Page 1

®

@echelon

CPD 3000 Lighting Controller

Integration Guide

078-0485-01A

Version 1

Page 2

Echelon, LONWORKS, LONMARK, and the Echelon logo are

trademarks of Echelon Corporation registered in the United

States and other countries.

Other brand and product names are trademarks or

registered trademarks of their respective holders.

ECHELON MAKES AND YOU RECEIVE NO WARRANT IES OR

CONDITIONS, EXPRESS, IMPLIED, STATUTORY OR IN ANY

COMMUNICATION WITH YOU, AND ECHELON SP ECIFICALLY

DISCLAIMS A N Y IMPLIED WARR A N T Y O F M ER C H ANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE.

No part of this publication may be reproduced, stored in a

retrieval system, or transmitted, in any form or by any means,

electronic, mechanical, photocopying, recording, or

otherwise, without the prior written permission of Echelon

Corporation.

Printed in the United States of America.

Copyright © 2013 Echelon Corporation.

Echelon Corporation

www.echelon.com

Page 3

Welcome

Echelon’s Power Line based lighting controller, the CPD 3000, can be used to

control outdoor street lights which support proportional level control level control

using 0-10V or PWM control. In addition to control, the CPD 3000 collects vital

data such as run hours, voltage, current, power consumption, energy usage,

diagnostic alarms, and power factor. The information collected is shared through

communication on the AC mains. The CPD 3000 optimizes communications with

integrated power line meshing.

Smart Street Lighting with a CPD 3000 involves remotely collecting vital data

from the lighting controller (such as LED drivers, HPS ballasts, Induction

Generators) and communicating over the power lines with a Segment Controller

(Echelon SmartServer) which manages switching and dimming schedules, and

captures and forwards diagnostic alarms and energy consumption data to

operations monitoring servers over TCP/IP networking, including support for

GRPS or GSM wireless networks.

This document describes the hardware installation and wiring specifications for

the CPD 3000, plus the lighting controller interface. Because much of this

interface is derived from an outdoor luminaire resource file set that is used by the

LonMark organization, you can gain a full understanding of the scope of resource

files at the LonMark International web site, www.LonMark.org

.

CPD 3000 Integration Guide iii

Page 4

Table of Contents

Welcome ......................................................................................................... iii

CPD 3000 Installation and Wiring Guidelines ........................................... 5

Installation ..................................................................................................... 6

Wiring Specification and Diagram ................................................................ 7

CPD 3000 Mechanical Dimensions ............................................................... 8

CPD 3000 Lighting Controller Interface ..................................................... 9

Application as Function Block ..................................................................... 10

UFPTlightingController Network Variables ...................................... 10

UNVTcontrolData – nvoControlData Details .............................. 11

Broadcast Support ................................................................................. 14

CPD 3000 Configuration (nciControlCfg) ....................................... 14

UNVTControlCfg .................................................................................. 15

Analog Control ....................................................................................... 17

LC Alarm Management ............................................................................... 18

nviLampValue -> nvoLampFb Relationship .......................................... 21

CPD 3000 Control Sequence ................................................................. 22

Creating the CPD 3000 Device on your SmartServer ............................... 23

iv

Page 5

1

CPD 3000 Installation and Wiring

Guidelines

The CPD 3000 Lighting Controller can be installed within

the lighting fixture, in the access hold of the lighting fixture

pole, in the gear tray, or in a separate box.

