use.

2. Check air pressure in tires every 10 hours of towing.

Tires are rated at 60 PSI maximum.

3. Check and repack wheel bearings with grease every

year.

4. When towing, use a 2" trailer ball and always

connect the safety chains. Make sure that the trailer

hitch bolts are tight and secure. Make sure to check

state laws on trailer towing requirements before

towing the machine.

3.7 Other Service Tips

3.7.1 Engine Models

1. Service engine according to the engine manual.

2. Remove discharge screen after using machine and

clean out any material in screen area. This will help

avoid material build up under screen mounting

surface.

3. Check all bolts and other fasteners after every 10

hours of operation for proper torque.

Torque Chart

Standard minimum tightening

torque for normal assembly

applications.

Bolts (SAE GR5)

Size Ft. Lbs.

5/16" 20

3/8" 35

Screws

Size Ft. Lbs.

5/16" Set 15

#10-24 Set 3

14

Page 18

Troubleshooting

T

ROUBLESHOOTING

Problem

1. Engine will not start

(Engine models)

2. Engine or rotor stalls

or stops

3. Hard to feed

Chipper requires

excessive power

required

4. Shredder requires

excessive power or

stalls

Probable Cause

a) Improper control

settings

b) Lack of fuel

c) Internal Problems

a) Obstructed

discharge

b) Plugged Rotor

a) Obstructed

discharge

b) Improper blade

clearance

c) Dull chipper blades

a) Obstructed

discharge

b) Plugged rotor

c) Green material will

not discharge

Suggested

Remedies

a) Use proper setting

b) Fill fuel tank

c) See your dealer

a) Use branch or

similar object to

clear discharge

b) Clear Rotor

a) Use branch or

similar object to

clear discharge

b) Adjust clearance

c) Sharpen blades

a) Use branch or

similar object to

clear discharge

b) Clear rotor, feed

material into

shredder more

evenly.

c) Alternately feed dry

material, or install

coarse discharge

screen or wet debris

screen.

