Page 1

LonPoint® Module

Hardware and Installation

User’s Guide

Version 2.0

C o r p o r a t i o n

078-0167-01B

Page 2

078-0167-01B

Echelon, LON, LONWORKS, LonBuilder, NodeBuilder, LonManager, LonTalk,

LONMARK, Neuron, 3120, 3150, LonPoint, the LonUsers logo, the LONMARK logo,

and the Echelon logo are trademarks of Echelon registered in the United States

and other countries. LonSupport and LonMaker are trademarks of Echelon

Corporation.

Other brand and product names are trademarks or registered trademarks of their

respective holders.

Neuron Chips, LonPoint Modules, and other OEM Products were not designed for

use in equipment or systems which involve danger to human health or safety or a

risk of property damage, and Echelon assumes no responsibility or liability for use

of the Neuron Chips or LonPoint Modules in such applications.

Parts manufactured by vendors other than Echelon and referenced in this

document have been described for illustrative purposes only and may not have

been tested by Echelon. It is the responsibility of the customer to determine the

suitability of these parts for each application.

ECHELON MAKES AND YOU RECEIVE NO WARRANTIES OR CONDITIONS, EXPRESS,

IMPLIED, STATUTORY OR IN ANY COMMUNICATION WITH YOU, AND ECHELON

SPECIFICALLY DISCLAIMS ANY IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE.

No part of this publication may be reproduced, stored in a retrieval system, or

transmitted, in any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without the prior written permission of

Echelon Corporation.

Model Number 39510

Printed in the United States of America.

Copyright ©1997 - 1999 by Echelon Corporation.

Echelon Corporation

4015 Miranda Avenue

Palo Alto, CA 94304, USA

www.echelon.com

Page 3

Regulatory Information

FCC NOTICE (for USA only)

Federal Communications Commission Radio Frequency Interference Statement

Warning: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential area

is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause undesired operation.

Safety

UL Listed, per UL-916.

c-UL (CSA) Certified, per C22.2, No. 205

Page 4

Page 5

Contents

1 Introduction 1-1

Applications 1-2

Audience 1-4

Content 1-4

Related Documents 1-4

2 Description of the LonPoint Modules and Base Plates 2-1

LonPoint Interface Modules 2-2

LonPoint Interface and Router Module Symbology 2-9

Network Connector 2-9

Front Panel Label 2-9

Service Switch/LED 2-9

Power or Power/Wink LED 2-10

I/O Number 2-10

Digital Input 2-10

Digital Output 2-10

Analog Input 2-10

Analog Output 2-11

Hand/Off/Auto Switch 2-11

Input Status LEDs 2-11

Output Status LEDs 2-11

Router Channel A 2-12

Router Channel B 2-12

Router Activity LED 2-12

3 Network Cabling and Connections 3-1

Network Cabling – TP/FT-10 Channel 3-2

System Performance and Cable Selection – TP/FT-10 Channel 3-4

TP/FT-10 Cable Termination 3-5

Free Topology 3-5

Doubly Terminated Bus Topology Segment 3-6

Terminating Shielded Cables for the TP/FT-10 Channel 3-6

Network Cabling – TP/XF-1250 Channel 3-7

Distribution Rule for TP/XF-1250 Channel 3-7

Terminator for TP/XF-1250 Channel 3-9

I/O Cabling 3-9

Power Cabling 3-9

4 Installation and Wiring of Base Plate 4-1

LonPoint Type 1 Base Plate Installation 4-2

Installing a Compatible Electrical Box 4-5

Connecting Wiring 4-8

LonPoint Type 1D DIN Base Plate Installation 4-9

Connecting Wiring 4-12

Connecting the Jumper Plug(s) 4-13

LonPoint Module Hardware and Installation Guide iii

Page 6

LonPoint Type 2 Base Plate Installation 4-17

Installing a Compatible Electrical Box 4-20

Connecting Wiring 4-23

LonPoint Type 2D DIN Base Plate Installation 4-24

Connecting Wiring 4-27

Connecting the Jumper Plug(s) 4-29

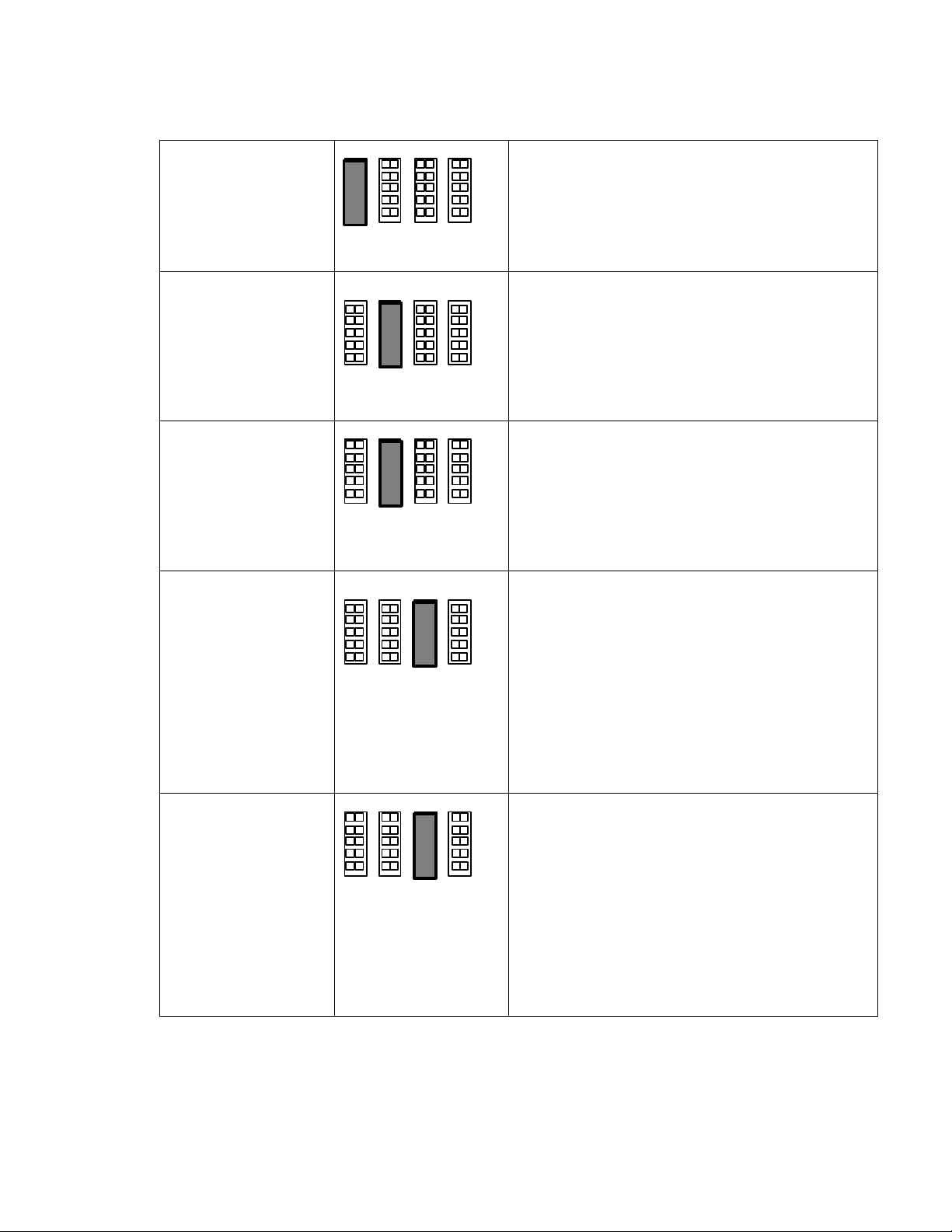

5 Installing the DI-10 Digital Input Module 5-1

LonPoint DI-10 Digital Input Module 5-2

DI-10 Module Software Settings 5-4

Installing the DI-10 Module 5-4

6 Installing the DIO-10 Digital Input/Output Module 6-1

LonPoint DIO-10 Digital Inpu/Outputt Module 6-2

DIO-10 Module Digital Inputs 6-3

DIO-10 Digital Input/Output Module Software Settings 6-5

DIO-10 Digital Input/Output Module Firmware 6-5

Installing the DIO-10 Digital Input/Output Module 6-5

7 Installing the DO-10 Digital Output Module 7-1

LonPoint DO-10 Digital Output Module 7-2

DO-10 Module Software Settings 7-5

Installing the DI-10 Module 7-5

8 Installing the AI-10 Analog Input Module 8-1

LonPoint AI-10 Analog Input Module 8-2

AI-10 Module Software Settings 8-6

Installing the AI-10 Module 8-6

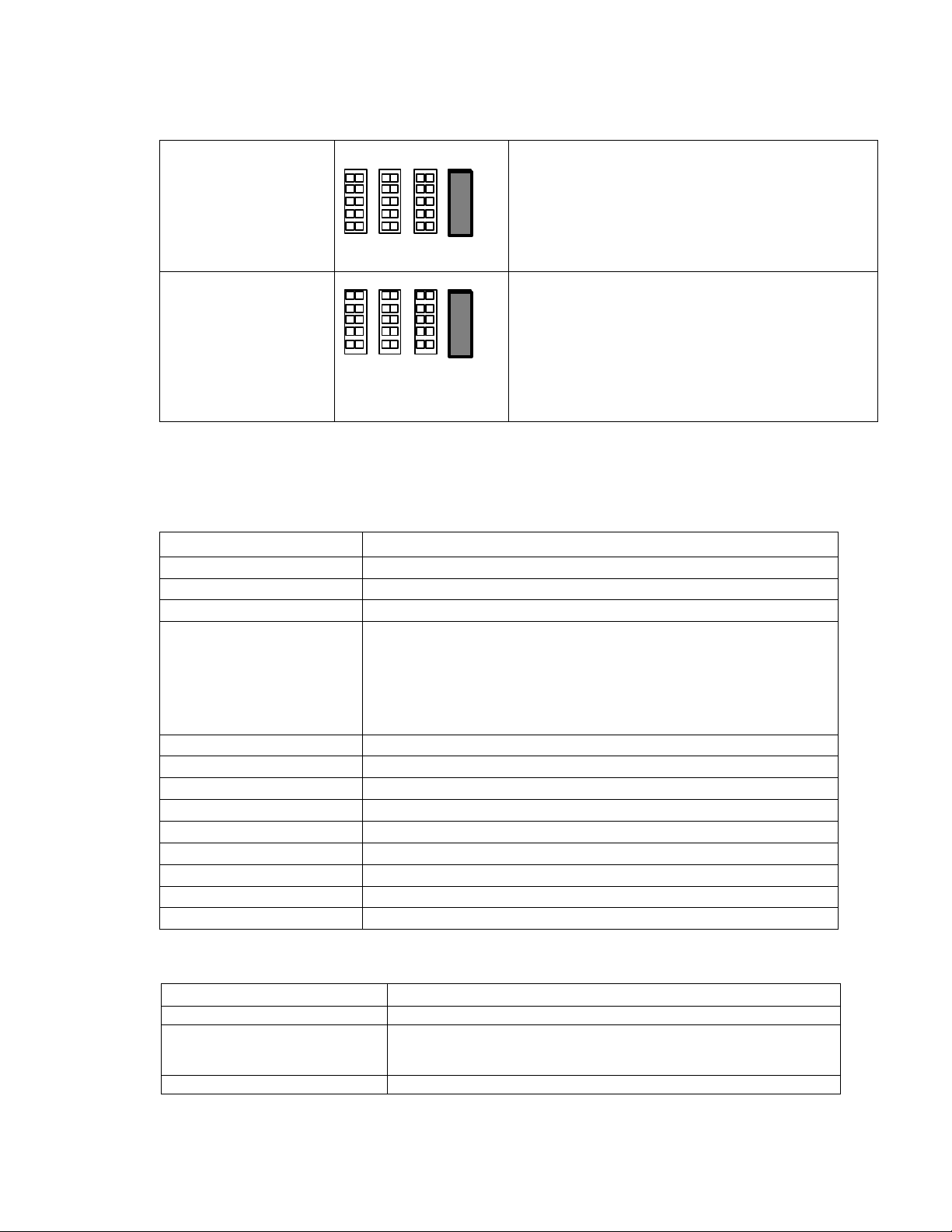

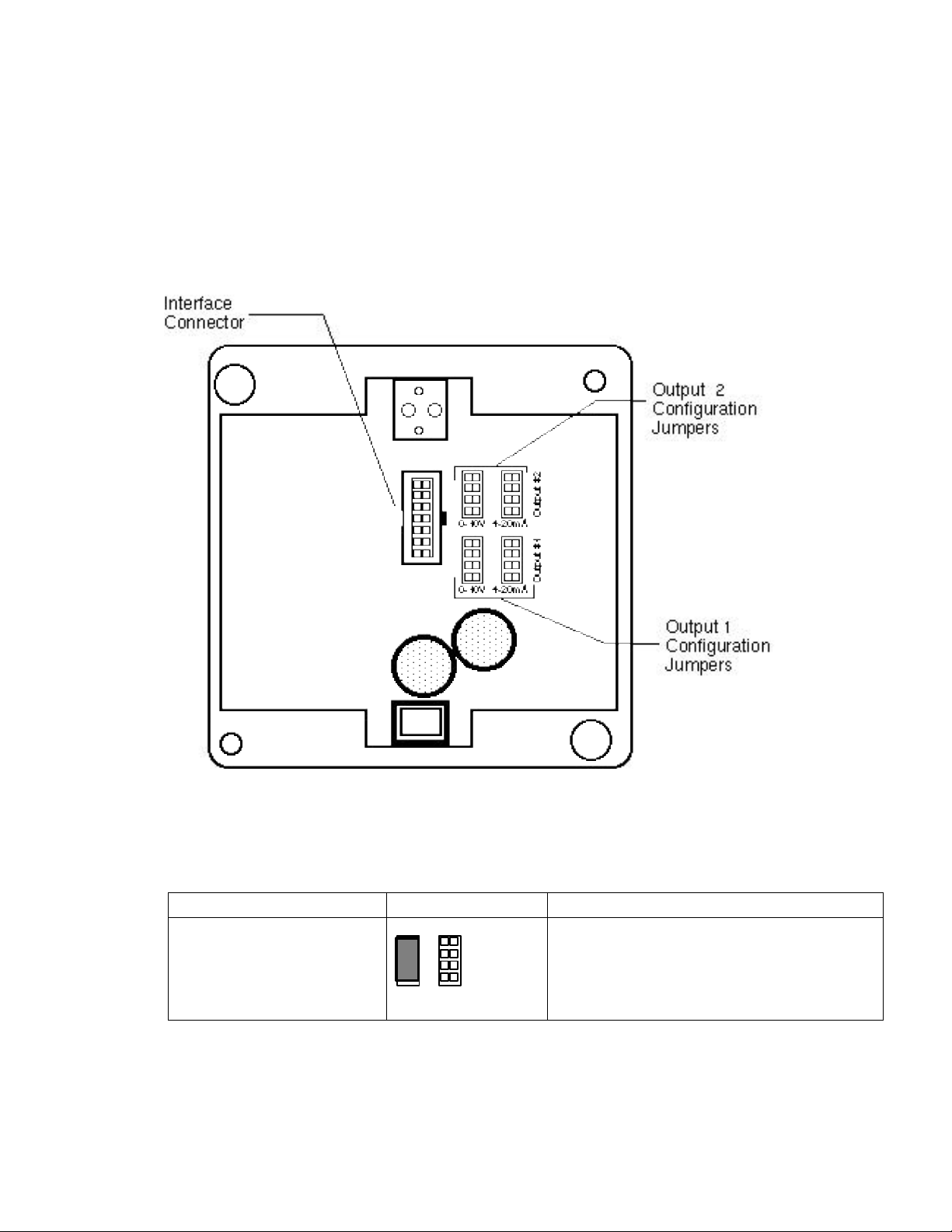

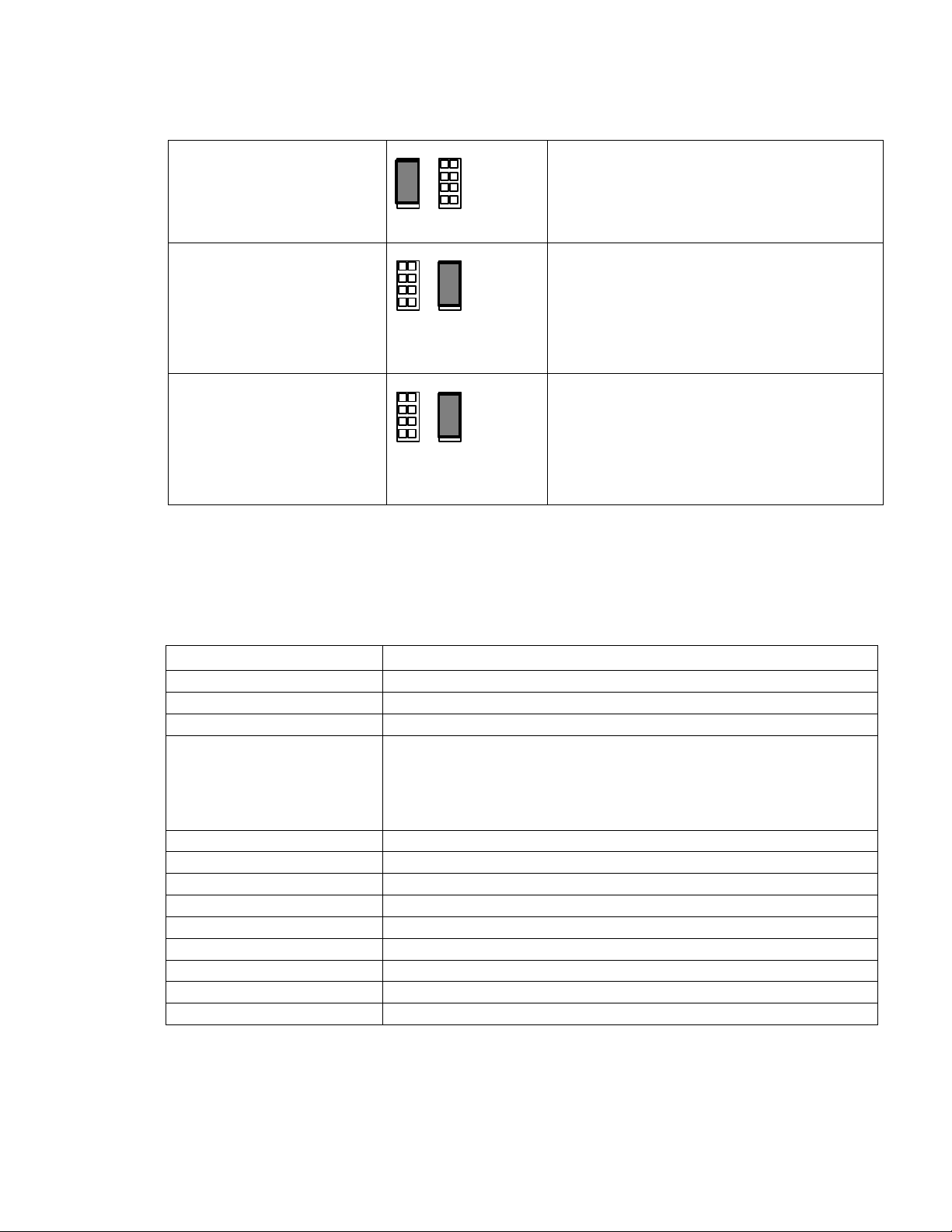

9 Installing the AO-10 Analog Output Module 9-1

LonPoint AO-10 Analog Output Module 9-2

AO-10 Module Software Settings 9-5

Installing the AO-10 Module 9-4

10 Installing the SCH-10 Scheduler Module 10-1

LonPoint SCH-10 Scheduler Module 10-2

SCH-10 Module Software Settings 10-4

Installing the SCH-10 Module 10-4

11 Installing the LPR Router Module 11-1

LonPoint LPR Router Modules 11-2

Installing the LPR Router 11-5

12 Troubleshooting 12-1

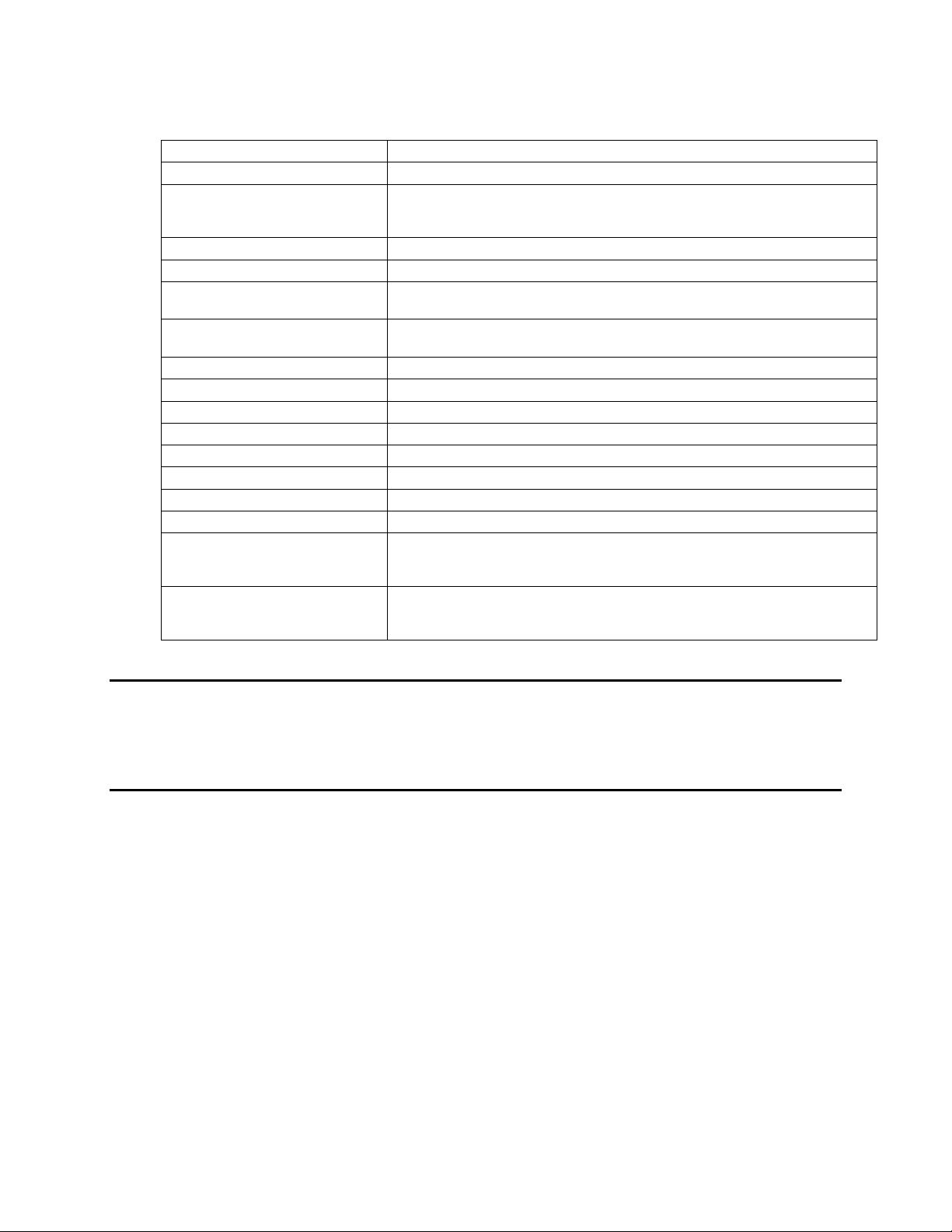

Troubleshooting Table 12-2

Declaration of Conformity

iv Echelon

Page 7

1

Introduction

The LonPoint System is a family of products designed to integrate both

new and legacy sensors and actuators into cost-effective, interoperable,

control systems for building and industrial applications. Designed to

take best advantage of the LONWORKS® Network Services (LNS)

operating system, LONMARK® interoperability, and the distributed

processing capability of the Neuron® Chip and LonTalk® protocol, the

LonPoint System provides a truly distributed control architecture that

reduces installation time, lowers installation and life-cycle costs, and can

be economically integrated into applications both large and small.

