Page 1

Chipper/Shredder

I

nstruction & Owners Manual

Chipper/Shredder Models:

71020, 71014 (Towable)

70554,70520 (PTO)

Crary Company

Box 849

West Fargo, ND 58078

(701) 282-5520 (800) 247-7335

FAX: (701) 282-9522

Manufactured in the

United States of America

by Crary Company

Cat. No. 16023

Manual No. 297

Page 2

B

EARCAT

Dear Bear Cat Customer,

Thank you for purchasing a Crary Bear Cat Chipper. The Bear Cat Chipper is

designed, tested, and manufactured to give years of dependable performance.

To keep your chipper operating at peak efficiency, it is necessary to adjust it

correctly and make regular inspections. The following pages will assist you in

the operation and maintenance of your machine. Please read and understand

this manual before operating the chipper.

If you have any questions or comments about this manual, please call us tollfree at 1-800-247-7335.

If you have any questions or problems with your chipper, please call or write

your local factory-authorized Bear Cat dealer.

Please Send Us Your Warranty Card

A warranty card is included in your owner's kit packaged with your chipper.

Please take the time to fill in the information requested on the card. When you

send your completed card to us, we will register your machine and start your

coverage under our limited warranty.

How to

Contact

Bear Cat

A

DDRESS

Crary Bear Cat

237 NW 12th Street

PO Box 849

West Fargo, ND 58078

P

HONE

800-247-7335

701-282-5520

Fax: 701-282-9522

H

OURS

M-F, 8 a.m. to 5 p.m.

Central Time

Owner's Record

Please take a moment to record the following

information about your chipper. If you need to

call for assistance, please be ready to provide

your model and serial numbers. This

information will allow us (or your dealer) to

help you more quickly when you call.

Model Number

Serial Number

This safety alert symbol identifies important safety messages in this manual.

When you see this symbol, be alert to the possibility of personal injury and

carefully read the message that follows.

Serial Number Decal Location

Serial Number Decal

Be alert! Your Safety is Involved.

Page 3

W

ARRANTY

Chipper and Hydraulic Feed Limited Warranty

Crary Bear Cat products are warranted for two years from the date of sale to the original cumsumer purchaser

and 90 days from the date of sale to a commercial or rental operation. On models 70380, 70500, 70520,

70554, 70580, 71014, 71020, 71620, 71825, 71854, there is a 90 day warranty for commercial business or

rental use, and a two year warranty when sold to a consumer for private use. The engine is warranted by the

original manufacturer with the terms and limitations listed in the manufactures manual.

Within the above stated period, Crary Co. will replace any part(s) found to be defectiv e in material and/or

workmanship, after the receipt of the part in our plant. Labor costs to replace these defective parts will be paid

at a Crary established labor rate and time allowed (flat rate) for repair. All transportation char ges incurred in

shipping part(s) are the responsibility of the purchaser.

This warranty is void in the case of accidents, failure to perform normal maintenance, or failure to follow

those instructions listed in the service manual. This warranty is also in lieu of all other expressed warranties

and voids any implied warranty as to the merchantability or fitness of the product for a particular purpose and

of any other obligation on the part of Crary Co. Some states do not allow limitations on how long the implied

warranty lasts, so the above limitation may not apply to you.

This warranty applies only to parts or components which are defective, and does not cover necessary repair

due to normal wear, misuse, accidents, or lack of proper maintenance. This includes belts, pulleys, and

chipper blades. Regular routine maintenance of the unit to keep it in proper operating condition is the

responsibility of the owner .

All warranty repair reimbursable under the Crary Co. warranty must be performed by an authorized Bearcat

service dealer using Bearcat approved replacement parts. Repair or attempted repair by anyone other than an

authorized Bearcat service dealer is not reimbursable under the Crary Co. warranty. In addition, these

unauthorized repair attempts may result in additional malfunction, the correction of which is not covered by

warranty.

Crary Co. is not liable for indirect, incidental, or consequential damages in connection with the use of this

product including any cost or expense or providing substitute equipment or service during periods of

malfunction or non-use.

Some states do not allow the exclusion of incidental or consequential damages, so the above exclusion may not

apply to you. This warranty gi ves you specific legal rights. You may also have other rights which vary from

state to state.

Be sure to note the Chipper serial number in any correspondence with Crary Co. or any authorized Bearcat

dealer. The serial number is located on the rotor assembly cover.

Warranty

Page 4

Contents

Section 1: Safety Instructions ................................... 2

1.2 Safety Decals...................................................................................4

Section 2: Assembly, Controls, and Operation ........ 6

2.1 Assembly ......................................................................................... 5

2.1.1 Assembly, Towable Models........................................................... 5

2.1.2 Assembly, PTO Models ................................................................ 5

2.1.3 Controls & Operation..................................................................... 6

2.1.4 Starting.......................................................................................... 8

2.1.5 Specifications & Recommendations ............................................... 8

2.2 Operation..........................................................................................9

2.2.1 Shredding ...................................................................................... 9

2.2.2 Chipping ........................................................................................ 9

2.2.3 Stopping Instructions..................................................................... 9

Section 3: Service and Maintenance ....................... 10

Service & Maintenance Chart ............................................................... 10

3.1 Changing Discharge Screens ........................................................11

3.2 Sharpening Chipper Blades............................................................11

3.2.1 Chipping Blade Sharpening Tips.................................................. 11

3.2.2 Setting Chipping Blade Clearance ............................................... 12

3.3 Replacing Shredder Kit ...............................................................13

3.3.1 Clearing Plugged Rotor(Towable) ................................................ 13

3.3.2 Clearing Plugged Rotor (PTO)..................................................... 14

3.3.3 Removing Rotor .......................................................................... 14

3.3.4 Replacing Drive Belts (Towable) ................................................. 14

3.3.5 Replacing Drive Belts (PTO) ....................................................... 1 4

3.3.6 Trailer Service Tips ..................................................................... 15

3.3.7 Additional Service Tips ............................................................... 15

C

ONTENTS

Service Accessories.................................................. 15

Troubleshooting......................................................... 16

Warranty

1

Page 5

S

ECTION

1

Safety Instructions

Your safety and the safety of others is very important.

