Page 1

LONWORKS®

PLT-22 Power Line Transceiver

User’s Guide

(110kHz – 140kHz Operation)

Version 1.2

@ ECHELON

C o r p o r a t i o n

078-0175-01C

®

Page 2

Echelon, LON, LONWORKS, LonBuilder, NodeBuilder, LonManager, LonTalk,

L

ONMARK, Neuron, 3120, 3150, the LonUsers logo, the LONMARK logo, and

the Echelon logo are trademarks of Echelon registered in the United States

and other countries. LonPoint, LonSupport, and LonMaker are trademarks

of Echelon Corporation.

Other brand and product names are trademarks or registered

trademarks of their respective holders.

Neuron Chips, Power Line products, and other OEM Products were not

designed for use in equipment or systems which involve danger to

human health or safety or a risk of property damage, and Echelon

assumes no responsibility or liability for use of the Neuron Chips or Power

Line products in such applications.

Parts manufactured by vendors other than Echelon and referenced in

this document have been described for illustrative purposes only and

may not have been tested by Echelon. It is the responsibility of the

customer to determine the suitability of these parts for each

application.

ECHELON MAKES AND YOU RECEIVE NO WARRANTIES OR CONDITIONS,

EXPRESS, IMPLIED, STATUTORY OR IN ANY COMMUNICATION WITH YOU,

AND ECHELON SPECIFICALLY DISCLAIMS ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

No part of this publication may be reproduced, stored in a retrieval

system, or transmitted, in any form or by any means, electronic,

mechanical, photocopying, recording, or otherwise, without the prior

written permission of Echelon Corporation.

Printed in the United States of America.

Copyright ©1996 - 2002 by Echelon Corporation.

Echelon Corporation

www.echelon.com

Page 3

Contents

1 Introduction 1-1

Audience 1-6

Content 1-6

Related Documentation 1-6

2 Using the PLT-22 Transceiver 2-1

Mechanical Dimensions 2-2

PLT-22 Transceiver Pinout 2-3

PLT-22 Transceiver Electrical Specifications 2-4

External Components 2-6

Crystal 2-6

Power Supply Bypassing and Grounding 2-7

Band-in-Use (BIU) and Packet Detect (PKD) LED Connections 2-7

Neuron

Transmit Output Level 2-10

TXON Output Signal 2-10

Application Schematic: Neuron 3150® Chip 2-11

Application Schematic: Neuron 3120

3 PLT-22 Transceiver Programming 3-1

Dual Carrier Frequency Mode 3-2

CENELEC Access Protocol 3-3

Power Management 3-3

Standard Transceiver Types 3-4

LonBuilder

Channel Definitions

4 Coupling Circuits 4-1

Power Line Communications 4-2

Coupling Techniques 4-4

Power Line Coupling Basics 4-4

Power Line Coupling Details 4-8

Safety Issues 4-11

Safety Isolation Considerations 4-11

Ground Leakage Currents 4-13

Capacitor Charge Storage 4-13

Line Surge Protection 4-13

Fuse Selection 4-16

Recommended Coupling Circuit Schematics 4-16

Example 1: Line-to-Neutral, Non-Isolated Coupling 4-18

Example 2: Line-to-Neutral, Transformer-Isolated Coupling 4-20

Example 3: Line-to-Earth, Non-Isolated Coupling 4-22

Example 4: Line-to-Earth, Transformer-Isolated Coupling 4-24

®

Chip Connections 2-8

®

Chip 2-12

®

and NodeBuilder® PLT-22 Transceiver 3-6

LONWORKS PLT-22 Transceiver User’s Guide i

Page 4

5 Power Supplies for the PLT-22 Transceiver

Introduction 5-2

Power Supply Design Considerations 5-2

Power Supply-Induced Attenuation 5-2

Power Supply Noise 5-3

Energy Storage Power Supplies 5-3

Energy Storage Capacitor-Input Power Supplies 5-5

Capacitor-Input Power Supply Schematic 5-7

Energy Storage Linear Supplies 5-8

Traditional Linear Power Supplies 5-9

Switching Power Supplies 5-9

Power Supply-Induced Attenuation 5-9

Noise at the Power Supply Input 5-12

Switching Power Supply Frequency Selection 5-12

Switching Power Supply Input Noise Masks 5-12

Switching Power Supply Output Noise Masks 5-17

Options 5-21

Pre-designed Switching Supplies 5-21

Off-the-Shelf Switching Supplies 5-22

Custom Switching Supplies 5-22

5-1

6 Design and Test for Electromagnetic Compatibility 6-1

EMI Design Issues 6-2

Designing Systems for EMC (Electromagnetic Compatibility) 6-2

ESD Design Issues 6-4

Designing Systems for ESD Immunity 6-4

Conducted Emissions Testing 6-6

7 Communication Performance Verification 7-1

Why Verify Communication Performance? 7-2

Verification Strategy 7-2

Power Line Test Isolator 7-3

Test Equipment 7-4

Good Citizen Verification 7-6

Unintentional Output Noise Verification 7-6

Excessive Loading Verification 7-7

Transmit Performance Verification 7-10

Receive Performance Verification 7-11

Packet Error Measurement with Nodeutil 7-11

Verification Procedure 7-12

8 References 8-1

Reference Documentation 8-2

Appendix A PLT-22 Transceiver Isolation Transformer A-1

Specifications

PLT-22 Transceiver Isolation Transformer Schematic A-2

PLT-22 Transceiver Isolation Transformer Electrical A-2

Specifications

PLT-22 Transceiver Isolation Transformer Vendors A-3

ii Echelon

Page 5

Appendix B PLT-22 Transceiver-Based Node Checklist B-1

PLT-22 Transceiver-Based Node Checklist B-2

PLT-22 Transceiver and Neuron Chip Connections B-2

PLT-22 Transceiver Programming B-4

PLT-22 Transceiver Coupling Circuit General B-4

PLT-22 Transceiver Coupling Circuit Components Key B-5

Specifications

PLT-22 Transceiver Power Supply - General B-6

PLT-22 Transceiver Power Supply - Switching Type B-6

EMI & ESD Design B-7

Product Qualification - EMC B-8

Product Qualification - Electromagnetic Immunity and B-8

Communication Performance

Appendix C External Power Supplies with Integrated

Coupling Circuits C-1

Vendors for External Power Supplies w/ Integrated Coupling Circuits C-2

LONWORKS PLT-22 Transceiver User’s Guide iii

Page 6

iv Echelon

Page 7

1

Introduction

The PLT-22 Power Line Transceiver provides a simple, cost-effective

method of adding LONWORKS® power line technology to any control

system. Network data are broadcast through the power mains,

eliminating the need for dedicated wiring and greatly reducing

installation costs. A replacement for Echelon's popular PLT-21 Power

Line Transceiver, the PLT-22 transceiver also includes several new

features to significantly improve communications reliability and lower

node cost.

LONWORKS PLT-22 Transceiver User’s Guide 1-1

Page 8

Intermittent noise sources, impedance changes, and attenuation make the power line

a hostile signal path. The PLT-22 transceiver operates reliably in this harsh

environment through a novel dual carrier frequency capability as well as custom

digital signal processing which provides adaptive carrier and data correlation,

impulse noise cancellation, tone rejection, and low-overhead error correction. These

innovations permit the transceiver to operate reliably in the presence of consumer

electronics, power line intercoms, motor noise, electronic ballasts, dimmers, and

other typical sources of interference.

Each PLT-22 transceiver operates as a backward compatible replacement for the

PLT-20 and PLT-21 transceivers when used with previous versions of configuration

parameters. In this mode, all transmissions can be received by any PLT-20, PLT-21,

or PLT-22 transceiver.

When used with new transceiver configuration parameters, the dual carrier

frequency mode of the PLT-22 transceiver is activated. In this mode, PLT-22 basednodes are able to communicate even when the primary frequency range (125kHz 140kHz) is blocked by noise. With dual frequency mode, a PLT-22 transceiver begins

each transaction by sending backward compatible packets. If impairments prevent

communication in this frequency range, the PLT-22 node will automatically switch

carrier frequencies in order to complete the transaction with other PLT-22 based

nodes.

The PLT-22 transceiver complies with FCC, Industry Canada, Japan MPT, and

European CENELEC EN 50065-1

1

regulations for signaling in the 125kHz-to140kHz and 95kHz-to-125 kHz frequency bands. The transceiver implements the

CENELEC access protocol, which can be enabled or disabled by the user. By

incorporating the access protocol into the power line transceiver, Echelon has

eliminated the need for users to independently develop the complex timing and

access algorithms mandated by the CENELEC EN 50065-1 regulation. The PLT-22

transceiver also is compliant with the Electronic Industries Association Standard

EIA-709.2.

The transceiver's power amplifier includes a selectable 3.5V peak-to-peak (p-p) or 7V

p-p mode for maximum communication performance. The 1Ω output impedance and

1A p-p current capability of the amplifier allow it to drive high output levels into low

impedance circuits, while the highly efficient design draws less total current than

previous transceivers.

The PLT-22 transceiver is powered by user-supplied +8.5 to +16VDC and +5VDC

power supplies. The wide supply range is a key benefit when designing inexpensive

power supplies. If a battery-backed power supply is used, the transceiver will

continue signaling even during a power failure on the power mains.

The PLT-22 transceiver incorporates a power management feature that constantly

monitors the status of the node's power supply. If during transmission the power

supply voltage falls to a level that is insufficient to ensure reliable signaling, the

transceiver tells the Neuron Chip to stop transmitting until the power supply voltage

rises to an acceptable level. This allows the use of a power supply with 1/3 the

current capacity otherwise required (100mA versus 300mA). The net result is a

reduction in the size, cost, and thermal dissipation of the power supply. Power

management is especially useful for high volume, low cost consumer products such as

electrical switches, outlets, and dimmers.

1-2 Introduction

Page 9

The PLT-22 transceiver uses a low-cost external coupling circuit and can

communicate over virtually any AC or DC power mains, as well as unpowered

twisted pair. The PLT-22 transceiver can use all of the same coupling circuits as the

PLT-21 transceiver.

The PLT-22 transceiver is supplied as a miniature uncoated Single In-Line Package

(SIP) which can be mounted on or inside an OEM product, directly adjacent to the

Neuron Chip with which it is used. The PLT-22 transceiver maintains drop-in pin

compatibility with the PLT-20 and PLT-21 transceivers while at the same time

providing smaller package dimensions to more easily fit into tight enclosures. When

connected to an external crystal, the transceiver can supply either a 1.25, 2.5, 5, or

10MHz clock signal for the Neuron Chip, eliminating the need for a separate Neuron

Chip crystal.

The transceiver communicates at a raw bit rate of 5kbps. With the CENELEC

protocol disabled, the transceiver has a maximum packet rate of 20 packets per

second. With the CENELEC protocol enabled, the transceiver has a maximum

throughput of 18 packets per second. This high throughput makes the transceiver

well suited for residential, commercial, and industrial automation applications.

For commercial and industrial applications in high rises, manufacturing plants,

utility substations, and other large facilities, the PLT-22 transceiver can be used

with Echelon's PLA-21 Power Line Amplifier. Capable of transmitting a 10Vp-p

signal with 2Ap-p current drive, the PLA-21 amplifier is ideal for driving multiple

phase coupling circuits, high attentuation power circuits, and very low impedance

loads near circuit breaker panels and distribution transformers.

This guide describes the use of the PLT-22 transceiver in the 110kHz to 140kHz

frequency range. The PLT-22 transceiver also supports communication in the

CENELEC utility band (European A-band from 70 to 95kHz) when the transceiver is

used with a different external crystal and modified coupling circuit. For CENELEC

