Page 1

INSTRUCTION MANUAL

MODEL TC80 TOTAL CHLORINE ANALYZER

MODEL DC80 DECHLORINATION ANALYZER

TC80 IM Rev. C

Page 2

Page 1 Model TC80

Page 3

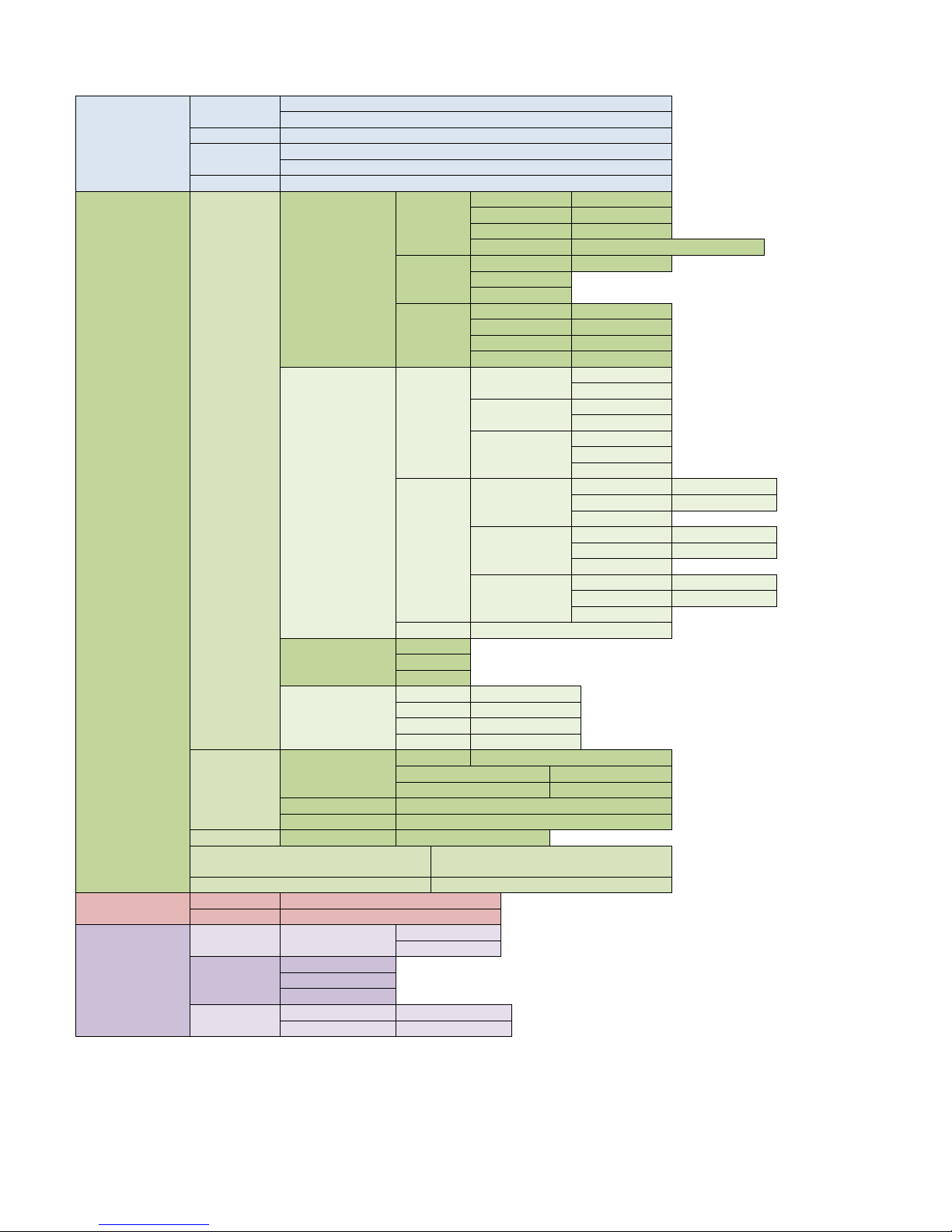

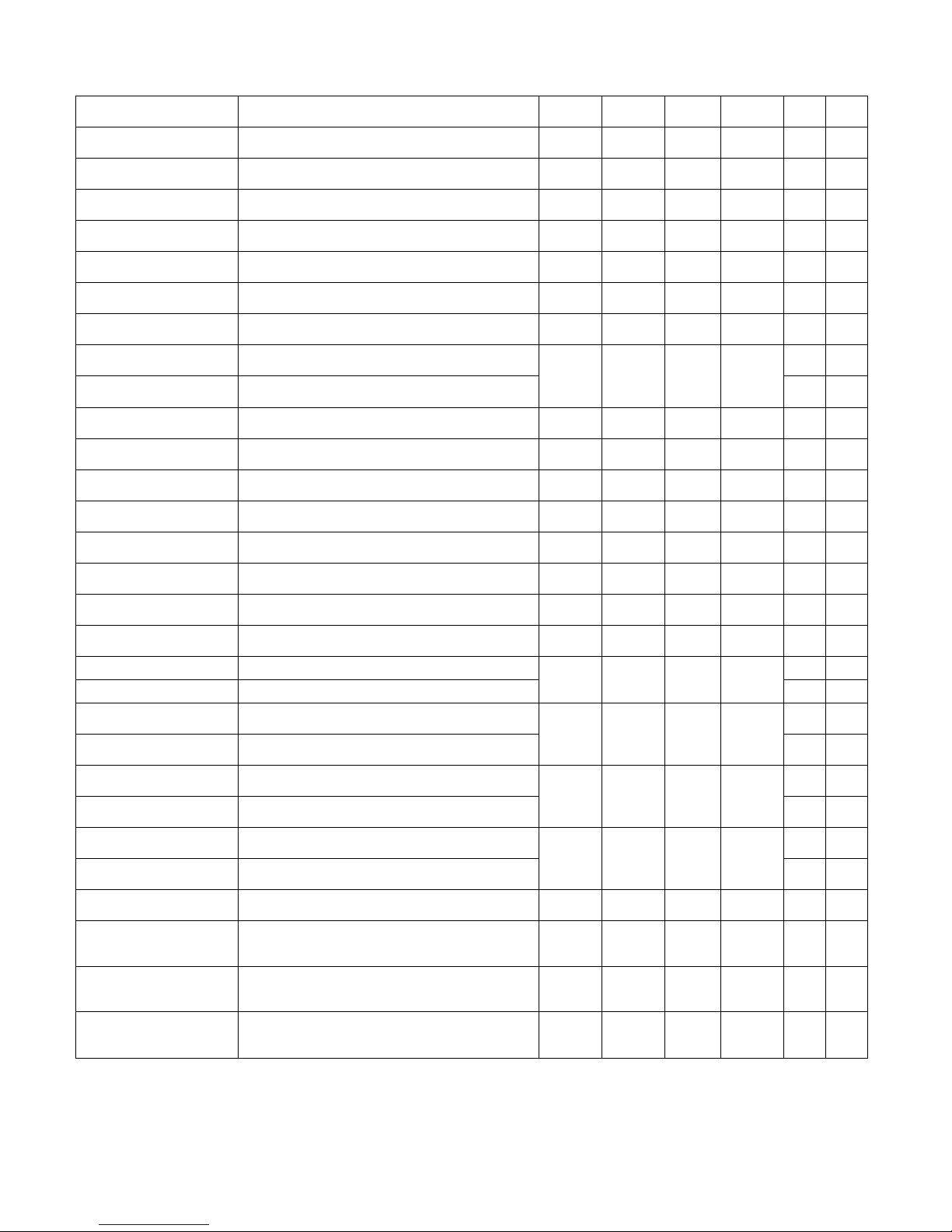

SCREEN MAP

CAL

(Calibration)

Auto

Cal 1 (Offset) using Calibration Solution

Cal 2 (Slope) using Calibration Solution

Standardize

Enter Grab Sample Determined Value

Manual

Enter Offset, the PV value and associated mV

Enter Slope, mV/pH, mV/decade, mV/ppm…

Temp

Enter measured Temperature

CONFIG

(Configuration)

XMTR

LCD

Set Up

Temp. Format

°C or °F

Contrast

Adj. 0-100%

Back Light

Enter ON time

Range Lock

Choose: Auto, ppb, ppm, ppT

Graph

Line

Screen Duration

Gauge

Bar

Label

TAG ID

Enter Name

TAG

ON/OFF

POP UP

ON/OFF

SENSOR

Enter Name

Output

4-20 mA

(1 or 2)

Range (PV or

Temp.)

4 mA =

20 mA =

More → CAL

Trim 4.00 mA

Trim 20.00 mA

More → Fault

3.5 mA

22 mA

NONE

RELAY

Relay 1

Alarm

Set Point

Timed

Period, Duration

Fault

Relay 2

Alarm

Set Point

Timed

Period, Duration

Fault

Relay 3

Alarm

Set Point

Timed

Period, Duration

Fault

HOLD

Time out: None, 15 min, 30 min…

Serial

Address

Baud rate

Format

Password

Menu

Off/On “ _ _ _ _ “

CAL

Off/On “ _ _ _ _ “

CNFG

Off/On “ _ _ _ _ “

SIM

Off/On “ _ _ _ _ “

Sensor

Sensor 1 or 2

Type

Choose Type: pH, Cond, ORP…..

T COMP

Enter % Comp

ISO PT

Enter mV value

Qty of Sensors

Choose 1 sensor or 2 sensors

COMP

Dissociation, Interference, Percentage, OFF

Load Default

Sensor/Transmitter

Yes/No

DAMP or MORE

Enter Signal Dampening (# of readings to

average, 0-100)

OFFSET (DC80 only)

Enter Offset value

INFO

(Information)

XMTR

Configuration, Serial #, Name, Outputs

Sensor

Calibration logs, Serial #, Name

SIM

(Simulate)

System

Sensor 1 or 2

Fixed value

Ramp

Relays

#1 ON/OFF

#2 ON/OFF

#3 ON/OFF

4-20 mA

4-20 mA Ch 1

Enter Value

4-20 mA Ch 2

Enter Value

2

Page 4

PREFACE

Purchasing products from Electro-Chemical Devices, Inc. provides you with the finest liquid analytical

instrumentation available. If this is your first purchase from ECD, please read the entire manual before installing

and commissioning your new equipment.

Manuals are accessible on the ECD website at http://www.ecdi.com/literature/manuals.html .

If there are any questions concerning this equipment, please contact your local ECD representative, or the

factory directly at:

Electro-Chemical Devices, Inc.

1681 Kettering

Irvine, CA 92614 USA

Telephone: +1-949-336-6060

FAX: +1-949-336-6064

Website: www.ecdi.com

Email: sales@ecdi.com

Page 3 Model TC80

Page 5

SYMBOLS USED IN MANUAL

This symbol is used to designate important information, warnings and cautions. Failure to follow

this information could lead to harm to the instrument or user.

No operator serviceable parts, service by authorized service personnel only.

This symbol is used to designate a WARNING “Risk of Electrical Shock”

Disconnect supply before servicing

Equipment protected throughout by double insulation.

Read the complete manual before installing or using the equipment.

Contents of this manual are believed to be correct at the time of printing and are subject to change without

notice. ECD is not responsible for damage to the instrument, poor performance of the instrument or losses

resulting from such, if the problems are caused by:

• Incorrect operation by the user.

• Use of the instrument in incorrect applications.

• Use of the instrument in an inappropriate environment or incorrect utility program (power supply).

• Repair or modification of the related instrument by anyone not authorized by ECD.

• There are no operator accessible parts. Service and maintenance to be done by authorized personnel only.

• If the equipment is used in a manner not specified by the manufacturer, the protection provided by the

equipment may be impaired.

© 2014 Electro-Chemical Devices, Inc. All rights reserved. No part of this manual may be used or reproduced in

any form or by any means, or stored in a database or retrieval system without prior written permission from

Electro-Chemical Devices, Inc. Making copies of any part of this manual for any purpose other than personal use

is a violation of United States copyright laws. Document printed in the United States of America.

4

Page 6

Table of Contents

Screen Map .................................................................................................................................................................2

TERMS AND CONDITIONS OF SALE .............................................................................................................................9

RETURN GOODS POLICY .......................................................................................................................................... 10

UNPACKING THE INSTRUMENT ............................................................................................................................... 11

INSTRUCTION MANUAL REVISION ........................................................................................................................... 11

1.0 GENERAL DESCRIPTION ..................................................................................................................................... 12

1.1 FEATURES ...................................................................................................................................................... 13

1.2 SPECIFICATIONS ............................................................................................................................................. 13

1.2.1 Sensors and Flow Train ........................................................................................................................... 13

1.2.2 TC80 Analyzer ......................................................................................................................................... 13

1.3 Model Codes .................................................................................................................................................. 14

2.0 INSTALLATION.................................................................................................................................................... 15

2.1 MOUNTING .................................................................................................................................................... 15

2.2 WIRING .......................................................................................................................................................... 16

2.2.1 Wiring, power ......................................................................................................................................... 16

2.2.2 Wiring, Sensor ........................................................................................................................................ 17

2.2.3 Wiring, 4-20 mA Outputs ........................................................................................................................ 17

2.2.4 Wiring, Contact Relay Outputs ............................................................................................................... 17

2.2.5 Wiring, Serial Output MODBUS RTU ...................................................................................................... 17

2.3 INSTALLING the SENSORS .............................................................................................................................. 18

2.4 PLUMBING ..................................................................................................................................................... 18

2.4.1 Sample Requirements ............................................................................................................................ 18

2.4.2 Connecting the Inlet and Drain fittings .................................................................................................. 18

2.4.3 Adjusting the Sample Flow Rate ............................................................................................................. 18

2.5 Connecting the Optional Spray Cleaner ........................................................................................................ 19

2.6 Connecting the Optional Chlorine Dosing Pump (DPC80) ............................................................................. 19

3.0 OPERATION ........................................................................................................................................................ 20

3.01 Influences on the Measurement ............................................................................................................. 20

pH Value .......................................................................................................................................................... 20

3.02 Influences on the Measurement ............................................................................................................. 20

Flow ................................................................................................................................................................. 20

Page 5 Model TC80

Page 7

3.03 Influences on the Measurement ............................................................................................................. 21

Temperature .................................................................................................................................................... 21

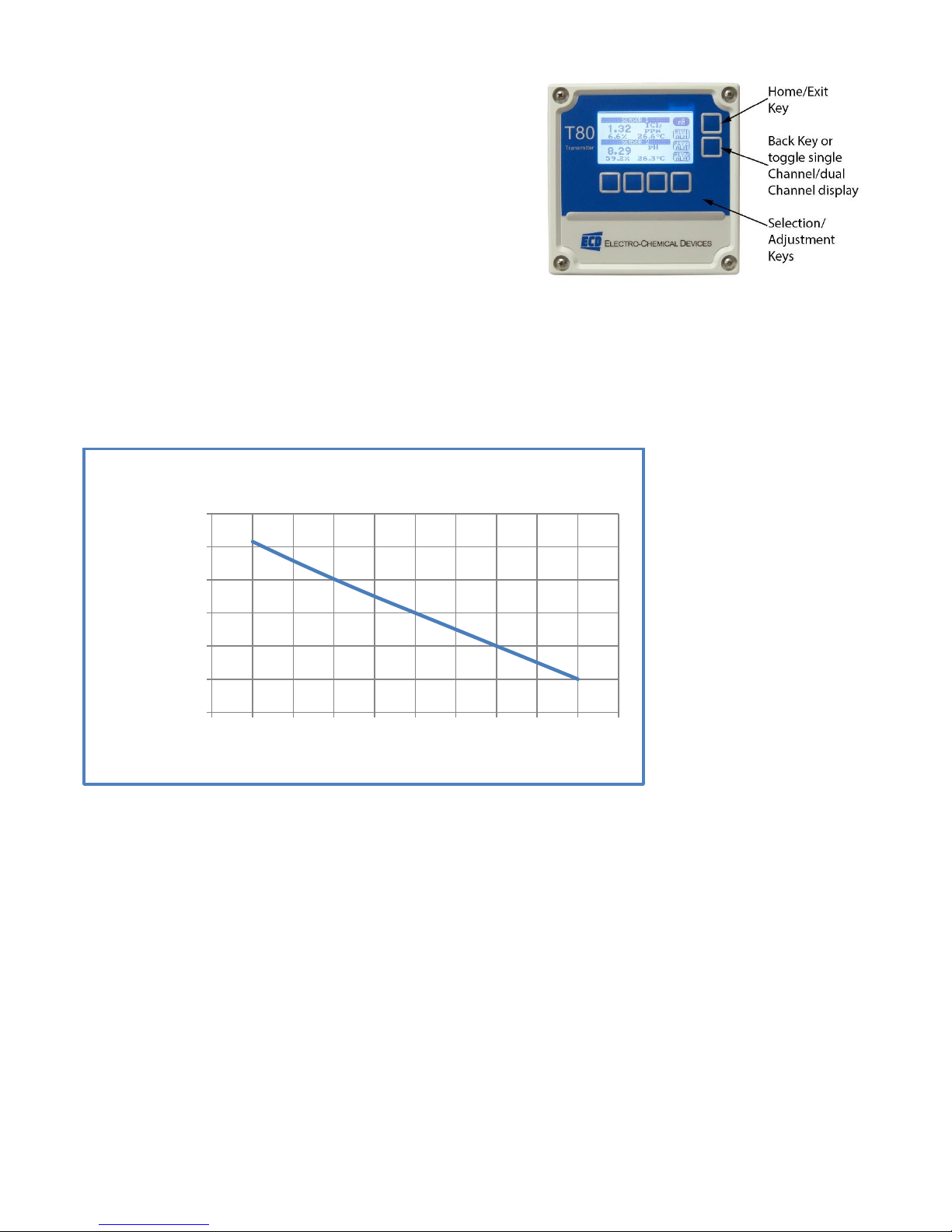

3.1 KEYS ............................................................................................................................................................... 22

