Page 1

847-540-8400

OPERATOR’S MANUAL

POWER SPRAYER

SHR-210

WARNING DANGER

READ INSTRUCTIONS CAREFULLY AND FOLLOW RULES FOR

SAFE OPERATION.

FAILURE TO DO SO COULD RESULT IN SERIOUS INJURY.

X750-004 14 4

X750604-530 4

-1564

Printed in Japan 1002Ash 1135 ES

Page 2

WARNING

The engine exhaust from this

product contains chemicals known

to the State of California to cause

cancer, birth defects or other

reproductive harm.

Copyright © 2002 All Rights Reserved.

Page 3

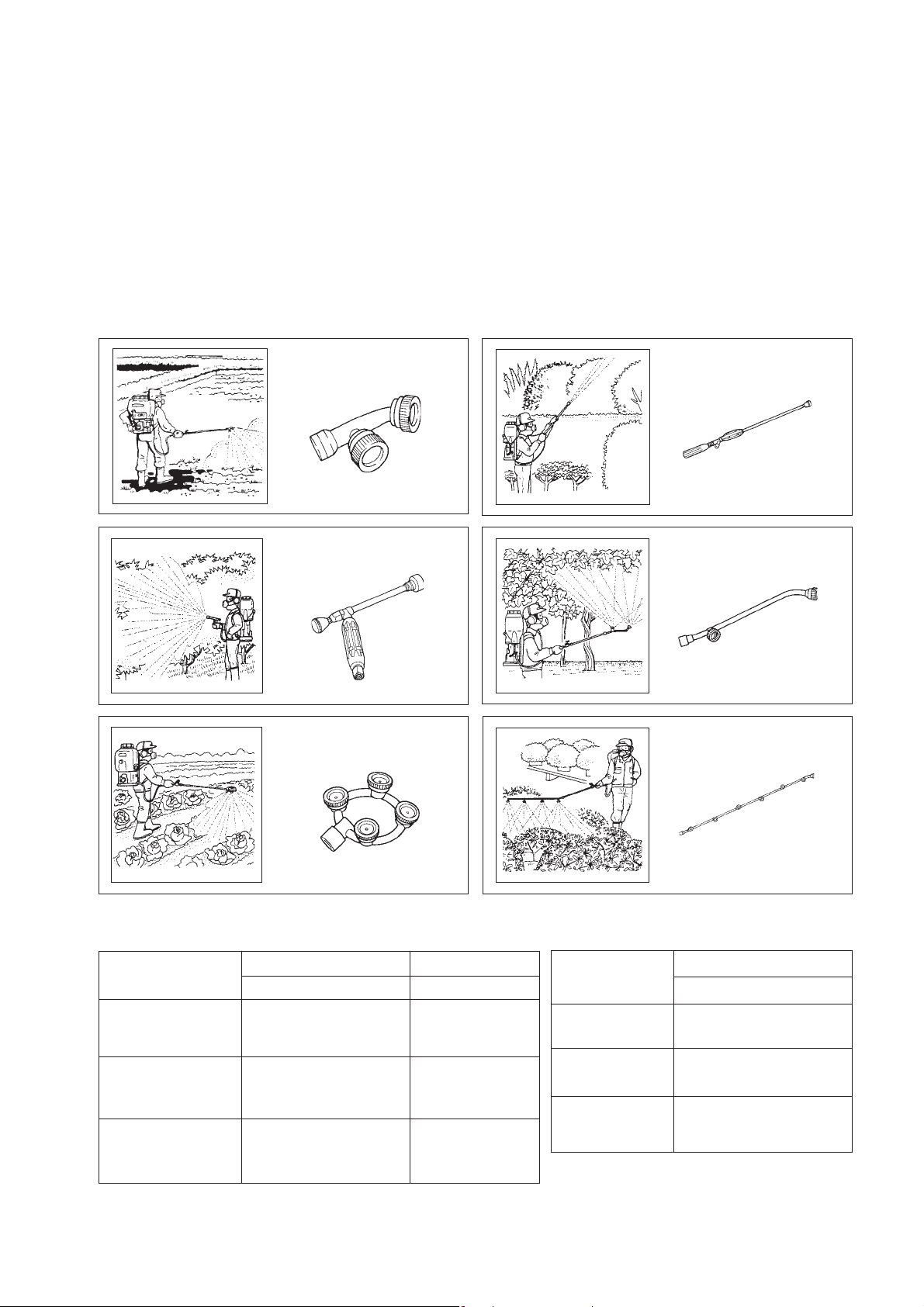

VARIETY OF NOZZLE FOR ECHO POWER SPRAYER SHR-210

Convenient to use and reliable, the go anywhere SHR210 power sprayer is highly versatile with a large variety of optional nozzles which adapts it to a wide range

of applications. The use of this power sprayer at home,

on the farm or in a commercial environment are limitless. Most importantly, what used to take hours takes

only minutes with the SHR-210, making it an

unequaled value for the homeowner and professional

alike.

2-head nozzle

(Standard line type)

Part No.

224 203-1061 0

Standard

Adjustable jet nozzle

(Pistol grip type)

Part No.

224 000-1061 0

Optional

4-head nozzle

(Ring type)

Adjustable jet nozzle

(Long distance type)

Part No.

E025-000260

Optional

2-head nozzle

(Line type)

Part No.

224 202-1061 0

Optional

7-head nozzle

(Line type)

Part No.

224 101-1061 0

Optional

Nozzle specifications (At 1.0 MPa [10kgf/cm2 ]:

142.2 psi)

Nozzle

2-head nozzle 2.4 81.2

(Standard line type)

Adjustable jet nozzle Mist: 2.4 81.2 3 10

(Pistol grip type) Spray: 5.0 169 5 16.7

Adjustable jet nozzle Mist: 2.4 81.2 3 10

(Long distance type) Spray: 5.0 169 5 16.7

Discharge volume

L/min : Fl oz US/min m : ft

Spraying distance

- 1 -

Part No.

224 104-1061 1

••

• For some country, a optional nozzle is supplied

••

* Optional nozzles are available at extra cost

Optional

as standard part.