LonPoint Hardware Guide 1-1

Page 8

Applications

Traditional control networks have been based on an hierarchical architecture using

proprietary controllers. This approach to control system design is expensive, complex,

and locks the customer into a closed, non-interoperable architecture. Ultimately, the

high costs of this design approach limits the market for control systems.

Overcoming the limits of traditional, closed, hierarchical systems is best accomplished

with a flat, fully distributed control architecture. Such a system must: (a) interface

with a broad range of sensors and actuators, (b) incorporate application programs that

blur the distinction between legacy sensors/actuators and intelligent, networked

devices, (c) include a design and installation tool that can seamlessly interconnect

everything in the control network, and (d) incorporate software that simplifies

hardware configuration and reduces commissioning time. Satisfying these diverse

requirements requires a systems approach to the architecture, hardware, and software;

it cannot be accomplished easily with a piecemeal collection of devices and components.

The LonPoint System is the result of just such a systems approach, providing at once

the low cost of a flat system architecture, the multi-user capabilities of the LNS

operating system, the distributed processing of capabilities of the Neuron Chip and

LonTalk protocol, and the wiring flexibility of free topology communications. The

system consists of the LNS-based LonMaker™ for Windows® Integration Tool, the

LonPoint Plug-In, LonPoint application programs, network interfaces, and LonPoint

interface, router, and scheduler modules.

The LonMaker for Windows tool is an LNS-based installation tool with a Visio™ user

interface and support for both LonPoint devices and 3rd party LONWORKS® devices. The

Visio user-interface provides a familiar, CAD-like design environment from which a control

system can be designed. Installation consists of interconnecting function blocks

(LONMARK objects) within LonPoint modules and 3rd party devices, using their

application resources to create a distributed control system. The LonMaker for Windows

tool can be used to design, configure, and commission a distributed control network, yet is

economical enough to be left behind as a maintenance tool. The LonPoint Plug-In is

provided with the tool to simplify the configuration of LonPoint devices.

Resident within each LonPoint module is a powerful, configurable LONMARK

application program. The program includes a variety of function blocks (i.e., PID

Controller, digital encoder, analog output, digital input, type translator) that are

configured by the LonMaker for Windows tool. Linking the function blocks of multiple

LonPoint modules, together with the resources of third pary LONWORKS® devices,

creates a distributed control system that is interconnected via the network, yet which

offers greater functionality, higher reliability, and lower cost than a traditional central

controller-based system. The LonPoint System may be operated as a self-contained

control system, integrated with other LONMARK or LONWORKS devices, or combined

with remote systems and a remote supervisory station via a WAN, IP, or PSTN

network to form a wide area control system.

The LonPoint interface, scheduler, and router modules provide I/O processing,

application resources, timekeeping, and routing for a LonPoint System. The interface

®

1-2 Introduction

Page 9

modules seamlessly integrate sensors, actuators, and controllers into peer-to-peer,

interoperable networks. There are several different interface modules, including the

DI-10 Digital Input Module (4 digital inputs with a status LED per input), DO-10

Digital Output Module (4 digital outputs with a separate hand/off/auto switch and

status LED per output), DIO-10 Digital Input/Output Module (2 digital inputs, 2 relay

outputs, status LEDs and hand/off/auto switches), AI-10 Analog Input Module (2

independent 16-bit analog inputs), and AO-10 Analog Output Module (2 independent

12-bit analog outputs with PID). The SCH-10 Scheduler Module provides scheduling or

data logging for the system.

LPR Router Modules can be used to create high speed backbones, optimize network

traffic, extend the size of the network, as well as to create bridges to other channels

containing third-party devices. LPR Routers are available in any combination of TP/FT10, TP/XF-78, and TP/XF-1250 channels.

Many innovative labor-saving features have been built into the LonPoint modules to

minimize installation time:

• A two-piece design allows pre-wiring and cable testing by an electrician prior to

installing the electronics. Technician time can be reserved for tasks such as node

configuration;

• Screw terminals and polarity-insensitive power and network connections

minimize the chance of miswiring;

• All modules operate from 16-30VAC or VDC, allowing the modules to be powered

from the same sources as the sensors and actuators;

• Power and network wiring are “looped” through each base plate, providing

continuity in case of module replacement without network disruption;

• All modules can be hot-plugged, minimizing service time;

• Every module includes a front panel jack that accesses the twisted pair network

without any disassembly, saving time when the network must be accessed for

configuration or maintenance;

• All modules include a front panel bar code with the model, software revision,

and two removable Neuron Chip ID stickers. When placed on the building or

system design plans, these stickers save installation time, especially for

inaccessible nodes.

When used in the context of a complete LonPoint System, the LonPoint modules

provide tremendous flexibility and lower overall equipment, installation, and life-cycle

costs. The modules simplify programming by using a CAD-like design environment,

minimize cabling requirements by using free topology transceivers, and reduce the

need for on-site calls by offering over-the-network downloading. The LonPoint

modules support a flat architecture that is at once interoperable, lower cost to install

and maintain, and flexible enough for future adds, moves, and changes.

LonPoint Hardware Guide 1-3

Page 10

Audience

This User’s Guide is intended for anyone designing or installing a control network

using LonPoint Modules. Electricians and installation technicians involved with the

physical installation of the cable plant and hardware will find this User’s Guide

sufficient for them to complete their work. Designers and those charged with

commissioning LonPoint Modules, including those who will configure the LonPoint

software, must also review the the user’s guide for the LonMaker for Windows

Integration Tool as well as the LonPoint Application and Plug-In Guide.

Content

This manual provides detailed technical specifications on the electrical and mechanical

interfaces and operating environment characteristics for the LonPoint Modules.

Related Documentation

The following Echelon documents are suggested reading:

SLTA-10 Adapter User’s Guide (078-0160-01)

LONWORKS PCLTA-10 PC LonTalk Adapter User’s Guide (078-0159-01)

LONWORKS PCC-10 PC Card User’s Guide (078-0155-01)

LonManager Protocol Analyzer User’s Guide (078-0121-01)

LonPoint Application and Plug-In Guide (078-0166-01)

LonMaker for Windows User’s Guide (078-0168-01)

Junction Box and Wiring Guidelines for Twisted Pair LONWORKS Networks

(engineering bulletin 005-0023-02)

1-4 Introduction

Page 11

2

Description of the LonPoint

Modules and Base Plates

This chapter provides a description of the LonPoint Interface, Router, and

Scheduler modules, Type 1 and Type 2 Base Plates, and Type 1D and

Type 2D DIN Base Plates mounting enclosures.

LonPoint Hardware Guide 2-1

Page 12

LonPoint Interface Modules

The LonPoint Interface Modules are designed to monitor and control a wide variety of

analog and digital sensors and actuators, and are the primary means of interfacing a

LonPoint system to devices that lack an integral LONWORKS interface, i.e., a Neuron

Chip and transceiver. By selecting the correct LonPoint Interface Module and

configuring both its hardware and software correctly, a wide and varied assortment of

sensors and actuators can be supported.

There are five types of LonPoint Interface Modules which share a common form factor

but differ in terms of their I/O and internal software functions. The five modules

include the DI-10 Digital Input Module, DO-10 Digital Output Module, DIO-10 Digital

Input Output Module, AI-10 Analog Input Module, and AO-10 Analog Output Module.

The DI-10 Digital Input Module provides four digital inputs for supervising voltage

ranges 0-5VDC through 0-32VDC or dry contacts. Inputs are isolated from the input

power and the network but not from each other. Separate status LEDs are provided for

each input.

The DO-10 Digital Output Module includes four digital outputs rated at 0-12V, 100mA

source/sink per output, 110mA source, 400mA sink all outputs combined. Outputs are

isolated from the input power and the network but not from each other. Each output

may be separately overridden by a hand/off/auto switch accessible from the front panel.

Separate status LEDs are provided for each output.

The DIO-10 Digital Input Output Module provides two digital inputs and two relay

outputs. The digital inputs include configurable input thresholds for supervising dry

contacts or 5V, 12V, 24V, or 31V DC inputs. In addition, the digital inputs can be set to

measure frequency (20kHz) inputs. The inputs are isolated from the input power and

the network, but are not isolated from each other. Each relay output consists of a Form

A (normally open) and Form B (normally closed) contact which share a common wiper.

The relay contacts are rated for 2A continuous, 6A momentary, at 30VAC or 42VDC.

Each output may be separately controlled by a hand/off/auto switch accessible from the

front panel. Separate status LEDs are provided for each input and output.

The AI-10 Analog Input Module provides two independent 16-bit resolution analog

inputs which are isolated from the input power and the network but not from each

other. Each input can be configured via jumper blocks to monitor RTDs, thermistors,

and other types of analog inputs. Inputs can be separately configured as a voltage input,

resistive transducer input, loop-powered 0-24mA current input, or remote-powered 024mA current input. Voltage input ranges can be selected via the LonPoint Plug-in to

be 0-156mV, 0-625mV, 0-10V, or 0-20V. Current input ranges can be set via the

LonPoint Plug-in to be 0-25mA, 0-12.5mA, 0-781µA, or 0-19.5µA. Resolution in the 020V range is 0.3mV per step; current input resolution in the 0 - 25mA range is 0.37µA

per step. For resistive transducers, the module includes a configurable current source

which can be set, under software control, to provide either 25µA or 400µA current for

resistance measurement of transducers from 100 to 15k (nominal).

The AO-10 Analog Output Module offers two independent 12-bit resolution analog

outputs. Each output can be separately configured for voltage or current output, and

can drive 0-10V into a 1k load or 0-20mA or 4-20mA @ 0-12V. Outputs are isolated

from the input power and the network but not from each other.

2-2 LonPoint Modules and Base Plates

Page 13

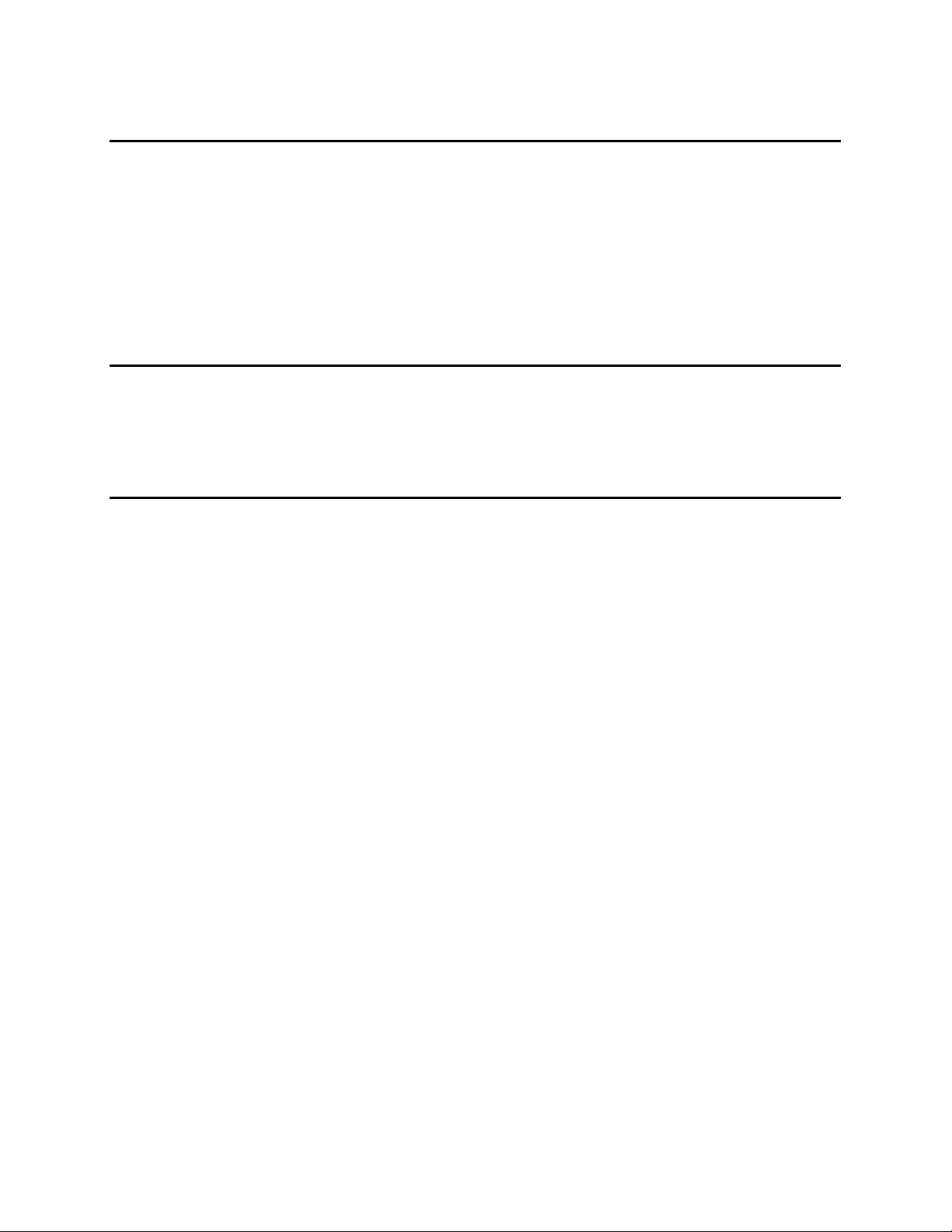

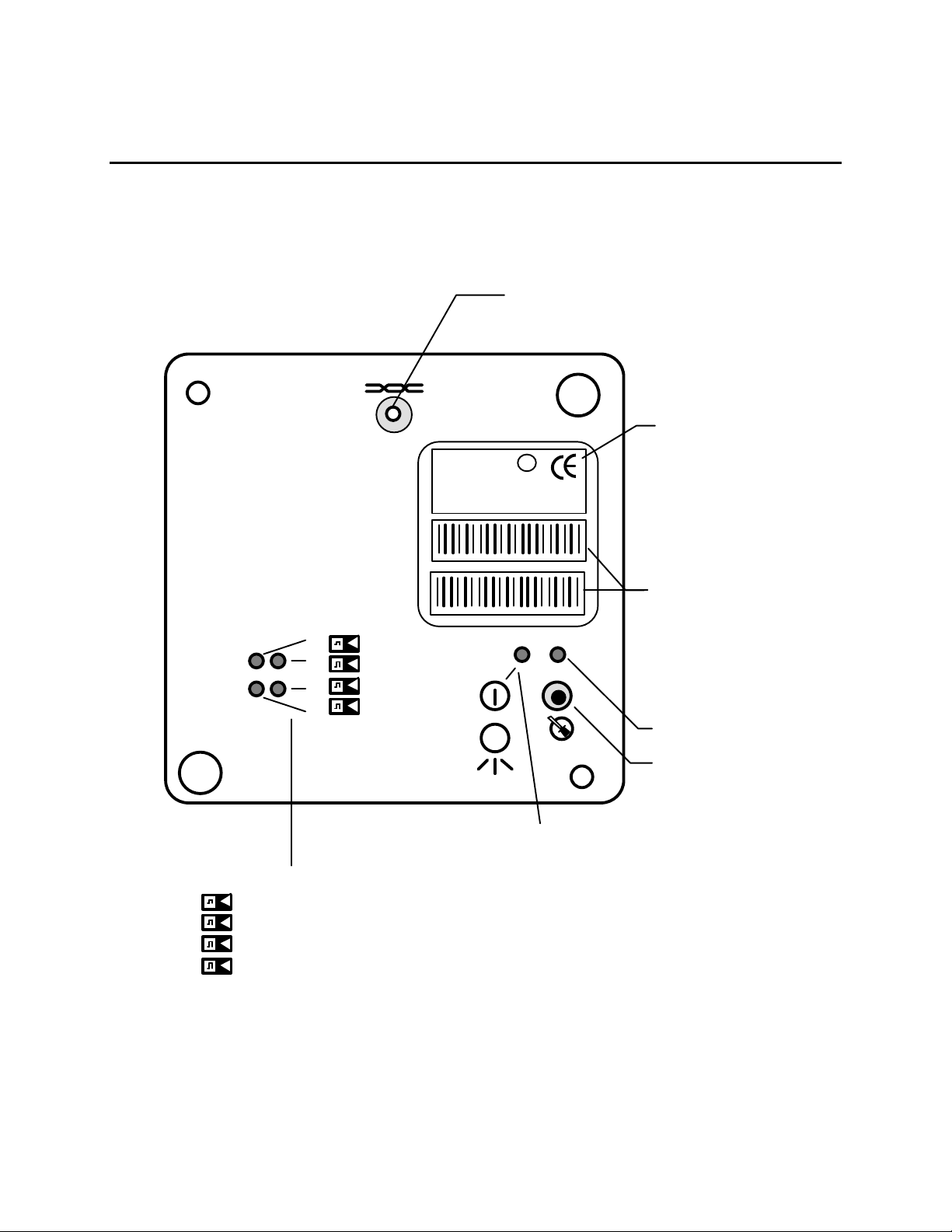

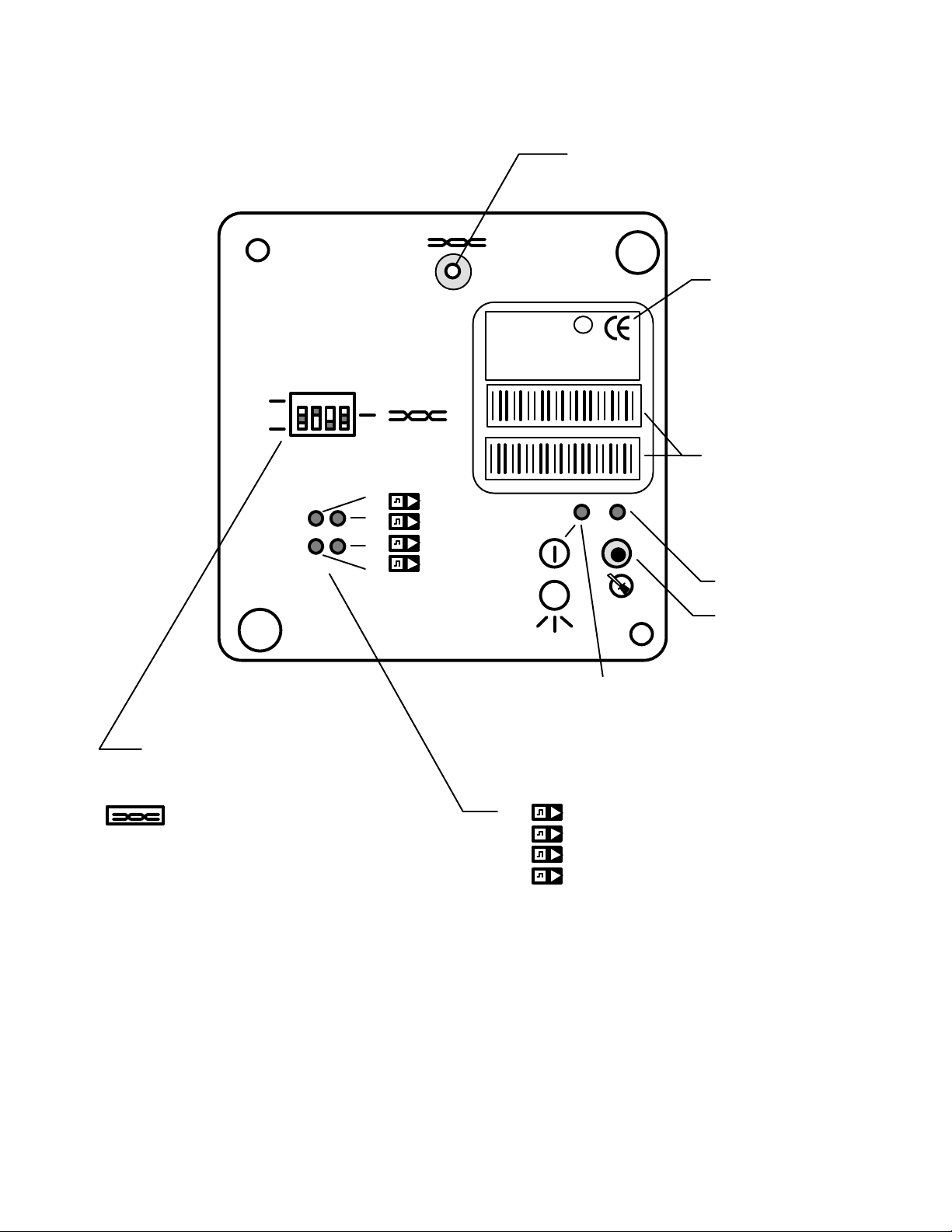

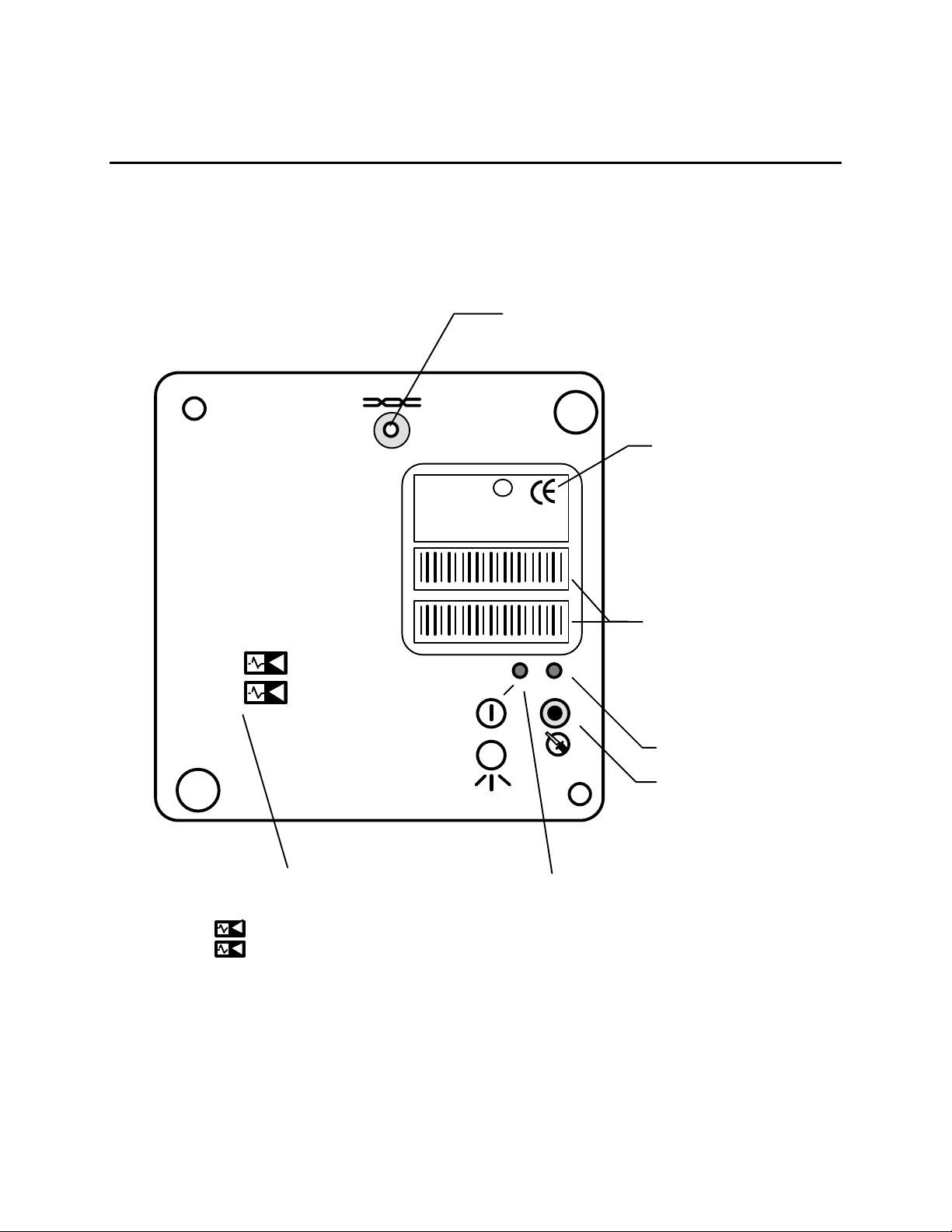

The LonPoint Interface Modules share a common form factor that includes a front panel

LonPoint™ Interface

assembly to which a printed circuit board (PCB) with active electronics is connected.