3.1.1 Home/Exit Key ........................................................................................................................................ 22

3.1.2 Back/Hold Key ......................................................................................................................................... 22

3.1.3 Selection Adjustment Keys ..................................................................................................................... 22

3.1.4 Alpha Numeric Entry............................................................................................................................... 23

3.2 MENU STRUCTURE ........................................................................................................................................ 23

3.2.1 HOLD (Output Hold) ............................................................................................................................... 23

3.2.2 CAL (Calibration Menu) .......................................................................................................................... 23

3.2.3 CONFIG (Configuration Menu) ............................................................................................................... 24

3.2.4 INFO (Information Menu) ....................................................................................................................... 25

3.2.5 SIM (Simulation Menu) ........................................................................................................................... 25

3.2.6 Fault Screens........................................................................................................................................... 26

3.3 OUTPUT CONFIGURATION GUIDE ................................................................................................................. 26

3.3.1 Configure 4-20 mA output range ............................................................................................................ 27

3.3.2 Configure 4-20 mA Fault Condition and Cal ........................................................................................... 27

3.3.3 Configure Alarm Relays (Relays Optional) .............................................................................................. 27

3.3.4 Exit Menus and Return to Main Display ................................................................................................. 28

3.3.5 Sensor Start Up ....................................................................................................................................... 28

3.4 USER SELECTABLE OPTIONS .......................................................................................................................... 28

3.4.1 Screen Lighting ....................................................................................................................................... 28

3.4.3 Graphical display .................................................................................................................................... 29

3.4.4 TAG Transmitter Name ........................................................................................................................... 29

3.4.5 Sensor Name........................................................................................................................................... 29

3.4.6 Password Protection ............................................................................................................................... 30

4.0 CALIBRATION ..................................................................................................................................................... 31

4.0.1 AUTO Calibration description ................................................................................................................. 31

4.0.2 STANDardize Calibration description ..................................................................................................... 31

4.0.3 MANUAL Calibration description............................................................................................................ 31

4.1 pH Calibration Procedures ............................................................................................................................. 33

4.1.1 AUTO Cal using pH 4.01, 7.00, 10.00 buffers ......................................................................................... 33

4.1.2 AUTO Cal using other pH buffers............................................................................................................ 33

6

Page 8

4.1.3 Standardize ............................................................................................................................................. 33

4.2 Total Chlorine Calibration Procedures .......................................................................................................... 34

4.2.1 Auto Cal .................................................................................................................................................. 34

4.2.2 Standardize ............................................................................................................................................. 35

4.2.3 Manual Cal .............................................................................................................................................. 35

5.0 MAINTENANCE .................................................................................................................................................. 36

5.1 Total Chlorine Sensor .................................................................................................................................... 36

5.1.1 Removing or Replacing the Membrane ................................................................................................. 36

5.1.2 Polishing the Cathode ............................................................................................................................. 36

5.1.3 Refilling the Sensor ................................................................................................................................. 36

5.2 pH Sensor ....................................................................................................................................................... 37

5.2.1 Electrode Cartridge Installation .............................................................................................................. 37

5.2.2Electrode Cartridge Replacement ........................................................................................................... 37

5.2.3 Electrode Cleaning .................................................................................................................................. 37

5.2.4 pH Electrode Cartridge Cleaning ............................................................................................................ 38

5.3 Constant Head Flow Controller (CHFC) ......................................................................................................... 38

6.0 TROUBLESHOOTING .......................................................................................................................................... 39

7.0 PARTS AND ACCESSORIES .................................................................................................................................. 41

7.1 TC80 Replacement parts ............................................................................................................................... 41

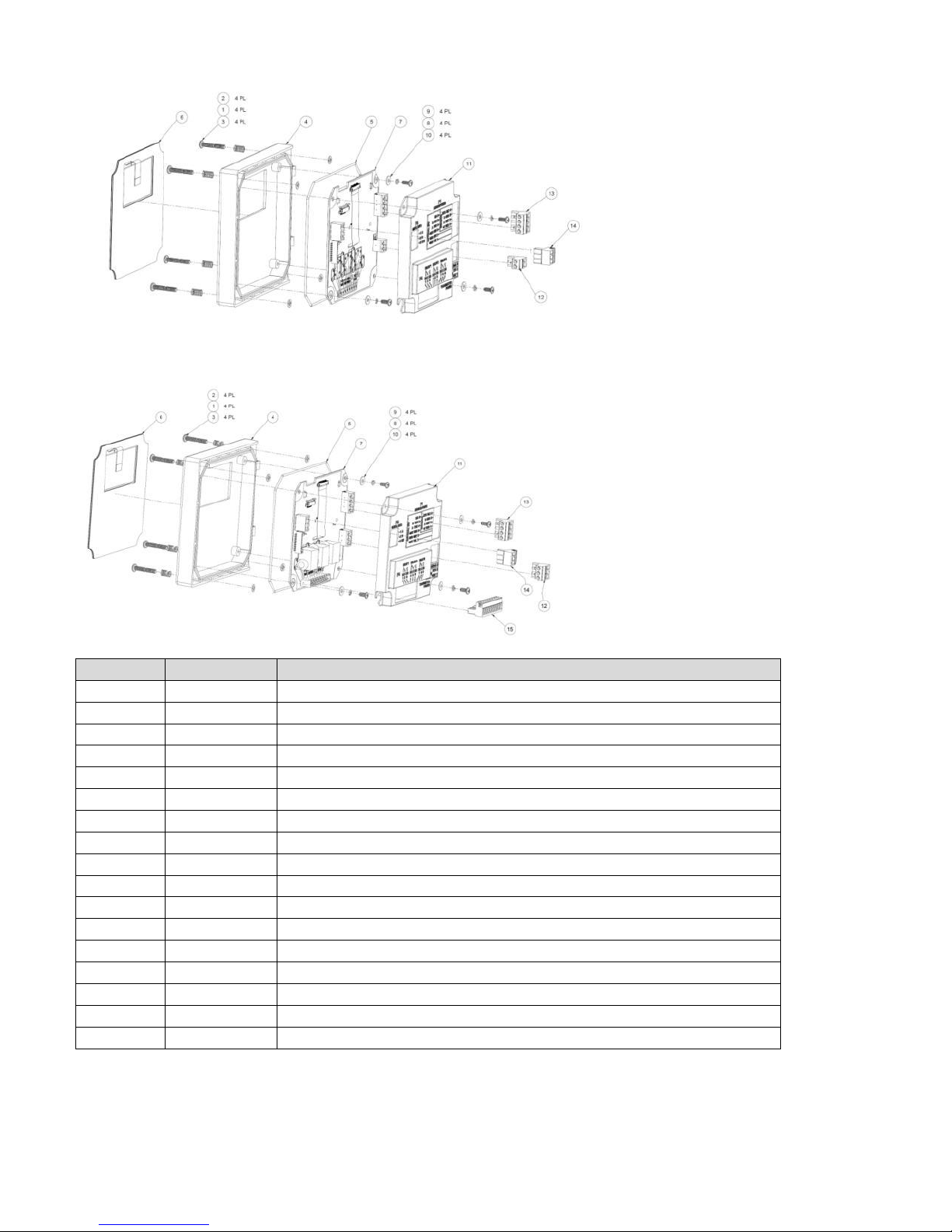

7.2 T80 Front Panel Control Board Exploded ...................................................................................................... 42

7.3 T80 Front Panel Control Board Exploded, with Relays .................................................................................. 42

7.4 T80 Transmitter Case, back with Cable Glands ............................................................................................. 42

7.5 T80 Replacement Parts .................................................................................................................................. 43

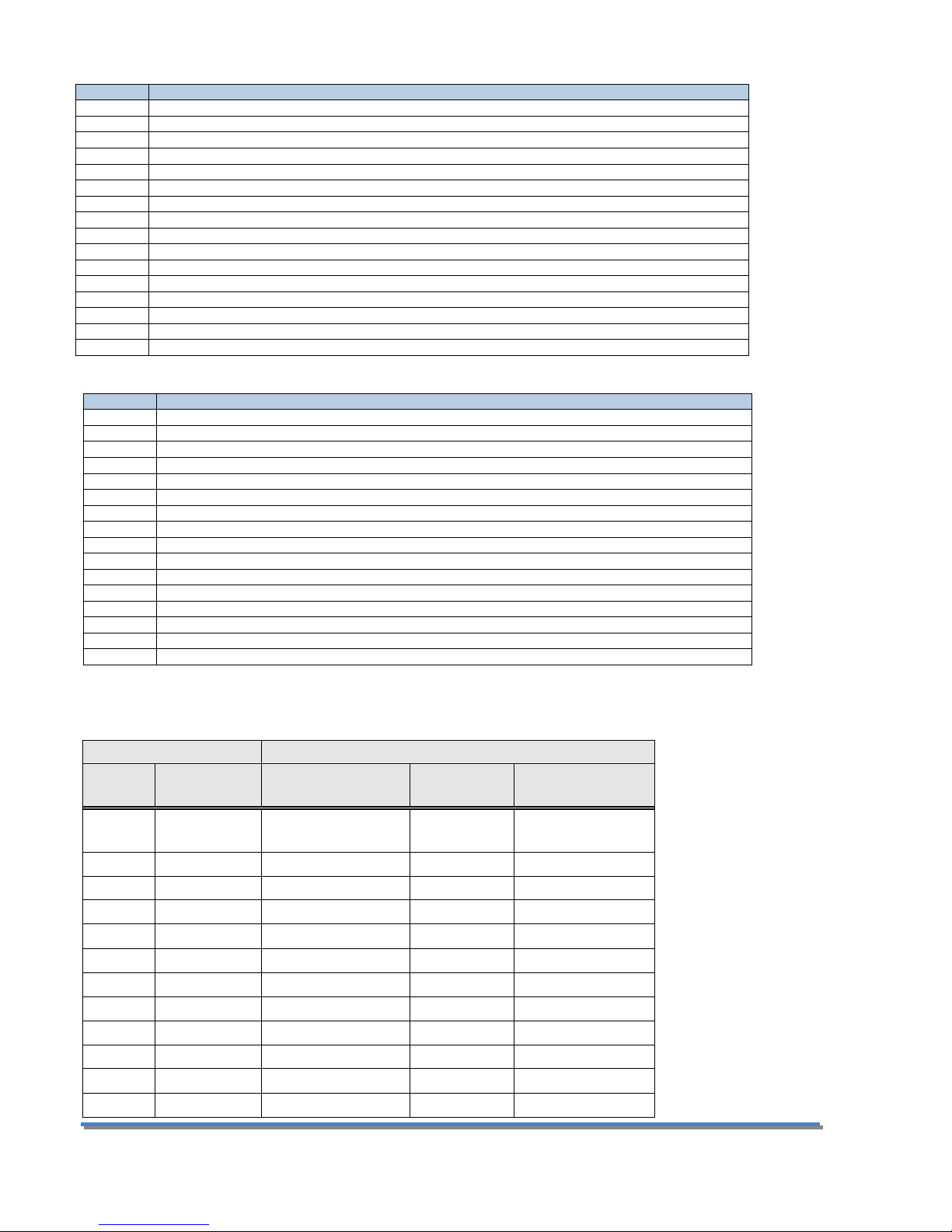

APPENDIX ................................................................................................................................................................ 44

A. Auto Cal Buffer Tables ..................................................................................................................................... 44

B.MODBUS RTU Register Listing .......................................................................................................................... 44

03 (0x03) Read Holding Registers .................................................................................................................... 44

06 (0x06) Write Single Register ....................................................................................................................... 45

Registers .......................................................................................................................................................... 45

Fault Status ...................................................................................................................................................... 49

Warning Status ................................................................................................................................................ 49

Sensor Type ..................................................................................................................................................... 49

C. Auto Spray Cleaner .......................................................................................................................................... 50

Page 7 Model TC80

Page 9

ADENDUM: DC80 De-Chlorination Analyzer ........................................................................................................... 51

DC80 Start Up Procedures ................................................................................................................................... 52

8

Page 10

TERMS AND CONDITIONS OF SALE

1. ACCEPTANCE. If this writing differs in any way from the terms and conditions of Buyer's order or if this writing is construed as an acceptance or as a confirmation acting as an

acceptance, then Seller’s acceptance is EXPRESSLY MADE CONDITIONAL ON BUYER’S ASSENT TO ANY TERMS AND CONDITIONS CONTAINED HEREIN THAT ARE DIFFERENT

FROM OR ADDITIONAL TO THOSE CONTAINED IN BUYER'S WRITING. Further, this writing shall be deemed notice of objection to such terms and conditions of Buyer. If this

writing is construed as the offer, acceptance hereof is EXPRESSLY LIMITED TO THE TERMS AND CONDITIONS CONTAINED HEREIN. In any event, Buyer's acceptance of the

goods shall manifest Buyer's assent to Seller's terms and conditions. No addition to or modification of these terms will be effective, unless set forth in writing and agreed to by

Seller.

2. WARRANTIES AND REMEDIES

a. Warranty. Seller warrants to Buyer that it holds and will pass marketable title to the goods sold hereunder. Seller warrants to Buyer that the items and components

manufactured by Seller will be free from defects in material and workmanship (subject, however, to tolerances and variances permitted by the trade hereunder) for a

period one (1) year for non-consumable products. Consumable electrodes and sensors have a conditional warranty based shelf life and process conditions and is

determined by Seller.

b. Exclusion and Conditions. Seller’s obligations with respect to the express warranties and remedies contained herein are conditioned on the following: (i) Buyer's return

of the non-conforming goods, if authorized by Seller: (ii) Buyer shall not assign its rights under these express warranties and any attempted assignment shall render

such warranties, but not any disclaimers or limitations, void and the goods sold shall be sold AS IS; and (iii) all products shall be carefully inspected for damage by Buyer

upon receipt, be properly calibrated for Buyer's particular use, and be used, repaired, and maintained by Buyer in accordance with the instructions set forth in Seller’s

product literature. Repair and maintenance by non-qualified personnel, product subjected to misuse or negligence, and/or damaged during shipment will invalidate the

warranty, as will the use of non-approved consumables or spare parts. As with any other sophisticated product, it is essential, and a condition of Seller’s warranty, that

all personnel using the product be fully acquainted with its use, capabilities and limitations as set forth in the applicable product literature.

3. DISCLAIMER OF IMPLIED WARRANTIES. Seller gives no warranties except those expressly contained herein. Seller disclaims all other warranties implied by law usage of the

trade, course of dealing or course of performance including, but not limited to, the implied warranties of MERCHANTABILITY and fitness for a particular purpose.

