Page 1

1

ECHELON

™

SNOW BLOWER

INSTRUCTION MANUAL

SKU: SNOW18

IMPORTANT: PLEASE READ MANUAL BEFORE ASSEMBLY OR USE

Key Technical Parameters

Working

Width

Max. Throwing

Distance

Max Output

Fuel Tank

Cap.

Startup

Mode

Vibration

Net

Weight

18in.

26ft

2.8HP/1.65KW

1.6L

Manual

4.0m/s2

24.5lbs

BASEMENT BRANDS ● WWW.BASEMENTBRANDS.COM ● CustomerService@BasementBrands.com ● 515-577-0977

Page 2

2

Introduction

This machine is intended for use by residential

homeowners. It is primarily designed to remove

snow from paved surfaces, such as driveways,

sidewalks, and other surfaces for traffic on

residential or commercial properties. It is not

designed to remove materials other than snow,

nor is it designed to clear off gravel surfaces.

Read this manual carefully to learn how to operate

and maintain your product properly, and to avoid

injury and product damage. You are responsible

for operating the product properly and safely.

This is the safety alert symbol. It alerts you to

potential personal injury hazards. Follow all safety

messages that follow this symbol to avoid possible

injury or death.

This manual uses two words to highlight

information: ―Important‖ calls attention to special

mechanical information and ―Note‖ emphasizes

general information worthy of special attention.

Safety

This machine meets or exceeds the ANSI B71.3

Specifications of the American National

Standards Institute in effect at the time of

production.

Read and understand the contents of this

manual before you start the engine.

This machine is capable of throwing objects

and of injuring hands and feet. Failure to

observe the following safety instructions could

result in serious injury.

Improperly using or maintaining this machine

could result in injury or death. To reduce this

potential, comply with the following safety

instructions.

Training

• Read, understand, and follow all instructions

on the machine and in the manual(s) before

operating this machine.

• Thoroughly familiarize yourself with the controls

and proper use of the machine. Know how to stop

the machine and disengage the controls quickly.

• Never allow children to operate the machine.

Never allow adults to operate the machine

without proper instruction.

• Keep the area of operation clear of all persons,

particularly small children.

• Exercise caution to avoid slipping or falling.

