Page 1

LONWORKS® Twisted Pair

Control Module User’s Guide

078-0015-01F

Page 2

Echelon, LONWORKS, LONMARK, NodeBuilder, LonTalk, Neuron,

3120, 3150, ShortStack, LonMaker, and the Echelon logo are

trademarks of Echelon Corporation registered in the United

States and other countries.

Other brand and product names are trademarks or

registered trademarks of their respective holders.

Smart Transceivers, Neuron Chips, and other OEM Products

were not designed for use in equipment or systems, which

involve danger to human health or safety, or a risk of

property damage and Echelon assumes no responsibility or

liability for use of the Smart Transceivers or Neuron Chips in

such applications.

Parts manufactured by vendors other than Echelon and

referenced in this document have been described for

illustrative purposes only, and may not have been tested

by Echelon. It is the responsibility of the customer to

determine the suitability of these parts for each

application.

ECHELON MAKES AND YOU RECEIVE NO WARRANTIES OR

CONDITIONS, EXPRESS, IMPLIED, STATUTORY OR IN ANY

COMMUNICATION WITH YOU, AND ECHELON SPECIFICALLY

DISCLAIMS ANY IMPLIED WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE.

No part of this publication may be reproduced, stored in a

retrieval system, or transmitted, in any form or by any means,

electronic, mechanical, photocopying, recording, or

otherwise, without the prior written permission of Echelon

Corporation.

Printed in the United States of America.

Copyright © 1992, 2011 Echelon Corporation.

Echelon Corporation

www.echelon.com

Page 3

Welcome

Echelon’s LONWORKS® Twisted Pair Control Modules contain the core elements

for device designs using L

module are an FT 5000 Smart Transceiver or Neuron

circuit, I

rectangular), Communications Transformer or twisted pair transceiver, and

unbuffered access to the I/O, SERVICE~, and RESET~ signals.

ONWORKS technology. The core elements of a control

2

C EEPROM or JEDEC MO-052 AE PLCC memory socket (32-pin

®

3150® Chip, crystal clock

All of the Neuron 3150 L

ONWORKS Twisted Pair Control Modules share a

common footprint and I/O interface to allow systems with different media

requirements to share common application electronics board designs. The FT

5000 Control Module has a similar I/O interface so that you can easily modify

designs that use a Neuron 3150 Control Module to use the FT 5000 Control

Module.

Table 1 lists the available modules.

Table 1. LONWORKS Twisted Pair Control Modules

Model

Module

Number Features

FT 5000 Control Module 55040R-10 Transformer-isolated, free topology, 78

kbps communications, up to 80 MHz

system clock (the system clock rate is

application configurable; see

Configuration for FT 5000 Control

Modules on page 41).

TP/FT-10 Free Topology Control

Module

TP/FT-10F Free Topology Flash

Control Module

55020R-01 Transformer-isolated, free topology, 78

kbps communications, 5 MHz clock

55020R-10 Transformer-isolated, free topology, 78

kbps communications, flash memory

support, 10 MHz clock

TP/XF-78 Control Module 55010R-00 Transformer-isolated, bus operation, 78

kbps communications, 5 MHz clock

TP/XF-78F Flash Control Module 55010R-10 Transformer-isolated, bus operation, 78

kbps communications, flash memory

support, 10 MHz clock

TP/XF-1250 Control Module 55030R-10 Transformer-isolated, bus operation, 1.25

Mbps communications, 10 MHz clock

This manual provides technical specifications for the electrical and mechanical

interfaces and operating environment characteristics for the control modules.

LonWorks Twisted Pair Control Module User's Guide iii

Page 4

Audience

This document provides specifications and user instruction for customers who

have purchased any of Echelon’s Twisted Pair Control Modules.

Related Documentation

The following manuals are available from the Echelon Web site

(www.echelon.com

applications for Neuron Chip or Smart Transceiver devices:

• FT 3120 / FT 3150 Smart Transceiver Data Book (005-0139-01D). This

manual provides detailed technical specifications on the electrical

interfaces, mechanical interfaces, and operating environment

characteristics for the FT 3120

• I/O Model Reference for Smart Transceivers and Neuron Chips (0780392-01B). This manual provides information about the I/O models used

by Echelon’s Neuron Chips and Smart Transceivers. It includes

hardware and software considerations for each of the I/O models.

) and provide additional information that can help you develop

®

and FT 3150 Smart Transceivers.

• Introduction to the L

ONWORKS Platform (078-0183-01B). This manual

provides an introduction to the ISO/IEC 14908-1 (ANSI/CEA-709.1 and

EN14908) Control Network Protocol, and provides a high-level

introduction to L

ONWORKS networks and the tools and components that

are used for developing, installing, operating, and maintaining them.

• L

ONMARK

®

Application Layer Interoperability Guidelines. This manual

describes design guidelines for developing applications for open

interoperable L

Web site, www.lonmark.org

ONWORKS devices, and is available from the LONMARK

.

• LonMaker User's Guide (078-0333-01A). This manual describes how to

®

use the Turbo edition of the LonMaker

Integration Tool to design,

commission, monitor and control, maintain, and manage a network.

• Mini FX User’s Guide (078-0398-01A). This manual describes how to use

the Mini FX Evaluation Kit. You can use the Mini FX Evaluation Kit to

develop a prototype or production control system that requires

networking, or to evaluate the development of applications for control

networks using the L

• NodeBuilder

how to develop a L

®

FX User’s Guide (078-0405-01A). This manual describes

ONWORKS platform.

ONWORKS device using the NodeBuilder tool.

• Neuron C Programmer’s Guide (078-0002-02H). This manual describes

how to write programs using the Neuron C Version 2.2 programming

language.

iv

• Neuron C Reference Guide (078-0140-02F). T

re

ference information for writing programs using the Neuron C Version

his manual provides

2.2 programming language.

• Series 5000 Chip Data Book (005-0199-01B). This manual provides

detailed technical specifications on the electrical interfaces, mechanical

Page 5

interfaces, and operating environment characteristics for the Neuron

5000 Chips and FT 5000 Smart Transceivers.

• ShortStack FX User's Guide (078-0365-01B). This manual describes how

to develop an application for a L

®

ShortStack

FX Micro Server. It describes the architecture of a

ShortStack device and how to develop a ShortStack device.

All of the Echelon documentation is available in Adobe

PDF files, you must have a current version of the Adobe Reader

download from Adobe at: get.adobe.com/reader

Reference Documentation

The following documents and books provide additional information that can help

you develop applications for Neuron Chip or Smart Transceiver devices:

• American Society for Testing and Materials (ASTM) B258 - 02(2008)

Standard Specification for Standard Nominal Diameters and CrossSectional Areas of AWG Sizes of Solid Round Wires Used as Electrical

Conductors. www.astm.org/Standards/B258.htm

• Comité européen de normalisation electrotechnique1 (CENELEC) EN

55022 – Information technology equipment – Radio disturbance

characteristics – Limits and methods of measurement.

• Comité international spécial des perturbations radioélectriques

22 – Information Technology Equipment – Radio Disturbance

Characteristics – Limits and Methods of Measurement.

ONWORKS device using Echelon’s

PDF format. To view the

, which you can

.

2

(CISPR)

• Digital Communications: Fundamentals and Applications, 2nd Edition,

by Bernard Sklar, Prentice Hall, 2001.

• Electrostatic Discharge Association standard ESD STM5.1: Electrostatic

Discharge Sensitivity Testing – Human Body Model.

www.esda.org/freedowloads.html

• EMC for Product Designers, Fourth Edition, by Tim Williams, Newnes,

2007.

• EMI Troubleshooting Techniques, by Michel Mardiguian, McGraw-Hill

Professional, 1999.

• European Union Restriction of Hazardous Substances (RoHS) Directive

2002/95/EC.

europa.eu.int/eur-lex/pri/en/oj/dat/2003/l_037/

l_03720030213en00190023.pdf

• Comité européen de normalisation3 (CEN) Electromagnetic

Compatibility (EMC) standards (such as the IEC 61000-4 series of

standards).

• High Speed Digital Design: A Handbook of Black Magic, by Howard

Johnson and Martin Graham, Prentice Hall, 1993.

1

European Committee for Electrotechnical Standardization

2

International Special Committee on Radio Interference

3

European Committee for Standardization

LonWorks Twisted Pair Control Module User's Guide v

Page 6

• High-Speed Digital System Design: A Handbook of Interconnect Theory

and Design Practices, by Stephen H. Hall, Wiley-IEEE Press, 2000.

• International Organization for Standardization (ISO) and International

Electrotechnical Commission (IEC) standard ISO/IEC 14908 Control

Network Protocol

• Introduction to Electromagnetic Compatibility (Wiley Series in

Microwave and Optical Engineering), by Clayton R. Paul, WileyInterscience, 2006.

• Institute for Printed Circuits (IPC) / Joint Electron Device Engineering

Council (JEDEC) Solid State Technology Association standard:

IPC/JEDEC J-STD-020D.1 – Moisture/Reflow Sensitivity Classification

for Nonhermetic Solid State Surface Mount Devices.

www.jedec.org/download/search/JSTD020D-01.pdf

• Neuron Chip data book:

o Motorola

®

LONWORKS Technology Device Data

o Toshiba Neuron Chip TMPN3150/3120

o Cypress™ Neuron Chip Technical Reference Manual

See the Echelon Series 5000 Chip Data Book (005-0199-01B) or FT 3120

/ FT 3150 Smart Transceiver Data Book (005-0139-01D) for information

about Echelon Smart Transceivers.