CPD 3000 Integration Guide 5

Page 6

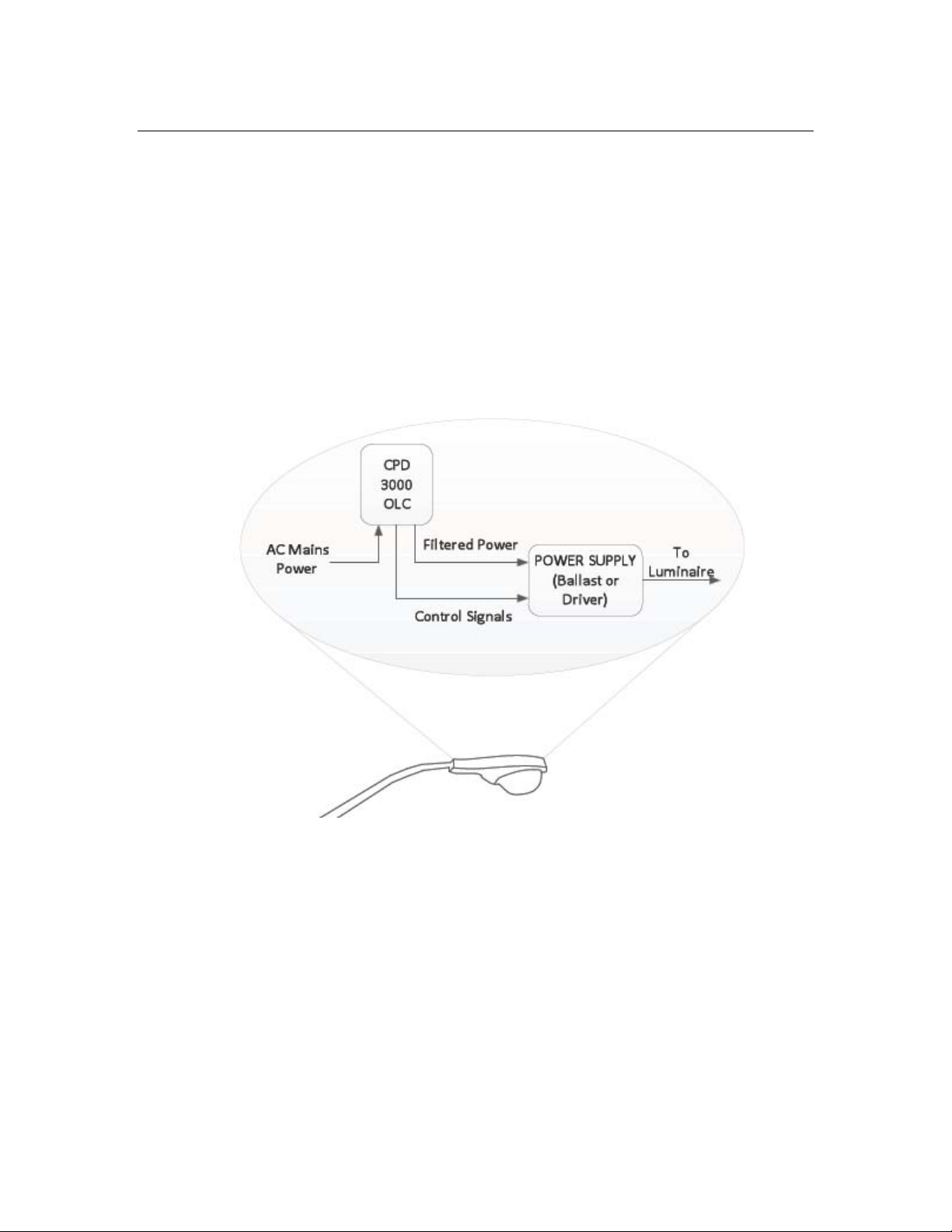

Installation

Installation for the CPD 3000 OLC uses the following steps. It is important to

disconnect line voltage before installing or replacing a CPD 3000 module.

1. Install the CPD 3000 OLC module.

2. Connect the AC mains power to the module.

3. Connect the filtered power output of the CPD 3000 OLC module to the

luminaire power supply (electronic ballast/generator, ballast, or driver).

4. Connect the CPD 3000 control signal wires to the luminaire control input.

Figure 1. CPD 3000 Installed in the Light Fixture

6

Page 7

Wiring Specification and Diagram

Here are the wiring specifications and diagram for US and European models of the

CPD 3000. The CPD 3000 is not suitable for installing above 15,000 feet altitude.

The controller must be installed in the light fixture, inside a street light pole, or in a

street light cabinet. The CPD 3000 is not intended to be installed in an open

outdoor environment.

US Model

Three AWG 16 wires for AC mains input:

Black Line In

White Neutral In or Line 2 In*

Green Ground

*

May be powered Line-to-Line if Line-to-Line Voltage is 100-277 VAC and all CPD 3000s, and the

segment controller, are connected to the same circuit pair.