4. LIMITATIONS OF LIABILITY. The following limitations of Seller's liability are acknowledged by the parties to be fair and reasonable and shall apply to any act or omission

hereunder, and to any breach of this contract of which these terms and conditions form a part:

a. Disclaimer of Damage. In no event shall Seller be liable for special, indirect, consequential or incidental damages whether arising under contract, warranty,

tort, strict liability or any other theory of liability. Such damages include but are not limited to loss of profits, loss of use of goods, damage to property, and

claims of third parties.

b. Suitability. Buyer acknowledges that it alone has determined the intended purpose and suitability of the goods sold hereunder. It is expressly agreed by the

parties that any technical or other advice given by the Seller with respect to the use of the goods or services is given without charge and at B uyer's risk;

therefore Seller assumes no obligation or liability for the advice given or results obtained.

c. Notice and Time of Claims.

i. Buyer agrees to check and inspect all products against shipping papers and for damage or shortage upon receipt of goods at destination.

ii. Every claim for shortage, damage in transit, or other cause visible upon inspection shall be deemed waived by the Buyer, or the Buyer’s customer in

iii. The parties expressly waive the statute of limitations and agree that any legal proceeding for any breach of this contract shall be waived unless filed

5. FORCE MAJEURE. Seller shall not be liable for any delay in delivery, or failure to deliver, due to any cause beyond the Seller’s control including but not limited to fires, floods, or

other forces of the elements; strikes, or other labor disputes; accidents to machinery; acts of sabotage; riots; precedence or priorities granted at the request or for the benefit,

directly or indirectly of the federal or any state government or any subdivision or agency thereof; delay in transportation or lack of transportation facilities; restrictions imposed

by federal, state or other governmental legislation or rules or regulations thereof. If Seller, in its sole discretion, determines that Seller’s performance hereunder would result in

a loss to Seller’s on this sale as computed under Seller’s normal accounting procedures because of causes beyond Seller's control, then the Seller may terminate this agreement

in whole or in part without liability for any delay in the delivery of, or failure to deliver, the goods sold hereunder

6. TAXES AND OTHER CHARGES. The Buyer will pay, or reimburse Seller if it pays, any and all taxes or tariffs or any other similar charges imposed upon this contract, the goods

covered hereby or the delivery or use or resale thereof.

7. FREIGHT CHARGES. If the sale hereunder is other than F.O.B. Seller's facility, this acknowledgement is based upon the freight charges now in effect. In the event of an increase

or decrease in applicable freight charges before the goods are shipped, such charge in freight will be for the Buyer's account.

8. PRICES AND DELIVERY. Prices quoted herein are F.O.B. shipping point. Deliveries specified are only our best estimate and are subject to change. This quotation is based upon

freight charges now in effect. Buyer will be invoiced at the freight charge prevailing at the date of shipment. Prices are firm for orders meeting Seller's normal shipping

schedules. If shipments are held or postponed for any reason other than Seller's fault, and a price increase becomes effective during the period of such hold or postponement,

the increase will apply to all shipments that are held or postponed thirty (30) days or more from the effective date of the increase.

9. PAYMENTS. If in the judgment of Seller the financial condition of Buyer at any time prior to shipment does not justify the terms of payment specified, Seller may cancel the

order, withhold shipment, and/or require full or partial payment in advance. If payment is not made when due, Seller may suspend all future delivery or other performance with

respect to Buyer without liability or penalty and, in addition to all other sums payable hereunder, Buyer shall pay to Seller (i) the reasonable costs and expenses incurred by

Seller in connection with all actions taken to enforce collection or to preserve and protect Seller’s rights hereunder, whether by legal proceedings or otherwise, including

without limitation reasonable attorneys’ fees, court costs and other expenses and (ii) interest on all amounts unpaid after 30 days charged at the monthly rate of 1-1/2% or the

highest rate permitted by law, whichever is lower.

10. CANCELLATION OR ALTERATION. Buyer may not alter or cancel any order without Seller’s written consent. For any order altered or cancelled with Seller's consent, Buyer must

pay for all expenses and labor incurred up to the time of Seller’s consent, plus a reasonable percentage for profit. Any order delayed or deferred by Buyer will be subject to price

escalation for increased costs of production, and any other expenses caused by the delay. Material on such orders will be stored at Buyer's risk. Seller reserves the right to

invoice Buyer and require payment before shipment of any delayed or deferred order.

11. TITLE AND RISK OF LOSS. Title and risk of loss shall pass to buyer at Irvine, California, unless otherwise specified in the contract. If delivery is made by common carrier, risk of

loss shall pass upon delivery to the carrier. Claims for loss or damage in transit must be made by Buyer to the carrier. Seller accepts no responsibility for loss or damage to

product in transit.

12. PATENT OR TRADEMARK INFRINGEMENT. If the goods sold hereunder are to be prepared for manufacture according to Buyers specification, Buyer shall indemnify Seller

against any claim or liability for patent, trademark, service mark or trade name infringement on account of preparation, manufacture and/or sale.

13. NON-WAIVER. If Government Contract Regulations require the addition, deletion, or modification of these terms and conditions upon prior n otification to Seller and Seller's

written acceptance thereof, such changes shall become a part of these terms and conditions. Seller shall not be bound by any Government Contract Regulations applicable to

Buyer’s contracts with the U.S. Government unless Buyer has expressly acknowledged, on the face of this document, the applicability of such Regulations to the transaction

between Buyer and Seller contemplated herein. Absent such acknowledgement, Seller is making the assumption in issuing this document that no such Regulations apply.

the case of resale, unless delivered in writing to Seller by Buyer thirty (30) days from the tender of delivery of the goods to Buyer, provided, however,

that claims for shortage must be made within seven (7) days of receipt.

within one (1) year after the accrual of the cause of action thereof.

Page 9 Model TC80

Page 11

14. JURISDICTION. All such disputes shall be resolved in a court of competent jurisdiction in Orange County, California. Buyer hereby consents to the jurisdiction of the State and

Federal Courts sitting in Orange County. Notwithstanding the above, should either party contest the jurisdiction of such courts, the other party may institute its suit in any court

of competent jurisdiction.

15. APPLICABLE LAW. All questions arising hereunder or in connection with the quotations or any order submitted in connection therewith and/or the performance of the parties

hereunder shall be interpreted and resolved in accordance with the laws of the state of California without regard to its conflict of law provisions and excluding the United

Nations Convention on the International Sale of Goods.

RETURN GOODS POLICY

All requests for returned goods must be initiated through our Customer Service Department. Please call our

phone number (949) 336-6060 with the specifics of your request. The following conditions must be satisfied for

consideration of applicable credit for the return of products purchased from Electro-Chemical Devices:

1) The item is unused and in the original package.

2) The item was shipped directly from Electro-Chemical Devices.

3) The item has not been damaged in shipment to Electro-Chemical Devices.

4) Items containing date-sensitive parts such as electrodes, must be returned within 1 month of the

invoiced date.

5) Items without date-sensitive parts must be returned within 3 months of the invoiced date.

A Return Merchandize Authorization Number must be obtained from Customer Service and be provided on all

paperwork and packaging. To obtain a Return Merchandize Authorization Number, please provide the reason

for return, the date of purchase, your original purchase order number, and either our order number or our

invoice number. The issuance of a Return Merchandize Authorization Number is a verbal approval for return

only and does not guarantee credit or allowance. Returned goods must be received within 30 days of the

issuance date of the Return Merchandize Authorization Number or it will become null and void.

Necessary physical and mechanical inspection is completed upon receipt of the item. Applicable credit or

equivalent allowance is determined after inspection of the returned item. If all of the above conditions are met,

and the item has been approved to return to our stock, a restocking charge of 25% of the purchase price is

deducted from the applicable credit.

10

Page 12

UNPACKING THE INSTRUMENT

WARNING Electrical installation must be in accordance with the National Electrical Code

(ANSI/NFPA-70), Canadian Electrical Code and/or any other applicable national or local

codes.

Your Electro-Chemical Devices instrument has been carefully packaged to protect it from damage during

shipment and dry storage. Upon receipt please follow the procedure outlined below.

1. Before unpacking, inspect the condition of the shipping container to verify proper handling by the

carrier. If damage is noted, save the shipping container as proof of mishandling for the carrier.

2. Check the contents of the shipping container with the items and quantities shown on the packing list.

Immediately report any discrepancies to ECD.

3. Save the original packing material until you are satisfied with the contents. In the event the product(s)

must be returned to ECD, the packing material will allow you to properly ship it to ECD.

4. Familiarize yourself with the instrument before installation, and follow proper installation and wiring

procedures.

5.

Installation and wiring

Failure to follow the proper instructions may cause damage to this instrument and warranty invalidation.

Use only qualified personnel to install, operate and maintain the product.

The Model T80 transmitter should only be used with equipment that meets the relevant IEC, American or

Canadian standards. ECD accepts no responsibility for the misuse of this unit.

Basic Parts List

1. Model TC80 Transmitter and sensors, Panel Mounted

2. Total Chlorine refill Solution

3. Instruction Manual

INSTRUCTION MANUAL REVISION

Revision Date Remarks

A 09/14 Initial release

B 12/14 Wiring updated

Page 11 Model TC80

Page 13

1.0 GENERAL DESCRIPTION

The TC80 is designed for use in drinking water, industrial cooling and

rinse water or other samples of fresh water that use chlorine in the

range of 0-20 ppm as a disinfectant. Chlorine is commonly added to

water as chlorine gas or sodium hypochlorite (bleach). Chlorine exists

in water as a pH dependent mixture of hypochlorous acid and

hypochlorite ion. The sum of these two components is referred to as

Free Chlorine. Organic compounds containing chlorine may be added

to the water or form in the water by reaction with the Free Chlorine.

Chlorine may also react with ammonia in the water to form

chloramines. Together these compounds are referred to as Bound or

Combined Chlorine.

Total Chlorine is the sum of the Bound Chlorine and Free Chlorine in the sample, the TC80 measures Total

Chlorine.

The TC80 is a complete system for measuring Total Chlorine. The panel mounted system includes a Constant

Head Flow Controller (CHFC), Total Chlorine sensor (TCS) and Flow Cell, pH sensor (S80pH) and Flow Cell and the

T80 Transmitter. Simply supply power to the T80 Transmitter and plumb the sample line in and the drain line

out and the TC80 is ready to use.

The CHFC maintains a constant sample flow to the pH and Chlorine flow cells. Pressure regulators and

rotameters are not needed to maintain a constant flow rate, the CHFC provides trouble free sample conditioning

between 10 and 80 gal/hr.

The Total Chlorine Sensor (TCS) is a three electrode amperometric sensor with a micro porous PTFE membrane,

a gold cathode, a silver/silver halide anode and a 304 SS counter electrode. The counter electrode design

provides a stable reference, virtually eliminating drift and the associated maintenance.

The T80 Transmitter applies a fixed voltage on the anode and cathode and measures the current flow.

Chlorine compounds diffuse through the PTFE membrane and react with a potassium iodide fill solution. The

iodide is oxidized to iodine by the various chlorine compounds. The iodine is then reduced (gains electrons) by

the gold cathode back to iodide ion. Silver on the anode is oxidized (donates electrons) to silver iodide

completing the current loop. With stable temperature, pH and sample flow, the current flow is proportional to

the total chlorine concentration.

Many competitive total chlorine analyzers require service on a monthly or bimonthly basis. The TCS is an

amperometric sensor that requires refilling every 3-6 months. The chloride concentration of the electrolyte

increases over time as the measured chlorine is reduced to chloride by the potassium iodide degrading the

electrolyte. The replaceable PTFE membrane is designed for long term stability and typically lasts over a year.

Replacing the PTFE membrane and recharging the electrolyte is easily accomplished without the use of tools.

The Model T80 transmitter can be 24 VDC powered or 100-240 VAC line powered. The standard configuration

has a 4-20 mA output and a RS485 serial communication port with MODBUS®RTU output. Alarm relays are

standard on either line powered transmitter.

12

Page 14

1.1 FEATURES

Panel Mounted System, Easy Installation

Plumb and Play Design, Ready to Use

Automatic pH Compensation, No Expensive Reagents to

mix or spill

Automatic Flow Control, Eliminates Pressure Regulators

and Rotameters

T80 Transmitter Capability, Dual Measurements,24VDC or

110/220 VAC Power, Graphical Plots

Compliant with EPA Method 334.0

1.2 SPECIFICATIONS

1.2.1 SENSORS AND FLOW TRAIN

Chlorine Sensor:

Digital protocol, Potentiostatic, Gold cathode/Silver-Silver Halide anode, 316L SS counter electrode

pH Sensor:

Digital S80 protocol, 316L stainless steel body with replaceable electrode cartridge

Measurement Range:

Chlorine: 0.05 to 20 ppm (High Range)

0.005 to 2.00 ppm (Low Range)

pH: 4 to 14 pH

Operating Temperature:

0° C to 50° C (32° F to 122° F)

Min/Max Flow:

38 L/hr. to 300 L/hr. (10 gal/hr. to 80 gal/hr.)

Wetted Materials:

PVC, PP, PVDF, PTFE, Glass, 316 SS

Process Connections:

Input ¼” FNPT with barb fitting, Drain ¾” FNPT

Response Time:

T90 in 2 minutes

Electrolyte Life:

3 to 6 months

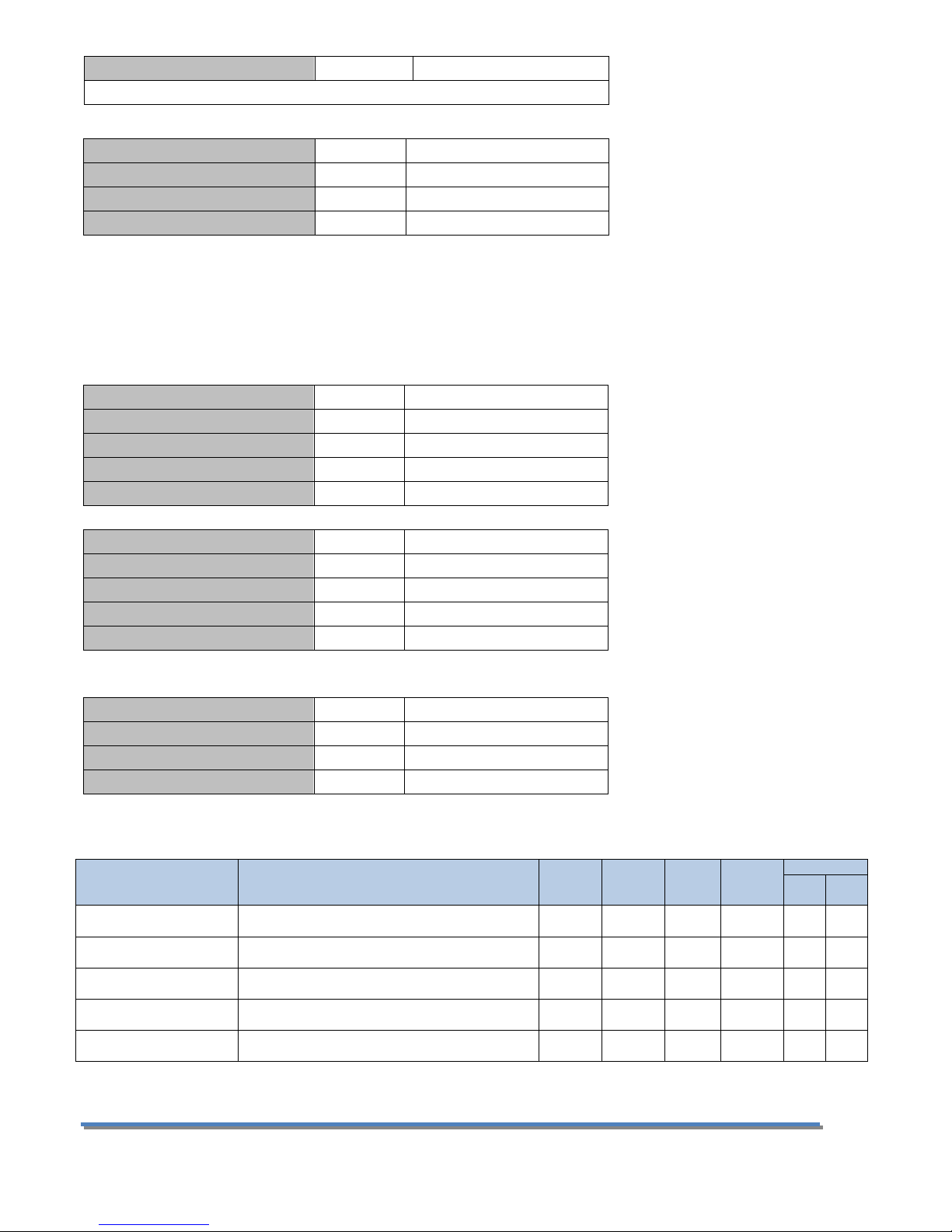

1.2.2 TC80 ANALYZER

Measurements:

Chlorine: 0.00 ppb to 22.00 ppm

pH: 0.00 to 14.00 pH

pH Compensation of Total Chlorine:

pH 4 - 12

Display:

128 x 64 pixels (2.75” x 1.5”) LCD, Black on Grey background, Blue on White background with LED backlight on

Outputs:

(1) 4-20 mA for Total Chlorine set to Sensors Range

Page 13 Model TC80

Page 15

(1) 4-20 mA for pH (Optional) set 0-14 pH

Model TC80-

Sensor type

and Range

0 0.05 to 20 ppm Total Chlorine (Standard)

1 0.005 to 2.00 ppm Total Chlorine

2 0.05 to 20 ppm Total Chlorine (Seawater)

3 0.005 to 2.00 ppm Total Chlorine (Seawater)

pH Comp

1 pH Sensor (Standard)

Power

-1 24 VDC Powered Transmitter

-2 100-240 VAC powered Transmitter

Outputs and

Relays

1 (x1) 4-20mA Outputs & (3) Relays

2 (x2) 4-20mA Outputs & (3) Relays (Standard)

Spray cleaner

00 No Spray Cleaner

10 Spray Cleaner on Chlorine

TC80- 0 1

-2

1

10

Modbus RTU (standard)

Alarm Relay Ratings:

Three (3) SPDT, 1 form C, 250 VAC, 10 Amp resistive maximum, relays, user configurable as Hi/Lo alarms with

expiration timer, Periodic Timers or Fault alarms

Input Power

Code -1 24 VDC (18-36 VDC @ 250 mW minimum)

Code -2 100-240 VAC, 50/60 Hz, 4W, protected with 250V, 1A, Slow Blow fuse

Enclosure:

Beige Polycarbonate, IP65, weatherproof, ½ DIN, (L x W x D) 5.7” X 5.7” X 3.5” (14.4cm X 14.4cm X 9.0cm)

Environmental Conditions:

Outdoor use (IP65)

Ambient Temperature -20°C - 70°C (24 VDC Models)

-20°C - 60°C (100-240 VAC Models)

Storage Temperature -30°C - 85°C

Relative Humidity 0 – 80%, up to 31°C

Decreasing linearly to 50% RH a 40°C

Altitude Up to 2000 m (6500 ft)

Mains Supply Voltage Fluctuations up to ±10% of the nominal voltage

Transient over voltages: CAT II

Pollution Degree: 2

1.3 MODEL CODES

Example above shows part# TC80-01-2110, a two channel TC80 transmitter, 0.05 to 20 ppm Total Chlorine range

and S80 pH sensor, 110/220 VAC powered with one 4-20 mA output with MODBUS RTU, 3 Relays (one used for

Spray Cleaning option) and spray cleaner.

14

Page 16

2.0 INSTALLATION

Mount the TC80 in a location where there is easy access to the analyzer and sensors. Install the system in an

area where vibrations, electromagnetic and radio frequency interference are minimized or absent.

Do not mount in direct sunlight or areas of extreme heat. The TC80 is suitable for outdoor use if mounted with a

protective cover or sunshield.

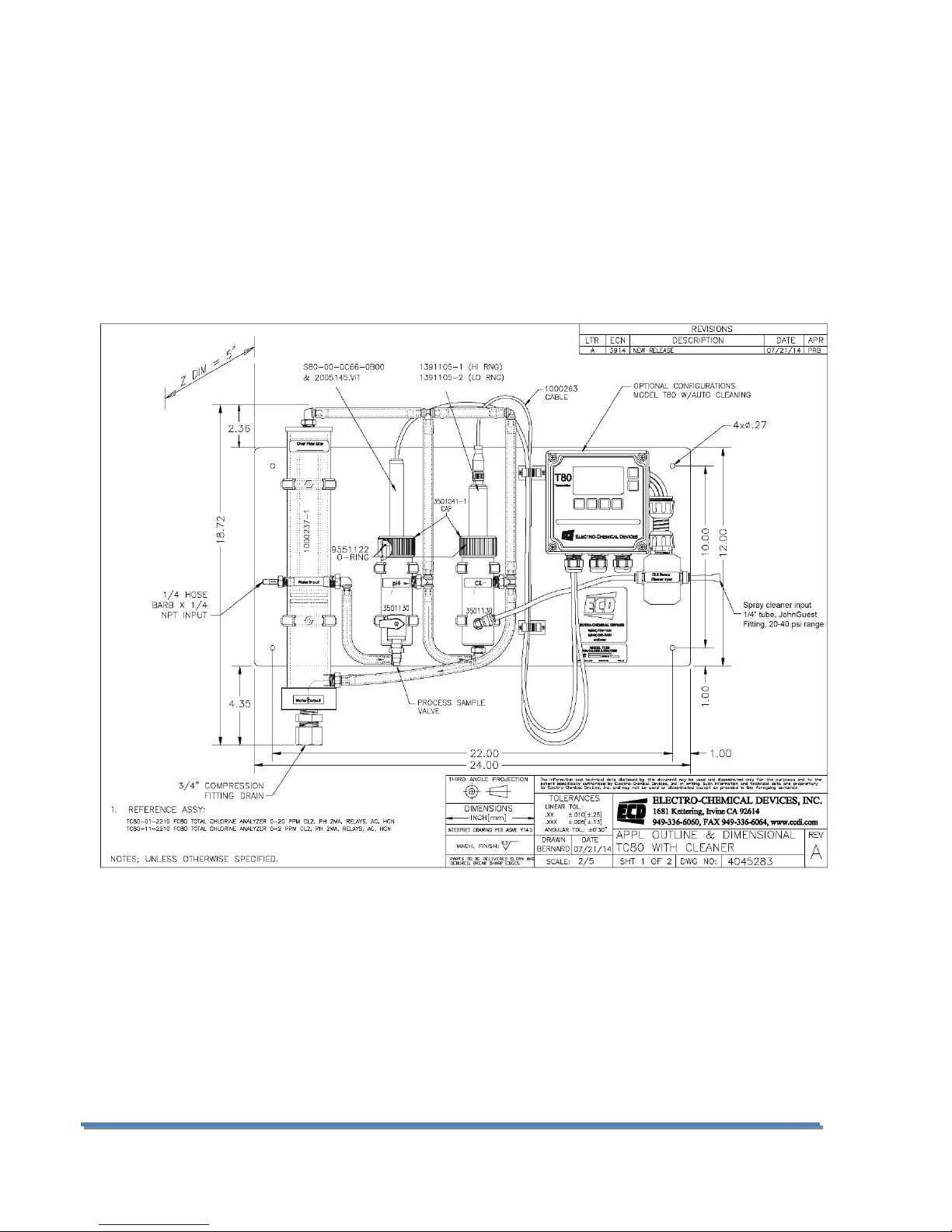

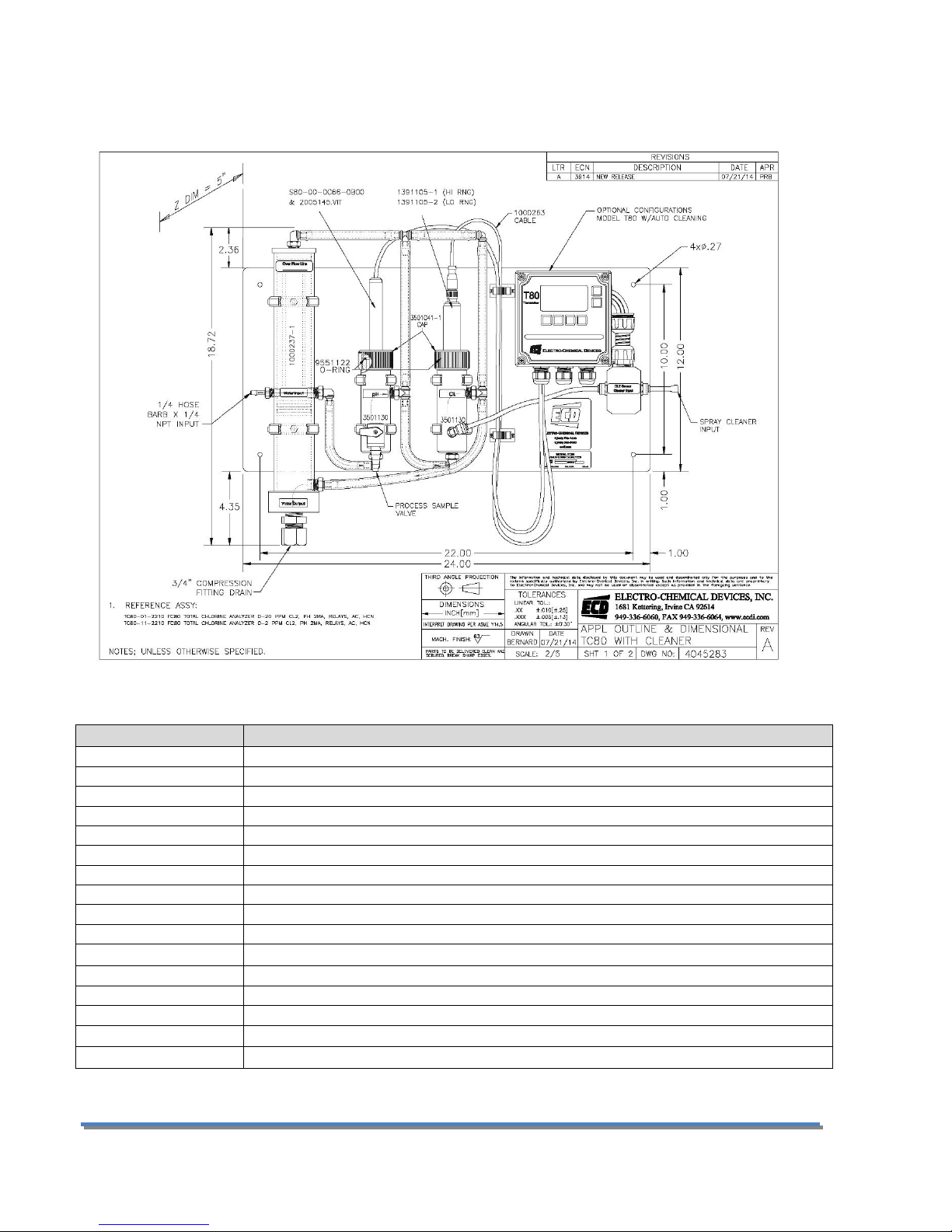

2.1 MOUNTING

The TC80 panel is drilled with 4 x 0.265” holes, one at each corner, and is designed to use ¼” -20 hardware or

6mm metric hardware.

Page 15 Model TC80

Page 17

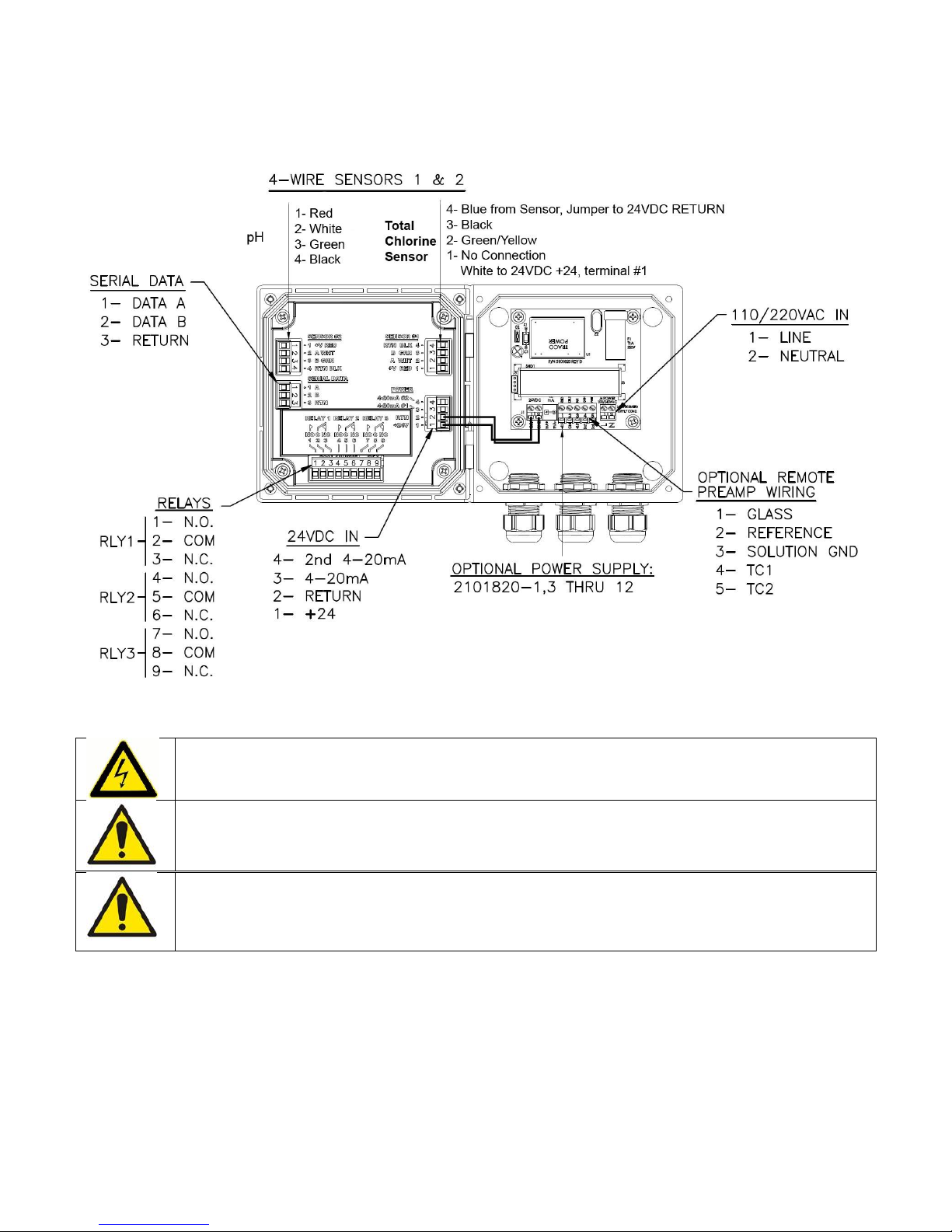

2.2 WIRING

Warning: RISK OF ELECTRICAL SHOCK

Disconnect Power before opening instrument.

WARNING Electrical installation must be in accordance with the National Electrical Code

(ANSI/NFPA-70), Canadian Electrical Code and/or any other applicable national or local

codes.

Electrical wiring should only be conducted by qualified personnel. See the T80 wiring diagram in Figure 2.2.2

Figure 2.2.2 4-Wire Transmitter, 24VDC or /110/22 VAC, MODBUS, Relays/Optional Digital Preamp

2.2.1 WIRING, POWER

ECD recommends using a thermoplastic, outdoor sunlight resistant jacketed cable, wet location rated and ½”

flexible conduit. The power should be hard wired with a switch or breaker to disconnect the analyzer from the

16

Page 18

main power supply. Install the switch or breaker near the analyzer and label it as the Power Switch for the

analyzer.

24VDC (4 wire configuration)

Attach the 24VDC power cable to terminals #1 and #2 as shown in Figure 2.2.2 and on the diagram inside of the

T80 cover. Attach the 4-20 mA1 cable to terminals #3 (out) and #2 (return)single channel unit and attach the 420 mA2 cable to terminals #4 (out) and #2 (return) for a two channel instrument. Feed the cables through the

gland fitting on the right hand side of the T80. Tighten the cable gland to provide a good seal to the cable. The

instrument can be powered up at this point with no harm to the analyzer but it is best to wait until the sensors

are installed.