Discharge volume

Nozzle

2-head nozzle

(Line type)

4-head nozzle

(Ring type)

7-head nozzle

(Line type)

L/min : Fl oz US/min

4.2 142

1.5 50.8

2.0 67.6

Page 4

IMPORTANT

RULES FOR SAFE OPERATION

1.Handle gasoline with care. It is highly inflammable.

- Refuel before starting work.

- Do not smoke while handling fuel.

- Do not refuel a hot engine.

- Avoid spilling fuel or oil. Always wipe unit dry before

using.

- Move at least 3 m (10 feet) away from the fueling

point before starting engine.

- Always store gasoline in an approved container.

2.Do not operate in unventilated area.

3.Do not allow bystanders in work area.

4.Do not point the nozzle in the direction of people.

5.Always wear safety glasses and gloves.

6.Avoid wearing loose clothing or loose scarf.

7.Always use a face filter mask to avoid breathing

chemicals.

8.Handle agricultural chemicals with care. It is

poisonous.

- Always remove chemicals from the tank when not

in use.

- Store chemicals in a safety container.

WARNING

Moving parts can amputate fingers or cause severe injuries. Keep hands, clothing and loose objects away from all

openings.

• ALWAYS stop engine, disconnect spark plug, and make sure all moving parts have come to a complete stop

before removing obstructions, clearing debris, or servicing unit.

• DO NOT start or operate unit unless all guards and protective covers are properly assembled to unit.

• NEVER reach into any opening while the engine is running. Moving parts may not be visible through openings.

WARNING

Check fuel system for leaks due to fuel tank damage, especially if the unit is dropped. If damage or leaks are found,

do not use unit, otherwise serious personal injury or property damage may occur. Have unit repaired by an authorized servicing dealer before using.

CONTENTS

RULES FOR SAFE OPERATION .............................................................................................................. 2

NOMENCLATURE ..................................................................................................................................... 3

ASSEMBLING .......................................................................................................................................... 4

OPERATION ............................................................................................................................................. 4

MAINTENANCE AND CARE ..................................................................................................................... 8

EMISSON DATA ........................................................................................................................................ 10

TROUBLE SHOOTING ............................................................................................................................. 11

STORAGE AFTER USE ........................................................................................................................... 13

TECHNICAL DATA .................................................................................................................................... 13

WARRANTY STATEMENTS ...................................................................................................................... 14

- 2 -

Page 5

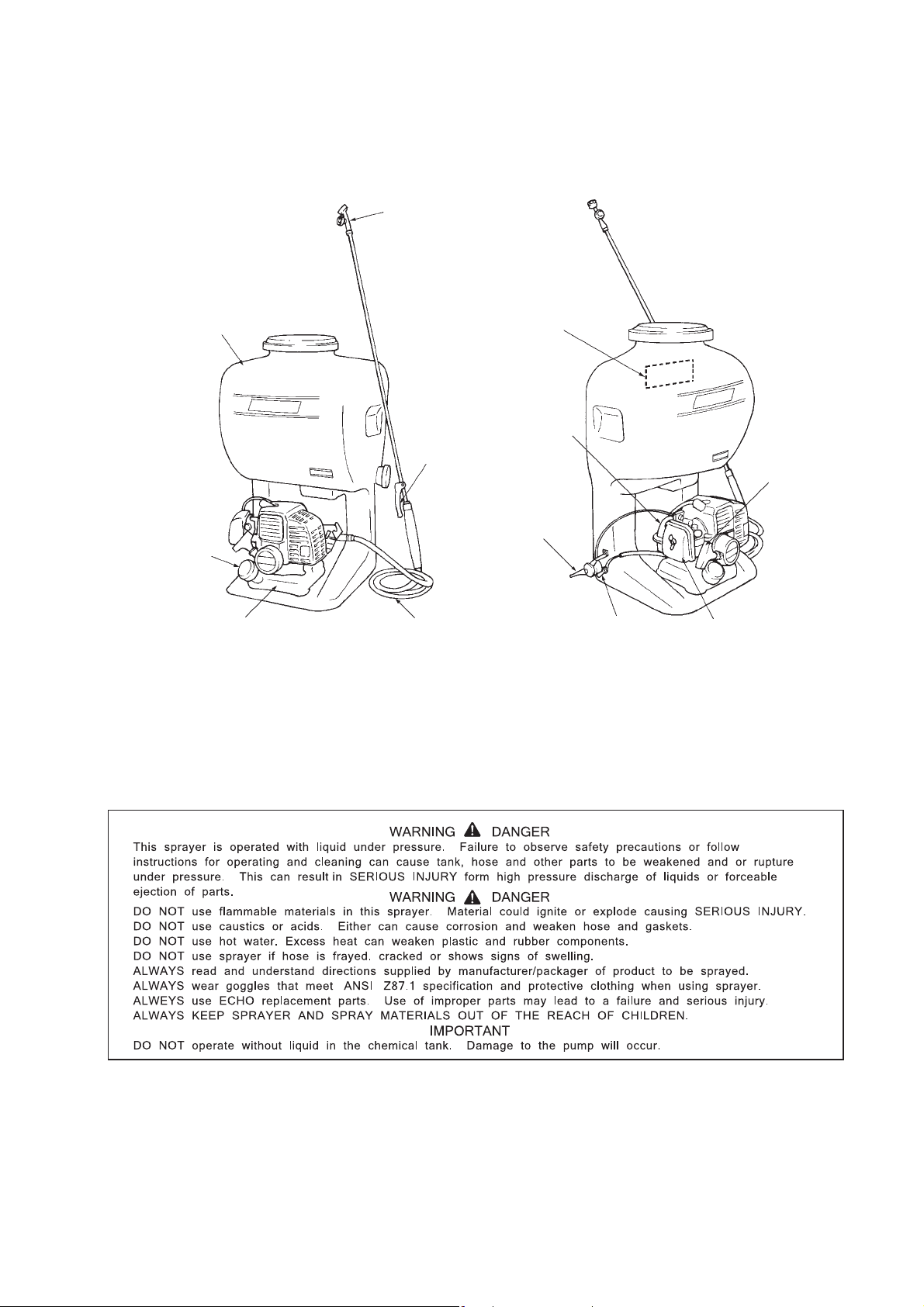

Chemical liquid tank

Fuel tank cap

NOMENCLATURE

Nozzle

Safety decal:

Part number 890160-13210

Pump

Liquid valve

Starter handle

Throttle lever

Fuel tank

Locate this safety decal on your unit. The complete unit illustration found in the “NOMENCLATURE” section, will help you locate them. Make sure the decal is legible and that you understand and follow the

instructions on them. If a decal cannot be read, a new one can be ordered from your ECHO dealer.