• Noise Reduction Techniques in Electronic Systems, 2nd ed., by Henry W.

Ott, John Wiley & Sons, 1988.

• Protection of Electronic Circuits from Overvoltages, by Ronald B.

Standler, John Wiley & Sons, 1989, 2002.

• Title 47 of the Code of Federal Regulations (CFR) Part 15, Radio

Frequency Devices. www.fcc.gov/oet/info/rules/

• US Military Standard MIL-STD-883 Test Method Standard,

Microcircuits: Method 3015.7, Electrostatic Discharge Sensitivity

Classification.

You can purchase copies of CENELEC documents, IEC EMC standards, ISO

standards, US Military Standards, and CISPR documents from the Information

Handling Services (IHS) Global page at: global.ihs.com

. IEC EMC standards are

also available from the IEC at: www.iec.ch.

vi

Page 7

Table of Contents

Welcome ......................................................................................................... iii

Audience ........................................................................................................ iv

Related Documentation ................................................................................ iv

Reference Documentation .............................................................................. v

Chapter 1. Electrical Interface ...................................................................... 1

FT 5000 Control Module ................................................................................ 2

JP1 Connector .......................................................................................... 2

Neuron 3150 Control Modules ...................................................................... 3

P1 and P2 Connector Terminals ............................................................. 4

Reset Pin ......................................................................................................... 5

Service Pin ...................................................................................................... 6

Chapter 2. Mechanical Considerations ....................................................... 7

FT 5000 Control Module ................................................................................ 8

Floorplan Layout ..................................................................................... 8

Mechanical Footprint .............................................................................. 8

Neuron 3150 Control Module ........................................................................ 8

Mechanical Footprint .............................................................................. 9

Chapter 3. Power Requirements ................................................................. 15

FT 5000 Control Module .............................................................................. 16

Control Module Power Requirements .................................................. 16

Neuron 3150 Control Modules .................................................................... 16

Control Module Power Requirements .................................................. 16

Chapter 4. Network Cabling and Connection .......................................... 19

Performance Characteristics and Cabling .................................................. 20

Free Topology TP/FT-10 and TP/FT-10F .................................................... 20

Wire Characteristics .............................................................................. 21

Cable Terminations – Free Topology ................................................... 21

Cable Terminations – Doubly Terminated Bus ................................... 21

TP/XF-78, TP/XF-78F, and TP/XF-1250 ..................................................... 22

Wire Characteristics .............................................................................. 22

Device Distribution Rule for TP/XF-1250 Segments ........................... 22

Cable Terminations – TP/XF-78, -1250 Segments .............................. 24

Chapter 5. Design Issues ............................................................................... 27

EMI Design Issues ....................................................................................... 28

Designing Systems for EMC ........................................................................ 28

EMC Design Tips ................................................................................... 28

FT 5000 Control Module PC Board Layout Guidelines ...................... 29

Neuron 3150 Control Module Keepout Areas ...................................... 31

ESD Design Issues ....................................................................................... 32

Designing Systems for ESD Immunity ................................................ 33

Designing for Interoperability ..................................................................... 34

Chapter 6. Programming Considerations ................................................. 35

External Memory Considerations ............................................................... 36

FT 5000 Control Module ....................................................................... 36

Using an Aardvark I2C/SPI Host Adapter .................................... 36

Clearing the Non-Volatile Memory ................................................ 37

Neuron 3150 Control Modules .............................................................. 38

LonWorks Twisted Pair Control Module User's Guide vii

Page 8

Application Program Development and Export ......................................... 40

NodeBuilder FX Development Tool ...................................................... 40

Configuration for FT 5000 Control Modules ................................. 41

Configuration for Neuron 3150 Control Modules ......................... 43

Programming ................................................................................... 45

Mini FX Evaluation Kit ......................................................................... 45

ShortStack FX Developer’s Kit ............................................................. 45

viii

Page 9

1

Electrical Interface

FT 5000 Control Modules interface to the device application

electronics and to the network through the JP1 connector.

Neuron 3150 Control Modules interface to the device

application electronics and to the network through two

connectors, P1 and P2, respectively.

LonWorks Twisted Pair Control Module User's Guide 1

Page 10

FT 5000 Control Module

MOV_GND

IO2

IO0

CP2_TXLED

SVC-

RST-

FT_NETA

IO10

IO8

IO6

IO4

SCL

SDA_CS1-

IO11

FT_NETB

IO3

IO1

IO5

IO9

IO7

VDD3V3

CP3_RXLED

JP1

HEADER 13X2

2

4

6

8

10

12

14

16

18

20

22

24

26

135791113

15

17

19

21

23

25

The following sections describe the electrical interface for the FT 5000 Control

Module.

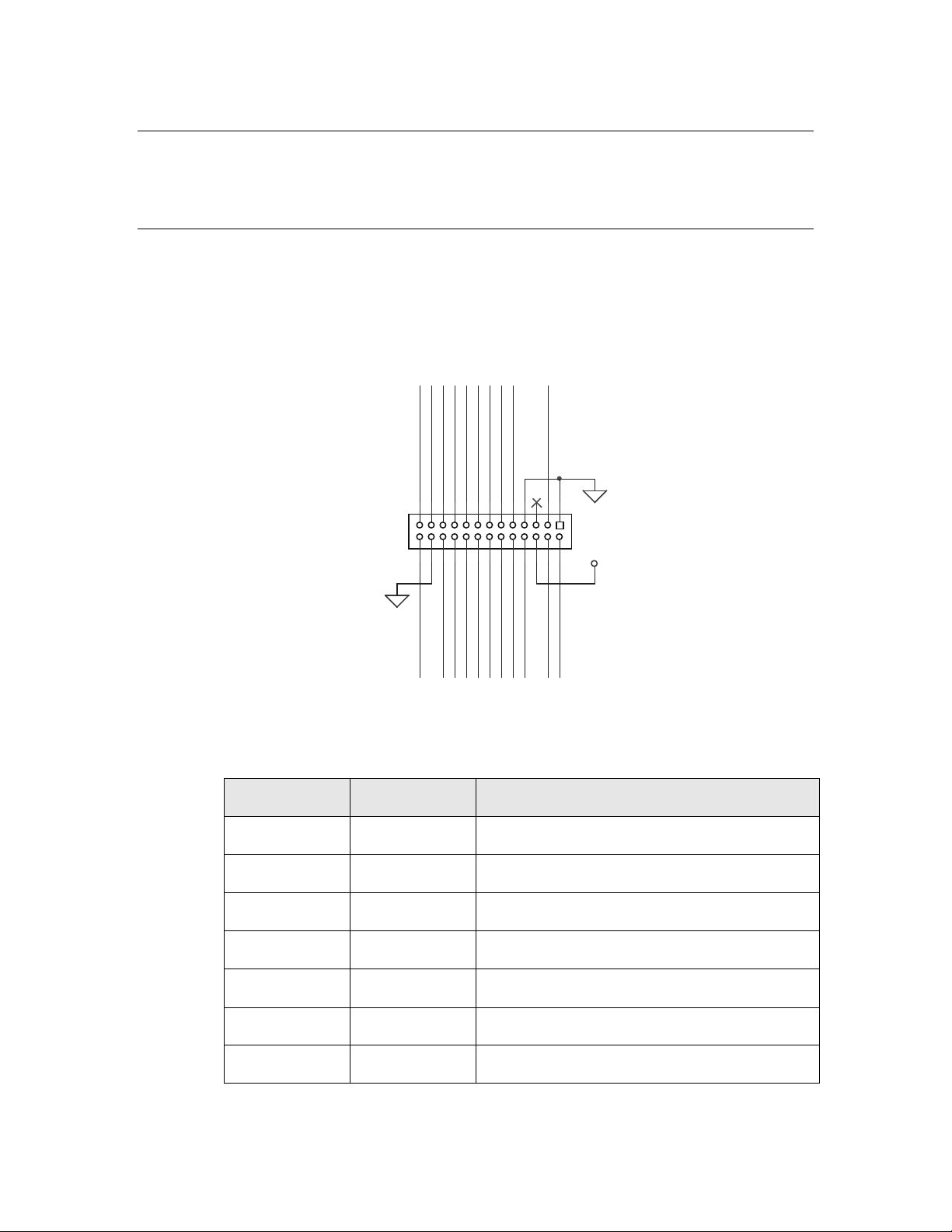

JP1 Connector

Figure 1 and Table 2 show the pinout of the JP1 header connector for the FT

5000 Control Module. The I/O pin function names defined in Table 2 are the

same as those used in the Series 5000 Chip Data Book, which defines the

functions and electrical characteristics for the signals. The I/O signals are

connected directly to the FT 5000 Smart Transceiver without buffering.

Figure 1. FT 5000 Control Module JP1 Connector

Table 2. FT 5000 Control Module JP1 Connector

Pin Number Signal Name Description

1 GND Ground

2 RST~ Reset (active low)

3 CP3_RXLED RxActive for network activity LED

4 CP2_TXLED TxActive for network activity LED

5 NC No Connect

6 VDD3V3 3.3 V Input Power

7 GND Ground

2 Electrical Interface

Page 11

Pin Number Signal Name Description

8 SCL I2C serial clock for in-circuit programming

9 SDA_CS1~ I2C serial data for in-circuit programming

10 SVC~ Service (active low)

11 IO0 IO0 for I/O objects

12 IO1 IO1 for I/O objects

13 IO2 IO2 for I/O objects

14 IO3 IO3 for I/O objects

15 IO4 IO4 for I/O objects

16 IO5 IO5 for I/O objects

17 IO6 IO6 for I/O objects

18 IO7 IO7 for I/O objects

19 IO8 IO8 for I/O objects

20 IO9 IO9 for I/O objects

21 IO10 IO10 for I/O objects

22 IO11 IO11 for I/O objects

23 MOV_GND Return (ground) for MOV ESD clamp

24 GND Ground

25 FT_NETA FT network connection

26 FT_NETB FT network connection

Note: The FT 5000 Control Module incorporates DC blocking capacitors and

therefore can directly connect to either non-link power or link power channels.