110/220 VAC (4 wire configuration)

Attach power cable as shown in Figure 2.2.2 or as on the diagram inside of the T80 cover. Feed the cable

through the gland fitting on the right hand side of the T80. Tighten the cable gland to provide a good seal to the

cable. The instrument can be powered up at this point with no harm to the analyzer but it is best to wait until

the sensors are installed.

2.2.2 WIRING, SENSOR

The Total Chlorine Sensor and the S80 pH Sensor were connected to the TC80 analyzer at the factory, no

additional connections are necessary. Color coded connections for these sensors are shown in the wiring

diagrams in Section 8.3 or on the inside cover of the T80 transmitter.

When replacing a sensor, attach the sensor wires as described above. Feed the sensor cable through the gland

fitting on the left hand side of the T80. Do not use the same gland fitting for the AC power or Alarm/Relays. The

green terminal strip connectors are detachable from the circuit boards. Remove the connector by pulling

straight back from the circuit board.

2.2.3 WIRING, 4-20 MA OUTPUTS

24 VDC or 110/220 VAC powered instruments:

For instruments powered with 24VDC or with the internal 110/220 VAC power supply, Model T80-XX-1X-XX

(24VDC) and T80-XX-2X-XX (110/220 VAC), connect the 4-20 mA cable(s) to terminals #3 (out) for channel 1 and

#2 (return) and to terminals #4 (out) for channel 2 and #2 (return).

2.2.4 WIRING, CONTACT RELAY OUTPUTS

The standard configuration has three SPDT 230V 5 A relays that can be wired either normally open (NO) or

normally closed (NC). The default configuration is set to use the relays as normally open. If the optional spray

cleaner was ordered then one of the relays is used to control the cleaning cycle.

2.2.5 WIRING, SERIAL OUTPUT MODBUS RTU

Attach the sensor wires as shown in Figure 2.2.2 or as described on the diagram inside the T80 cover. Feed the

sensor cable through the gland fitting on the left hand side of the T80. Do not use the same gland fitting for the

AC power or Alarm/Relays. See MODBUS command register in Appendix B.

Page 17 Model TC80

Page 19

2.3 INSTALLING THE SENSORS

The TC80 is supplied with the sensor cables pre-wired to the analyzer. The TC80 instrument and sensors were

calibrated at the factory and should be ready for use when assembled. However, changes may have occurred

during shipping and storage requiring recalibration. (See Calibration section 4.2 below)

The pH sensor mounts in the Flow Cell using an o-ring sealed flange/union mount with threaded locking cap.

First remove the protective cap from the sensing end of the sensor and save it for future use, the cap contains a

potassium chloride solution use care when removing the cap from the sensor. Insert the sensor into the flow

cell. There is an o-ring seal inside the flange that seals against the face of the flow cell. Slide the sensor into the

flow cell and then hand tighten the knurled compression cap to fix its position.

The Chlorine sensor is held in the flow cell with a union nut. Slide the sensor into the flow cell and hand tighten

the compression cap after filling the sensor with electrolyte.

1. Lift the silicone band to Expose the vent hole and unscrew the measuring cap from the sensor.

2. Fill the cap to the bottom of the threads with the gelled electrolyte and tap it gently to dislodge any

trapped bubbles inside the cap.

3. Screw the sensor into the measurement cap at a 45° angle ensuring all air inside the chamber is purged

through the vent hole on the side of the cap.

4. When the o-ring begins to seal continue slowly tightening until it hits the stop.

5. Replace the silicone band back over the vent hole and rinse the purged electrolyte from the sensor body

with water.

The sensor is ready to use, re-polarize the sensor for 60 minutes before calibration.

Refill the sensor with electrolyte (PN 100246-1) every 3-6 months, depending on the chlorine level measured.

The measured chlorine is reduced to chloride inside the cell and must be periodically removed. Samples with

around 5 ppm total chlorine require the sensor to be refilled every 3-4 months.

2.4 PLUMBING

2.4.1 SAMPLE REQUIREMENTS

The constant head flow controller can adapt to changing sample flows between 10 and 80 gal/hr. (40-300 L/hr.)

Minimum flow: 10 gal/hr. (38 L/hr.)

Sample Pressure: 1 to 30 psig (0.1 - 2 bar)

Temperature: 32° to 122°F (0° to 50°C)

2.4.2 CONNECTING THE INLET AND DRAIN FITTINGS

The TC80 is intended for wall mounting only.

Sample Inlet:

A ¼” barbed fitting is provided for the sample inlet. If desired, a ¼”compression fitting can be used. The sample

inlet is ¼” FNPT. Attach the feed water line to the Constant Head Flow Controller with an adjustable shut off

valve.

Sample Drain:

The sample drains through the ¾” FNPT hole at the bottom of the CHFC. Attach a ¾” fitting to a length of soft

tubing and allow the waste to drain to open atmosphere. Do not restrict the drain line.

The sample can be introduced after the sensors have been calibrated and installed in the flow cells.

2.4.3 ADJUSTING THE SAMPLE FLOW RATE

Adjust the flow so the sample water fills the tube and slightly overflows into the center tube to drain. This

provides a constant flow to the chlorine and pH sensors controlled by the height of the water column. The

sample flow rate must always be high enough to over flow the center tube or variations in the flow rate will

occur causing decreased output from the Total Chlorine Sensor.

18

Page 20

Once the sample has been introduced, purge the air in the lines by squeezing and releasing the tubing

connecting the flow cells. First the tubing from the CHFC to the first flow cell and the tubing between the flow

cells. The water draining back to the CHFC typically flows fast enough to arc to the center drain hole. A dribbling

flow indicates an obstruction or air bubble trapped in the flow train.

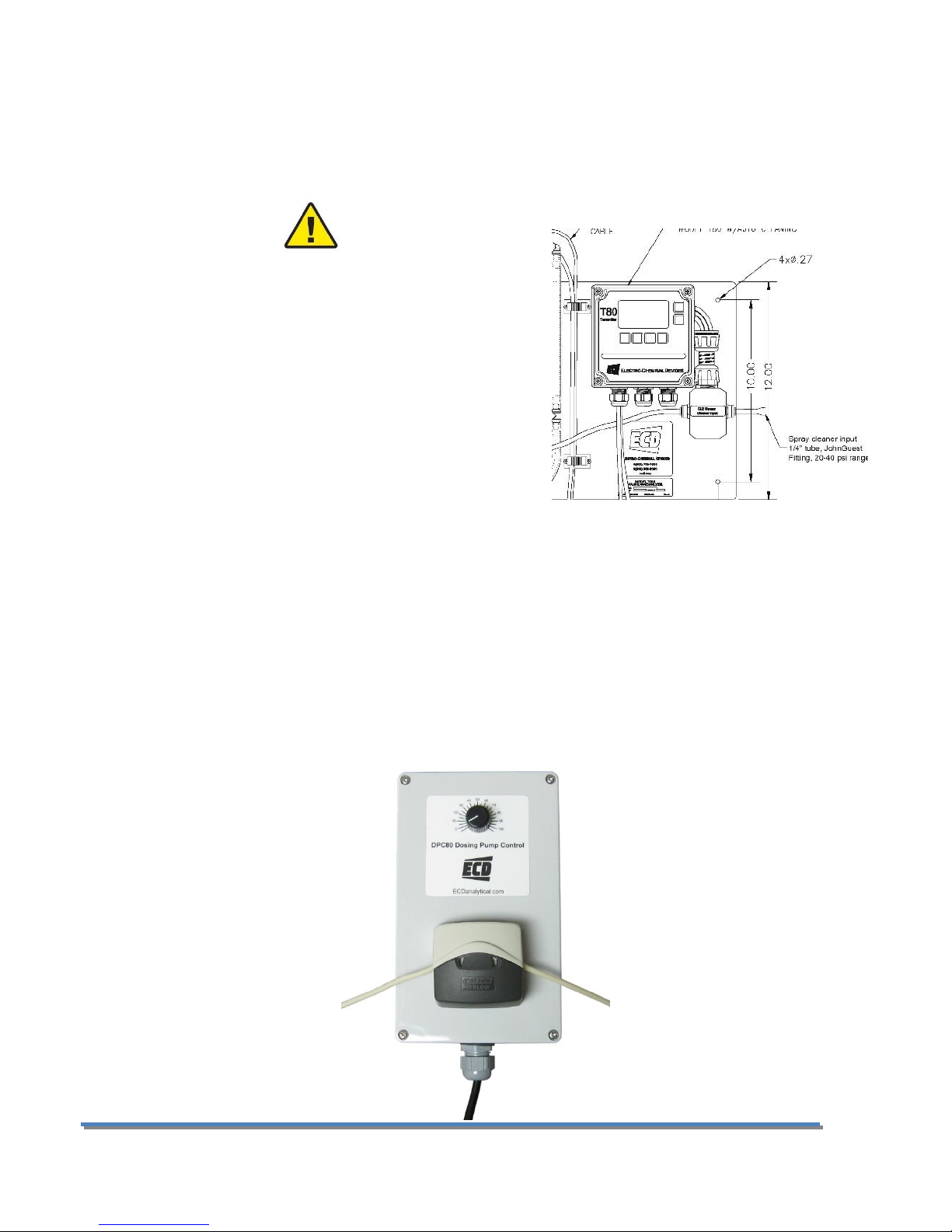

2.5 CONNECTING THE OPTIONAL SPRAY CLEANER

Warning: The Relay controlling the solenoid will trigger upon

Power Up which starts a cleaning cycle. The Sensors should be

installed with the Sample flowing before powering the analyzer.

1. Remove the ¼” polypropylene tube from the

John Guest fitting on the right side of the

solenoid cleaner enclosure.

2. Provide 20-40 psi water or air to the ¼” John

Guest fitting.

3. Manually actuate the relay for test purpose in

SIM > RELAYS > RLY 1 > ON/OFF

2.6 CONNECTING THE OPTIONAL CHLORINE DOSING PUMP (DPC80)

Remove the lid from the DPC80. Connect a power cord, 110 VAC, to the Line and Neutral terminals inside the

DPC 80 chlorine metering pump. Replace the lid. Mount the pump/controller near the TC80 panel. The DC80 is

supplied with 10 ft. of tubing for the peristaltic pump. Lift the Tan portion of the pump from the middle to

expose the rollers. Place the tubing into the pump and close the tan cover.

Page 19 Model TC80

Page 21

3.0 OPERATION

70

80

90

100

110

120

130

3 4 5 6 7 8 9 10 11 12 13

% Output

with pH8

= 100%

pH

TCS output vs. pH value

This section provides a basic overview of the ECD TC80 Total

Chlorine Analyzer. It covers physical and chemical influences on

the measurement and the menu structure of the analyzer.

3.01 INFLUENCES ON THE MEASUREMENT

PH VALUE

The TCS measures Total Chlorine and the total chlorine

concentration does not change with changes in the pH, there is

always the same amount of Total Chlorine. The output of the

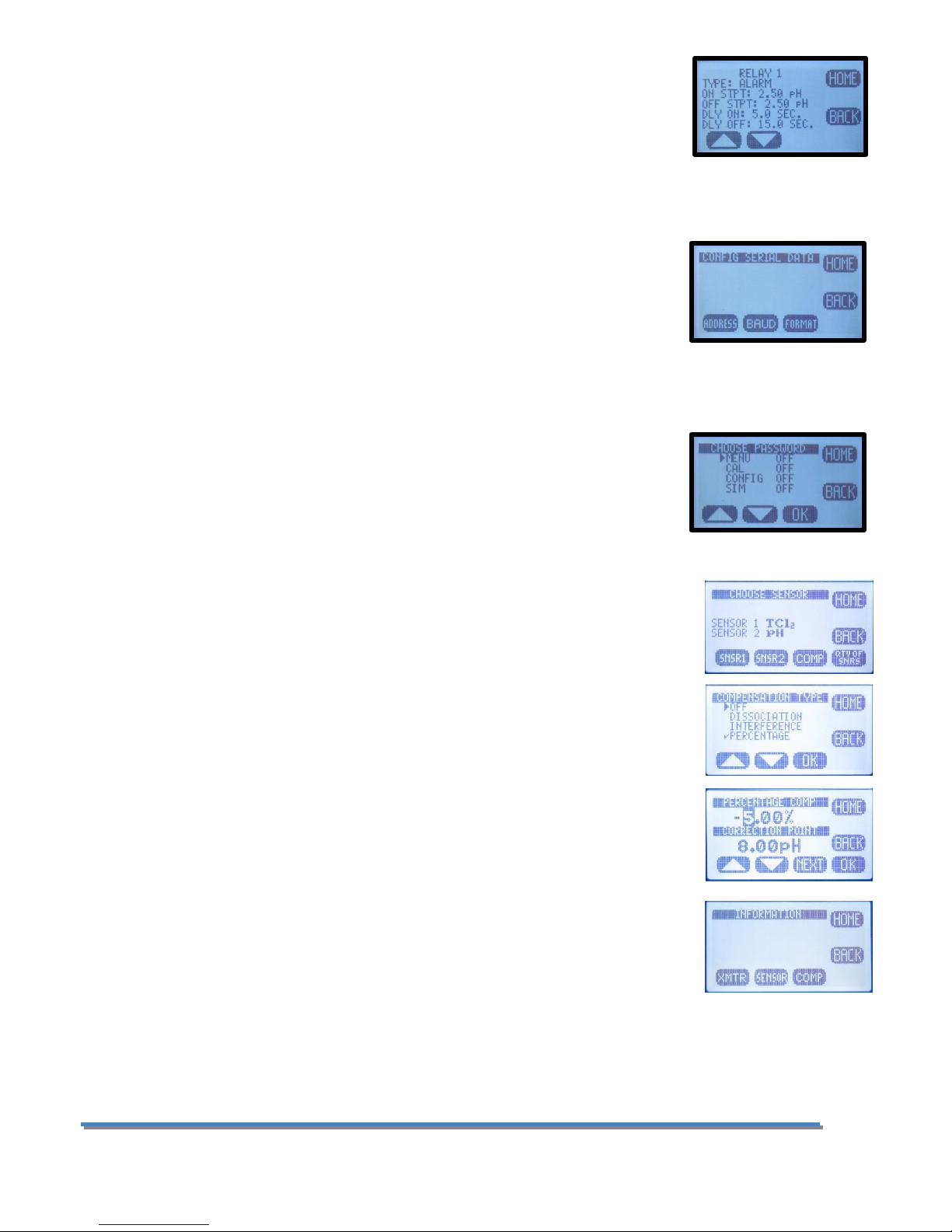

sensor is however pH dependent, see figure 2.1, the output of the sensor decreases 5%/pH as the pH increases.

The T80 transmitter uses the pH signal from the S80 pH sensor to compensate for the decreasing output. The

measured value and the pH value are combined and the corrected Total Chlorine concentration is displayed.

The highest accuracy is attained when calibrations are performed at neutral pH values and higher chlorine

concentrations.

Figure 3.1

3.02 INFLUENCES ON THE MEASUREMENT

FLOW

The TCS consumes chlorine to produce the signal. The area near the sensing tip will become depleted of chlorine

without adequate flow to replenish the sample. The sensor requires a minimum velocity of 0.5 ft./sec past the

membrane. Below this value the sensor will indicate a lower concentration than the actual value. Higher flow

rates have little to no effect on the measurement. See Figure 3.2.

20

Page 22

0

20

40

60

80

100

0 5 10 15 20 25 30

% output

Flowrate, gal/hr

TCS Flow dependence

Figure 3.2

3.03 INFLUENCES ON THE MEASUREMENT

TEMPERATURE

The Total Chlorine Sensor (TCS) digitally outputs a temperature corrected value to the transmitter. The

temperature sensor is located in the TCS sensor and it has a response time of several minutes. Rapid changes of

temperature will introduce an error until the sensor has equilibrated to the new temperature. Calibration should

be done close to the process temperature for the highest accuracy.

Page 21 Model TC80

Page 23

3.1 KEYS

The functions associated with each key are displayed on the screen,

above the key for the Selection Adjustment Keys and to the left of

the key for the HOME and BACK keys. Press any Selection

Adjustment key twice within one second to enter the HOME Menu

Screen.

