Page 1

WaveRIDER

Hardware & Software Users Guide

WaveRIDER

Wave Solder Machine Analyzer

A36-9283-00 Rev 2.1

Page 2

SINCE 1964

ECD

4287-B S.E. International Way

Milwaukie, Oregon 97222-8825

Telephone: (800) 323-4548

(503) 659-6100

FAX: (503) 659-4422

Technical Support: (800) 323-4548

Email: ecd@ecd.com

Internet: http://www.ecd.com

Copyright © 1996-2008 ECD. All Rights Reserved, Printed in U.S.A. Foreign and U.S. Products of ECD. are covered by Foreign and

U.S. patents or patents pending. No part of this Publication may be translated and/or reproduced or stored in a data retrieval system, or

transmitted in any form or by any means without the express written permission of ECD Information in this publication supersedes all

previously published material. Specification and price change privileges reserved.

The trapezoidal ECD logo M.O.L.E.(Multichannel Occurrent Logger Evaluator) and WaveRIDEare registered trademarks of

ECD Windows is a registered trademark of Microsoft Corporation.

The WaveRIDER product is covered by U.S. Patent No. 5767424

Page 3

WaveRIDER Users Guide

TABLE OF CONTENTS

Introduction .................................................................................................................. vi

y Terms used in this Manual.....................................................................................vii

y Fonts Used in this Manual.....................................................................................viii

y Computer Hardware Requirements.......................................................................viii

Operators Safety Information...................................................................................... ix

1.0 System Description................................................................................................. 1

1.1 Rider Description ................................................................................................. 2

1.2 Coupon Description .............................................................................................4

1.3 Software Description............................................................................................ 5

1.3.1 WR SPC Workbook Features...................................................................... 5

1.4 Standard WR SPC Worksheet functions.............................................................. 7

1.4.1 Worksheet tabs............................................................................................ 7

1.4.2 Selecting Worksheets.................................................................................. 7

1.4.3 Split-bar.......................................................................................................7

1.4.4 Worksheet Tab Scroll Arrows......................................................................7

1.4.5 Scrollbars..................................................................................................... 8

2.0 Setup........................................................................................................................9

2.1 Charging the Power Pack Battery........................................................................9

2.2 Software Installation........................................................................................... 11

2.2.1 Starting the Software................................................................................. 11

2.3 Communications Setup...................................................................................... 12

2.4 M.O.L.E. Installation........................................................................................... 16

3.0 Operation ............................................................................................................... 17

3.1 Data Collection................................................................................................... 17

3.2 Transferring Data............................................................................................... 22

3.3 Expert Matrix......................................................................................................23

3.4 Cleaning the Rider............................................................................................. 27

3.5 Storing the RIDER ............................................................................................. 28

WaveRIDER i

Page 4

4.0 Worksheet Descriptions ....................................................................................... 29

4.1 The Welcome Worksheet................................................................................... 29

4.1.1 Welcome Worksheet Menus and Toolbar..................................................30

4.1.2 Company/Report Name............................................................................. 31

4.2 WaveRIDER Data Worksheet............................................................................ 32

4.2.1 WaveRIDER Data Worksheet Menus and Toolbar Buttons.......................33

4.2.2 Interpreting the WaveRIDER Data Sheet .................................................. 34

4.2.3 Data Coloring and LSL / USL .................................................................... 35

4.3 Spreadsheet Worksheet .................................................................................... 36

4.3.1 Spreadsheet Menus and Toolbar Buttons ................................................. 37

4.3.2 Parameter Groups..................................................................................... 38

4.3.3 Parameter Labels......................................................................................40

4.3.4 Parameter Units......................................................................................... 40

4.3.5 Data Run Rows .........................................................................................41

4.3.6 Selected Run............................................................................................. 41

4.3.7 Filters.........................................................................................................42

4.3.8 Statistics.................................................................................................... 45

4.4 Profile Worksheet............................................................................................... 46

4.4.1 Profile Menus and Toolbar Buttons ...........................................................47

4.4.2 M.O.L.E. Status......................................................................................... 48

4.4.3 Tool Status Box.........................................................................................49

4.4.4 Magnify Map.............................................................................................. 50

4.4.5 The Data Table.......................................................................................... 51

4.4.6 Sensor Locations....................................................................................... 56

4.4.7 Channel Check Boxes............................................................................... 57

4.4.8 Status Bar..................................................................................................58

4.4.9 Data Tabs.................................................................................................. 60

4.4.10 The Data Graph....................................................................................... 68

4.5 Administration Worksheet.................................................................................. 76

4.5.1 Administration Menus and Toolbar Buttons............................................... 77

4.5.2 Spreadsheet Parameters........................................................................... 78

4.5.3 Parameter check boxes............................................................................. 78

4.5.4 Specification and Control Limit Cells ......................................................... 79

4.5.5 SPC Sheet Boxes...................................................................................... 83

4.6 Guide Worksheet............................................................................................... 88

4.7 SPC Worksheet ................................................................................................. 89

4.7.1 Menus & Toolbar....................................................................................... 90

4.7.2 X-Bar Chart................................................................................................ 91

4.7.3 R Chart...................................................................................................... 92

4.7.4 Statistics Box............................................................................................. 93

4.7.5 Renaming SPC Worksheets...................................................................... 94

ii WaveRIDER

Page 5

5.0 Menu and Tool Commands .................................................................................. 95

5.1 File Menu........................................................................................................... 95

5.1.1 New Workbook.......................................................................................... 95

5.1.2 Open Workbook......................................................................................... 97

5.1.3 Close Workbook........................................................................................ 97

5.1.4 Import ........................................................................................................ 98

5.1.5 Save Workbook.........................................................................................99

5.1.6 Save Workbook As.................................................................................... 99

5.1.7 Save As Text...........................................................................................100

5.1.8 Save as Text Archive............................................................................... 100

5.1.9 Load Text Archive.................................................................................... 101

5.1.10 Configuration......................................................................................... 102

5.1.11 Preferences...........................................................................................103

5.1.12 Page Setup............................................................................................ 111

5.1.13 Print Options.......................................................................................... 112

5.1.14 Page Header / Footer............................................................................ 113

5.1.15 Print Preview ......................................................................................... 114

5.1.16 Print....................................................................................................... 115

5.1.17 Report Setup ......................................................................................... 116

5.1.18 Print Report ........................................................................................... 116

5.1.19 Send to Mail Recipients......................................................................... 117

5.1.20 Recent Files 1, 2, 3, etc......................................................................... 118

5.1.21 Exit......................................................................................................... 118

5.1.22 Language............................................................................................... 118

5.2 Edit Menu......................................................................................................... 119

5.2.1 Undo........................................................................................................ 119

5.2.2 Redo........................................................................................................ 119

5.2.3 Copy........................................................................................................ 119

5.2.4 Paste ....................................................................................................... 119

5.2.5 Remove Row........................................................................................... 120

5.2.6 Hide Row................................................................................................. 120

5.3 View Menu....................................................................................................... 121

5.3.1 Zoom In ................................................................................................... 121

5.3.2 Zoom Out................................................................................................. 121

5.3.3 100% ....................................................................................................... 121

5.3.4 Data Table Tabs...................................................................................... 121

5.4 Format Menu.................................................................................................... 122

5.4.1 Bold ......................................................................................................... 122

5.4.2 Italic......................................................................................................... 122

5.4.3 Underline.................................................................................................122

5.4.4 Alignment (Left, Center, Right)................................................................ 122

5.5 Window Menu.................................................................................................. 123

5.5.1 Cascade .................................................................................................. 123

5.5.2 Tile........................................................................................................... 124

5.5.3 Open File................................................................................................. 124

WaveRIDER iii

Page 6

5.6 WaveRIDER Menu........................................................................................... 125

5.6.1 Configuration Wizard............................................................................... 125

5.6.2 Set M.O.L.E. Clock.................................................................................. 127

5.6.3 WaveRIDER Settings .............................................................................. 128

5.6.4 Read WaveRIDER Data..........................................................................129

5.7 Profile Menu ..................................................................................................... 130