We have provided important safety messages in this

manual and on the machine. Please read these messages

carefully.

A safety message alerts you to potential hazards that

could hurt you or others. Each safety message is

preceeded by one of three words: DANGER,

WARNING, or CAUTION.

You WILL be KILLED or

DANGER

WARNING

CAUTION

SERIOUSL Y HUR T if you don't

follow instructions

You CAN be KILLED or

SERIUOLSY HUR T if you don't

follow instructions.

Y ou CAN be HUR T or DAMAGE

machine if you don't follow

instructions.

Before Operating

1. Become familiar with the owner's manual before

attempting to operate this equipment. See engine

owner's manual for additional safety information.

2. Do not allow children to operate this equipment.

3. Do not operate this equipment in the vicinity of

bystanders.

4. Carbon monoxide can be extremely dangerous in

enclosed areas; do not run the machine in an enclosed area. The exhaust from the engine contains

carbon monoxide, which is colorless, odorless, and

tasteless.

this machine wearing loose clothing particularly if it

has drawstrings which could wrap around or get

caught in the machine.

3. Operate the machine only on a level surface. Do not

operate the machine on a paved, concrete, or hard

gravel surface. Operating on a hard surface may

cause discharged material to rebound and kickback.

It will also cause increased machine vibration.

Increased vibration may cause the machine to move

and will promote premature wear of parts or loosening of fasteners.

4. Before starting the machine, visually check that all

screws, nuts, bolts, and other fasteners are properly

secured. Once every 10 hours of operation, all

screws, nuts, bolts, and other fasteners should be

checked for proper tightness to insure everything is

in proper working condition.

Operation

1. Before starting the machine, make certain that the

cutting chamber is empty .

2. When feeding chipable material into the machine, be

extremely careful to exclude pieces of metal, rocks,

bottles, cans, and other foreign objects.

3. If the cutting mechanism strikes any foreign object

or if the machine should start making an unusual

noise or vibration, immediately shut off the engine,

and allow the machine to come to a complete stop.

After machine stops:

a) Inspect for damage.

5. Do not allow hands, or any part of body or clothing,

inside the feeding chamber, dischar ge chute, or near

any moving part.

6. Before inspecting or servicing any part of the

machine, shut off the engine, and make sure all

moving parts have come to a complete stop.

Preparation

1. Obtain and wear safety glasses at all times while

operating the machine. One pair of safety glasses is

provided with each chipper .

2. A v oid wearing loose-fitting clothing. Ne v er operate

2

b) Replace or repair any damaged parts.

c) Check for and tighten any loose parts.

4. Every 10 hours of operation, check the bolts on the

following for correct torque (75 ft. lbs.):

• Chipper rotor bearing

• Chipper blades (use 5/16" bolts (20 ft lbs))

Failure to maintain proper fastening torque (75 ft.

lbs.) on bolts for the components listed above may

result in severe damage to the chipper and/or

personal injury!

Page 6

S

ECTION

1

5. Do not allow processed material to build up in the

discharge area; this may prevent proper discharge

and can result in kickback of material through the

feed opening.

6. Do not attempt to operate the chipper with any of

the guards, deflectors, or shrouds removed. Keep

away from moving parts.

7. Keep all guards, deflectors, and shrouds in good

working condition.

8. Always stand clear of the discharge area when

operating this machine.

9. Keep your face and body back from the feed opening.

10. Do not overreach. Keep proper balance and footing

at all times.

11. Do not transport or move machine while the machine is running.

12. If the machine becomes clogged, shut off engine.

Allow machine to come to a complete stop before

clearing debris.

13. On electric start models, disconnect cables from

battery before doing any inspection or service.

14. Do not tamper with the engine governor settings on

the machine; the governor controls the maximum

safe operating speed and protects the engine and all

moving parts from damage caused by over-speed.

Additional Safety Rules for PTO

Models

1. Connect 3 pt. hitch pins and snap pins, connect PTO

shaft and have leg stands downa and secure when in

use.

2. To move the unit: shut off the PTO, lift 3 pt. hitch,

and adjust leg stands if needed.

3. Keep guards and shields in place at all times while

operating. Al ways disengag e tractor PTO and shut

off engine before removing guards or shields.

4. Keep hands, feet, and clothing away from all PTO

drive parts.

5. Never clean, lubricate, or adjust the chipper/shredder when it is running.

pants when working around PTO.

7. Before starting tractor always make sure transmission is in neutral or park and PTO is disengaged.

WARNING! Recommended tractor PTO horsepower is 15

HP to 30 HP. Use of these units on tractors above 30 PTO

horsepower may cause belt and machine damage in overload

conditions.

Additional Safety Rules for Towing

1. Always connect hitch safety chains. Make sure

trailer hitch bolts are tight and secure. Do not

attempt to tow the trailer if vehicle is not equipped

with a 2" ball.

2. Maximum towing speed should not exceed 55

M.P.H. Inflate tires to manufactures specs. as stated

on the tire sidewall. Check wheel lug bolts periodically to be sure they are tight and secure.