3.1.1 HOME/EXIT KEY

The HOME key performs two functions, it selects which Home

Screen is displayed and it returns the active screen to the HOME Menu Screen from anywhere inside the menu

structure.

Three Display screens are available: (Press BACK Key until a single channel is displayed then the HOME Key)

1. DATA SCREEN: Displays the measurement type, numerical value, engineering Units, % Output of the 4-

20 mA channel and temperature.

2. nA SCREEN: Displays the measurement type, the sensor’s raw nano-amp

Value, % Output of the 4-20 mA channel and temperature.

3. GRAF SCREEN: Displays a Graphical representation of the 4-20 mA channel

% Output, the measurement type, the engineering units, and temperature.

Only one of the three graphical display styles is available through the

HOME key, either the Bar, Gauge or Line display. Choose which style will

be displayed in the Graph Menu. (pathway to Graph Menu: CONFIG →

XMTR → LCD → Graph menu)

Each of the above screens also displays the condition of the optional Alarm Relays,

black if energized and white if de-energized.

The HOME key changes to the EXIT key in the HOME Menu Screen, pressing EXIT

prompts the user to “Save Changes” YES/NO when exiting the HOME Menu. YES

applies any changes made in the menus, NO exits the HOME Menu without

applying any changes made in the menus.

3.1.2 BACK/HOLD KEY

The BACK key changes the screen to the previously displayed screen when inside a menu, it moves BACK one

screen. On a dual channel transmitter it toggles between the PV1, PV2 and Dual

Channel Screens. The HOLD key toggles the output HOLD function ON/OFF in the

MENU HOME screen.

3.1.3 SELECTION ADJUSTMENT KEYS

The (4) Selection/Adjustment keys allow navigation and numerical adjustments to

be made in the MENUs. To enter the HOME Menu screen press any of the

Selection/Adjustment keys twice within one second. The various Menu choices

and adjustment tools are displayed above the buttons once inside the MENU.

22

Page 24

3.1.4 ALPHA NUMERIC ENTRY

The LABEL and PASSWORD (Caps and Numbers only) Menus allow alphanumeric entry. Entry is accomplished by

scrolling through the alphanumeric list with the ▲ (forward) and ▼ (backwards) arrows to the character of

choice and then moving to the NEXT digit. Pressing and holding the ▲ or ▼ keys will initiate two speed auto

scrolling. The character set is sequentially listed below. The first character in the set is an empty space.

! ” # $ % & ‘ ( ) * + , - . / 0 1 2 3 4 5 6 7 8 9 : ; < = > ? @ A B C D E F G H I J K L M N O P Q R S T U V W X Y Z [ ¥ ] ^ _

‘ a b c d e f g h I j k l m n o p q r s t u v w x y z { | } → ←

3.2 MENU STRUCTURE

Double tap any Selection/Adjustment key to enter the HOME Menu Screen. Five menu choices will appear, CAL,

CONFIG, INFO, SIM and HOLD. Each of the Menus is detailed below.

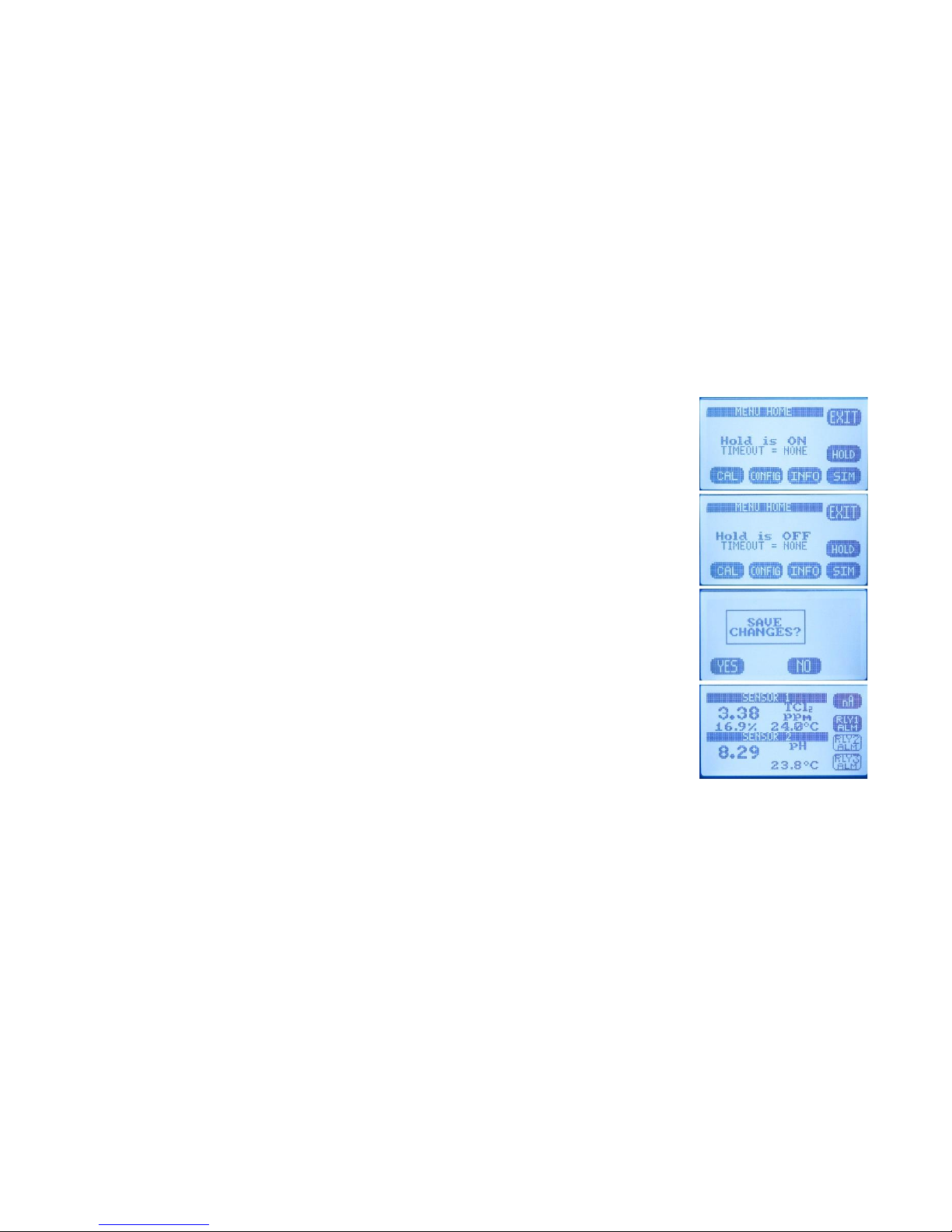

3.2.1 HOLD (OUTPUT HOLD)

Pressing the HOLD Key activates the HOLD function, HOLD is ON, displayed.

Freezes the 4-20 mA output at the last value prior to activation

Freezes optional Alarm Relays in the current state

While in the HOLD mode the % Output display toggles between the last value and HOLD

Pressing HOLD again turns the hold function off, Hold is OFF, displayed. The HOLD function remains ON until it is

turned OFF. (See Time Out in CONFIG>XMTR>OUTPUT>HOLD)

3.2.2 CAL (CALIBRATION MENU)

Four options are available, AUTO, STAND, MANUAL and TEMP. On dual channel

instruments choose Sensor 1 or Sensor 2 when prompted.

The first screen asks, “Is this a New Sensor, YES / NO”. If YES the calibration history from the previous sensor is

cleared from memory and a new register is started, if NO then the calibration is written to the memory stack, (3)

sets of data are stored.

AUTO is a two point calibration. The calibration proceeds in two steps, Auto Cal 1 is an offset calibration

and Auto Cal 2 is a slope calibration. Auto Cal provides automatic solution

recognition of the calibration solutions used for each measurement in

accordance with the following list:

1. pH Calibration Buffers (US Standard), pH 4.01, pH 7.00 and pH 10.00

(see Appendix A)

2. Total Chlorine: Zero ppm (Sodium sulfite, Na

Any two solutions can be used for AUTO calibration however if solutions other than those listed above

are used for calibration then the calibration values must be entered manually.

STAND is standardization, a single point calibration. Standardizations are typically used to adjust the

process reading to agree with a laboratory determined “grab sample” reading.

MANUAL is a data entry screen. Manual calibration allows the user to enter a

concentration with the corresponding mV value and a slope for an electrode.

Laboratory generated calibration data for an electrode can be input to a

remote analyzer where calibration is difficult or impractical.

in water), Chlorinated water, DPD Tested

2SO3

Page 23 Model TC80

Page 25

TEMP allows the displayed temperature to be trimmed to agree with actual process temperature.

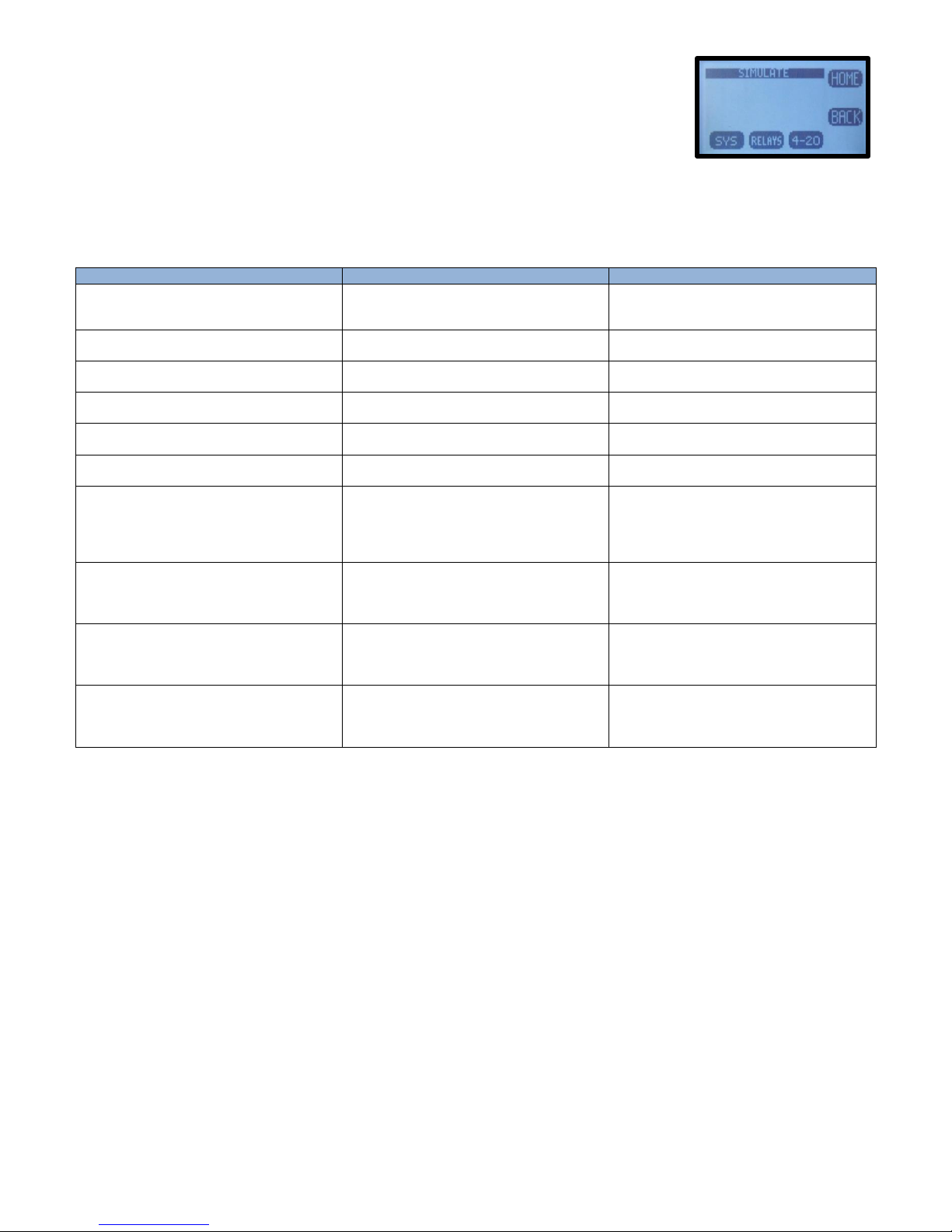

3.2.3 CONFIG (CONFIGURATION MENU)

Four options are available in the Configure Menu, XMTR, SENSOR, LOAD DEFAULT and Dampen.

XMTR enters the Transmitter Configuration menu.

o LCD access the Display Configuration Menu

SETUP adjust screen lighting characteristics

Temp. Choose °C or °F

CONT adjust Contrast

BACK LIGHT adjust Backlight Timeout, from always

ON to OFF after 10 minutes

GRAPH provides the choice of which Graph style is displayed

on the Home screen.

LINE , Moving average, vertical scale set to 0-100%

of the 4-20 mA output and user defined time scale

GAUGE, Current reading 0-100% of 4-20 mA range

BAR, Current reading 0-100% of 4-20 mA range

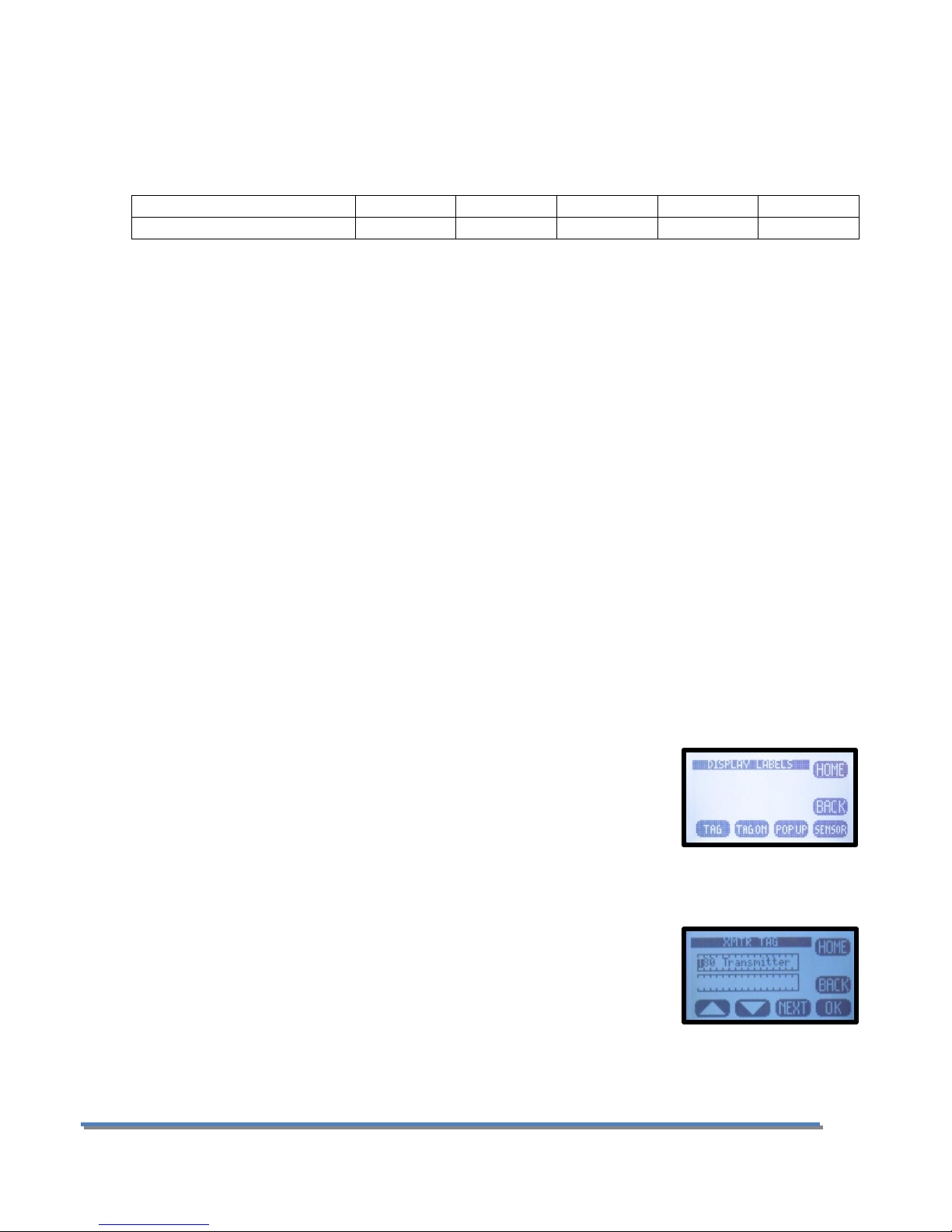

LABELS

TAG, Enter up to 2 lines x 16 characters, example,

Name, tag #... Displayed in INFO screen

TAG ON, Turn TAG ON/OFF, adds TAG to Main

Display Sequence, DATA → mV → GRAF → TAG →

DATA

POP UP, Turns ON/OFF, the double tap HOME

Screen pop up memo

SENSOR, Enter up to 2 lines x 16 characters

o OUTPUT access the Output Configuration Menu

4-20 mA configure 4-20 mA output (PV or Temp or More)

PV RANGE Enter 4 mA value and 20 mA value

Temp RANGE Enter 4 mA value and 20 mA value

MORE

o CAL Trim 4.00 mA and 20.00 mA output

o FAULT Choose fault condition 3.5 mA, 22

mA, None

RELAY

RLY1,2,3 Choose relay type:

o Alarm, enter the Set point ON, Set Point OFF, Expiration time, Delay ON

and Delay OFF times and the State, energize: changes state from deenergized to energized on alarm.

o Timed, Enter Period, Duration times and

Hold On/Off

o Fault, No input required, relay condition

changes from energize to de-energize.