Neuron 3150 Control Modules

The following sections describe the electrical interface for the Neuron 3150

Control Modules.

LonWorks Twisted Pair Control Module User's Guide 3

Page 12

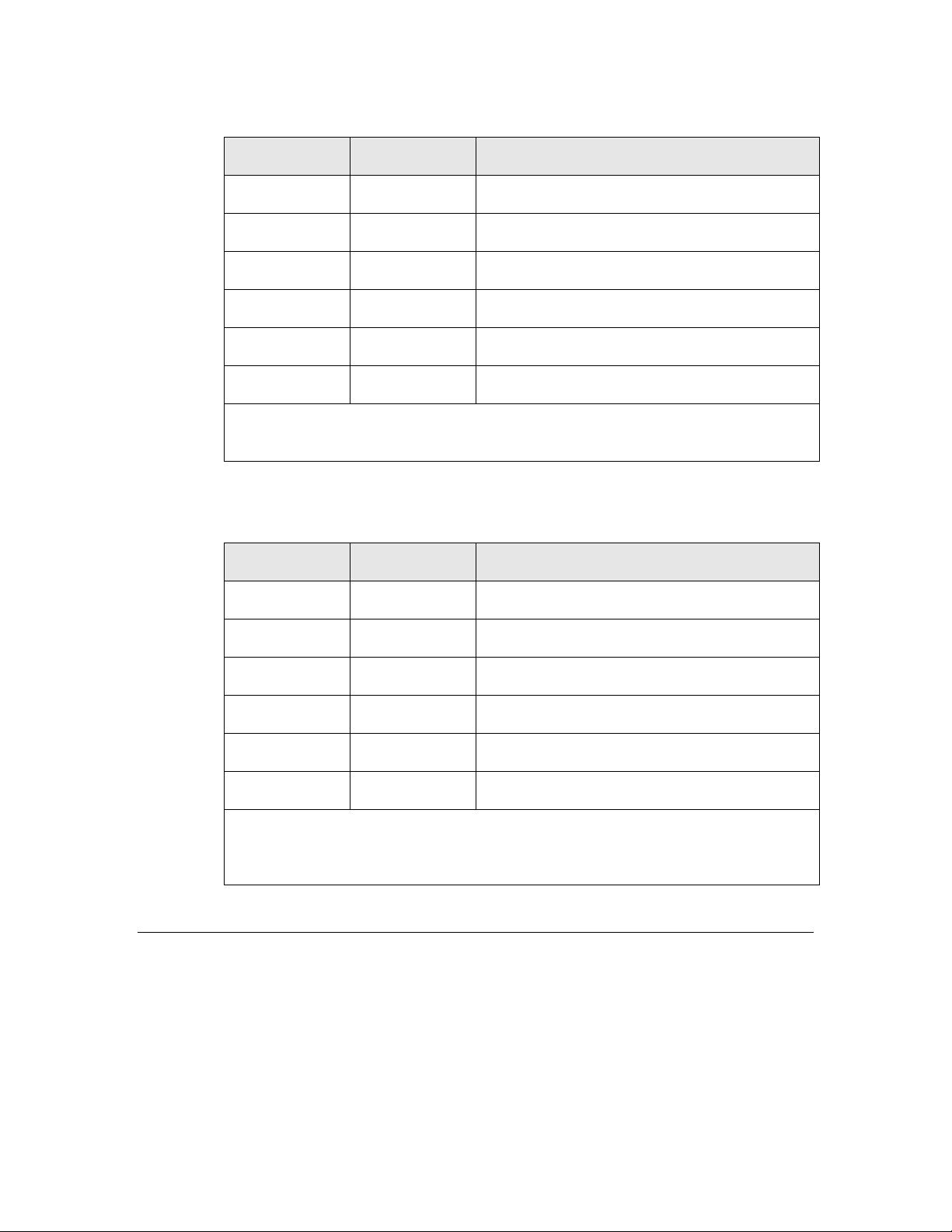

P1 and P2 Connector Terminals

Table 3, Table 4 on page 5, and Table 5 on page 5 show the pinout of the P1

and P2 connector terminals for the Neuron 3150 Control Modules. The I/O pin

function names defined in Table 3 are the same as those used in the Neuron

Chip Data Book, which defines the functions and electrical characteristics for the

signal names. The I/O signals are connected directly to the Neuron 3150 Chip

without buffering.

Table 3. 18-pin I/O Connector (P1) for Neuron 3150 Control Modules

Pin Number Name Description

1 NC No Connect

2 IO0 IO0 for I/O objects

3 GND Ground

4 IO1 IO1 for I/O objects

5 GND Ground

6 IO2 IO2 for I/O objects

7 GND Ground

8 IO3 IO3 for I/O objects

9 RESET~ Reset (active low)

10 IO4 IO4 for I/O objects

11 IO5 IO5 for I/O objects

12 +5 V 5 V Input Power

13 IO6 IO6 for I/O objects

14 IO9 IO9 for I/O objects

15 IO7 IO7 for I/O objects

16 IO10 IO10 for I/O objects

17 IO8 IO8 for I/O objects

18 SERVICE~ Service (active low)

4 Electrical Interface

Page 13

Table 4. 6-pin Network Connector (P2) for the TP/XF Control Modules

Pin Number Name Description

1 CTB Transformer center tap

2 CTA Transformer center tap

3 Data B Network data B signal

4 Data A Network data A signal

5 NC No connection

6 NC No connection

Note: CTA and CTB must be shorted together on the applications electronics

board.

Table 5. 6-pin Network Connector (P2) for the TP/FT-10 and TP/FT-10F

Control Modules

Pin Number Name Description

1 1 No connection

2 2 No connection

3 Data B Network data B signal

4 Data A Network data A signal

5 5 No connection

6 6 No connection

Note: The TP/FT-10 and TP/FT-10F Control Modules incorporate DC blocking

capacitors and therefore can directly connect to either non-link power or link

power channels.

Reset Pin

Pin 2 of the JP1 header on the FT 5000 Control Module is the Smart Transceiver

reset pin (RST~). Pin 9 of the P1 header on the Neuron 3150 Control Module is

the Neuron Chip reset pin (RESET~).

The reset pin on the Smart Transceiver or Neuron Chip can be driven low

externally or can be used as an open drain output to provide a reset signal for the

application circuit. The details of the recommended circuit and loading on the

LonWorks Twisted Pair Control Module User's Guide 5

Page 14

reset pin are described in the Series 5000 Chip Data Book or the Neuron Chip

SVC~

VCC

VCC

Control Module

VCC

SERVICE~

Smart Transceiver

or Neuron Chip

P1.18

JP1.10

VCC = +3.3V for FT 5000 Control Module

VCC = +5V for Neuron 3150 Control Module

Data Book.