3. Make sure that the jack stand on trailer is in the UP

position to clear the ground during towing. Place the

jack stand on a level surface and secure it in the

DOWN position before use.

4. Shut off fuel supply to engine when towng.

5. Disconnect spark plug wire when towing.

Maintenance and Storage

1. When this equipment is stopped for servicing,

inspection, storage, or to change an accessory , mak e

sure that the spark plug or PTO is disconnected.

2. Store the machine out of the reach of children and

where fuel vapors will not reach an open flame or

spark. For storage periods of three months or more,

drain the fuel and dispose of it in a safe manner.

Always allow the machine to cool before storing.

Torque Chart

Standard minimum

tightening torque for

normal assembly

applications.

Bolts (SAE GR5)

Size Ft. Lbs.

5/16" 20

3/8" 35

Size Ft. Lbs.

5/16" Set 15

#10-24 Set 3

Screws

6. Never wear loose jackets, shirts, shirt sleeves or

3

Page 7

S

ECTION

1

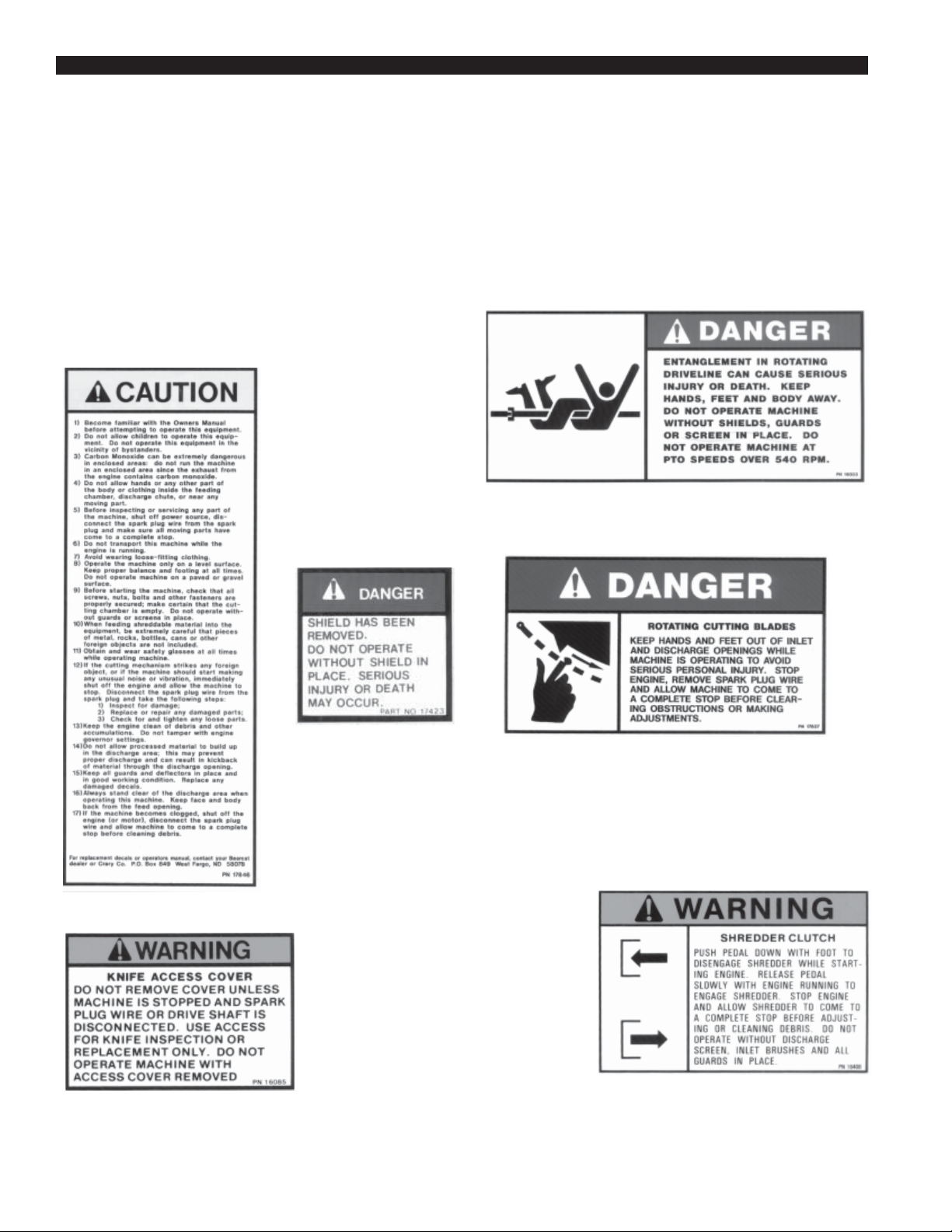

1.2 Safety Decals

Safety and instruction decals are located on the chipper frame and engine. Replace any decal that is damaged or

unreadable. For location of safety decals on the chipper frame, see parts drawings and lists in section 4.

NOTE: For engine safety and instruction decals, see engine owner's manual or contact the engine manufacturer.

Part #16033

PN 17846

Part #16085

Part #17423

Part #17837

Part #16408

4

Page 8

Assembly

S

ECTION

2

Your chipper/shredder may arrive totally or partially

assembled. If your machine arrives partially assembled,

you may need to perform the steps in this section.

2.1.1 Assembly Towable Models

1. Remove the chipper/shredder and hopper assembly

from shipping crate.

2. Place hopper assembly on top of shredder frame.

The tabs on the bottom of the hopper should be

placed inside of the shredder frame. Secure with 11

5/16" x 3/4" Bolts, washers and locknuts. Insert the

bolts from the inside of the hopper outwards.