5.7.1 Part.......................................................................................................... 130

5.7.2 Process.................................................................................................... 131

5.7.3 Scaling.....................................................................................................132

5.7.4 X-Axis Units............................................................................................. 133

5.7.5 Temp Ref Lines (Temperature Reference Lines) .................................... 134

5.7.6 Profile Colors........................................................................................... 135

5.8 Tools Menu...................................................................................................... 136

5.8.1 Magnify Tool............................................................................................ 136

5.8.2 Slope Tool ............................................................................................... 138

5.8.3 Peak Difference Tool............................................................................... 140

5.8.4 Overlay Tool............................................................................................141

5.8.5 3-D View.................................................................................................. 143

5.8.6 Measure Tool........................................................................................... 145

5.8.7 Notes Tool............................................................................................... 146

5.8.8 Erase Object(s)........................................................................................ 147

5.8.9 Erase All.................................................................................................. 147

5.9 Navigate Menu.................................................................................................148

5.10 Help Menu...................................................................................................... 149

5.10.1 Help....................................................................................................... 149

5.10.2 ECD on the Web.................................................................................... 149

5.10.3 About WaveRIDER................................................................................ 149

6.0 Service and Calibration ...................................................................................... 150

6.1 Service Troubleshooting .................................................................................. 150

6.1.1 RIDER Troubleshooting Steps................................................................. 151

6.2 RIDER Coupon Replacement..........................................................................152

6.3 Checking the Coupon Thermocouples............................................................. 153

6.4 How to Get Additional Help.............................................................................. 153

iv WaveRIDER

Page 7

APPENDIX A: Specifications.................................................................................... 154

APPENDIX B: Statistical Process Control (SPC) Background Information ......... 155

APPENDIX C: Measurement Definitions.................................................................. 161

APPENDIX D: WR SPC Parameter Definitions........................................................ 168

APPENDIX E: WaveRIDER Accuracy and the Influencing Factors....................... 181

APPENDIX F: Pull-Down Menus & Toolbar Buttons............................................... 188

APPENDIX G: WaveRIDER Accessories ................................................................. 191

WaveRIDER v

Page 8

Introduction

This User’s Guide explains how to use ECD’s (Electronic Controls Design Inc.)

WaveRIDER Wave Solder machine analyzer.

You do not need to be a computer expert to use this manual or the WaveRIDER

software.

The manual assumes you are familiar with Microsoft Windows.

The hardware portions of this manual are written to reflect SuperM.O.L.E. Gold

firmware versions 9.08 and higher. The software portions reflect versions 5.22

and higher.

vi WaveRIDER

Page 9

y Terms used in this Manual

ECD. introduced the original M.O.L.E. (Multichannel Occurrent Logger Evaluator) in

1986. Over the years ECD has produced several models of the M.O.L.E. for use in a

wide variety of applications. In this manual, we may refer to the SuperM.O.L.E. Gold

data recording device as the M.O.L.E..

Informs the user that the note includes important information.

Informs the user that the note includes a handy tip.

The following statements describe special terms that will be used in this manual.

Hardware Terms:

Informs the user that the note identifies conditions or practices that

could result in damage to the equipment.

Informs the user that the note identifies conditions or practices that

could result in personal injury or damage to property other than the

equipment.

WARNING – Surfaces may be Hot!

SuperM.O.L.E. Gold, may be referred as the M.O.L.E..

WaveRIDER Ready refers to the M.O.L.E. being configured to collect wave solder

data when used with the WaveRIDER kit.

Thermocouple, may be referred to as T/C.

Software Terms:

WaveRIDER SPC software may be referred to as WR SPC.

Workbook, contains all of the worksheets and the uploaded data set saved with file

extension (.MWR).

Worksheet, the individual pages or sheets in the workbook file.

Data Set, multiple data runs uploaded into the workbook file.

Data Run / Experiment, the data uploaded from the M.O.L.E..

WaveRIDER vii

Page 10

y Fonts Used in this Manual

This manual uses a special font to indicate terms or words that can be found directly on

the PC display.

For Example: Select the Open Workbook command from the File menu to open a new

workbook file. This font indicates the words Open Workbook and File are actually found

in the PC display.

y Computer Hardware Requirements

CPU, RAM, Hardware: 300mhz processor or equivalent

128 megabytes of RAM (minimum).

50 megabytes of free disk space.

Operating System: Windows XP & 2000.

Disk Drive: CD Rom drive.

Mouse: Windows compatible mouse.

Communication Port: Serial Port, USB (with port replicator).

Video: Color VGA or better video card and appropriate video

monitor. (SVGA is highly recommended)

It is recommended that the minimum computer display area be set to 800 x 600.

For best performance set the display to 1024 X 768 (Refer to your Microsoft

Windows documentation for details).

Printer: Color printer is recommended.

viii WaveRIDER

Page 11

Operators Safety Information

The safety information in this summary is for the benefit of operating personnel.

Warnings and Cautions will also be found throughout the manual where they apply.

Hardware changes or modifications to the components are not expressly

approved by ECD could void the product’s warranty.

For protection of the kit components, observe the following:

Do not subject the components to sharp impacts.

Do not expose the components to corrosive environments.

Do not expose the RIDER, above the specified maximum temperature.

The warranty will not cover damage caused by neglect or abuse of this product.

To maintain the safety features incorporated in this product, operation must be in

strict compliance with the requirements specified herein.

WaveRIDER ix

Page 12

1.0 System Description

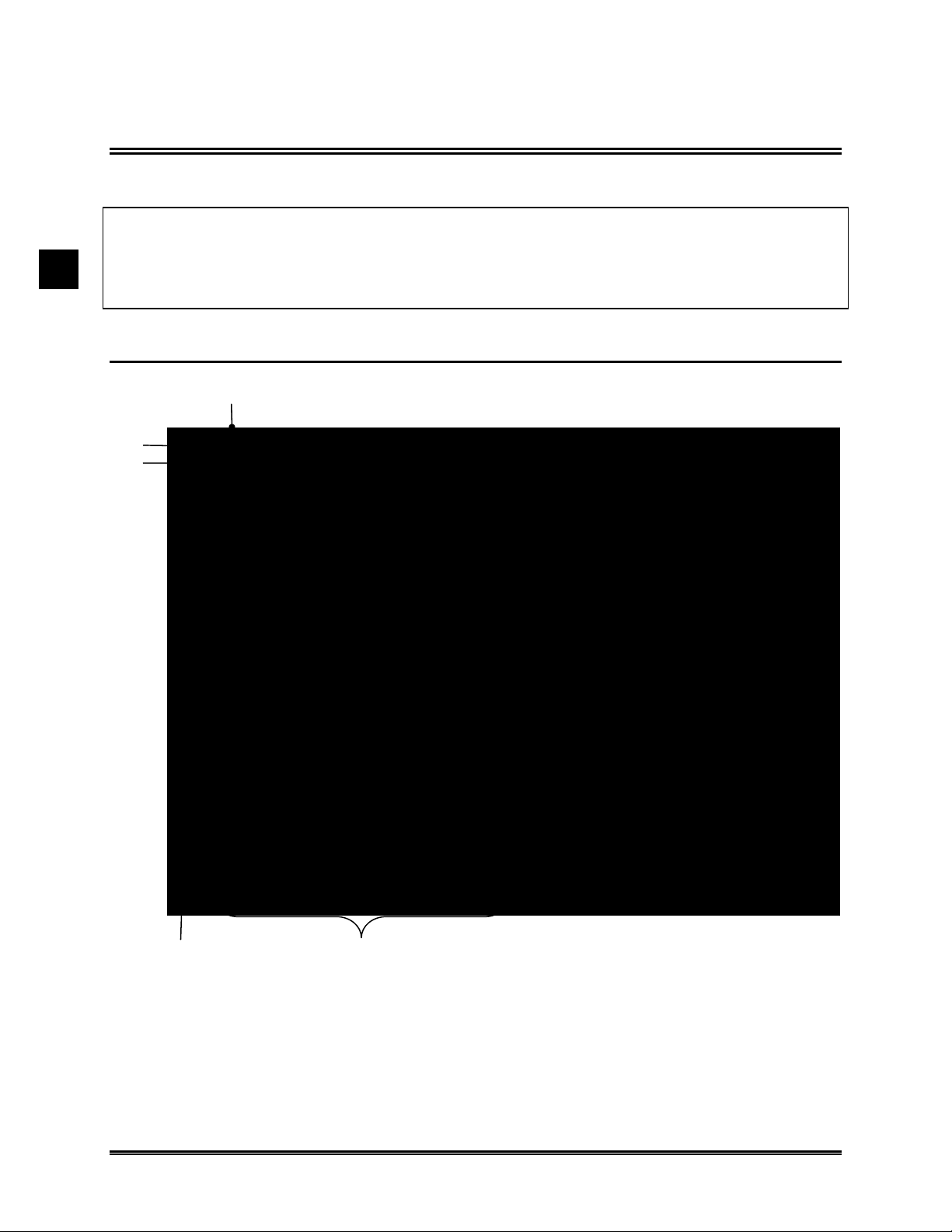

The main WaveRIDER hardware component is called the RIDER. The RIDER is a

solder machine data collection pallet with ECD’s SuperM.O.L.E. Gold at the heart of it.