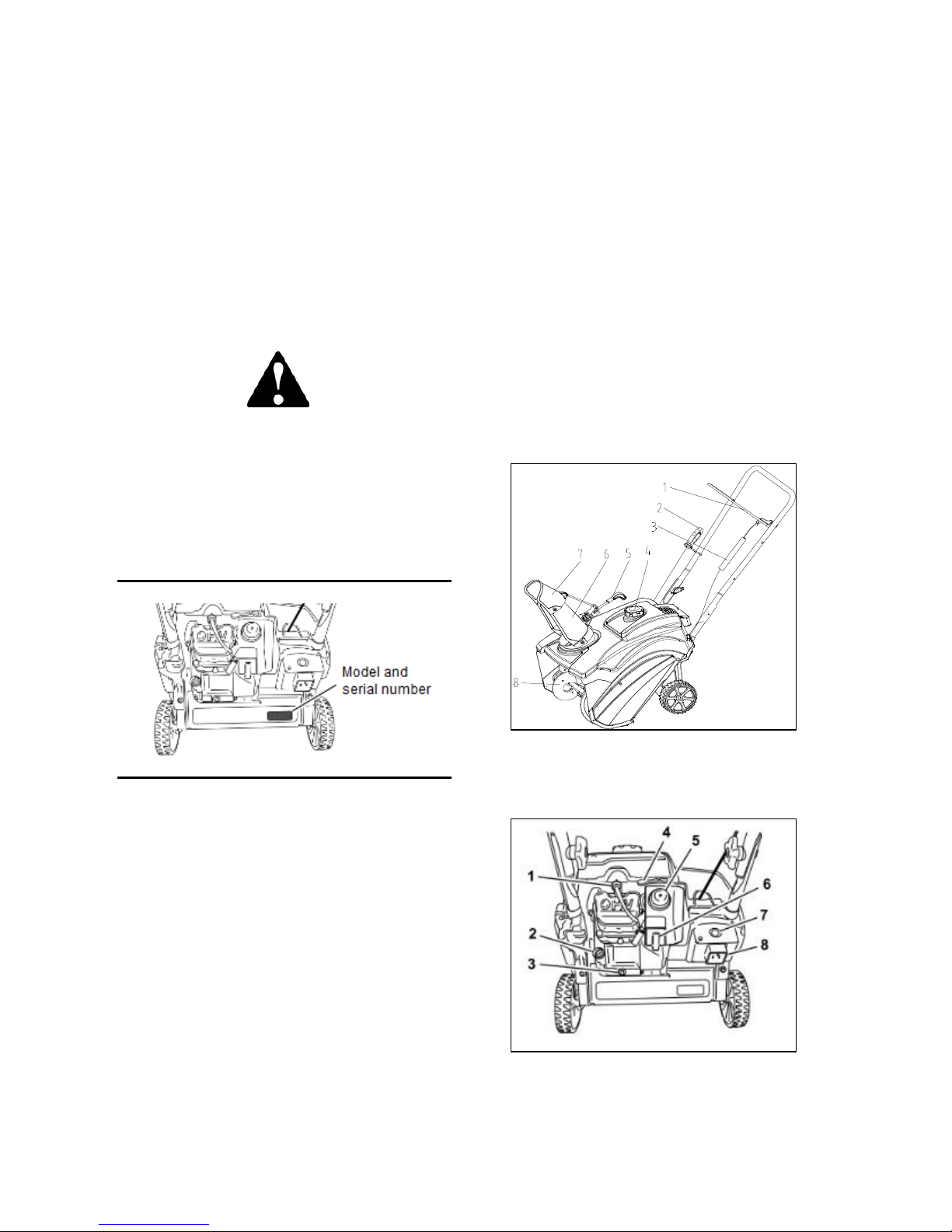

Product Overview

1. Control bar 5. Control handle

2. Recoil start handle 6. Discharge chute

3. Spring cover 7. Chute deflector

4. Fuel tank cap 8. Rotor Blade

1. Spark plug 5. Primer

2. Oil fill cap 6. Ignition key

3. Oil drain plug 7. Electric start button

4. Choke leveler 8. Electric plug-in

Page 3

3

Preparation

• Thoroughly inspect the area where the

machine is to be used. Remove all door mats,

sleds, boards, wires, and other foreign objects.

• Do not operate the machine without wearing

adequate winter garments. Avoid loose fitting

clothing that can get caught in moving parts.

Wear footwear that will improve footing on

slippery surfaces.

• Handle fuel with care; it is highly flammable.

- Use an approved fuel container.

- Never add fuel to a running engine or to a

hot engine.

- Use extreme care while filling a fuel tank

outdoors. Never fill a fuel tank indoors.

- Never fill containers inside a vehicle or on

a truck or trailer bed with a plastic liner.

Always place containers on the ground,

away from your vehicle, before filling.

- When practical, remove gas-powered

machinery from the truck or trailer and

refuel it on the ground. If this is not

possible, then refuel such machinery on a

trailer with a portable container, rather

than from a gasoline dispenser nozzle.

- Keep the nozzle in contact with the rim of

the fuel tank or container opening at all

times, until refueling is complete. Do not

use a nozzle lock-open device.

- Replace the gasoline cap securely and

wipe up any spilled fuel.

- If any fuel is spilled on clothing, change

clothing immediately.

• Use extension cords and receptacles as

specified by the manufacturer for all machines

with electric-starting motors.

• Do not attempt to clear snow from a gravel or

crushed rock surface. This product is only

intended for use on paved surfaces.

• Never attempt to make any adjustments while the

engine is running, unless specifically

recommended by the manufacturer.

• Always wear safety glasses or eye shields to

protect eyes from foreign objects that may be

thrown from the machine during operation, or

while performing an adjustment or repair.

Operation

• Do not put hands or feet near or under rotating

parts. Stay clear of the discharge opening at

all times.

• Exercise extreme caution when operating on

or crossing gravel drives, walks, or roads. Stay

alert for hidden hazards or traffic.

• After striking a foreign object, stop the engine,

remove the ignition key, thoroughly inspect the

machine for any damage, and repair the

damage before restarting and operating the

machine.

• If the machine should start to vibrate

abnormally, immediately stop the engine and

check the machine for the cause of vibration.

Vibration is generally a warning of trouble.