Safety decal: Part number 890160-13210

Spray hose

Ignition switch

Air cleaner

- 3 -

Page 6

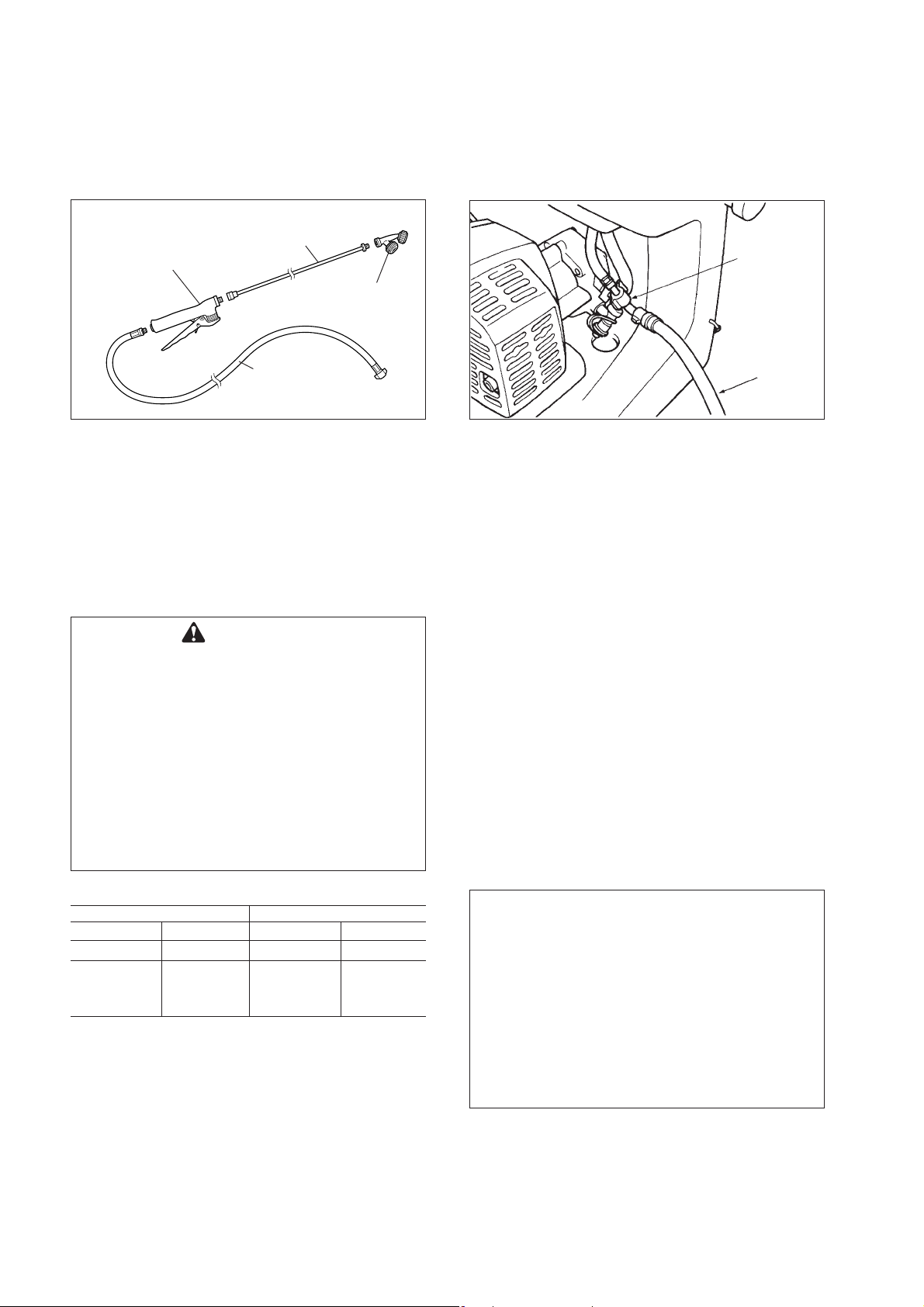

ASSEMBLING

SPRAY HOSE AND NOZZLE

• Install spray hose, liquid valve, nozzle pipe and nozzle to the machine.

Nozzle pipe

Liquid valve

Nozzle

Nipple

Spray hose

SHOULDER STRAPS

• Shoulder straps are adjustable to fit any operator.

• Adjust straps so that pads rest comfortably on the operator’s shoulders.

OPERATION

GENERAL CHECK

• Ensure that all nuts, screws and bolts installed are properely tightened.

FUEL STATEMENT

WARNING

Alternative fuels, such as E-20 (20 % ethanol),

E-85 (85 % ethanol) or any fuels not meeting

above requirements are NOT approved for use

in ECHO 2-stroke gasoline engines.

Use of alternative fuels may cause

performance problems, loss of power,

overheating, fuel vapor lock, and unintended

machine operation, including, but not limited

to, improper clutch engagement.

Alternative fuels may also cause premature

deterioration of fuel lines, gaskets, carburetor

and other engine components.

Fuel mix chart (50 : 1)

US METRIC

GAS OIL GAS OIL

GAL. FL.OZ. L mL

1 2.6 4 80

2 5.1 8 160

5 12.8 20 400

GASOLINE - Use 89 Octane [(R+M)/2] (mid grade or

higher) gasoline or gasohol known to be good quality.

Gasohol may contain up to 10 % Ethyl (grain) alcohol

or 15 % MTBE (methyl tertiary-butyl ether). Gasohol

containing methyl (wood) alcohol is NOT approved.

TWO-STROKE OIL - A two-stroke engine oil meeting

ISO-L-EGD (ISO/CD 13738) and JASO M345-FC/FD

Standards must be used. ECHO brand premium Power

Blend XTM Universal 2-Stroke Oil meets these

standards. Engine problems due to inadequate

lubrication caused by failure to use an ISO-L-EGD

(ISO/CD 13738) and JASO M345-FC/FD certified oil,

such as ECHO premium Power Blend XTM, will void

the two-stroke engine warranty.