When the M.O.L.E. is connected to the RIDER it takes on a special WaveRIDER

configuration for proper data interpretation. While riding on the solder machine,

conveyor data from the solder machine is collected by the RIDER and stored in the

internal memory of the M.O.L.E. After the RIDER has completed the data collection, it is

then connected to a PC and the data is uploaded into the WR SPC software for

analysis.

RIDER

PC

1

2

COUPON TEMP.

SENSORS

DISTANCE/TIME SENSORS

3

4

5

6

B

A

C

M.O.L.E.

Figure 1- 1: System Block Diagram

WaveRIDER 1

Page 13

1.1 Rider Description

This section covers brief descriptions for the external and internal features of

WaveRIDER.

External features:

Barrier box: This is the thermal protective barrier for the M.O.L.E..

Barrier locking latch: This latch secures the cover of the barrier to prevent it

from opening.

Coupon: Sensors that record temperature data from the solder machine. (Refer

to section 1.2 Coupon Description for more information).

BARRIER BOX

COUPON

COVER LATCH

Figure 1- 2: WaveRIDER

2 WaveRIDER

Page 14

Internal Features:

Connector bridge: This is where the M.O.L.E. plugs into the WaveRIDER so it

can collect data from the RIDER sensors.

Extractor handle: This handle assists in the removal of the M.O.L.E..

Configuration plug: This plug configures the M.O.L.E. to operate in

“WaveRIDER” mode.

CONNECTOR BRIDGE

EXTRACTOR HANDLE

CONFIGURATION PLUG

Figure 1- 3: WaveRIDER Internal Features

WaveRIDER 3

Page 15

1.2 Coupon Description

Temperature data about a solder machine is taken from three type "K" thermocouples

(T/C) attached to the Coupon. Their purpose is to sense the impact of a solder machine

setup on circuit board "like" material, as opposed to the RIDER pallet material.

THREE TYPE “K”

THERMOCOUPLES

“TOP FOIL” T/C

COUPON

“SOLDER” T/C

“BOTTOM FOIL” T/C

Figure 1- 4: Coupon Description

The "Bottom Foil" T/C is inserted into the coupon as close to the bottom surface as

possible without breaking through. The "Solder" T/C is exposed below the bottom

surface of the coupon so it will contact the solder. The "Top Foil" T/C is inserted into the

coupon near the top surface.

“BOTTOM FOIL”

THERMOCOUPLE

“SOLDER”

THERMOCOUPLE

“TOP FOIL”

THERMOCOUPLE

Figure 1- 5: Coupon Cross section

4 WaveRIDER

Page 16

1.3 Software Description

This section presents an overview of a workbook management window. When the

software is started, it will automatically load the previously saved workbook file.

The first time the software is started a sample file (i.e. WRSample.mwr) will be

opened for users to familiarize themselves with the program. It is recommended

when the user starts collecting process data, a new or existing workbook should

be used.

1.3.1 WR SPC Workbook Features

The workbook has several features as described in the following section.

TITLE BAR

MENUS

TOOLBAR

STATUS BAR

WORKSHEET TAB

SCROLL ARROWS

WORKSHEET TABS

SPLIT BAR

Figure 1- 6: Workbook Features

VERTICAL SCROLL BAR

HORIZONTAL

SCROLL BAR

WaveRIDER 5

Page 17

Title Bar: This bar contains the program name, version, and the active workbook

file name.

Menus: These menus contain the commands and tools for each worksheet.

Each worksheet may contain different commands that supply specific support for

each worksheet. Individual worksheet menus are described in detail in their

specified sections of this manual.

Toolbar: The Toolbar has buttons to serve as shortcuts to the menu commands.

Individual worksheet toolbar buttons are described in detail in their specified

sections of this manual. Each worksheet may have different items on the toolbar

because of the different features offered by each worksheet.

Worksheet Tabs: These tabs are used to gain access to each worksheet.

Tab Scroll Arrows: These arrows are used to view other worksheet tabs if the

Horizontal scroll bar is covering them.

Split-bar: This bar slides the Horizontal Scroll bar to the left or right so all or part

of the worksheet tabs can be viewed.

Status Bar: This bar on the bottom of the worksheet display, shows the available

Help information, mouse pointer X-Y position, current date and time.

Horizontal Scroll Bar: This bar scrolls the worksheet display horizontally left

and right.

Vertical Scroll Bar: This bar scrolls the worksheet display vertically up and

down.

6 WaveRIDER

Page 18

1.4 Standard WR SPC Worksheet functions

1.4.1 Worksheet tabs

There are six standard worksheets and up to nine optional SPC sheets. These tabs are

located on the bottom left of the display.

Figure 1- 7: Worksheet Tabs

1.4.2 Selecting Worksheets

To a view worksheet, use the mouse pointer to click on a worksheet tab. The worksheet

tab will then become highlighted, and the worksheet will now be visible.

The keyboard does not allow access to the worksheets. The only way to select

the worksheet is by using the mouse pointer.

Figure 1- 8: Selecting a Worksheet

1.4.3 Split-bar

The Split-bar on the tab bar lets the user slide the Horizontal scroll bar to the left or

right, so all of the worksheet tabs can be viewed. This feature is located on the left edge

of the Horizontal scroll bar.

1.4.4 Worksheet Tab Scroll Arrows

Worksheet tabs may be hidden behind the horizontal scroll bar. To view them, the user

can either use the Tab Scroll Arrows located on the left of the worksheet tabs, or use

the Split-bar.

WaveRIDER 7

Page 19

1.4.5 Scrollbars

The worksheets have both Horizontal and Vertical screen scroll bars so the non-visible

areas of the worksheet can be scrolled into view. The Horizontal scroll bar is located in

the lower right corner and can be scrolled left or right by pressing the left or right arrows

located on each end of the scroll bar. The user may also scroll the display by sliding the

center scroll bar left or right. The Vertical scroll bar located on the right side of the

screen has the same features as the Horizontal scrollbar except it scrolls the worksheet

display up and down.

CLICK TO

CLICK HERE TO SCROLL WORKSHEET TABS

CLICK AND DRAG TO VIEW

WORKSHEET TABS

CLICK AND DRAG TO SLIDE

THE VIEW HORIZONTALLY

Figure 1- 9: Worksheet Options

SINGLE STEP

WORKSHEET

VIEW LEFT OR

RIGHT

It is recommended that the minimum PC display area be set to 800 x 600. For best

performance set the display to 1024 X 768 (Refer to your Microsoft Windows

documentation for details).

8 WaveRIDER

Page 20

2.0 Setup

This section provides the necessary information to setup M.O.L.E. components for data

collection.

2.1 Charging the Power Pack Battery

Because the M.O.L.E. is powered by a rechargeable Power Pack battery, it is important

that it is charged and operating properly prior to performing every experiment. A spare

Power Pack battery may be ordered so the one battery is charging while the other one

is being used.