• Stop the engine whenever you leave the

operating position, before unclogging the rotor

blade housing or discharge chute, and when

making any repairs, adjustments or

inspections.

• When cleaning, repairing, or inspecting the

machine, stop the engine and make certain

that the rotor blades and all moving parts have

stopped.

• Do not run the engine indoors, except when

starting the engine and for transporting the

machine in or out of a building. Open the

outside doors; exhaust fumes are dangerous.

• Exercise extreme caution when operating the

machine on sloped surfaces.

• Never operate the machine without proper

guards and other safety protective devices in

place and working.

• Never direct the discharge toward people or

areas where property damage can occur.

Keep children and others away.

• Do not overload the machine capacity by

attempting to clear snow at too fast a rate.

• Look behind you and use care when backing up

with the machine.

• Disengage power to the rotor blades when

machine is transported or not in use.

• Never operate the machine without good visibility

or light. Always be sure of your footing, and keep

a firm hold on the handles. Never run with the

machine.

• Never touch a hot engine or muffler.

Page 4

4

Clearing a Clogged Discharge

Chute

Important: The most common cause of injury

associated with snow blowers is from hand

contact with rotating rotor blades inside the

discharge chute. Never use your hand to clean

out the discharge chute.

To clear the chute:

• Shut the engine off!

• Wait 10 seconds to be sure the rotor blades

have stopped rotating.

• Always use a clean-out tool, not your hands.

Maintenance & Storage

Check all fasteners often, to ensure proper

tightness and that the machine is in safe working

condition.

Allow the engine to cool before storing it in any

enclosure. Never store the machine with fuel in the

fuel tank inside a building where ignition sources

are present, such as hot water heaters, space

heaters, or clothes dryers.

Always refer to the manual for important details if

the machine is to be stored for an extended period.

Maintain or replace safety and instruction labels as

necessary.

Continue running the machine for a few minutes

after throwing snow to prevent rotor blades from

freezing up.

Snow Blower Safety

The following list contains safety information that you

must know before operating this machine.

• Rotating rotor blades can injure fingers or hands.

Stay behind the handles and away from the

discharge opening while operating the machine.

• Keep your face, hands, feet, and any other part

of your body or clothing away from moving or

rotating parts.

• Before adjusting, cleaning, repairing, and

inspecting the machine, and before unclogging

the discharge chute, stop the engine, remove the

key, and wait for all moving parts to stop.

• Before leaving the operating position, stop the

engine, remove the ignition key, and wait for all

moving parts to stop.

• If a shield, safety device, or decal is damaged,

illegible or lost, repair or replace it before

beginning operation. Tighten any loose fasteners.

• Do not smoke while handling gasoline.

• Do not use the machine on a roof.

• Do not touch the engine while it is running or soon

after it has stopped because the engine may be

hot enough to cause a burn.

• Only perform those maintenance instructions

described in this manual. Before performing any

maintenance, service, or adjustment, stop the

engine and remove the key. Contact an

Authorized Service Dealer if major repairs are

necessary.

• Do not change the governor settings on the

engine.

• Remove the key from the ignition switch before

storing the machine. Store fuel in an approved

container. When storing the machine for more

than 30 days, drain the fuel from the fuel tank to

prevent a potential hazard.