3. Install rims and wheels onto trailer frame, using the

wheel bolts supplied.

4. Using three 5/16" x 1" bolts, six 5/16" washers, and

three 5/16" locknuts, install the fender onto the

existing fender bracket on the chipper chute side of

the unit. A washer is used on both the bolt head and

the nut in this application. Torque bolts and nuts to

20 ft. lbs.

1. Remove from crate.

2. Place hopper assembly on top of shredder frame.

The tabs on the bottom of the hopper should be

placed inside of the shredder frame. Secure with 11

5/16" x 3/4" Bolts, washers and locknuts. Insert the

bolts from the inside of the hopper outwards.

3. Connect 3 pt. mounts on chipper/shredder and

tractor (a special bushing kit is needed for category

2 & 3 hitches). Secure connection with snap rings.

4. Adjust leg stands so that the PTO drive shaft runsa

as straight as possible. PTO shaft angle should not

o

exceed 7

.

5. Connect PTO shaft between Chipper/Shredder and

tractor. Mak e sure you are using the correct RPM

machine, there are two models, 540 rpm and 2000

rpm. Do not operate machine at speeds different

than specified on shield.

5. Using three 5/16" washers and three 5/16" nylock

nuts, mount the left side fender onto the large belt

guard. There are three weld stubs on the belt guard

to which the fender is attached. Torque to 20 ft. lbs.

6. Insert trailer hitch into track on the bottom of the

trailer frame and secure with three 3/8" bolts,

washers and nuts that connect under the trailer

frame. Tighten to 35 ft. lbs. torque

7. Read and become familiar with the Engine Owners

Manual. Be sure to fill the engine oil before starting

the machine.

8. Install 12 volt battery (not supplied) into tray on

hitch assembly. Connect cables, be sure black cable

is attached to negative battery terminal and red cable

to positive terminal. Secure battery with angle and

bolt. (NOTE: Battery size-Group U1 12 v olt 32

amp-250 cold cranking amps.)

9. Connect spark plug wire.

2.1.2 Assembly PTO Model

NOTE: Minimum & maximum telescoping on the PTO shaft

is 18" to 26". This will leave a 4 inch overlap at maximum

telescoping distance.

NOTE: The maximum distance between the chipper/

shredder and the tractor should not exceed 22-1/2 inches.

2

5

Page 9

S

ECTION

2

6. Never inspect or work on PTO drive area without

first disengaging PTO and shutting off the tractor

engine.

7. Start tractor engine and engage PTO drive clutch

(refer to the tractors owner's manual). Increase

engine speed to rated PTO rpm position.

2000 RPM PTO Models

NOTE: When the tractor used has an electric PTO clutch

and brake, a different PTO shaft should be used.

1. Remove existing PTO shaft shield

2. Remove existing PTO shaft from Chipper/

Shredder.

3. Install new PTO shaft onto Chipper/Shredder.

4. Install new PTO shaft shield onto Chipper/Shredder.

5. Check slip clutch adjustment while the machine is

running to ensure it is operating correctly. Adjust if

needed.

2.1.3 Controls and Operation

Towable Models

1. Engine Throttle. Changes engine speed. (20 hp

A

There are two different

types of unclutched

PTO shaft kits available

for the 2000 RPM units.

Check the PTO end of

your tractor to determine

if you need a Male Drive

Shaft Kit (P/N 70912)

or a Female Drive Shaft

Kit (P/N 70913). There

is a Clutched PTO shaft

Kit (P/N 70885) for

tractors with electric

brake on the PTO.

1,2,3

B

D

C

4

5

7

6

6

Page 10

S

ECTION

2

engine)Turn knob clockwise for full throttle operation. T urn knob counter clockwise for idle on w arm

up. Turn knob all the way down to shut engine off.

(14 hp engine) Pull lever up for full throttle operation. Push lever down for idle on warm up. Push

lever all the down to shut engine off. Refer to

engine owners manual for further engine operating

instructions.

2. Engine Choke. Use when starting cold engine. Pull

to on position when starting. Push lever to of

position when engine is running. Refer to engine

owners manual for further operating instructions.

3. Key Switch. (Not Shown) located above recoild

starter on engine case. Activate starter switch,

release switxh as soon as the engine is running. Do

not crank starter for more than 10 seconds or

damage may result.

4. Engine Fuel Tank. Use unleaded fuel only.

DONOT MIX OIL AND GASOLINE.

5. T r ailer Hitch. Always use 2" ball and hook safety

chains to towing vehicle.

6. Jack Stand. Always have up and clear from the

ground when moving the unit. When the in use,

be sure jack stand is down and locked in position

with the snap pin.

7. Foot Pedal. Used to engage rotor drive belt.

PTO Models

1. 3 pt. Hitch Connections. Mount Chipper/Shred-

der to tractor. Connect direct for categorys 0 & 1. A

bushing kit must be installed on 3 pt. connections

for category 2 hitches.

2. PTO Shaft. Connects tractor PTO to Chipper/

Shredder Drive Shaft. Avoid angle greater than 20

0

up or down when unit is in use.

3. Leg Stands. Adjustable to allow proper driveshaft

angle. Don not move machine unless the legs clear

the ground.

4. Jackshaft. Used for correct belt tension adjustment.

Common Parts

A. Shredder Hopper. Material to be shredded are fed

through the hopper to the shredding knives.

B. Chipper Chute. Material to be chipped are fed

through the chipper chute to the chipper blades.

C. Drive Belt Shield. Never remove shield while

the unit is running.

D. Rotor Access Cover . Used to remove chipper blades

and service rotor assembly.