Three AWG 22 wires for control of signal ouput (IEC60929)

Blue 10V signal for PWM control

Black Ground

Violet Signal for 0-10V control

European Model

Three AWG 16 wires for AC mains input:

Brown Line In

Blue Neutral In or Line 2 In*

Green/Yellow Ground

May be powered Line-to-Line if Line-to-Line Voltage is 100-277 VAC and all CPD 3000s, and the

*

segment controller, are connected to the same circuit pair.

Three AWG 22 wires for control of signal ouput (IEC60929)

Blue 10V signal for PWM control

Black + Signal for 0-10V control

White - Signal for 0-10V control

CPD 3000 Integration Guide 7

Page 8

Two AWG 16 wires for filtered power output (both models)

Red Line Out

Blue Neutral Out or Line 2 Out

The 0-10V control signal of the CDP 3000 works with current sourcing inputs.

The CPD 3000 will sink up to 1500mA. The filtered switch AC output will

handle load up to 500 VA.

CPD 3000 Mechanical Dimensions

This diagram shows the dimensions of the CPD 3000 in millimeters.

Figure 2. CPD 3000 Housing Profile

See the CPD 3000 Outdoor Lighting Controller data sheet (003-0513-01) on the

Echelon web site for all specifications of the CPD 3000.

8

Page 9

2

CPD 3000 Lighting Controller

Interface

The CPD 3000 Lighting Controller borrows much of its

interface from the SFPToutdoorLuminairController

(3512) defined in the LonMark standard resource file set

version 13.10. To meet the memory requirements of the

PL3120-E4 Smart Transceiver, a specific profile is defined in

an Echelon device specific scoped resource file set defined in

the DRF files set EchelonLighting.* (Program ID [scope

4] 80 00001 1E00 03 11 03). These resource definitions were

first defined in version 1.03, and apply to version 1.05, the

current release at thewriting of this document

CPD 3000 Integration Guide 9

Page 10

Application as Function Block

The application for the CPD 3000 is developed as a sole function block. The

UFPTlightingController is referred to as the LC in the remainder of this

document.

Figure 3. UFPTlightingController Funtional Profile Interface used in

CPD 3000

UFPTlightingController Network Variables

The following table describes the network variables defined for the CPD 3000

implementation of the UPFTlightingController. The CPD 3000 implements

only the mandatory network variables and CPs in the initial release.

10

Page 11

Table 1 LC Network UNVTfaults Variables Implemented on the CPD 3000

Network Variable Type Notes

nviLampValue

nviStatReset UNVTstatControl

nvoControlData UNVTcontrolData

nvoLampFb SNVT_switch

SNVT_switch

Primary control input. The level

translates to a 0-10V control signal with

the transform being subject to the values

configure in nciControlConfig defined

below. By default, 50% results in a 5V

control signal to the ballast, driver, or,

generator controlled by the CPD 3000.

Sets/initializes energy, runtime, and

error counts.

A structured variable describing all

current operating values and state of

the LC. This is described in the

following section.

Feedback of the current

nviLampValue. In normal operating

conditions, this value will reflect the

nviLampValue. It may differ if the

heartbeat interval is exceeded and the

defaultLevel differs from the value

in nviLampValue.

nvoLcStatus UNVTfaults

nvoVersion UNVTversion

Feeds alarm logs only on change to

minimize the data requirement on the

IP network. The frequency of changes

to this variable is carefully managed

to conserve bytes consumed by data

logs.

A string describing the version of the

OLC application, such as 1.00.09.

UNVTcontrolData – nvoControlData Details

The LC conserves power line bandwidth by reporting the operating state of the

LC in a single output network variable nvoControlData (UNVTcontrolData),

described in this section. Previous profile designs typically require three poll

CPD 3000 Integration Guide 11

Page 12

transactions to capture level control feedback, environmental variables, and

alarm conditions. This network variable reflects all of this information in one

single-structured data type defined by UFPTcontrolData

.

Figure 4. UNVTcontrolData(nvoControlData) Fields

The fields for UNVTcontrolData are described in table 2.