The front panel of all of the modules includes a service switch and service LED, a

combination power/wink LED, and a network connector (figure 2.1).}

E

DI-10

MODEL 41100 972

SW VERSION 1.0

ID NUMBER

INPUT: 0-32VDC

DI-10 MODEL 41100 ID NUMBER

DI-10 MODEL 41100 ID NUMBER

U

®

L

c us

m

LISTED 178K

ENERGY MANAGEMENT

EQUIPMENT SUBASSEMBLY

1

2

3

4

Figure 2.1 LonPoint Interface Module - Typical Front Panel

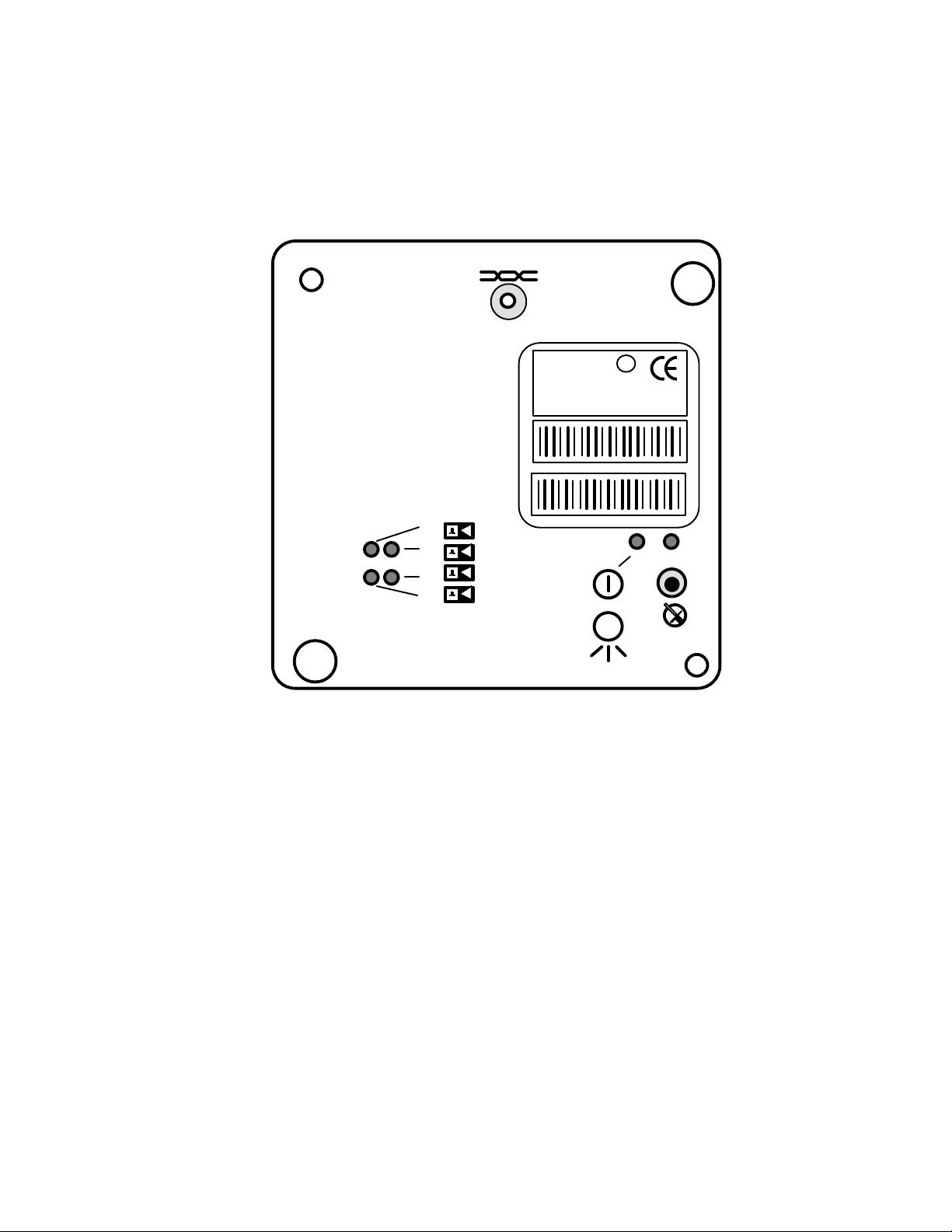

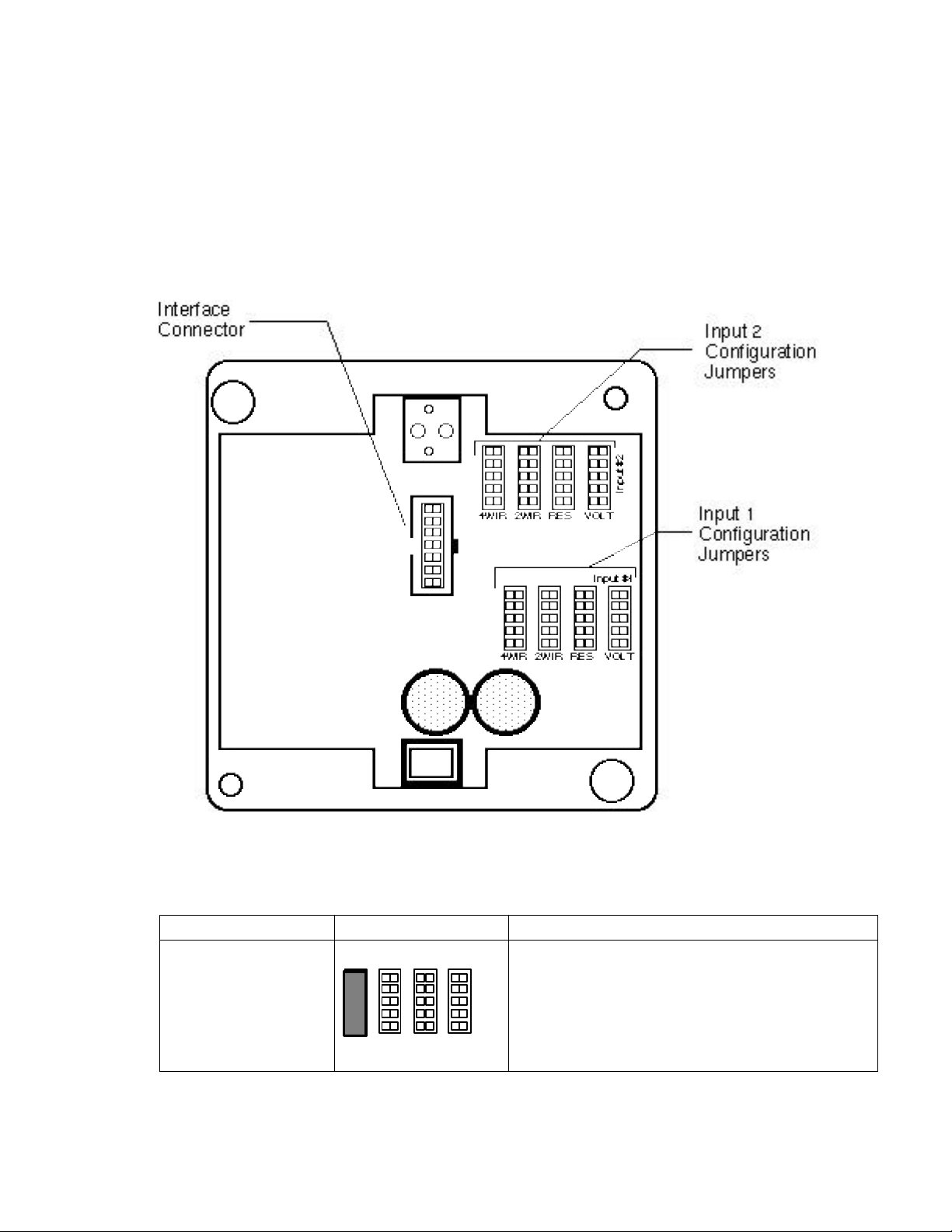

The rear of the PCB assembly includes a polarized, shrouded, 14-pin interface connector

that connects to a mating socket in a Type 1 Base Plate or Type 1D DIN Base Plate. Any

user-configured jumpers are also located on the rear of the PCB assembly (figure 2.2).

LonPoint Hardware Guide 2-3

Page 14

Figure 2.2 LonPoint Interface Module - Typical Rear Panel and Jumpers

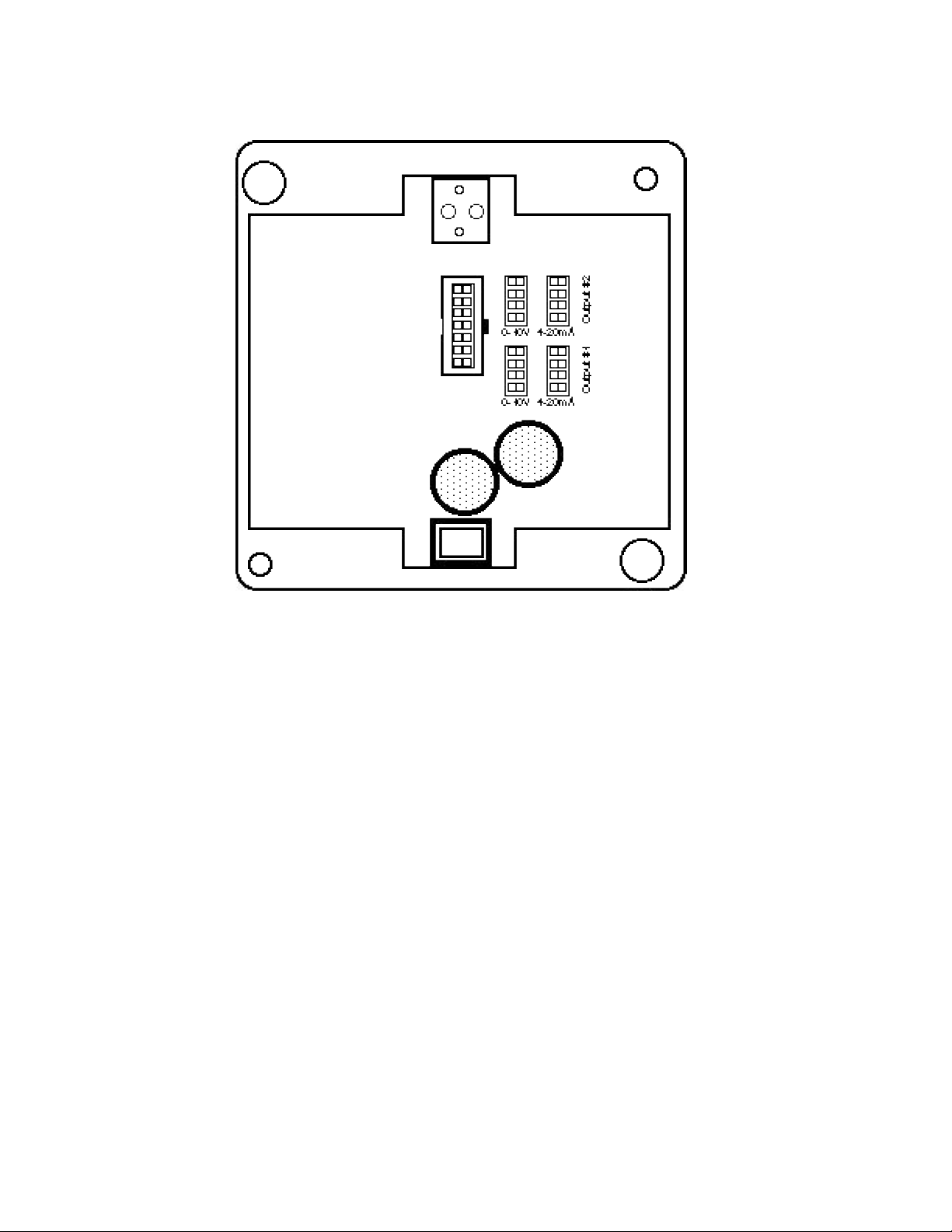

Network, power, and I/O wiring is connected to screw terminals located on a Type 1

Base Plate (figure 2.3) or Type 1D DIN Base Plate (figure 2.4), into which the LonPoint

Interface Module is plugged; no wiring is ever connected directly to an Interface Module.

A writing space is provided on the back of the Type 1 Base Plate for recording the date

of installation or other pertinent information. Installers should take care to use a finepoint (smudge-free) pen.

Type 1/1D and Type 2/2D Base Plates are keyed to prevent accidental insertion of an

incorrect module type. The Type 1 Base Plate (Model 40111) and the Type 1D DIN Base

Plate (Model 48111) will only accommodate Interface Modules and Scheduler Modules.

The Type 2 Base Plate (Model 40222) and the Type 2D DIN Base Plate (Model 48222)

will only accept LPR-1X Router Modules.

In either Type 1/1D or Type 2/2D Base Plates, the associated module is affixed to the

Base Plate by means of two 8-32, 3/8” screws (Echelon 205-0130-01) that are provided

with each module.

2-4 LonPoint Modules and Base Plates

Page 15

Figure 2.3 LonPoint Type 1 Base Plate

LonPoint Hardware Guide 2-5

Page 16

18 17 16 15 14 13 12 11 10

CAUTION

18

17

16 15 14

I/O

1A

13

12 11 10

Front View

Network

1 2

3 4 5 6 7 8 9

1 2 3 4 5 6 7 8 9

Jumper Plug

(one supplied with

each DIN Base

Plate)

Figure 2.4 LonPoint Type 1D Base Plate

2-6 LonPoint Modules and Base Plates

Page 17

The Type 1 Base Plate is mounted to either a suitable US 4” square, 2” deep (10.16cm x

5.08cm) electrical box, US double gang electrical box, plastic Echelon EuroBox (figures

2.5-2.7), or an IP-65 (NEMA 4) enclosure.

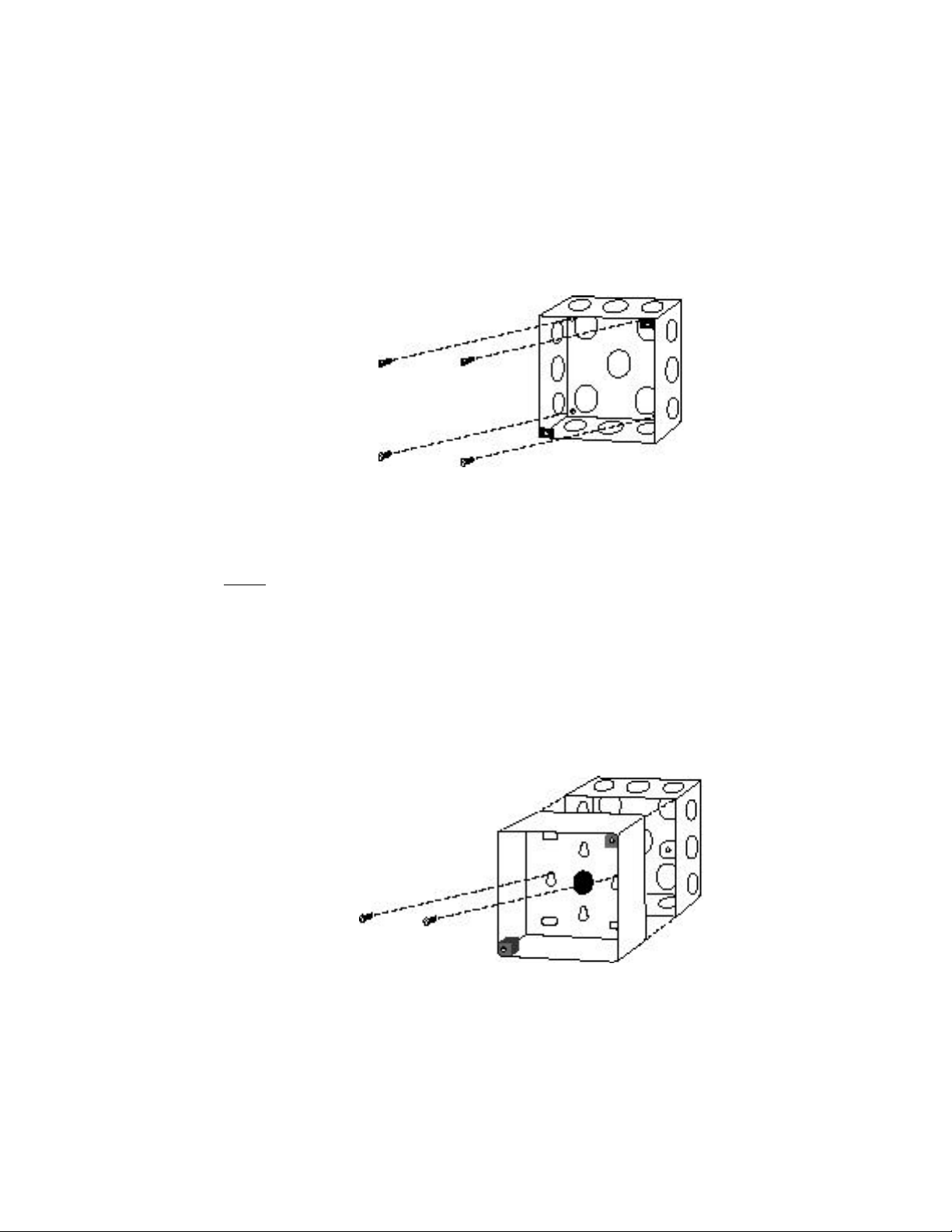

Figure 2.5 LonPoint Interface Module 4” Square (2” Deep) Electrical Box Mounting Configuration

Figure 2.6 LonPoint Interface Module Double Gang (2” Deep) Electrical Box Mounting Configuration

Figure 2.7 LonPoint Interface Module Eurobox Mounting Configuration

LonPoint Hardware Guide 2-7

Page 18

The Type 1D DIN Base Plate may be mounted to either a 35mm DIN rail or to a wall

panel (figures 2.8). A jumper plug supplied with the Base Plate permits the power and

network connections of several Type 1D DIN Base Plates to be interconnected without

additional wiring.

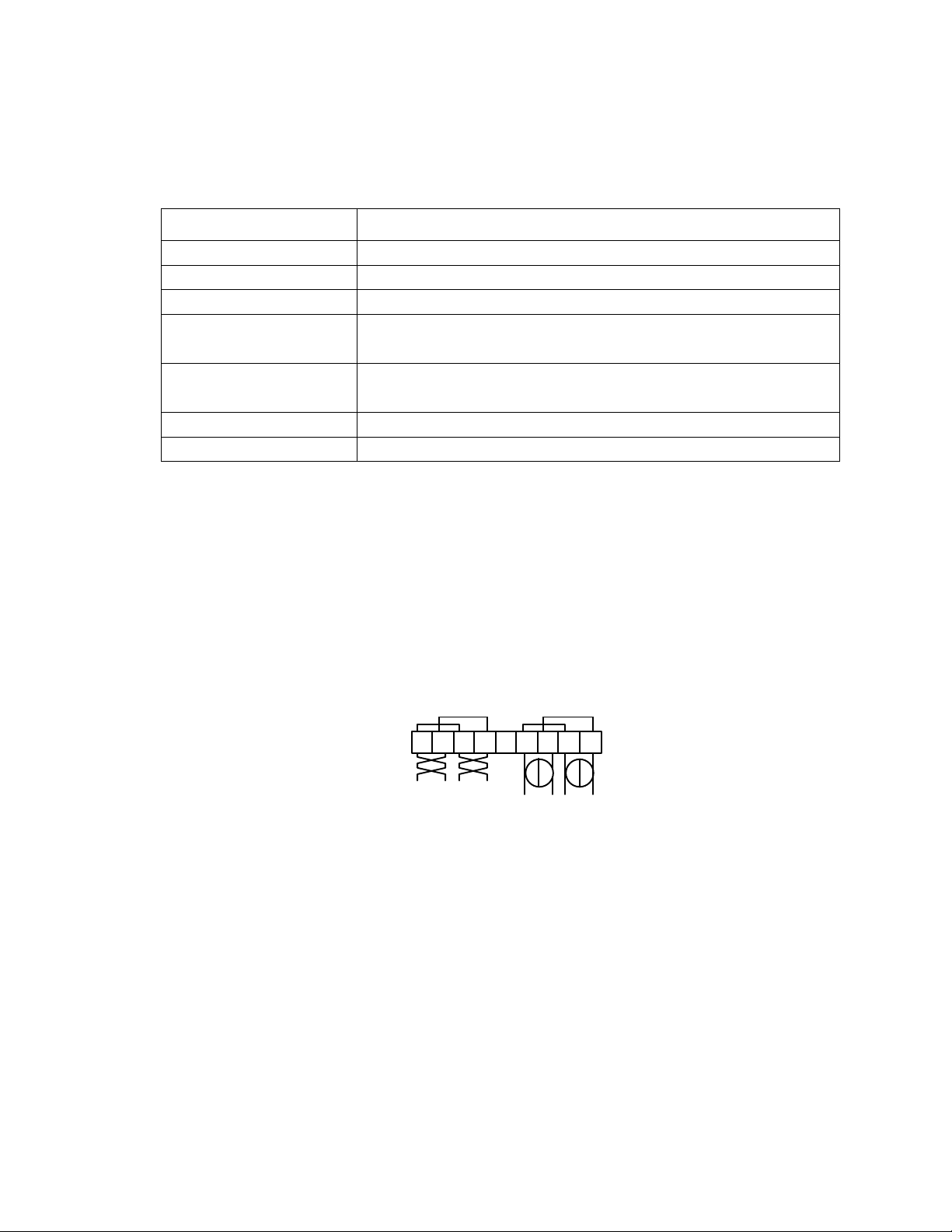

Figure 2.8 LonPoint Interface Type 1D Base Plate Mounting Configuration

Prior to installing the base plate, it is important to understand the symbology used on

the base plates, interface modules, and router modules.

2-8 LonPoint Modules and Base Plates

Page 19

LonPoint Interface and Router Module Symbology

DI-10 MODEL 41100 ID NUMBER

The front and rear panels of the LonPoint Modules and Base Plates contain legends that

identify the function of the module and its various LEDs, switches, and network

connector. A common legend marking scheme is used that allows the module to be

rotated clockwise 90° and still be legible, in the event that the mounting enclosure is

installed off axis. The symbols used are as follows:

Network Connector

Each module includes a network connector for accessing the TP/FT-10 network directly

from the front panel. This feature is intended to allow a laptop PC equipped with a

Model 73200 PCC-10 PC Card and Model 78303 cable assembly to plug into the

LonPoint module and program, monitor, troubleshoot, or update a LonPoint system.

The 3.5mm mating plug is a Hosiden 315-0201-01 miniature phone jack, or equal.

Front Panel Label

U

®

c us

DI-10

MODEL 41100 972

SW VERSION 3.0

ID NUMBER

INPUT: 0-32VDC

L

m

LISTED 178K

ENERGY MANAGEMENT

EQUIPMENT SUBASSEMBLY

DI-10 MODEL 41100 ID NUMBER

Every module is supplied with a front panel label that identifies the model number and

software version number of the module. The front panel label also includes two peel-off

Code 39 bar code labels on which are printed the Neuron Chip ID of that module (LPR

modules have two Neuron Chip IDs, one per channel). These labels are intended to

assist the installer during installation time, and may be removed from the module and

placed on installation drawings for reference purposes.

Service Switch/LED

Every module includes a service switch and LED which may be used during module

installation and to identify configured and unconfigured modules.

LonPoint Hardware Guide 2-9

Page 20

Power or Power/Wink LED

Every module includes either a power LED or a combination power/wink LED. The

wink function is used by a network management/installation tool to visually identify a

particular module; the wink command causes the power LED to blink.

I/O Number

1

2

3

4

Every input and output symbol is accompanied by an I/O Number designating which

hardware input or output the function is associated. The DI-10 has four inputs, the DO10 has four outputs, the DIO-10 has two inputs and two outputs, the AI-10 has two

inputs, and the AO-10 has two outputs.

Digital Input

This symbol designates the I/O as a digital input and is accompanied by an I/O Number.

Digital Output

This symbol designates the I/O as a digital or relay output and is accompanied by an I/O

Number.

Analog Input

This symbol designates the I/O as an analog input and is accompanied by an I/O

Number.

2-10 LonPoint Modules and Base Plates

Page 21

Analog Output

0

4

4

This symbol designates the I/O as an analog output and is accompanied by an I/O

Number.