A

C

1

B

D

4

2

3

7

Page 11

S

ECTION

2

2.1.4 Starting(Towable Model)

Caution: Move machine to a clear, level area outdoors

before starting. do not operate machine on a paved,

concrete, or gravel surface. do not operate in the vicinity of

bystanders. Make sure cutting chamber is empty before

starting.

1. Before starting, check engine oil level and fill if

necessary. See engine owners manual for operation and maintenance instructions.

NOTE: Some oil usage is normal. Check oil level with each

use.

4

WARNING: Handle fuel (gasoline) with care. It is

highly flamable. Always use an approved

container and fill tank outdoors. Never add fuel

to a running or hot engine.

2. Before starting, fill fuel tank with fresh, clean

unleaded regular gasoline. DO NO T MIX OIL

WITH GASOLINE.

3. Disengage clutch lever by pressing foot clutch

pedal.

4. Place engine throttle lever at 3/4 - full open position.

Place engine choke lever to choke position.

NOTE: When restarting a warm engine after a short shut down

period, it may not be necessary to use full choke. If engine fails

tostart, move lever to run or partial choke.

5. Activate the starter switch. Release the key as soon

as the engine starts. Do not crank for more than 10

seconds. Repeat if necessary.

6. Move choke lever to run position after engine starts.

Some choke may be needed until engine is fully

warmed up.

7. Once engine is running and no choke is needed,

slowly let foot clutch pedal up. This will engage

the drive belt and the rotor will turn.

NOTE: If engine kills when engaging foot clutch pedal, either

use more choke or increase engine RPM. When the clutch is

engaged the foot pedal may vibrate or chake until the engine

and rotor have increased to full operating RPM.

2.1.5 Specifications &

Recommendations

The Bear Cat chipper/shredder is designed to gind,

shred, and chip a variety of materials into a more readily

decomposing or handled condition. The following

guidelines can be used to help get you started.

1. Shredding/Grinding. Small materials such as

leaves, grass clippings, and garden

debris(cornstalks, plants, vines, etc.) can easily be

processed through the shredder. Sticks and branches

should be limited to 1-/2 inches in diameter and no

longer than 24 inches long to avoid excess whipping

and wrapping. Wet materials may require use of the

coarse (large hole) or wet debris discharge screen to

avoid plugging. The processed material can be

placed in a compost pile or spread on the ground as

a mulch. The shredder can also be used to process

such materials as newspapers, plastics, aluminum

cans, milk cartons, etc. It may be necessary to use a

branch, cardboard tube, leaf tamper or similar object

to help push material through the inlet guard. When

grinding small dry matrial, use the optional fine

(small hole) discharge screen.

WARNING! Do not reach into either feeding

chamber or discharge area until engine is

stopped, spark plug wire disconnected and the

rotor has stopped turning.

2. Chipping. The chipper can be used to make chips

from branches up to 5 inches in diameter. Lar ger

branches may have to be trimmed so that the limb

will fit into the chipper chute. Several small

branches can be grouped together and fed into the

chipper chute at one time. Changing to the optional

medium discharge screen will make smalled sized

chips. The processed chips can be used as a decorative mulch or placed in a compost pile.

2.2 Operation

2.1.4 Starting(PTO Model)

1. Start tractor engine and engage PTO drive clutch

(See tractor owners manual). Increase engine speed

to reated PTO RPM position.

5

8

2.2.1 Shredding (See Figure 4)

WARNING! Always stand clear clear of the

discharge opening when operating the machine.

Keep hands or any other part of the body or

clothing out of inlet and discharge openings.

WARNING!! DUE TO THE AGRESSIVENESS OF THE

Page 12

S

ECTION

2

MACHINE'S SHREDDING CAPABILITY, DO NOT ATTEMPT

TO HOLD ON TO MATERIAL INTENDED FOR SHREDDING

ONCE IT HAS BEEN PLACED IN THE HOPPER.

1. Place materials to be shredded (grass, leaves, garden

refuse, sticks and branches less the 1-1/2 inches in

diameter and 24 inches long, etc.) into the hopper. If

necessary,

use a leaf

tamper,

branch or

other similar

object to

push material

through the

inlet guards.

Feed material evenly

into the

shredder so

that the

engine does

not lug down

or the

shredder

Figure 4

becomes

plugged.

Attempting

to use the clutch to clear a plugged rotor will cause

belt damage. Refer to Section 3, Clearing Plugged

Rotor, for instructions. Branches or items that plug

or cause the machine to stall should be fed in more

evenly or put through the chipper chute.

2.2.2 Chipping (See Figure 5)

The actual feed rate of the limb into the chipper will

depend on the type of material being fed, the

sharpness of the cutting blades and the size of the

machine. Alternately insert and retract the limb or

insert continuously at a rate that will not kill the

engine. Rotating the branch as it is being fed will

improve cutting action.

The chipping blades will dull with use and require

periodic sharpening. Refer to Section 3, Sharpening

Chipper Blades, for instructions.

Figure 5

2.2.3 Stopping(Towable Models)

To stop the machine, proceede as follows:

1. Move throttle to slow position.

2. Disengage rotor clutch by pressing foot pedal.

3. Move throttle to stop position or turn off ignition

switch and remove spark plug wire from spark plug.

4. Allow machine to come to a complete stop.

WARNING! Keep face and body away from the feed

opening. Do not overreach. Keep proper balance and

footing at all times.

1. Select limbs that are between 3/4 and 5 inches in

diameter; trim side branches off that cannot be bent

over enough to fit into the chipper chute. Some

small branches can be broken off on the chipper

chute transport handle. Small diameter branches

can be held together in a bundle and fed in

simultaneously.

2. Place limb, butt end first, into the chipper chute

until it contacts the chipping blades (See figure 5).