Page 5

5

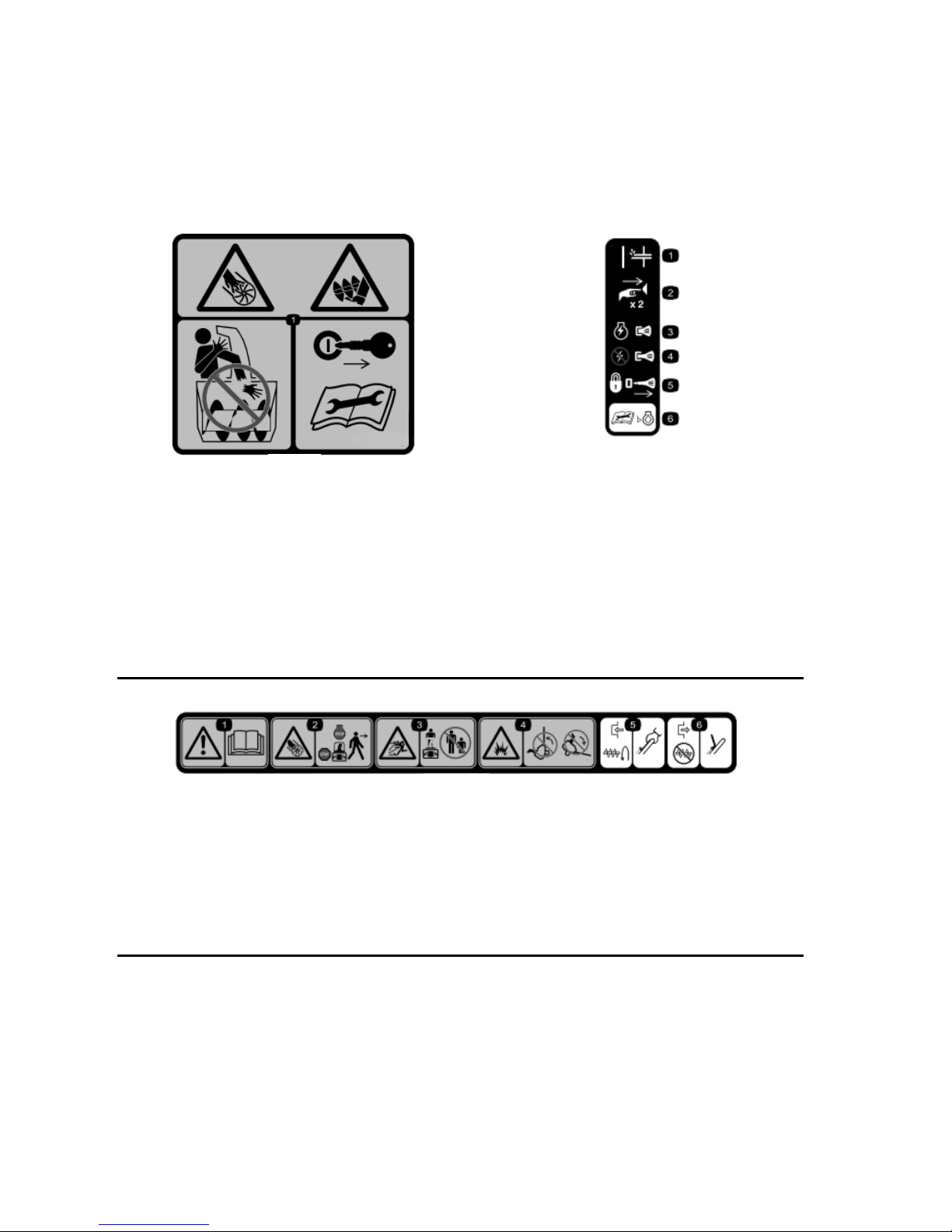

Safety and Instructional Decals

Important: Safety and instruction decals are located near areas of potential danger.

Replace lost or damaged decals.

Cutting/dismemberment hazard,

impeller and cutting/dismemberment

hazard, auger hazards—do not place

your hand in the chute; remove the

ignition key and read the instructions

before servicing or performing

maintenance.

1. Primer

2. Push the primer two times to prime

the engine

3. Push key in to switch the engine ―On‖

4. Pull key to switch the engine ―Off‖

5. Remove key to lock the engine

6. Read the engine’s operator’s manual

before checking the engine oil level

1. Warning: read the Operator's Manual.

2. Cutting/dismemberment hazard, impeller—stop the engine before leaving the machine.

3. Thrown object hazard—keep bystanders a safe distance from the machine.

4. Fuel spill hazard—do not tip machine forward or backward.

5. To engage the auger, squeeze the control bar.

6. Release the control bar to disengage the auger.

Page 6

6

SETUP

Loose Parts

Use the chart below to verify that all parts have been shipped.

Procedure

Description

Qty

Use

1

Oval-head bolts

Curved washers

Handle knobs

2

2 2 Install the handle.

2

No parts required

-

Install the recoil starter handle.

3

Discharge chute assembly

Screws

Washers

Locknuts

1

2

2

2

Install the discharge chute

assembly.

4

Bottle of engine oil

1

Fill the engine with oil.

5

No parts required

-

Adjust the control cable.

1. Installing the Handle

Parts needed for this procedure:

Oval-head bolts

Curved washers

Handle knobs

2

2

2

Procedure

1. Position the ends of the upper handle on

the inside of the lower handle and align

the holes.