Charging:

1) Remove the Power Pack battery by separating from the unit.

Figure 2- 1: Removing the Power Pack Battery

WaveRIDER 9

Page 21

2) Plug the transformer end of the charger into a (60Hz 120VAC, in North America)

or (230VAC) wall outlet and the connector end into the Power Pack.

POWER PACK BATTERY

POWER PACK CHARGER

Figure 2- 2: Power Pack Charger

A completely discharged Power Pack takes about 14 hours to be fully charged.

3) When the charging cycle is complete, connect the Power Pack to the M.O.L.E..

When the Power Pack is first connected, the LED will flash once to indicate that

the M.O.L.E. is ready to collect data. If the LED flashes more than once, a

complete reset has occurred and the M.O.L.E. will need to be re-configured.

(Refer to the software manual for detailed configuration information).

The Power Pack battery can be charged continously whenever the M.O.L.E. is not

being used, however, if the M.O.L.E. is going to sit idle for five days or more, you

may want to remove it from the charger.

10 WaveRIDER

Page 22

2.2 Software Installation

1) Insert the CD in the drive.

2) Select Run from the Start menu.

3) Select the Browse command button and navigate to the software CD. Double-

click the installation .EXE file.

4) Select the OK command button to start the installation.

Figure 2- 3: Run Dialog Box

5) Closely follow the setup instructions provided with the software.

2.2.1 Starting the Software

Prior to starting, click the README icon from the WaveRIDER sub-menu in the

documentation program menu to read the latest release notes

After the software is installed, start the software program by double-clicking the

WaveRIDER SPC icon from the desktop.

Figure 2- 4: Program Icon

Once the software installation is complete, it is important to start the software

and configure the software to communicate with the M.O.L.E. (refer to section 2.3

Communications Setup).

WaveRIDER 11

Page 23

2.3 Communications Setup

1) Locate the PC Interface cable and plug the 9-pin connector into a PC COM port

and the other end into the M.O.L.E. Data Port.

If no Serial port exists, use the included USB adaptor to connect the interface

cable to the computer.

COMPUTER

REAR PANEL

RS232 COM PORT

PC INTERFACE CABLE

M.O.L.E.

DATA PORT

Figure 2- 5: PC to M.O.L.E. Connection

2) After the Computer interface cable is connected to a computer and Station, the

Communication (COM) port must be configured in the software to match the

same COM port as the oven computer so they can communicate.

12 WaveRIDER

Page 24

3) Start the software program by either double-clicking the WaveRIDER SPC icon

A

or selecting it from the program sub-menu.

Figure 2- 6: Program Icon

4) Once the software is running, select the Admin worksheet tab.

DMIN WORKSHEET TAB

Figure 2- 7: Admin Worksheet

WaveRIDER 13

Page 25

5) Select the Configuration command from the File menu on the Admin worksheet

and the Configuration dialog box appears.

CONFIGURATION

COMMAND

Figure 2- 8: Configuration Command

14 WaveRIDER

Page 26

6) Click the Auto command button to have the software automatically find the COM

port the M.O.L.E. is connected. If the M.O.L.E. is not detected, there is a

communication problem (Refer to section 6.0 Service and Calibration for help).

Figure 2- 9: Port Configuration Dialog Box

7) Click the OK command button to finish.

WaveRIDER 15

Page 27

2.4 M.O.L.E. Installation

When inserting the M.O.L.E. into the WaveRIDER, make sure it is properly connected to

the RIDER thermocouple bridge and the configuration plug is secure.

CONNECTOR BRIDGE

EXTRACTOR HANDLE

M.O.L.E.

CONFIGURATION PLUG

Figure 2- 10: M.O.L.E. Installation

To remove, pull the extractor handle up and slide the M.O.L.E. away from the connector

bridge.

16 WaveRIDER

Page 28

3.0 Operation

The following section will guide the user through a typical data collection process. These

steps may vary depending on the process your company uses.

Prior to data collection, the M.O.L.E. must be “WaveRIDER Ready” as indicated

by a “WaveRIDER Ready” or “Xpert” sticker on the front of the M.O.L.E..

3.1 Data Collection

1) To start collecting data, the width of the conveyor must be set to match the width

of the RIDER.

2) Set the solder wave, pre-heat temperatures and conveyor speed, as a common

product would be processed.

If the Wave solder machine has an in-line conveyor washer, it must be turned

“OFF” or the RIDER must be removed before it reaches the washer. Washing the

RIDER with the M.O.L.E. installed may cause damage.

WaveRIDER 17

Page 29

3) Open the barrier box and make sure the configuration plug is in place and the

M.O.L.E. is connected to the Connector Bridge.

4) Press the start/stop button once to start the M.O.L.E.. When the M.O.L.E. turns

“ON” the activity light will flash and then illuminate and stay constant for the

duration of the run.

5) Close the barrier box cover and latch securely.

Figure 3- 1: Starting the M.O.L.E.

18 WaveRIDER

Page 30

6) Place the RIDER on to the Wave solder machine conveyor. Make sure the

A

RIDER is being fed into the machine in the proper direction. There are two

arrows on the RIDER barrier that indicates the proper direction. If a manual feed

wave solder machine is being used, hold the RIDER until the conveyor fingers

have completely grabbed the RIDER.

CONVEYOR

DIRECTION

RROW

Figure 3- 2: Proper RIDER Loading

WaveRIDER 19

Page 31

7) Retrieve the RIDER when it has traveled completely through the wave solder

machine. The bottom of the RIDER will be HOT so using protective gloves,

retrieve the RIDER from the conveyor. The best way to handle the RIDER when

retrieving from the solder machine is to place one hand under the RIDER and

use the other hand to grab the barrier box cover.

8) Now that the data collection is complete, it is important to open the barrier box

cover to prevent the internal temperature of the M.O.L.E. to rise above operating

temperature specification. To turn the M.O.L.E. “OFF”, press and HOLD the

Start/Stop button until the M.O.L.E. indicator light turns off, then release the

button.

9) Remove the M.O.L.E. from the barrier by removing the configuration plug and

pulling the extractor handle up. Allow the RIDER and M.O.L.E. cool to room

temperature before collecting data again.

EXTRACTOR HANDLE

M.O.L.E.

CONFIGURATION PLUG

Figure 3- 3: Removing the M.O.L.E.

20 WaveRIDER

Page 32

Data Collection Tips:

When turning the WaveRIDER “OFF” after the data collection process is

complete, do not release the button until the light goes off. Pressing the

Start/Stop button briefly will restart the data collection process and erase all the

data in memory.

The WaveRIDER continues to capture data until its memory is full or until it is

turned “OFF". It is recommended to turn RIDER “ON” after it is placed on the

wave solder machine conveyor, then turn it “OFF” as soon as possible after it

exits the solder machine.

If the production process uses pallets, the WaveRIDER sensors may not come in

contact with the solder wave. If this condition occurs, try the following options:

a) Install the RIDER into one of the pallets, which can adjust to fit the RIDER.

b) Raise the solder wave(s) height. (This does not represent actual machine use so

this option should be avoided).

WaveRIDER 21

Page 33

3.2 Transferring Data

When the data collection process is complete, data can then be analyzed using the WR

SPC software.

To read WaveRIDER data:

1) Connect the M.O.L.E. to the PC (refer to section 2.3 Communications Setup for

more information).

2) Start the software and select the Read WaveRIDER Data command from the

WaveRIDER menu. A status bar dialog box appears indicating that data retrieval

from the M.O.L.E. has begun.

Figure 3- 4: Read WaveRIDER Dialog Box

Once data transfer is complete, the dialog box will disappear and will return to the

current worksheet.

If the WaveRIDER has not collected enough data to create a complete profile a

message box appears.

Figure 3- 5: Communication Error Dialog box

22 WaveRIDER

Page 34

3.3 Expert Matrix

If the WaveRIDER has detected a problem during the data collection process, the

Expert Matrix is designed to guide the Operator (Expert) to trouble-shoot potential

causes that may have been discovered while interpreting the data printout. The kit

includes an Expert Matrix to be used in conjunction with the WaveRIDER Data

worksheet in the software to help diagnose and correct soldering problems caused by

solder machine setup or malfunction.