2.2.4 Stopping(PTO Models)

1. Move the tractor throttle to slow position.

2. Disengage the PTO lever and shut off the tractor

engine.

3. Allow the machine to come to a complete stop.

Note: The rotor is heavy and has inertia that will make the rotor

continue to turn for some time after the clutch has been

disengaged. You can tell that the rotor has come to a complete

stop when there is no noise, machine vibration, or the exposed

end of the rotor shaft is not rotating. The stopping time can be

shortened by inserting a branch into the chipper chute so it

contacts the blades and slows the rotor.

9

Page 13

S

ECTION

3

Service and Maintenance

Inspection Items

Check Nuts & Bolts(Including Wheels &

Tire Pressure)

Check

Engine Oil

Replace

Replace Spark Plug

Check

Air Filter Element

Replace Fuel Filter

Clean

Replace

Before

Each

Use

Every

10

Hours

Every

25

Hours

Every

50

Hours

*

Interval

Every

100

Hours

Every

200

Hours

Every

300

Hours

Every

800

Hours

Every

1

years

Check Sharpness of Chipper Blades

Grease Bearings and Pivots

Check Bolts: Chipper Blades

Check Drive Belt

Clean Machine

Note: (*) Service more frequently when used in dusty conditions

Before inspecting or repairing any part of the machine, shut off the engine and make sure all

moving parts have come to a complete stop.

Indicates first hours of use.

10

Page 14

Service and Maintenance

S

ECTION

3

Before inspecting or servicing any part of the

machine, shut off the engine, and make sure all

moving parts have come to a complete stop. The

chipping blades are sharp! Use care when working

on machine to avoid injury.

3.1 Removing Discharge Screen

1. Remove the discharge screen by removing the two

5/16 inch retaining bolts from the bottom of the

screen.

2. Pull the bottom of the screen outward. This will

cause the screen to rotate off the lip on top and fall.

3. To reinstall the discharge screen, place the top lip of

the screen into the slot under the top slope.

4. Rotate the screen so that the bolt holes align with

the holes in the chipper base and the plate butts

against the kicker bar.

5. Reinstall bolts and torque to proper specs.

3.2 Sharpening Chipper

Blades

The chipper blades will eventually become dull, making

chipping difficult. It is recommended that the chipper

blades are sharpened every 5-15 hours of chipper

operation. To remove the chipping blades for

sharpening:

1. Remove the discharge screen by removing the 5/16

inch retaining bolt and pulling the screen outward.

2. Romove the access cover on the chipper chute side

of the machine.

3. Rotate the rotor so that the bolts holding the chipper

blade are most accessable.

heat treated properties. Use short grinding times and

cool with water . Try to remove an equal amount off each

blade to maintain balance. Replace the chipping blades

and tighten bolts to 20 ft. lbs.

NOTE: Never sharpen or grind on the back side of the

chipper blade. This will cause the edge to roll and the

chipping blade will be damaged, causing poor chipping and

feeding of material. Small imperfections, nicks, burrs, etc.

on the flat side of the blade will not affect performance of

the machine.

3.2.1 Chipping Blade Sharpening

Tips

Poor chipping performance is usually a result of dull

chipping blades. If your chipper's performance has

decreased, check for the following symptoms:

• Severe vibration when feeding material into the

chipper.

• Small diameter branches do not self-feed.

• Chips discharge unevenly or have stringy tails–

especially when chipping green branches.

Before you sharpen the chipping blades, check for

permanent damage. Replace the blade if:

• The blade is cracked (especially around the bolt

holes) or the edges are too deeply chipped to be

ground smooth.

• The base of the cutting edge is worn or has been

re-sharpened so that it is too close to the rotor

chipping slot.

4. Remove the two hex head bolts holding the blade

itself. Repeat for all four blades.

Grind the angled edge of the chipping blade to 45

degrees (see figure 6): Grind the blades on a slow-speed

wet grinder if possible, or have them sharpened by a

professional. If you use a bench grinder, be careful when

grinding so that the blade material does not get too hot

and change color–this will remove the blade's special

6

45

0

11

Page 15

S

ECTION

3

3.2.2 Setting Chipping Blade

Clearance

The chipping blades should clear the chipper block

located directly under the chipper chute by 1/16 inch to

1/8 inch. To adjust the blade clearance, proceede as

follows:

1. Remove the lower belt guard, the discharge screen

and the access cover.

2. Loosen the bushing bolts holding the pulley to the

rotor shaft on the front side.

3. Remove the cover cap on rotor shaft rear side.

4. Use a punch and hammer to to tap the lock collars in

a direction opposite of normal rotation so that they

rotate and can be removed.

5 . Using a rubber mallet tap the end of the rotor

shaft to obtain 1/16 to 1/8 of an inch clearance (See

figure 7). The blade clearance can be viewed

through the discharge opening. Rotate the rotor and

check the cleanance on both chipping blades.

6. Once clearance has been set, the lock collars must

be replaced to retain setting. Slip the lock collars

over the eccentric hub on the bearings. Using a

punch and a hammer, rotate the lock collars in the

direction of shaft rotation (i.e. clockwise on the rear

bearing and counter-clockwise on the front bearing)

and "set" them with a positive hammer tap. Tighten

the lock collar set screws.

7. Loosen the bushing holding the belt pulley on the

rotor shaft. Move the pulley on the shaft so it is

aligned directly below the similar pulley on the

engine shaft (the pulley should be moved an

equal but opposite amount the rotor was moved).

8. Replace the lower belt guard, discharge screen, and

rotor shaft cover.