IMPORTANT

• ECHO premium Power Blend X

Stroke Oil may be mixed at 50 : 1 ratio for

application in all ECHO engines sold in the past

regardless of ratio specified in those manuals.

• Use of unmixed, improperly mixed, or fuel older

than 90 days, (stale fuel), may cause hard

starting, poor performance, or severe engine

damage and void the product warranty. Read

and follow instructions in the Storage section of

this manual.

Spray hose

TM

Universal 2-

- 4 -

Page 7

DANGER

Fuel is VERY flammable. Use extreme care

when mixing, storing or handling or serious

personal injury may result.

••

• Use an approved fuel container.

••

••

• DO NOT smoke near fuel.

••

••

• DO NOT allow flames or sparks near fuel.

••

••

• Fuel tanks/cans may be under pressure.

••

Always loosen fuel caps slowly allowing

pressure to equalize.

••

• NEVER refuel a unit when the engine is

••

HOT!

••

• NEVER refuel a unit with the engine

••

running.

••

• DO NOT fill fuel tanks indoors.

••

ALWAYS fill fuel tanks outdoors over bare

ground.

••

• Securely tighten fuel cap after refueling.

••

••

• Inspect for fuel leakage. If fuel leakage is

••

found, do not start or operate until leakage

is repaired.

••

• Move at least 3 m (10 feet) from refueling

••

location before starting the engine.

HANDLING FUEL

MIXING INSTRUCTIONS -

1. Fill an approved fuel container with half of the

required amount of gasoline.

2. Add the proper amount of two-stroke oil to gasoline.

3. Close container and shake to mix oil with gasoline.

4. Add remaining gasoline, close fuel container, and

remix.

IMPORTANT

• Spilled fuel is a leading cause of hydrocarbon

emissions. Some states may require the use of

automatic fuel shut-off containers to reduce fuel

spillage.

• Stored fuel ages. Do not mix more fuel than you

expect to use in thirty (30) days, ninety (90)

days when a fuel stabilizer is added.

• Stored two-stroke fuel may separate. ALWAYS

shake fuel container thoroughly before each

use.

AFTER USE -

DO NOT store a unit with fuel in its tank. Leaks can

occur. Return unused fuel to an approved fuel storage

container.

STORAGE -

Fuel storage laws vary by locality. Contact your local

government for the laws affecting your area. As a

precaution, store fuel in an approved, unoccupied

building, away from sparks and flames.

Chemical liquid tank

Strainer

CHEMICAL (Liquid) TANK

• Fill the tank with liquid chemical through the

strainer. Do not fill without strainer.

(Dust in the tank may cause clogging of the

liquid line or pump.)

• The tank contains 19 L (5.0 gal. US) of liquid.

(NOTE)

Each mark on the side of the tank indicates the

5, 10, and 15 L levels.

• Ensure that tank cap is on tightly to avoid

chemical leak.

• It is not necessary to apply grease / oil to

pump.

- 5 -

Page 8

Shoulder level

STARTING ENGINE

Never start and operate engine before filling

chemical tank to avoid damage to pump.

Choke lever

START (Close)

Purge bulb

RUN (Open)

Fuel return line

Fuel tank

Starter handle

WARNING DANGER

••

•WHEN ENGINE IS STARTED, CONFIRM IF

••

THERE IS NOT ANY ABNORMAL VIBRATION

OR SOUND. IF THERE IS ABNORMAL

VIBRATION OR SOUND, ASK YOUR DEALER

TO REPAIR.

••

•AFTER REFUELING TIGHTEN FUEL CAP

••

FIRMLY AND CHECK FOR LEAKAGE. IN

CASE OF FUEL LEAKAGE REPAIR BEFORE

STARTING OPERATION SINCE THERE IS A

DANGER OF FIRE.

• Fill fuel tank with fuel.

• It is not permitted to fill fuel above the shoulder

level of fuel tank.

• Place ignition switch in START/RUN position.

• Turn choke lever to CLOSE (START) position.

• Keep throttle lever at idle position (in the middle

of scale).

• Operate the carburetor’s purge bulb several

times with your finger (press← →release) to

make sure that fuel flows from the fuel return

line.

• Pull starter handle until engine starts.

High speed

START

HOLD THE MACHINE FIRMLY

Starter handle

Idling

Throttle lever

(NOTE)

- Recoil starter: Use short pulls Do not pull starter rope all the way out, and

rewind it back gradually.

• Pull back choke lever (OPEN position) slowly

after engine starts, and keep at idle speed for a

while to warm it up.

• If temperature is high or engine is warm, keep

choke lever half opened or totally opened.

WARNING

Engine exhaust IS HOT, and contains Carbon

Monoxide (CO), a poison gas. Breathing CO

can cause unconsciousness, serious injury, or

death. Exhaust can cause serious burns.

ALWAYS blow exhaust away from your face

and body.

- 6 -

Page 9

SPRAYING

• Ensure that chemical liquid valve is closed before starting engine.

• After engine is warmed up, turn throttle lever to the high speed position (Upper position) and open

liquid valve.

(NOTE)

Since this unit is equipped with a centrifugal clutch, sprinkling is not possible when the engine is running at

low speeds (idling).

- FOR SAFE OPERATION -

1. Secure the chemical tank cap.

2. Check all connections to avoid chemical leak. (Nozzle, Nozzle pipe, hose etc.)

3. Avoid wearing loose clothing and always wear safety glasses and gloves.

4. Use a face filter mask to avoid breathing chemical.

5. Check wind direction before spraying.

6. Do not point nozzle in the direction of people.

7. Stop the engine when refueling and / or replacing parts.

8. Close fuel chemical liquid valve when not in use.

9. Avoid using at engine speeds where the clutch slips.

STOPPING ENGINE

• Turn throttle lever to the lowest position and the

ignition switch to STOP position.

Ignition switch

1

1. Nozzle body

2. Guide

3. Strainer

3

2

4. Nozzle

5. Cap

(CAUTION)

When misting liquid is over, stop the engine.

Do not keep engine running, when chemical

tank has been emptied.

NOZZLE

• 2-head nozzle (Standard type) is provided with

this power sprayer.

5

4

• Standard nozzle discharge volume and

pressure are as follows.