There are three main areas on the expert guide:

Problem (1): This column is used to indicate the wave solder machine problem.

Potential Cause (2): This is a list of potential machine causes.

WaveRIDER Parameter (3): This column is a list of information the WaveRIDER

supplies on the printout that correlates to the potential

cause.

The numbers assigned to the Potential Causes are on a scale of 1-3. (1) Low impact on

that particular cause and (3) would mean that it has a High impact.

WaveRIDER 23

Page 35

WaveRIDER Parameter (3) Problem (1)

A36-9283-06 Rev 1.2

Solder Wave Parallelism

Solder Wave Immersion Depth

Solder Wave Contact Lengths (A, B, C)

Solder Wave Dwell Times (A, B, C)

Solder Wave Temp

Delta Temp at Solder Wave

Chip Wave Parallelism

Chip Wave Immersion Depth

Chip Wave Contact Lengths (A, B, C)

Chip Wave Dwell Times (A, B, C)

Chip Wave Temp

Delta Temp at Chip Wave

Conveyor Speed

Maximum Preheat Slope

Minimum Preheat Temperature

Maximum Preheat Temp.

Potential Cause (2)

1

1

2

3

312

1

333

333

333

3

233

2.0 inches

< 0.3 sec

0.062

2

2

3

3 sec

3

1

1

1

495°F

100°F

2

3

333

333

333

2

2

3

.062 inches

< 0.3 sec

1

1

1

0.5 inches

2

2

3

3

3

2

1 sec

1

3

1

1

1

495°F

N/A

3

Conveyor speed too fast….Reduces dwell time in wave and forces preheat t o be to high

2

3

Preheat temp low….Solder pads not within 100°F of solder wave temperature

3

Conveyor speed too low….increases dwell time in solder wave

Carrier bent or damaged….Board must run parallel (flat ) over wave

Conveyor fingers bent….Board may not b e parallel over solder wave

Vibrator, 2nd wave OFF….Solder is not evenly distributed

Flux applied is insufficient….Spotty application or weak activity flux

Rails not parallel (flat) over nozzles….One side of board deeper in solder wave than the other

Wave or nozzles not level….Must be parallel to conveyor

Wave temperature too high….Solder and components are getting cooked

Conveyor width too tight….May warp board up or down while in wave

2

3

Preheat too high….Heating slope is too steep

Assembly too heavy….Weight or components bending board

Board too wide….Wide boards lack strength to support their weight

3

Conveyor jerky or vibrating….Disturbs solder joints whil e cool ing

Flux not uniform across bottom of board….Spotty application of flux

3

3

Preheat slope too steep….Heats components faster than recommended

Chip wave OFF….Solder is not evenly distribut ed

Chip wave activity too low….Solder is not evenly distributed

Wave height/exit incorrectly set….Exit speed of solder should match conveyor speed

Wave solder splash….Too active wave splashes solder on exit

3

Assembly removed too early….Solder not hardened before distributed

Carrier too tight….May warp board up or down while in wave

Conveyor too low….Boards below wave

Chip nozzle clogged….Solder is not evenly distributed

Vibrator, 2nd wave too low

Wave height too high….Wave height greater than thickness of board

Flux air knife too strong….Blows flux off board

Board not run in best direction….Component shadowing

Flux activator low….Low flux density

Flux activity too low….Flux not aggressive enough

2

3

Cooling rate too slow….Solder not hardened bef ore distributed

Dross recirculating from pot to wave….Excessive dross build up

Pallet center support missing or poor

Vibrator, 2nd wave too high….Causes splashing of liquid solder

Chip wave lower in spots….Solder is not evenly distributed

Air knife after wave set incorrectly….Air knife not effectively blowing off excess solder

Flux liquid in holes….Flux density too high or too much flux applied to board

Room Temp

5°F/Sec

4 ft/Min

225°F

Cracked Components

Solder Balls on Assembly

3

3

3

3

2

3

3

2

2

1

Cold Solder Joints

Grainy or Disturbed Joints

Solder Wave Over Flooding Board

Unfiltered Via Holes

Solder Bridges

Solder Skips

3

331

3

3

3

2

3

233

222

3

3

1

2

122

112

2

3

1

2

3

3

3

3

3

3

3

3

3

3

3

3

3

1

1

2

1

1

1

1

1

1

2 = Moderate Impact

3 = High Impact

1 = Low Impact

Typical Values

24 WaveRIDER

Page 36

Interpreting the Expert Guide:

Example problem: Use the troubleshooting Expert’s Guide shown below.

PROBLEM (1)

In the example, Solder Bridges is the problem that has been detected.

The next step is, follow the row to the right. Now determine the potential cause that

best fits the problem. In the columns, there are impact numbers rated 1,2 or 3.

These impact numbers help the user to decide which potential cause is most

important to the problem. There is a legend on the Expert Guide, 3 = High Impact, 2

= Moderate Impact, and 1 = Low Impact. Now read and sort out the potential

causes that best fit the problem. In the example, the solder bridges row has several

columns with impact numbers. All the probable causes should be read and the

highest potential cause that was selected is in the next step.

POTENTIAL CAUSE (2)

Conveyor speed to slow…….Increases dwell time in solder wave.

Once the potential cause has been determined, continue following the column down

to the rows with impact numbers.

If there are no impact numbers in the WaveRIDER parameter rows, the

WaveRIDER cannot assist the user in this area.

Now read all the WaveRIDER parameters that have impact numbers. Once the

problem WaveRIDER parameter has been determined, correct adjustments can be

made. In the example, there are several impact numbers and the one that has been

selected is in the next step.

WaveRIDER® PARAMETER (3)

It is determined that the Conveyor Speed best indicates the likely cause and the

proper adjustments should be made.

WaveRIDER 25

Page 37

WaveRIDER Parameter (3 ) Problem (1)

A36-9283-06 Rev 1.2

Solder Wave Contact Lengths (A, B, C)

Solder Wave Dwell Times (A, B, C)

Chip Wave Contact Lengths (A, B, C)

Chip Wave Dwell Times (A, B, C)

Conveyor Speed

Potential Cause (2)

Solder Bridges

Conveyor speed too fast….Reduces dwell time in wave and forces preheat to be to high

1

2

1

2

Preheat temp low….Solder pads not within 100°F of solder wave tempe rature

3

Conveyor speed too low….increases dwell time in solder wave

Carrier bent or damaged….Board must run parallel ( flat) over wave

Conveyor fingers be nt….Board may not be parallel over solder wave

Flux applied is insufficient….Spott y application or weak activity flux

Rails not parallel (fl at ) ov e r noz zles….One side of board deeper in s ol der wav e th an th e ot her

Wave or nozzles not level….Must be parallel to conveyor

Wave height/exit inc or rec t l y s et … . E x i t s pee d of s ol der s hou ld mat ch conveyor speed

Board not run in best direction….Component shadowing

Dross recirculating from pot to wave….Excessive dross build up

3

3

3

3

2

2

2

1

3

1

1

1

2 = Moderate Impact

3 = High Impact

1 = Low Impact

< 0.3 sec

0.062

2.0 inches

495°F

100°F

3 sec

Typical Values

Air knife after wave set incorrectly….Air knife not effectively blowing off excess solder

495°F

N/A

5°F/Sec

4 ft/Min

Room Temp

225°F

.062 inches

0.5 inches

< 0.3 sec

1 sec

Figure 3- 6: Troubleshooting Process

26 WaveRIDER

Page 38

3.4 Cleaning the Rider

After completing the data collection process, cleaning the RIDER is very important

because some types of flux tend to build up on the RIDER very quickly. The following

information will discuss various cleaning machines and methods used to clean the

RIDER, and how to get it ready for the data run.

The M.O.L.E. must be removed before the RIDER is cleaned because it may be

damaged or destroyed by water or solvents.

1) Turn the locking latch and the raise barrier box cover until it comes to a rest.