2. Insert the oval-head bolts into the aligned

holes, with the bolt heads on the outside

of the handle (Figure 1).

3. Install the curved washers and the handle

knobs on the bolt on the inside of the

handle (Figure 1) and tighten the knobs

securely.

Important: Ensure that the cable is

routed to the outside of the handle.

2. Installing the Recoil

Starter Handle

Parts needed for this procedure:

(none)

Procedure

Install the recoil starter handle in the rope

guide as shown in Figure 2.

Figure 1

Figure 2

Page 7

7

3. Installing the Discharge

Chute

Parts needed for this procedure:

Discharge chute assembly

Screws

Washers

Locknuts

1

2

2

2

Procedure

Install the discharge chute assembly (Figure 3).

Note: Install the bolts from inside the discharge

chute assembly so that the washers and

locknuts are on the outside of the chute.

Important: Do not over-tighten locknuts.

4. Filling the Engine with Oil

Parts needed for this procedure:

Bottle of engine oil

Important: Before starting the engine, fill the

engine with oil. Your machine does not come

with oil in the engine, but it does come with a

bottle of oil.

Max fill: 12 oz. (0.35 L)

Type: Automotive detergent oil with an API

service classification of SJ, SL, or higher.

Use Figure 4 to select the best oil viscosity for

the outdoor temperature range expected.

Procedure

1. Move the machine to a level surface.

2. Clean around the oil fill cap.

3. Unscrew the oil fill cap and remove it.

4. Slowly pour oil into the oil fill hole. Wait 3

minutes, and then check the oil level on the

dipstick by wiping the dipstick clean and

then inserting, but not screwing in, the oil fill

cap into the hole.

Note: Refer to Figure 5 to determine the

proper oil level on the dipstick.

Note: Fill the engine crankcase with oil until

the dipstick indicates that the engine oil

level is correct as in Figure 5. If you overfill

the engine with oil, remove the excess oil

as directed in ―Changing the Engine Oil.‖

Note: You may tip the machine forward

slightly to make adding oil easier. Remember

to return the machine to its operating position

before checking the oil level.

Important: Do not tip the machine all the

way forward onto its nose or fuel may

leak out of the machine.

5. Screw the oil fill cap into the oil fill hole and

hand tighten it securely.

Figure 4

Figure 5

Figure 3

Page 8

8

5. Adjusting the Control Cable

Parts needed for this procedure:

(none)

Service Interval

After the first hour & yearly: check the

control cable and adjust it if necessary

Important: You may need to adjust the

control cable before you operate the

machine for the first time.

Important: The control cable must have

some slack when you disengage the control

bar for the rotor blades to stop properly.

Checking the Control Cable

Move the control bar back toward the

handle to remove the slack in the

control cable (Figure 6).

Adjusting the Control Cable

1. Slide up the spring cover and unhook the

spring from the adjuster link (Figure 7).

Pulling up on the adjuster link and cable

may make unhooking the spring easier.

2. Move the Z-fitting to obtain a higher or

lower hold on the adjuster link as needed

to obtain the 1/16-inch to 1/8-inch (2mm

to 3mm) gap between the control bar and

the handle (Figure 7).

Note: Moving the Z-fitting higher decreases

the gap between the control bar and the

handle; moving it lower increases the gap.

3. Hook the spring to the adjuster link and

slide the spring cover over the adjuster link.

4. Check the adjustment (refer to ―Checking

the Control Cable‖ above).

Note: The belt may slip (squeal) in wet

conditions; to dry out the drive system, start

the rotor and run it without a load for 30

seconds.

Figure 7

Figure 6

Page 9

9

Operation

Note: Determine the left and right sides of the

machine from the normal operating position.

Gasoline is extremely flammable and explosive.

A fire or explosion from gasoline can burn you

and others.

• To prevent a static charge from igniting the

gasoline, place the container and/or machine

on the ground before filling, not in a vehicle or

on an object.

• Fill the tank outdoors when the engine is cold.

Wipe up spills.

• Do not handle gasoline when smoking or around

an open fame or sparks.

• Store gasoline in an approved fuel container,

out of the reach of children.

• Do not tip the machine either forward or

backward with fuel in the fuel tank; otherwise,

fuel may leak out of the machine.