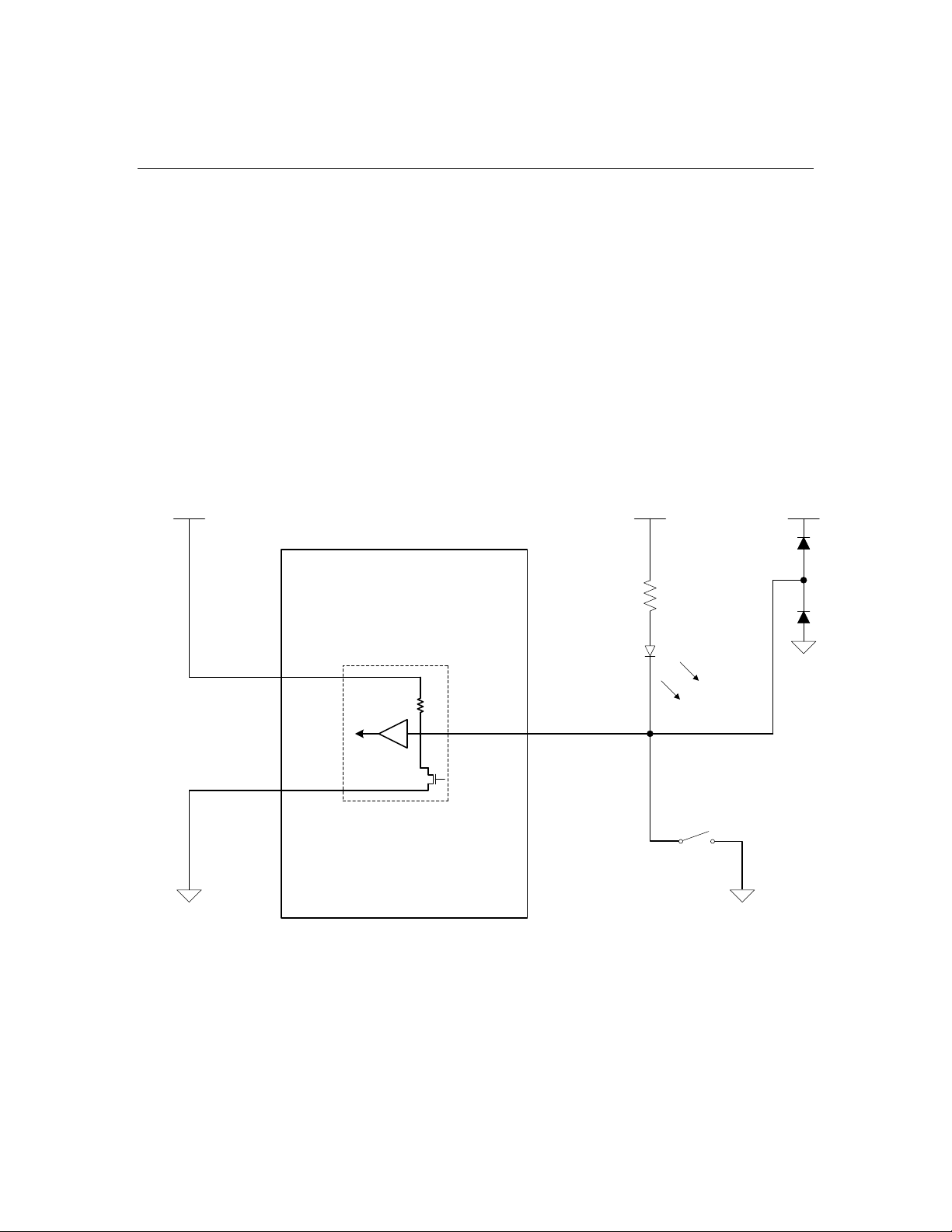

Service Pin

You can access the service pin (SVC~) of the FT 5000 Control Module at pin 10 of

the JP1 header. You can access the service pin (SERVICE~) of the Neuron 3150

Control Module at pin 18 of the P1 header.

This pin is used for various network installation and maintenance scenarios. The

function of this pin is described in the Series 5000 Chip Data Book or Neuron

Chip Data Book.

Figure 2 shows a typical circuit for the device service pin. Typical applications

do not require debounce conditioning of momentary push buttons attached to the

service or reset pins. The software response time associated with these inputs is

long enough to effectively provide a software debounce for switches with a contact

bounce settling time as long as 20 msec.

6 Electrical Interface

Figure 2. Typical Service Pin Circuit

Page 15

2

Mechanical Considerations

This chapter discusses the mechanical footprint and connectors of the

Twisted Pair Control Modules. Details of mounting to an application

electronics board are provided.

LonWorks Twisted Pair Control Module User's Guide 7

Page 16

FT 5000 Control Module

FT-X3

1

1

2

3

4

8

7

6

5

FT

5000

AT

24C

512

Y1

1

RV1

C7,17

43.18 mm

(1.7 in)

29.85 mm

(1.175 in)

Back View Front View

Side

View

16 mm

(0.63 in)

The following sections describe the mechanical interface for the FT 5000 Control

Module.

Floorplan Layout

Figure 3 shows three views of the floorplan layout of the FT 5000 Control

Module with some of its prominent features labeled.

Figure 3. FT 5000 Control Module Floorplan Layout

Mechanical Footprint

Figure 4 shows the mechanical footprint for an FT 5000 Control Module. You

can solder the module directly to your PCB as a through-hole part or mount it in

a connector. The module includes a male Samtec, Inc. TSW-113-08-T-D-RA

square post header, which fits into a 13x2 pin female connector, such as a

Samtec, Inc. SSM-113-L-DV surface mount socket strip.

Figure 4. FT 5000 Control Module Mechanical Footprint

The figure also shows positioning for Richco

mount card guides for the Control Module. The card guides are optional,

depending on your application.

Neuron 3150 Control Module

The following sections describe the mechanical interface for the Neuron 3150

Control Modules.

®

Inc. VMCGE-30M-01 vertical

8 Mechanical Considerations

Page 17

Mechanical Footprint

The Neuron 3150 Twisted Pair Control Modules share a common footprint and

connectors as shown in Figure 5 on page 10. The most common control module

mounting scenario uses socket strips on the application electronics board which

connect with P1 and P2 as shown in Figure 6 and Figure 7 on page 11.

Example vendor information for socket strips that mate with the 0.025 inch (0.64

mm) square header posts of P1 and P2 are listed in Table 6 on page 11.

If necessary, taller socket strips can be used to gain more clearance between the

control module and the application board. Decisions about component placement

on the application electronics board must also consider the electromagnetic

interference (EMI) and electrostatic discharge (ESD) issues discussed in Chapter

5, Design Issues, on page 27.

Figure 6 and Figure 7 show the maximum height of parts on both sides of the

control modules. Application designs using the transformer-isolated twisted pair

transceivers should maintain a minimum of 0.15 inch (3.81 mm) clearance from

P2 pins and traces on the network side of the transformer to achieve the

minimum isolation specified for these modules. Refer to EMI Design Issues on

page 28 and Neuron 3150 Control Module Keepout Areas on page 31 for isolation

requirements.

Three plated mounting holes that accept No. 6 (3.5 mm) mounting screws are

electrically connected to the control module ground plane. When the 0.025 inch

(0.64 mm) square posts of P1 and P2 are inserted into the sockets they provide

enough holding strength (3 oz (85 g)/pin) to secure the control module against

shock and vibration to the operating limits of the components on the control

module. However, at least one metal standoff and fastening screw located at the

mounting hole near the P2 connector is recommended to meet EMI limits and for

ESD protection (see Chapter 5).

For the TP/FT-10 control modules, the recommended metal standoff height is

0.56 inch (14.3 mm) to provide adequate clearance. Note that the Methode

Socket (referenced in Table 6) in this case is not recommended, because its

minimum insertion depth requirement is not met. Use of metal 0.50 inch (12.7

mm) #6 standoffs together with metal spacers can achieve this. Alternately,

metal 0.56 inch (14.3 mm) #6 standoffs alone will be adequate. For the TP/XF

and TP/FT-10F control modules, 0.50 inch (12.7 mm) #6 metal standoffs alone are

recommended.

Figure 8 on page 12 presents the height restrictions of the component side of the

control module. The board is divided into two height zones: the maximum height

of components in the first zone is 0.20 inch (5.1 mm). The second zone's

components are 0.47 inch (11.93 mm) for the TP/XF and TP/FT-10F control

modules and 0.555 inch (14.1 mm) for the TP/FT-10 control module. Care should

be taken to ensure that no components on the application electronics board

interfere with the height restricted areas of the control modules.

Figure 9 on page 13 shows the recommended PCB pad layout for the application

electronics board to interconnect a control module with an application board that

has socket strips mounted on the component side.

LonWorks Twisted Pair Control Module User's Guide 9

Page 18

Figure 5. Neuron 3150 Control Module Mechanical Footprint

10 Mechanical Considerations

Page 19

Table 6. Socket Strips Suitable for Use with the Control Module Header Pins

Manufacturer P1: 18-pin (2 X 9) P2: 6-pin (1 X 6)

Samtec SSW-109-01-T-D SSW-106-01-T-S

Methode * 9000-209-303 9000-106-303

Advanced

Interconnections

* Not recommended for use with the TP/FT-10 or TP/FT-10F Control Modules.

Figure 6. Recommended Spacing between the TP/XF-78, TP/XF-78F, and TP/XF-1250

Control Modules and the Application Electronics Board

BC-009-124TL BC006-123TL

Figure 7. Recommended Spacing between the TP/FT-10 and TP/FT-10F Control Modules

and the Application Electronics Board

LonWorks Twisted Pair Control Module User's Guide 11

Page 20

Figure 8. Vertical Component Profile for the Control Modules

12 Mechanical Considerations

Page 21

Figure 9. Required Pad Layout for Application Electronics Board

LonWorks Twisted Pair Control Module User's Guide 13

Page 22

Page 23

3

Power Requirements

This section describes the power requirements for the control modules

as well as considerations for noise filtering in order to comply with

both conducted and radiated emissions requirements.

LonWorks Twisted Pair Control Module User's Guide 15

Page 24

FT 5000 Control Module

The following sections describe the power requirements for the FT 5000 Control

Module.

Control Module Power Requirements

FT 5000 Control Modules require a +3.3 VDC power source with sufficient

current to power the control module in all modes of operation.

The supply current requirements for the FT 5000 Control Modules are outlined

in Table 7, including typical requirements for the different operating states of

the FT 5000 Smart Transceiver at various system clock rates.

Table 7. FT 5000 Current Requirements

Active SysClk Typical Maximum

5 MHz 9 mA 15 mA

10 MHz 9 mA 15 mA

Receive Current

Transmit Current

The FT 5000 Control Module requires a 3.3 V nominal power supply (3.0 V to 3.6

V range). The current requirements assume no load on digital I/O pins, and that

the I/O lines are not switching. In addition, the current consumption in transmit

mode represents a peak value rather than a continuous usage value because an

FT 5000 Smart Transceiver does not typically transmit data continuously.

Note that the stated current requirements do not include the requirements for

performing reads or writes to the external memory (the two-wire serial

EEPROM), which typically add 1 to 2 mA. When not in use, the EEPROM

typically requires only 2 μA.

20 MHz 15 mA 23 mA

40 MHz 23 mA 33 mA

80 MHz 38 mA 52 mA

5 – 80 MHz Receive Current

+ 15 mA

Neuron 3150 Control Modules

The following sections describe the power requirements for the Neuron 3150

Control Modules.

Receive Current

+ 18 mA

Control Module Power Requirements

Twisted Pair Control Modules require a +5 VDC power source with sufficient

current to power the control module in all modes of operation.

16 Power Requirements

Page 25

The supply current requirements for the control modules are outlined in Table 8,

which includes peak requirements for the different operating states of the

Neuron Chip. The control modules require a 5 V ±5% power supply. The current

requirements are characterized for maximum number of devices on the channel

with I/O pins programmed as outputs at a logic low level with no load.