utility applications, refer to the companion user’s guide, Using the L

22 Power Line Transceiver in European Utility Applications.

ONWORKS PLT-

LONWORKS PLT-22 Transceiver User’s Guide 1-3

Page 10

GND

CKOUT

CKSEL1

CKSEL0

XIN

XOUT

PKD

BIU

RXIN

RXCOMP

TXLVL

TXOUT

CP0

CP1

CP2

CP4

~RESET

GND

GND

V

A

V

DD5

RX

FRONT

END

A/D

TX

AMP/

FLTR

DSP

D/A

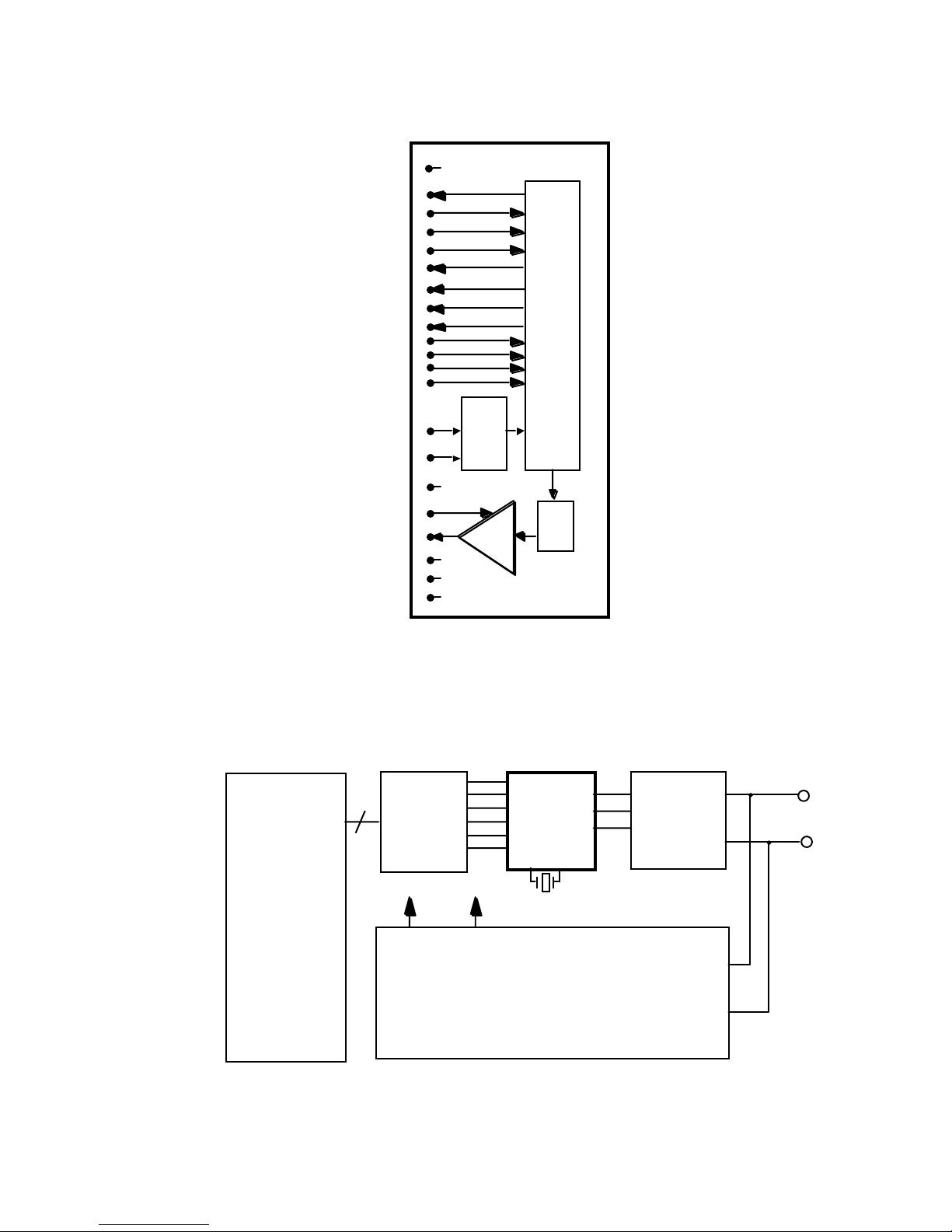

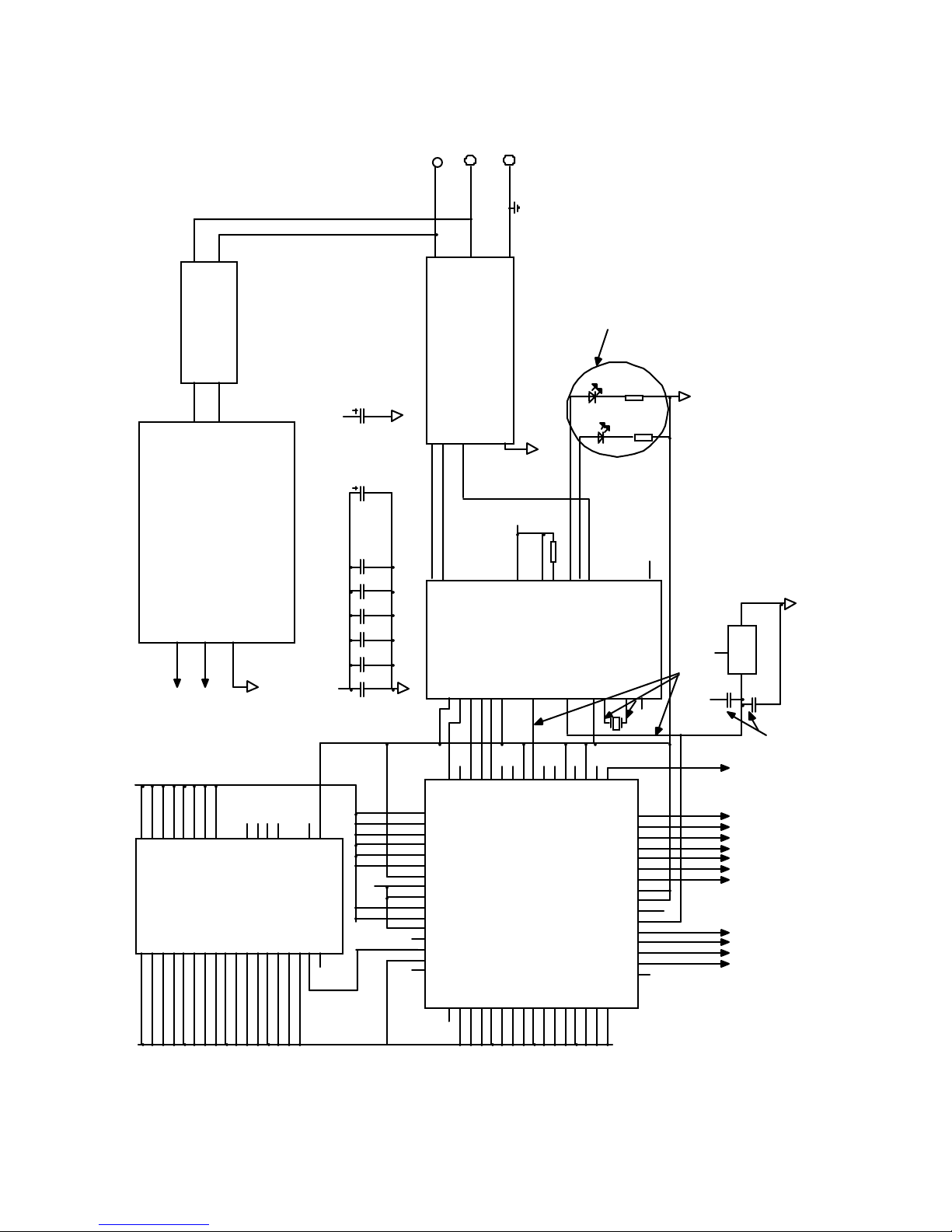

Figure 1.1 PLT-22 Transceiver Block Diagram

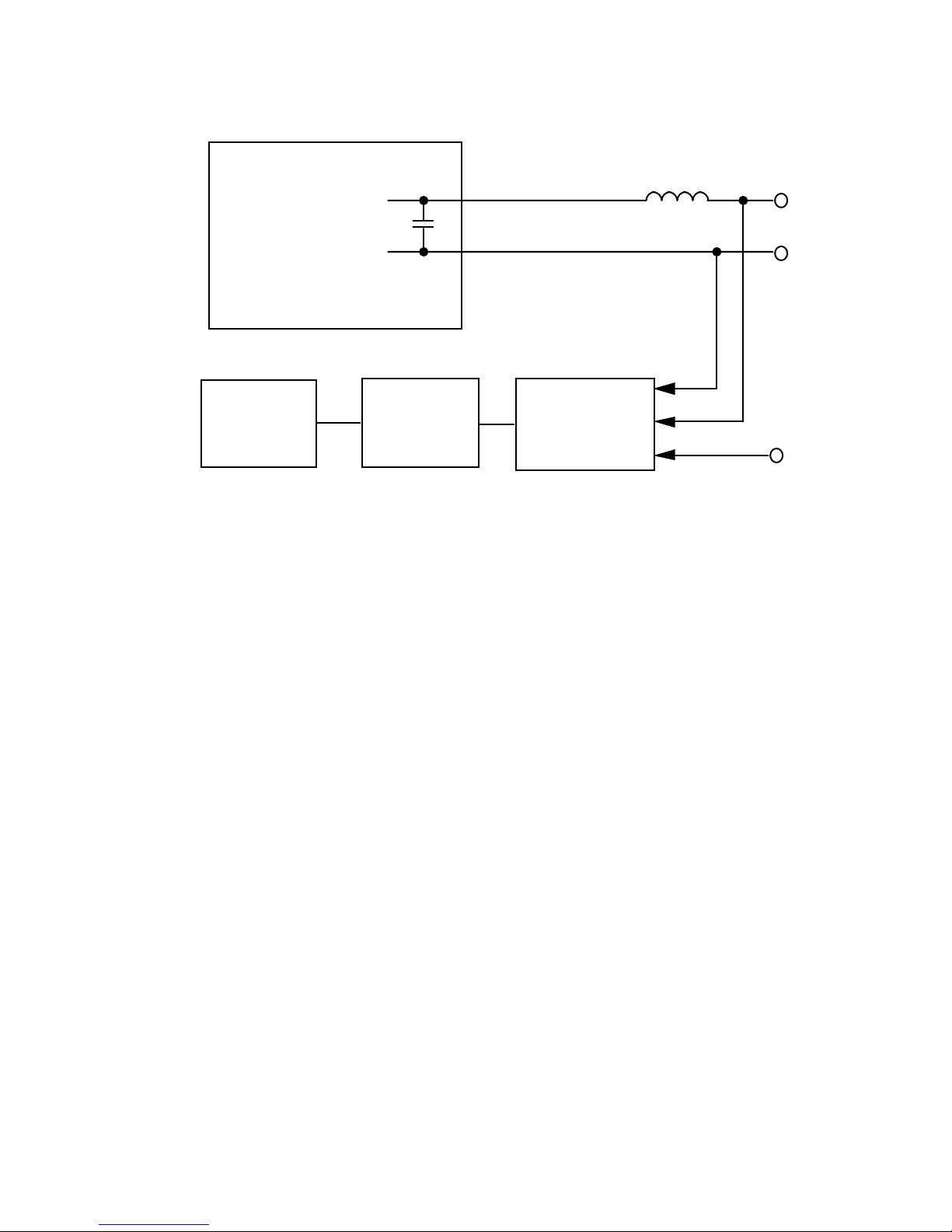

The compact PLT-22 transceiver must be mounted using hand or wave soldering and

requires only the addition of a Neuron 3120

®

Chip or Neuron 3150® Chip, crystal, power

line coupling network, power supply, and application electronics to build a complete node

(figure 1.2).

User's

Application

Electronics

1-4 Introduction

11

Neuron

Chip

V

DD5

Transceiver

V

A

PLT-22

Coupling

Circuit

Power Supply

Figure 1.2 Typical PLT-22 Transceiver-Based Node

Power

Mains

Page 11

The PLT-22 transceiver meets the regulations for AC mains signaling of the FCC

(Federal Communication Commission), Industry Canada (formerly DOC), CENELEC

(European Committee for Electrotechnical Standardization), and Japanese MPT

(Ministry of Post and Telecommunications).

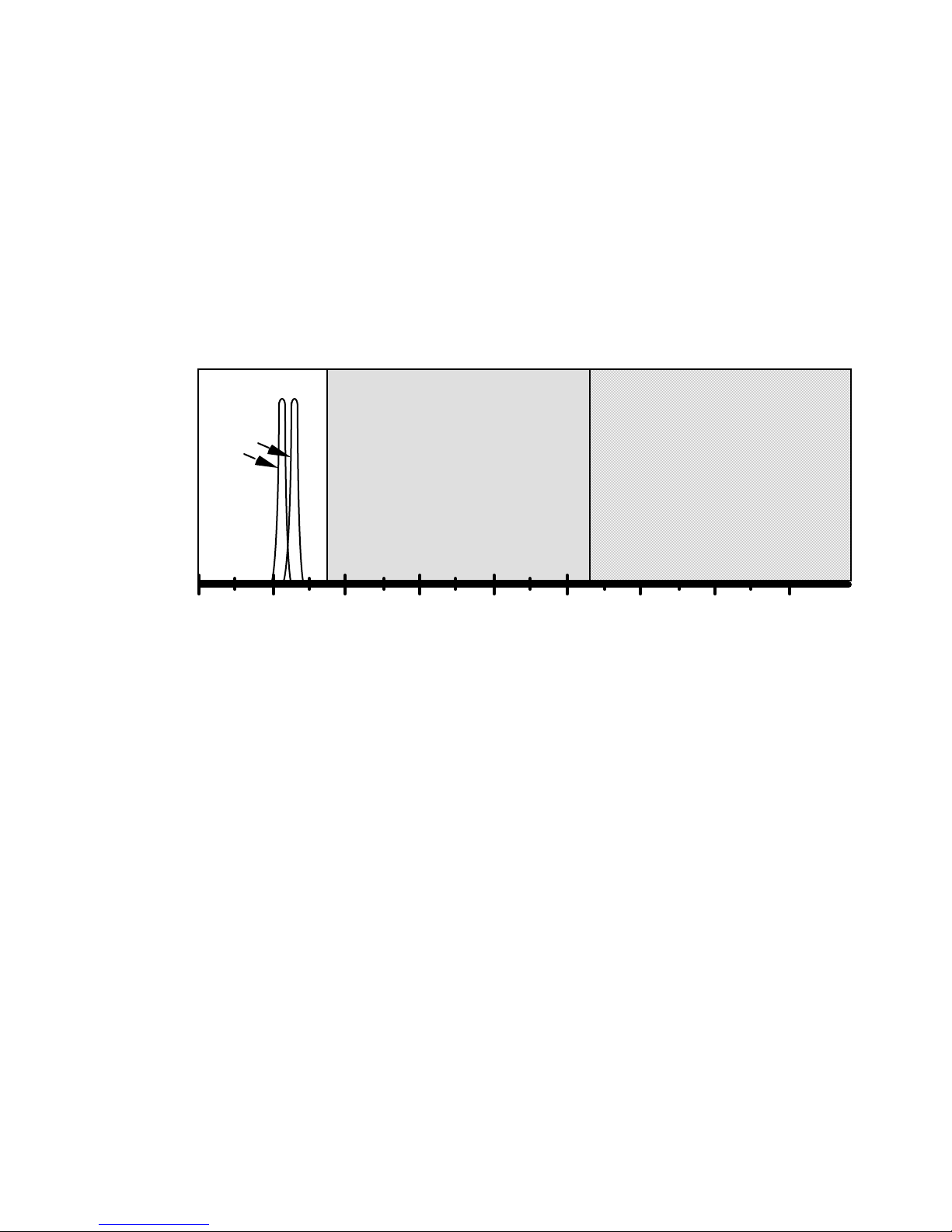

Under FCC Section 15.107 "Limits for carrier current systems," as well as Industry

Canada guidelines, communication frequencies are allocated as shown in figure 1.3.

To protect aircraft radio navigation systems operating between 190kHz and 525kHz,

restrictions on power line communication above 185kHz are being considered

PLT-22 transceiver avoids interfering with these systems by signaling in the

frequency range of 110kHz to 140kHz.