Hand/Off/Auto Switch

1 2 3 4

1 2 3 4

1

1 2

DO-10 Hand/Off/Auto Switch DIO-10 Hand/Off/Auto Switch

The DO-10 and DIO-10 modules include a Hand/Off/Auto switch that allows the user to

determine the mode of operation of the outputs. One three-position switch is provided

for each of the four outputs. The switch positions function as follows:

1 2 3 4

1 Output turned ON (voltage level high or relay actuated)

0 Output turned OFF (voltage level low or relay not actuated)

Output state is determined automatically according configuration programs

loaded into the LonPoint modules on the network.

Input Status LEDs

1

2

3

Input status LEDs indicate the state of the inputs.

Output Status LEDs

1

2

3

Output status LEDs indicate the logical state of the outputs.

LonPoint Hardware Guide 2-11

Page 22

Router Channel A

A

LPR Routers route packets between two twisted pair channels, designated A and B.

Router Channel B

B

LPR Routers route packets between two twisted pair channels, designated A and B.

Router Activity LED

Indicates that a router is transferring packets from one channel to another.

2-12 LonPoint Modules and Base Plates

Page 23

3

Network Cabling and Connections

This chapter provides information about network, power, and

input/output cabling for the LonPoint system.

LonPoint Hardware Guide 3-1

Page 24

Network Cabling - TP/FT-10 Channel

The LonPoint modules (excluding some LPR Routers) use Echelon’s FTT-10A Free

Topology Transceiver for network communications. This transceiver operates at 78

kilobits per second and is designed to support free topology wiring; it will accommodate

bus, star, loop, or any combination of these cabling topologies using a twisted pair cable.

By eliminating restrictions on the cabling topology, the installer is free to locate

LonPoint modules anywhere on the network cabling provided only that the maximum

cabling distance limitations are observed99 This capability simplifies system installation

and makes it easy to add nodes should the network need to be expanded. Figures 3.1

through 3.5 present five typical network topologies.

In free topology cabling it is necessary to use one Echelon Model 44100 terminator.

In bus topology cabling it is necessary to use two Echelon Model 44101 terminators.

Terminators are required for proper network operation and must not be omitted.

Termination

Figure 3.1 Singly Terminated Bus Topology (Model 44100 Terminator)

Termination

Figure 3.2 Star Topology (Model 44100 Terminator)

Termination

Figure 3.3 Loop Topology (Model 44100 Terminator)

3-2 Network Cabling and Connections

Page 25

Termination

Figure 3.4 Mixed Topology (Model 44100 Terminator)

TerminationTermination

Figure 3.5 Doubly Terminated Bus Topology - Used for Very Long Cabling Distances

(Two Model 44101 Terminators)

A network consisting of LonPoint modules using the FTT-10A transceiver is said to

reside on a “TP/FT-10 channel.” In some cases all of the LonPoint modules will be

connected to a single TP/FT-10 channel. A maximum of 64 devices (LonPoint

modules, routers, PCLTA-10 and PCC-10 PC adapters, third-party LONMARK

®

devices) may be connected to any one channel. If more than 64 devices are to be

used, or if it is necessary to add more cabling than is permitted on a single channel,

then one or more model 42100 LPR-10 Routers (TP/FT-10 to TP/FT-10) would be

placed in series with the network cabling.

Another application for the LPR Router is to limit the amount of network

communications passing between different parts of a control network. For example,

LPR Routers can restrict the transfer of messages from a portion of the network

with many active PID loops to other, more quiescent parts of the network. In this

case one or more model 42100 LPR-10 Routers would be placed in series with the

network cabling.

The LPR Router can also be used to create a high-speed backbone that brings

together many different channels, perhaps to a monitoring PC. In this case it may

be desirable to increase the speed of the backbone channel in order to better manage

the communication traffic. For example, in a highrise building it might be desirable

to have a78 kilobit per second TP/FT-10 free topology channel operating on each

floor, and use a 1.25 megabit per second channel to link together all of the floor

channels with a PC in the basement. In this case, one model 42102 LPR-12 Router

(TP/FT-10 to TP/XF-1250) would be placed on each floor and a separate 1.25Mbps

twisted pair channel would serve as a backbone.

LonPoint Hardware Guide 3-3

Page 26

The Model 42100 LPR-10 Router (TP/FT-10 to TP/FT-10) uses the TP/FT-10 channel

cabling scheme. The Model 42102 LPR-12 Router (TP/FT-10 to TP/XF-1250) uses a

different cabling scheme that is designed to handle high speed, 1.25Mbps

communications. This 1.25Mbps cabling scheme is described in a later section.

System Performance and Cable Selection - TP/FT-10 Channel

The system designer may choose a variety of cables, depending on cost, availability,

and performance. Currently, Echelon has documented system performance on the

cable types shown in tables 3.1 and 3.2. Up to 64 devices may be connected to each

channel; one or more Model 42100 LPR-10 Routers may be used to increase the

number of devices and cable distance. Network performance specifications assume

that the average wire temperature is +55°C, although individual segments of wire

may be as hot as +85°C.

The free topology transmission specification includes two components which must

both be met for proper system operation. The distance from each LonPoint module,

network interface, or third party device to all other devices, and the distance from

each LonPoint module, network interface, or third-party device to the Model 44100

Terminator, must not exceed the maximum node-to-node distance. If multiple paths

exist, e.g., a loop topology, then the longest path should be used for the calculations.

The maximum total wire length is the total amount of wire connected per channel.

Table 3.1 Free Topology Specifications

Maximum

node-to-node

distance

Belden 85102 500 meters 500 meters 16AWG/1.3mm

Belden 8471 400 meters 500 meters 16AWG/1.3mm

Level IV, 22AWG 400 meters 500 meters 22AWG/0.65mm

JY (St) Y 2x2x0.8 320 meters 500 meters 20.4AWG/0.8mm

TIA Category 5 250 meters 450 meters 24AWG/0.51mm

Maximum total

wire length

Wire Diameter

AWG/mm

3-4 Network Cabling and Connections

Page 27

If a shielded cable is used, the shield should be connected to earth ground via the

termination circuit shown in the LONWORKS FTT-10A Free Topology Transceiver

User's Guide, version 5 or later.

Distributors of cable are listed in Echelon’s engineering bulletin, Junction Box and

Wiring Guidelines, part number 005-0023-01.

Table 3.2 Doubly-Terminated Bus Topology Specifications

(Requires Two Model 44101 Terminators)

Wire Diameter

Maximum bus length

AWG/mm

Belden 85102 2700 meters 16AWG/1.3mm

Belden 8471 2700 meters 16AWG/1.3mm

Level IV, 22AWG 1400 meters 22AWG/0.65mm

JY (St) Y 2x2x0.8 900 meters 20.4AWG/0.8mm

TIA Category 5 900 meters 24AWG/0.51mm

A doubly-terminated bus may have cable lengths (stubs) of up to 3 meters from the

bus to each LonPoint module, network interface, or third-party device.

TP/FT-10 Cable Termination

The TP/FT-10 channel must be terminated for proper data transmission performance.

Free Topology

If free topology cabling is used then only one Model 44100 Terminator is required and

may be placed anywhere on the free topology segment, as shown in figure 3.6. The

Model 44100 Terminator's orange wires should be connected to the twisted pair

network. The Terminator's green wire must be connected to earth ground. The green

wire must never be connected to the shield of a twisted pair cable.

orange

44100

Terminator

Figure 3.6 Single Termination for Free Topology (Model 44100 Terminator)

green

Network

Termination

LonPoint Hardware Guide 3-5

Page 28

Doubly Terminated Bus Topology Segment

+

+

If a doubly-terminated bus topology is used, then two Model 44101 terminators are

required, one at each end of the bus, as shown in figure 3.7. The Model 44100

Terminator's orange wires should be connected to the twisted pair network. The

Terminator's green wire must be connected to earth ground. The green wire must

never be connected to the shield of a twisted pair cable.

orange

green

44100

Terminator

orange

green

Network

TerminationTermination

Network

Figure 3.7 Double Termination for Bus Topology (Two Model 44101 Terminators)

Terminating Shielded Cables for the TP/FT-10 Channel

Model 44100 and 44101 Terminators are intended for use exclusively with unshielded

twisted pair cables and must NOT be used as terminators for shielded cables. If a

shielded cable is to be used then special Terminators must be fabricated for both free

topology and bus cabling architectures. These special Terminators will ensure the

effectiveness of the shield in providing noise immunity in electromagnetically harsh

environments. Figure 3.8 presents the schematic for a Free Topology Shielded Cable

termination.

C1 R2 R4

Network

Cable

Terminator

Ground

44101

R1

Network

Cable

Cable

Shield

C2 R3

78.7

1%, 1/8W

R1, R2, R3

R4

C1, C2

ž,

150ž, 1%, 1/8W

100µF±10%, 50V minimum aluminumelectrolytic type (observe polarity)

Figure 3.8 Free Topology Network Terminator for use with Shielded Cables

(Use only one Terminator.)

Figure 3.9 presents the schematic for a Bus Topology Shielded Cable termination.

3-6 Network Cabling and Connections

Page 29

C1 R2 R4

+

+

Network

Cable

R1

Network

Cable

C2 R3

ž,

316

R1,

R2, R3

R4

C1, C2

1%, 1/8W

ž,

78.7

1%, 1/8W

150ž, 1%, 1/8W

100µF±10%, 50V minimum aluminumelectrolytic type (observe polarity)

Figure 3.9 Bus Topology Network Terminators for use with Shielded Cables (Two Required)

Network Cabling - TP/XF-1250 Channel

If a high-speed backbone is created using the Model 42102 LPR-12 Routers (TP/FT-10

to TP/XF-1250), then a doubly-terminated bus topology using data grade cable that is

intended specifically for this channel must be installed. The TP/XF-1250 channel can

be used only with Level IV, 22 AWG (0.65mm) twisted pair cable, and the channel

must be terminated at each end with a Model 44200 Terminator (do NOT use the

Model 44100 or 44101 Terminators.) Suppliers of cable are listed in Echelon’s

engineering bulletin, Junction Box and Wiring Guidelines, part number 005-0023-01,

Rev D or higher.

Ground

Cable

Shield

Under no circumstances should smaller gauge Level IV cable be substituted for Level

IV, 22 AWG (0.65mm) twisted pair cable. Echelon periodically qualifies new cables for

twisted pair transceivers, and it is advisable to check with Echelon from time to time

to determine if new cables are available. DO NOT attempt to use any other type of

cabling, including but not limited to Category 5 data cabling, or improper or erratic

operation will result.

A maximum of sixty-four (64) Model 42102 LPR-12 Routers (TP/FT-10 to TP/XF-1250), PC

adapters, and other devices can be installed on a backbone channel, with a maximum

cable length of 130 meters with a maximum stub length of 1 feet (0.3m). If additional

cabling or devices must be installed, then one or more model 42105 LPR-15 (TP/XF-1250

to TP/XF-1250) Routers may be placed in series with the backbone cabling.

Distribution Rule for TP/XF-1250 Channel

Due to the transmission characteristics of the TP/XF-1250 channel, communication

failures may result from reflections of the TPT/XF-1250 transceiver’s 1.25Mbps

LonPoint Hardware Guide 3-7

transmitted signal under conditions where devices are concentrated in one point of

cabling. These communication failures are eliminated when devices are used in a

Page 30

distributed configuration. For this reason, it is essential to follow a simple topology

rule when using the TPT/XF-1250 channel.

Referred to as the “8-in-16” topology rule, this rule requires that no more than 8

devices be connected to the TP/XF-1250 channel within any 16 meter length of cable.

This means that no matter where along the bus the 16 meter measurement is taken,

there should be no more than 8 devices. Figure 3.10 provides a diagram of such a

measurement technique.

Figure 3.10 8-in-16 Topology Rule Example

In the example we see an installation with six groups of devices, varying in size from 2

to 7 devices, in a doubly-terminated bus that is terminated with Model 44200

Terminators. By using a 16 meter measurement stick that we can move from side-toside over the length of the bus, we can determine whether the 8-in-16 rule has been

met (designated by the word "OK") or violated (shown by the designation "PROBLEM").

In the case of the PROBLEM area, a total of 13 devices are located within a 16 meter

length of the bus, which amounts to five more devcies than are permitted under the 8in-16 rule.

There are two solutions that can be applied to situations in which the 8-in-16 rule has

been, or must be, violated by virtue of the installation scenario. The first and simplest

remedy is to insert a Model 42105 LPR-15 Router (TP/XF-1250 to TP/XF-1250) and two

Model 44200 Terminators in the bus to break the network into two channels (figure 3.11).

Since each side of the router comprises a different channel, the bus is effectively split and

the nodes divided between two channels.

Figure 3.11 Using a Router to Meet the 8-in-16 Topology Rule

The second remedy to a violation of the 8-in-16 rule is to add additional cable to the

bus such that the rule is no longer violated (figure 3.12). It is important to ensure

that the maximum bus length (130 meters of 22AWG/0.65mm Level IV twisted pair)

is not exceeded by the additional cable. Due to the complex interactions between the

bus and the devcies with regard to reflections and transmission line delays, it is not

possible to substitute an inductor/capacitor network in lieu of the additional cable to

resolve this rule violation.

3-8 Network Cabling and Connections

Page 31

Figure 3.12 Using Additional Bus Cable to Meet the 8-in-16 Topology Rule

Terminator for TP/XF-1250 Channel

It is necessary to terminate both endpoints of the TP/XF-1250 channel twisted pair

bus for proper data transmission performance. Failure to terminate the bus will

degrade network performance. Use only the Model 44200 Terminator, and connect

it as shown in figure 3.13.

orange

44200

Terminator

Network

green

Figure 3.13 Double Termination for Bus Topology (Two Model 44200 Terminators)

I/O Cabling

The installer generally has wide latitude in the type of cabling selected for the I/O.

It is good practice to ensure that all I/O cabling is made from twisted pair wire, as

this has the advantage of minimizing susceptibility to differential noise. If the sensor

or actuator requires a shield then a ground will have to be provided in the electrical

box since the LonPoint modules are floating and do not include a ground screw

connection. Note when selecting the I/O cabling that the Base Plate screw terminals

accommodate wire guages from 24AWG/0.5mm to 12AWG/2mm. In all cases, use at

least 90°C rated wire.

Power Cabling

orange

TerminationTermination

Network

green

44200

Terminator

It is important to note that a maximum of 16 Amperes RMS at 24VAC RMS can be

passed through the internal jumpers on the Power terminals of the Type 1/2 Base

Plates, 10 Amperes RMS at 24 VAC RMS for Type 1D/2D DIN Base Plates using

Jumper Plugs. This means that if power wiring is looped in and out of the power

terminals of the LonPoint Base Plates, the current load presented by all of the

LonPoint modules and any other devices powered by that circuit must be 16

Amperes ( 10 Amperes for Type 1D/2D DIN Base Plates using Jumper Plugs), as

LonPoint Hardware Guide 3-9

Page 32

shown in figure 3.14. If >16 Amperes (>10 Amperes RMS at 24 VAC RMS for Type

1D/2D DIN Base Plates using Jumper Plugs) must be supplied then the loopthrough capability of the LonPoint Base Plate power terminals must not be used and

the power cabling should be run in parallel, as shown in figure 3.15. To calculate

the load current, divide the total VA (sum of all devices powered by the power

supply) by the power supply voltage. For example, if the total VA of all LonPoint

Modules and sensors/actuators equals 100VA, and the power supply provides 24

VAC, then the load current is 4.16A.

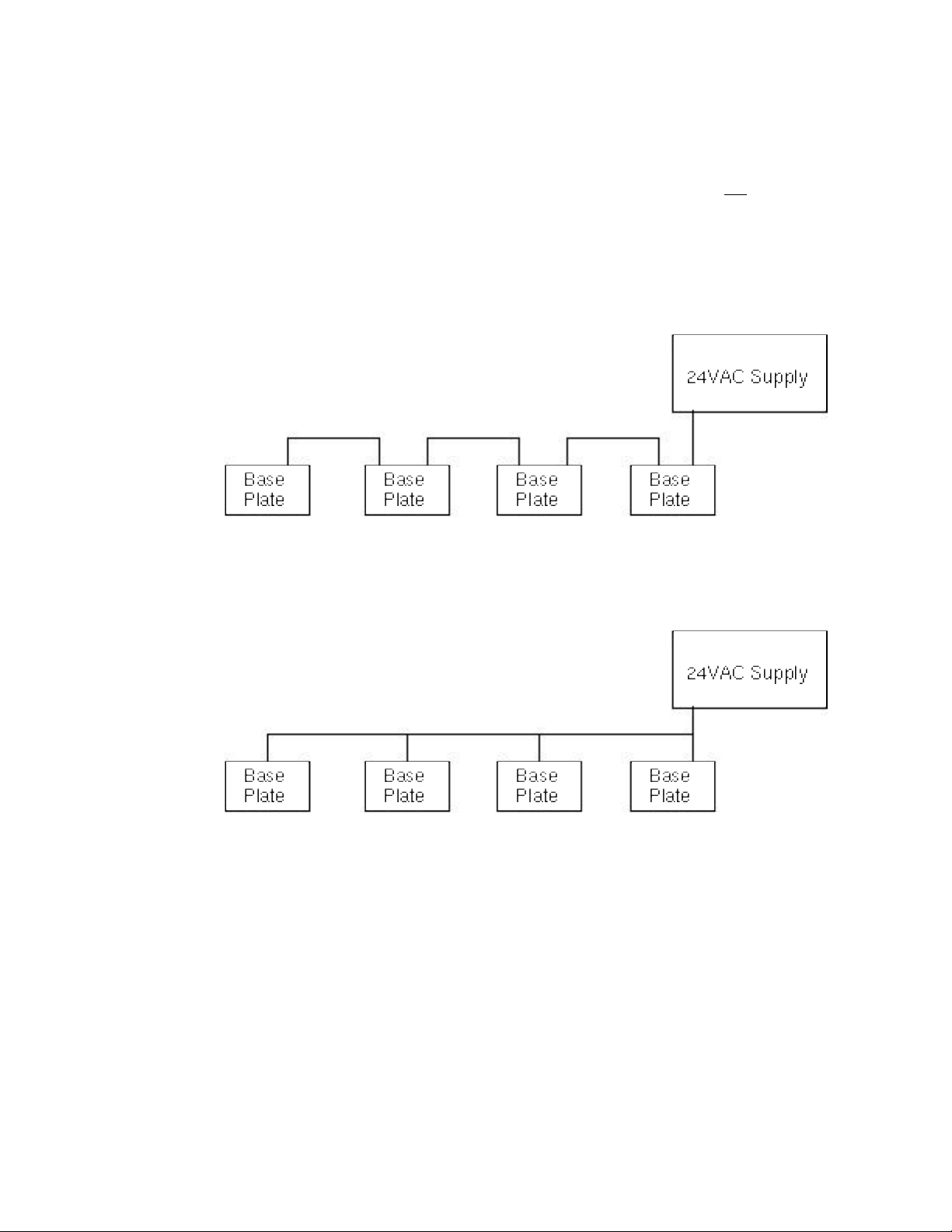

Figure 3.14 Looped-through Power Wiring - •16 Amperes at 24VAC for Type 1/2 Base

Plates, •10 Amperes for Type 1D/2D DIN Base Plates using Jumper Plugs

Figure 3.15 Parallel Power Wiring - >16 Amperes at 24VAC for Type 1/2 Base Plates,

•10 Amperes for Type 1D/2D DIN Base Plates using Jumper Plugs

As a rule of thumb, it is recommended that power and I/O cabling be separated by

18”/ 46cm to prevent inadvertent pick-up of noise from the power circuit by sensitive

analog I/O cabling. Power and network twisted pairs may be combined in a common

cable if using an approved network cable.

Depending on the model, the LonPoint modules require between 2 and 6.5VA at an

operating voltage of 16 to 30V DC or AC. The LonPoint Type 1/1D and Type 2/2D

Base Plates include a power-looping capability that provides continuity through the

Base Plate - even if the LonPoint module is removed - when the power cabling is

daisy-chained through each Base Plate.

3-10 Network Cabling and Connections

Page 33

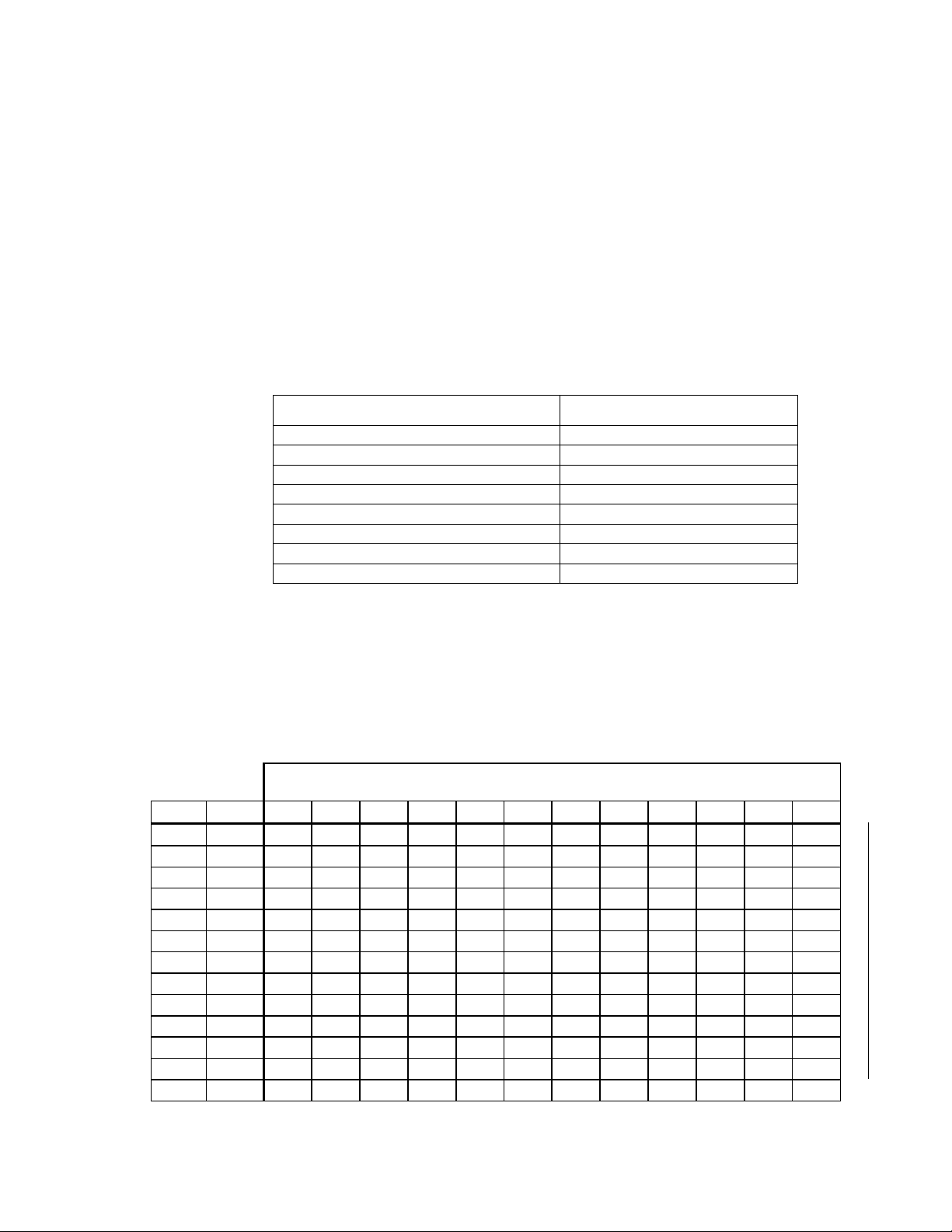

Tables 3.4 and 3.5 present the wire gauge that should be used in order to deliver the

Meters

AWG

specified power (total VA) across the distance shown. These tables only include wire

gauges from 24AWG (0.5mm) to 12AWG (2mm) as these are the wire gauges

supported by the Base Plate screw terminals. For the supply cabling use at least

24AWG/0.5mm, 90° C rated wire.

To determine the total power that a power cable must carry, total the VA

requirements for all of the devices that will be drawing power from that cable,

including both LonPoint modules and other devices. The VA ratings for the

LonPoint Modules are shown in the module data sheets and are summarized in the

following table.