Filling the Fuel Tank

Fill the fuel tank with fresh unleaded gasoline

having an octane rating at or near 87 from a

major name-brand service station (Figure 8).

Important: Do not add oil to the gasoline.

Important: Do not use E85 or E20 fuel.

Alternative fuels with high alcohol content can

cause hard starting, poor engine performance,

and may cause internal engine damage.

Note: For best results, purchase only the quantity of

gasoline that you expect to use in 30 days. Otherwise,

you may add fuel stabilizer to newly purchased

gasoline to keep it fresh for up to 6 months.

Checking the Engine Oil

Service Interval:

Before each use or daily —Check the engine

oil level and add oil if necessary.

Procedure

1. Ensure that the fuel tank is not overfilled (see

Figure 8) and that the fuel cap is securely in place.

2. Move the machine to a level surface.

3. Clean around the oil fill cap.

4. Unscrew the oil fill cap and remove it.

5. Wipe the dipstick that is on the oil fill cap with

a clean cloth.

6. Insert, but do not screw in, the oil fill cap into

the oil fill hole.

7. Remove the oil fill cap and check the dipstick.

8. To determine the proper oil level on the

dipstick, refer the Figures and accompanying

instructions under ―Filling the Engine with Oil.‖

9. Screw the oil fill cap into the oil fill hole and hand

tighten it securely.

Starting the Engine

1. Push the ignition key fully inward to the

―On‖ position (Figure 9).

2. Move the choke lever fully to the right (Figure 10).

Figure 9

Figure 10

½ inch

(13mm)

Figure 8

Page 10

10

3. Firmly push in the primer 2 times with your

thumb holding the primer in for a second

before releasing it each time (Figure 11).

Note: Remove your glove when you push in

the primer so that air cannot escape from

the primer hole.

Important: Do not use the primer or

choke if the engine has been running and

is hot.

Excessive priming may flood the engine

and prevent it from starting.

4. Connect an extension cord to a power

source and the machine, and push the

electric-start button (model 38282 only)

(Figure 12), or pull the recoil start handle

(Figure 13).

Note: Only use a UL-listed, 16-gauge

extension cord recommended for outdoor

use that is not longer than 50 feet (15m).

The electrical cord can become damaged,

causing a shock or fire.

Thoroughly inspect the electrical cord

before plugging it into a power source. If

the cord is damaged, do not use it to

start the machine. Replace or repair the

damaged cord immediately. Contact an

Authorized Service Dealer for assistance.

Important: Run the electric starter no more than

10 times at intervals of 5 seconds on, and then 5

seconds off. Running the electric starter

extensively can overheat and damage it. If the

engine does not start after this series of

attempts, wait at least 40 minutes to allow the

starter to cool before attempting to start it again.

If the engine does not start after the second

series of attempts, take the machine to an

Authorized Service Dealer for service.

Note: If the recoil starter does not operate

properly, it may be frozen. Thaw out the starter

before attempting to start the machine.

5. While the engine is running, move the choke

lever gradually to the left.

6. Unplug the extension cord from the power

source and the machine (model 38282 only).

If you leave the machine plugged into a

power source, someone can inadvertently

start the machine and injure people or

damage property. Unplug the power cord

whenever you are not starting the machine.

Figure 11

Figure 12

Figure 13

Page 11

11

Figure 17

Engaging the Rotor Blades

To engage the rotor blades, hold the control bar

against the handle (Figure 14).

Disengaging the Rotor Blades

To disengage the rotor blades, release the control

bar (Figure 15).

Stopping the Engine

To stop the engine, pull the ignition key outward until

it clicks into the ―Off‖ position (Figure 16) or move the

choke lever fully to the right (Figure 10).

Adjusting the Discharge

Chute and Chute Defector

1. Adjust the control handle to change the direction

of snow (Figure 17).

2. Pull the handle apart from the gear to adjust the

angle of chute cap (Figure 18).

Clearing a Clogged Discharge

Chute

Important: The most common cause of injury

associated with snow blowers is from hand

contact with the rotating rotor blades inside

the discharge chute. Never use your hand to

clean out the discharge chute.

To clear the chute:

• Shut the engine off!

• Wait 10 seconds to be sure the rotor blades

have stopped rotating.

• Always use a clean-out tool, not your hands.