PLT-22

Transmit

Signals

General

Use

Restrictions Under

Consideration

Restricted

7

. The

100kHz 200kHz 300kHz 400kHz 500kHz 600kHz 700kHz

Figure 1.3 FCC and Industry Canada Frequency Allocation

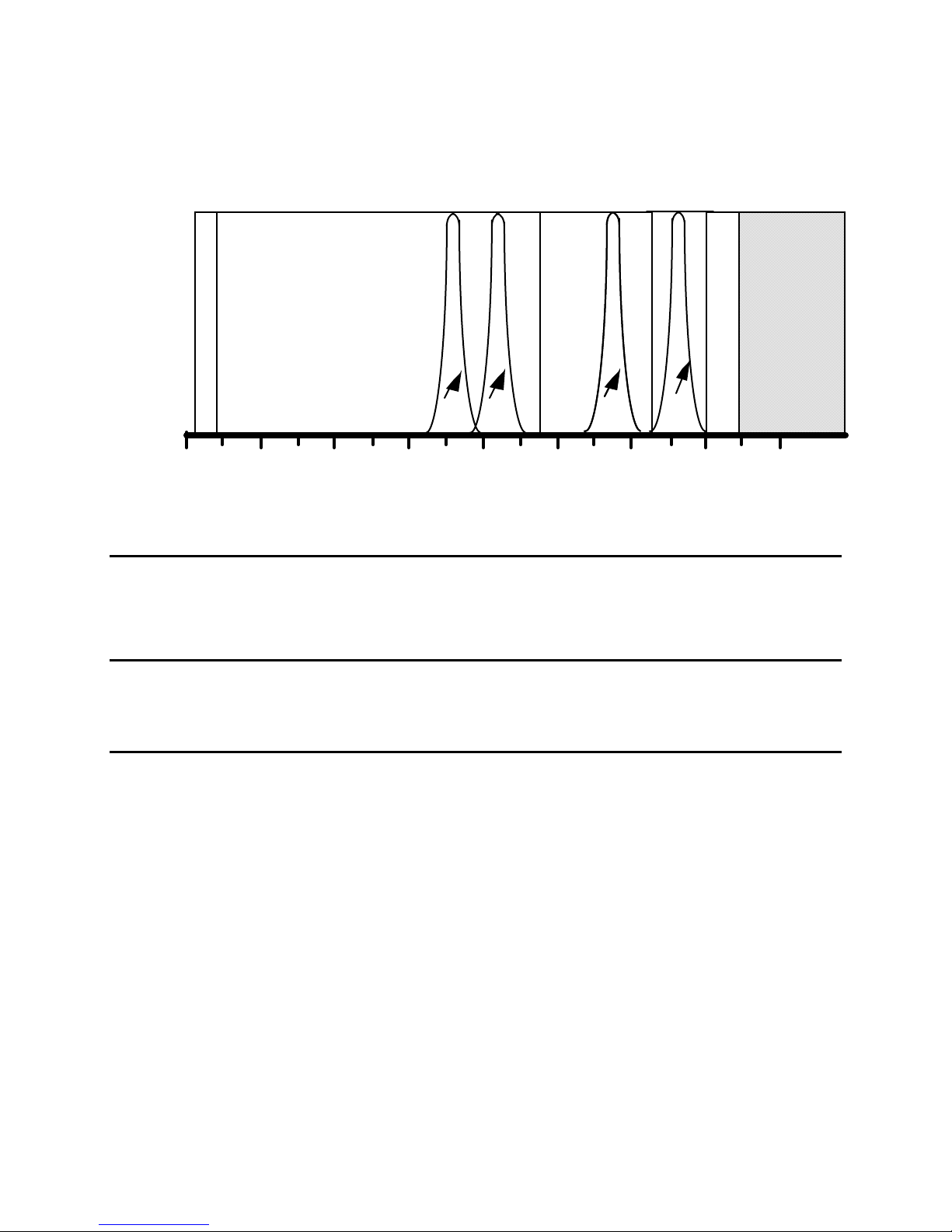

Under CENELEC EN 50065-1 “Signaling on low-voltage electrical installations in the

frequency range 3kHz to 148.5kHz” Part 1 “General requirements, frequency bands

and electromagnetic disturbances," communication frequencies are allocated as shown

in figure 1.4. When used with a 10MHz crystal, the PLT-22 transceiver signals in

CENELEC C and B bands and implements the access protocol as specified in

CENELEC EN 50065-1 (see CENELEC Access Protocol section in Chapter 3 for more

information). For operation in the CENELEC A-band, refer to Using the L

PLT-22 Power Line Transceiver in European Utility Applications.

ONWORKS

LONWORKS PLT-22 Transceiver User’s Guide 1-5

Page 12

Band Designations:

PLT-22 with

70 - 95kHz Operation

"A"

{

PLT-22 with

110 - 140kHz Operation

{

"B"

"C" "D"

Electricity Suppliers

Audience

This document is intended for designers of products using the PLT-22 Power Line

Transceiver.

Content

This manual provides detailed operating instructions for the PLT-22 transceiver.

Electricity Suppliers

and Their Licensees

PLT-22

Secondary

Signal

20kHz 40kHz 60kHz 80kHz 100kHz 120kHz 140kHz 160kHz

Figure 1.4 CENELEC Frequency Allocation

PLT-22

Primary

Signal

No Protocol

Consumer Use

PLT-22

PLT-22

Secondary

Secondary

Signal

Signal

Consumer Use

PLT-22

Primary

Signal

No Protocol

With Protocol

Restricted

Consumer Use

Related Documentation

The following documents are suggested reading:

PLT-22

PLCA-22 Power Line Communication Analyzer User’s Guide (078-0147-01)

PLA-21 Power Line Amplifier Specification and User’s Guide (078-0161-01)

Centralized Commercial Building Applications with the L

Transceiver (005-0056-01)

Demand Side Management with the L

(005-0070-01)

Using the L

Applications (078-0180-01)

1-6 Introduction

Power Line Transceiver data sheet (003-0250-01)

ONWORKS PLT-22 Power Line Transceiver in European Utility

ONWORKS PLT-21 Power Line

ONWORKS Power Line Transceivers

Page 13

LONWORKS Custom Node Development (005-0024-01)

L

ONMARK

L

ONMARK Application Layer Interoperability Guidelines (078-0120-01)

®

Layers 1-6 Interoperability Guidelines (078-0014-01)

Neuron Chip Data Book as published by Motorola and Toshiba

LONWORKS PLT-22 Transceiver User’s Guide 1-7

Page 14

1-8 Introduction

Page 15

2

Using the PLT-22 Transceiver

This chapter describes the mechanical and electrical characteristics of

the PLT-22 transceiver along with the interface to a Neuron Chip and

external circuitry requirements. Typical application schematics are

included.

LONWORKS PLT-22 Transceiver User’s Guide 2-1

Page 16

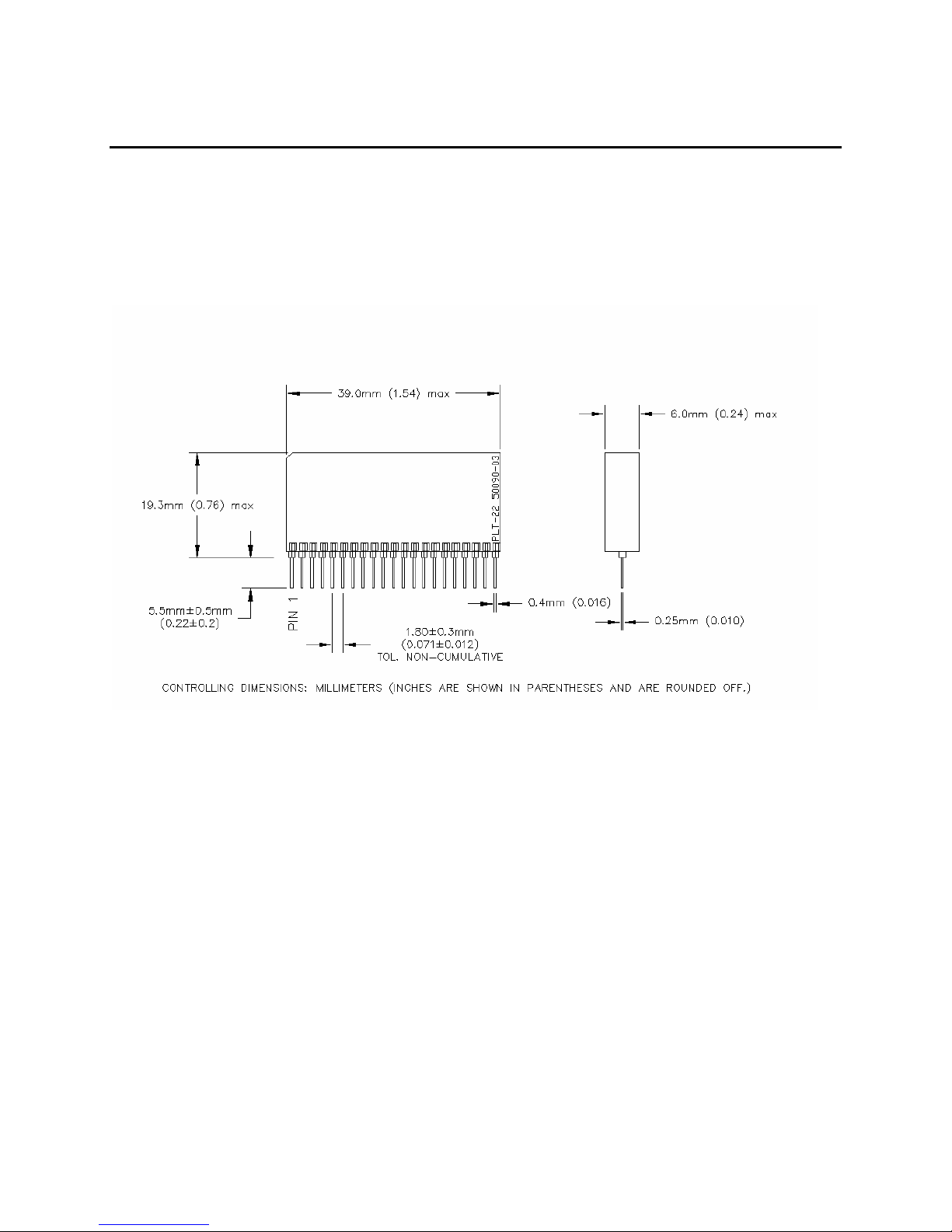

Mechanical Dimensions

Figure 2.1 presents the mechanical dimensions of the PLT-22 transceiver.

The PLT-22 is produced as an uncoated SIP (in contrast to the coated PLT-20 and

PLT-21 transceivers).

Figure 2.1 PLT-22 Transceiver Dimensions

Note: If a socket is required for prototype purposes, a Mill-Max #317-93-121-41-005

connector may be used. For more information, contact:

Mill-Max Manufacturing Corporation

190 Pine Hollow Road

Oyster Bay, New York, 11771

Telephone: +1-516-922-6000

Fax: +1-516-922-9253

Internet: http://www.mill-max.com

2-2 Using the PLT-22 Transceiver

Page 17

PLT-22 Transceiver Pinout

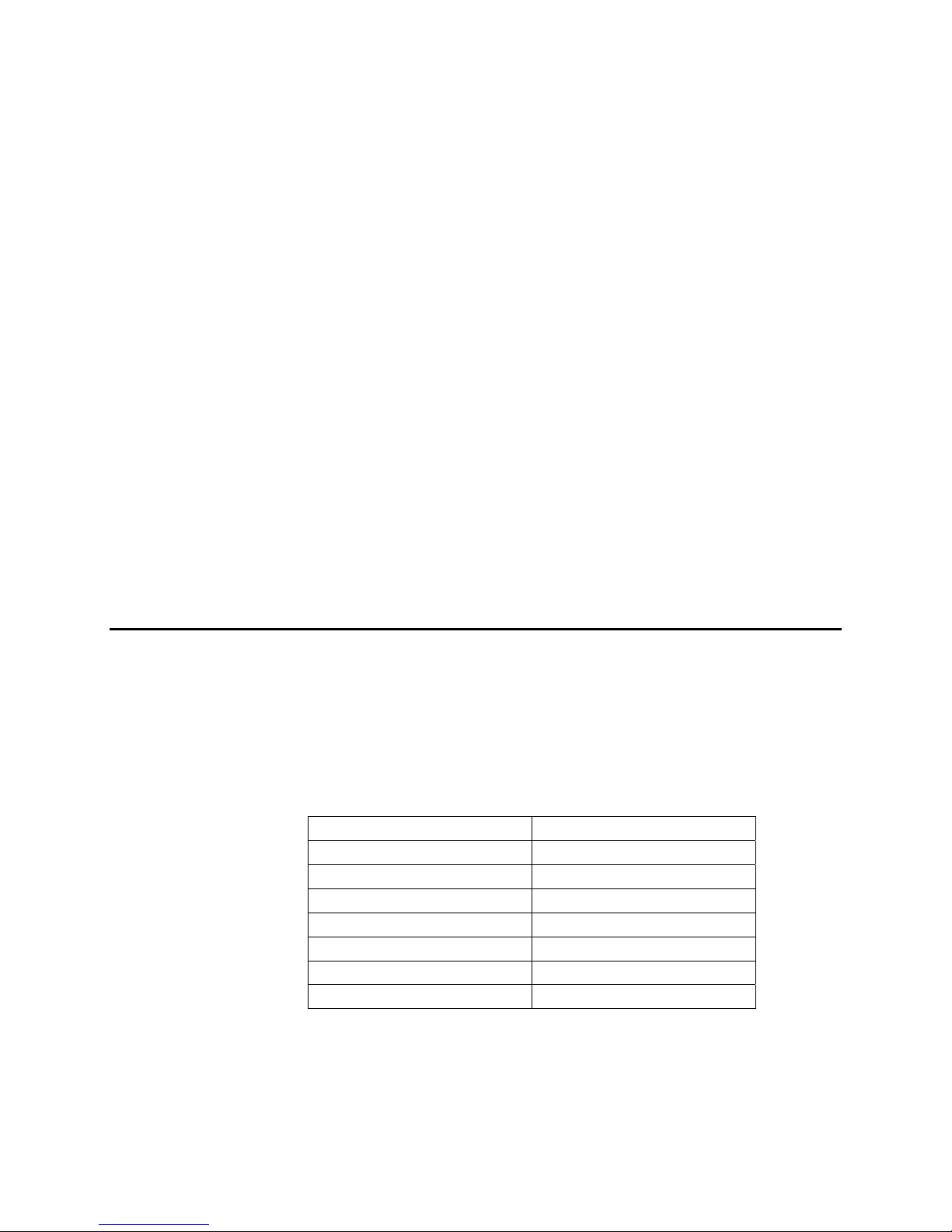

Table 2.1 lists the functions of the PLT-22 transceiver pins.