Reference

Engine Manual

Section 3

Section 3

Section 3

5. Engine stalls or belt

squeals when

engaging clutch

6. Material from

chipper wraps

around rotor shaft

a) Engaging clutch too

fast

b) Plugged Rotor

a) Stringy, green

material bypasses

chipper blades

b) Improper blades

clearance

c) Plugged discharge

screen

a) Lift clutch lever

more slowly

b) Clear rotor

a) Rotate branch or

material when

feeding to cut

completely

b) Adjust clearance

c) Install wet debris

discharge screen

Section 3

Section 3

15

Page 19

S

ERVICE ACCESSORIES

Service Accessories

Description Part Number

Towable PTO

Discharge Screens

Fine 70703 70703

Medium 70531 70531

Coarse 70332 70332

Wet Debris Screen 70559 70559

Goggles (One pair supplied with machine) 17842 17842

Maintenance Kit (Includes spark plug, air filer, oil filter, v-belt) 14 hp 70452

Maintenance Kit (Includes spark plug, air filer, oil filter, v-belt) 20 hp 71043

Leaf Tamper 70649 70649

Tool Steel Chipper Blades (Set of 4) 70453 70453

Shredder Kit 70972 70456

Light Kit 70454 70454

Collection Bag 17854 17854

Spark Plug 16069

3 pt. Hitch Bushing Kit, Category 2 16022

16

Page 20

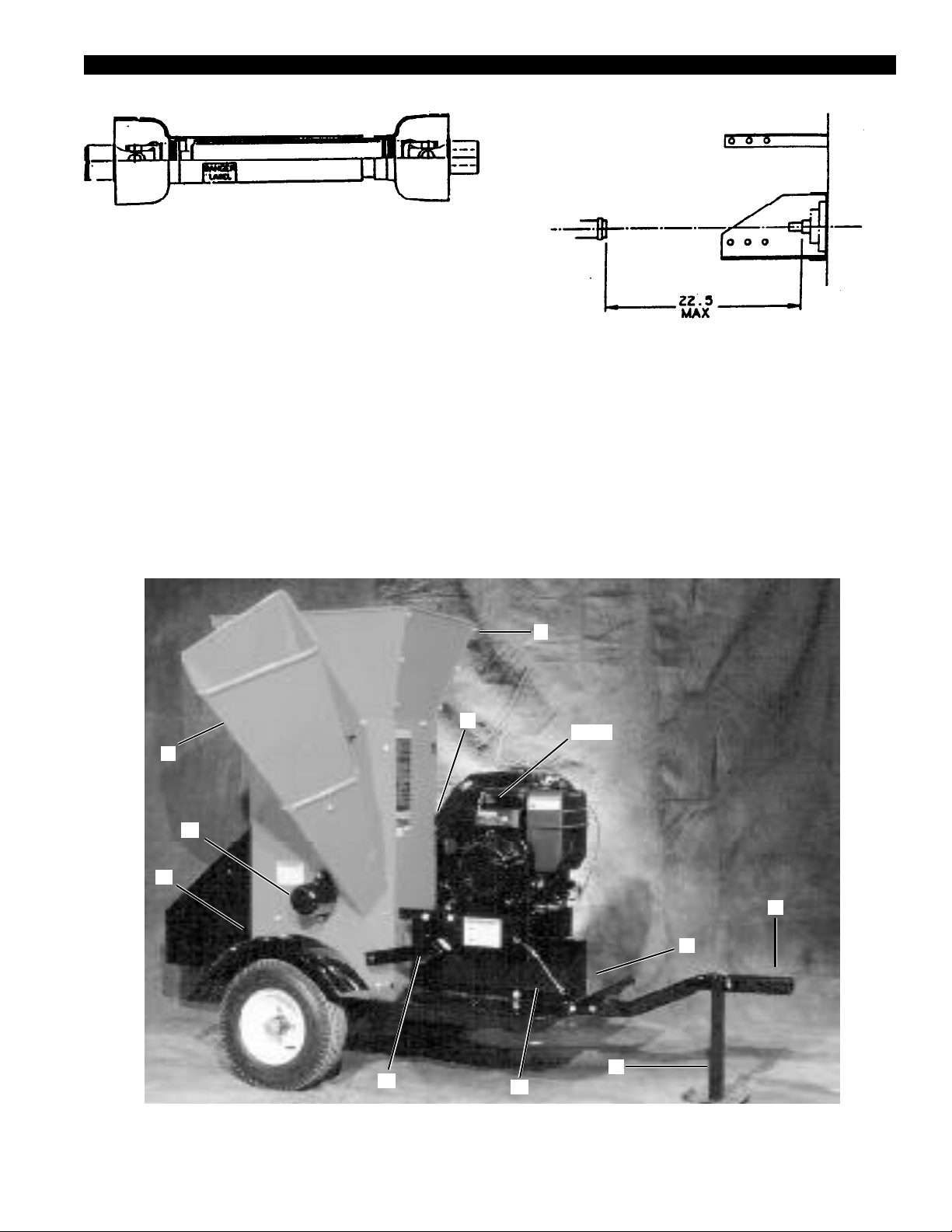

Figure 4-1

Figure 4-2

S

ECTION

4

10

8

7

9

12

13

11

1, 2, 3

Fuel Tank Not

Shown on Picture

6

5

4

Figure 4-3

17

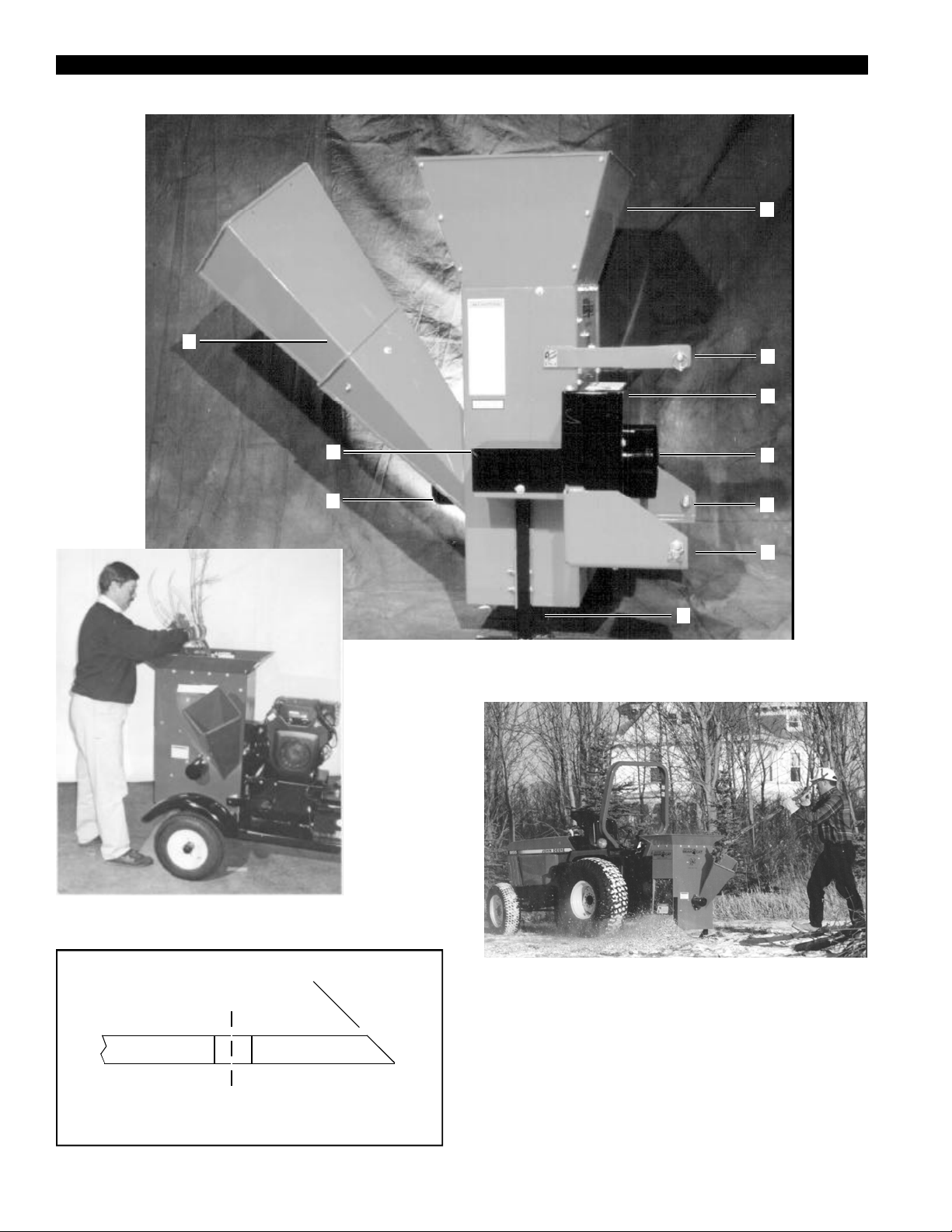

Page 21

S

ECTION

4

4

5

Pto shaft not shown

on picture

7

8

6

1

3

2

1

1

Figure 4-4

18

Figure 4-5

Figure 4-7

45

Figure 4-6

0

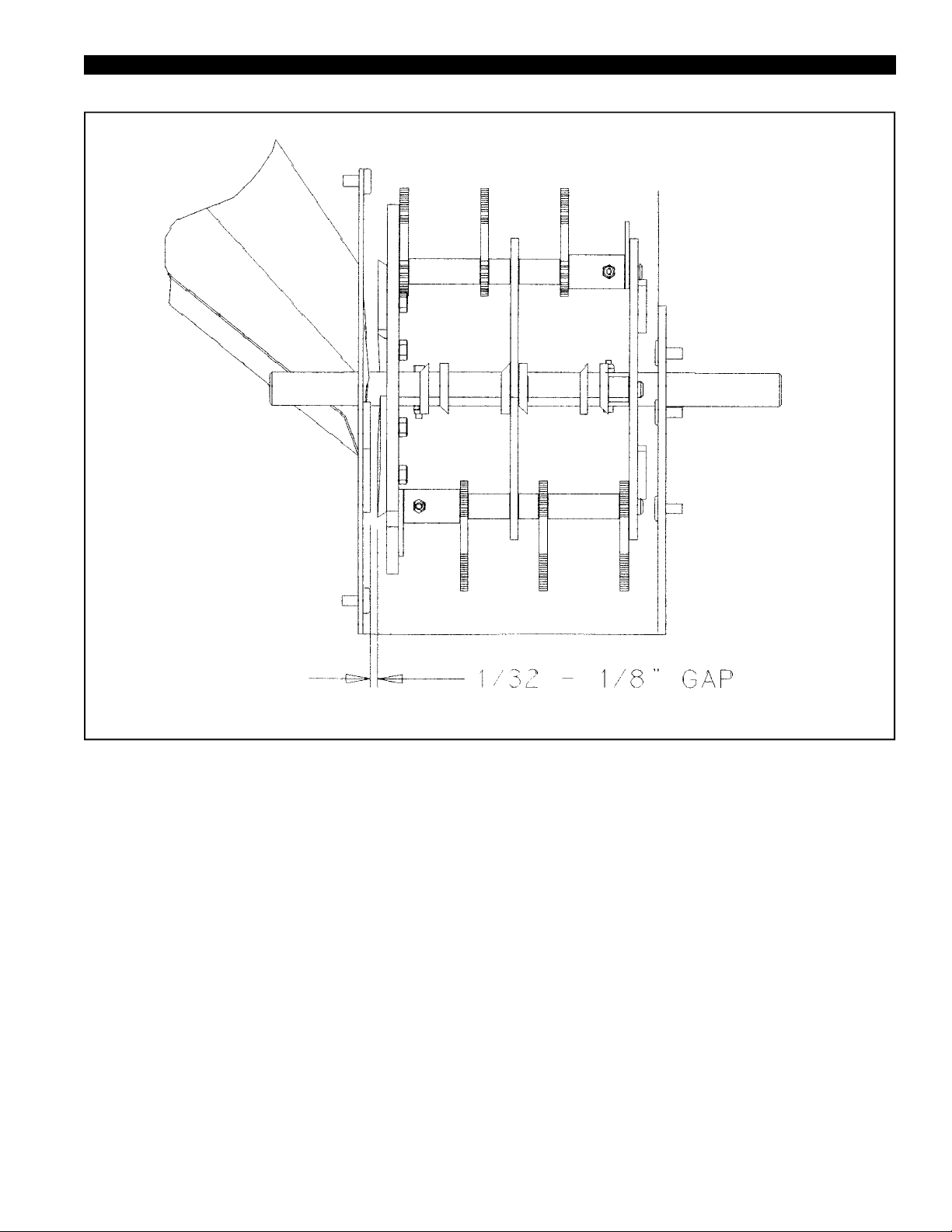

Page 22

S

ECTION

4

Figure 4-8

19

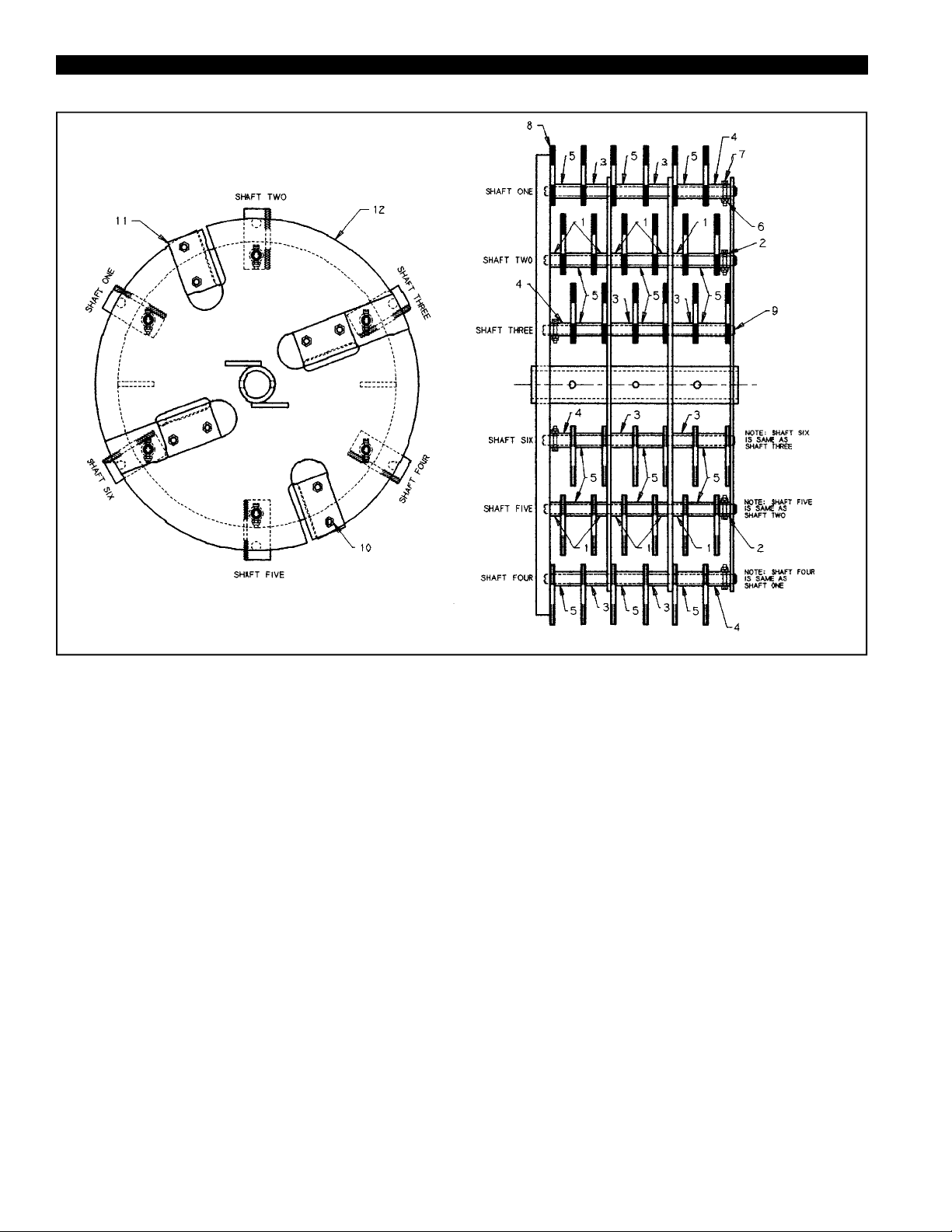

Page 23

S

ECTION

4

Figure 4-9

20

Page 24

T

ABLE DES MATIÈRES

Table des matières

Section 1 : Instructions de sécurité................................... 2

1.2 Décalcomanies de sécurité................................................................................ 4

Section 2 : Montage, commandes et fonctionnement...... 6

2.1 Montage...................................................................................................................6