Figure 15

Figure 14

Figure 18

Figure 16

Page 12

12

Self-Propelling the Snow

Blower

Lift the machine handle until the wheels are just off

the ground and the scraper and rotor blades touch

the ground. The machine will propel forward

(Figure 19).

Note: By slightly varying lifting force on the handle,

you can control the forward speed of the machine. In

heavy snow, push forward on the handle if

necessary, but let the machine work at its own pace.

Do not lift the handle any more than necessary,

because the scraper will lift off the ground and snow

will escape behind the machine.

Preventing Freeze-up After Use

• Let the engine run for a few minutes to prevent

moving parts from freezing. Stop the engine,

wait for all moving parts to stop, and remove ice

and snow from the machine.

• Clean off any snow and ice from the base of

the chute.

• Rotate the discharge chute left and right to free

it from any ice buildup.

• With the ignition key in the Off position, pull the

recoil starter handle several times or connect

the electrical cord to a power source and the

machine and push the electric star t button once

to prevent the recoil starter and/or the electric

starter from freezing up.

• In snowy and cold conditions, some controls

and moving parts may freeze. Do not use

excessive force when trying to operate frozen

controls. If you have difficulty operating any

control or part, start the engine and let it run for

a few minutes.

Operating Tips

The rotor blades can throw stones and other

foreign objects and cause serious personal injury

to the operator or to bystanders.

Keep the area to be cleared free of all objects

that the rotor blades could pick up and throw.

Keep all children and pets away from the area

of operation.

• Remove snow as soon as possible after it falls.

• Overlap each pass to ensure complete snow

removal.

• Discharge snow downwind whenever possible.

Figure 19

Page 13

13

Maintenance

Recommended Schedules:

Maintenance Service Interval

Maintenance Procedure

After the first hour

• Check the control cable and adjust it if necessary

• Check for loose fasteners and tighten them if necessary

After the first 2 hours

• Check the engine oil

Daily or before each use

• Check the engine oil level and add oil if necessary

Annually

• Check the control cable and adjust it if necessary

• Inspect the rotor blades and have an Authorized Service

Dealer replace the rotor blades and scraper if necessary

• Change the engine oil

• Service the spark plug and replace it if necessary

• Check for loose fasteners and tighten them if necessary

• Have an Authorized Service Dealer inspect the drive belt

and replace it if necessary

Annually or before storage

• Prepare the machine for storage

Adjusting the Control Cable

Refer to ―Adjusting the Control Cable‖ in Setup.

Inspecting the Rotor Blades

Service Interval

Yearly. Inspect the rotor blades and have an

Authorized Service Dealer replace the rotor

blades and scraper if necessary.

Before each session, inspect the rotor blades

for wear. When a rotor blade edge has worn

down to the wear indicator hole, have an

Authorized Service Dealer replace the rotor

blades and the scraper (Figure 20).

Changing the Engine Oil

Service Interval

After the first 2 hours, then yearly. Run the

engine a few minutes before changing the

oil to warm it. Warm oil flows better and

carries more contaminants.

Procedure

1. Ensure that the fuel tank is not overfilled

(Figure 8) and that the fuel cap is secure.

2. Move the machine to a level surface.

3. Place a drain pan under the oil drain plug.

Remove the drain plug, and tip the machine

backward (handle down) halfway to the

ground to drain the used oil into the drain pan.

Important: Do not tip the machine all the

way to the ground or fuel may leak out.

4. After draining the used oil, return the

machine to the operating position.

5. Re-install the drain plug and tighten it securely.

6. Clean around the oil fill cap.

7. Unscrew the oil fill cap and remove it.

8. Refill the engine with oil by referring to the

instructions under ―Filling the Engine with Oil.‖

9. Screw the oil fill cap into the oil fill hole,

and hand tighten it securely.

10. Wipe up any spilled oil.

11. Dispose of used oil properly at a local

recycling center.

Figure 20

Page 14

14

Servicing the Spark Plug

Service Interval: Yearly. Service the spark plug

and replace it if necessary.

1. Stop the engine and wait for all moving

parts to stop.

2. Disconnect the wire from the spark plug.

3. Clean around the spark plug.

4. Remove the spark plug from the cylinder head.

Important: Replace a cracked, damaged,

or dirty spark plug. Do not clean the

electrodes because grit entering the

cylinder can damage the engine.

5. Set the gap on the plug to 0.030 inch

(0.76mm) (Figure 21).