Table 2 nvoControlData Fields (UNVTcontrolData)

Field Type Notes

power SNVT_power

energy SNVT_elec_kwh_l

runtime UNVTruntime

12

Reflects the instantaneous power consumed by the

LC and controlled fixture. (0.1w resolution) This

value is updated each second by the power

measurement chip on the LC.

Reports the accumulated energy usage to 0.1kwh

resolution. The LC writes this to EEPROM memory

every 12 hours, and at the transition to OFF.

Installations which kill power to the streetlight

segment at dawn should delay the switch of the

power for several minutes after the lights are

scheduled OFF to allow the controller to store this

value in EEPROM memory.

The number of operating minutes for the fixture.

Stored to EEPROM with each OFF transition. The

presentation format for this field is an integer value

of hours.

Page 13

supplyVoltage SNVT_volts

Measured supply voltage 0.1V resolution. This

value is updated every second.

supplyCurrent unsigned long

cycleCount SNVT_count

LevelFB SNVT_lev_cont

faults UNVTfaults

nvUpdates Unsigned

rcvTimeouts SNVT_count

Measured current with 0.01 amp resolution. This

value is updated every second.

Number of operating cycles (ON-OFF). Updated

with each transition to OFF.

0.5% resolution 0-100%. Tracks the .value field of

nvoLampFb. 0% if the state is 0.

Fault bits. Details are provided in the alarms

section. These bits represent current conditions of

the last alarm evaluation and not the latched values

as reflected in nvoLcStatus.

Used to assess application level communication

performance. Every 30 minutes, this field is

updated to report the number of times

nviLampValue was updated in the previous

interval. If the defined heartbeat for

nviLampValue is defined as 10 minutes, this value

reports a value of 2-4 during steady state operation.

The maximum receive timeout for this device (part

of nciControlCfg) is set to three times the control

input heartbeat. In practice, this number increases

only when an update is not received after three

heartbeat intervals.

powerFactor SNVT_pwr_factor

LCtemperature SNVT_temp_p

LCstate OLC_State

Reports the measured power factor for the

LC/Fixture combination. When the controlled load

is OFF, this value will be very low (around .3).

Alarms against power factor are only evaluated

when the load is turned ON. For efficient light

operation, it is good practice to limit the control

signal the CPD 3000 drives to keep the power factor

above 0.8.

Reports the temperature sensed by the power

measurement chip on the CPD 3000. Typical

accuracy is +/-5 degrees C.

Reports the current state of the CPD 3000 LC

controller. Valid values include: OLC_INIT,

OLC_COOLDOWN, OLC_WARMUP, OLC_ON, and

OLC_OFF.

CPD 3000 Integration Guide 13

Page 14

Broadcast Support

The CPD 3000 supports the limited broadcast message support implemented on

SmartServer 2.1 Firmware (service release 1). Control updates through this

mechanism are reflected on the network variable interface (nviLampValue, and

nvoLampFb). Note that the nviLampValue data point should not have a defined

heartbeat to properly use the broadcast feature. Behavior for reflection in

nvoLampFb follows the Use Case Realization described by the LonMark organization

at http://types.lonmark.org/index.html

Enumeration (value) Description Notes

(see SFPTisiLampActuator).

SW_NUL (-1)

SW_SET_OFF (0)

SW_SET_ON (1)

SW_SET_LEVEL (5)

Invalid value

Set state OFF

Set State ON

Set level

This is the initial value for nviLampValue.

The default output state is taken as

unconfigured, and configured nodes with no

hw RTC. Hw RTC nodes that are

configured adopt the state defined by the

backup schedule.

Sets the output state to OFF. The Relay is

open. 0-10v output driven to 0v. If a

rampTime is non-zero, the 0-10v sweeps

from the current value to 0v over the

defined time, which opens the Relay.

Sets the output state to ON, 100% level.

The relay coil is energized, and the level is

set to 100%.

Provide SNVT_switch behavior. Use the

SW_SET_ON, and SW_SET_OFF behaviors

described above. RampTime applies

CPD 3000 Configuration (nciControlCfg)

The CPD 3000 uses a limited number of configuration properties (CPs) implemented

using network variables on the CPD 3000. The main portion of the configuration is

defined by the fields in nciControlCfg (UCPTcontrolCfg).