2.1.1 Modèles tractables ........................................................................................................................ 6

2.1.2 Modèles à prise de force (P.D.F.) ................................................................................................ 6

2.2 Commandes.............................................................................................................7

2.1.1 Modèles à moteur .......................................................................................................................... 7

2.2.2 Modèles à prise de force............................................................................................................... 7

2.3 Fonctionnement ....................................................................................................... 8

2.3.1 Démarrage des modèles tractables ............................................................................................. 8

2.3.2Préparation : modèles à prise de force ......................................................................................... 8

2.3.3 Coupe et déchiquetage (tous modèles) ....................................................................................... 9

2.3.4 Arrêt des modèles à moteur ......................................................................................................... 9

2.3.5 Arrêt des modèles à prise de force .............................................................................................. 9

Tableau d’entretien ......................................................................................................10

Section 3 : Service courant et entretien ...........................

11

3.1 Affûtage des lames de la coupeuse ........................................................................ 11

3.1.1 Démontage des lames de la coupeuse...................................................................................... 11

3.1.2 Conseils pour l’affûtage des lames de la coupeuse ..................................................................11

3.1.3 Ajustage du dégagement des lames de la coupeuse ............................................................... 11

3.2 Remplacement des couteaux de la déchiqueteuse .................................................12

3.3 Nettoyage du rotor obstrué .....................................................................................12

3.4 Remplacement des courroies d’entraînement ......................................................... 13

3.4.1 Modèles à moteur ........................................................................................................................ 13

3.4.2 Modèles à prise de force............................................................................................................. 13

3.5 Changement de grilles de décharge .......................................................................14

3.6 Conseils pour l’entretien de la remorque.................................................................14

3.7 Conseils de service courant divers .........................................................................14

3.7.1 Modèles à moteur ........................................................................................................................ 14

3.7.2 Modèles à prise de force............................................................................................................. 14

Dépannage ........................................................................ 15

Pièces accessoires de service......................................... 16

Section 4 : Graphiques et photographies .................. 17-20

Garantie ............................................................................. 21

1

Page 25

S

ECTION

1

Instructions de

sécurité

Votre sécurité et celle des autres sont très importantes. Vous

trouverez d’importants messages de sécurité dans ce manuel

et sur la machine. Vous êtes prié de lire consciencieusement

ces messages.

Un message de sécurité vous met en garde contre un danger

potentiel qui risque de vous blesser, vous ou les autres.