12

7

Page 16

S

ECTION

3

3.3 Replacing Shredder Kit

Care must be taken to insure knives and spacers are

installed properly to maintain rotor balance.

1. Remove discharge screen cov er , dischar ge screen

and rear side access cover.

2. Remove #10-24 nuts and bolts from the knife shafts.

3. Align shaft with access hole in rear of frame.

4. Using a small punch or rod, drive the shaft towards

the access hole.

5. Remove spacers and shredder knives. Be carefull to

keep track of the order the spacers were installed on

the shafts so they can be returned to the original

locations. Reverse or replace knives and reassemble

back onto the rotor. Install a ne w #10-24 nut and

bolt.

6. Repeat steps #3 through #5 to assemble the other

three shafts.

NOTE: Never reuse rotor shafts or bolts and nuts if they

show signs of wear or abuse. Install new ones.

3.3.1 Cleaning Plugged Rotor

(Towable Models)

WARNING! If the machine becomes plugged, shut off the

engine, disconnect the spark plug wire and allow the

machine to come to a complete stop before clearing debris.

Do not operate machine without proper guards and

screens in place.

1. Stop engine, disengage rotor clutch and allow

machine to come to a complete stop. Remove the

spark plug wire.

2. Remove the discharge screen in place.

3. Clean the debris out of the shredding rotor. Turn the

rotor by hand to be sure it is free to rotate.

4. Replace discharge screen.

8

13

Page 17

S

ECTION

3

5. Replace spark plug wire, restart engine and resume

operation.

3.3.2 Cleaning Plugged Rotor (PTO

Models

Do not operate machine without proper guards and

screens in place.

1. Disengage PTO and shutoff tractor engine.

2. Remove the discharge screen.

3. Clean the debris out of the shredding rotor. Turn

the rotor by hand to be sure it is free to rotate.

4. Replace discharge screen.

5. Start tractor, engage PTO and resume operation.

3.3.3 Removing Rotor

Do not operate machine without proper guards and

screens in place.

1. Remove the discharge screen, belt guards and the

rotor shaft end cover.

Models)

Check the condition of the drive belts annually or every

30 hours of operation, whichever comes first. If the belt

is cracked, frayed or worn, it should be replaced. To

replace the belt, proceed as follows:

1. Depress the foot clutch pedal. Shut off the engine

and remove the spark plug wire.

2. Remove the large belt guard.(4-5/26" Bolts)

3. Remove the inner belt guide from under the drive

belt.

4. Disconnect and plug the fuel line from the fuel tank.

Remove the fuel tank from the frame assembly.

5. Adjust for correct belt tension by loosening the four

bolts the mount the engine to the frame and slidding

the engine forward as much as possible.

6. T o rque engine mount bolts, replace fuel tank and

reconnect fuel line.

7. Install lower belt guide and start the engine to test if

belt is tensioned correctly. If the belt continues to be

loose, it will have to be replaced.

2. Loosen the bushing bolts holding the drive pulley to

the shaft and remove the pulley.

3. Loosen the set screw in the lock collars. Using a

punch and hammer, tap the lock collars in a direction opposite of normal rotation so that they can be

removed.

4. Loosen the set screw in the center of the rotor

assembly.

5. Remove the two 3/8x2-1/2" bolts running through

the rotor shaft.

6. Using a rubber mallet or other soft hammer, drive

the shaft towards the chipper chute side of the

machine.

7. Once the shaft has been removed, the rotor assembly

can be taken from the chamber through the discharge opening.

8. To ease reinstallation, smooth any divots or marks in

the shaft caused by the set screws. Clean shaft as

much as possible before installing into machine.

3.3.4 Replacing Drive Belts (Towable

8. Replace large belt guard and resume operation.

9. To replace the drive belt,

1. Remove the large belt guard and lower belt guide.

2. Lift belt idler pulley off the belt and remove the

belt from the pulleys.

3. Install a new belt onto the pulleys and lower belt

idler. Check belt tension before start-up. Install the

lower belt guide.

4. Install the large belt guard and resume oepration.

3.3.5 Replacing Drive Belts (PTO

Models)

Check the condition of the drive belts annually or

every 30 hours of operation, whichever comes first.

If the belt is cracked, frayed or worn, it should be

replaced. To replace the belt, proceed as follows:

1. Disengage PTO and shut off tractor engine.

2. Remove PTO shaft from tractor and disconnect

machine from 3 pt. hitch.

14

Page 18

S

ECTION

3

3. Remove the round shield connected to the belt guard

the covers the PTO shaft by removing the two 5/16"

nuts.

4. Remove the PTO shaft from the chipper/shredder by

loosening the two set screws and pulling the shaft

off.

5. Loosen the bolts mounting the jack shaft pillow

blockand move the shaft towards the frame so belts

can be removed.

6. Install new belts and make sure pulleys are alligned

to within 1/16". If not adjust pulleys.

7. Slide jack shaft away from frame. Tighten bolts so

that 1/4" deflection at center of belt span is obtained

with 10 lb. force applied at the center of the span.

Make sure the jack shaft is aligned parallel to the

rotor shaft before tightening the pillow block bolts.

8. Reinstall belt shields and guards. Install PTIO shaft

and tighten the two set screws. install pTO shield.

Never run PTo without all sjields in place.

3.3.6 Trailer Service Tips

1. Check wheel bolt torque every 10 hours of towing

use.

2. Check air pressure in tire every 10 hours. Fill to 60

PSI.

3. Check and repack wheel bearings with grease every

year.

3.3.7 Additional Service and

Maintenace Tips.

1. Service engine according to engine owners manual.

2. Every 10 hours of operation, all bolts and other

fasteners should be checked for correct torque.