24

Page 26

o Disable, Inactivates relay and removes the

relay button from the HOME Screen display.

HOLD, Freezes outputs at current value and locks relays in

their current state.

Hold Timeout, Removes HOLD after a certain period

of time, default setting: No Timeout, selections include 15 minutes, ½ hour, 1

hour

o SERIAL MODBUS configure serial output,

ADDRESS, enter address: 001 to 247

BAUD, Choose baud rate, default 9600

FORMAT, set serial data format, default value: 8N1, 8 bit, no

parity bit, 1 stop bit

o PASSWD Enter 4 character password to protect access to MENU Level, CAL Menu, CONFIG

Menu and SIM Menu (simulate). Each level can be turned ON or OFF and can have a unique

password.

MENU ON/OFF _ _ _ _ Locks Main Menu

CAL ON/OFF _ _ _ _ Locks CAL and CONFIG

CONFIG ON/OFF _ _ _ _ Locks CONFIG

SIM ON/OFF _ _ _ _ Locks SIM and CONFIG

SENSOR enters the sensor configuration menu.

o Choose SENSOR 1 or 2

TYPE, Allows T80 transmitter to configure the S80 sensor. For

use only when switching the measurement electrode type in

an S80 sensor, i.e. for a pH electrode to a pION electrode.

Select Sensor Type: pH, ORP, DO2, NH3, NH

Conductivity, Resistivity, Cu++, CN-, F-, NO

+

, Br-, Ca++, Cl-,

4

-

, K+, Ag+, Na+, S--

3

T COMP, Enter % temperature compensation per degree: pH,

0.33%, Total Chlorine 0%,

o COMP Dual Channel Only, Sets compensation type: Dissociation (pKa),

+

NH

, Free Chlorine, HF, S-2, Interference, X ppm Sensor 2 = 1 ppm

4

Sensor 1, Percentage % change per pH, Total Chlorine -5%.

o Qty of SENSORS, Choose 1 or 2

Load Default resets all Menus to factory default configuration.

Dampen, sets the number of measurements averaged for the displayed PV

3.2.4 INFO (INFORMATION MENU)

The Information Menu provides two choices,

Transmitter Screen, details the Name, Power type, Serial #, Firmware version

and the output configuration(s).

Sensor Screen, details the Name, Part #, Serial # and three sets of Calibration data.

COMP, displays the pKa, the sensor affected and the dissociation Factor,

3.2.5 SIM (SIMULATION MENU)

The Simulation menu allows the Input or Output signals to be simulated.

Page 25 Model TC80

Page 27

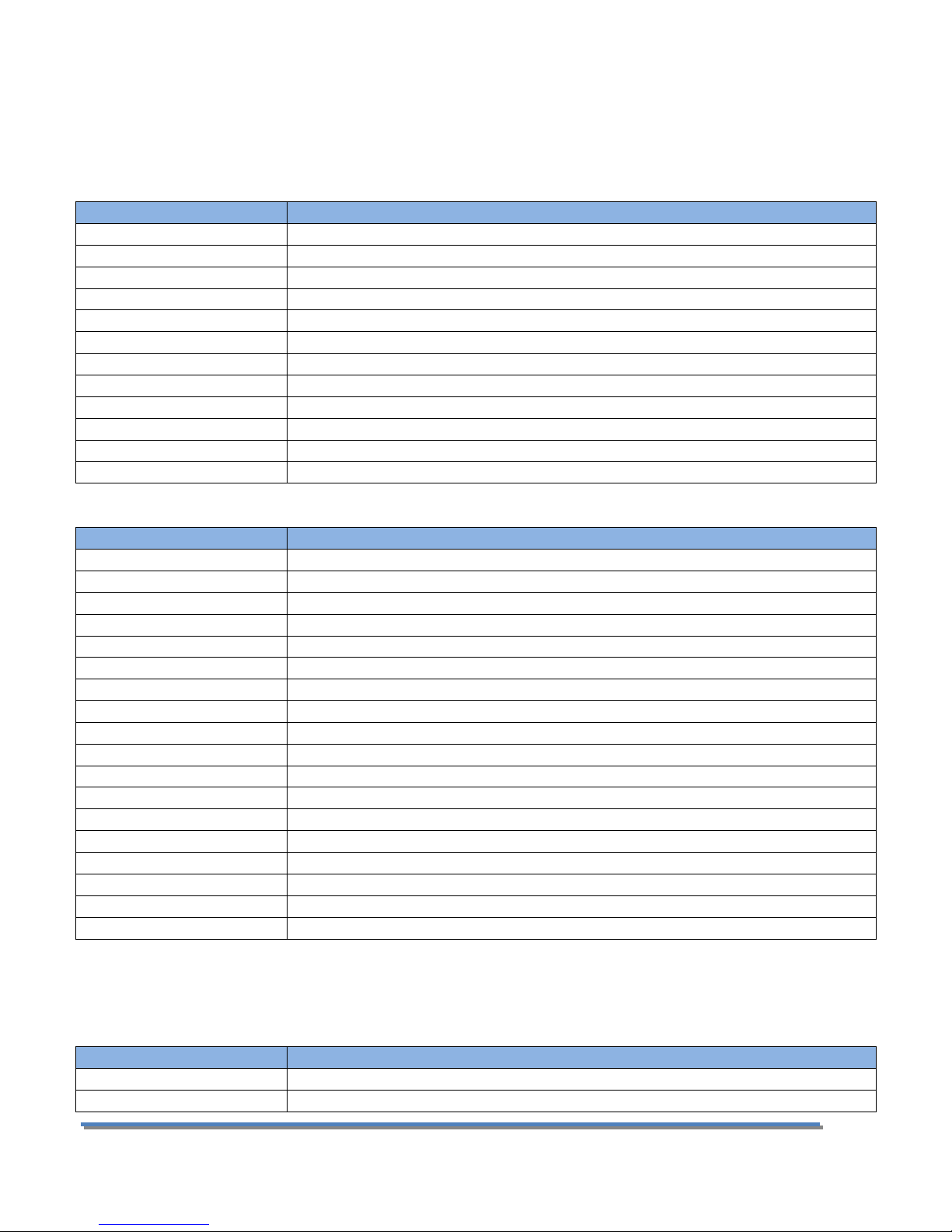

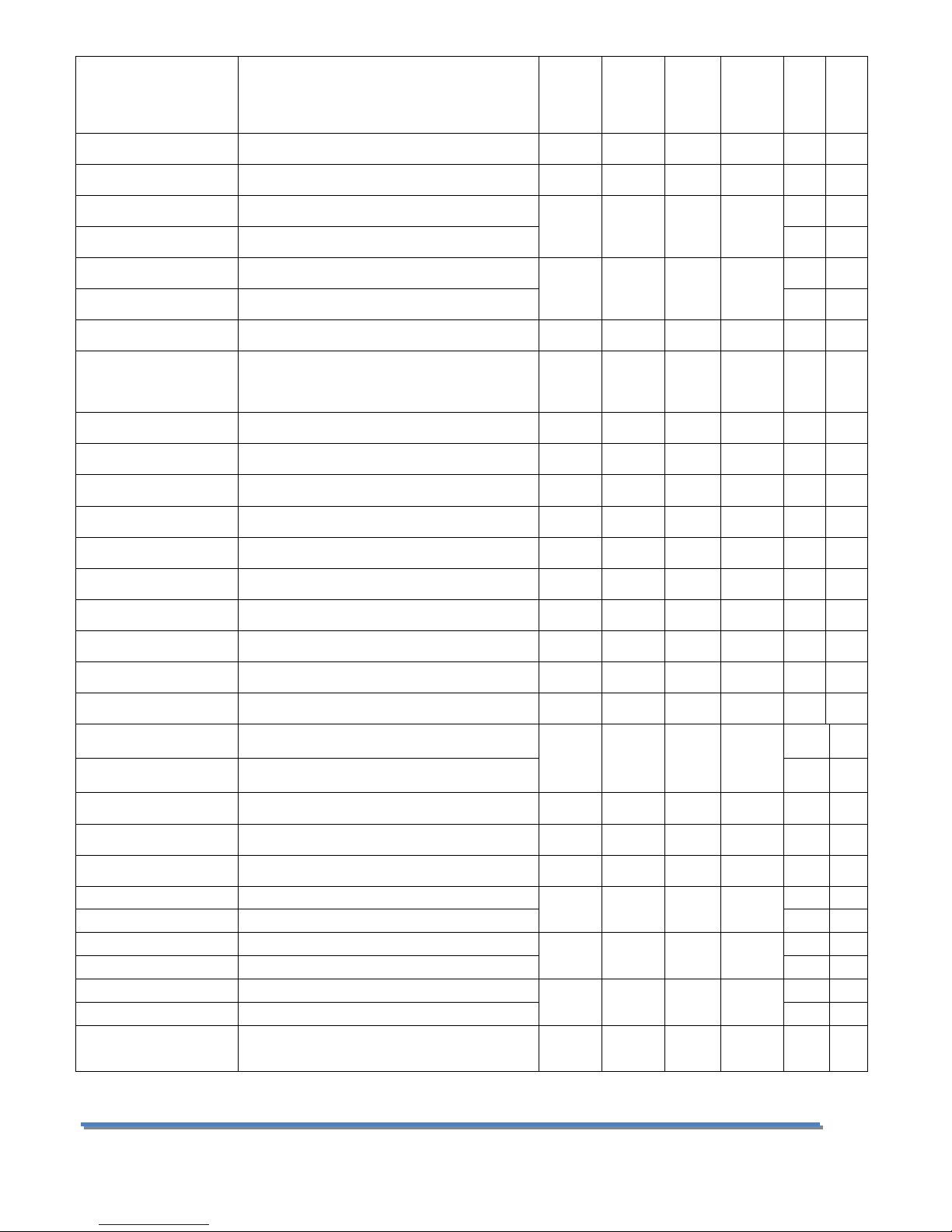

SYSTEM allows the Input to be simulated. Two choices are available, FIXED is

Fault

Definition

Recommendation

Memory Error

AN ERROR WAS FOUND

WITH THE MEMORY OF

THE MICROCONTROLLER

RETURN TO FACTORY

FOR SERVICE

Input Voltage OOT

POWER IS OUT OF

TOLERANCE

CHECK WIRING TO

THE TRANSMITTER

+12V OOT

ONBOARD 12V IS

OUT OF TOLERANCE

RETURN TO FACTORY

FOR SERVICE

+3.3V OOT

ONBOARD 3.3V IS

OUT OF TOLERANCE

RETURN TO FACTORY

FOR SERVICE

Loss of Comm

COMMUNICATION WITH

THE SENSOR WAS LOST

CHECK WIRING TO

THE SENSOR

No Sensor

NO SENSOR WAS FOUND

AT START-UP

CHECK WIRING TO

THE SENSOR

Cal Failed

SENSOR CALIBRATION

FAILED

1) CLEAN SENSING TIP

2) VERIFY SOLUTIONS

3) DO NOT LEAVE

UNATTENDED

4) RE-CALIBRATE

Relay 1 Expired

RELAY 1 TIME

ON EXPIRED

1) CHECK SENSOR OP

2) CHECK AUX EQUIP

A) PUMPS

B) TANKS

Relay 2 Expired

RELAY 2 TIME

ON EXPIRED

1) CHECK SENSOR OP

2) CHECK AUX EQUIP

A) PUMPS

B) TANKS

Relay 3 Expired

RELAY 3 TIME

ON EXPIRED

1) CHECK SENSOR OP

2) CHECK AUX EQUIP

A) PUMPS

B) TANKS

a fixed value, RAMP varies the signal across the 4-20 mA range, from the

lowest value to the highest value and back, activating and deactivating relays

if present. The RAMP has two adjustments the Ramp period, 30 seconds to 2

minutes and Duration; 1 cycle, 5, 10, 20, 30 minutes.

RELAYS allows individual relays, #1, #2, and #3 to be activated and deactivated

4-20 mA allows the output to be simulated from 4.00 mA to 20.00 mA.

3.2.6 FAULT SCREENS

3.3 OUTPUT CONFIGURATION GUIDE

Install and wire the T80 Transmitter as described in Sections 2.1 and 2.2 above.

Connect the sensor to the transmitter as described in Section 2.2 above.

Supply power to the Model T80 transmitter.

Verify the proper measurement type is displayed, pH and TCl2. The sensor automatically uploads the measured

parameter, the calibration data and the range of measurement to the transmitter. The default configuration of

the 4-20 mA output is the range of the sensor, 0-14 pH for pH sensors and 0.00 -20.00 ppm for Total Chlorine. To

change the 4-20 mA range, follow the instructions in Section 3.3.1 below.

26

Page 28

3.3.1 CONFIGURE 4-20 MA OUTPUT RANGE

Double press any key except the HOME key to enter the HOME Menu. Follow

the path below to set the 4-20 mA range.

HOME Menu → Press CONFIG → XMTR → OUTPUT → 4-20 (1)(2) → PV or

TEMP

Press CHANGE to enter New Values.

Choose 4 mA value, press OK

Enter value using ▲ or ▼and NEXT to move to the next digit, press OK→Back

Choose 20 mA value, press OK,

Enter value using ▲ or ▼and NEXT to move to the next digit, press OK→Back

Press BACK to return to the CONFIGURE 4-20 mA screen or HOME to return to

the HOME Menu screen.

3.3.2 CONFIGURE 4-20 MA FAULT CONDITION AND CAL

In the CONFIGURE 4-20 mA screen, Press MORE → FAULT or

Choose Low Fault 3.5 mA or Hi Fault 22 mA or NONE, (default setting NONE),

Press OK

Press BACK → CAL, (enter PW 0000) connect DVM to 4-20 mA line, Press 4.00

mA then adjust value to the DVM reading, Press 20.00 mA and adjust value to

the DVM reading. The 4-20 mA output is calibrated.

3.3.3 CONFIGURE ALARM RELAYS (RELAYS OPTIONAL)

HOME Menu → Press CONFIG → XMTR → OUTPUT → RELAYS→RLY1

Choose the ALARM, TIMER, FAULT or DISABLE mode for Relay 1

ALARM Displays:

o SET POINT ON: The Process Variable Value that activates the relay.

o EXPIRATION: Enter a time that should not be exceeded before the PV

should have changed enough to activate the OFF set point. At the

Expiration time the relay is deactivated and a Fault condition is

initiated. Fault: Relay 1 Time expired: Cause: Loss of reagent, failed

sensor ….

o Delay ON: The amount of time the PV must remain above/below the

set point before the relay activates.

o SET POINT OFF: The Value of the process variable that deactivates the

relay.

SET POINT OFF > Set Point → Low Set Point

SET POINT OFF < Set Point → Hi Set Point

o Delay OFF: The amount of time the PV must remain above/below the

hysteresis point before the relay deactivates.

o STATE: Energize (relay is energized on activation)/De-energize (relay

is de-energized on activation)

TIMER activates the relay periodically for a specific duration, user configured

period and duration

FAULT sets the relay condition to a de-energize state and NC relay closes in

response to a Fault condition or power failure.