Chaque message de sécurité est précédé de l’un des trois mots

\suivants : DANGER, AVERTISSEMENT ou MISE EN

GARDE.

Vous serez tué ou gravement

DANGER

AVERTISSEMENT

MISE EN GARDE

blessé si vous ne suivez pas les

instructions.

Vous risquez d’être tué ou

gravement blessé si vous ne

suivez pas les instructions.

Vous risquez d’être blessé si vous

ne suivez pas les instructions.

2. Evitez de porter des habits amples. Ne faites jamais

fonctionner cette machine si vous portez des habits

amples, en particulier des habits avec des cordons qui

risquent de se prendre dans la machine.

3. Ne faites fonctionner cette machine que sur une surface

de niveau. Ne la faites pas fonctionner sur des surfaces

pavées, bétonnées ou recouvertes de gravillons. En cas de

fonctionnement sur une surface dure, la machine peut

être sujette à un recul et à un rebond ainsi qu’à des

vibrations plus intenses. Ces dernières peuvent provoquer

un déplacement de la machine et de ce fait entraîner

l’usure prématurée ou le desserrage de certaines pièces.

4. Avant de démarrer la machine, vérifiez visuellement si

tous les boulons, les écrous, les vis et les autres systèmes

de fixation sont bien serrés. Vérifiez tous les boulons, les

écrous, les vis et autres systèmes de fixation toutes les

dix heures de fonctionnement pour vous assurer que tout

soit bien serré et en bon état de marche.

Fonctionnement

1. Avant de démarrer la machine, assurez-vous que la

chambre de coupe soit vide.

Avant de faire fonctionner la

machine

1. Familiarisez-vous avec le manuel de l’utilisateur avant

d’utiliser cet équipement. Consultez le manuel de

l’utilisateur du moteur pour des renseignements de

sécurité supplémentaires.

2. Ne permettez pas aux enfants de faire fonctionner cette

machine.

3. Ne faites pas fonctionner cet équipement en présence

d’autres personnes.

4. Le monoxyde de carbone libéré dans un endroit fermé

peut être extrêmement dangereux ; ne mettez pas la

machine en route dans un endroit fermé. Les gaz

d’échappement du moteur contiennent du monoxyde de

carbone qui est incolore, inodore et sans saveur.

5. Ne mettez pas les mains (ou toute autre partie du corps

ou de l’habillement) à l’intérieur de la chambre

d’alimentation, de la glissière de décharge ou à proximité

de toute pièce en mouvement.

6. Avant d’inspecter ou d’effectuer le service de toute partie

de la machine, veuillez arrêter le moteur et assurez-vous

que toutes les pièces en mouvement soient venues à

l’arrêt complet.

Préparation

1. Portez des lunettes de sécurité pendant toute la durée du

fonctionnement de la machine. Une paire de lunettes de

sécurité est fournie avec chaque coupeuse.

2. Lorsque vous introduisez des matériaux à couper dans la

machine, veillez à exclure toute pièce de métal, tous

cailloux, bouteilles, boîtes en fer blanc et autre corps

étrangers.

3. Le matériau à déchiqueter est entraîné avec vigueur dans

la machine. Une fois que le matériel est engagé, lâchez-le

immédiatement et reculez.

4. Si le mécanisme de coupe rencontre un corps étranger ou

si la machine se met à vibrer ou fait un bruit anormal,

arrêtez immédiatement le moteur pour que la machine

puisse venir à l’arrêt complet.

Quand la machine est à l’arrêt :

a) Vérifiez quels sont les dommages.

b) Remplacez ou réparez toute pièce endommagée.

c) Vérifiez s’il y a des pièces desserrées et resserrez-les.

5. Toutes les dix heures de fonctionnement, vérifiez le serrage

(101,7 N.m) des boulons des pièces suivantes :

• le palier du rotor de la coupeuse

• les lames de la coupeuse (utiliser des boulons de 5/16"

(7,94 mm). Serrez à 27,1 N.m.

Si les boulons des composants ci-dessus ne sont pas serrés au

couple correct (101,7 N.m), la coupeuse et/ou l’utilisateur

risque de subir de graves dommages.

2

Page 26

S

ECTION

1

6. Ne laissez pas le matériau traité s’accumuler dans la zone

de décharge ; cela empêche la décharge normale et peut

provoquer des projections de matériau à travers

l’ouverture d’alimentation.

7. N’essayez pas de faire marcher la machine sans avoir mis

en place tous les écrans protecteurs, les déflecteurs ou les

boucliers. Restez à distance de toute pièce en

mouvement.

8. Maintenez les écrans, les déflecteurs et les blindages en

bon état.

9. Restez toujours à bonne distance de la zone de décharge

quand vous faites fonctionner cette machine.

10. Maintenez votre visage et votre corps à distance de

l’ouverture d’alimentation.

11. Ne présumez pas trop de vos forces. Gardez un bon

équilibre à tout moment.

12. Ne déplacez pas, ni ne transportez pas une machine qui

tourne.

13. Si la machine se bouche, arrêtez le moteur. Attendez

qu’elle soit à l’arrêt complet avant de dégager les débris.

14. Pour les modèles à démarrage électrique, débranchez les

câbles de la batterie avant de faire toute vérification ou

réparation.

15. Ne touchez pas aux réglages du régulateur de vitesse du

moteur dans le cas des machines à moteur ; le régulateur

contrôle la vitesse maximale de fonctionnement en

sécurité et protège le moteur et toutes les pièces en

mouvement de dommages résultant d’une survitesse.