Remove the configuration plug, and pull the extractor handle to remove the

M.O.L.E..

p

o

n

Figure 3- 7: SuperM.O.L.E. Gold Removal

q

2) Using a brass wire brush with fine bristles, clean the contact sensors on the

bottom of the RIDER pallet. When cleaning the sensors, use enough force to get

them cleaned and free from debris but not too much that they will be damaged.

3) Once the M.O.L.E. is removed, make sure that the configuration plug is tucked

under the cover while it is closed and rotate the locking latch to secure.

4) Open the barrier box cover allowing inside completely dry. Once the RIDER is

dry and insert the M.O.L.E. into the RIDER.

WaveRIDER 27

Page 39

3.5 Storing the RIDER

The operator has several options when deciding how to store the RIDER. Deciding

where and how to store the RIDER will depend on how the work area is set up. The

RIDER has two holes on the left and right side so the operator can hang the RIDER in a

place that is out of the way of normal production flow. If there is not an available area to

hang the RIDER, put it back into the packaging case.

If the RIDER is not going to be used for a long period of time, the Power pack

battery may lose its charge and may need to be recharged.

Figure 3- 8: Proper RIDER Storage

STORAGE

HOLES

28 WaveRIDER

Page 40

4.0 Worksheet Descriptions

The following sections offer brief explanations for the worksheet functions, and how they

benefit the user. Refer to section 5.0 Menu and Tool Commands for information on the

menu commands.

4.1 The Welcome Worksheet

The Welcome worksheet is the introductory worksheet. This worksheet contains a

WaveRIDER introductory illustration and a text box for entering a company or workbook

name.

Welcome worksheet features:

Menus and Toolbar

Company/Report Name Text Box

MENUS

TOOLBAR

COMPANY NAME TEXT BOX

Figure 4- 1: Welcome Worksheet

WaveRIDER 29

Page 41

4.1.1 Welcome Worksheet Menus and Toolbar

Menus: File, View, WaveRIDER, Navigate, and Help.

Toolbar Buttons: Print, Zoom In, Zoom Out, 100%, Read WaveRIDER Data,

and About.

Figure 4- 2: Welcome Worksheet Menus and Toolbar Buttons

30 WaveRIDER

Page 42

4.1.2 Company/Report Name

The text box located on the bottom half of the Welcome worksheet allows the user enter

a company or report name.

To enter a name:

1) Using the mouse pointer, click in the text box.

2) Type a desired name and then hit the [enter] key to accept or [esc] to cancel.

Figure 4- 3: Entering a Company Name

WaveRIDER 31

Page 43

4.2 WaveRIDER Data Worksheet

The WaveRIDER Data worksheet is where individual data runs are viewed in single

page format.

WaveRIDER Data worksheet features:

MENUS

TOOLBAR

DATA SHEET

Menus and Toolbar

Data sheet

Figure 4- 4: WaveRIDER Data Worksheet

32 WaveRIDER

Page 44

4.2.1 WaveRIDER Data Worksheet Menus and Toolbar Buttons

Menus: File, View, WaveRIDER, Navigate, and Help.

Toolbar buttons: Print, Zoom In, Zoom Out, 100%, Read WaveRIDER Data,

About, First (data run of the data set), Back (to previous data run), Forward (to

the next data run), and Last (data run of the data set).

Figure 4- 5: WaveRIDER Data Worksheet Menus and Toolbar Buttons

WaveRIDER 33

Page 45

4.2.2 Interpreting the WaveRIDER Data Sheet

(1)

2

)

(3)

(4)

(6)

(5)

The following section defines the features of the WaveRIDER Data sheet. The Group

Parameters on the data sheet are color coded so when they are viewed on other

worksheets they can be easily associated with the Label Parameters.

(

Figure 4- 6: Document View

(1) Company Name, Machine Name, and Part Number configured by user.

(2) Pre-heat Parameters and Conveyor speed.

(3) Chip Wave Parameters (Blank column if there is no chip wave).

(4) Solder Wave Parameters.

(5) M.O.L.E. Internal Status.

(6) Overall Coupon Parameters.

Refer to APPENDIX C: Measurement Definitions for Parameter defintions

If a parameter has no value (blank) that means that there was insufficient

contacts detected to give a complete reqort.

34 WaveRIDER

Page 46

4.2.3 Data Coloring and LSL / USL

The parameter data and the user specified LSL (Lower Specification Limit) and USL

(Upper Specification Limit) text fields on the Admin (Administration) worksheet are

linked to indicate that a parameter has exceeded a user specified specification limit. If a

USL has been exceeded, that parameter will be underlined and appear on the Data

sheet in Red (indicating it is above the specification limit). If a parameter is less than the

user specified LSL, that parameter will be underlined and appear in the Data sheet in

Blue (indicating below the specification limit).

EXCEEDED USL

PARAMETER (RED)

EXCEEDED LSL

PARAMETER (BLUE)

Figure 4- 7: Data Coloring

See section 4.5.4 Specification and Control Limit Cells for information on how to

enter user LSL and USL values.

WaveRIDER 35

Page 47

4.3 Spreadsheet Worksheet

The Spreadsheet worksheet contains data that is collected by the WaveRIDER, and is

put into standard spreadsheet format. Each row in the spreadsheet represents one data

run. Using the Admin worksheet in conjunction with the Spreadsheet worksheet the user

can select parameters to be displayed on the worksheet.

Spreadsheet Worksheet features:

Menus and Toolbar Statistics

Parameter Group (color coded) User Definable Columns

Parameter Labels Parameter Units

Data Run Rows Filters

MENUS

TOOLBAR

PARAMETER

GROUPS

DATA RUN

ROWS

SELECTED

DATA RUN

PARAMETER

LABELS

PARAMETER

UNITS

FILTERS

USER DEFINABLE

COLUMNS

Figure 4- 8: Spreadsheet Worksheet

36 WaveRIDER

Page 48

4.3.1 Spreadsheet Menus and Toolbar Buttons

Menus: File, Edit, View, Format, Window, WaveRIDER, and Help.

Toolbar buttons: New, Open, Save Workbook, Print, Undo, Redo, Zoom In,

Zoom Out, 100%, Align left, Center, Align right, Bold, Italic, Underline, Read

WaveRIDER Data, Dock Printout Settings, and About.

Figure 4- 9: Spreadsheet Worksheet Menus and Toolbar Buttons

WaveRIDER 37

Page 49

4.3.2 Parameter Groups

S

Parameter Groups are the headers for a specific group of data parameters collected by

the M.O.L.E.. They are color coded with the associated Parameter Labels so they can

be easily identified together.

The width of each parameter column can be adjusted to be larger or smaller by

placing the mouse pointer over a split line dividing the parameter columns and

sliding it to the desired width.

PARAMETER GROUP

PLIT-LINE POINTER.

Figure 4- 10: Parameter Group

38 WaveRIDER

Page 50

The Parameter Groups are defined as the following:

User Defined Parameter Group: These parameter columns can be used to

enter text to help identify the row with unique

information about that run (i.e. shift, operator,

line number, part number). This information will

also appear in the Tool Status box on the

Profile worksheet.

General Parameter Group: This group contains file information associated

with the run such as; date and time, (of profile)

and the data file tag.

Preheat Parameter Group: This group contains Pre-heat Temperature

Data.

M.O.L.E. Parameter Group: This group contains the physical condition of

the M.O.L.E. at the end of the run.

Chip Wave Parameter Group: This group contains the thermal and

mechanical data from the Chip Wave (first of

two waves).

Solder Wave Parameter Group: This group contains the thermal and

mechanical data from the Solder Wave.

Coupon Parameter Group: This group contains the coupon temperature,

and Slope data.

WaveRIDER 39

Page 51

4.3.3 Parameter Labels

The Parameter Labels are where all of the specific parameters for each group are listed.

The user can decide which parameters will be shown on the Spreadsheet worksheet

from the Admin worksheet as discussed in section 4.5.3 Parameter check boxes.

PARAMETER LABEL

Figure 4- 11: Parameter Label

4.3.4 Parameter Units

The Parameter Units are the units of measurement for that parameter. For example, in

the Preheat Group Parameter, the Parameter Label Temp: is in F.