Configuration

Property

nciControlCfg UNVTcontrolCfg

nviLocation SNVT_geo_position

nciLimit UNVTfaultLimits

14

Type Notes

Defines many of the operating

parameters for the LC.

Provides tagging for GPS

location, and physical asset

tagging. Version 13.04

standard.

Used for alarm thresholds as

defined in Alarming, below.

Page 15

nciPowerProfile UNVTpowerProfile

UNVTControlCfg

This section describes how the fields in this configuration property are applied in the

LC.

Defines the nominal power

measured at 5 commanded

nviLampValues 0.5%, 25%,

50%, 75%, 100%) while driving

the driver/lamp combination.

This CP must be set for

lowPower/HighPower, and

measured with nvoLampFb

values to work correctly. They

will depend on the minPWM and

maxPWM fields defined in the

following section.

Figure 5. UNVTcontrolConfig Field Details

Field Type Notes

defaultLev SNVT_lev_cont

CPD 3000 Integration Guide 15

This is the initial value before an update

to nviLampValue is received by the LC to

drive the lamp value at power ON or reset.

The default value is 100%. This value only

applies after the CPD 3000 is commission

by the SmartServer. When unconfigured,

the CPD 3000 will turn ON the controlled

light to full ON. When power is applied to

the OLC, the application enforces a 10s

minimum time (even if CoolDownTm =0)

before applying this value. A non-zero

Page 16

CoolDownTmwill extend this time.as

required when controlling certain lamp

types such as HPS.

rampTm SNVT_time_sec

Controls how the LC ramps between level

transitions. Only used after the lamp is

ON to go between intermediate steps. The

CPD 3000 limits this value to a maximum

of 30s. (Default value – 1.5s)

supplyVoltage SNVT_volt

The nominal supply voltage for the fixture.

Used of voltage level alarms. (Default

value – 240V).

warmupTm unsigned short

The number of minutes the LC allows the

fixture to warm up before allowing

dimming commands. During warm up, the

dimming commands are deferred. If the

LC is set to go to 75% ON, the LC will set

the 0-10V signal to 10V for warmupTm

minutes before issuing the appropriate

dimming level. In LED applications, this

is typically 0. Any nviLampValue less

than 100% will be delayed while the LC is

in the state OLC_WARMUP. (Default value –

0s). This also delays power alarm

processing which is important in the case

of control of magnetic ballast technology.

coolDownTm unsigned short

The number of minutes the LC will delay

commands to turn ON after the fixture has

been turned OFF. This is important for

improving certain lamp technology life

times. The CPD 3000 enforces a 10s

COOLDOWN to allow recovery of the

inrush protection circuit. This 10s

minimum is subject to change in the

future. (Default value – 0s)

maxRcvTm SNVT_time_sec

If the LC fails to receive an update to

nviLampValue for this time (0s default),

the LC will drive the lamp to the

defaultLevel. The segment controller

should update nviLampValue up to three

times within this period. If the maxRcvTm

is 900s, the heartbeat rate of 300s should

be used by the segment controller. Note

that maxRcvTm = 0 means lights will

retain the last commanded value if the

SmartServer cannot communicate to the

device, or if it fails.

minPWM unsigned long

It may be necessary to set the lowest 010V signal to a value that can be used to

drive the controlled fixture. This value

16

Page 17

lower limit of the PWM output with the

nviLampValue is at 0.5%. Limit to 0-

255. (Default value – 0). Use this to limit

the low level light setting to maintain

efficient operation.

maxPWM unsigned long

pwmClock unsigned short

alarmClrMode FlagManamentMode

clrTime unsigned short

It may be necessary to set the highest 010V signal to a value that can be used to

drive the controlled fixture. This value

upper limit of the PWM output with the

nviLampValue is at 100%. Limit to 0-

255. (Default value – 255)

Allows programming of the PWM clock.

The values (0-7) are valid values as

defined in Neuron C. The default value

of 6 should be used.

Not supported. Controls how the alarm

flags are cleared by the LC. (FL_DAILY is

only supported)

Depending on alarmClrMode, this number

is used to manage automatic clearing of

fault flags. See the section on LC Alarms.