Règles de sécurité supplémentaires

pour les modèles tractables

1. Connectez toujours les chaînes de sécurité de l’attelage.

Assurez-vous que les boulons de l’attelage de la

remorque soient bien serrés de façon sûre. N’essayez pas

de tirer la remorque si le véhicule n’est pas équipé d’un

boulet de 5 cm.

2. La vitesse maximum de remorquage ne doit pas dépasser

88 km à l’heure. Gonflez les pneus selon les

recommandations du fabricant indiquées sur la paroi

latérale du pneu. Vérifiez régulièrement les boulons à

collet des roues pour vous assurer de leur serrage

adéquat.

3. Assurez-vous que le support à vérin de la remorque soit

dans la position UP ( en haut) pour qu’il ne touche pas le

sol pendant le déplacement. Placez le support à vérin sur

une surface horizontale et immobilisez-le dans la position

DOWN (en bas) avant d’utiliser la machine.

4. Coupez l’arrivée d’essence au moteur pendant le

remorquage.

5. Déconnectez le câble de la bougie pendant le

remorquage.

Entretien et rangement (modèle

tractables)

1. Quand cet équipement est à l’arrêt pour le service

courant, l’inspection et le rangement, ou lors du

remplacement d’une pièce accessoire, assurez-vous que

la bougie soit déconnectée.

2. Rangez cette machine loin de la portée des enfants.

Assurez-vous qu’aucune flamme ou étincelle n’entre en

contact avec les vapeurs de carburant. Pour des

rangements de trois mois ou plus, vidangez le carburant

et débarrassez-vous en de manière appropriée. Ne rangez

la machine qu’après refroidissement.

Règles de sécurité supplémentaires

pour les modèles P.D.F.

1. Connectez les goupilles d’attelage et les goupilles à

déclic, connectez l’arbre de P.D.F., et mettez les pieds

stabilisateurs dans la position DOWN (en bas) quand la

machine fonctionne.

2. Pour déplacer la machine : arrêtez la prise de force,

soulevez le crochet d’attelage à 3 points et ajustez les

pieds stabilisateurs si nécessaire.

3. Laissez les écrans protecteurs en place pendant toute la

durée du fonctionnement. Débrayez toujours la prise de

force du tracteur et arrêtez le moteur avant d’enlever des

écrans protecteurs.

4. Gardez les mains, les pieds et les habits loin de toutes les

pièces motrices de la transmission de la P.D.F.

5. Ne nettoyez, ne lubrifiez, ni n’ajustez jamais la coupeuse/

déchiqueteuse quand elle est en marche.

6. L’opérateur doit porter des habits relativement serrés. Ne

portez jamais des habits amples ou ayant des cordons

lorsque vous travaillez autour de la P.D.F.

7. Avant de démarrer le tracteur, assurez-vous toujours que

la transmission soit dans la position neutre ou de

stationnement et que la prise de force soit débrayée.

Remarque : les spécifications de P.D.F. prévues

pour le fonctionnement de cette machine sont de 15

à 30 CV (chevaux vapeur). L’utilisation d’une P.D.F.

supérieure à 30 CV risque d’endommager la

courroie et la machine par suite d’un

fonctionnement en surcharge.

Entretien et rangement (modèle à

prise de force)

1. Quand cet équipement est à l’arrêt pour service, inspection, rangement ou lors du remplacement d’une pièce

détachée, assurez-vous que la P.D.F. soit débrayée et que

le moteur du tracteur soit arrêté.

2. Rangez cette machine loin de la portée des enfants. Pour

des rangements de trois mois ou plus, nettoyez

complètement la machine et rangez-la dans un endroit sec.

3

Page 27

S

ECTION

1

Décalcomanies de sécurité

Des décalcomanies de sécurité et d’instruction sont situées sur le châssis et sur le moteur de la coupeuse. Remplacez toute

décalcomanie endommagée et illisible. Consultez les dessins et les listes de pièces dans la section 4 pour savoir où sont placées

les décalcomanies.

Remarque : Pour la sécurité et les instructions relatives au moteur, consultez le manuel de l’utilisateur du moteur ou contactez le

fabricant du moteur.

12172

12168

1

2

Gardez les mains, les pieds et le corps loin de l’arbre

d’entraînement de la transmission pendant le fonctionnement de

la machine pour éviter qu’ils ne s’y prennent. Faites fonctionner

la machine à une vitesse d’entrée de 540 tours par minute.

12169

Gardez les mains et les pieds en dehors des espaces

d’alimentation et de décharge pendant le fonctionnement de

la machine pour éviter toute blessure.

12170

12171

3

5 6

Panneau 1 - MISE EN GARDE

Panneau 2 - Lisez et familiarisez-vous avec le manuel de

l’utilisateur avant de faire fonctionner cette

machine.

Panneau 3- Protégez les yeux et les oreilles de manière

appropriée pendant le fonctionnement de cette

machine.

Panneau 4- Arrêtez la machine et attendez que toutes les

pièces soient à l’arrêt complet avant de procéder

au nettoyage, au réglage ou à la réparation de la

machine.

Panneaux 5 et 6 - Arrêtez le moteur et enlevez le câble de la

bougie ou la clé avant de procéder au nettoyage,

au réglage ou à la réparation de la machine.

4

Lisez et familiarisez-vous avec le manuel de l’utilisateur avant

de faire fonctionner cette machine.