6. Install the spark plug and torque it to

20–22ft-lb (27–30 N-m).

7. Connect the wire to the spark plug.

Replacing the Drive Belt

If drive belt becomes worn, oil-soaked, excessively

cracked, frayed, or otherwise damaged, replace it.

1. Remove the 4 bolts that hold the drive belt

cover (Figure 22) in place.

Note: The transmission belt cover is fixed by

two small bolts, one nut, two tapping screws

and a piece of reinforced plate.

2. Remove the belt from the rotor pulley.

3. Press down on the idler arm and remove the

belt from between the tab on the idler arm

brake and the rotor pulley.

Note: The engine pulley belt guide is very

close to the pulley, and the belt may not fit

through the gap.

4. Twist the belt out in front of the belt guide so

that the belt is wedged between the belt

guide and the engine pulley.

5. Insert a screw driver into the hole in the belt

guide as shown in Figure 23, and flex the

belt guide toward the rotor pulley enough to

pull the belt through the gap.

Note: Take care not to distort or damage the

belt guide.

6. To install the new drive belt, reverse the

steps above.

Important: Ensure that you install the

drive belt so that it sits above the two

tabs on the idler arm and below the idler

arm brake. (Figure 24).

7. Install the drive belt cover with the

fasteners that you removed in step 1.

Figure 21

Figure 24

Figure 23

Figure 22

Page 15

15

Storage

Gasoline fumes are highly flammable,

explosive, and dangerous if inhaled. If you

store the product in an area with an open

fame, the gasoline fumes may ignite and

cause an explosion.

Do not store the machine in a house (living

area), basement, or any other area where

ignition sources may be present, such as hot

water and space heaters, clothes dryers,

furnaces, and other like appliances.

Do not store the machine with its handle

tipped down onto the ground, because oil will

leak into the engine cylinder and onto the

ground, and the machine will not start or run.

1. On the last refueling of the season, add fuel

stabilizer to fresh fuel as directed by the

engine manufacturer.

2. Run the engine for 10 minutes to distribute

the conditioned fuel through the fuel system.

3. Change the engine oil while the engine is still

warm. Refer to ―Changing the Engine Oil.‖

4. Drain the fuel from the tank and carburetor

by performing the following steps:

A. Loosen the fuel tank cap.

B. Unscrew, but do not remove, the small

screw on the side of the carburetor fuel

bowl (Figure 25) until the fuel begins to

drain from the carburetor. Drain the fuel

into an approved fuel container.

Important: Do not remove the

carburetor bowl bolt on the bottom of

the carburetor.

C. Wait for a few minutes until the fuel has

drained, then install the fuel cap and

tighten the small screw on the carburetor.

5. Dispose of unused fuel properly. Recycle it

according to local codes, or use it in your

automobile.

6. Remove the spark plug.

7. Squirt 2 teaspoons of oil into the spark plug

hole.

8. Install the spark plug by hand and then

torque it to 20–22ft-lb (27–30 N-m).

9. With the ignition key in the ―Off‖ position, pull

the recoil starter slowly to distribute the oil on

the inside of the cylinder.

10. Disconnect the ignition key from the lanyard

and store the ignition key in a safe place.

11. Clean the machine.

12. Touch up chipped surfaces with paint

available from an Authorized Service Dealer.

Sand affected areas before painting, and

use a rust preventative to prevent the metal

parts from rusting.

13. Tighten any loose fasteners. Repair or

replace any damaged parts.

14. Cover the machine and store it in a clean, dry

place out of the reach of children. Allow the

engine to cool before storing it in any enclosure.

Residual Risks

Even when the machine is used as prescribed

it is not possible to eliminate all residual risk

factors. The following hazards may arise in

connection with the machine’s construction

and design:

1. Damage to lungs if an effective dust mask

is not worn.

2. Damage to hearing if effective hearing

protection is not worn.

3. Damages to health resulting from vibration

emission if the power tool is being used over

longer period of time or not adequately

managed and properly maintained.

This machine produces an electromagnetic

field during operation. This field may under

some circumstances interfere with active or

passive medical implants. To reduce the risk

of serious or fatal injury, we recommend

persons with medical implants to consult

their physician and the medical implant

manufacturer before operating this machine.

Figure 25

Loading...

Loading...