PARAMETER UNITS

Figure 4- 12: Parameter Units

40 WaveRIDER

Page 52

4.3.5 Data Run Rows

All of the data runs uploaded into a workbook file are listed on the Spreadsheet

worksheet as individual rows. The first data run uploaded into the workbook file is on the

bottom and the most recent data run uploaded is on the top.

When any data run row is selected, all of the cells in the entire row are highlighted in

purple and blue. The purple cells indicate that the cells can be modified and the blue

cells indicate the data cannot be modified.

When any individual data cell in a data run row is selected, all of the cells in the entire

row are highlighted in green and yellow. The green cells indicate that the cells can be

modified and the yellow cells indicate the data cannot be modified.

The data run rows can also be moved into any order desired. This is useful when the

user wants to place similar data runs together.

To change the order of the data run:

1) Select the number cell of a data run row with the mouse pointer. The row will

then become highlighted in purple and blue.

2) Drag the row and drop it to a desired location.

Figure 4- 13: Drag and Drop Data Rows

4.3.6 Selected Run

When a data run row is selected, the data for that row will be shown in the Sel= row

located at the bottom of the data run rows. This row also allows the user to easily

compare the selected data row to the statistics calculations located below the selected

run row.

Entire selected rows and columns can be “copied” by pressing keys (CTRL + C)

and then “pasted” (Ctrl + V) into other spreadsheet applications.

WaveRIDER 41

Page 53

4.3.7 Filters

There are Filters for each parameter label that filter specific data out of runs listing.

Filtering more than one column at a time acts as a Logical AND Function. All

conditions of all set filters must be met for data row(s) to remain visible.

How to use the Filter function:

1) Click the Filter button to reveal the unique data as populated in that column

under that particular parameter label.

2) Select a desired data value to filter, or the two standard filters All and Special.

FILTER ARROW BUTTON

Figure 4- 14: Filter Function

42 WaveRIDER

Page 54

To use the All option:

1) Select All to reset the filter for that column and view all of the data run rows that

meet the other column filters.

To use the Special option:

1) Select Special to select data run rows within a range of values. There are multiple

options to select information to filter by clicking the appropriate relational

operators option button (See Figure 4- 15). The user can either select data from

a populated list or type it in the text box on the top of the column.

= equal to >= greater than or equal to

> Greater than <= less than or equal to

< less than <> Not equal to

Figure 4- 15: filter option buttons

WaveRIDER 43

Page 55

2) Select a data filter by:

Clicking the greater than relational operator option button beside the left data

column.

Click a parameter value from the list or type it in the text box.

Click the AND logical operator option button.

Click the less than relational operator option button beside the right data column.

Click a parameter value from the list or type it in the text box.

The Clear command button can be selected at any time to clear the selections and

the new values can be selected.

3) Click the OK command button to accept the selected data filters or Cancel to

return to the worksheet without executing the filter request.

Figure 4- 16: Special Filter Feature Dialog Box

In this example, the data filtered would be all times between, but not including 06:25:33

and 14:08:00.

To reset all of the data set rows to restore the entire set of collected data, click

the Filter Reset button on the Spreadsheet worksheet.

44 WaveRIDER

Page 56

4.3.8 Statistics

There are rows located on the bottom of the Spreadsheet worksheet, which are the

combined calculations for all the data runs that are currently being viewed in the

Spreadsheet worksheet display. The following information is the definitions for each

Statistics row:

N = Number of samples included in the calculations

Min. = The lowest value in the parameter column.

Max. = The highest value the parameter column.

Avg = The average of all values in the parameter column.

Std. Dev. = The standard deviation of the values in that column.

WaveRIDER 45

Page 57

4.4 Profile Worksheet

The Profile worksheet is where a selected data run is represented graphically. The

software allows the user to analyze the data and to compute statistics based on the

data.

Profile worksheet features:

y Menus and Toolbar y Data Tabs

y M.O.L.E. Status y Status Bar

y Tool Box Status y Data Table

y Magnify Map y Scale

y Sensor Locations y Data Graph

y Channel Check Boxes

MENUS

TOOLBAR

M.O.L.E.

STATUS

TOOL

STATUS

BOX

MAGNIFY

MAP

CHANNEL

CHECK

BOXES

DATA TABS

STATUS BAR

SENSOR LOCATIONS

Figure 4- 17: Profile Worksheet

DATA

GRAPH

DATA TABLE

46 WaveRIDER

Page 58

4.4.1 Profile Menus and Toolbar Buttons

Menus: File, Edit, Window, WaveRIDER, Profile, Tools, Navigate, and Help.

Toolbar buttons: New, Open, Save Workbook, Print, Magnify, Slope, Peak

Difference, Overlay, 3-D, Notes, Erase Object(s), Erase All, Read WaveRIDER

Data, Dock Printout Settings, About, First (data run of the data set), Back (to

previous data run), Forward (to the next data run), and Last (data run of the data

set).

Figure 4- 18: Profile Worksheet Menus and Toolbar Buttons

WaveRIDER 47

Page 59

4.4.2 M.O.L.E. Status

The M.O.L.E. STATUS box contains information about the status of the M.O.L.E. while it

collected the data the selected run.

MOLE STATUS

Figure 4- 19: M.O.L.E. Status Window

Max Internal T: This is the highest internal temperature logged during the displayed

profile and is displayed in degrees Celsius. If the highest temperature logged is in

the specified internal operating temperature range of is 0-54C, it appears in

BLACK. When the internal temperature is 55-64C, it appears in YELLOW

indicating that the M.O.L.E. has reached the Warning zone and is approaching

the maximum recommended operating temperature of 65C. If the internal

operating temperature is above 65C, it appears in RED indicating that the

maximum internal operating range has been reached.

Battery: The battery voltage measured during the upload of that run. The nominal

range for normal operation is 5.1 to 4.7V.

Points: The number of data samples recorded at the configured interval.

Active: Indicates which channels were active during the experiment. A number

means an active channel; a “O” is an inactive channel. An "X" means an open or

out of range T/C was detected on that channel during the data run.

Interval: Time between data shown in hours, minutes, seconds, and tenths of

seconds data points: hh:mm:ss.t.

Date: Date of last data point logged.

Time: Time of last data point logged.

V: Firmware Version displays the operating code of the M.O.L.E. (This is where

customer service will ask you to find the version number for the M.O.L.E.)

48 WaveRIDER

Page 60

4.4.3 Tool Status Box

The Tool Status box displays information on how to use a selected tool command and

other information during tool use. Prior to using a tool command, the Tool Status box

displays the Spreadsheet worksheet User definable column information that is

associated with the selected data run.

When a Tool command, such as Magnify, is selected, a message appears in the box

stating “Click and drag to select area”.

TOOL

STATUS

Figure 4- 20: Tool Status Message

Once the user has completed the tool command, the user data will be displayed again.

WaveRIDER 49

Page 61

4.4.4 Magnify Map

The Magnify Map displays a small map of the entire profile and indicates the area

currently magnified with a red crosshatched box.

MAGNIFIED

AREA

Figure 4- 21: Magnify Map

50 WaveRIDER

Page 62

4.4.5 The Data Table

The Data Table includes various values depending on which Data Tab is selected. The

rows always indicate the channel and the columns vary depending on which data tab is

active.

DATA TABLE

Figure 4- 22: Data Table

WaveRIDER 51

Page 63

4.4.5.1 Value Pop-up

Each value in the Data Table can be displayed as a Value Pop-up. A Value Pop-up is

graphically illustrated on the Data Graph showing how and where that value was

extracted from the profile.

Only one Value Pop-up can be displayed on the Data Graph at a time.

VALUE POP-UP

SELECTED VALUE

Figure 4- 23: Value Pop-up

To display a Value Pop-up:

1) Select the Profile worksheet.

2) Move the mouse cursor and pause over a desired value in the Data Table. That

value will automatically be displayed on the Data Graph where that value was

extracted.

The last displayed Value Pop-up will remain on the Data Graph until the user

selects a different worksheet.