Table 2.1

Pin # Pin Name Function

1 RXCOMP Connection to receive compensation component

2 RXIN Receive signal input from line coupling circuit

3 GND Ground

4 CP4 Frame clock synchronization from Neuron Chip (FCLK)

5 CP2 Bit clock synchronization from Neuron Chip (BCLK)

6 CP1 Transmit data and configuration from Neuron Chip (TXD)

7 CP0 Receive data and status to Neuron Chip (RXD)

8 GND Ground

9 V

10 CKOUT Buffered CMOS clock output: 10, 5, 2.5 or 1.25 MHz

11 CKSEL0 Selects frequency of CKOUT—see table 2.4

12 CKSEL1/TXON Selects frequency of CKOUT—see table 2.4 / TXON (supports

13 ~RESET Reset input from Neuron Chip

14 BIU CENELEC Band-In-Use indication output

15 PKD Packet detect indication output

16 TXOUT Transmit signal output to line coupling circuit

17 GND Ground

18 XIN 10MHz oscillator input

19 XOUT 10MHz oscillator output

20 VA Analog power supply input

21 TXLVL Transmit level selection input

+5VDC power supply input

DD5

PLA-21 Power Line Amplifier)

PLT-22 Transceiver Pinout

LONWORKS PLT-22 Transceiver User’s Guide 2-3

Page 18

PLT-22 Transceiver Electrical Specifications

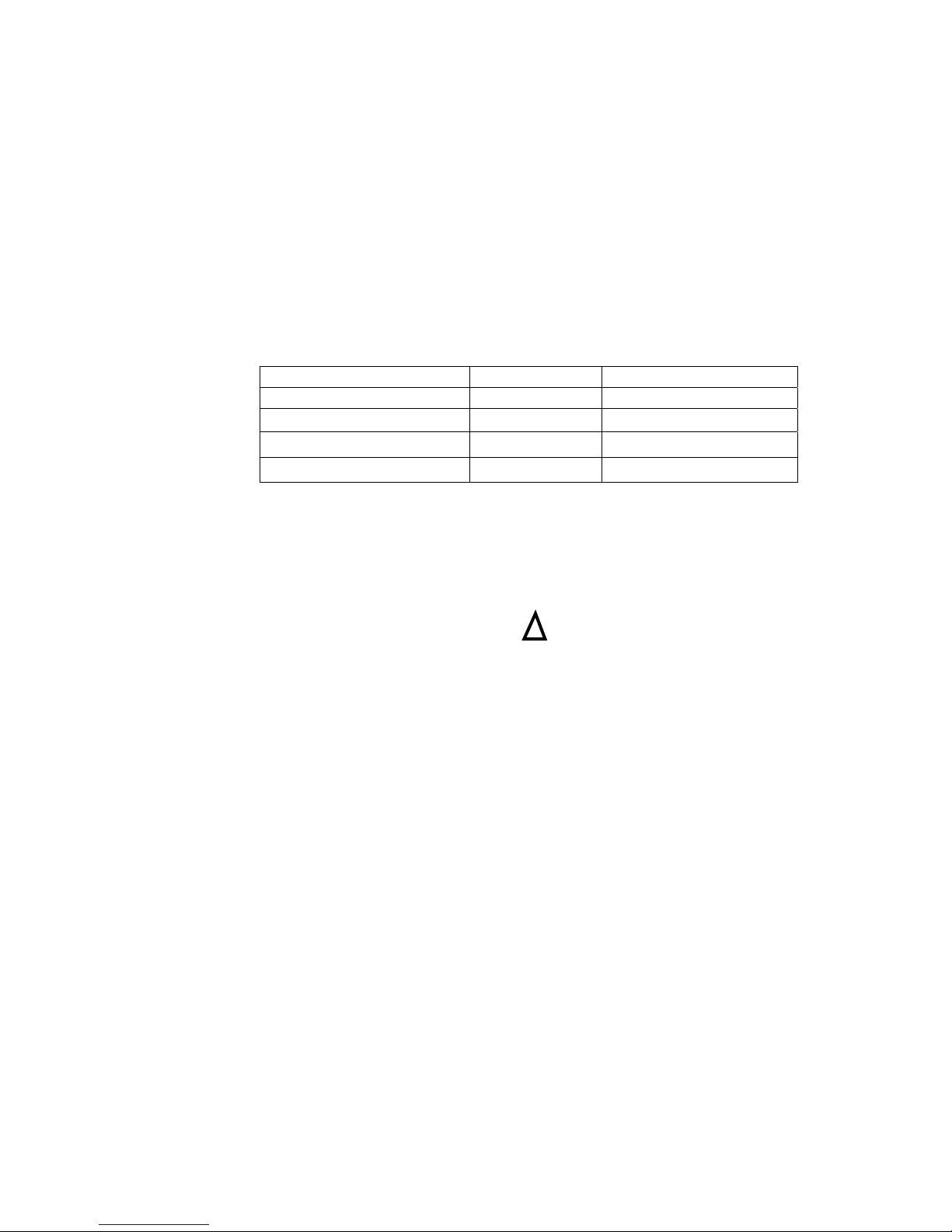

Table 2.2 lists the electrical specifications of the PLT-22 transceiver when used in

the 110kHz – 140kHz frequency range. All specifications apply over the full

operating temperature and supply voltage ranges unless otherwise indicated.

Table 2.2

Parameter Min Typ Max Units

Operating temperature range1

V

input supply voltage 4.75 5 5.25 Volts

DD5

VA input supply voltage

TXLVL = open 8.5 9.7 16 Volts

TXLVL = GND2

I

input supply current (not including PKD and BIU LED Current)

DD5

receive 16 23 mA

transmit 13 18 mA

IA input supply current

receive 4 6 mA

transmit 130 250 mA

TXOUT signal level: TXLVL=open, into 50Ω load 3.6 Volts p-p

TXOUT signal level: TXLVL=GND, into 50Ω load 7 Volts p-p

Output current limit 1.0 Amps p-p

Output impedance, in-band (transmit) 0.9 1.1 Ohms

Input impedance, in-band (receive) 500 Ohms

PKD output source current @ V

BIU output source current @ V

Power management, lower threshold 7.2 7.9 8.5 Volts

Power management, upper threshold 11.1 12.0 12.9 Volts

PLT-22 Transceiver Electrical Specifications

-40 +85 ° C

11.4 12.0 16 Volts

-0.6 V 8 mA

DD5

-0.6 V 8 mA

DD5

Notes:

1. Maximum operating temperature is a function of VA supply voltage and the maximum

transmission duty cycle for the node. A maximum operating temperature of 85°C is

specified for a V

A

the maximum achievable with LONMARK interoperable transceiver parameters and

messages of ≤34 Bytes. For other cases see figure 2.2.

2. While operating in the 7V p-p mode (TXLVL = GND), the V

11.4V under conditions of typical line voltage, room temperature, and typical current drain

(including the PLT-22 transceiver’s typical IA transmit current of 130mA). This condition

ensures adequate transmit amplifier headroom to drive the full 7Vp-p signal

2-4 Using the PLT-22 Transceiver

supply ≤12.6V and a maximum transmit duty cycle of 65%, which is

supply must not drop below

A

Page 19

onto typical lines. Under worst case conditions, the minimum VA supply voltage may be

relaxed if the following additional condition is met. With worst case power supply

loading (including PLT-22 I

= 250mA), worst case component tolerances, worst case line

A

voltage, and worst case temperature, VA must remain greater than or equal to 9.0V.

This condition ensures adequate transmit amplifier headroom when driving low

impedance power lines.

When using an energy storage type power supply refer to Chapter 5 for additional timing

requirements on the above conditions.

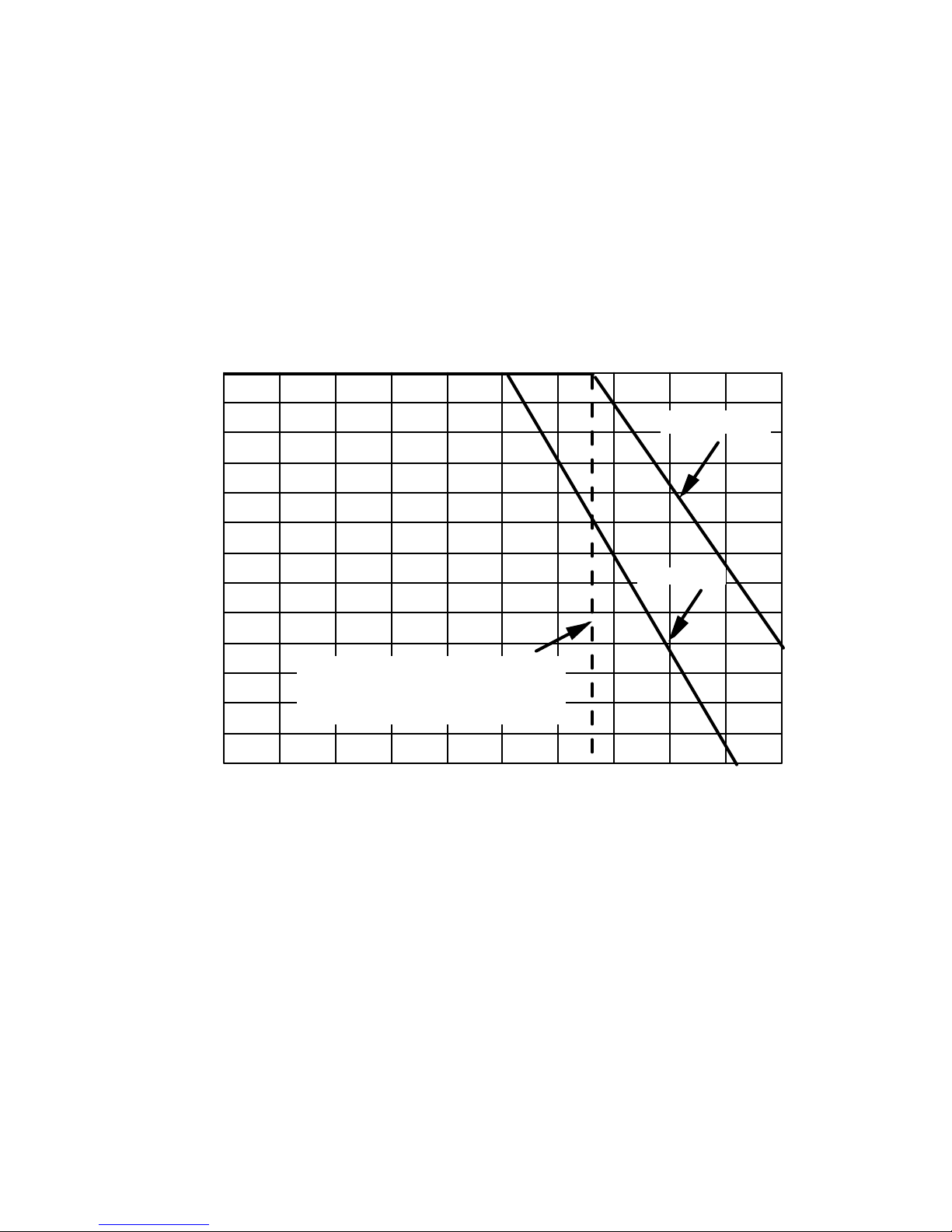

85

80

75

VA Max =12.6V

70

65

60

55

50

VA Max =16V

45

40

35

Maximum possible transmit duty cycle

using LONMARK interoperable

30

Maximum Operating Temperature (°C)

25

transceiver parameters and messages

Š34 bytes

10%

20%

30%

40%

50% 60%

70%

80% 90%

Transmit Duty Cycle

Figure 2.2 PLT-22 Transceiver Maximum Operating Temperature vs. Transmit Duty Cycle

100%

LONWORKS PLT-22 Transceiver User’s Guide 2-5

Page 20

External Components

Crystal

The PLT-22 transceiver requires the connection of an external 10.0000MHz crystal.

The crystal connects directly to two pins of the PLT-22 transceiver, with no other

oscillator components being required external to the transceiver. The crystal should

be mounted as close as possible to the transceiver to minimize parasitic effects. The

traces connecting the crystal to the transceiver preferably should be less than 10mm

(0.4") in length, and under no circumstances can they exceed 20mm (0.8") in length.

In addition to the nominal frequency specification of 10.0000MHz, the crystal should

be a parallel resonant type with a load rating of 13 to 20pF (series resonant crystals

should not be used). The frequency accuracy of the oscillator must be held to ±200

ppm over the full temperature range of operation. The PLT-22 oscillator design is

centered for the use of a crystal with a 16pF load rating. If a 13pF crystal is used,

the nominal frequency of oscillation will be 30 to 55ppm low, leaving 145ppm

available for crystal accuracy, temperature, and aging. If a 20pF crystal is used, the

nominal frequency will be 50 to 85ppm high, leaving 115 ppm for accuracy,

temperature, and aging.

While the PLT-22 transceiver design is centered around the use of a crystal whose

load capacitance rating is 16pF, it is possible to recenter the design for a crystal

whose load capacitance rating is higher than 16pF. The PLT-22 transceiver

effectively contains two 32pF capacitors, one from XIN to ground and one from

XOUT to ground. Note that the series combination of the two capacitors equals the

load capacitance of the recommended crystal. Recentering the design for the use of a

crystal with a higher load capacitance specification requires the addition of two

external capacitors whose series equivalent capacitance is equal to the load

capacitance specification of the crystal less 16pF. For instance, to use a crystal with

a load capacitance specification of 30pF, the operating frequency can be centered by

adding two 27pF capacitors, one from XIN to ground and one from XOUT to ground.

If a 10.0000MHz ±200ppm 0-5V clock signal is already available as part of the node

hardware then it may be used as a clock source for the PLT-22 transceiver by

connecting it to Pin 18 (XIN) of the transceiver. In this instance pin 19 (XOUT) of

the PLT-22 should be left unconnected. With this option, appropriate high speed

clock distribution techniques must be strictly followed in order to ensure that a clean

clock signal is present at the XIN pin of the PLT-22 transceiver.

Oscillator frequency accuracy should be checked during the design verification phase

of every PLT-22 based product. Frequency accuracy should be measured by using a

frequency counter connected to the CKOUT pin to compare the frequency of that pin

to the selected value (i.e., 10, 5, 2.5, or 1.25MHz). Be sure that no instruments or

extra cabling are connected to either the XIN or XOUT pins of the PLT-22 since even

2pF of extra load on either pin will significantly change the oscillator frequency.