Chemical liquid Discharge:

2.4 L /min 81.2 Fl.oz US/min

(1.0 MPa) (142.2 psi)

(NOTE)

- You can use a nozzle other than standard nozzle discharges liquid under 7.0 L at nozzle pressure:

1.0 MPa (10 kgf/cm2) as required.

- Long hose (approx. 100 m) is available as required.

- In this case, use standard nozzle indicated above or less discharge volume nozzle.

• As for variety of optional nozzles, please refer to Page 1.

- 7 -

Page 10

MAINTENANCE AND CARE

- ALWAYS KEEP THE MACHINE CLEAN -

Filter

Air cleaner cover

Carburetor

Case

AIR FILTER

• Check before every use.

• Remove filter cover.

- Remove wing nut.

• Brush off dust lightly or wash in a noninflammable solvent if necessary. Dry well

before reinstalling.

0.6 - 0.7 mm (0.024 - 0.028 in.)

CHECK FUEL SYSTEM

• Check before every use.

• After refueling make sure fuel does not leak or

exude from around fuel pipe, fuel grommet or

fuel tank cap.

• In case of fuel leakage or exudation there is a

danger of fire. Stop using the machine

immediately and request your dealer to inspect

or replace.

SPARK PLUG

• Clean or replace the plug if fouled with heavy or

oily deposits. Replace the plug if the center

electrode is worn or rounded at the end.

- The standard spark gap is 0.6 to 0.7 mm

(0.024 to 0.028 in.).

- Correct the spark gap if it is wider or narrower

than the standard gap.

• Fastening torque = 15 to 17 N•m

(130 to 145 in•lb.)

- 8 -

Page 11

Breather valve

Breather hole

CHEMICAL TANK BREATHER

• Clean breather valve and breather hole

periodically.

• Bad sealing of the breather valve may cause a

leakage of the chemical.

Clogging of the breather hole may cause a “dent”

or a breakage of the chemical tank.

CHEMICAL STRAINER

• Clean chemical strainer periodically.

• Clogging of the chemical strainer may cause

insufficient discharge of the chemical.

Return pipe

Chemical strainer

Bypass nozzle plate

Nipple

BYPASS NOZZLE PLATE

• Clean bypass nozzle plate, if liquid chemical is

not well stired-up in the tank.

WHEN SPRAYING IS FINISHED

• Fill chemical tank with water and spray through

nozzle for 2 to 3 minutes for cleaning.

• Drain water from the machine through misting

nozzle and remove pump drain plug.

• Wipe off the liquid chemical on the machine

after use.

Remove the drain plug

Drain plug

- 9 -

Page 12

EMISSION DATA

EMISSION CONTROL

(EXHAUST ) EPA 2010 and/or C.A.R.B. TIER III

The emission control system for the engine is EM/

TWC (Engine Modification and 3-way Catalyst)

An Emission Control Label is located on the

engine. (This is an example only, information on

label varies by engine family).

High Altitude Operation

This engine has been factory adjusted to maintain

satisfactory starting, emission, and durability

performance up to 1100 feet above sea level (ASL)

(96.0 kPa). To maintain proper engine operation

and emission compliance above 1100 feet ASL the

carburetor may need to be adjusted by an

authorized ECHO service dealer.

PRODUCT EMISSION DURABILITY

(EMISSION COMPLIANCE PERIOD)

The 300 hours emission compliance period is the

time span selected by the manufacturer

certifying the engine emissions output meets

applicable emissions regulations, provided that

approved maintenance procedures are followed

as listed in the Maintenance Section of this

manual.

IMPORTANT

If the engine is adjusted for operation above 1100

feet ASL, the carburetor must be readjusted

when operating the engine below 1100 feet ASL,

otherwise severe engine damage may result.

- 10 -

Page 13

TROUBLE SHOOTING

Poor performance of the engine and/or spraying mechanism can normally be prevented by carefully following

the above instructions.

Poor performances can easily be corrected even by a beginner.

When the engine does not function properly check the following three (3) points first.

• Is engine compression adequate?

• Is fuel system in good condition and is enough fuel being supplied?

• Is electrical system in good condition and is spark plug operating normally?

When there is serious trouble with the unit, do not try to repair it yourself but have your distributor or dealer do it

for you. For detailed TROUBLE SHOOTING refer to tables 1 and 2. Locate the problem on the following charts

and repair as necessary.

Table 1

Engine does not start (or, is difficult to start)

Engine cranks

There is fuel in the tank

Fuel is reaching carburetor

Fuel is not

reaching

carburetor

Fuel is not

reaching

cylinder

No spark at high

tension cord end

No spark at plug

Fuel is reaching cylinder

There is spark at high

tension cord end

Acceleration and

There is spark at plug

low speed

function

defective

Starting procedures

correct

Fuel does

not keep

running

Carburetor

overflow

Fuel filter clogged Clean or replace.

Fuel pipe clogged Clean.

Suction insufficient Make sufficient.

Fuel filter clogged Clean or replace.

Carburetor out of order Disassemble and check.

C.D.I. module defective Remove and replace.

Ignition coil defective Remove and replace.

Wire connection defective Reconnect.

High-tension cord Repair as necessary.

connection defective

Switch is grounded Switch on.

Insulator cracked Replace plug.

Spark gap incorrect Adjust.

Covered with carbon Clean or replace.

Fouled with fuel Clean or replace.

Starting procedures Start correctly.

incorrect

Fuel passage clogged Disassemble and clean.

with dust

Fuel passage locked Remove air.

with air

Fuel leaking from fixing Retighten all screws.

surfaces of carburetor

Air passage, fuel tank Replace or clean.

clogged with dust

Fuel inlet needle valve Clean.

clogged with dust

This is because fuel mixture

is too rich.

Muffler sticky Start the engine several

with fuel times with choke rod fully

open and run at fast idle until

engine does not smoke.

Engine does

not crank

Bearing damaged Disassemble and replace.

Piston and / or cylinder Disassemble and replace.

seized

Crankshaft worn Disassemble and replace.

Crankshaft contacting Disassemble and replace.

crankcase

- 11 -

Page 14

Table 2

Engine overheated

Improper fuel is used Use fuel with correct mixing

ratio. Never use gasoline of

poor quality.