The values in Table 8 are subject to change. Please consult current data sheets

for the latest information.

Table 8. Typical Control Module +5 Volt Current Requirements

Control Module Typical DC Characteristics (+5.0 V)

Active, Receive (mA) Active, Transmit (mA)

TP/FT-10 (5 MHz) 25 40

TP/FT-10F (10 MHz) 50 60

TP/XF-78 (5 MHz) 35 45

TP/XF-78F (10 MHz) 50 60

TP/XF-1250 (10 MHz) 55 80

Notes:

1. Assumes internal I/O pullups are disabled and I/O lines are not connected

to a load.

2. Assumes SERVICE~ pullup is enabled.

3. Includes CMOS EPROM or flash chip running typical application with

system code.

4. These figures include typical PROM current consumption of 4 mA at 5

MHz or 5 mA at 10 MHz; the TP/FT-10F and TP/XF-78F figures include

flash memory reads, however, flash memory writes require an

additional 50 mA. These figures exclude current due to loading on the

I/O connector pins.

LonWorks Twisted Pair Control Module User's Guide 17

Page 26

Page 27

Network Cabling and Connection

4

This chapter addresses cabling and termination for the FT

5000 Control Module and the Neuron 3150 Control Modules

(TP/FT-10, TP/FT-10F, TP/XF-78, TP/XF-78F, and TP/XF1250 Twisted Pair Control Modules).

LonWorks Twisted Pair Control Module User's Guide 19

Page 28

Performance Characteristics and Cabling

For performance characteristics and cabling information, refer to the sources of

information shown in summary Table 9. The specifications shown in Table 9

are provided for convenience only and are not intended to be comprehensive.

Table 9. Module Performance Summary

Module Cable Distance Number of

Nodes

FT 5000,

TP/FT-10,

TP/FT-10F

TP/XF-78,

TP/XF-78F

TP/XF-1250 Bus: 130 m (430 feet)

Bus: 2700 m (8850 feet)

worst case with Belden

85102 cable

Free topology: 500 m

(1640 feet) worst case

with Belden 85102 cable

and with no repeaters

(1000 m [3280 ft] total

wire with one repeater)

Bus: 1400 m (4600 feet)

worst case with 3 m (10

feet) stubs with 22

AWG (0.65 mm) Level

IV Cable

worst case with 0.3 m (1

foot) stubs with 22

AWG (0.65 mm) Level

IV Cable, or Category 5

or 6 cable

®

64 at -40 to +85 °C

64 at 0 to +70 °C

44 at -40 to +85 °C

64 at 0 to +70 °C

32 at -20 to +85 °C

16 at -40 to +85 °C

Information Sources

• Series 5000 Chip Data

Book (005-0199-01)

• FTT-10 User's Guide (078-

0114-01)

• FTT-10A User's Guide

(078-0156-01)

• LPT-10 User's Guide (078-

0105-01)

• Control Module Data

Sheet (003-0121-01)

• TPT User's Guide (0780025-01)

• Control Module Data

Sheet (003-0121-01)

Control Module Data Sheet

(003-0121-01)

Notes:

1. Worst case distance figures are based on variations in device distribution,

device temperature, device voltage, wire characteristics, and FT 5000

Smart Transceiver or Neuron Chip characteristics, and allow for an

average wire temperature of up to +55 °C.

2. Network length for TP/FT-10 channel varies by wire type.

Free Topology TP/FT-10 and TP/FT-10F

The following sections describe the wire characteristics and cabling terminations

for Free Topology TP/FT-10 channels. The FT 5000 Control Module and the

Neuron 3150 TP/FT-10 and TP/FT-10F Control Modules use a Free Topology

TP/FT-10 channel.

20 Network Cabling and Connection

Page 29

Wire Characteristics

Due to the many cabling and termination options available for the TP/FT-10

channel, please refer to the Series 5000 Chip Data Book, FTT-10 Free Topology

Transceiver User's Guide, or FTT-10A Free Topology Transceiver User's Guide, as

applicable, for information on wire characteristics and terminations.

The Junction Box and Wiring Guidelines for Twisted Pair LonWorks Networks

engineering bulletin (005-0023-01) provides a list of cable vendors for each type of

supported cable. This bulletin is available from the Echelon Web site

(www.echelon.com

).

Cable Terminations – Free Topology

In a TP/FT-10 free topology segment, only one termination is required and can be

placed anywhere on the free topology segment. There are two choices for the

termination:

1. RC network (see Figure 10), with R1 = 52.3 Ω.

2. LPI-10 or LPI-11 Link Power Interface, with jumper at "1 CPLR" setting.

Figure 10. RC Network Termination for TP/FT-10 Segments

Cable Terminations – Doubly Terminated Bus

In a TP/FT-10 doubly terminated bus topology, two terminations are required,

one at each end of the bus. There are two choices for each termination:

1. RC network (see Figure 10), with R1 = 105 Ω.

2. LPI-10 or LPI-11 Link Power Interface, with jumper at "2 CPLR" setting

if resident on a link power segment. Only one LPI-10 or LPI-11 Interface

LonWorks Twisted Pair Control Module User's Guide 21

Page 30

is supported per segment, so at least one of the terminations must be the

RC-type.

TP/XF-78, TP/XF-78F, and TP/XF-1250

The following sections describe the wire characteristics and cabling terminations

for TP/XF-78, and TP/XF-1250 channels. In addition, the device distribution rule

for TP/XF-1250 network segments is described.

Wire Characteristics

The Neuron 3150 TP/XF-78, TP/XF-78F, and TP/XF-1250 control modules are

designed for distributed control applications using low-cost, Level IV twisted pair

wire. The TP/XF-1250 Control Module can also use AWG 24 (0.511 mm)

ANSI/TIA/EIA-568-B.2-2001 Category 5 or Category 6 twisted-pair wire. The

characteristics of the wire used to implement a network affects the overall system

performance with respect to total distance, stub length, and total number of

nodes supported on a single channel.

The TP/XF-78 and TP/XF-78F control modules have been qualified using the

following cable types:

• Primary bus: Level IV, AWG 22 (0.65 mm)

• Stubs (where permitted): Level IV, AWG 24 (0.511 mm) cable or Level

IV, AWG 22 cable

The TP/XF-1250 Control Module has been qualified using the following cable

types:

• Primary bus: Level IV, AWG 22 (0.65 mm); or AWG 24 (0.511 mm)

ANSI/TIA/EIA-568-B.2-2001 Category 5 or Category 6 twisted-pair cable

• Stubs (where permitted): Level IV, AWG 24 (0.511 mm) cable; Level IV,

AWG 22 cable; or AWG 24 (0.511 mm) ANSI/TIA/EIA-568-B.2-2001

Category 5 or Category 6 twisted-pair cable

For all of the control modules, under no circumstances should smaller gauge

Level IV cable be substituted for Level IV, AWG 22 (0.65 mm) twisted pair cable

for the bus, or should Category IV cable be used in place of Level IV cable.

Echelon periodically qualifies new cables for twisted pair transceivers, and it is

advisable to check with Echelon from time to time to determine if new cables are

available for use with the control modules.

The characteristics and suppliers of Level IV cable are described in the Junction

Box and Wiring Guidelines for Twisted Pair LonWorks Networks engineering

bulletin (005-0023-01).

Device Distribution Rule for TP/XF-1250 Segments

Because of the transmission characteristics of the TP/XF-1250 channel,

communication failures can result from reflections of the TP/XF-1250 module’s

1.25 Mbps transmitted signal under conditions of concentrated device loading.

These communication failures are eliminated when devices are used in a

distributed configuration. For this reason, it is essential to follow a simple

topology rule when using TP/XF-1250 control modules, TPT/XF-1250

22 Network Cabling and Connection

Page 31

transceivers, or TPM-1250 SMX transceivers to eliminate the possibility of

reflection-related transmission failures. No such topology rule applies to the

use of TP/XF-78 control modules, TPT/XF-78 transceivers, or TPM-78

SMX transceivers.

Referred to as the “8-in-16” topology rule, this rule requires that no more than 8

TP/XF-1250 Control Modules, TP/XF-1250 Transceivers, or TPM-1250 SMX

Transceivers be located within any 16 meter length of cable. This means that no

matter where along the bus the 16 meter measurement is taken, there should be

no more than 8 devices. Figure 11 provides a diagram of such a measurement

technique. In the figure, the numbers in the boxes represent the number of

devices connected to the bus and the “T” represents the bus termination.

Figure 11. 8-in-16 Topology Rule Example

In the example, we see an installation with six groups of devices, varying in

number from 2 to 8 devices, in a doubly terminated bus. By using a 16 meter

measurement stick that we can move from side-to-side over the length of the bus,

we can determine whether the 8-in-16 rule has been met (designated by the word

“OK”) or violated (shown by the designation “PROBLEM”). In the case of the

PROBLEM area, a total of 13 devices are located within a 16 meter length of the

bus, which amounts to five more devices than are permitted under the 8-in-16

rule.

There are two solutions that can be applied to situations in which the 8-in-16 rule

has been, or must be, violated by the installation scenario. The first and simplest

remedy is to insert a router and two termination networks in the bus to break the

network into two channels (see Figure 12 on page 24). Because each side of the

router comprises a different channel, the bus is effectively split and the devices

divided between two channels.