4

12173

Restez à distance de l’ouverture de décharge pendant le

fonctionnement de la machine. Assurez-vous que la

décharge ne soit pas dirigée vers les personnes autour

de vous ou vers tout objet risquant d’être endommagé

par des débris volants.

Page 28

S

ECTION

1

12174

Gardez les mains et autres parties du corps loin des pièces en

mouvement. Remplacez les écrans avant de faire fonctionner

la machine.

12176

Ne mettez pas des matériaux de diamètre supérieur à 19 mm

dans la déchiqueteuse.

12183

12250

Vérifiez le serrage des boulons de la lame de la coupeuse, de

l’enclume et du rouleau d’alimentation toutes les dix heures de

fonctionnement. Consultez les instructions du manuel de

l’utilisateur.

12251 12252

Enfoncez la pédale d’embrayage avec le pied pour débrayer

lors du démarrage du moteur. Relâchez lentement le pied

pour engager l’embrayage de la coupeuse après la mise en

route du moteur.

12184

Restez à distance de

l’ouverture de décharge

non couverte pendant le

fonctionnement de la

machine. Ne faites pas

fonctionner la machine

sans avoir mis en place le

Pendant le fonctionnement

de la machine, tenez les

spectateurs à distance de

l’avant de la machine.

Evitez les blessures

causées par des débris

volants.

sac ou le récipient de

décharge.

12254

Gardez les mains, les pieds et toutes les parties du corps loin

des lames pendant le fonctionnement de la machine pour

éviter des blessures graves.

Montez lentement le levier pour embrayer la coupeuse/

déchiqueteuse après la mise en route du moteur. Baissez le

levier pour débrayer l’embrayage.

5

Page 29

S

ECTION

2

Montage,

commandes et

fonctionnement

2.1 Montage

2.1.1 Modèles tractables

1. Retirez de la caisse.

2. Procédez au montage de l’ensemble de la trémie en

utilisant onze boulons, rondelles et contre-écrous de 5/

16"• 3/4" (7,93 mm • 19 mm). Insérez les boulons et les

rondelles de l’extérieur vers l’intérieur de la trémie.

Attachez fermement les boulons à l’aide des rondelles et

des contre-écrous.

3. Montez les jantes et les pneus sur le châssis de la

remorque à l’aide des boulons de roue fournies.

4. Utilisez trois boulons de 5/16"• 1" (7,93 mm • 25,4 mm),

six rondelles de 5/16" (7,93 mm) et trois écrous Nylock

de 5/16" (7,93 mm) pour monter l’aile de la coupeuse

(côté glissière) sur le support de l’aile déjà installé sur la

remorque. Mettez les rondelles sous les têtes de boulons

et au-dessus des écrous. Serrez les boulons à 27 N.m.

5. Utilisez trois rondelles de 5/16" (7,93 mm) et trois écrous

Nylock de 5/16" (7,93 mm) pour fixer l’aile gauche sur le

grand protège-courroie. Il y a trois mentonnets de

soudure situés sur le protège-courroie pour fixer l’aile.

Serrez les boulons à 27 N.m.

2.1.2 Modèles à prise de force

1. Retirez de la caisse.

2. Procédez au montage de la trémie en utilisant onze

boulons, rondelles et contre-écrous de 5/16"• 3/4" (7,93

mm • 19 mm). Insérez les boulons et les rondelles de

l’extérieur de la trémie. Attachez fermement les boulons

à l’aide des rondelles et des contre-écrous.

3. Connectez l’extrémité femelle de l’arbre de P.D.F. à

l’extrémité mâle déjà installée sur la coupeuse/

déchiqueteuse.

4. Attachez la coupeuse/déchiqueteuse au crochet d’attelage

à 3 points du tracteur et connectez l’arbre de prise de

force.

AVERTISSEMENT ! Soyez extrêmement

prudent lorsque vous faites marcher

l’arbre de P.D.F. Restez à distance de tout

arbre d’entraînement. Débrayez toujours

l’arbre de prise de force et arrêtez le moteur du

tracteur quand vous effectuez des travaux sur la

machine.

5. Ajustez les pieds stabilisateurs de manière à ce que

l’arbre de P.D.F. puisse tourner aussi droit que possible

(voir figure 4-1, page). L’angle de l’arbre de P.D.F. doit

ne pas dépasser 7 degrés (plus ou moins). La distance

maximale entre la coupeuse/déchiqueteuse et le tracteur

ne doit pas dépasser 57 cm (voir figure 4-2, page).

6. Montez le crochet de la remorque sous le châssis de la

remorque à l’aide de trois boulons, rondelles et écrous de

3/8" (9,52 mm). Serrez à 34 N.m.

7. Mettez de l’huile dans le moteur. Consultez le manuel

relatif au moteur pour les spécifications et les quantités

d’huile.

8. Placez la batterie de 12 volts (non livrée) sur le plateau

attaché à l’ensemble d’attelage.

Remarque : Utilisez des batteries de type U1, 12 volts, 32

ampères avec 250 ampères de démarrage à froid.

9. Attachez le câble noir à la borne négative de la batterie et

le câble rouge à la borne positive. Attachez fermement la

batterie à l’aide de la cornière et des boulons fournis.