2-6 Using the PLT-22 Transceiver

Page 21

Power Supply Bypassing and Grounding

The PLT-22 transceiver requires the connection of external bypass capacitors. The

bypass capacitors should be placed as close as possible to the PLT-22 transceiver,

and low-impedance ground and supply traces should be used between the PLT-22

transceiver and the bypass capacitors. In addition to the bypass capacitors specified

for the Neuron Chip (see Neuron Chip Data Book

the V

and VA bypass capacitors are, as follows:

DD5

2,3,18

), the recommended values of

: None required if the V

V

DD5

supply at the PLT-22 transceiver pin 9

DD5

meets the noise masks described in Chapter 5. It is recommended

that PCB designs initially incorporate a 10µF 10V tantalum capacitor

and a 0.1µF ceramic capacitor on the V

suppy. These capacitors

DD5

can be eliminated if the design meets the noise masks in Chapter 5

and passes the receive performance tests described in Chapter 7

without the capacitors installed.

VA: 120µF (minimum) 16V, low-ESR (<0.3Ω @ 100kHz), high-frequency

aluminum electrolytic capacitor. Low ESR is required in order to

minimize VA ripple voltage when the transceiver drives low

impedance loads, drawing several hundred milli-Amperes of peak-topeak ripple current. Note that the VA bypass capacitor is an integral

part of the mains surge protection circuitry described in Chapter 4.

In particular, the coupling circuits of Chapter 4 require the use of an

aluminum electrolytic type capacitor with a voltage rating of 16V.

Higher or lower voltage ratings will likely result in surge immunity

which is significantly below the verified levels documented in

Chapter 4.

The PLT-22 transceiver provides three ground pins. For proper operation,

all three pins must be connected to ground with low-impedance traces, or

to a ground plane between the transceiver and the Neuron Chip.

Band-In-Use (BIU) and Packet Detect (PKD) LED Connections

The PLT-22 transceiver supplies two output signals, PKD and BIU, that are

intended to drive low-current light-emitting diodes (LEDs). Both signals are activehigh and must be connected to separate LEDs, with series current-limiting resistors

added between the LEDs and ground.

A Band-In-Use detector, as defined under CENELEC EN 50065-1, must be active

whenever a signal that exceeds 80dBµVrms anywhere in the frequency range

131.5kHz to 133.5kHz is present for at least 4ms. The Band-In-Use detector is

defined by CENELEC EN 50065-1 as part of the CENELEC access protocol. The

PLT-22 transceiver incorporates the CENELEC access protocol, and the PLT-22

transceiver may be programmed to enable or disable its operation. (See CENELEC

Access Protocol in Chapter 3 for more information.) When the PLT-22 transceiver is

programmed such that the CENELEC access protocol is enabled, the BIU signal is

active high whenever the CENELEC-defined conditions for Band-In-Use are met.

When the transceiver is programmed such that the CENELEC access protocol is

LONWORKS PLT-22 Transceiver User’s Guide 2-7

Page 22

disabled, the threshold for the BIU signal is increased to 84dBµVrms to reduce the

possibility that power mains noise activates the BIU indicator. When the CENELEC

access protocol is disabled, an active BIU signal does not prevent the PLT-22

transceiver from transmitting. Connecting the BIU signal to an LED is most useful

when the CENELEC access protocol is enabled, since in this case the BIU signal

indicates when the PLT-22 transceiver's transmissions are restricted.

The PKD signal is active whenever a valid LonTalk

PLT-22 transceiver. The receive sensitivity of the transceiver is considerably greater

than that of the BIU indicator. The PKD signal will go active when the PLT-22

transceiver receives packets whose signal level is as small as 36dBµVrms. Thus it is

not uncommon for the PKD indicator to signal that a packet is present without the

BIU indicator turning on; this occurs in cases where the received packet signal

strength is less than the BIU threshold.

Both the BIU and PKD signals are driven directly by the PLT-22 transceiver’s DSP

processor. ESD protection diodes should be connected to these pins in applications

where the BIU and PKD signals drive LEDs that could be subject to ESD exceeding

2kV. In applications where the LEDs are surrounded by a metallic ground plane,

such as a hole in a grounded metal enclosure, the ESD diodes may not be necessary.

However, if a plastic or metal enclosure without a good ground connection is used,

then ESD diodes are needed to prevent damage to the PLT-22 transceiver. ESD

protection diodes include industry part types 1N4148 (thru-hole) and BAV99 (SMT).

Typical sources for BAV99 diodes include Motorola (BAV99LT1), National (BAV99),

and Diodes, Inc. (BAV99).

Neuron Chip Connections

The link between the Neuron Chip and the PLT-22 transceiver makes use of the

Neuron Chip's special-purpose mode interface. This interface requires that the CP

and ~RESET lines of the two devices be interconnected as shown in table 2.3.

Table 2.3 Neuron Chip and PLT-22 Transceiver Interconnections

®

packet is being received by the

The Neuron Chip and PLT-22 transceiver should be placed adjacent to one another

on the same printed circuit board. The length of the ~RESET and CP lines should be

kept to an absolute minimum and in no case should exceed 50mm (2"). In addition,

2-8 Using the PLT-22 Transceiver

Neuron Chip Pin PLT-22 Pin

CP0 7

CP1 6

CP2 5

CP3 Do not connect

CP4 4

~Reset 13

CLK1 10

Page 23

the ground traces and V

trace between the PLT-22 transceiver and the Neuron

DD5

Chip should have impedances as low as possible.

The PLT-22 transceiver's CKOUT pin provides a clock suitable for driving the

Neuron Chip CLK1 at 1.25MHz, 2.5MHz, 5MHz, or 10MHz. The frequency of the

CKOUT pin (Neuron Chip CLK1 input) is selected by two pins, CKSEL0 and

CKSEL1/TXON, as shown in table 2.4. The Neuron Chip CLK2 pin is not connected.

The length of the CKOUT line should be kept to an absolute minimum and should in

no case exceed 50mm (2").

Table 2.4 PLT-22 Transceiver Output Clock Frequency Settings

CKSEL1/TXON CKSEL0 CKOUT FREQ. (MHz)

≥ 4.7k to GND (or open) GND 1.25

≥ 4.7k to GND (or open) VDD 2.5

4.7k to VDD V

5

DD

4.7k to VDD GND 10

The CKSEL1/TXON pin must never be connected directly to a supply rail. The

CKSEL1/TXON pin will draw large currents and potentially damage the

PLT-22 transceiver if it is connected directly to a supply rail. The CKSEL0

pin may be tied directly to V

or GND.

DD5

!

Note that when the PLT-22 transceiver is operated in its new dual

frequency mode (as described in Chapter 3, PLT-22 Transceiver

Programming) the Neuron Chip clock must be set to be 2.5MHz or higher.

The PLT-22 transceiver ~RESET pin is designed to connect directly to the Neuron

2,3,18

Chip ~RESET pin. The Neuron Chip Data Book

provides information on the

Neuron Chip’s external reset circuitry. Depending on the particular Neuron

Chip version used, a Low Voltage Indicator (LVI) circuit such as the

Motorola MC33064 or Dallas 1233 may be necessary to supply a reset signal

to both the Neuron Chip and the PLT-22 transceiver. All of the application

circuits shown in this documentation include an LVI chip. Consult your Neuron

Chip manufacturer for the latest reset circuit requirements. Whether an LVI chip or

a simpler discrete circuit is required, the ~RESET pin of the PLT-22 should always

be tied directly to the ~RESET pin of the Neuron Chip. To minimize the effect of

ESD discharges on the Neuron Chip ~RESET pin, use two external 56pF ceramic

capacitors, one tied between ~RESET and V

, the other between ~RESET and

DD5

GND. The capacitors should be placed as close as possible to the Neuron

Chip ~RESET pin. Note that the PLT-22 transceiver already incorporates two

56pF capacitors on the ~RESET line internal to the transceiver. These internal

capacitors should be taken into account when calculating the total allowable

capacitive load on the Neuron Chip ~RESET pin, as specified in the Neuron Chip

Data Book

2,3,18

.

LONWORKS PLT-22 Transceiver User’s Guide 2-9

Page 24

Transmit Output Level

The TXLVL input pin on the PLT-22 transceiver determines the output voltage of the

transmit signal. When the TXLVL pin is left floating, the transceiver's open-circuit

output voltage is 3.5V p-p. When the TXLVL pin is grounded, the open-circuit

output voltage is increased by 6dB to 7Vp-p. The appropriate setting for TXLVL is

summarized in table 2.5.

TXLVL OUTPUT

grounded 7Vp-p Preferred mode of operation. Use for FCC,

open 3.5Vp-p Use for CENELEC EN50065-1 class 116

Table 2.5 TXLVL Setting

APPLICATION

VOLTAGE

Industry Canada, CENELEC class 134, Japan

MPT, and all dedicated wiring applications.

applications

TXON Output Signal

The PLT-22 transceiver provides an output signal suitable for controlling a PLA-21

Power Line Amplifier via the CKSEL1/TXON pin. The CKSEL1/TXON pin functions

as an input during the period in which the ~RESET pin of the PLT-22 transceiver is

held active (low). During the reset active period the logical states of the

CKSEL1/TXON and CKSEL0 pins are sampled and stored by the PLT-22

transceiver. The stored state is used to determine the frequency of CKOUT, as

described in table 2.4. After RESET becomes inactive (high) CKSEL1/TXON changes

to an output (CKSEL0 remains an input, but its state is ignored). The output, called

TXON, is a buffered version of the internal signal used to control the transceiver's

output amplifier. The TXON signal output is active high when the PLT-22

transceiver transmits packets.

The TXON signal is typically used to provide tri-state control of an external booster

amplifier, such as the PLA-21 Power Line Amplifier model 53001-01. For more

details see the PLA-21 Power Line Amplifier Specification and User's Guide.

2-10 Using the PLT-22 Transceiver

Page 25

Optional power supply filter

(not required for linear

power supplies) See

chapter 5

See chapter 5

Power Supply

LINE

120 µF, 16VDC

Aluminum Electrolytic.

Close to PLT-22 VA pin.

See coupling circuits in

chapter 4

+VA

5

TANT,

Close to PLT-22

VDD pin

5 10 µF,10VDC

bypass

capacitors:

0.1 µF, 25VDC

6 places

VDD

1

2

RXIN

RXCOMP

EARTH

NEUTRAL

See chapter 4

Coupling Circuit

+5V

111215

5

VDD

CKSEL0

Optional Packet Detect and

Band-In-Use Indicators

470ž

470ž

* Refer to the Neuron 3150 Chip External

Memory Interface application note for

memory connection information.

GND for 7V p-p

transmit level;

Open for 3.5V p-p

4.7kž

14

16

BIU

PKD

TXOUT

CKSEL1

transmit level

21

TXLVL

3

A

+5V

+V

D0D1D2D3D4D5D6

13141518192021

O0O1O2O3O4O5O6

A0A1A2A3A4A5A6A7A8A9A10

98765

11

10

A0A1A2A3A4A5A6A7A8A9A10

D7

22

O7

4

292824

11217

26

NCNCNC

PROM

27C256

A11

A12

273303123

A11

A12

A13

2

+5V

PLT-22

~RESET

GND

CP4

CP2

+5V

+5V

32

16

NC

VDD

A13

A14

CE~

OE~

2

25

A14

A15

D7

D6

D5

D4

GND

D3

D2

+5V

D1

D0

VPP

+5V

33

34

35

36

37

38

39

40

41

42

43

44

open

45

46

A15

47

48

CP1

567

4

3

open

323130292827262524232221201918

CP4

CP3

CP2

CP1

D7

D6

D5

D4

D3

D2

VSS

VDD

VDD

D1

D0

VDD

R/~W

~E

A15

NC

NC

A14

A13

A12

495051525354555657585960616263

A11

A12

A13

A14

CKOUT

CP0

GND

8

10913

+5V

+5V

open

+5V

open

NC

CP0

VDD

VDD

VSS

CLK1

CLK2

VDD

VSS

Neuron 3150 Chip

A11

A10A9A8A7A6A5A4A3A2A1A0

GND

XIN18XOUT

17

19

10MHz

open

17

NC

VSS

IO10

~SERVICE

IO9

IO8

IO7

IO6

IO5

IO4

VSS

VSS

VDD

~RESET

IO3

IO2

IO1

IO0

NC

64

A0A1A2A3A4A5A6A7A8A9A10

Keep these lines short.

VA

20

+VA

16

15

14

13

12

11

10

9

8

7

+5V

6

5

4

3

2

1

MC33064D

1

56pF

+5V

56pF

Figure 2.2 Neuron 3150 Chip Application Schematic

Locate close to Neuron Chip

To User's Application Electronics

LONWORKS PLT-22 Transceiver User’s Guide 2-11

Page 26

Optional power supply filter

(not required for linear

power supplies) See

Chapter 5

See Chapter 5

Power Supply

LINE

NEUTRAL

See Chapter 4

Coupling Circuit

1

2

RXIN

RXCOMP

EARTH

+5V

5

VDD

4.7kž

14

111215

BIU

CKSEL1

CKSEL0

Optional Packet Detect and

Band-In-Use Indicators

470ž

470ž

GND for 7V p-p

transmit level;

Open for 3.5V p-p

transmit level

PKD

16

TXOUT

21

TXLVL

CP2

567

open

CP3

D

D

V

+5V

CP1

CP1

VSS

CP0

CP0

CLK2

open

GND

8

+5V

17

VDD

CLK1

PLT-22

CKOUT

10913

CP2

VSS

~RESET

XIN18XOUT

10MHz

VA

19

20

VA

GND

17

Figure 2.3 Neuron 3120 Chip Application Schematic

3

2

+5V

MC33064D

1

56pF

+5V

56pF

Keep these lines short.

Locate close to Neuron Chip

A

V

+5V

CP4

GND

3

4

120 µF, 16VDC

Aluminum Electrolytic.

Close to PLT-22 VA

pin. See coupling

10 µF, 10VDC, TANT

VA

Close to PLT-22

VDD pin

+5V

5

circuits in chapter 4

5

VDD bypass

capacitors:

0.1 µF, 25VDC,

5 places

To User's

Application

Electronics

IO6

IO7

IO2

IO3

+5V

VDD

IO8

IO9

IO10

Neuron

3120 Chip

~SERVICE

IO0

IO1

VSS

Electronics

Application

To User's

CP4

VSS

D

D

V

VSS

10111213141516

+5V

+5V

323130292827262524232221201918

IO5

VSS

VDD

~RESET

VDD

IO4

123456789

+5V

2-12 Using the PLT-22 Transceiver

Page 27

3

PLT-22 Transceiver Programming

Certain parameters of the PLT-22 transceiver are programmed by the

user. This chapter presents a list of these parameters and their

values, plus a description of how they are programmed via the

LonBuilder

Development Tool.