52 WaveRIDER

Page 64

4.4.5.2 Show/Hide Columns

Data Table parameter columns on the Profile worksheet can be hidden. This is useful

when an operator wants to focus attention to the most important parameter columns.

Figure 4- 24: Show/Hide Columns

To display Show/Hide columns:

1) Select the Profile worksheet.

2) Right click a parameter column header.

3) Clear a parameter check box to hide or select to display.

Hidden Parameter columns do not affect the data being collected for that

parameter. If all Parameter columns are hidden, right-click the Sensor locations

column header to open the Show/Hide column dialog box.

WaveRIDER 53

Page 65

4.3.5.3 Change Summary Stats Settings

When creating a new workbook, a dialog box appears allowing the user to specify

Summary Statistics settings based on user selected values.

If the process changes or an operator wishes to perform test experiments, these

settings can be changed by clicking a parameter column header on the Profile

worksheet.

Figure 4-25: Modify Summary Stat Settings

To Change Summary Stats Settings:

1) Select the Profile worksheet.

2) Select the Summary Stats tab.

3) Click the Time Above or Time between column header.

4) Change the desired Summary Stats settings and select the OK command to

accept.

5) Once the new settings have been accepted, the software prompts the user to

decide if these new settings should be applied to future data run profiles.

54 WaveRIDER

Page 66

4.3.5.4 Change Slope Calculator

Positive and negative slope profile parameter calculator allows the user to calculate

straight line slopes between any two temperatures. (Default to liquidous and liquidous to

peak).

If the process changes or an operator wishes to perform test experiments, these

settings can be changed by clicking a parameter column header on the Profile

worksheet.

Figure 4- 26: Modify Summary Stat Settings

To Change Slope Calculator:

1) Select the Profile worksheet.

2) Select the Summary Stats tab.

3) Click a Peak Slope column header.

4) Change the desired settings and select the OK command to accept.

5) Once the new settings have been accepted, the software prompts the user to

decide if these new settings should be applied to future data run profiles.

WaveRIDER 55

Page 67

4.4.6 Sensor Locations

The location for each sensor labeled in the Data Table. The color and description

indicates which Data Plot on the Data Graph it designates. The top three sensor

location descriptions are the Coupon Top, Coupon Solder, and Coupon Bottom sensors.

The bottom three are the A, B and C speed sensors.

SENSOR

DESCRIPTIONS

Figure 4- 27: Sensor Location Descriptions

56 WaveRIDER

Page 68

4.4.7 Channel Check Boxes

The Channel check boxes control whether the associated Data Plot is displayed on the

Data Graph and whether the data for that channel are included in the data table. To

view or remove a Data Plot, click the channel check box beside a sensor location

description to turn it “ON” or “OFF”.

CHANNEL CHECK BOXES

Figure 4- 28: Channel Check Boxes

WaveRIDER 57

Page 69

4.4.8 Status Bar

The Status Bar shows the available Help information, X-Y position of the mouse pointer,

current date and time.

HELP INFORMATION

Figure 4- 29: Status Bar Features

58 WaveRIDER

X-Y READOUT

DATE & TIME

Page 70

Help Information

When the mouse pointer is placed over a Toolbar button the left side of the Status bar

will display the action that button performs.

X/Y Readout

It is easy to find the exact X and Y-values of any point on the Data Graph using the

mouse pointer. The X/Y Readout continuously displays the X and Y-axes values of the

mouse pointer location.

The units displayed for X and Y-values are the same as those displayed on the graph.

The user can select between F and C for the Y-value units. The X-value units can be

a data point number, time, or distance. Units can be changed on the X and Y-axes at

any time by selecting the Units command in the Profile menu.

While using the Magnify tool, the X/Y Readout displays the size of the selected

area of interest.

Other ways to view exact X- and Y-coordinates of a data point is to select the

Value Tab.

y Date and Time

This area of the Status bar displays the current time and date of the PC.

WaveRIDER 59

Page 71

4.4.9 Data Tabs

Data Tabs is where the user can view a variety of sensor information in the Data Table.

The Data Tabs are:

Value

Time to Ref

T above Ref

Statistics

Summary Statistics

KPI (Key Process Indicators)

Only one data tab can be active at a time. Each is described below.

When the Magnify tool is used to zoom in on a portion of the Data Graph, the Data

Table displays the statistics for those values that are displayed. (This feature

does not apply to the Summary Stats Data Tab).

60 WaveRIDER

Page 72

4.4.9.1 Value

When the Value Tab is selected, the Data Table lists the temperature at the point where

an X-cursor intersects a Data Plot. There are four X-cursors and the positions can be

changed at any time by moving the X-cursor (Refer to the descriptions in section

4.4.10.5 X-Cursors). As an X-cursor is moved, the values in the Data Table are

automatically updated.

Figure 4- 30: Value Data Tab

Values in the Data Table depend on the units of the X and Y-axis.

WaveRIDER 61

Page 73

4.4.9.2 Time to Reference

When the Time to Reference Tab is selected, the Data Table displays the time it takes

the channels to reach fixed Temperature Reference Line(s). Times are expressed as

HH:MM:SS (H=hours, M=minutes, S=seconds). Up to three Temperature Reference

Lines can be added to the Data Graph that are used in this statistic by using the Temp

Ref Lines command in the Profile menu.

Figure 4- 31: Time to Ref Data Tab

62 WaveRIDER

Page 74

4.4.9.3 T Above Ref

When the T Above Ref Tab is selected, the Data Table shows the amount of time each

sensor measured data above the Temperature Reference Lines. Times are expressed

as HH:MM:SS (H=hours, M=minutes, S=seconds) and are the total time above

reference line regardless of when the value was above.

Figure 4- 32: T Above Ref Data Tab

Temperature Reference Lines can be added, deleted, or moved at any time using

the Temp Ref Lines command in the Profile menu.

WaveRIDER 63

Page 75

4.4.9.4 Statistics

When the Statistics Tab is selected, the first four columns of the Data Table displays the

minimum and maximum temperature found for each Data Plot and the value of X (time,

distance, or point number) at which it occurred.

The last two columns of the Data Table displays the Average (Mean) and Standard

Deviation of the temperature values recorded for each sensor.

Figure 4- 33: Statistics Data Tab

If a portion of the Data Graph is magnified using the Magnify tool, the Data Table

displays the Mean and Standard Deviation of the values currently displayed.

64 WaveRIDER

Page 76

4.4.9.5 Summary Statistics

When the Summary Stats Tab is selected, the Data Table displays a summary of primary

statistics from the entire data set. These summary statistics always display the statistics

derived from the entire profile regardless of the level the Data Graph is zoomed.

Figure 4- 34: Summary Statistics

WaveRIDER 65

Page 77

4.4.9.6 KPI (Key Process Indicators)

When KPI is the active data tab, the Data Table displays statistics from the Profile

configured by the user. This is useful so the user can display the most important

information that best suits their needs or application.

Figure 4- 35: KPI Data Tab

66 WaveRIDER

Page 78

Key Process Indicators Setup:

1) Make sure the KPI Data Tab is active.

2) Click the KPI Setup button above the Sensor Locations descriptions.

The KPI Setup can also be activated by right-clicking a column header.

Figure 4- 36: KPI Setup

3) Click the desired parameters to display in the Data Table. The parameters are

grouped by Temperature, Cursor data with slope between, and Time. The user

can also select to display Range, Average and Standard Deviation rows for each

of the columns.

4) When finished select the OK button to display the new settings or Cancel to return

to the worksheet without making any changes.

A maximum of 12-16 parameter columns can be displayed at one time. As

columns populate the Data Table, they are automatically sized to fit. It is

recommended that the most beneficial column information is displayed to

achieve the best results.

WaveRIDER 67

Page 79

4.4.10 The Data Graph

The Data Graph is a display that shows the data collected from the data run overlaid on

a graph. The user can analyze and highlight various process features with the tools

listed below.

X and Y-Axes and Labels

Autoscaling

Data Plots

Process Origin

X-Cursors

X-axis Units

Temperature Reference Lines

The Data Graph features are described in the sections that follow. Some of these

features described are also controlled using the appropriate menu options. Refer to