This value is scaled with a 6 minute

resolution. It should be set to allow

for alarm logs to be sent on schedule,

well after sunrise has occurred.

Default = 300

Analog Control

Dimming drivers and ballast controllers will exhibit different end results with

respect to power usage and light output response when subjected to a linear

control signal. An LED fixture with a particular Phillips driver was specified to

operate over the range of 0-10VDC. When tested for power efficiency and visible

light level response, the result was 2-8.6VDC. The fields minPWM and maxPWM are

used to control how nviLampValue.value translates to a control signal that

drives the controlled driver/ballast. The values are determined by experimenting

with an actual controlled fixture. In one particular application, the minPWM value

may be established by monitoring the reported power factor, or the measured

delivered light level of the installed fixture. For example, at 1.5V control signal,

the power factor may be adequate at .82, but the delivered light level is not

adequate until 2.5V. Measuring the control signal while driving a specific driver

is required to determine at what minPWM value, 2.5V is measured. The value for

maxPWM may be determined by observing the measured power or the delivered lux

level to the pavement using a lux sensor. You may find the last volt of control

signal has no effect on the delivered light or power level measured for the load so

you could choose a value for maxPWM at around 240.

CPD 3000 Integration Guide 17

Page 18

Working with the CPD 3000 and the target driver/ballast is required to determine

the limits for the best scaling of the nviLampValue.value to the actual control

signal. These values must be set before the nciPowerProfile initialization can

be determined.

LC Alarm Management

The LC provides rich support for status bits which are derived from the power

measurement chip included in CPD 3000 hardware. Alarms require

characterization of nominal operating conditions defined by various CP fields

described in this section. The current existing alarm conditions are always

reflected in nvoControlData.faults before any time filters are applied. The

alarms reported in nvoControlData.faults have no filters applied and are

potentially quite dynamic at the transition. The CPD 3000 applies several filters

to limit the frequency of alarm events. First, at each state transition (OFF to ON,

or WARMUP to ON) Alarms are not checked for 120s. Second, the network

variable nvoLCstatus contains latched versions of the fault bits that have a 60

second active before setting condition as reported in nvoControlData.faults.

If a defined condition exists of 60s, the alarm flag in nvoLcStatus is set and it

will persist until power to the CPD 3000 is cut, action is taken by updating the

value of nviStatReset, or UNVTcontrolCfg.ClrTm minutes have expired after

the lamp is switched OFF at sunrise.

It is important to understand how alarm conditions are filtered to prevent nuance

alarm conditions. Alarms are only checked if the CPD 3000 state is OLC_ON or

OLC_OFF. If the output level or the state is changed, alarm conditions are not

checked for 120s. If you reset the CPD 3000 at T = 0s, and set control the line

voltage to 100VAC with a 120V nciControlCfg.supplyVoltage value, the

nvoControlData.faults.lowSupplyVoltage flag will not be set until T = 130s

(the transition from OLC_COOLDOWN occurs 10s after reset). To be registered as a

fault in nvoLcStatus, the condition of low supply voltage must exist for an

additional 60s. The flag in nvoLcStatus is latched, and will not be cleared until

the configured time after the CPD 3000 switches the load OFF at sunrise, as

described below.

CP Field Type Notes

nciControlCfg.supplyVoltage SNVT_volt

nciControlCfg.defaultLev SNVT_lev_cont

nciControlCfg.maxRcvTm SNVT_time_sec

Nominal supply voltage for

the installed streetlight

segment. (Default - 240V)

Value to use at reset, or if

maxRcvTmo expires.

(Default: 100%)

The time used to determine

if communication to the

segment controller no

longer exists. At this point,

the RcvTmo alarm is

triggered, and the fixture is

18

Page 19

controlled to defaultLev

(Default –0s; which means

HB checking is disabled)

nciPowerProfile UNVTpowerProfile

Defines the nominal power

at 0.5, 25, 50, 75, 100%

lamp

nviLampValue.value.