®

Developer’s Workbench and the NodeBuilder™

LONWORKS PLT-22 Transceiver User’s Guide 3-1

Page 28

Dual Carrier Frequency Mode

Each PLT-22 transceiver incorporates a new dual carrier frequency capability which

allows it to communicate with other PLT-22-based nodes, even if noise is blocking its

primary communication frequency range. If impairments prevent communication in

this range, a PLT-22-based node can automatically switch to a secondary carrier

frequency to complete a transaction with other PLT-22-based nodes.

With dual carrier frequency mode enabled, the last two retries of acknowledged

service messages are sent using the secondary carrier frequency. Thus when

acknowledged service is used with three retries (four total tries), the first two tries

are sent using the 132kHz primary carrier frequency. If the last two tries are needed

to complete the transaction, they are sent (and acknowledged) using the 115kHz

secondary carrier frequency. A minimum of two retries must be used if the PLT-22

transceiver is to be able to use both carrier frequency choices. For optimum

reliability and efficiency, Echelon recommends the use of three retries when using

acknowledged service messaging with the PLT-22 transceiver.

When unacknowledged repeat message service is used, the PLT-22 transceiver

leverages the reliability of both carrier frequencies by alternating between them. In

this case an unacknowledged repeat message with three repeats results in the first

and third packets being sent using the 132kHz primary carrier frequency, while the

second and fourth packets are sent using the 115kHz secondary carrier frequency. A

minimum of one repeat must be used for the PLT-22 transceiver to use both carrier

frequency choices.

Every PLT-22 transmission at the 115kHz secondary carrier frequency is

accompanied by a simultaneous 132kHz “pilot” signal which older PLT-20 and PLT21-based nodes can use to recognize that the channel is busy. This pilot signal

prevents PLT-20- or PLT-21-based nodes (which cannot detect the 115kHz secondary

carrier frequency) from transmitting at the same time that a PLT-22 is transmitting

on its 115kHz secondary carrier frequency.

The user can configure a PLT-22-based node to operate with the dual carrier

frequency mode either enabled or disabled. When a PLT-22-based node is operated

with dual carrier frequency mode enabled, it will operate as described above. When

a PLT-22-based node is operated with dual carrier mode disabled, it will only

transmit using its 132kHz primary carrier frequency. Note that the selection of dual

frequency mode on a PLT-22-based node only affects its transmission characteristics.

Each PLT-22 transceiver is always able to automatically detect and properly receive

packets at either frequency, regardless of whether or not dual frequency

transmission is enabled. Activation of dual carrier frequency mode is controlled by

the revision level of standard transceiver parameters, as described later in this

chapter.

3-2 PLT-22 Transceiver Programming

Page 29

CENELEC Access Protocol

To allow multiple power line signaling devices from different manufacturers to

operate on a common AC mains circuit, the CENELEC standard EN 50065-1

specifies an access protocol for the C-band (125kHz to 140kHz). The frequency

132.5kHz is designated as the primary band-in-use frequency that indicates when a

transmission is in progress.

Every power line signaling device must both monitor the 132.5kHz band-in-use

frequency and be able to detect the presence of a signal of at least 80dBµVrms

anywhere in the range from 131.5kHz to 133.5kHz which has a duration greater

than or equal to 4 milliseconds. A power line signaling device is permitted to

transmit if the band-in-use detector shows the band to have been free for at least 85

milliseconds. Each device must randomly choose an interval for transmission, and at

least seven evenly distributed intervals must be available for selection. A group of

power line signaling devices is allowed to transmit continually for a period less than

or equal to one second, after which it must cease transmitting for at least 125

milliseconds.

The PLT-22 transceiver incorporates the CENELEC access protocol and the user can

enable or disable the CENELEC access protocol at the time of channel definition.

When enabled, the PLT-22 transceiver enforces the CENELEC access protocol while

still maintaining the benefits of the LonTalk protocol. When the CENELEC access

protocol is enabled, overall network throughput is reduced by 11%.

Power Management

The PLT-22 transceiver incorporates a power management feature that supports the

design of very low cost power supplies in low cost consumer applications such as

networked light dimmers, switches, and household appliances. This class of

consumer applications have low transmit duty cycle operation requirements. These

low cost power supplies take advantage of a number of PLT-22 features: the low

receive current requirements of the PLT-22 transceiver; the 9:1 difference between

the PLT-22 transceiver transmit and receive mode currents and the wide (+8.5VDC

to +16VDC) V

A low transmit duty cycle implies that the device transmits packets infrequently,

e.g., the product waits for a minimum of 10 packet times between transmitting each

packet - a 10% transmit duty cycle. A power supply design that takes advantage of

this duty cycle can store energy on a capacitor during the relatively long period

between transmissions, when the PLT-22 transceiver draws minimal current, and

then consume the stored energy to transmit a packet. This type of power supply,

referred to as an “energy storage power supply,” stores energy by charging an energy

storage capacitor to a relatively high voltage (e.g., 15V) while in receive mode. The

voltage on the capacitor then falls or "droops" toward a lower limit (e.g., 9.0V) while

transmitting. The energy storage capacitor is then slowly recharged to the higher

voltage during the relatively long time between transmissions. Traditionally, the

proper design of such a power supply required knowledge of the maximum transmit

duty cycle to be supported, and an implementation that accounted for all worst case

operating voltage of the PLT-22 transceiver.

A

LONWORKS PLT-22 Transceiver User’s Guide 3-3

Page 30

operating conditions (temperature, line voltage, component variation and

transmitter loading).

The cost of such a power supply can be significantly reduced if, instead of designing

the supply for the maximum possible transmit duty cycle and for the worst case

environmental conditions, the supply can be designed for typical operating

conditions. However, designing for typical operating conditions implies that a

mechanism exists to "manage" the worst case operating conditions such that reliable

operation is assured. This management feature must also address products whose

operating conditions (especially transmit duty cycle) are not defined prior to use in a

network, but rather are controlled by application programs loaded after installation.

The PLT-22 power management feature implements the needed management

functionality by intelligently monitoring the energy storage power supply. Should

the node attempt to transmit too frequently, the power management feature

enforces a limit on the transmit duty cycle by preventing the Neuron Chip from

transmitting until the node's power supply recovers to the point that sufficient

energy is available to transmit a packet. Details of this feature and application

examples are provided in Chapter 5.

When power management is enabled, the PLT-22 transceiver requires a V

A

power supply voltage of 12.9V before it will attempt to transmit a packet.

Products with fixed V

power supplies lower than 12.9V should never be

A

programmed to enable the power management feature as they may never

be allowed to transmit. Likewise a node whose power supply relies on

power management to operate correctly should never

be programmed with

the power management feature disabled.

The user can enable or disable power management at the time of channel definition

by selecting a standard transceiver type with a "low" suffix. The only difference

between a set of standard transceiver parameters with the "low" suffix and the

corresponding set without the "low" suffix is that the power management feature is

enabled with the "low" set and disabled with the set without the suffix.

Note that some installation tools load a device's communication parameters as part

of the installation and replacement process and calculate those parameters based on

the channel (rather than the particular device). Such tools can not be used for

systems that contain a mixture of nodes with and without power management

enabled on the same channel.

Tools based on the L

ONWORKS Network Services (LNS) architecture, such as

LonMaker for Windows Integration Tool, correctly support all configurations of PLT22 (and PLT-21) nodes with or without power management. For a tool not based on

LNS, contact your tool vendor to determine if it can support a mixture of power

management and non-power management nodes on the same channel.

Standard Transceiver Types

Four standard transceiver types are defined for the PLT-22 transceiver operating in

the 110 kHz – 140kHz range. These standard transceiver types specify

communications parameters for a PLT-22 (or PLT-20 or PLT-21) node. The

3-4 PLT-22 Transceiver Programming

Page 31

communication parameters of the four standard types are identical except for the

state of the CENELEC protocol and power management features (enabled or

disabled) of the PLT-22 node. The revision level for each of these parameter sets

determines whether the dual carrier frequency feature of the PLT-22 transceiver is

enabled or disabled. When used with a STDXCVR.TYP file with a date prior to 1999,

the PLT-22 transceiver will only transmit packets using its 132kHz primary carrier

frequency. In this mode, all transmissions are compatible with prior generation

PLT-20 and PLT-21 transceivers.

The dual carrier frequency mode can be enabled by using updated standard

transceiver parameters. Standard transceiver parameters are used in the

LonBuilder and NodeBuilder development tools, and in the firmware of a number of

Echelon’s “connectivity” products as well (e.g., the Echelon RTR-10 router core). See

the next section for a discussion of how to update the LonBuilder and NodeBuilder

tools, and see the power line products section of Echelon’s web site

(www.echelon.com) to determine how to update other devices used in a PLT-22 power

line network.

With dual frequency mode activated, a PLT-22 transceiver begins each transaction

by sending backward compatible 132kHz packets. In this mode, the last two tries of

acknowledged service messages are sent using the 115kHz secondary carrier

frequency. For unacknowledged repeated messages, every other repeat is sent at the

secondary frequency. When the primary frequency range is not blocked by noise, a

PLT-22-based node can inter-communicate with any other PLT-20, PLT-21, and PLT22 node. In addition, with the dual frequency mode activated, PLT-22-based nodes

can intercommunicate even if the primary frequency range is blocked by noise.

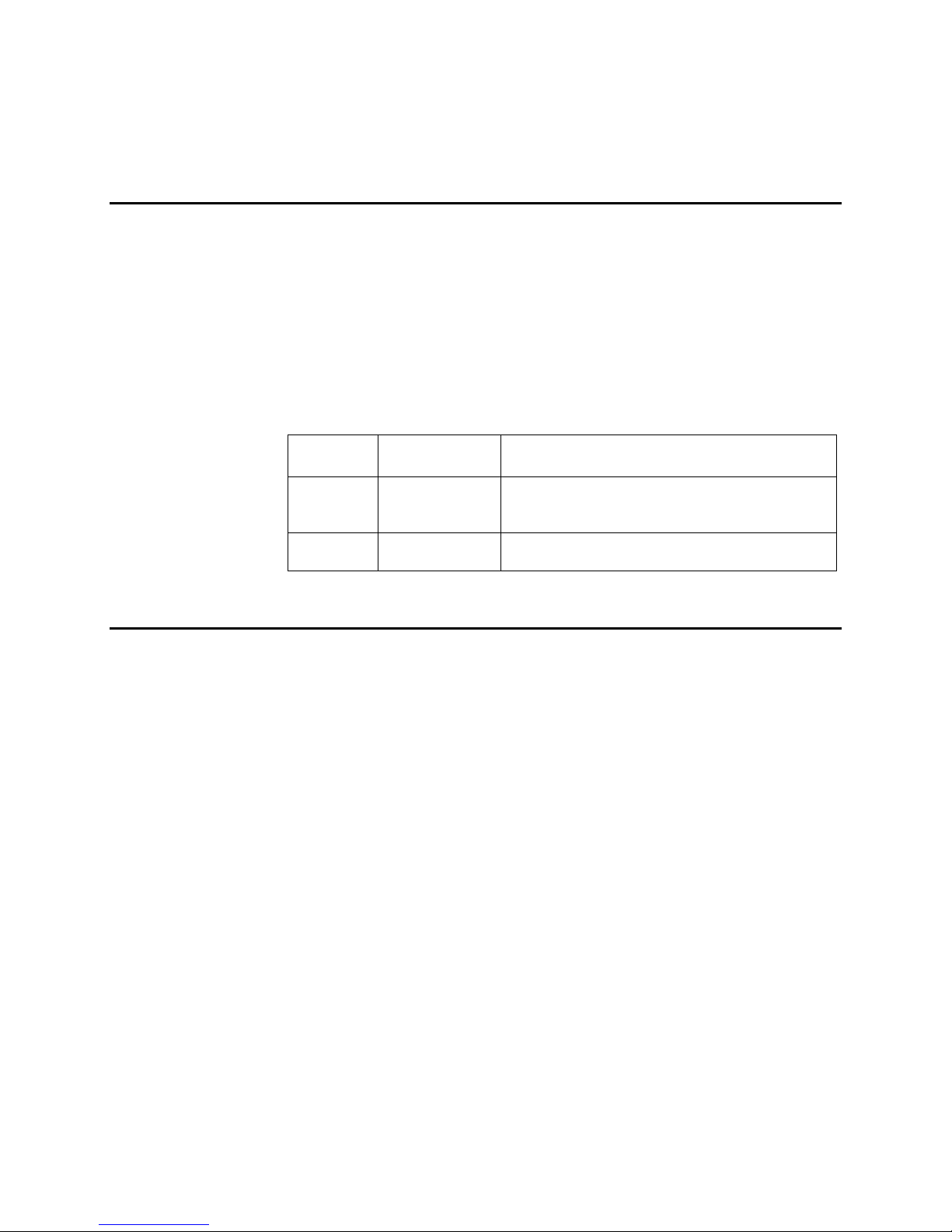

Table 3.1 lists the names of the four standard transceiver types and shows the

differences between them.

Table 3.1 Standard PLT-22 Transceiver Types

Standard Transceiver Type CENELEC Protocol Power Management

PL-20C Enabled Disabled

PL-20N Disabled Disabled

PL-20C-LOW Enabled Enabled

PL-20N-LOW Disabled Enabled

Table 3.2 shows which combinations of standard transceiver types and power supply

types are allowed.

LONWORKS PLT-22 Transceiver User’s Guide 3-5

Page 32

Table 3.2 Allowed Power Supply Types Versus Standard Transceiver Types

Standard Transceiver

Type Selection

PL-20C OK Not allowed if the power supply design

PL-20N OK Not allowed if the power supply design

Fixed V

supply <12.9V

power

A

Energy Storage VA power supply

>12.9V

relies on power management for worst

case duty cycle and load conditions

relies on power management for worst

case duty cycle and load conditions

PL-20C-LOW Not allowed: node

may not transmit

PL-20N-LOW Not allowed: node

may not transmit

OK

OK

LonBuilder and NodeBuilder PLT-22 Transceiver Channel

Definitions

To use the PLT-22 transceiver in dual frequency mode with the LonBuilder or

NodeBuilder tools, you must have STDXCVR.TYP file with a date stamp of 1999 or

later. PLT-22-based nodes built from a system with a STDXCVR.TYP file earlier than

1999 will transmit using only a single carrier frequency, even if it is blocked by noise.