10. Connectez le câble de la bougie à la bougie.

6

Tableau des

couples de serrage

Serrage standard minimum

pour montage normal

Boulons (SAE GR5)

Taille N.m

7,93 mm 27,1 N.m

9,52 mm 47,5 N.m

Vis

Taille N.m

Lot de 7,93 mm 20,3 N.m

Lot de # 10-24 4,1 N.m

Page 30

S

ECTION

2

2.2 Commandes

2. Modèles à moteur (voir figure 4-3,

page)

1. Manette des gaz ( 20 CV Kohler) : fait varier la vitesse

du moteur. Tournez la manette dans le sens horaire pour

un fonctionnement à plein gaz. Tournez la manette dans

le sens antihoraire pour le ralenti. Tournez entièrement

dans le sens inverse pour arrêter le moteur. Consultez le

manuel du moteur pour des instructions supplémentaires

concernant le fonctionnement du moteur.

Manette des gaz (14 CV Kohler) : fait varier la vitesse

du moteur Tirez le levier vers le haut pour un

fonctionnement à plein gaz. Abaissez le levier pour le

ralenti lors du réchauffage. Abaissez le levier

complètement pour arrêter le moteur. Consultez le

manuel du moteur pour des instructions supplémentaires

concernant le fonctionnement du moteur.

2. Starter : Utilisez-le pour démarrer un moteur froid.

Mettez sur la position ON (MARCHE) pour démarrer.

Poussez le levier sur la position OFF (ARRET) lorsque le

moteur tourne. Consultez le manuel du moteur pour des

instructions supplémentaires concernant le

fonctionnement du moteur.

3. Contact à clé : situé au-dessus du démarreur à main sur

le carter du moteur. Actionnez l’interrupteur du

démarreur et relâchez-le aussitôt que le moteur tourne.

N’engagez pas le démarreur pendant plus de 10

secondes, sinon cela peut produire des dommages

sérieux.

4. Réservoir du moteur : utilisez de l’essence sans plomb.

Ne mélangez pas le carburant avec de l’huile.

5. Attelage de la remorque : utilisez toujours des boulets

de 5 cm et des chaînes de sécurité.

6. Support à vérin : toujours en position UP (en haut) et

au-dessus du sol lorsque vous déplacez la machine.

Placez-le en position DOWN (en bas) sur une surface de

niveau. Avant de faire fonctionner la machine, stabilisez

le vérin en bonne position à l’aide des goupilles à ressort.

7. Courroie d’entraînement du moteur et écran :

n’enlevez jamais l’écran durant le fonctionnement de la

machine.

11. Batterie du moteur : non fournie. Utilisez une batterie

de type U1, 12 volts, 32 ampères avec 250 ampères de

démarrage à froid.

12. Couvercle de l’extrémité de l’arbre du rotor : couvre

le palier extrémité arbre du rotor.

13. Pédale: sert à engager la courroie de transmission de

l’ensemble du rotor

2.2.2 Modèles à prise de force (voir

figure 4-4, page)

1. Connexion à 3 points de l’attelage : attache la

coupeuse/déchiqueteuse à l’attelage à 3 points du

tracteur. La connexion est directe pour les catégories 0 et

1. Des coussinets doivent être installés pour les

connexions à 3 points de catégorie 2.

2. Arbre de P.D.F. : connecte la coupeuse/déchiqueteuse à

l’arbre de P.D.F. du tracteur. Evitez des angles de

transmission supérieurs à 7 degrés (plus ou moins)

lorsque l’appareil est en marche.

3. Ecran de la courroie d’entraînement : n’enlevez

jamais l’écran durant le fonctionnement de la machine.

4. Trémie de la déchiqueteuse : engagez le matériau à

déchiqueter par la trémie.

5. Glissière de la coupeuse : engagez le matériau à couper

par la glissière.

6. Pieds stabilisateurs : ajustez de manière à obtenir un

angle d’arbre d’entraînement correct. Ne déplacez jamais

la machine avant de s’assurer que les pieds ne touchent

pas le sol.

7. Arbre secondaire transversal : sert à ajuster la tension

de la courroie.

8. Couvercle de l’accès au rotor : est utilisé lors du

démontage des lames de la coupeuse et lors de l’entretien

du rotor.

Remarque : les spécifications de P.D.F. prévues

pour un fonctionnement optimal de cette machine

sont de 15 à 30 CV. L’utilisation de puissance

supérieure à 30 CV risque d’endommager la

courroie et la machine par suite d’un

fonctionnement en surcharge.

8. Trémie de la déchiqueteuse : engagez le matériau à

déchiqueter par la trémie.

9. Glissière de la coupeuse : engagez le matériau à couper

par la glissière.

10. Grille de l’ouverture de décharge : les copeaux et le

matériau déchiqueté sortent par la grille et l’ouverture.

7

Page 31

S

ECTION

2

2.3 Fonctionnement

MISE EN GARDE : le rotor de la coupeuse/

déchiqueteuse peut continuer à tourner

même si le moteur est à l’arrêt. N’effectuez

aucune réparation ou réglage avant que la

machine toute entière soit complètement arrêtée.

Enlevez le câble de la bougie avant tout entretien et

réparation. Ne faites jamais fonctionner cette

machine sans avoir mis en place la grille de

décharge.

2.3.1 Démarrage des modèles

tractables

MISE EN GARDE : placez la machine

dehors dans un endroit éclairé, sur une

surface de niveau avant de la démarrer. Ne

faites pas fonctionner la machine sur une

surface pavée, bétonné ou couverte de graviers. Ne