Page 27 Model TC80

Page 29

DISABLE turns off the relay and removes it’s icon from the HOME screen

Setting up an Alarm Relay

Choose ALARM

Press CHANGE to enter new values

Choose ON Set Point, Press OK

Enter value using ▲ or ▼and NEXT to move to the next digit, press OK, press BACK (Min –Max values

indicate the range of acceptable values)

Choose Expiration, Press OK,

Choose time from drop down menu using ▲ or ▼, press OK, press BACK

Choose OFF Set Point, Press OK

Enter value using ▲ or ▼and NEXT to move to the next digit, press OK, press BACK

Choose Delay ON, Press OK

Enter value using ▲ or ▼and NEXT to move to the next digit, press OK, press

BACK

Choose Delay OFF, Press OK

Enter value using ▲ or ▼and NEXT to move to the next digit, press OK, and

press BACK when done to exit Relay 1.

Repeat for Relay 2 and Relay 3.

3.3.4 EXIT MENUS AND RETURN TO MAIN DISPLAY

Press HOME Key to return to the Home Menu Screen

Press Hold to turn OFF Hold

Press EXIT Key to exit the menu

“Save Changes?” press YES

Choose Display Mode, DATA, mV or GRAF by pressing selection Key. The

selection key displays which screen will be displayed next.

o The type of graphical display used, Line, Bar or Gauge is selected in

CONFIG → XMTR → LCD → GRAPH → LINE, GAUGE, BAR

3.3.5 SENSOR START UP

All sensors are supplied with protective caps over the sensing end. Remove the cap(s) from the sensor before

installing in the process. All sensors were calibrated at the factory before shipment, no calibration should be

necessary before use. Allow the sensor to equilibrate to the process solution conditions for ½ hour before

verifying the reading against a grab sample. If calibration is required follow the instruction in Section 4.0 below.

3.4 USER SELECTABLE OPTIONS

3.4.1 SCREEN LIGHTING

LED back lighting is available on AC and DC powered instruments only.

Contrast can be adjusted for optimal viewing. The Backlight can be adjusted to timeout after a set period of time

or remain on.

Location: CONFIG → XMTR → LCD → Set Up → CONT, BACK LIGHT

28

Page 30

3.4.3 GRAPHICAL DISPLAY

Full Screen Period

15 minutes

1 hour

12 hours

1 day

2 days

Sample Rate ( 1 point every)

10 seconds

40 seconds

8 minutes

15 minutes

30 minutes

There are three graphical display choices:

LINE, The Line graph is a moving average of the process variable with the 4-20 mA range as the

maximum/minimum values and a choice of time scales.

The Time scale is the amount of time displayed across the full screen. Choices include:

GAUGE, Live reading displaying 0-100% of 4-20 mA range. The Alarm Relay number(s), #1, #2 and#3

mark the respective set points on graph.

BAR, Live reading displaying 0-100% of 4-20 mA range. The Alarm Relay number(s), #1, #2 and#3 mark

the respective set points on graph.

Pressing OK after selecting a Graphical Display will exit the menu structure and return to the Main Display.

Location: CONFIG → XMTR → LCD → GRAPH

3.4.4 TAG TRANSMITTER NAME

Two 16 character lines are available for naming the transmitter, Upper and Lower case characters, Numbers and

Punctuation are available. The information entered will be displayed in the INFO screen and optionally in the

Main display sequence if activated in the TAG ON menu. The character set is listed below sequentially; the first

character in the set is an empty space.

! ” # $ % & ‘ ( ) * + , - . / 0 1 2 3 4 5 6 7 8 9 : ; < = > ? @ A B C D E F G H I J K L M N O P Q R S T U V W X Y Z [ ¥ ] ^ _

‘ a b c d e f g h I j k l m n o p q r s t u v w x y z { | } → ←

Entry is accomplished by scrolling through the alphanumeric list with the ▲ (forward →) and ▼ (backwards ←)

arrows to the character of choice and then pressing NEXT to advance the cursor to the next digit. Pressing and

holding the ▲ or ▼ keys will initiate two speed auto scrolling. Press BACK to exit the screen.

Location: CONFIG → XMTR → LCD → LABELS → TAG

3.4.5 SENSOR NAME

Two 16 character lines are available for naming the Sensor, Upper and Lower case

characters, Numbers and Punctuation are available. The information entered will

be displayed in the INFO screen. Entry is accomplished by scrolling through the alphanumeric list with the ▲

(forward →) and ▼ (backwards ←) arrows to the character of choice and then pressing NEXT to advance the

cursor to the next digit. Pressing and holding the ▲ or ▼ keys will initiate two

speed auto scrolling. Press BACK to exit the screen.

Location: CONFIG → XMTR → LCD → LABELS → SENSOR

Page 29 Model TC80

Page 31

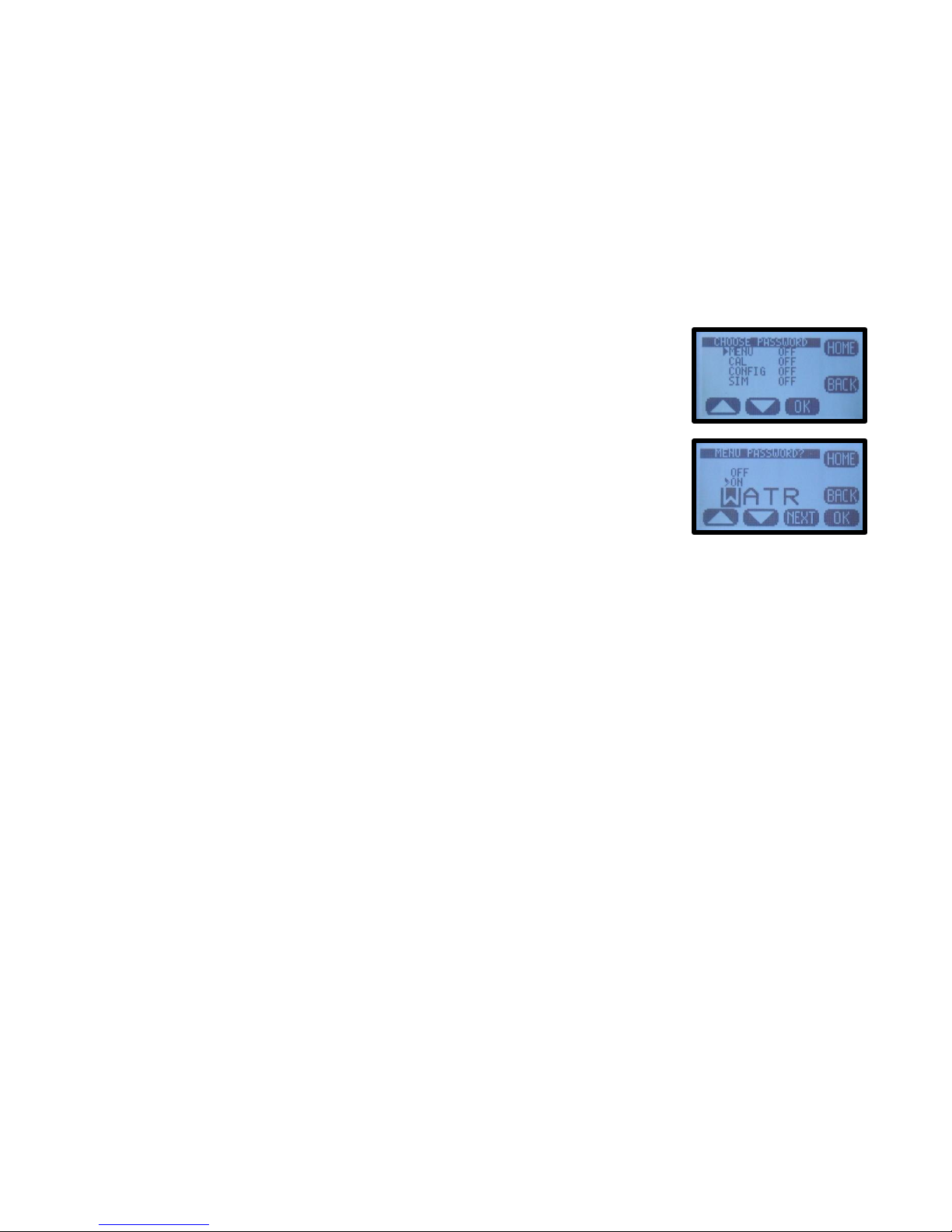

3.4.6 PASSWORD PROTECTION

PASSWD Enter 4 character password to protect access to MENU Level, CAL Menu, CONFIG Menu and SIM Menu

(simulate). Each level can be turned ON or OFF and can have a unique password. Upper Case Characters and

Numbers are available for use.

Place the cursor in front of the level to be changed and Press OK. Move the cursor to ON and press OK to change

the password status from OFF to ON.

Entry is accomplished by scrolling through the alphanumeric list with the ▲ (forward →) and ▼ (backwards ←)

arrows to the character of choice and then pressing NEXT to advance the cursor to the next digit. Pressing and

holding the ▲ or ▼ keys will initiate two speed auto scrolling.

o MENU ON/OFF _ _ _ _ Locks Main Menu

o CAL ON/OFF_ _ _ _ Locks CAL and CONFIG

o CONFIG ON/OFF _ _ _ _ Locks CONFIG

o SIM ON/OFF _ _ _ _ Locks SIM and CONFIG

In the case of a Lost or Forgotten password enter MSTR to access the screen.

Location: CONFIG → XMTR → PSSWD

4-20 mA Calibration password “0000”

Location: CONFIG → XMTR → OUTPUT → 4-20 (1)(2) →MORE → CAL

30

Page 32

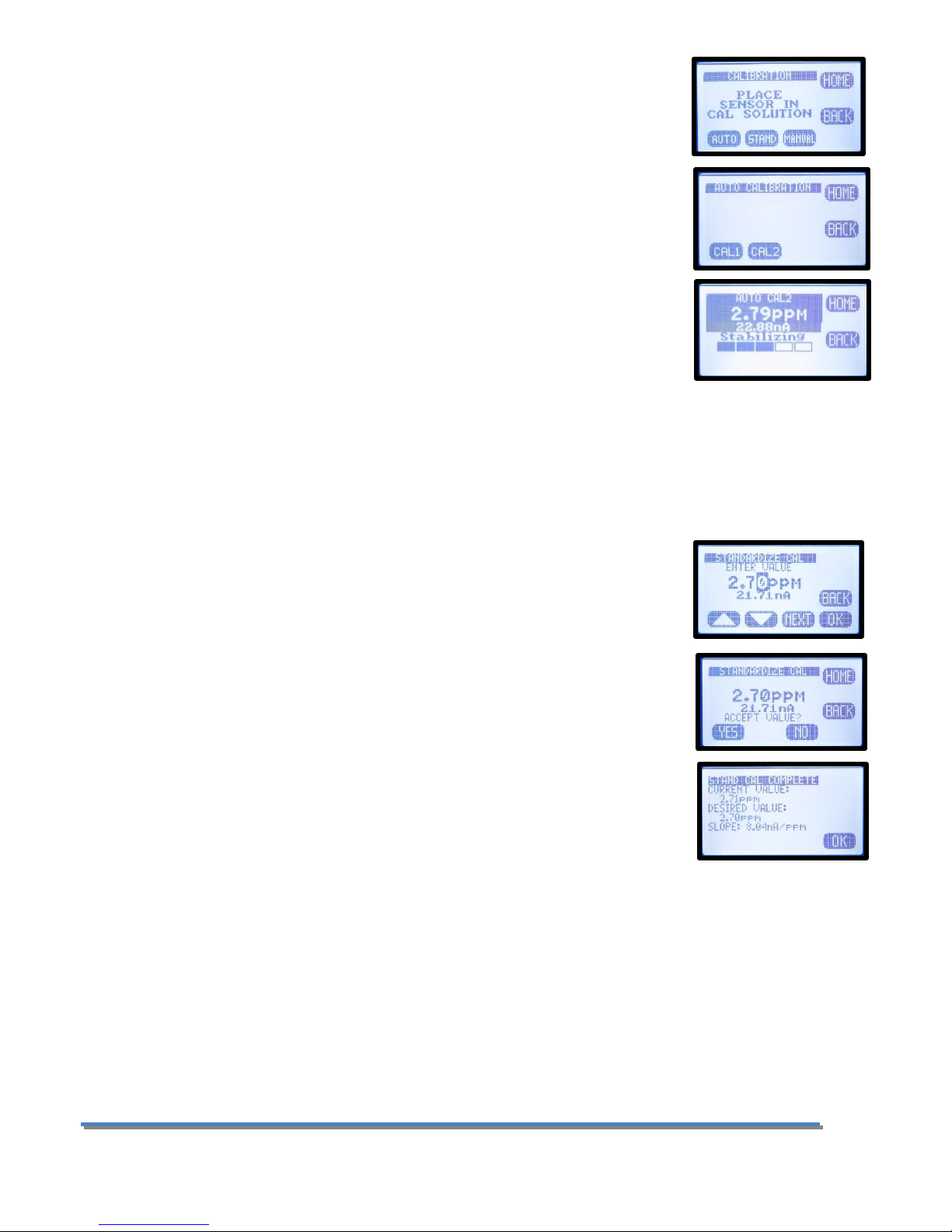

4.0 CALIBRATION

The Model T80 transmitter provides three methods of calibration:

4.0.1 AUTO CALIBRATION DESCRIPTION

Auto calibration is the primary calibration method for all measurements. AUTO

calibration automatically recognizes the calibration solution the sensor is in and

proposes the actual temperature compensated value for acceptance. AUTO

calibration can be a single point or two point calibration. A single point calibration

sets the zero point or offset value of the sensor. The second calibration sets the slope

or span of the sensor.

When the AUTO key is pressed and Cal 1 or Cal2 is selected the transmitter displays

the PV (Process Variable) and the associated mV signal from the sensor. When the

reading has stabilized a calibration value is Automatically proposed, i.e. 7.00 pH, 0.00

ppm Chlorine. The user is prompted to accept the proposed calibration value or enter and accept another

value. Once Cal 1 is accepted the user is ask to continue to Cal 2, yes/no. If yes, the sensor is moved to the

second calibration solution and a second calibration value is proposed when the sensor has stabilized. Accept

the value and the calibration is complete.

At the end of each calibration the Offset and Slope are displayed in the respective units, pH, mV, ppm, Press OK

to save the calibration and write it to the sensor’s memory.

4.0.2 STANDARDIZE CALIBRATION DESCRIPTION

A Standardize Calibration is a single point calibration where the transmitter’s reading

is adjusted to agree with a solution of known value, either a calibration standard, a

grab sample or laboratory determined value. In many cases the constituents and the

pressure and temperature of the process solution are very different from the

calibration solution. In these cases, once the sensor has equilibrated to the process

environment, the Zero Point or Offset value may have shifted from the original

calibration point. Standardization allows for correction of this type of offset. It

changes the Offset value in a pH calibration. It changes the Slope value in a Chlorine

calibration. It is the primary calibration for Chlorine Sensors. Enter the Chlorine

value determined by a DPD test on the process water.

When the STAND key is pressed, the user is prompted to ENTER VALUE. The user enters the pH or Chlorine value

they want the transmitter to read and press OK. The user is then prompted to accept the value, yes/no, and the

calibration is complete. Standardizations are single point calibrations.

At the end of each calibration the Offset and Slope are displayed in the respective units, pH, mV or ppm, Press

OK to save the calibration and write it to the sensor’s memory.

4.0.3 MANUAL CALIBRATION DESCRIPTION

Manual calibration allows the user to enter calibration data for an electrode into the transmitter without

performing a calibration. A MANUAL Calibration requires the entry of three pieces of data, (1) A concentration

Page 31 Model TC80

Page 33

with the (2) corresponding mV and (3) a slope for the electrode. This allows

laboratory generated calibration data for an electrode to be entered in a remote

analyzer where calibration is difficult or impractical.

The pictures show a Manual Calibration for a Total Chlorine sensor using the default

values of 0.00 ppb = 0.00 mV and 8.0 nA/ppm.

Example: MANUAL Calibration for a pH electrode