Spark plug defective (burnt) Replace.

As cooling fins clogged, air Clean fins.

does not pass well

Excessive deposits in Disassemble and remove

combustion chamber carbon.

Output (engine speed) insufficient

Engine keeps running,

Firing function defective

Carburetor defective

Other troubles

Spray is not a fine mist

Plug damaged or fouled Replace or clean.

Combustion poor due to Check wiring.

defective wiring

Carburetor overflow Refer to Table 1.

Air filter clogged Clean as necessary.

Compression insufficient Disassemble, check and

(piston ring stuck or worn replace if necessary.

out)

Cylinder chromium plating Replace cylinder.

peeled or worn out

Exhaust port clogged with Clean as necessary.

carbon

Throttle is not fully open Readjust.

Pump case/blade worn out Replace.

(Low pressure)

Chemical liquid line Replace.

defective

(Mechanical seal or packing

etc.)

Cracked spraying hose is Replace.

used

Nozzle orifice is too large Replace.

(Too much chemical is

released)

Chemical line is completely Clean.

clogged with dirt

No spray

Output (engine speed) sufficient

Chemical tank is empty Refill.

Pump is damaged Replace.

WARNING DANGER

FUEL VAPORS ARE EXTREMELY FLAMMABLE AND MAY CAUSE FIRE AND/OR EXPLOSION. NEVER

TEST FOR IGNITION SPARK BY GROUNDING SPARK PLUG NEAR CYLINDER PLUG HOLE,

OTHERWISE SERIOUS PERSONAL INJURY MAY RESULT.

- 12 -

Page 15

STORAGE AFTER USE

• Drain remaining liquid out of the chemical tank.

• Inspect and adjust every part of the sprayer.

- Completely clean every part, and repair, if

necessary.

- Apply thin coating of oil on metal parts to

prevent rust.

- Remove spraying hose and pipe.

• Drain fuel tank, pull starter slowly a few times to

drain fuel from carburetor.

• Pour a small amount of clean motor oil into

spark plug hole, pull starter and crank the

engine until the TOP DEAD CENTER.

• Store in a dry area, free from dust.

TECHNICAL DATA

Dimension L × W × H mm (in.) 330 × 405 × 590 (13.0 × 15.9 × 23.2)

Mass w/o Spraying hose kg (lb) 7.4 (16.3)

and nozzle

Capacity Chemical liquid tank L (gal.US) 19.0 (5.0)

Engine Type Air cooled, two stroke single cylinder

Displacement mL (cu.in.) 21.2 (1.3)

Rated speed r/min 7500

Carburetor ZAMA diaphragm type

Ignition Flywheel magneto : CDI (Capacitor discharge

ignition) system

Spark plug NGK BPM8Y

Starter Recoil starter

Fuel Mixing ratio Mixture of gasoline (unleaded, 89 octane

minimum) and specially blended 50 : 1 ECHO two

cycle engine oil.

Tank capacity L (fl.oz.US) 0.5 (16.9)

Pump Type Regenerative pump

Discharge volume L/min 0.8 - 7.0 (27 - 236.7)

(Nozzle) (fl.oz.US/min)

Pressure MPa 0.6 - 1.0

kgf/cm2 (psi.) 6 - 10 (85.3 - 142.2)

Nozzle 2-head nozzle*

Spraying hose 7.5 mm φ (Inner diameter)

* Technical data may be changed without advance notice.

- 13 -

* Other nozzles are available as optional supply.

Page 16

WARRANTY STATEMENTS

ECHO LIMITED WARRANTY STATEMENT FOR

PRODUCT SOLD IN USA AND CANADA BEGINNING 01/01/2010

ECHO’S RESPONSIBILITY

ECHO Incorporated’s Limited Warranty, provides to the original purchaser that this ECHO product is free from defects in

material and workmanship. Under normal use and maintenance from date of purchase, ECHO agrees to repair or replace at

ECHO’s discretion, any defective product free of charge at any authorized ECHO servicing dealer within listed below

application time periods, limitations and exclusions. THIS LIMITED WARRANTY IS ONLY APPLICABLE TO ECHO

PRODUCTS SOLD BY AUTHORIZED ECHO DEALERS. IT IS EXTENDED TO THE ORIGINAL PURCHASER ONLY, AND

IS NOT TRANSFERABLE TO SUBSEQUENT OWNERS EXCEPT FOR EMISSION RELATED PARTS. Repair parts and

accessories replaced under this warranty are warranted only for the balance of the original unit or accessory warranty period.

Any damage caused by improper installation or improper maintenance is not covered by this warranty. All parts or products

replaced under warranty become the property of ECHO, Inc. This warranty is separate from the Emission Control Warranty

Statement supplied with your new product. Please consult the Emission Control Warranty Statement for details regarding

emission related parts. For a list of Authorized ECHO Dealers refer to WWW.ECHO-USA.COM or call 1-800-432-ECHO.

OWNER’S RESPONSIBILITY

To ensure trouble free warranty coverage it is important that you register your ECHO equipment on-line at WWW.ECHOUSA.COM or by filling out the warranty registration card supplied with your unit. Registering your product confirms your

warranty coverage and provides a direct link if we find it necessary to contact you.

The owner shall demonstrate reasonable care and use, and follow preventative maintenance, storage, fuel and oil usage as

prescribed in the operator’s manual. Should a product difficulty occur, you must, at your expense, deliver or ship your ECHO

unit to an authorized ECHO servicing dealer for warranty repairs (within the applicable warranty period), and arrange for pickup or return of your unit after the repairs have been made. For your nearest authorized ECHO servicing dealer, call ECHO’s

Dealer Referral Center, at 1-800-432-ECHO or you can locate an ECHO servicing dealer at WWW.ECHO-USA.COM. Should

you require assistance or have questions concerning ECHO’s Warranty Statement, you can contact our Consumer Product

Support Department at 1-800-673-1558 or contact us through the web at WWW.ECHO-USA.COM.

PRODUCT WARRANTY PERIOD

RESIDENTIAL APPLICATION

• 5 YEAR WARRANTY - All units for residential, or non-income producing use will be covered by this limited warranty for five

(5) years from date of purchase.