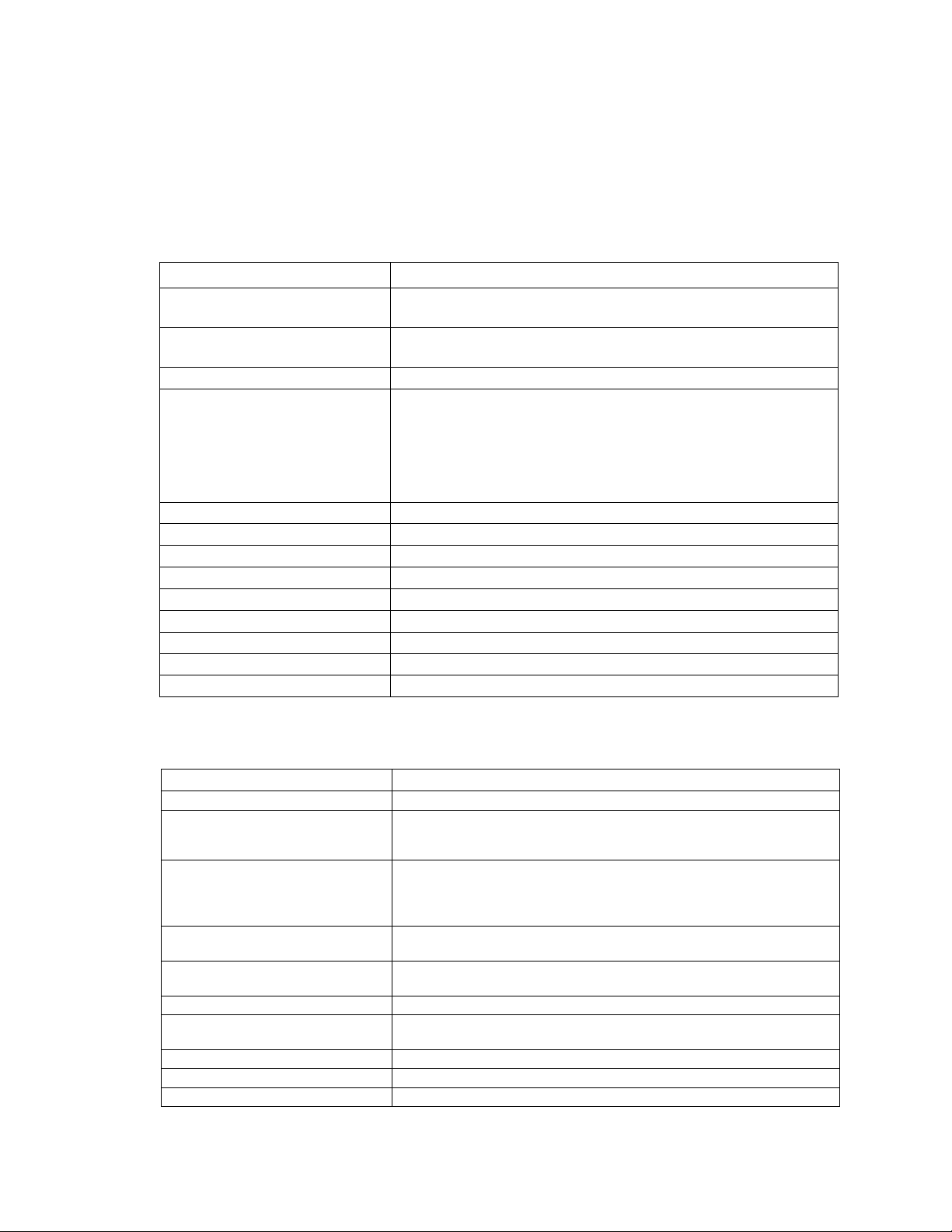

Table 3.3 VA Ratings for LonPoint Modules

LonPoint Module VA Rating

DI-10 2.2VA

DO-10 6.5VA

DIO-10 4.75VA

AI-10 (all modes except 2-wire mode) 2.1VA

AI-10 (2-wire mode) 4.5VA

AO-10 4.5VA

SCH-10 2.4VA

LPR 2.0VA

To determine what gauge cable (in AWG or metric) will be required based on the total distance of

the power cabling, refer to table 3.4 for cabling measured in AWG and table 3.4 for cabling

measured in mm. If the wire gauge used is smaller than required, improper operation of one of

more modules will result. All data in tables 3.4 and 3.5 assume an average wire temperature of

+55°C.

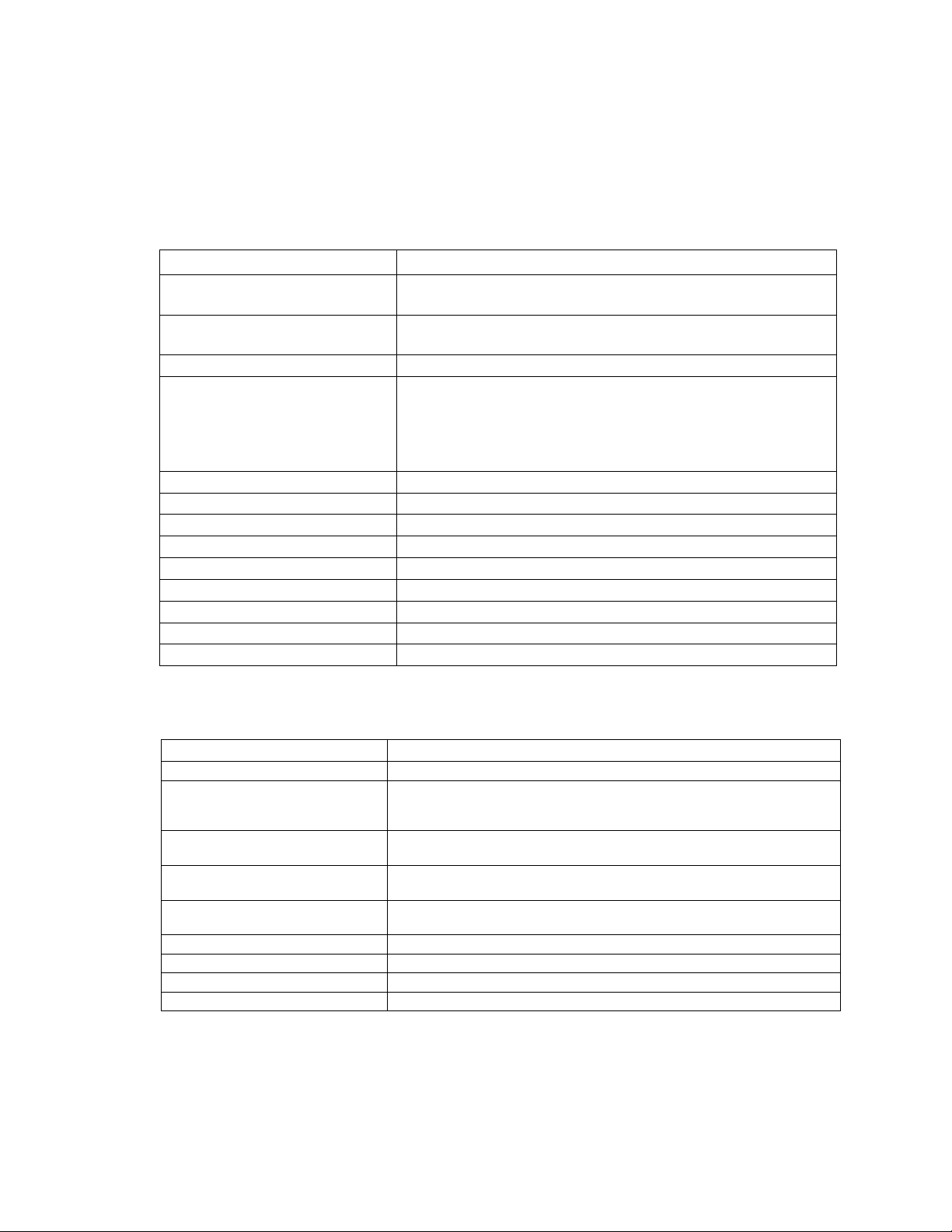

Table 3.4 Power Cabling Requirements in AWG

Load (VA)

Feet

10 15 20 25 30 40 55 75 100 130 180 200

35 10.7 22 22 22 22 22 22 22 22 22 22 22 22

40 12.2 22 22 22 22 22 22 22 22 22 22 22 20

55 16.8 22 22 22 22 22 22 22 22 22 22 20 20

65 19.8 22 22 22 22 22 22 22 22 22 20 20 18

70 21.3 22 22 22 22 22 22 22 22 22 20 18 18

75 22.9 22 22 22 22 22 22 22 22 22 20 18 18

90 27.4 22 22 22 22 22 22 22 22 20 20 18 18

100 30.5 22 22 22 22 22 22 22 22 20 18 18 16

105 32.0 22 22 22 22 22 22 22 20 20 18 18 16

115 35.1 22 22 22 22 22 22 22 20 20 18 16 16

135 41.1 22 22 22 22 22 22 22 20 18 18 16 16

145 44.2 22 22 22 22 22 22 20 20 18 18 16 16

150 45.7 22 22 22 22 22 22 20 20 18 16 16 16

LonPoint Hardware Guide 3-11

Page 34

155 47.2 22 22 22 22 22 22 20 20 18 16 16 14

Meters

103.6

111.3

114.3

120.4

121.9

128.0

143.3

144.8

152.4

166.1

176.8

181.4

192.0

193.5

228.6

230.1

AWG

242.3

263.7

288.0

304.8

307.8

362.7

365.8

384.0

419.1

457.2

484.6

501.4

165 50.3 22 22 22 22 22 22 20 18 18 16 16 14

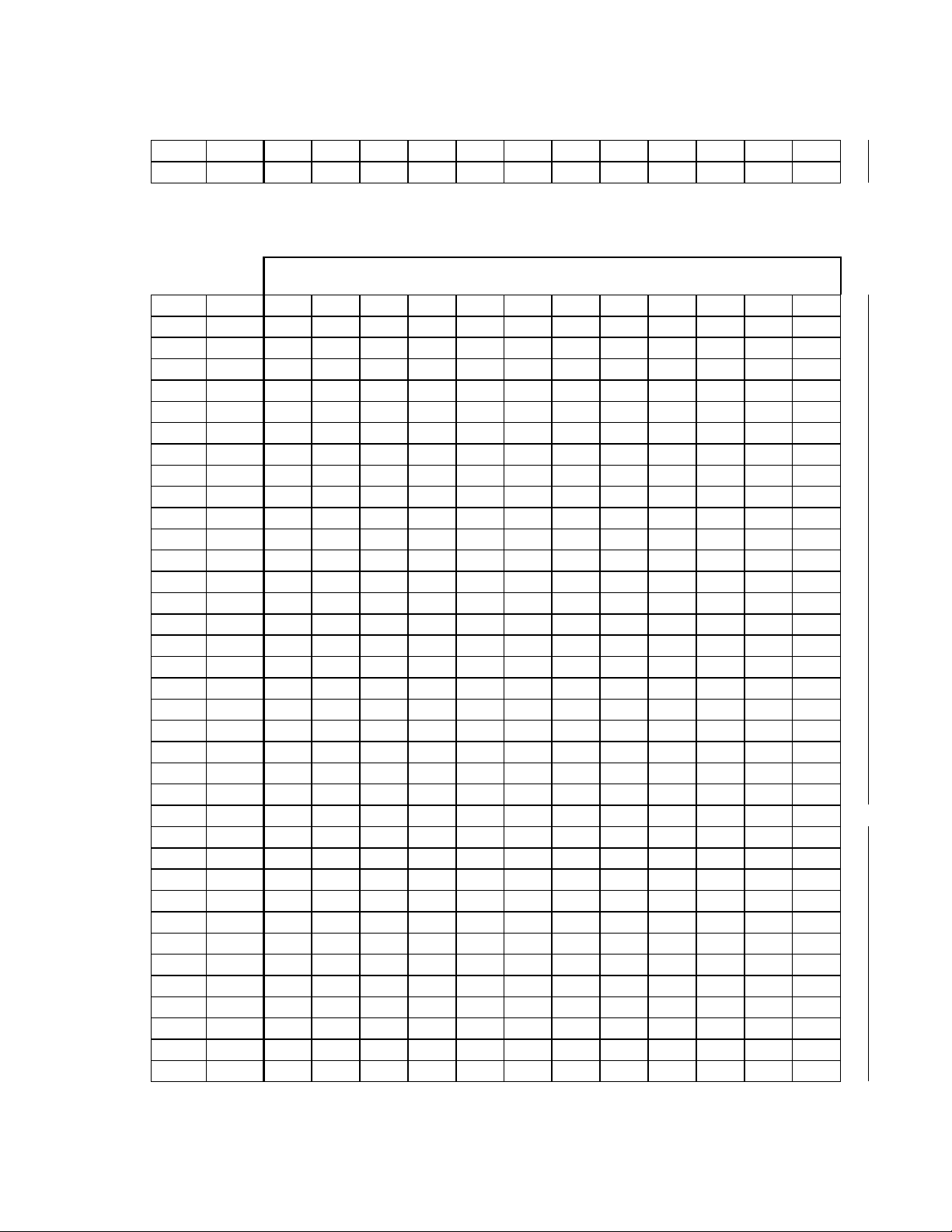

Table 3.4 Power Cabling Requirements in AWG (continued)

Load (VA)

Feet

10 15 20 25 30 40 55 75 100 130 180 200

185 56.4 22 22 22 22 22 22 20 18 18 16 14 14

215 65.5 22 22 22 22 22 20 20 18 16 16 14 14

230 70.1 22 22 22 22 22 20 18 18 16 16 14 14

235 71.6 22 22 22 22 22 20 18 18 16 14 14 14

250 76.2 22 22 22 22 22 20 18 18 16 14 14 12

265 80.8 22 22 22 22 20 20 18 16 16 14 14 12

295 89.9 22 22 22 22 20 20 18 16 16 14 12 12

300 91.4 22 22 22 22 20 18 18 16 16 14 12 12

340

365

375

395

400

420

470

475

500

545

580

595

630

635

750

755

795

865

945

1000

1010

1190

1200

1260

1375

1500

1590

1645

22 22 22 20 20 18 18 16 14 14 12 12

22 22 22 20 20 18 16 16 14 14 12 12

22 22 22 20 20 18 16 16 14 12 12 12

22 22 20 20 20 18 16 16 14 12 12

22 22 20 20 18 18 16 16 14 12 12

22 22 20 20 18 18 16 14 14 12 12

22 22 20 20 18 18 16 14 14 12

22 22 20 20 18 16 16 14 14 12

22 22 20 18 18 16 16 14 12 12

22 20 20 18 18 16 16 14 12 12

22 20 20 18 18 16 14 14 12 12

22 20 20 18 18 16 14 14 12

22 20 18 18 18 16 14 14 12

22 20 18 18 16 16 14 14 12

22 20 18 18 16 16 14 12 12

20 20 18 18 16 14 14 12 12

20 20 18 16 16 14 14 12

20 18 18 16 16 14 14 12

20 18 18 16 16 14 12 12

20 18 16 16 16 14 12 12

20 18 16 16 14 14 12 12

20 18 16 16 14 14 12

18 18 16 16 14 12 12

18 18 16 14 14 12 12

18 16 16 14 14 12 12

18 16 16 14 14 12

18 16 14 14 14 12

18 16 14 14 12 12

3-12 Network Cabling and Connections

Page 35

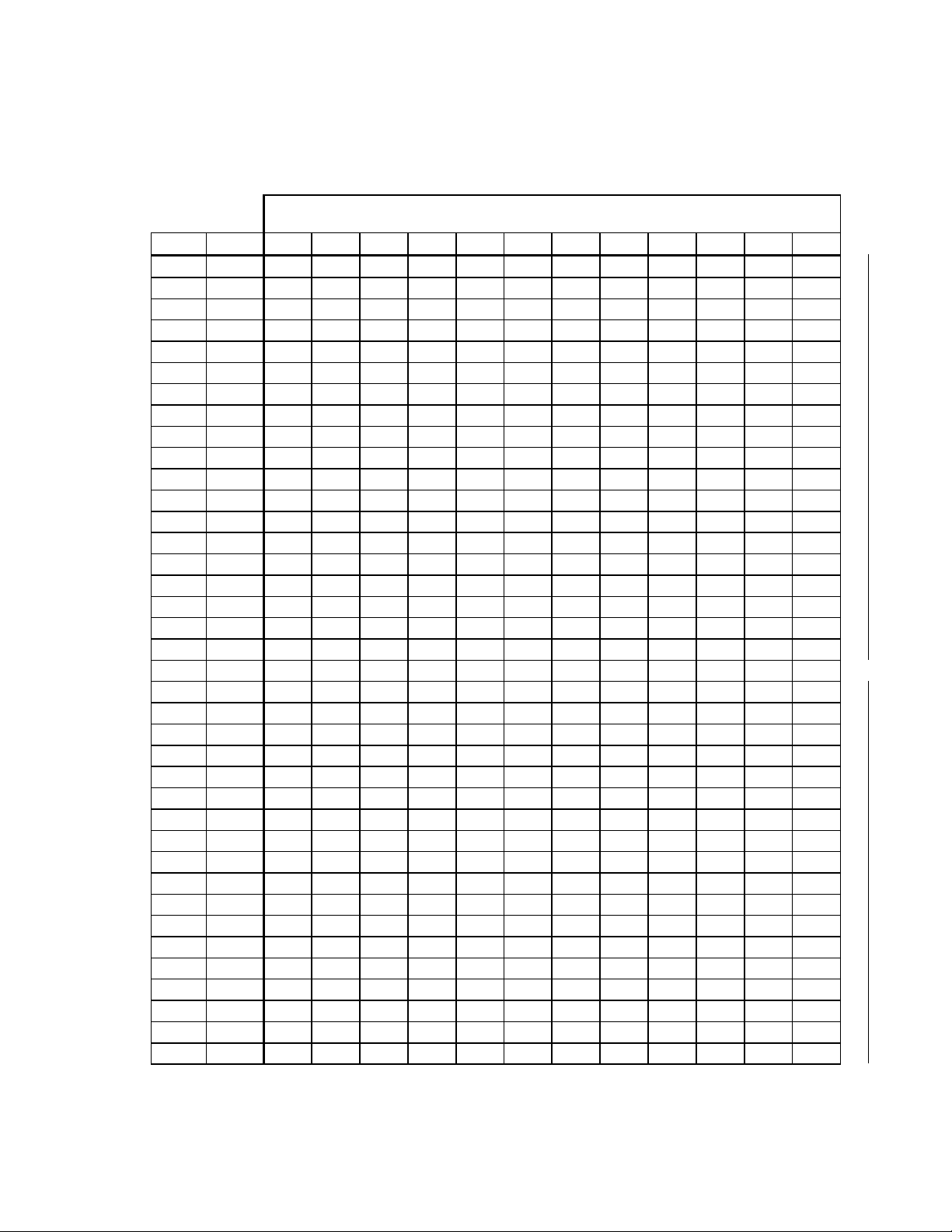

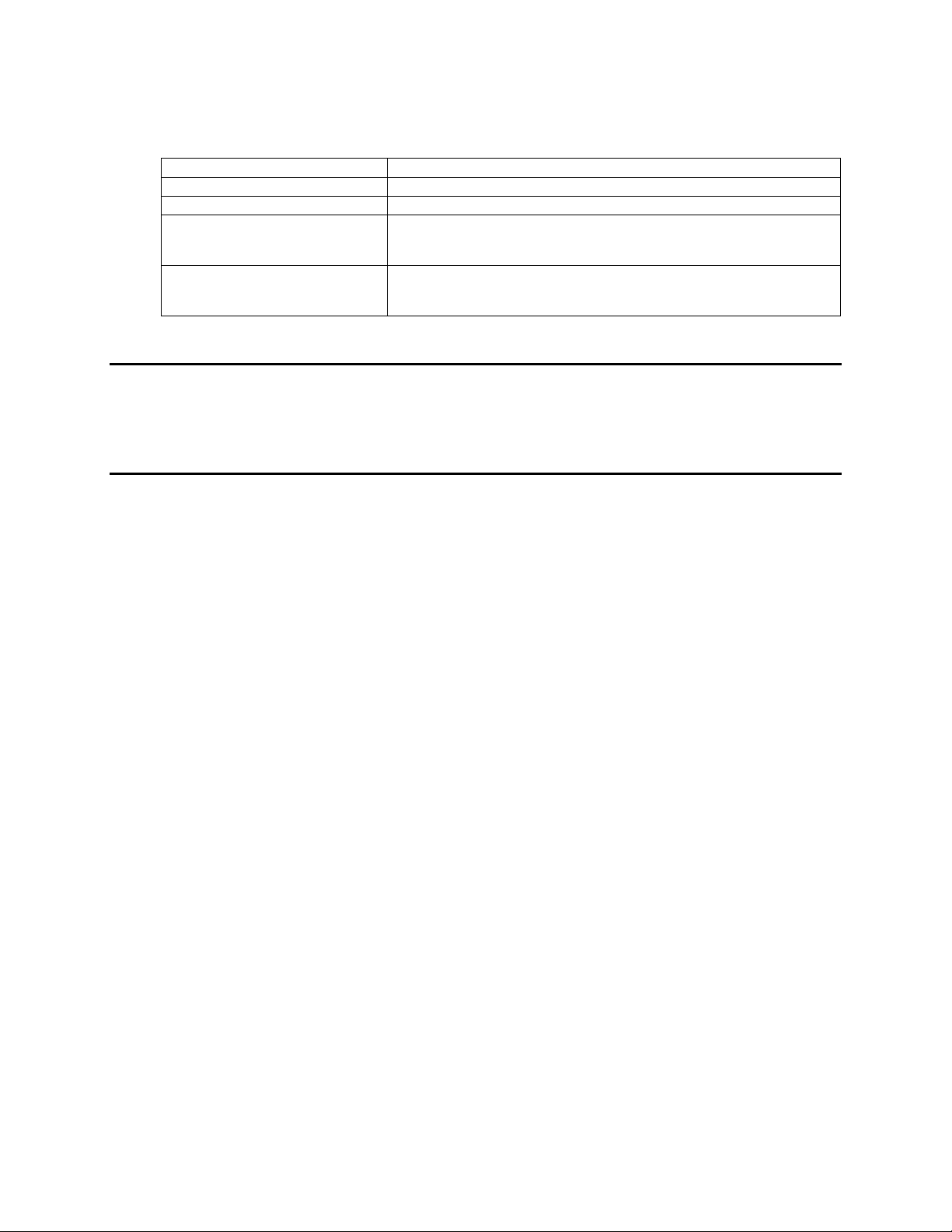

Table 3.5 Power Cabling Requirements In mm

Meters

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.65

0.65

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.65

0.65

0.65

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.65

0.65

0.80

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.65

0.80

0.80

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.65

0.65

0.80

0.80

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.65

0.65

0.80

1.00

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.65

0.65

0.80

0.80

1.00

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.65

0.65

0.80

1.00

1.00

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.65

0.80

0.80

1.00

1.00

0.50

0.50

0.50

0.50

0.50

0.50

0.65

0.65

0.80

0.80

1.00

1.00

0.50

0.50

0.50

0.50

0.50

0.50

0.65

0.65

0.80

1.00

1.00

1.00

101.7

0.50

0.50

0.50

0.50

0.50

0.50

0.65

0.65

0.80

1.00

1.00

1.30

114.8

0.50

0.50

0.50

0.50

0.50

0.50

0.65

0.80

0.80

1.00

1.30

1.30

141.1

0.50

0.50

0.50

0.50

0.50

0.65

0.65

0.80

1.00

1.00

1.30

1.30

150.9

0.50

0.50

0.50

0.50

0.50

0.65

0.80

0.80

1.00

1.30

1.30

1.30

154.2

0.50

0.50

0.50

0.50

0.65

0.65

0.80

0.80

1.00

1.30

1.30

1.30

170.6

0.50

0.50

0.50

0.50

0.65

0.65

0.80

1.00

1.00

1.30

1.30

1.60

183.7

0.50

0.50

0.50

0.50

0.65

0.65

0.80

1.00

1.00

1.30

1.60

1.60

193.6

0.50

0.50

0.50

0.65

0.65

0.65

0.80

1.00

1.30

1.30

1.60

1.60mm213.3

0.50

0.50

0.50

0.65

0.65

0.80

0.80

1.00

1.30

1.30

1.60

1.60

229.7

0.50

0.50

0.50

0.65

0.65

0.80

1.00

1.00

1.30

1.30

1.60

1.60

232.9

0.50

0.50

0.65

0.65

0.65

0.80

1.00

1.00

1.30

1.30

1.60

1.60

239.5

0.50

0.50

0.65

0.65

0.65

0.80

1.00

1.00

1.30

1.30

1.60

2.00

242.8

0.50

0.50

0.65

0.65

0.65

0.80

1.00

1.00

1.30

1.60

1.60

2.00

259.2

0.50

0.50

0.65

0.65

0.65

0.80

1.00

1.30

1.30

1.60

1.60

2.00

292.0

0.50

0.50

0.65

0.65

0.80

0.80

1.00

1.30

1.30

1.60

2.00

2.00

305.1

0.50

0.50

0.65

0.65

0.80

1.00

1.00

1.30

1.30

1.60

2.00

2.00

308.4

0.50

0.65

0.65

0.65

0.80

1.00

1.00

1.30

1.30

1.60

2.00

2.00

334.6

0.50

0.65

0.65

0.80

0.80

1.00

1.00

1.30

1.60

1.60

2.00

2.00

360.9

0.50

0.65

0.65

0.80

0.80

1.00

1.30

1.30

1.60

1.60

2.00

2.00

387.1

0.50

0.65

0.65

0.80

0.80

1.00

1.30

1.30

1.60

2.00

2.00

390.4

0.50

0.65

0.80

0.80

0.80

1.00

1.30

1.30

1.60

2.00

2.00

400.3

0.50

0.65

0.80

0.80

1.00

1.00

1.30

1.30

1.60

2.00

2.00

413.4

0.50

0.65

0.80

0.80

1.00

1.00

1.30

1.30

1.60

2.00

459.3

0.50

0.65

0.80

0.80

1.00

1.00

1.30

1.60

1.60

2.00

469.2

0.65

0.65

0.80

0.80

1.00

1.30

1.30

1.60

1.60

2.00

518.4

0.65

0.65

0.80

1.00

1.00

1.30

1.30

1.60

2.00

2.00

Load (VA)