LonWorks Twisted Pair Control Module User's Guide 23

Page 32

Figure 12. Using a Router to Meet the 8-in-16 Topology Rule

The second remedy to a violation of the 8-in-16 rule is to add additional cable to

the bus such that the rule is no longer violated (see Figure 13). It is important

to ensure that the maximum bus length (130 meters of 22 AWG [0.65 mm] Level

IV or AWG 24 [0.511 mm] ANSI/TIA/EIA-568-B.2-2001 Category 5 or Category 6

twisted-pair cable) is not exceeded by the additional cable. Because of the

complex interactions between the bus and the transceivers with regard to

reflections and transmission line delays, it is not possible to substitute an LC

network in place of the additional cable to resolve this rule violation.

Figure 13. Using Additional Bus Cable to Meet the 8-in-16 Topology Rule

Cable Terminations – TP/XF-78, -1250 Segments

Twisted pair network segments require termination for proper data transmission

performance. For doubly terminated bus topologies, a termination must reside at

both endpoints of the bus. The terminations required for TP/XF-78, TP/XF-78F,

and TP/XF-1250 segments are shown in Figure 14 on page 25.

24 Network Cabling and Connection

Page 33

Figure 14. Required Bus Termination for TP/XF-78 and TP/XF-1250 Twisted

Pair Networks

LonWorks Twisted Pair Control Module User's Guide 25

Page 34

Page 35

5

Design Issues

This chapter describes design issues, including a discussion

of Electromagnetic Interference (EMI), and Electrostatic

Discharge (ESD), and Designing for Interoperability. This

chapter applies to both FT 5000 Control Modules and

Neuron 3150 Control Modules.

LonWorks Twisted Pair Control Module User's Guide 27

Page 36

EMI Design Issues

The high-speed digital signals associated with microcontroller designs can

generate unintentional Electromagnetic Interference (EMI). High-speed voltage

changes generate RF currents that can cause radiation from a product if a length

of wire or piece of metal can serve as an antenna.

Products that use the Twisted Pair Control Modules generally need to

demonstrate compliance with EMI limits enforced by various regulatory agencies.

In the USA, the Federal Communications Commission (FCC) requires that

unintentional radiators comply with Part 15 level “A” for industrial products, and

level “B” for products that can be used in residential environments. In Europe,

the CENELEC committee requires that unintentional radiators comply with the

EN 55022 standard. Similar regulations are imposed in most countries

throughout the world.

Echelon has designed the Twisted Pair Control Modules with low enough RF

noise levels for design into level “B” products. Echelon encourages level “B”

compliance for all L

considerations for control module-based products to meet EMI regulations.

ONWORKS compatible products. This section describes design

Designing Systems for EMC

Echelon has demonstrated that designs using the control modules can meet both

FCC and EN55022 level “B” limits. Careful design of application electronics is

important to guarantee that a control module-based node will achieve the desired

electromagnet compatibility (EMC). This section provides useful design tips for

EMC. The FT 5000, TP/FT-10, and TP/FT-10F Control Modules have been

designed to comply with IEC 61000-4-2, IEC 61000-4-3, IEC 61000-4-4, IEC

61000-4-5, and IEC 61000-4-6 standards. For more information, see the Series

5000 Chip Data Book, FTT-10 Free Topology Transceiver User's Guide, or FTT10A Free Topology Transceiver User's Guide, as applicable.

EMC Design Tips

The following design tips can greatly aid in EMC design:

• Most of the RF noise originates in the CPU portion of the control module,

and in any high-frequency or high-speed application circuitry in the

device.

• Most of the EMI will be radiated by the network cable and the power

cable.

• Filtering is generally necessary to keep RF noise from getting out on the

power cable.

• EMI “Keepout” area restrictions should be observed to prevent internal

RF noise from coupling onto the network cable.

• The control module must be well grounded within the device to ensure

that its built-in EMI filtering works properly.

• Early EMI testing of prototypes at a certified test facility is an extremely

important step in the design of level “B” products. This testing ensures

28 Design Issues

Page 37

that grounding and enclosure design questions are addressed early

enough to avoid most last-minute changes (and their associated schedule

delays).

It is possible for a plastic enclosure to be used with Twisted Pair Control Modules

in level “B” applications in some specialized configurations. Because external

cables must be kept away from the “RF hot” keepout area on the modules (see

Figure 16 on page 32), the product configuration must constrain the routing of

cables so that they cannot pass across the surface of the plastic enclosure near

the module. During FCC EMI testing, cable position is typically varied to

generate maximum emission levels (within constraints of normal product usage).

For Neuron 3150 Control Modules, the three standoff holes are generally not

needed for mechanical support, but the hole nearest connector P2 is important

for EMI grounding of the control module. Best results are achieved by a solid

ground connection from the control module to the application mother board and

to a metalized enclosure using the P2 standoff.

The Twisted Pair Control Modules include adequate filtering on the network data

communication lines for most device designs to meet level “B” emission limits. In

rare cases, such as designs including circuits with extremely fast edges,

additional noise attenuation is required. In such cases it may be necessary to use

a common-mode choke connected in series with the data communication lines

adjacent to the device’s external network connector. Common-mode chokes can

provide an additional 10 to 15 dB of EMI attenuation over the 30 to 500 MHz

range. A choke adds a few pF of differential capacitance to the data

communication lines, and therefore reduces network performance and can affect

interoperability. In general, application designs should not require a commonmode choke.

FT 5000 Control Module PC Board Layout Guidelines

Electrostatic discharge (ESD) and electromagnetic interference (EMI) are two of

the most important design considerations when laying out the PCB for a device.

Tolerance of ESD and other types of network transients requires careful layout

for power, ground, and other device circuitry. In general, ESD currents return to

Earth ground or to other nearby metal structures. The device’s ground scheme

must be able to pass this ESD current between the network connection and the

device’s external ground connection without generating significant voltage

gradients across the device’s PCB. The low-inductance star-ground configuration

accomplishes this task. The star-ground configuration conducts transients out of

the device with minimal disruption to other function blocks.

The following list describes some of the general features of a careful PCB design

layout for an FT 5000 Control Module:

Star-Ground Configuration: The various blocks of the device that directly

interface with off-board connections (the network, any external I/O, and

the power supply cable) should be arranged so that the connections are

together along one edge of the PCB. This arrangement allows any

transient current that comes in by one connection to flow back out of the

device by one of the other connections.

If connection is made between the PCB ground and a metal enclosure,

that connection should be made using a low-inductance connection (like a

short standoff) in the center of the star ground. The center of the star

LonWorks Twisted Pair Control Module User's Guide 29

Page 38

ground is anywhere within the common ground area around the off-board

connections.

For a 4-layer PCB, the ground plane serves to distribute ground from the

center of the star ground out to the various function blocks in the

floorplan. For a 2-layer PCB, ground pours should be placed on the

bottom layer (and also on the top layer where possible) in order to connect

the grounds of the various function blocks to the center of the star

ground.

EMC Keepout Area: The area around the FT 5000 Control Module network

connection traces (from pins 25 and 26 of the JP1 header) and associated

components should be considered “ESD Hot”. Other traces and

components (and inner planes) should be kept at least 3.5 mm (0.14 inch)

away from the network connection traces and components to prevent

ESD arc-overs. In addition, digital signal traces (and other high-speed

switching signal traces) should be routed around this keep out area. If

you route signals under this area, be sure to add a return plane (ground

or power) between the network connection trace layer and the other

signal layers.

The PCB layout should be designed so that substantial ESD hits from the

network discharge directly to the star-ground center point.

The PCB layer ground at the center of the star-ground should have a lowinductance return to an external metal package if there is one. If there is

no metal package, then this ground area should connect to the ground

areas near the power supply connector and the external I/O connectors,

as applicable.

Ground Planes: As ground is routed from the center of the star out to the

function blocks on the board, planes or very wide traces should be used to

lower the inductance (and therefore the impedance) of the ground

distribution system.

Host Microprocessor Kept Away From Network Connection: The

(optional) host microprocessor (for a ShortStack device) is a potential

source of digital noise that could cause radiated EMI problems if that

noise is allowed to couple onto the external network, power, or I/O wiring.

To help prevent this coupling, the host microprocessor and any other

noisy digital circuitry should be kept away from the network side of the

FT 5000 Control Module. For example, place the host microprocessor on

the opposite side of the FT 5000 Control Module from the network, power,

and I/O connectors.

Figure 15 on page 31 shows a simplified view of a PCB layout for the FT 5000

Control Module. In the figure, the center of the star ground is shown as a short

standoff that would connect to the device’s enclosure.

Variations on this suggested PCB layout are possible as long as the general

principles discussed in this chapter are followed. Through-hole capacitors and

diodes can be used, but SMT components are generally superior because of their

lower series inductance.

30 Design Issues

Page 39

FT 5000 Control Module

Network

Connector

Host Microprocessor

(Optional)

Power Supply

Circuitry

I/O Circuitry

I/O

Connectors

Power Supply

Connector

Center

of Star

Ground

EMC

Keepout

Area

Figure 15. Example PCB Layout Design for an FT 5000 Control Module

Neuron 3150 Control Module Keepout Areas

Figure 16 on page 32 shows three “keepout” areas on the Neuron 3150 Control

Modules. Area #1, the “EMI Radiated Keepout Area,” covers the Neuron Chip

and the PROM. This is the area of the control module that generates the most

RF noise. Cables, long metal chassis parts, and drive circuits for external cables

must be kept away from this part of the control module.

Area #2, the “EMI Susceptibility Area,” is the main twisted pair transceiver area

on the control module, and any RF energy that couples into this part of the

module circuit will be conducted out onto the network cable. High frequency and

high-speed circuits should be kept well away from this area of the control module

(and away from the network connector).