Used to determine the

expected power draw using

linear interpolation for

nviLampValue.values in

between steps defined in

the table.

nciLimits.powerLowFault SNVT_lev_cont

The percentage deviation

of expected power below

which the LowPower alarm

is triggered. (Default value

- 15%)

nciLimits.powerHighFault SNVT_lev_cont

The percentage deviation

of expected power above

which a HighPower alarm

is triggered. (Default

value - 15%).

nciLimits.voltageLow SNVT_lev_cont

The percentage deviation

below the configure

supplyVoltage at which

the LowSupplyVoltage

alarm is triggered.

(Default value - 15%).

nciLimits.voltageHigh SNVT_lev_cont

The percentage deviation

above the configured

supplyVoltage at which

the HighSupplyVoltag

alarm is triggered.

(Default value - 15%).

nciLimits.pfLow SNVT_pwr_fact

Power factor alarm point.

Power factor alarms are

only tested when the

controlled load is ON.

(Default value - .65)

nciLimits.rcvHb SNVT_time_sec

The rate at which the

segment controller is

expected to update

nviLampValue. Best

practice is to set this value

at 3x shorter than

nciControlCfg.rcvTmo

(Default value – 0s).

nciLimits.highTemp SNVT_temp_p

The temperature above

which a high temperature

CPD 3000 Integration Guide 19

Page 20

nciLimits.lampFailFault SNVT_lev_cont

The field nciControlCfg.clrTm controls when the alarm flags reported in

nvoLcStatus will be cleared. In an SLV managed lighting system, alarm logs are

scheduled for daily delivery at some point after the sunrise OFF command. For

example, this could be scheduled for 10:00AM. Over the year, sunrise time varies

with the season and the geographic location. For example, it could occur between

5:15 and 7:45 AM. To support proper management of alarms, alarms should not

be cleared until at least five hours or more after sunrise.

nciControlCfg.clrTm should be set to 300 minutes to support clearing of the

alarms after the logs have been delivered.

alarm is triggered.

(Defaults value - 65.0 C)

The threshold of power

drop measured when the

lamp fails. In some

technologies, induction

lights for example, the

power draw at bulb failure

may be quite high.

(Default value - 20%).

Figure 6. Fault Limits

During characterization of a driver/lamp combination, it may be useful to use

nviStatReset.cmd, a value of SM_CLEAR_ALARMS. The following table lists the

fault bits reported by nvoControlData.faults and nvoLCstatus.

Table 3. Fault Bit Reported by nvoControlData.faults, and nvoLCstatus

Fault Bit Condition

LowPower

HighPower

20

Measured power is nciLimits.powerLowFault % below the

expected power

Measured power is nciLimits.powerHighFault % above the

expected power

Page 21

LowSupplyVoltage

HighSupplyVoltage

RelayFailed

FailedStart

Cycling

CommMargin

RcvTmo

HighTemp

LampFailed

LowPF

Measured voltage is nciLimits.voltageLow % below the voltage

defined by nciControlCfg.supplyVoltage

Measured voltage is nciLimits.voltageHigh % above the voltage

defined by nciControlCfg.supplyVoltage

Power measured when the load switch relay is disengaged above 6.0W.

This would occur if the relay contacts were to weld shut.

Not supported at this time

Not supported at this time

Set if no update to nviLampValue is received before

nciLimits.rcvHb. It is recommended that the rcvHb parameter be

set to a value that is 50% longer that the configured update rate for

nviLampValue by the segment controller.

Set if the no update to nviLampValue is received before

nciControlCfg.maxRcvTm. This alarm typically results in the load

under control being driven to the level defined by

nciControlCfg.defaulLev.

Set when the onboard temperature sensor exceeds 65 degrees C.

Occurs when the power measured is below the % low value defined by

nciLimits.lampFailFault.

Set if the power factor of the controlled load falls below nciLimits.pfLow

when the load is ON. It is normal for the power factor reported in

nvoControlData to be in the range of .30-.40 when the load is OFF.