To take advantage of the PLT-22 transceiver's ability to automatically change

frequency if the primary frequency range is blocked by noise, verify that the year on

the date of your STDXCVR.TYP file is 1999 or later. This file is located in the

L

ONWORKS TYPES directory (c:\lonworks\types by default) for the NodeBuilder

software, and in the LonBuilder TYPES directory (c:\lb\types by default) for the

LonBuilder software. If the date on your STDXCVR.TYP file is older than 1999, you

can download an update from Echelon's web site at www.echelon.com/toolbox.

Once you have verified that you are using the correct version of the STDXCVR.TYP

file, specify PL-20N, PL-20C, PL-20N-LOW, or PL-20C-LOW as the standard

transceiver type in the NodeBuilder Device Template, as shown in figure 3.1, or the

LonBuilder Channel Create window. Select “Yes” for the “Enforce Standard Type”

field.

3-6 PLT-22 Transceiver Programming

Page 33

Figure 3.1 NodeBuilder Device Template Window

Table 3.3 shows the channel definition parameters for the PLT-22 transceiver. If you

do not have access to an updated STDXCVR.TYP file, these channel definition

parameters may be entered in the Channel Modify screen and sub-screens to create a

standard PLT-22 transceiver definition which will activate the PLT-22 transceiver's

dual frequency mode.

Table 3.3 Channel Definition Parameters for the PLT-22

Transceiver

Parameter Value

Channel Modify Screen

Std Xcvr Type Custom

Comm Mode Special Purpose

Comm Rate 1.25Mbps

Number of Priorities 8

Min Clock Rate 2.5MHz

Avg Pkt Size 15 bytes

Osc Accuracy 200ppm

Osc Wakeup 0 µsec

LONWORKS PLT-22 Transceiver User’s Guide 3-7

Page 34

Table 3.3 Channel Definition Parameters for the PLT-22

Transceiver (continued)

Comm Mode Specific Parameters

Channel Bit Rate 3987 bps

Alternate Bit Rate 3987 bps

Wakeup Pin Dir Output

Xcvr Controls Preamble? Yes

General Purpose Data (power management disabled)

CENELEC Access Protocol OFF

CENELEC Access Protocol ON

General Purpose Data (power management enabled)

CENELEC Access Protocol OFF

CENELEC Access Protocol ON

0E 01 00 10 00 00 00

4A 00 00 10 00 00 00

0E 01 00 12 00 00 00

4A 00 00 12 00 00 00

Allow Node Override?

PL-20N, PL20C PL-20N-LOW, PL-20C-LOW

Layer 1 Time Factors

YES

Rcv Start Delay 7.3 bits

Rcv End Delay 1.6 bits

Indeterm Time 10.1 bits

Min Interpacket 17.5 bits

Preamble Len 33.5 bits

Use Raw Data? No

The standard transceiver definitions in table 3.1 were chosen as the best balance between

flexibility in network design and network throughput. Flexibility is provided by the

selection of 8 priority slots on the channel and a minimum input clock of 2.5MHz (a Neuron

Chip input clock frequency as low as 2.5MHz may be chosen in order to reduce node power

consumption). These parameters support a packet rate of 10 packets/sec with 80%

throughput, 4% collisions, and 11 byte packets.

Note that when the PLT-22 transceiver is operated in its dual carrier mode, the minimum

Neuron Chip clock is 2.5MHz. When the PLT-22 transceiver is operated in its single carrier

frequency mode, the minimum Neuron Chip clock is 1.25MHz.

3-8 PLT-22 Transceiver Programming

!

Page 35

4

Coupling Circuits

This chapter includes a technical discussion about the means by which

communication signals are coupled to power mains. Coupling circuit

designs, including schematics and electrical safety issues, are included.

LONWORKS PLT-22 Transceiver User’s Guide 4-1

Page 36

Power Line Communications

The PLT-22 transceiver employs sophisticated digital signal processing techniques, a

transmit power amplifier with a very low output impedance, and a very wide (80dB)

dynamic range receiver to overcome the signal attenuation and noise inherent in

power mains communication. Maintaining the full communication capability of the

PLT-22 transceiver requires careful selection and implementation of the mains

coupling circuitry external to the PLT-22 transceiver. This section gives an overview

of the sources of signal attenuation as a basis for understanding choices in selecting

and implementing mains coupling circuits.

Attenuation is the difference between the signal level at the output of the power line

transmitter and the level of that same signal at the input of the intended receiver.

While attenuation is technically defined as the ratio of power levels, it is referred to

in this document as the ratio of the transmitted signal voltage (unloaded) to the

voltage of that same signal at the receiver input. A voltage ratio is more convenient

to measure since power measurements require knowledge of the circuit impedance

which, in the case of the power mains, varies with both location and time.

In power mains communications the attenuation of transmitted signals spans a wide

range and is most conveniently denoted in decibels (dB), where voltage attenuation is

defined in dB as 20log

signal was reduced by a factor of 10 by the time it arrived at the receiver, 40dB of

attenuation corresponds to a factor of 100, 60dB a factor of 1000, and so on. A PLT-22

transceiver is capable of reliably communicating on a low-noise line, such as a

dedicated twisted wire pair, when the transmit signal is attenuated by as much as

80dB (a factor of 10,000). Thus a signal transmitted at 7Vp-p (2.5Vrms) may be

received when reduced to less than 700µVp-p (250µVrms).

To better understand the sources of attenuation in a power mains network, it is

helpful to look at a simplified model of a power distribution network. This example

is based on an installation having one power distribution panel and two phases of

mains power. While many applications for power line communication employ more

phases, different topologies, voltages, and wire types, this example illustrates some

of the key issues affecting the successful application of the PLT-22 transceiver.

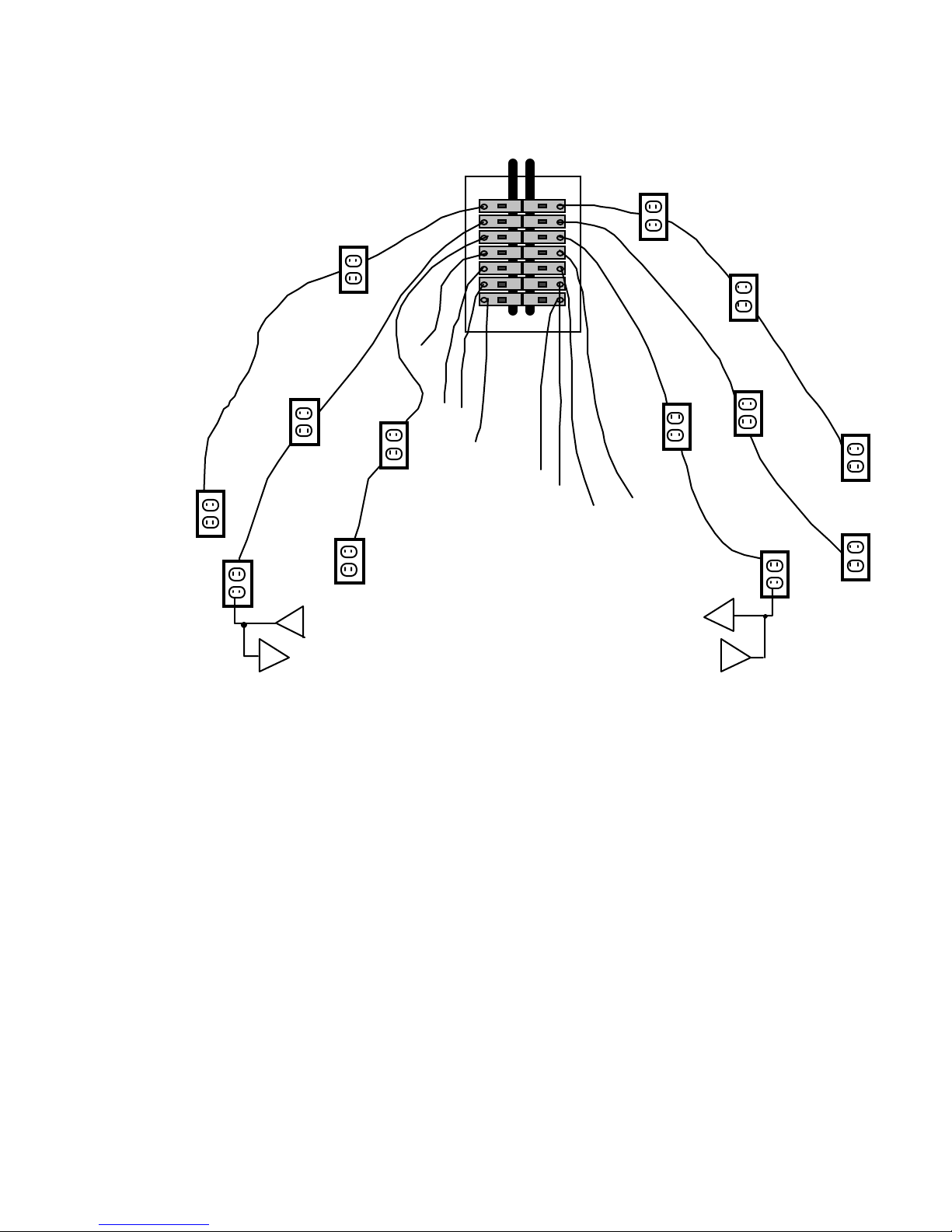

Figure 4.1 depicts the path that a power line communication signal might traverse,

starting from a wall socket and passing through the building's electrical wiring and

circuit breaker panel, across power phases, and ultimately to another wall socket.

Each socket in the power network may power a device that generates noise and loads

the transmitted signal. For clarity, neutral and earth wires have not been shown.

(

V

10

transmit/Vreceive

). Thus 20dB of attenuation means that the

4-2 Coupling Circuits

Page 37

L2

L1

TX

RX

TXRX

Figure 4.1 Power Distribution Model

Attenuation is most easily understood in terms of a voltage-divider circuit formed by

the output impedance of the transmitter, the impedance of the various mains circuit

branches, and any loads present on the mains branch circuits. At the communication

frequencies of the PLT-22 transceiver (110kHz to 140kHz), the significant

impedances are due to the series inductance of the mains wiring itself, capacitive

loads between line and neutral, resistive loads between line and neutral, and the

coupling between L1 and L2 which occurs due to mutual inductance and parasitic

capacitance between phases. If these distributed impedances are lumped together

and treated as if a single frequency is being transmitted, the simple model shown in

figure 4.2 results.

LONWORKS PLT-22 Transceiver User’s Guide 4-3

Page 38

Transmitter

Transmitter

Z

o

ZZ

Wiring

Phase-to-Phase

Z

Wiring

Receiver

Z

Load

Figure 4.2 Power Mains Attenuation Model

This model illustrates that minimizing the series impedances and maximizing the

line-to-return path impedances reduces the attenuation of the transmitted signal.

Coupling Techniques

Power Line Coupling Basics

Injecting a communication signal into a power mains circuit is normally

accomplished by capacitively coupling a transceiver's output to the power mains. In

addition to the coupling capacitor, an inductor or transformer is generally present.

The coupling capacitor and the inductor or transformer together act as a high-pass

filter when receiving the communications signal. The high-pass filter attenuates the

large AC mains signal (at either 50Hz or 60Hz), while passing the transceiver's

communication signal. Figure 4.3 below shows a basic mains coupling circuit. The

value of the capacitor is chosen to be large enough so that its impedance at the

communication frequencies is low, yet small enough that its impedance at the mains

power frequency (50Hz or 60Hz) is high. The impedance of the capacitor can be

considered as part of the transmitter's output impedance (Z

figure 4.2. Keeping the impedance of the coupling capacitor low minimizes the signal

injection loss caused by the voltage divider formed between the output impedance of

the amplifier and the mains loading (Z

Z

Load

Power Line Signal Return Path

Z

Load

).

Load

Receiver

Z

i

o

Transmitter

) shown in

The value of the inductor is chosen to have a relatively high impedance at the PLT22 transceiver's communication frequencies. The inductor impedance can be

considered part of the receiver input impedance (Z

Keeping the inductor impedance high helps minimize any signal loss at the receiver

due to the voltage divider formed by the wiring impedance and the receiver input

impedance.

4-4 Coupling Circuits

i Receiver

) shown in figure 4.2.

Page 39

PL Transmitter

Power Line

(AC Mains)

PL Receiver

Figure 4.3 Basic Mains Coupling Circuit

A key factor affecting the type of mains coupling circuit to be used is the wiring style

of the power distribution system to which the coupling circuit will be connected.

Wiring topologies vary from application to application, e.g., homes versus commercial

buildings, as well as from country to country. Even so, wiring styles can be divided

into two major categories: wiring systems where a separate earth conductor is

present and accessible (i.e., safety ground, which is not the same as a neutral wire

with an earth bond), and wiring systems where there is no earth conductor.

When earth is always present, a coupling method known as line-to-earth coupling is

preferred. In line-to-earth coupling the communications signal is coupled to the line

wire relative to earth, and earth is used as the communications signal return path.

This coupling technique is also referred to as earth-return coupling. Local restrictions

may apply to the use of line-to-earth coupling; see Ground Leakage Currents later in

this chapter.

A simple example of a line-to-earth coupling circuit is shown in figure 4.4.

LONWORKS PLT-22 Transceiver User’s Guide 4-5

Page 40

PL Transmitter

Line

Earth

PL Receiver

Figure 4.4 Line-to-Earth Coupling Method

To understand the advantage of line-to-earth coupling, recall that a major component

of signal attenuation is due to the loads presented by devices that are connected to

the power mains between the line and neutral wires. These loads do not affect signal

attenuation when line-to-earth coupling is used. Field measurements have shown

consistent improvements in received signal-to-noise ratios of more than 15dB for

transceivers using line-to-earth coupling, relative to transceivers using non-earthreturn coupling. For this reason, when a safety ground connection is known to be

available throughout the wiring system, a line-to-earth coupling scheme is preferred.

In applications where a safety ground connection may not exist, or line-to-earth

coupling is precluded by local regulations, the coupling circuit must be connected

between the line and neutral wires. This style of coupling is known as line-to-neutral

coupling and is shown in figure 4.5.