EXCEPTIONS:

• For two-stroke engine powered products, the electronic ignition module, flexible drive cables, SRM solid drive shafts, and

TC tines are warranted for the life* of the product on parts only.

• Cutting attachments such as, but not limited to, bars, chains, sprockets, blades, and nylon trimmer heads for residential or

non-income producing use will be covered for failures due to defects in material or workmanship for a period of 60 days

from original product purchase date. Any misuse from contact with concrete, rocks, or other structures is not covered by

this warranty.

• ECHO’s Rapid Loader String Head carries a lifetime warranty on the line locking system, parts only; no labor. Refer to

your operator’s manual for string head installation and maintenance instructions.

• All SB-Series and PRO ATTACHMENT SERIES Split Shaft attachments carry the same warranty duration as the units

they are designed to fit.

COMMERCIAL APPLICATION

• 1 YEAR WARRANTY - All Chain Saws, QuikVent Saws, and Cut-Off Saws for commercial, institutional, agricultural,

industrial, or income producing use will be covered by this limited warranty for a period of one (1) year from the date of

purchase.

• 2 YEAR WARRANTY - All other units for commercial, institutional, agricultural, industrial, or income producing use will be

covered by this limited warranty for a period of two (2) years from the date of purchase.

EXCEPTIONS:

• For two-stroke engine powered products, the electronic ignition module, flexible drive cables, SRM solid drive shafts and

TC tines, are warranted for the life* of the product on parts only.

• Cutting attachments such as, but not limited to, bars, chains, sprockets, blades, and nylon trimmer heads for commercial,

institutional, agricultural, industrial, rental, or income producing will be covered for failures due to defects in material or

workmanship for a period of 30 days from original product purchase date. Any misuse from contact with concrete, rocks,

or other structures is not covered by this warranty.

• ECHO’s Rapid Loader String Head carries a lifetime warranty on the line locking system, parts only; no labor. Refer to

your operator’s manual for string head installation and maintenance instructions.

• All SB-Series and PRO ATTACHMENT SERIES Split Shaft attachments carry the same warranty duration as the units

they are designed to fit.

RENTAL APPLICATION - 90 DAYS WARRANTY

• Units for rental use will be covered against defects in material and workmanship for a period of 90 days from the date of

purchase.

* ECHO’s liability under the “Lifetime” coverage is limited to furnishing parts specified under the PRODUCT WARRANTY

PERIOD section of this Warranty Statement for “Life” free of charge for a period of ten (10) years after the date of the

complete unit’s final production.

- 14 -

Page 17

PURCHASED REPAIR PARTS, SHORT BLOCKS AND ACCESSORIES

• 90-day residential, or non-income producing warranty

• 30-day commercial, institutional, agricultural, industrial, income producing, or rental application warranty

ATTENTION TWO-STROKE ENGINE POWER PRODUCT OWNERS

This ECHO two-stroke engine power product is a quality-engineered unit which has been manufactured to exact tolerances to

provide superior performance. To help ensure the performance of the unit, it is required to use two-stroke oil which meets the

ISO-L-EGD Standard per ISO/CD 13738 and JASO M345-FC/FD Standards. ECHO Power Blend X™ Two-Stroke Oil is a

premium two-stroke oil specifically formulated to meet ISO-L-EGD (ISO/CD 13738) and JASO M345-FC/FD Standards. The

use of two-stroke oils designed for other applications, such as for outboard motors or lawnmowers can result in severe

engine damage, and will void your two-stroke engine limited warranty.

THIS WARANTY DOES NOT COVER DAMAGE CAUSED BY:

• Lack of lubrication or engine failure, due to the use of two-stroke oils that do not meet the ISO-L-EGD (ISO/CD 13738) and

JASO M345-FC/FD Standards. Engine problems due to inadequate lubrication caused by failure to use an ISO-L-EGD

compliant and JASO M345-FC/FD registered oil, will void the two-stroke engine limited warranty. ECHO Power Blend X™

Two-Stroke Oil meets the ISO-L-EGD and JASO M345-FC/FD Standard. Emission related parts are covered for 5 years

residential use or 2 years commercial use regardless of two-stroke oil used, per the statement listed in the EPA or California

Emission Defect Warranty Explanation.

• Damage caused by use of gasohol, containing methanol (wood alcohol), or gasoline containing less than 89 octane. Only

use gasoline which contains 89 octane or higher. Gasohol which contains a maximum 10 % ethanol (grain alcohol) or 15 %

MTBE (methyl/tertiary/butyl/ether) is also approved. The prescribed mixing ratio of gasoline to oil is listed on the ECHO oil

label and covered in your operator’s manual.

• Engine damage caused by use of ether or any starting fluids.

• Damage caused by tampering with engine speed governor or emission components, or running engines above specified and

recommended engine speeds as listed in your operator’s manual.

• Operation of the unit with improperly maintained/removed cutting shield or removed/damaged air filter.

• Damage caused by dirt, pressure or steam cleaning the unit, salt water, corrosion, rust, varnish, abrasives, and moisture.

• Defects, malfunctions or failures resulting from abuse, misuse, neglect, modifications, alterations, normal wear, improper

servicing, or use of unauthorized attachments.

• Incorrect storage procedures, stale fuel, including failure to provide or perform required maintenance services as prescribed

in the operator’s manual. Preventative maintenance as outlined in the operator’s manual is the customer’s responsibility.

• Failures due to improper set-up, pre-delivery service or repair service by anyone other than authorized ECHO servicing

dealer during the warranty period.

• Certain parts and other items are not warranted, including but not limited to: lubricants, starter cords, and engine tune-ups.

• Use of spark plugs other than those meeting performance and durability requirements of the OEM spark plug listed in the

Operator’s Manuals.

• Overheating or carbon scoring failures due to restricted, clogged exhaust port or combustion chamber, including damage to

spark arrester screen.

• Adjustments after the first (30) thirty days and beyond, such as carburetor adjustment and throttle cable adjustment.

• Damage to gears or gear cases caused by contaminated grease or oil, use of incorrect type or viscosity of lubricants, and/

or failure to comply with recommended grease or oil change intervals.

• Damage caused by loading SHRED ‘N’ VAC® beyond recommended capacity.

• Damage caused by pump or sprayer running dry, pumping or spraying caustic or flammable materials, or lack of or broken

strainers.