LonWorks Twisted Pair Control Module User's Guide 31

Page 40

Figure 16. Control Module Keepout Areas

Area #3 is the “High Voltage Isolation Area.” The transceiver coupling

transformer on all Neuron 3150 Control Modules provides electrical isolation

between the control module’s local ground (primary side) and the network wiring

(secondary side). The transformers and associated filter components are

designed to withstand moderately large primary-to-secondary voltages (see the

control module data sheets for the exact ratings). To take advantage of this

isolation, it is important to keep application circuitry, logic ground, metal chassis

parts, and other primary-side components at least 3.8 mm (0.15 inches) away

from the secondary area on the control module and the network connector.

ESD Design Issues

Electrostatic Discharge (ESD) is encountered frequently in industrial and

commercial use of electronic systems. Reliable system designs must consider the

effects of ESD and take steps to protect sensitive components. Static discharges

occur frequently in low-humidity environments when operators touch electronic

equipment. The static voltages generated by humans can easily exceed 10 kV.

Keyboards, connectors, and enclosures provide paths for static discharges to

reach ESD-sensitive components such as the Neuron Chip. This section

describes techniques to design ESD immunity into control module-based

products.

32 Design Issues

Page 41

Designing Systems for ESD Immunity

ESD hardening includes the following techniques:

• Provide adequate creepage and clearance distances to prevent ESD hits

from reaching sensitive circuitry

• Provide low impedance paths for ESD hits to ground

• Use diode clamps or transient voltage suppression devices for accessible,

sensitive circuits

The best protection from ESD damage is circuit inaccessibility. If all circuit

components are positioned away from package seams, the static discharges can

be prevented from reaching ESD sensitive components. There are two measures

of “distance” to consider for inaccessibility: creepage and clearance. Creepage is

the shortest distance between two points along the contours of a surface.

Clearance is the shortest distance between two points through the air. An ESD

hit generally arcs farther along a surface than it does when passing straight

through the air. For example, a 20 kV discharge can arc about 10 mm (0.4

inches) through dry air, but the same discharge can travel over 20 mm (0.8

inches) along a clean surface. Dirty surfaces can allow arcing over even longer

creepage distances.

When ESD hits to circuitry cannot be avoided through creepage, clearance and

ground guarding techniques (for example, at external connector pins), explicit

clamping of the exposed lines is required to shunt the ESD current. Consult a

good text on EMC for advice about ESD and transient protection for exposed

circuit lines. In general, exposed lines require diode clamps to the power supply

rails or Zener clamps to chassis ground to shunt the ESD current to ground while

clamping the voltage low enough to prevent circuit damage. The control module’s

I/O and control lines are connected directly to the external connector (JP1 for the

FT 5000 Control Module; P1 for the Neuron 3150 Control Modules) without any

ESD protection beyond that provided by the Smart Transceiver or Neuron Chip

itself. If these lines are likely to be exposed to ESD in an application, protection

must be added on the application electronics board. Figure 17 on page 34 shows

an example of the use of diode clamps to protect the control module I/O lines in a

keypad scanning application.

The control modules use diode clamping and transformer isolation to shunt ESD

from the network connector (JP1 for the FT 5000 Control Module; P2 for the

Neuron 3150 Control Modules) to ground. It is therefore important to provide a

low impedance ground path from the JP1 connector or the mounting hole near

P2 to the main system ground. The Neuron 3150 TP/FT-10 also includes spark

gaps (designed to arc at approximately 1000 to 2000 V) between each of the

network lines to ground and a diode-capacitor protection circuit to absorb ESD

energy. The Neuron 3150 TP/FT-10F uses similar, but not identical, protection

circuitry.

LonWorks Twisted Pair Control Module User's Guide 33

Page 42

Figure 17. Example of Diode Clamping Protection for Control Module I/O Lines

Designing for Interoperability

To meet the LONWORKS interoperability guidelines for the Neuron 3150 TP/XF78, TP/XF-78F, and TP/XF-1250 devices, the following printed circuit layout

guideline for the application electronics board is recommended.

Mutual capacitance of data pair conductors (differential capacitance) from the

twisted pair medium tap connector to the connector which mates to the TP/XF

control module P2 header must be kept within the maximum limit specified in

Table 10.

Table 10. Mutual Capacitance of Data Pair Conductors

Maximum mutual

Module type

TP/XF-78, -78F 5 pF 50 mm

TP/XF-1250 2 pF 20 mm

capacitance

Maximum PCB trace

lengths

34 Design Issues

Page 43

6

Programming Considerations

This section explains the integration of control modules

using the NodeBuilder FX Development tool. It covers

considerations relating to memory specifications, device

definition, channel definition, and target hardware.

LonWorks Twisted Pair Control Module User's Guide 35

Page 44

External Memory Considerations

JP5

CONN HDR 5x2

"AARDVAR K"

2

4

6

8

10

1

3

5

7

9

ACS_1_SD A

ARST-

ACS_2_SC L

The following sections describe considerations for the external memory devices on

the FT 5000 Control Module and Neuron 3150 Control Modules.

FT 5000 Control Module

The FT 5000 Control Module includes an Atmel® AT24C512BN-SH25-T two-wire

serial EEPROM to hold the application image. You can program the external

memory for the FT 5000 Smart Transceiver on the control module using either of

the following methods:

• Program the memory part in-circuit using a serial I

device, such as the Total Phase™ Aardvark™ I2C/SPI Host Adapter.

2

C programming

• Program the memory part over the L

manager such as the LonMaker

ONWORKS network, using a network

®

Integration tool or the NodeLoad utility.

Using an Aardvark I2C/SPI Host Adapter

For the Aardvark I2C/SPI Host Adapter with the Flash Center Memory

Programmer software:

• Rename the .NME application image file that is generated by the

NodeBuilder tool to a .HEX file.

• Select the memory part to program ("Atmel 24C512B" I2C EEPROM for

the first release of the Control Module; check the part on the board to

verify the part number).

Important: Specify a byte padding value of “00” (the default padding

value used by the Aardvark I2C/SPI Host Adapter is “FF”).

For device development, it is recommended that your motherboard include a

programming header for use with Aardvark I2C/SPI Host Adapter, such as a

Samtec, Inc. TST-105-01-G-D shrouded square header. Figure 18 shows the

recommended schematic for this header connector. Table 11 on page 37 shows

the connections between the Aardvark programmer header and the FT 5000

Control Module JP1 connector.

Figure 18. Recommended Schematic for the Aardvark Programmer

36 Programming Considerations

Page 45

Table 11. Pin Connections for Aardvark Programmer and JP1 Header

Aardvark Programmer Header FT 5000 Control Module JP1 Header

Pin Signal Pin Signal

1 ACS_2_SCL 8 SCL

3 ACS_1_SDA 9 SDA_CS1~

10 ARST~ 2 RST~

The connection between the Aardvark programmer header’s ARST~ signal and

the FT 5000 Control Module JP1 connector’s RST~ signal ensures that the FT

5000 Smart Transceiver is held in reset during device programming.

Clearing the Non-Volatile Memory

In general, if you have a working device, you should not need to clear the

external EEPROM non-volatile memory for a Series 5000 chip. For a working

device, you can receive a service-pin message and reload the non-volatile memory

from the network as needed. However, if it should become necessary to clear the

EEPROM non-volatile memory (for example, during device development),

perform the following tasks:

1. Reset the device by pressing and holding the device’s Reset button. If the

device does not have a Reset button, temporarily connect the RST~ pin

(pin 2 of the JP1 header) of the control module to GND to hold the chip in

the reset state.

2. Temporarily connect the EEPROM's SCL pin (pin 8 of the JP1 header) to

GND.

3. Release the device’s Reset button (or remove the GND connection from

the RST~ pin).

4. Wait a few seconds until the device’s Service Pin LED is illuminated (on

solid, not flashing). If the device does not have a Service Pin LED,

connect a logic analyzer or oscilloscope to the SVC~ pin (pin 10 of the

JP1 header) of the control module and verify that it changes state (low to

high) at a 76 Hz rate.

5. Disconnect the EEPROM's SCL pin from GND.

6. Use the NodeUtil utility to set the memory configuration and set the

state for the device:

a. Connect the PC that will run the NodeUtil utility to the same

network interface that connects to the device. For example, if you

connect to the device using LON1, connect the NodeUtil utility to

LON1.

b. Start the NodeUtil utility.

LonWorks Twisted Pair Control Module User's Guide 37

Page 46

c. Press the Service Pin button on the device to send a service-pin

message to the NodeUtil utility. If you cannot receive a servicepin message from the device, repeat steps 1 to 5.

d. Within the NodeUtil utility, select the L option to see all

connected devices.

e. Select the G option to manage the device that just sent a service-

pin message. Typically, this is device 1.

f. Select W to write to a memory location. When prompted, do not

update the application checksum and do not update the

configuration checksum.

g. Enter F037 for the starting address. Enter a value of 0 (zero) for

address 0xF037. This value triggers device re-initialization at the

next reset.

Important: The memory address F037 applies to system

firmware versions 18 and 19. For later versions of the firmware,

this address might change; contact Echelon Support to verify the

correct memory address.

h. Enter a period (.) to exit the memory write session.

i. Select E to exit device management mode.

j. Select E to exit the NodeUtil utility.

7. Reset the device by pressing the device’s Reset button. If the device does

not have a Reset button, briefly connect the RST~ pin (pin 2 of the JP1

header) of the control module to GND.