Feet

23.0 7

32.8 10

36.1 11

42.7 13

45.9 14

55.8 17

59.1 18

62.3 19

75.5 23

82.0 25

88.6 27

91.9 28

31

35

43

46

47

52

56

59

65

70

71

73

74

79

89

93

94

102

110

118

119

122

126

140

143

158

10 15 20 25 30 40 55 75 100 130 180 200

LonPoint Hardware Guide 3-13

Page 36

Table 3.5 Power Cabling Requirements In mm (continued)

Meters

0.65

0.80

0.80

1.00

1.00

1.30

1.30

1.60

2.00

2.00

0.65

0.80

0.80

1.00

1.00

1.30

1.30

1.60

2.00

0.65

0.80

0.80

1.00

1.00

1.30

1.60

1.60

2.00

0.65

0.80

1.00

1.00

1.00

1.30

1.60

1.60

2.00

0.65

0.80

1.00

1.00

1.30

1.30

1.60

1.60

2.00

0.65

0.80

1.00

1.00

1.30

1.30

1.60

2.00

2.00

0.65

0.80

1.00

1.00

1.30

1.30

1.60

2.00

0.65

0.80

1.00

1.30

1.30

1.30

1.60

2.00

0.80

0.80

1.00

1.30

1.30

1.60

1.60

2.00

0.80

1.00

1.00

1.30

1.30

1.60

1.60

2.00

mm

0.80

1.00

1.00

1.30

1.30

1.60

2.00

2.00

0.80

1.00

1.30

1.30

1.30

1.60

2.00

2.00

1036.7

0.80

1.00

1.30

1.30

1.30

1.60

2.00

1177.8

0.80

1.00

1.30

1.30

1.60

1.60

2.00

1227.0

1.00

1.00

1.30

1.30

1.60

2.00

2.00

1243.4

1.00

1.30

1.30

1.30

1.60

2.00

2.00

1312.3

1.00

1.30

1.30

1.60

1.60

2.00

2.00

1555.1

1.00

1.30

1.30

1.60

1.60

2.00

1571.5

1.00

1.30

1.60

1.60

1.60

2.00

1640.4

1.00

1.30

1.60

1.60

2.00

2.00

Load (VA)

Feet

554.5 169

564.3 172

587.3 179

613.5 187

626.6 191

721.8 220

734.9 224

777.6 237

784.1 239

856.3 261

918.6 280

961.3 293

316

359

374

379

400

474

479

500

10 15 20 25 30 40 55 75 100 130 180 200

3-14 Network Cabling and Connections

Page 37

4

Installation and Wiring of Base Plates

This chapter describes the process of installing LonPoint Base Plates.

Type 1 Base Plates are used for mounting LonPoint Interface and

Scheduler Modules to 4-inch square electrical boxes or Echelon's

Eurobox. Type 1D DIN Rail Base Plates are used for mounting

LonPoint Interface and Scheduler Modules to 35mm DIN rails

(CENELEC EN 50022) or to walls or panels.

Type 2 Base Plates are used for mounting LonPoint LPR Router

Modules to 4-inch square electrical boxes or Echelon's Eurobox. Type

2D DIN Rail Base Plates are used for mounting LonPoint LPR Router

Modules to 35mm DIN rails or to walls or panels.

LonPoint Hardware Guide 4-1

Page 38

LonPoint Type 1 Base Plate Installation

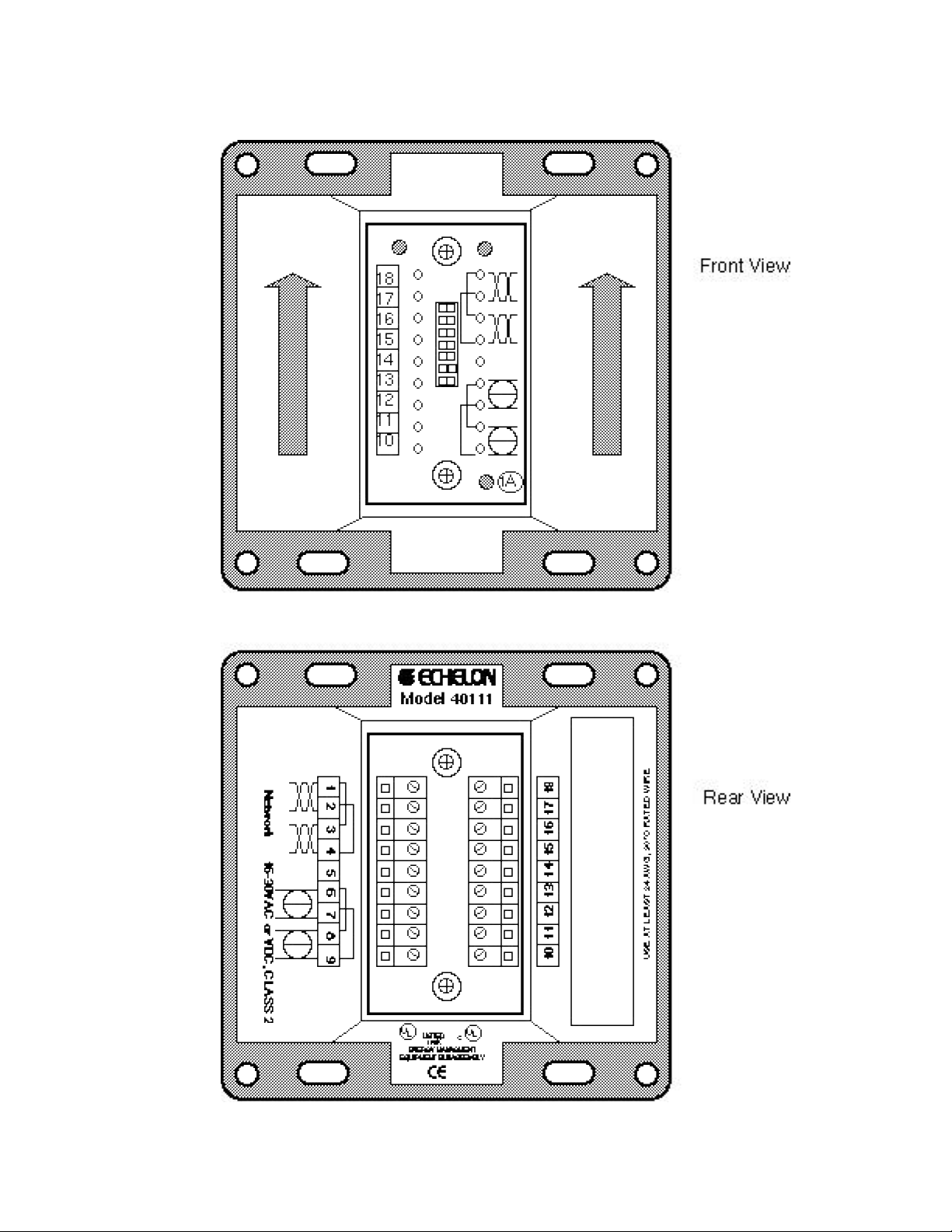

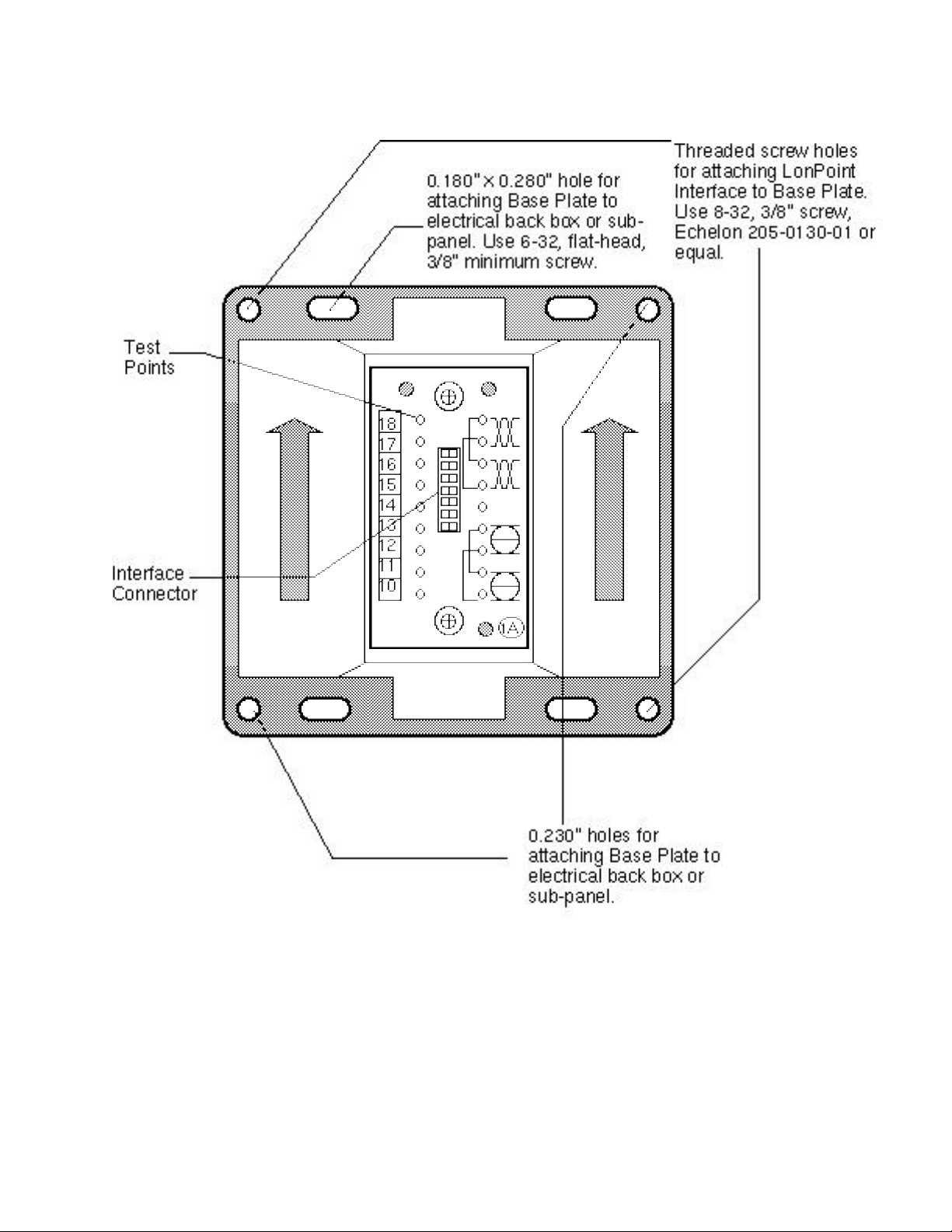

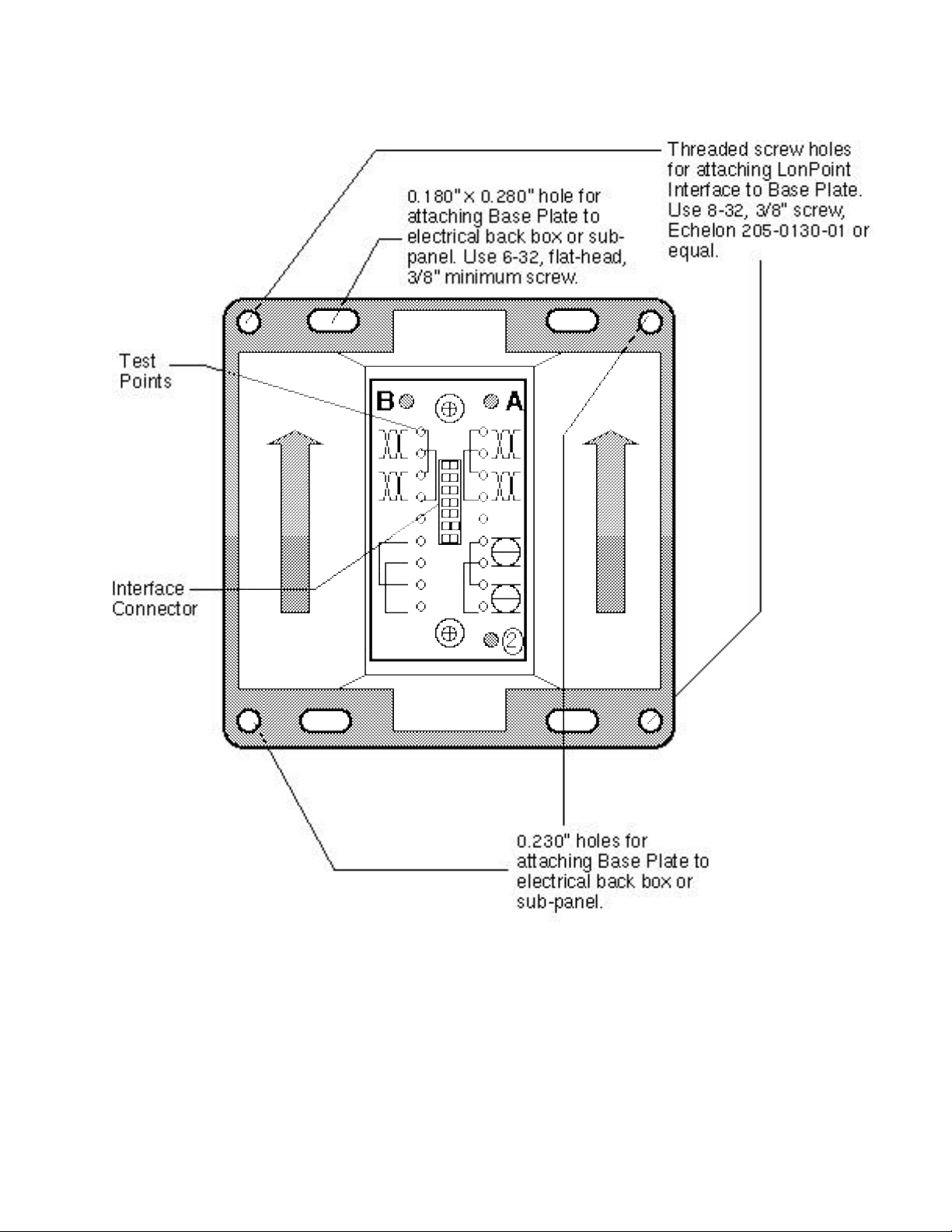

Figure 4.1 presents a detailed view of the front side of the base plate. The circuit

board inside the Type 1 Base Plate includes a large number “1A” in the lower right

corner, as viewed from the front of the base plate, designating it as a Type 1 Base

Plate with a Revision A circuit board. The “1A” designation indicates compatibility

with LonPoint modules such as the DIO-10, that make use of screw terminal 14.

Screw terminal 14 is NOT connected on older base plates marked “1”.

Test points are provided on the circuit board for measuring all of the wiring

connections. Symbols are silk-screened on the PCB to identify the functions of the

test points.

4-2 Installation and Wiring of Base Plates

Page 39

Figure 4.1 LonPoint Type 1 Base Plate - Front Panel

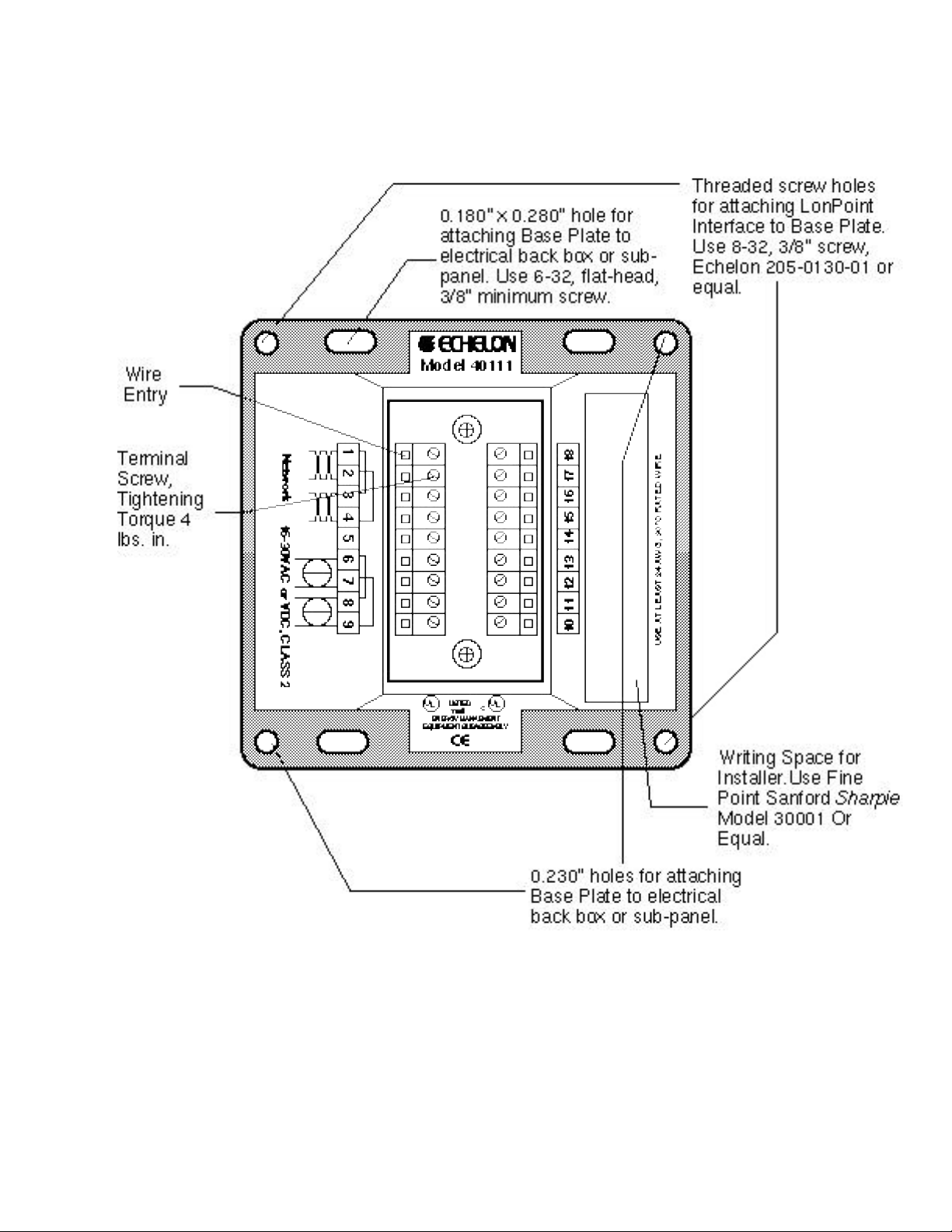

Figure 4.2 shows a detailed view of the rear side of the base plate, the side to which

LonPoint Hardware Guide 4-3

Page 40

wiring connections are made.

Figure 4.2 LonPoint Type 1 Base Plate - Rear Wiring Panel

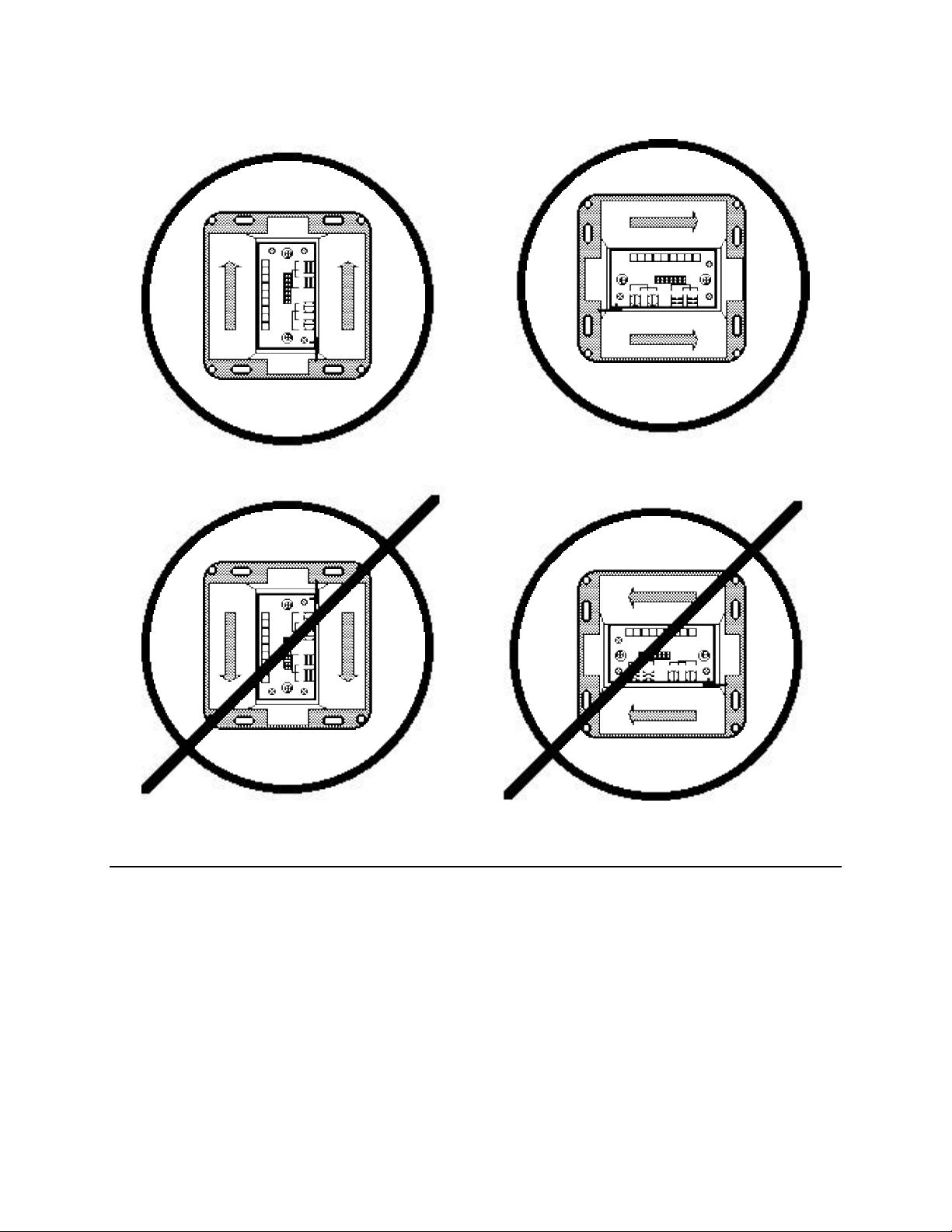

As shown in figure 4.3, the Type 1 Base Plate is intended to be installed in an electrical

box either vertically (base plate interior arrows pointing up) or rotated clockwise 90°

(base plate interior arrows pointing to the right). These two orientations provide optimal

viewing of the front panel legends of an installed LonPoint module, and also

accommodate different methods of installing electrical boxes.