4-6 Coupling Circuits

Page 41

PL Transmitter

Line

Neutral

PL Receiver

Figure 4.5 Line-to-Neutral Coupling Style

In the following section the simple circuits shown in figures 4.4 and 4.5 are expanded

to make them practical in real applications. The following discussion applies to both

line-to-neutral coupling and line-to-earth coupling, as the coupling circuit topology

for each is the same. However, in addition to the different mains connections, the

required component values differ for line-to-neutral coupling and line-to-earth

coupling. At the end of this chapter, recommended coupling circuit schematics and

component specifications are provided for both line-to-neutral coupling and line-toearth coupling.

LONWORKS PLT-22 Transceiver User’s Guide 4-7

Page 42

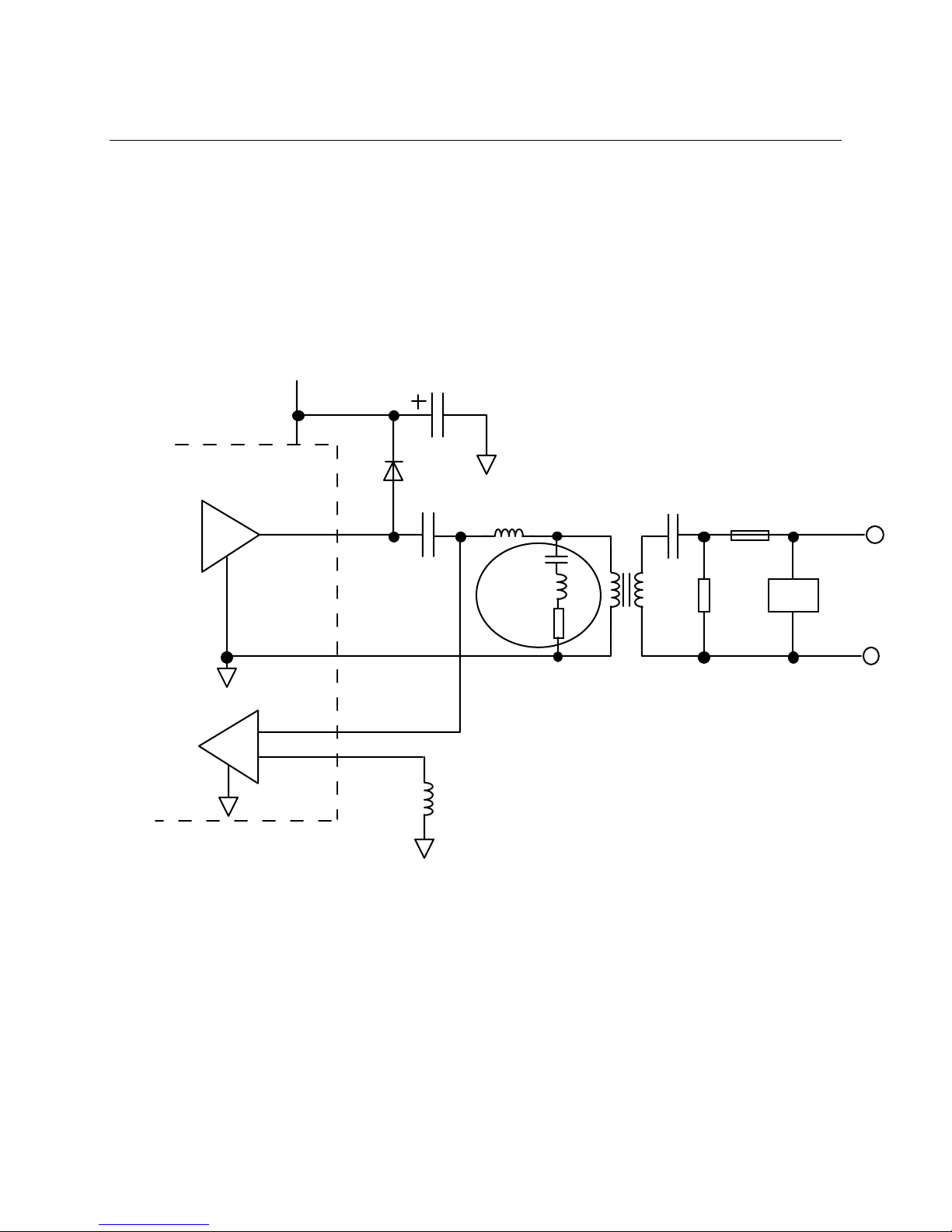

Power Line Coupling Details

The coupling circuits shown in figures 4.4 and 4.5 require the addition of a small

number of components to make them practical. Figure 4.6 shows the addition of an AC

coupling capacitor (C2) to prevent the inductor from shorting the transmit amplifier's

DC bias voltage.

PLT-22

Transmit

Amp

Receive Front End

Figure 4.6 Simplified Coupling Circuit with Blocking Capacitor

Given the attenuation model presented earlier in figure 4.2, one critical design

constraint is that the series combination of C1 and C2 must have a low impedance at

the PLT-22 transceiver's communication frequencies. The impedance of these

capacitors, along with the PLT-22 transceiver's transmit output impedance,

corresponds to “Zo Transmitter” in figure 4.2. Since the equivalent load impedance of

the power line may in some cases be as low as 1-2 Ohms, and since the output

impedance of the PLT-22 transceiver is less than 1 Ohm, the impedance of these

capacitors should be on the order of 1 Ohm so that they do not add significantly to “Zo

Transmitter”. While the values of C1 and C2 could be set high enough to meet this

goal, doing so would significantly increase the cost of the high-voltage capacitor C1.

Since C2 is connected only to low voltage, and thus is lower cost for a given value, its

value can be set higher relative to the value of the high-voltage capacitor C1. A simple,

cost-effective solution is obtained when an inexpensive inductor, L2, is added as shown

in figure 4.7 below. This inductor forms a series-resonant circuit with C1 and C2, and

its value can therefore be chosen to optimize coupling at the PLT-22 transceiver's

communication frequencies while minimizing the cost of C1 and C2.

C2

C1

L1

4-8 Coupling Circuits

Page 43

PLT-22

Transmit Amp

C2

L2

Receive Front End

C1

L1

Figure 4.7 Simplified Coupling Circuit with Resonant Inductor

An important design constraint on L2 is that its DC resistance be kept very low since

it is in the transmit signal path and effectively part of the transmitter's output

impedance. Low-cost inductors with DC resistance on the order of 0.2 Ohms are

widely available.

Capacitors C1 and C2 should be of metalized polyester construction in order to

minimize equivalent series resistance and provide adequate surge immunity.

!

It is critical that no additional series impedance be added in the signal path

between the TXOUT pin of the PLT-22 transceiver and the power mains (or

in the return path from the power mains to the ground pins of the PLT-22)

unless verified to be significantly less than 1 Ohm near 130kHz. If, for

example, a ferrite bead with an impedance of 9 Ohms at 130kHz were added then the

signal injected into a 1 Ohm power line would be reduced by a factor of 10. Under

typical conditions the end product would still function, however, communication

margin and reliability over a full range of power line environments would be severely

compromised. For the same reason, the impedance of series circuit protection

elements must also be kept very low. Low current fuses (<2A), protection devices

that can be reset, and ferrite beads generally add unacceptable series impedance to

the signal path.

LONWORKS PLT-22 Transceiver User’s Guide 4-9

Page 44

Figure 4.8 shows additions to the coupling circuit which are required to make it fully

functional. The first is a 1.0mH inductor, L3, connected to the PLT-22 transceiver receive

filtering circuitry. The DC resistance of L3 can be up to 50 Ohms. The second is a diode,

D1, connected from the transmitter to the amplifier supply voltage (V

) to protect the

A

inputs of the PLT-22 transceiver from large (>15V) transients. This diode works in

conjunction with a diode internal to the PLT-22 transceiver that connects from the

transmitter output to ground. Bypass capacitor C3 also has been added to emphasize the

fact that it is an integral part of the coupling circuit. One of the functions of this

capacitor is to protect the V

supply line from excessive overshoot when positive going

A

line surges discharge through diode D1. The last addition is an optional circuit that

improves performance in environments where large (>50V) impulses may be present from

devices such as SCR-controlled light dimmers. This circuit consists of an LCR series

network that acts as a notch filter whose center frequency is at the characteristic

“ringing” frequency of the coupling circuit. This optional circuit should be included on

nodes containing an SCR or triac switching device, and in nodes operating from a nominal

V

supply of less than 12V.

A

V

A

C3

+

PLT-22

D1

Transmit Amp

C2

L2

TXOUT

C1

Line

Optional

circuit

L1

Neutral or

Earth

Receive

Front

End

RXIN

RXCOMP

L3

Figure 4.8 Functional Line-to-Neutral or Line-to-Earth Coupling Circuit

In instances where large ambient fields may be present (such as from switched mode

power supply open frame magnetic elements), it is possible that one or more of the

PLT-22 coupling circuit inductors may pick up these stray fields and conduct them

4-10 Coupling Circuits

Page 45

onto the power mains. Depending on the frequency and amplitude of these fields

they could result in failure to meet CENELEC conducted emission regulations.

If noise from parasitic coupling is suspected, it can be confirmed by inserting a 10cm

(4”) twisted wire pair in series with one of the inductors in question. If the conducted

noise spectrum varies by more than a few dB when this inductor is moved closer to,

and farther from, other components, then parasitic coupling may be the source of the

problem.

If stray coupling is a problem, regulations can usually be met by adjusting the

location or orientation of the radiating device relative to the coupling circuit

inductors. Alternately, shielded or toroidal inductors may be used to reduce coupling

as long as all electrical parameters specified in the example coupling circuit tables

given later in this chapter are met. If, however, a toroidal or shielded inductor is

used in place of L2, then the selected part must handle the maximum 1App output

current of the PLT-22 transceiver without approaching saturation. If L2 even

approaches saturation it can add harmonics of the PLT-22 transmit signal which

may result in failure to meet CENELEC emission regulations (in this instance, due

to inductor distortion instead of a stray pickup). For this reason, a shielded or

toroidal inductor used for L2 may need to have DC current rating two or three times

higher than listed in the example circuits given later in this chapter. The

recommended open frame axial inductor does not need this extra operating margin

due to the linearity provided by its magnetic path being partly in air.

Safety Issues

This guide is intended only as an introduction to some of the safety issues associated

with designing circuits using the PLT-22 transceiver. This document is not a primer

on electrical safety or electrical codes, and it is the responsibility of the user to

familiarize himself or herself with any applicable safety rules or regulations. A

review of all designs by competent safety consultants and the pertinent regulatory or

safety agencies is strongly recommended.

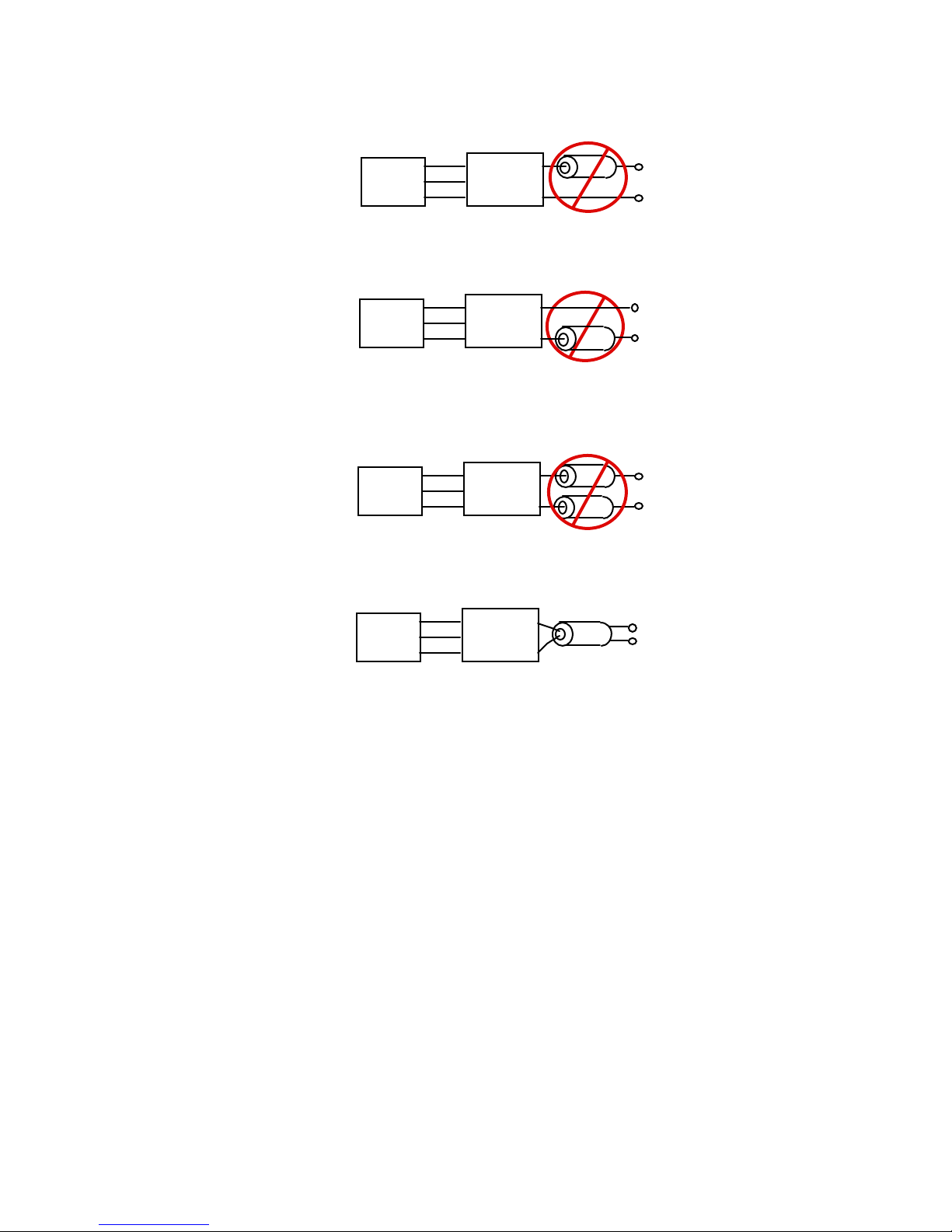

Safety Isolation Considerations

Many products include an isolation barrier in the form of an insulated enclosure