Alarm is only set if the load is ON.

nviLampValue -> nvoLampFb Relationship

The SNVT_switch type defines the range of control from 0-100% which maps to

control voltages between minPWM and maxPWM as determined appropriate for a

particular fixture application. A fixture used near an intersection, for example,

may have a maxPWM of 255 to generated full light output, while the same fixture

applied to a residential street may clip the light level maximum output by setting

maxPMW to 220. The value setting is a %, not a delivered light level. The

response of a driver/ballast is implementation dependent over the range of 0100% level. Ideally the response of the driver over the control range is a

continuous change in light level, or change in measured power. A 0VDC signal to

the driver results in a minimum light level, and power draw for the fixture which

are not 0. It is not uncommon for power at minimum controlled level to be 25% of

full brightness power.

The nvoLampFb typically reports value of nviLampValue. The only time this is

not the case is if the LC is configured to monitor the update rate, and a receive

timeout occurs forcing the brightness to the define nciControlCfg.defaultLev.

CPD 3000 Integration Guide 21

Page 22

The CPD 3000 uses the nciPowerProfile table to define the expected power at

five equally spaced nviLampValue.values (.5%, 25%, 50%, 75%, 100%) once the

minPWM and maxPWM CP fields have been established.

Note that nviLampValue.state is set to -1 at powerup/reset.

CPD 3000 Control Sequence

The CPD 3000 implements the state machine diagram depicted in figure 5 below.

The field nvoControData.LCstate reports the current active state for the

controller. To manage inrush current, the CPD 3000 uses an NTC Thermistor to

limit current inrush current commonly encountered with LED drivers and other

electronic ballasts. To be effective, the device needs a recovery time of 10s after

the load is switched ON. This means that power loss or reset will switch the load

OFF for 10s before turning the load ON. The configuration property field

nciControlCfg.cooldownTm provides additional if required by the load under

control.

Figure 7. CPD 3000 State Diagram

Table 4. CPD 3000 Control State Transition Descriptions

Path Condition Comments

A Power-up or Reset

B

C

D

22

COOLDOWN state timer expires AND (command ON

OR .defaultLev > 0)

COOLDOWN state timer expires AND (.defaultLev ==

0 AND rcvTmo) OR command OFF

(Command ON OR (.defaultLev > 0 AND rcvTmo))

AND .warmup > 0

10s COOLDOWN minimum

enforced for inrush limiter

recovery.

An unconfigured node will

follow this path FULL_ON level

Warmup state always drives

the control signal to the

configured high limit.

Page 23

E WARMUP state timer expires OR commanded OFF

F

G

H command OFF OR (rcvTmo AND .defaultLev == 0)

I

COOLDOWN state timer expires AND (.defaultLev > 0

AND rcvTmo) OR command ON

WARMUP state timer expires AND (commanded ON

OR (rcvTmo AND .defaultLev > 0))

.warmupTm == 0 AND (Command ON OR (rcvTmo

AND .defaultLev > 0)

During the transition from OFF to ON, the CPD 3000 drives the 0-10V control

signal directly to the final level at the time the load switching relay is engaged. If

the CPD 3000 is configured with a nciControlCfg.warmupTm > 0, the control

signal is driven to the 100% level, and finally the level defined by

nviLampValue.value after the warmupTm has completed. Changes in lamp level

while the load is ON are applied as a smooth ramp over the time specified by

nciControlCfg.rampTm (0 – 30.0 s, 0.1s steps). The transition to OFF will sweep

the 0-10V control to the minimum level before releasing the load switching relay.

Updates to nviLampValue are

delayed until out of WARMUP.

Occurs when .warmupTm is > 0

COOLDOWN for at least 10 for

inrush circuit recovery

Creating the CPD 3000 Device on your SmartServer

To create a LONWORKS device, follow these steps. For more information, see

Creating LonWorks Devices in Chapter 5 of the SmartServer User’s Guide.

If you are using the SmartServer in Standalone mode, copy the following files to

the SmartServer flash disk:

• Copy the external interface (XIF) files of the devices to be managed by the

SmartServer to the root/LonWorks/import folder on the SmartServer flash

disk.

• Copy the device resource files to the root/LonWorks/types/user folder.

• If you plan on upgrading the devices using the SmartServer, you need to copy

the devices’ application image files to the root/LonWorks/import folder.

• Reboot the SmartServer.

CPD 3000 Integration Guide 23

Loading...

Loading...