4-4 Installation and Wiring of Base Plates

Page 41

Figure 4.3 LonPoint Type 1 Base Plate Mounting Orientations

Installing A Compatible Electrical Box

Compatible electrical boxes that will accept a Type 1 Base Plate include a 4” square

electrical enclosure (Raco model No. 232, 236, 7232, 7054 or equal), two-gang PVC

switch box (Raco 7834 or equal), and Echelon’s Model 48001 EuroBox for wall or

electrical box applications.

A 4” square electrical enclosures should be either affixed to a wall or to equipment

using suitable mounting screws, or recessed using a suitable mounting clamp (figure

4.4). Due to variations in the location of knock-outs, care must be taken to ensure

that 3/4” conduit fittings do not interfere with the Base Plate when it is installed in

the electrical box; 1/2” conduit fittings have not been found to cause an interference

problem.

LonPoint Hardware Guide 4-5

Page 42

Figure 4.4 4” Square Electrical Box Mounting

There are four mounting options if Echelon’s EuroBox is used. The Eurobox

requires the installer to drill cabling holes: ensure that suitable holes are drilled

prior to mounting. In order to avoid interference with the Base Plate enclosure

walls, all glands and conduit fittings must be located within 1.4”/35cm of the bottom

of the box (as measured from the outside of the box). Wire glands and conduit

fittings must not extend more than 0.63”/16mm into the EuroBox in order to prevent

associated cabling from interfering with the Base Plate screw terminals.

For UK applications, a second mounting option is to affix the EuroBox to a single

gang 25mm BS4662 flush mounting box (MK 866ZIC or similar). Two keyhole slots

are provided in the EuroBox to accomodate the flush mounting box as shown in

figure 4.5. Use screws with flush mounting and ensure that suitable cabling holes

are drilled in the Eurobox prior to mounting, as discussed above.

Figure 4.5 MK Electrical Box Mounting the EuroBox

4-6 Installation and Wiring of Base Plates

Page 43

For continental applications, a third mounting option is to affix the EuroBox to a

recessed 6.5cm diameter plastic DIN box (Kaiser or equal). Two keyhole slots are

provided in the EuroBox to accommodate DIN box mounting, as shown in figure 4.6.

Use the screws provided with the DIN box and ensure that suitable cabling holes are

drilled in the EuroBox prior to mounting.

Figure 4.6 DIN Box Mounting the EuroBox

A fourth mounting option is to affix the EuroBox to 35mm DIN rail using DIN Clips

(one pair included). Two sets of rectangular slots are provided for the DIN clips.

Ensure that the clips provided with each EuroBox lock in place on the box and then

snap them onto the DIN rail (figure 4.7). Ensure that suitable cabling holes are

drilled in the EuroBox prior to mounting.

Figure 4.7 DIN Rail Mounting the EuroBox

The Type 1D DIN Base Plate offers a lower profile and easier access to

wiring terminals for DIN rail applications.

LonPoint Hardware Guide 4-7

Page 44

Connecting Wiring

Route network, power, and input/output cabling into the electrical enclosure using

suitable conduit fittings, bushings, or wire glands. It is good practice to separate the

input/output cabling as much as possible from the network and power cabling,

especially if low level analog signals are being supervised. Once the cabling has been

brought into the electrical enclosure, leave a service loop of 6 inches (15cm) of cable

to simplify wiring the Type 1 Base Plate. Dress the cables using tie wraps or tape to

ensure that the cabling is not compressed or caught when the base plate is screwed

into place.

Strip the cable jacket and wire conductors. The base plate screw terminals will accept

26AWG (0.4mm) to 12AWG (2.2mm) wire, which should be stripped to a length of

0.32” (8mm). Although not required, it may be useful to use a soldering iron to tin the

stripped lengths of any stranded wires to prevent fraying and inadvertent contact

with adjactent terminals. The screw terminal blocks on the real panel of the Type 1

Base Plate are color coded to simplify wiring. The color coding scheme is shown in

table 4.1. The optimum tightening torque for the Type 1 Base Plate screw terminals

is 4 lbs. in. (0.5Nm) maximum. The ideal flathead screwdriver tip width is 0.125”

(3mm).

Terminal Number Terminal Color Function

1 - 4 Orange Network

5 Orange Cable shield, if used

6 - 9 Black Power

10 - 18 Green I/O

Table 4.1 Type 1 Base Plate Terminal Block Color Coding*

* In beta release Type 1 Base Plates, terminals 5 and 14 were

connected together but not connected to any I/O. In Type 1 Base

Plate marked 1A, terminal 5 is floating and may be used to

connect cable shield wires; terminal 14 is reserved for I/O.

Two sets of screw terminals are provided for both the power and network wiring

connections. These connections are internally jumpered on the Type 1 Base Plate

PCB to provide continuity of the network and power wiring, even if no LonPoint

module is installed, as shown figure 4.8. This feature permits the base plate wiring

to be pre-installed and the network and power circuits checked for continuity

throughout the installation, before a single LonPoint module is ever installed. This

feature also prevents network and power interruptions as a result of hot-swapping

LonPoint modules during commissioning or service operations. Finally, providing

two sets of screw terminals permits incoming and outgoing wiring to be landed at

separate screw terminals without the need to insert more than one wire in any given

screw terminal.

4-8 Installation and Wiring of Base Plates

Page 45

1 2 3 4 5 6 7 8 9

Network

16-30VAC or VDC

Figure 4.8 Base Plate Power and Network Wiring Connections

See chapters 5 through 9 for specific I/O wiring connections.

LonPoint Type 1D DIN Base Plate Installation

Figure 4.9 presents a detailed view of the front side of the base plate. The circuit

board inside the Type 1D DIN Base Plate includes an arrow with the designation

"1A," designating it as a Type 1 Base Plate with a Revision A circuit board. The 1D

Base Plate is intended to be installed either on a 35mm DIN rail, or using the

integral keyhole slots, on a wall or panel. Two arrows indicates the vertical

orientation of the Base Plate that will provide the best viewing of the front panel

legends.

LonPoint Hardware Guide 4-9

Page 46

Wire entry

points

flathead

Terminal screw,

tightening torque 4lbs.

in. (0.5Nm) maximum

18 17 16 15 13 12 11 1014

CAUTION

18 17 16 15 14 13 12 11 10

I/O

Keyhole slot for wall

or panel mounting

1A

Threaded screw holes for

attaching LonPoint

modules to the Base Plate.

Use 8-32, 3/8" screw,

Echelon 205-0130-01 or

equal

Network

1 2 3

4

5 6 7 8 9

Jumper Plug

storage location remove before

1 2 3 4 6 7 8 95

installing LonPoint

Module

DIN rail release activate with

Jumper Plug

insertion

Figure 4.9 Front Side of Type 1D DIN Base Plate

4-10 Installation and Wiring of Base Plates

Page 47

The base plate contains two integral DIN rail tabs that securely grab a 35mm DIN

rail onto which the base plate is mounted. The base plate may be used on both

35mm x 7.5mm and 35mm x 15mm DIN rails. To release the Base Plate from the

DIN rail, sequentially insert a flathead screwdriver into the DIN rail release tabs

and gently pull away from the DIN rail (figure 4.10).

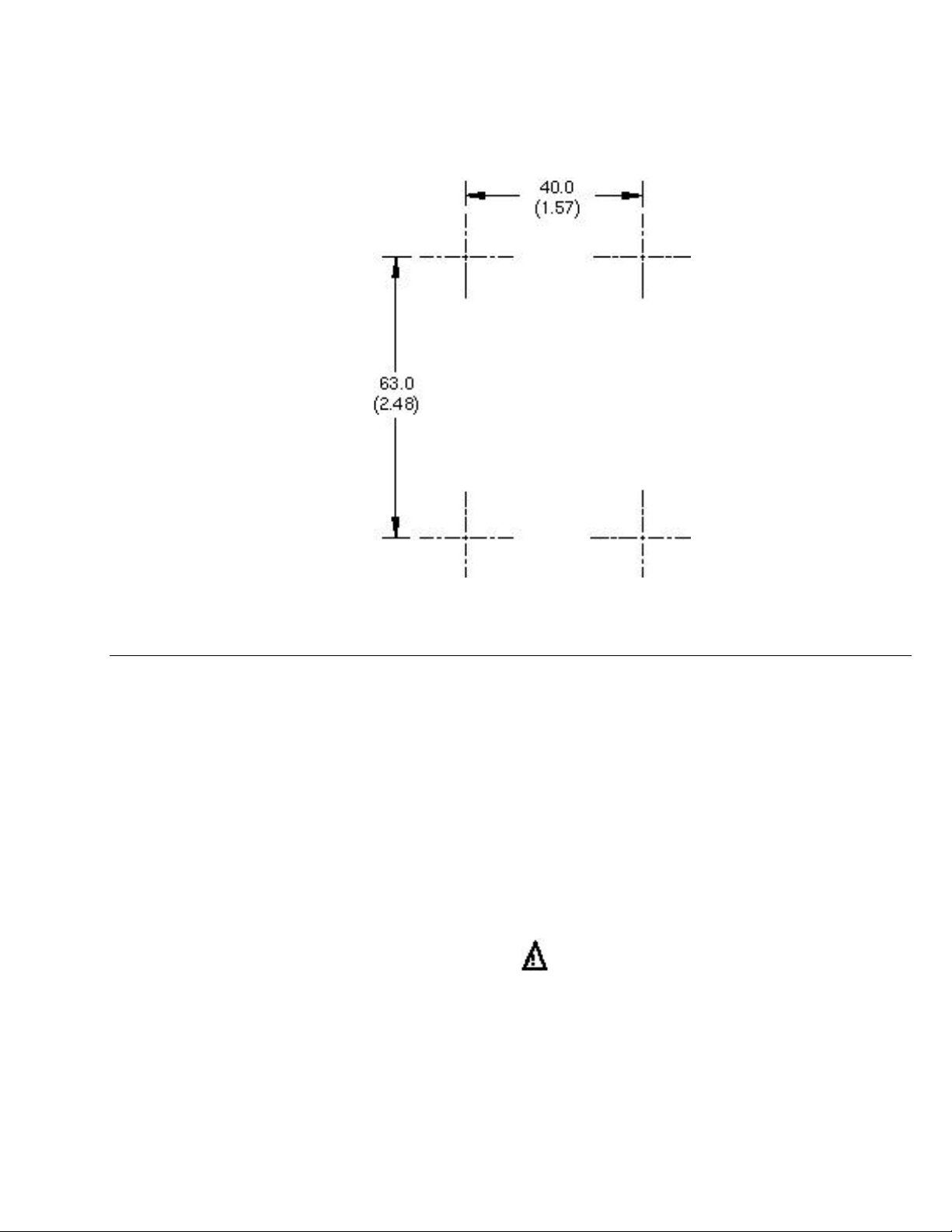

Four keyhole slots are provided for affixing the Type 1D DIN Base Plate to a wall or

panel (figure 4.11).

The 1D Base Plate is supplied with a jumper plug that connects the power and

network connections between adjacent base plates. The Jumper Plug is shipped

inserted into the main cavity of the Base Plate, and can be removed by gently

pulling the plug handle in the direction of the mounting arrow. The Jumper Plug

must be removed before a LonPoint module can be inserted into the Base Plate.

Figure 4.10 DIN Rail Base Plate Dimensions (Dimensions are in mm (inches).)

LonPoint Hardware Guide 4-11

Page 48

Figure 4.11 Mounting Holde Pattern Dimensions for Type1D Base Plates

Connecting Wiring

Route all network, power, and input/output cabling to the pertinent screw terminals

located at the top and bottom of the Base Plate. It is good practice to separate the

input/output cabling as much as possible from the network and power cabling,

especially if low-level analog signals are being supervised.

Strip the cable jacket and wire conductors. The base plate screw terminals will

accept 24AWG (0.5mm) to 12AWG(2.2mm) wire, which should be stripped to a

length of 0.32" (8mm). Although not required, it may be useful to use a soldering

iron to tin the stripped lengths of any strand wired to prevent fraying and

inadvertent contact with adjacent terminals. Identifying screw terminal numbers

are conveniently located both above and below each screw terminal. Symbols and/or

language identifying the function of the screw terminals also are provided.

Note that terminals 1 and 9 are numbered from left to right, but terminals 10 to 18

are numbered from right to left.

The optimum tightening torque for the screw terminals is approximately 4 pounds

(0.5Nm). The ideal flathead screwdriver tip width is 3/32" (2.5mm).

4-12 Installation and Wiring of Base Plates

Page 49

Table 4.2 Type 1D Base Plate Terminal Block Connections

Network

16-30VAC or VDC

Terminal Number Function

1 -4 Network

5 Cable shield, if used

6 - 9 Power

10 - 18 I/O

Two sets of screws are provided for both the power and network wiring connections.

These connections are internally jumpered on the Type 1D Base Plate PCB to

provide continuity of the network and power wiring, even if no LonPoint module is

installed, as shown in figure 4.12. This feature permits the base plate wiring to be

pre-installed and the network and power circuits checked for continuitiy throughout

the installation, before a single LonPoint module is ever installed. This feature also

prevents network and power interruptions as a result of hot swapping LonPoint

modules during commissioning or service operations. Finally, providing two sets of

screw terminals permits incoming and outgoing wiritng to be landed at separate

screw terminals without the need to insert more than one wire in any given screw

terminal.

1 2 3 4 5 6 7 8 9

Figure 4.12 Base Plate Power and Network Wiring Connections

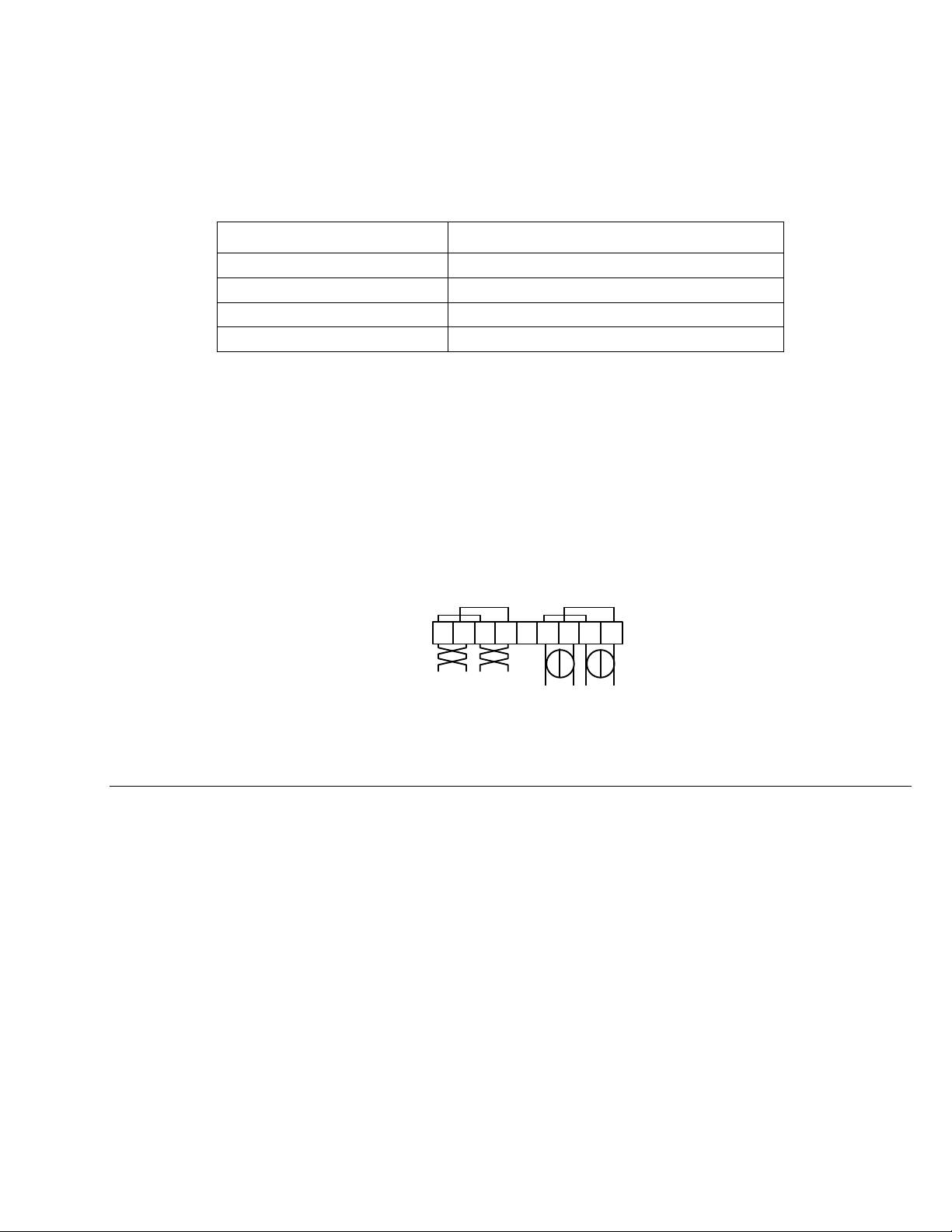

Connecting the Jumper Plug(s)

From time to time it may be necessary to mount two or more LonPoint Type 1D or

2D Base Plates adjacent to one another. In these instances, power and network

wiring must be daisy-chained between each Base Plate. Routing power and network

wiring between multiple base plates can be a laborious and time consuming task,

and there is always the risk of a wiring error. For this reason, the Type 1D and 2D

Base Plates are each supplied with a Jumper Plug and Jumper Plug connecotrs

which simply and easily bus the power and network between adjacent Base Plates.

The Jumper Plug connectors are located on either side of the terminal block with

connections 1 to 9 . The Jumper Plug connectors are wired in parallel with the

network and power connections on the screw terminals. When two Base Plates are

mounted adjacent to each other, with the mounting arrows pointing in the same

direction, the Jumper Plug connectors will be aligned such that a Jumper Plug may

be inserted into the two connectors, thus bridging power and network between the

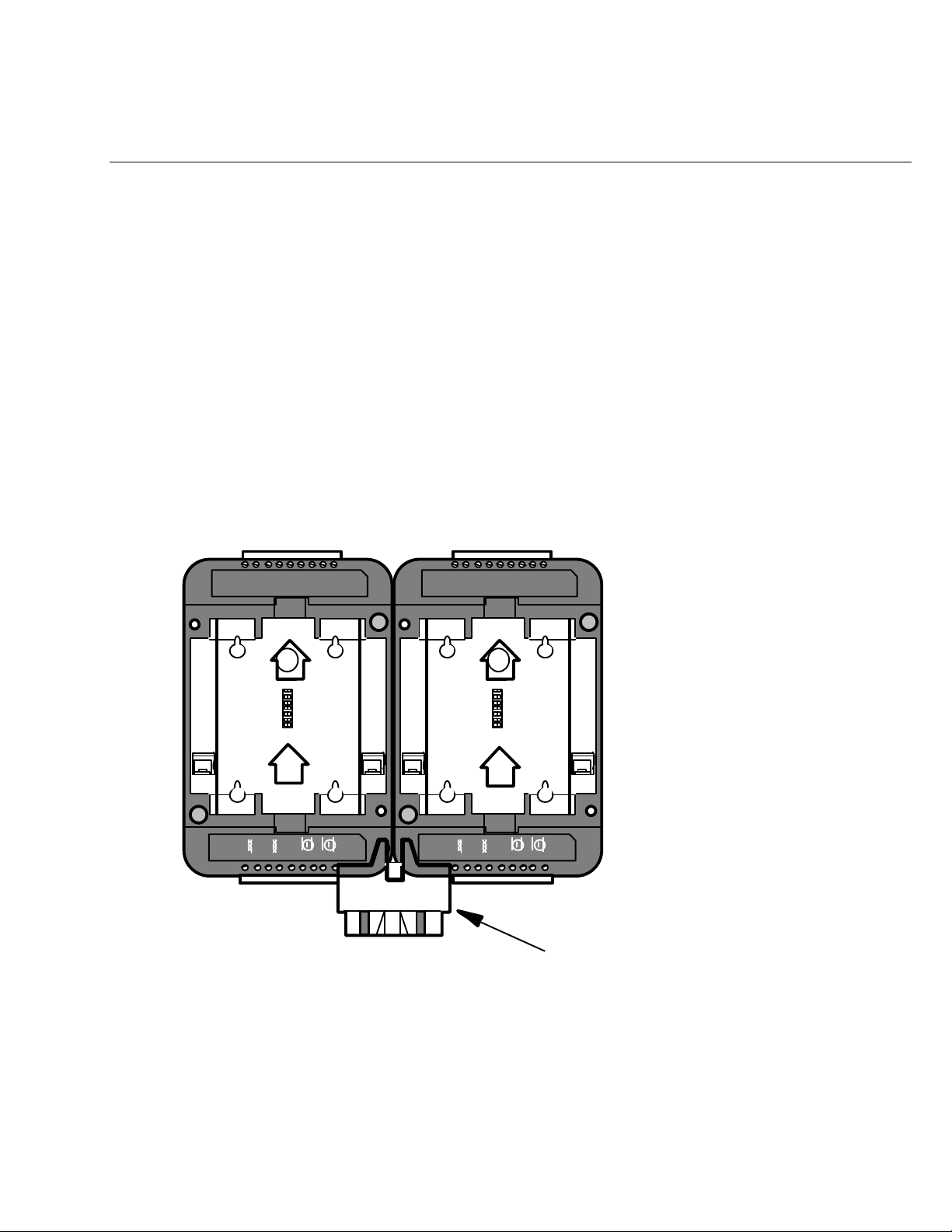

two Base Plates (figure 4.13).