• Additional damage to parts or components due to continued use after operational problem or failure occurs. Should

operational problem or failure occur, the product should not be used, but delivered as is to an authorized ECHO servicing

dealer.

It is a dealer’s and/or customer’s responsibility to complete and return the warranty registration card supplied with your ECHO

product or by visiting WWW.ECHO-USA.COM. Your receipt of purchase including date, model and serial number must be

maintained and presented to an authorized ECHO servicing dealer for warranty service. Proof of purchase rests solely with

the customer. Some states do not allow limitations on how long an implied warranty lasts, so the above limitations may not

apply to you. Some states do not allow the exclusion or limitation of incidental or consequential damages, so you may also

have other specific legal rights which vary from state to state. This limited warranty is given by ECHO Incorporated, 400

Oakwood Rd., Lake Zurich, IL 60047.

DISCLAIMER OF IMPLIED WARANTIES

This limited warranty is in lieu of all other expressed or implied warranties, including any warranty of FITNESS FOR A

PARTICULAR PURPOSE OR USE and any implied warranty of MERCHANTABILITY otherwise applicable to this product.

ECHO and its affiliated companies shall not be liable for any special incidental or consequential damage, including lost profits.

There are no warranties extended other than as provided herein. This limited warranty may be modified only by ECHO.

- 15 -

Page 18

ECHO INCORPORATED EMISSION CONTROL WARRANTY STATEMENT FOR ECHO BRAND

The Environmental Protection Agency (EPA) and the California Air Resources Board (C.A.R.B.) and ECHO Incorporated

(ECHO Inc.) are pleased to explain the emission control system warranty on your 2010 and later equipment/small off-road

engine (SORE). New equipment/SORE must be designed, built and equipped to meet stringent EPA and C.A.R.B. anti-smog

standards. ECHO Inc. must warrant the emission control system on your equipment/SORE for the periods of time listed

below, provided there has been no abuse, neglect or improper maintenance of your equipment/SORE. Your emission control

system may include parts such as: carburetor, fuel-injection system, ignition system, catalytic converter/muffler, fuel tank, fuel

feed lines, fuel cap assembly, spark plug, air filters, and other associated components. Where a warrantable condition exists,

ECHO Inc. will repair your equipment/SORE at no cost to you including diagnosis, parts and labor. The Emission Control

System Warranty is extended to the original owner including all subsequent owners.

MANUFACTURER’S WARRANTY COVERAGE:

The emission control system is warranted for 2 years or the length of the ECHO Inc. warranty, whichever is longer. If any

emission-related part on your equipment is defective, the part will be repaired or replaced by ECHO Inc. or its Authorized

Service Representative.

OWNER’S WARRANTY RESPONSIBILITIES:

As the equipment/SORE owner, you are responsible for the performance of the required maintenance listed in your Operator’s

Manual. ECHO Inc. recommends that you retain all receipts covering maintenance on your equipment/SORE however, ECHO

Inc. cannot deny warranty solely for the lack of receipts or for your failure to ensure the performance of all scheduled

maintenance. As the equipment/SORE owner, you should be aware that ECHO Inc. may deny you warranty coverage if your

equipment/SORE or a part has failed due to abuse, neglect, improper maintenance or unapproved modifications.

You are responsible for presenting your equipment/SORE to an ECHO Inc. authorized service representative as soon as a

problem exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days. If a

warrantable condition exists and there is no Authorized Dealer within 100 miles, ECHO Inc. will pay to ship the unit to the

nearest authorized dealer. If you have questions regarding your warranty coverage, you should contact ECHO Inc. at 1-800673-1558, web site WWW.ECHO-USA.COM.

WHAT DOES THIS WARRANTY COVER?

ECHO Inc. warrants that your equipment/SORE was designed, built and equipped to conform with applicable EPA and

C.A.R.B. emissions standards and that your equipment/SORE is free from defects in material and workmanship that would

cause it to fail to conform with applicable requirements for 2 years or the length of the ECHO Inc. warranty, whichever is

longer. The warranty period begins on the date the product is purchased by an end user.

HOW WILL A COVERED PART BE CORRECTED?

If there is a defect in a part covered by this warranty, any ECHO Inc. Authorized Service Dealer will correct the defect. You

will not have to pay anything to have the part adjusted, repaired or replaced. This includes any labor and diagnosis for

warranted repairs performed by the dealer. In addition, engine parts not expressly covered under this warranty but whose

failure is a result of a failure of a covered part will be warranted.

WHAT PARTS ARE COVERED?

Any applicable emission related part not scheduled for “required maintenance” will be repaired or replaced within the warranty

period. The repaired or replaced part will be warranted for the remaining ECHO Inc. warranty period.

Any warranted part that is scheduled only for regular inspection in the written instructions supplied is warranted for the

warranty period stated above. Any such part repaired or replaced under warranty will be warranted for the remaining ECHO

Inc. warranty period.

Any emission related part scheduled for replacement during “required maintenance” is warranted for the period of time prior to

the first scheduled replacement point for that part. Any such part repaired or replaced under warranty shall be warranted for

the remainder of the period prior to the first scheduled replacement point for that part.

Any manufacturer-approved replacement part may be used in the performance of any warranty maintenance or repairs on

emission related parts, and must be provided without charge if the part is still under warranty.

Any replacement part that is equivalent in performance and durability may be used in non-warranty maintenance or repairs,

and shall not reduce the warranty obligations of the manufacturer.

Throughout the equipment/SORE warranty period, ECHO Inc. will maintain a supply of warranted parts sufficient to meet the

expected demand for such parts.

SPECIFIC EMISSION RELATED WARRANTED PARTS:

• Electronic Ignition System • Spark Plug

• Catalytic Converter / Muffler Assembly • Carburetor (complete assembly or replaceable components)

• Choke • Fuel-Injection Assembly (or replaceable components)

• Fuel Tank • Fuel Cap Assembly

• Air Filter • Fuel Feed Line (and associated clamps/connectors as applicable)

WHAT IS NOT COVERED?

Any failure caused by abuse, neglect, improper maintenance, unapproved modifications, use of unapproved add-on parts/

modified parts or unapproved accessories.

This Emission Control Warranty is valid only for the U.S.A., it’s Territories, and Canada.

- 16 -

Loading...

Loading...