3. The PTO model has 2 greasable bearings on the

rotor shaft. There are also two greasable bearings

on the main jack shaft under the small belt guard.

These bearing need only to be greased once per year

under normal working conditions. Be carefull not to

damage seals on the brearing by over greasing.

4. The PTO shaft also has 4 grease zerks that can be

lightly greased every 50 hours of use.

5. Remove the discharge screen (all models) daily to

avoid material buildup under normal mounting

surfaces. Clean away material and reinstall screen.

3.4 Service Accessories

Description Part Number

Towable PTO

Discharge Screens

Fine 70703 70703

Medium 70531 70531

Coarse 70332 70332

Wet Debris Screen 70559 70559

Goggles (One pair supplied with machine) 17842 17842

Maintenance Kit (Includes spark plug, air filer, oil filter, v-belt) 14 hp 70452

Maintenance Kit (Includes spark plug, air filer, oil filter, v-belt) 20 hp 71043

Leaf Tamper 70649 70649

Tool Steel Chipper Blades (Set of 4) 70453 70453

Shredder Kit 70972 70456

Light Kit 70454 70454

Collection Bag 17854 17854

Spark Plug 16069

2000 PTO Male Chuted Drive Shaft 70885

2000 PTO Male Drive Shaft 70912

2000 PTO female Drive Shaft 70913

3 pt. Hitch Bushing Kit, Category 2 16022

15

Page 19

Troubleshooting

T

ROUBLESHOOTING

Problem

1. Engine will not start

2. Engine or rotor stalls

or stops

3. Hard to feed Chipper

requires

excessive power

required

4. Shredder requires

excessive power or

stalls

Probable Cause

a) Improper control

settings

b) Lack of fuel

c) Internal Problems

a) Obstructed

discharge

b) Plugged Rotor

a) Obstructed

discharge

b) Improper blade

clearance

c) Dull chipper blades

a) Obstructed

discharge

b) Plugged rotor

c) Green material will

not discharge

Suggested

Remedies

a) Use proper setting

b) Fill fuel tank

c) See your dealer

a) Use branch or

similar object to

clear discharge

b) Clear Rotor

a) Use branch or

similar object to

clear discharge

b) Adjust clearance

c) Sharpen blades

a) Use branch or

similar object to

clear discharge

b) Clear rotor, feed

material into

shredder more

evenly.

c) Alternately feed dry

material, or install

coarse discharge

screen or wet debris

screen.

Reference

Engine Manual

Section 3

Section 3

Section 3

5. Engine stalls or belt

squeals when

engaging clutch

6. Material from

chipper wraps

around rotor shaft

16

a) Engaging clutch too

fast

b) Plugged Rotor

a) Stringy, green

material bypasses

chipper blades

b) Improper blades

clearance

c) Plugged discharge

screen

a) Lift clutch lever

more slowly

b) Clear rotor

a) Rotate branch or

material when

feeding to cut

completely

b) Adjust clearance

c) Install wet debris

discharge screen

Section 3

Section 3

Page 20

Declaration of Conformity

The undersigned manufacturer:

Crary Industries, Inc.

237 NW 12

P.O. Box 849

West Fargo, ND 58078-0849

Declares that hereunder specified unit:

CHIPPER SHREDDER

Brand: Crary Bear Cat

Type: PTO driven Chipper/Shredder

Model Number: 70554S

Complies with the requirements of:

Machinery Directive 2006/42/EC

Garden equipment-Integrally power shredders/chippers-Safety EN13683:2003 + A3 2009

EN ISO 12,100, Part 1-Safety of Machinery-Basic Conce pt s, General Principles for Design

Noise Emissions Directive 2000/14/EC

-Conformity Assessment Procedure: Annex V

(Use of harmonized standard EN ISO 3744:2010)

Sound Pressure Level: 99 dB L

Guaranteed Sound Power Level: 113 dB LWA

70554S Serial number X00117 and up

West Fargo, ND 58078-0849

June 29, 2011

CRARY INDUSTRIES, INC. The authorized representative in Europe who is authorized to

compile the technical file:

Company: Atlantic Bridge Limited

Address: Atlantic House, PO Box 4800

Earley, Reading RG5 4GB, United Kingdom

______________________________

Arlan Mathias Mr. Phillip Wicks

Senior Project Engineer

PA

th

Street

Data contained in this document pertains only to machines sold in areas that require CE compliance

standards. To identify if your machine is CE compliant, it will have the following CE mark decal:

Page 21

HEALTH WARNING

GASOLINE, DIESEL, AND

OTHER PETROLEUM PRODUCTS

Harmful or fatal if swallowed.

Long-term exposure to vapors has caused cancer in

laboratory animals.

• Avoid prolonged breathing of vapors.

• Keep face away from nozzle and gas tank/container

opening.

• Never siphon by mouth.

Failure to use caution may cause serious injury or illness.

WARNING

CHEMICALS KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS, OR

OTHER REPRODUCTIVE HARM ARE FOUND IN

GASOLINE, DIESEL, CRUDE OIL, AND MANY O THER

PETROLEUM PRODUCTS AND THEIR V APORS, OR

RESULT FROM THEIR USE.

READ AND FOLLOW LABEL DIRECTIONS AND USE

CARE WHEN HANDLING OR USING ALL PETROLEUM PRODUCTS.

ENGINE EXHAUST FROM THIS PRODUCT CONT AINS CHEMICALS KNO WN T O THE ST ATE OF CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS, OR

OTHER REPRODUCTIVE HARM.

Box 849

West Fargo, ND 58078

(701) 282-5520 (800) 247-7335

FAX: (701) 282-9522

Loading...

Loading...