LonPoint Hardware Guide 4-13

Page 50

18 171615141312111

Jumper Plug (x-ray view)

0

1A 1A

18 171615141312111

0

1 23456 7

8 9

1 23456 7

8 9

Figure 4.13 Mounting Two Base Plates with Jumper Plug Connectors

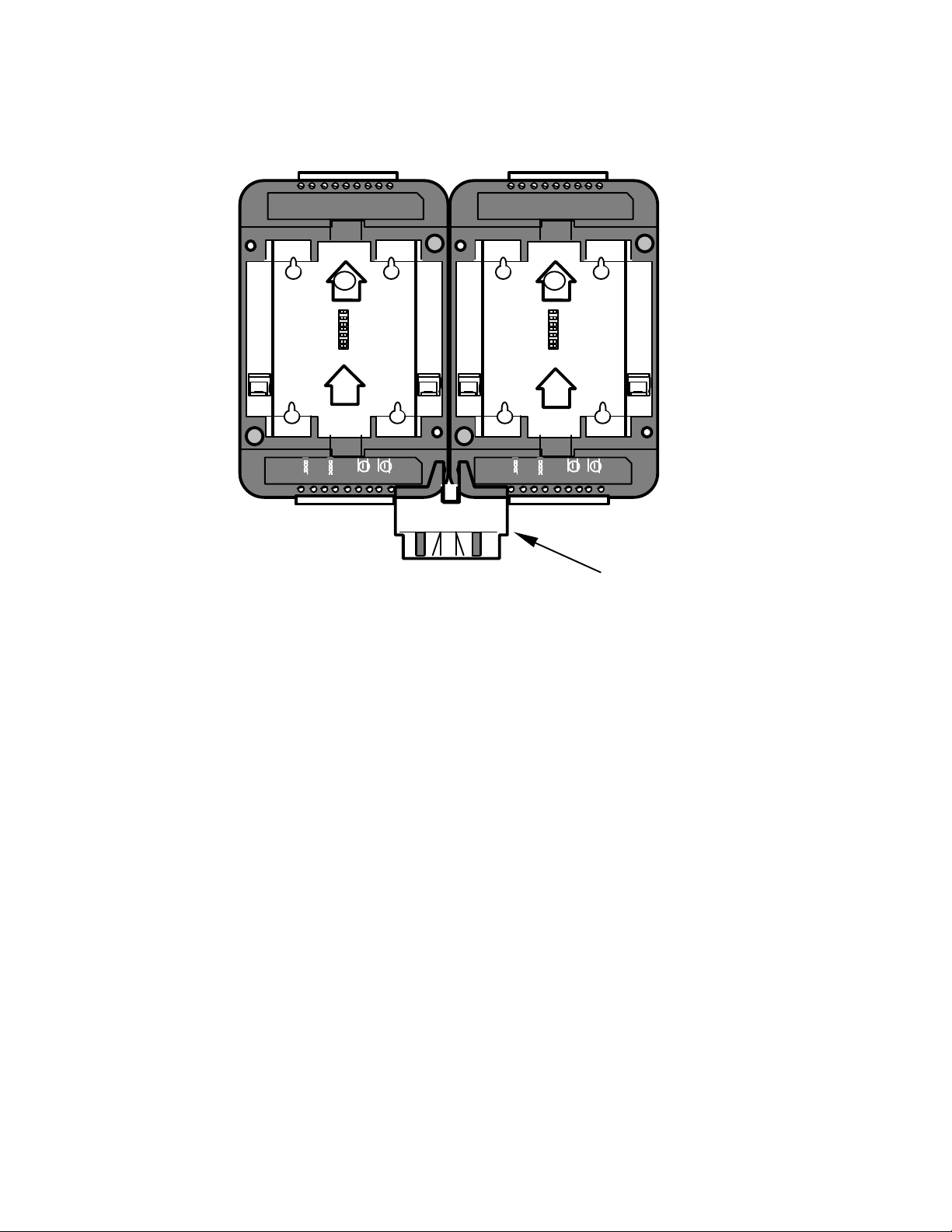

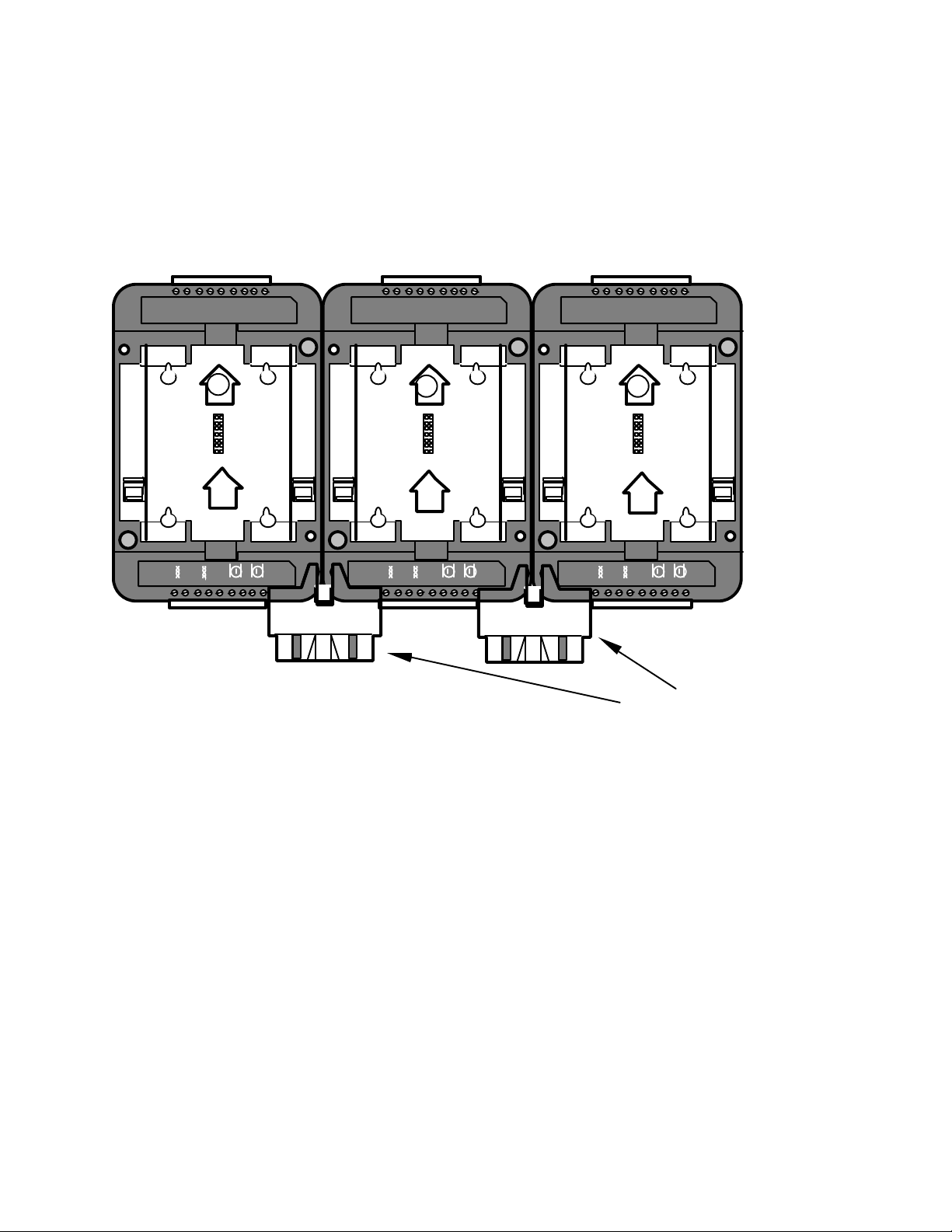

When used with a Type 2D Base Plate, there are restrictions about the placement of

the Type 2D Base Plates (and the routers they contain) relative to the adjacent Type

1D Base Plates. In all cases, any Type 2D Base Plates must be located to the left

side of any Type 1D Base Plates (figure 4.14) with which they will share a common

channel.

4-14 Installation and Wiring of Base Plates

Page 51

Jumper Plugs (x-ray view)

Type 2D Type 1D Type 1D

18 171615141312111

0

2 1A

1 2 3 4 5 6 7 8 9

Figure 4.14 Mixing Type 1D and Type 2D Base Plates

18 171615141312111

1 2 3 4 5 6 7 8 9

0

18 171615141312111

0

1A

1 2 3 4 5 6 7 8 9

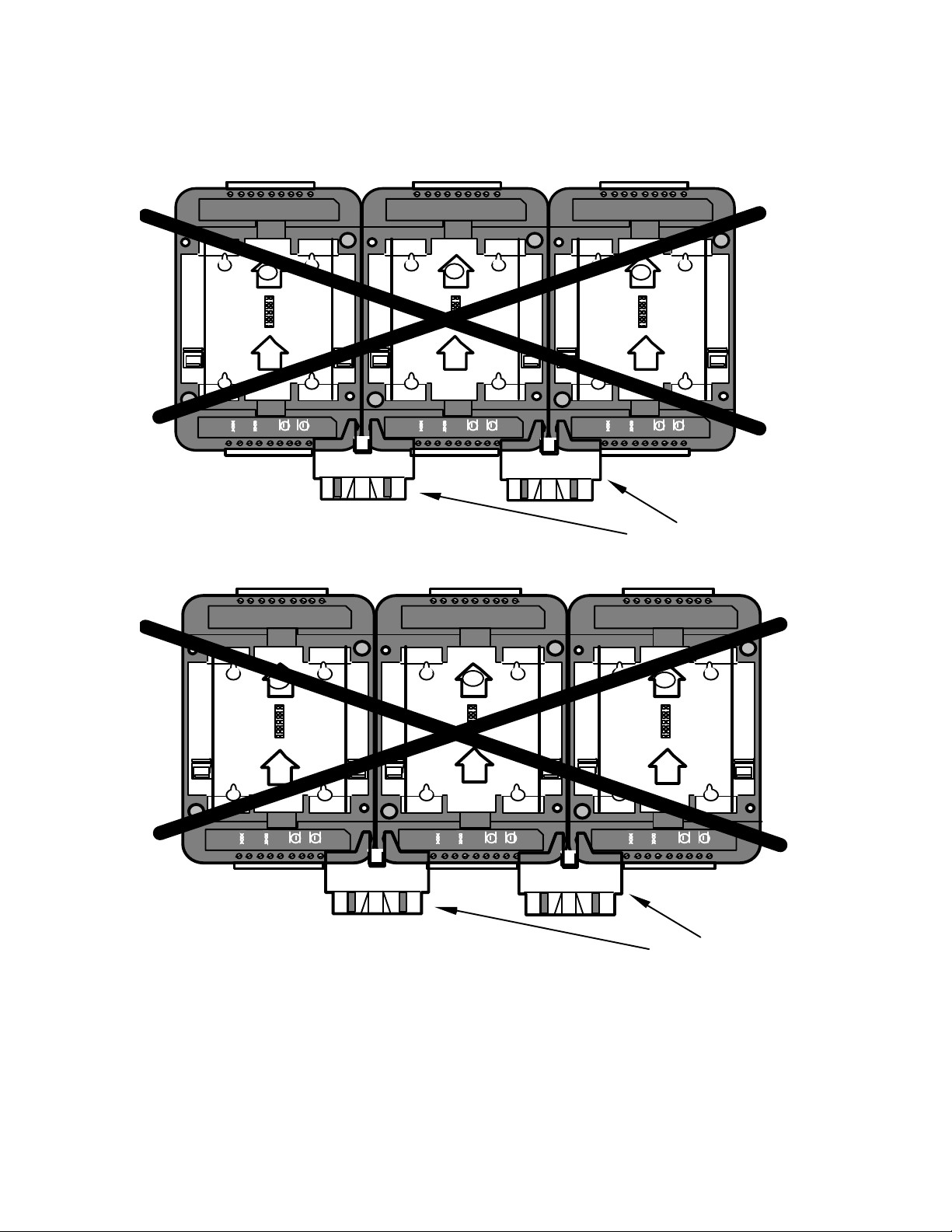

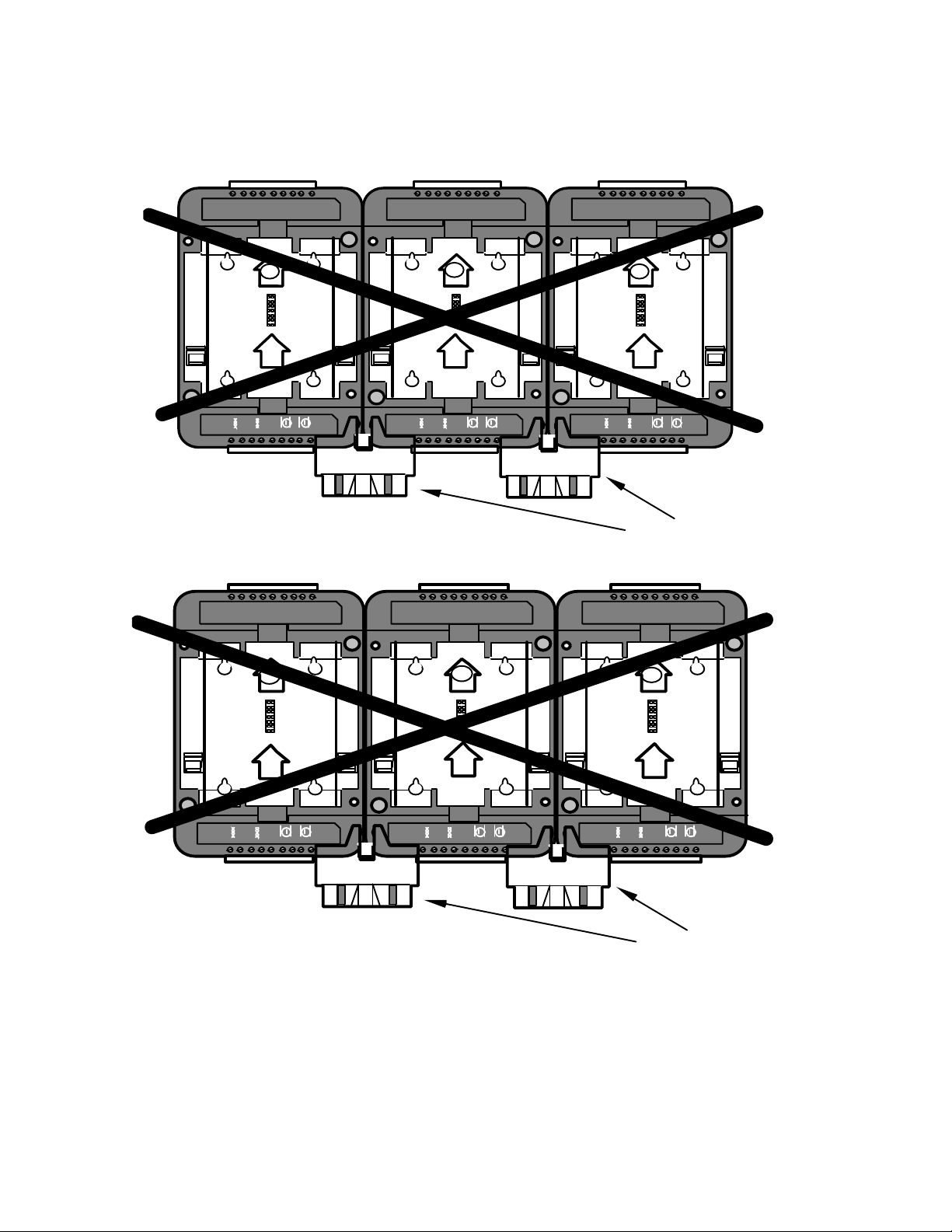

The reason for this limitation is that only the right Jumper Plug connector on a

Type 2D Base Plate bridges the network connection; the left Jumper Plug connector

on a Type 2D Base Plate bridges only the power connection. This arrangement

permits several routers, each with a different channel type, to be mounted on a

common DIN rail and share a common power supply. Figure 4.15 shows mounting

configurations that are problematic and must be avoided because the router will

be unable to communicate with the other LonPoint modules via the Jumper Plug.

If such a mounting arrangement must tbe used, then the base plates must be

interconnected using wiring instead of the Jumper Plug.

LonPoint Hardware Guide 4-15

Page 52

Jumper Plugs (x-ray view)

Type 1D Type 2D Type 1D

Jumper Plugs (x-ray view)

18 171615141312111

1A

1 2 3 4 5 6 7 8 9

Type 1D

18 171615141312111

0

18 171615141312111

0

2

1 2 3 4 5 6 7 8 9

Type 1D

0

18 171615141312111

0

18 171615141312111

1A

1 2 3 4 5 6 7 8 9

Type 2D

18 171615141312111

0

0

1A

1 2 3 4 5 6 7 8 9

1A

1 2 3 4 5 6 7 8 9

2

1 2 3 4 5 6 7 8 9

Figure 4.15 Problematic Mounting Configurations when Using Routers

4-16 Installation and Wiring of Base Plates

Page 53

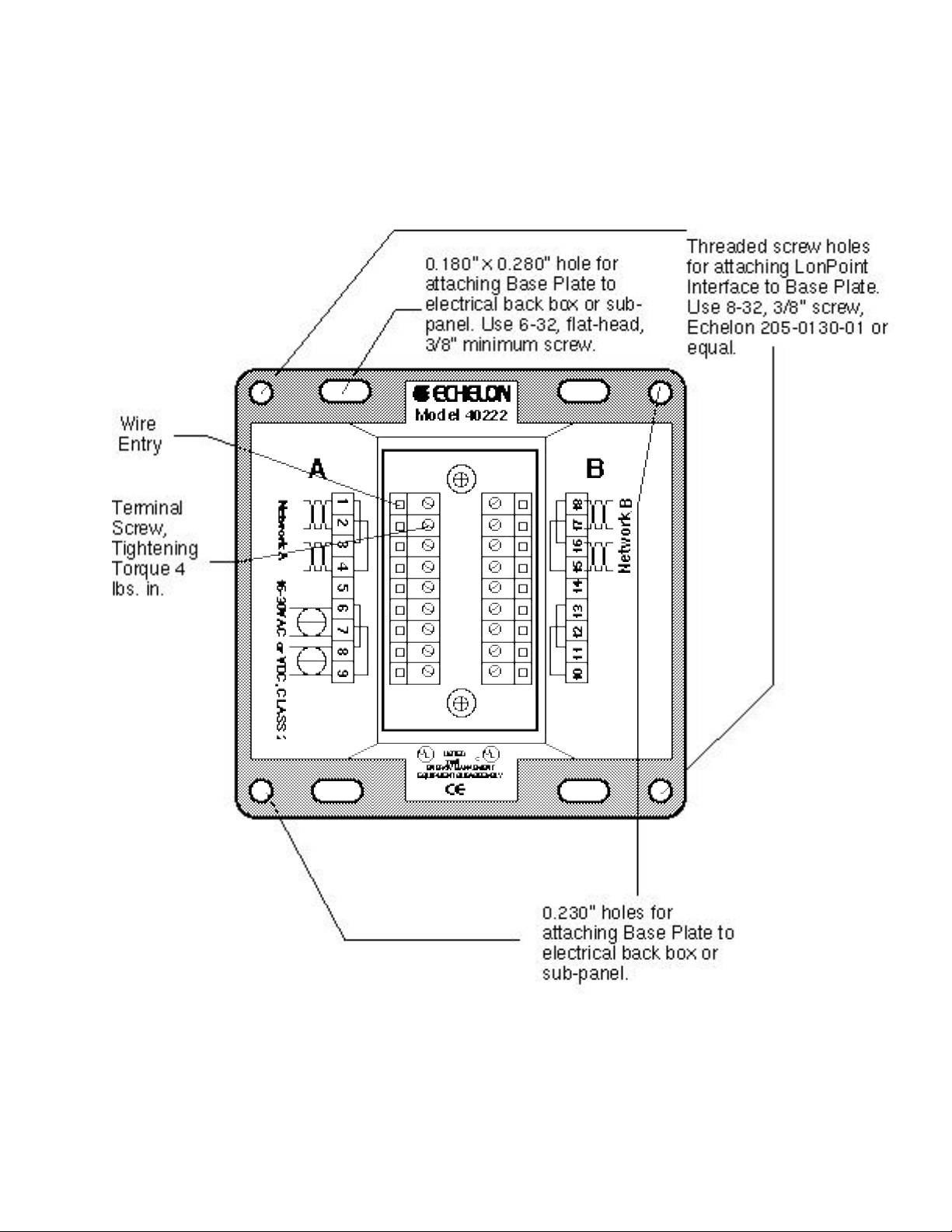

LonPoint Type 2 Base Plate Installation

All LonPoint LPR Routers may be installed in either a Type 2 Base Plate (Model

40222) or a Type 2D DIN Base Plate (Model 48222). Figure 4.16 presents a detailed

view of the front side of the Base Plate. The circuit board inside the Type 2 Base

Plate includes a large number “2” in the lower right corner, as viewed from the front

of the base plate, designating it as a Type 2 Base Plate. Test points are provided on

the circuit board for measuring all of the wiring connections; symbols are silkscreened on the PCB to identify the functions of the test points.

LonPoint Hardware Guide 4-17

Page 54

Figure 4.16 LonPoint Type 2 Base Plate - Front Panel

4-18 Installation and Wiring of Base Plates

Page 55

Figure 4.17 shows a detailed view of the rear side of the Base Plate, the side to

which wiring connections are made.

Figure 4.17 LonPoint Type 2 Base Plate - Rear Wiring Panel

LonPoint Hardware Guide 4-19

Page 56

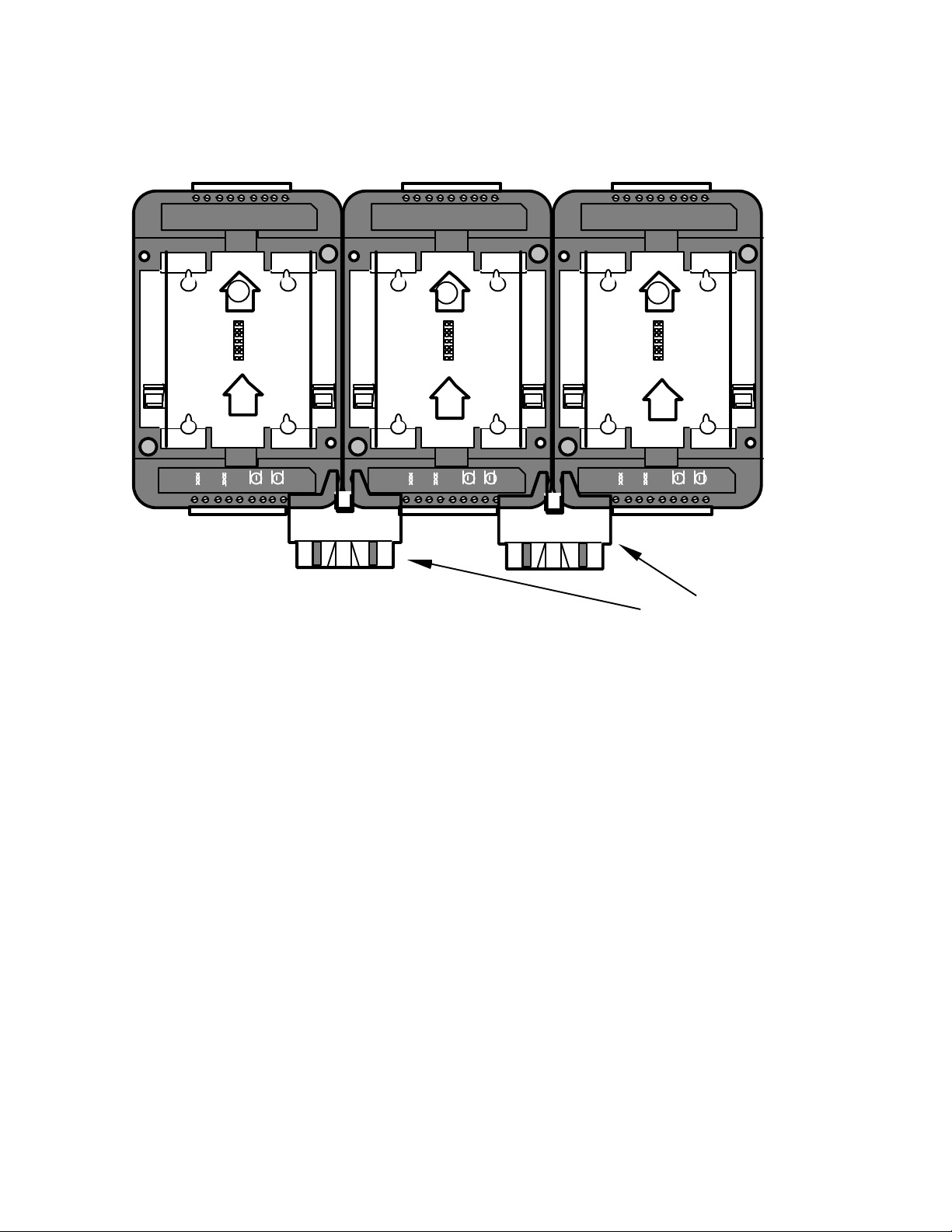

As shown in figure 4.18, the Type 2 Base Plate is intended to be installed in an electrical

box either vertically (base plate interior arrows pointing up) or rotated clockwise 90°

(base plate interior arrows pointing to the right). These two orientations provide

optimal viewing of the front panel legends of an installed LonPoint module, and also

accommodate different methods of installing electrical boxes.

Figure 4.18 LonPoint Type 2 Base Plate Mounting Orientations

Installing A Compatible Electrical Box

Compatible electrical boxes that will accept a Type 2 Base Plate include a 4” square

by 2” deep electrical enclosure (Raco model No. 232, 236, 7232, 7054 or equal), two-

4-20 Installation and Wiring of Base Plates

Page 57

gang PVC switch box (Raco 7834 or equal), and Echelon’s Model 48001 EuroBox for

wall and 35mm DIN rail applications.

A 4” square electrical enclosures should be either affixed to a wall or to equipment using

suitable mounting screws, or recessed using a suitable mounting clamp (figure 4.19). Due

to variations in the location of knock-outs, care must be taken to ensure that 3/4” conduit

fittings do not interfere with the Base Plate when it is installed in the electrical box; 1/2”

conduit fittings have not been found to cause an interference problem.

Figure 4.19 4” Square Electrical Box Mounting

There are four mounting options if Echelon’s EuroBox is used. The Eurobox

requires the installer to drill cabling holes: ensure that suitable holes are drilled

prior to mounting. In order to avoid interference with a Type 1 or Type 2 Base

Plate, all glands and conduit fittings must be located within 1.4”/35cm of the bottom

of the box (as measured from the outside of the box). Wire glands and conduit