Step 6 above writes values to specific bytes of the in-RAM copy of data that is in

the EEPROM device. During device re-initialization and reset, the FT 5000

Smart Transceiver reads these bytes and copies the default chip configuration

(including memory map and mode table) to the external EEPROM device. After

the device completes reset, it is in the applicationless state. If you need to clear

additional data within the EEPROM device, use a device programmer, such as

the Aardvark I2C/SPI Host Adapter.

At this point, you can reload the device with whatever application is required (for

example, a Neuron C application or a ShortStack Micro Server). Because the

device has returned to its default (empty) state and default settings, if you use

the NodeLoad utility, use the -X switch when loading an application or Micro

Server image. Do not use the LonMaker Integration Tool to load an image

following this procedure because the LonMaker application download utility does

not update the device configuration data (such as the clock rate).

Neuron 3150 Control Modules

The Neuron 3150 Control Modules include a plastic leaded chip carrier (PLCC)

type memory socket for a 32-lead Joint Electron Devices Engineering Council

(JEDEC) Solid State Technology Association 32 KB one-time programmable readonly memory (PROM) or a flash memory chip, depending on the module. You

must provide the PROM device to hold the application image.

The TP/XF-78, TP/FT-10, and TP/XF-1250 modules support read-only access to

external memory. The access time requirement for the memory device depends

38 Programming Considerations

Page 47

on the control module. The standard TP/XF-78 and TP/FT-10 Control Modules

have a 5 MHz input clock, and require a memory access time of 200 ns or faster.

The TP/XF-1250 Control Module has a 10 MHz input clock, and requires a

memory access time of 90 or 120 ns or faster, depending on the production date of

the module. TP/XF-1250 modules produced before January 1995 (revision code A

to G) require a 90 ns access time or faster. TP/XF-1250 modules produced after

February 1995 (revision code H or higher) require a 120 ns access time or faster.

You can use any 32 Kbyte, PLCC OTP ROMs that fit the socket on the three nonflash control modules, such as an Atmel AT27C256R-70JI 256K (32K x 8) OTP

EPROM. LCC devices that support UV erasures are not physically compatible

with the PLCC socket. Atmel AT29C256 flash devices work as ROM memory in

the control modules designed to use ROMs. However, none of the PROM-based

control modules support write control of the flash memory. Also, this memory

device is not pin compatible with the AT29C257 used in the flash memory-based

control modules.

The TP/FT-10F and TP/XF-78F Flash Control Modules have a 10 MHz input

clock and require an Atmel AT29C257-90J (32 KB), AT29C517-90J (64 KB total,

56 KB usable, 8 KB unusable), or AT29C010A-90J (128 KB total, 56 KB usable,

72 KB unusable) flash memory. Table 12 lists vendor part numbers for flash

memory devices.

The Neuron Chip firmware must be aware of the flash memory sector size to

properly support write operations. The AT29C257 has a 64-byte sector size,

whereas the AT29C512 and AT29C010A devices have a 128-byte sector size.

Using the large memory devices as an alternate part for the AT29C256 requires

the generation of a new exported image built with a device definition which

contains the correct sector size.

Important: When programming flash memory, the part must be explicitly

secured with Software Data Protection (SDP) enabled by the PROM programmer.

If this feature is not supported by the PROM programmer, the program memory

can become corrupted.

Table 12. Flash Memory Devices for TP/FT-10F and TP/XF-78F Control Modules

Supplier Flash Memory

Atmel Corporation AT29C257-90JC (32K x 8)

AT29C512-90JC (64K x 8, 56 KB usable)

AT29C010A-90JC (128K x 8, 56 KB usable)

Greenliant™ Systems, Inc.

(formerly Silicon Storage Technology)

In June 2010, Atmel Corporation announced an end of life plan for the following

parts:

GLS29EE512-90 (64K x 8, 56 KB usable)

GLS29EE010-90 (128K x 8, 56 KB usable)

• AT29C256

• AT29C257

• AT29C512

• AT29C010A

LonWorks Twisted Pair Control Module User's Guide 39

Page 48

Table 13 lists Greenliant parts that you can use as replacements for obsoleted

Atmel parts.

Table 13. Greenliant Replacements for Atmel Parts

Atmel Parallel Flash Part Number

(PLCC32 Package)

AT29C512-70JU

AT29C512-90JU

AT29C010A-90JI GLS29EE010-70-4I-NHE

Greenliant Parallel Flash Part Number

(PLCC32 Package)

GLS29EE512-70-4I-NH

GLS29EE512-70-4I-NHE (Pb free)

Application Program Development and Export

Application programs are developed, tested, and debugged using the NodeBuilder

FX Development tool; see the NodeBuilder FX User’s Guide for detailed

information about developing and testing Neuron C applications. You can also

use the Mini FX application for initial device development; see the Mini FX

User’s Guide for more information about using the Mini FX application.

In addition, you can develop a ShortStack device with the FT 5000 Control

Module; see the ShortStack FX User’s Guide for more information about

developing ShortStack devices.

Important: Table 14 lists the minimum required Neuron firmware version for

applications built for either of the flash-based Neuron 3150 Control Modules.

Table 14. Neuron Firmware Version Required for Neuron 3150 Control Modules

Name and Model

Number Board Number Revision

TP/FT-10F Free

Topology Flash

Control Module

55020R-10

TP/XF-78F Flash

Control Module

55010R-10

801-1059-01 Any Any

801-1059-51 xxxxC or earlier Any

801-1059-51 xxxxD or later Version 13.1 or later

801-1047-01 Any Any

801-1047-51 xxxxB or earlier Any

801-1047-51 xxxxC or later Version 13.1 or later

NodeBuilder FX Development Tool

The NodeBuilder FX Development Tool is a hardware and software platform that

is used to develop applications for Neuron Chips and Echelon Smart

Transceivers. The NodeBuilder tool enables you to do the following tasks:

• View standard resource file definitions for SNVTs, SCPTs, and standard

functional profiles.

Minimum Neuron

Firmware Version

40 Programming Considerations

Page 49

• Create your own resource files with your UNVTs, UCPTs, and user

functional profiles.

• Automatically generate Neuron C code that implements your device

interface.

• Edit your Neuron C code to implement your device functionality.

• Compile and build your application, and download it to an Echelon

Evaluation Board, Control Module, or to your own devices.

• Test with prototype hardware to test your device’s I/O and related

hardware.

• Install your device into a L

interoperating with other L

• Use the LNS Plug-in Framework to develop an LNS plug-in for your

device.

• Test your LNS plug-in with the LonMaker Integration Tool to ensure that

your device is easy to configure and install.

The NodeBuilder FX Development Tool (Service Release 1 or later) is required to

build applications for Series 5000 devices.

For more information about using the NodeBuilder FX Development Tool, see the

NodeBuilder FX/FT Quick Start and the NodeBuilder FX User’s Guide.

The NodeBuilder FX Development Tool uses device template files to represent

target device hardware configuration information. The NodeBuilder Device

Template wizard runs during the creation of a new device template. This wizard

provides an opportunity to select predefined hardware templates. At a later

point in the development process, you can access the hardware template through

the Development and Release folders of the project pane.

After you create the hardware template, drag the new hardware template to the

device. Drag the newly created icon in the User Templates folder to the Release

folder of the device template to complete the procedure.

You can update the user-defined hardware template at any time by doubleclicking the template icon. Your new changes affect any projects opened and

compiled using this template. A Build All might be required if you change a

hardware template without making any other changes.

ONWORKS network and test your device

ONWORKS devices.

The following sections describe how to configure the development environment

for Neuron 3150 Control Modules and FT 5000 Control Modules.

Configuration for FT 5000 Control Modules

The NodeBuilder FX Development Tool, Service Release 1 (4.01), does not include

hardware templates for the FT 5000 Control Module. However, a future release

of the NodeBuilder FX Development Tool will include appropriate hardware

templates for the FT 5000 Control Module.

You can use the FT 5000 Evaluation Board hardware template as a base for

creating a custom hardware template for the FT 5000 Control Module. Table 15

on page 42 shows the values required for each tab in the NodeBuilder device

template editor to support an FT 5000 Control Module. Use this hardware

template as a basis for your device development.

LonWorks Twisted Pair Control Module User's Guide 41

Page 50

Table 15. Hardware Template Values for an FT 5000 Control Module

NodeBuilder Hardware Template

Specification FT 5000

Hardware Tab

Platform Custom

Transceiver Type TP/FT-10

Neuron Chip Model FT 5000

External Clock Speed 10 MHz

Clock Multiplier 8

System Clock 80 MHz

System Image Version Default

Image Name BFT5000

Firmware Version 19

Memory Tab

Off-Chip ROM N/A

Extended Non-Volatile 0x4000 to 0xC7FF

Extended On-Chip RAM 0xC800 to 0xE7FF

I/O N/A

On-Chip ROM 0x0000 to 0x3FFF

On-Chip RAM 0xE800 to 0xEFFF

Mandatory EEPROM 0xF000 to 0xF7FF

Extended On-Chip EEPROM 0

Non-Volatile Memory Type EEPROM

You can specify any of the clock multiplier settings (½ to 8) for the FT 5000

Control Module, so that the system clock runs from 5 MHz to 80 MHz. In

addition, you can specify memory values for extended non-volatile memory and

extended on-chip RAM to appropriate ranges for your application.

42 Programming Considerations

Page 51

Configuration for Neuron 3150 Control

Modules

The NodeBuilder FX Development Tool includes hardware templates for the

Neuron 3150 Control Modules. Table 16 and Table 17 on page 44 show the

values required for each tab in the NodeBuilder device template editor to support

the Neuron 3150 Control Modules. Use these hardware templates as a basis for

your device development.