Page 1

NSTRUCTION MANUAL

I

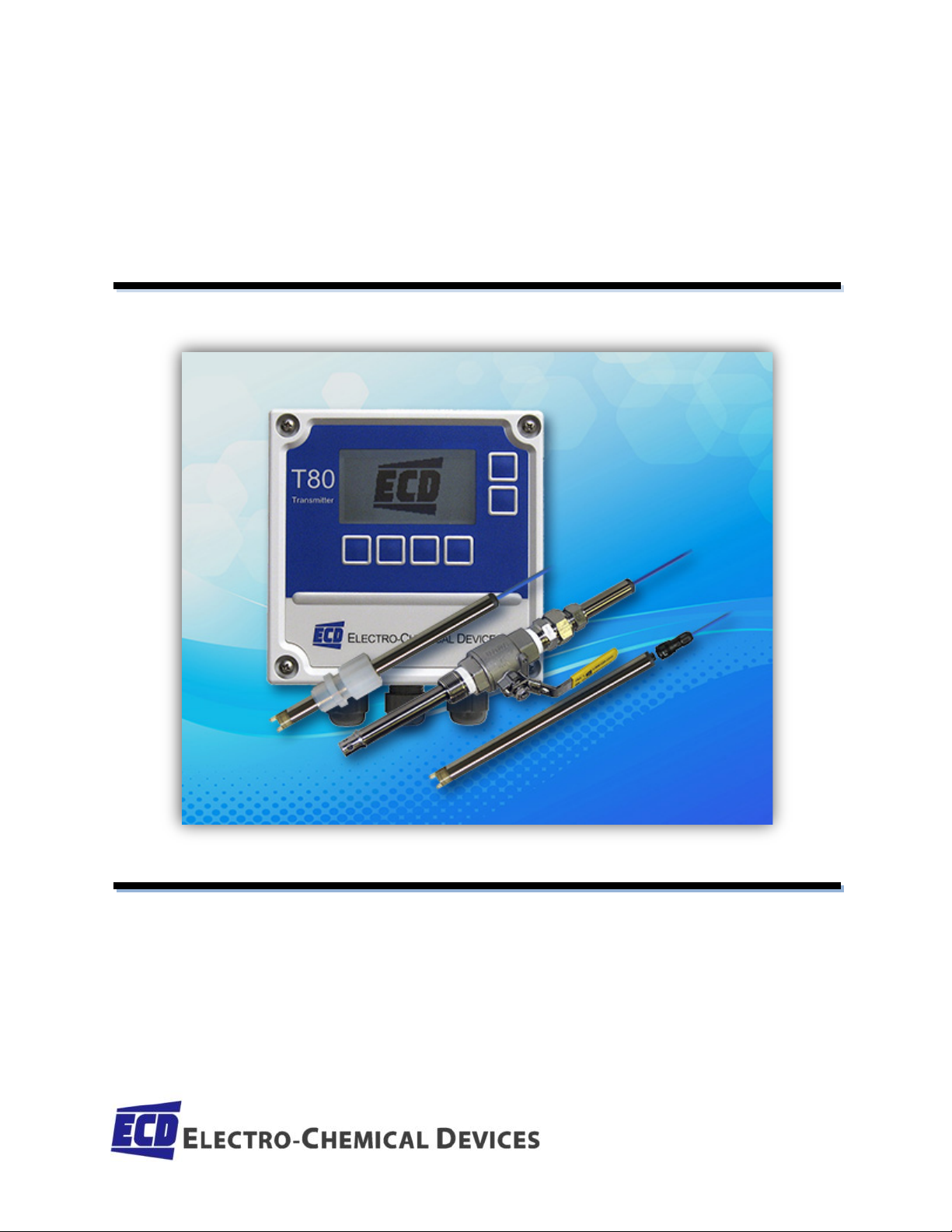

MODEL T80 UNIVERSAL TRANSMITTER

T80 IM Rev. I

Page 2

Page 1 Model T80

Page 3

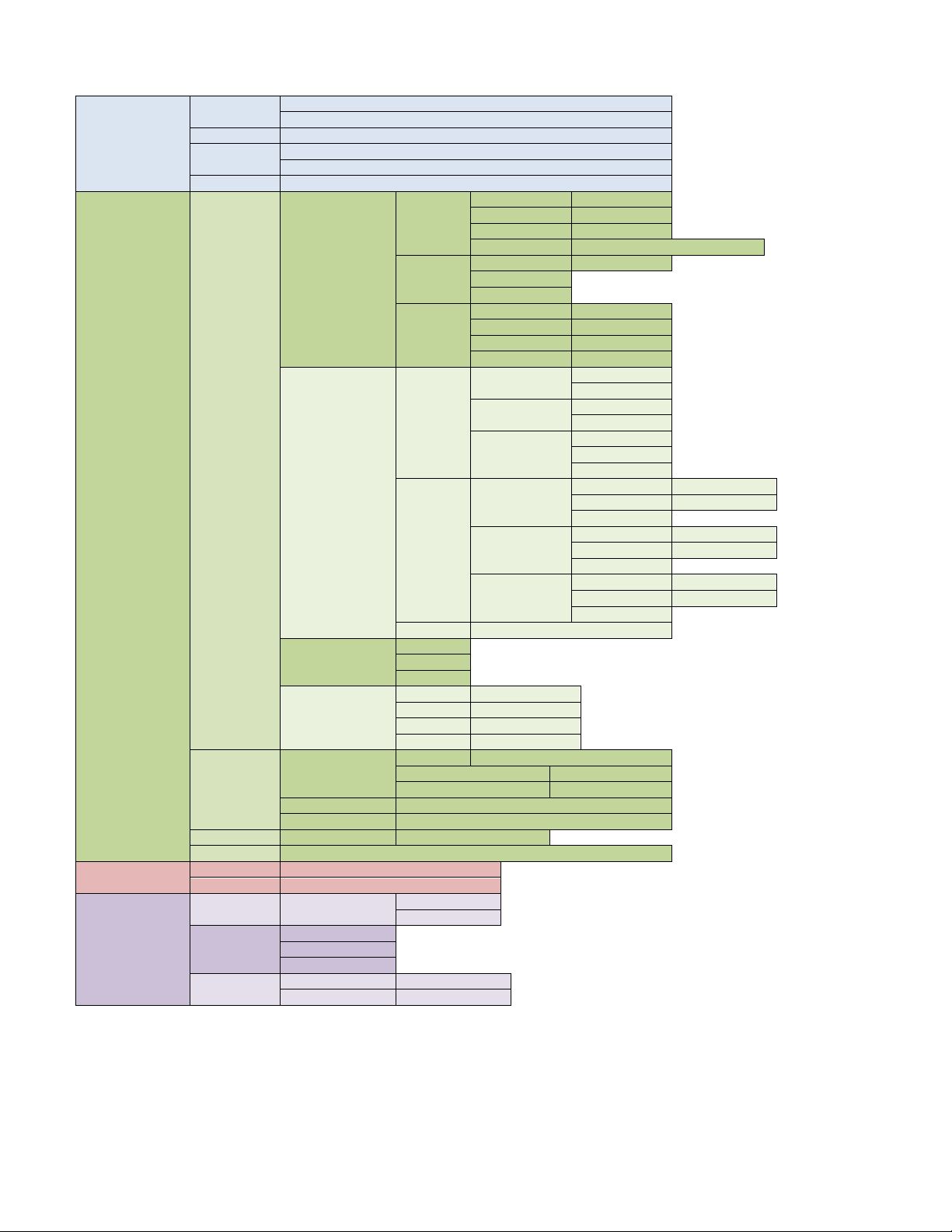

SCREEN MAP

Cal 1 (Offset) using Calibration Solution

Cal 2 (Slope) using Calibration Solution

Standardize

Enter Grab Sample Determined Value

Enter Offset, the PV value and associated mV

Enter Slope, mV/pH, mV/decade, mV/ppm…

Temp

Enter measured Temperature

Temp. Format

°C or °F

Contrast

Adj. 0-100%

Back Light

Enter ON time

Range Lock

Choose: Auto, ppb, ppm, ppT

Line

Screen Duration

Gauge

Bar

TAG ID

Enter Name

TAG

ON/OFF

POP UP

ON/OFF

SENSOR

Enter Name

Range (PV or

Temp.)

4 mA =

20 mA =

Trim 4.00 mA

Trim 20.00 mA

3.5 mA

22 mA

NONE

Alarm

Set Point

Timed

Period, Duration

Fault

Alarm

Set Point

Timed

Period, Duration

Fault

Alarm

Set Point

Timed

Period, Duration

Fault

HOLD

Time out: None, 15 min, 30 min…

Address

Baud rate

Format

Menu

Off/On “ _ _ _ _ “

CAL

Off/On “ _ _ _ _ “

CNFG

Off/On “ _ _ _ _ “

SIM

Off/On “ _ _ _ _ “

Type

Choose Type: pH, Cond, ORP…..

T COMP

Enter % Comp

ISO PT

Enter mV value

Qty of Sensors

Choose 1 sensor or 2 sensors

COMP

Dissociation, Interference, Percentage, OFF

Load Default

Sensor/Transmitter

Yes/No

DAMP

Enter Signal Dampening (# of readings to average, 0-100)

INFO

(Information)

XMTR

Configuration, Serial #, Name, Outputs

Sensor

Calibration logs, Serial #, Name

Fixed value

Ramp

#1 ON/OFF

#2 ON/OFF

#3 ON/OFF

4-20 mA Ch 1

Enter Value

4-20 mA Ch 2

Enter Value

Auto

CAL

(Calibration)

Manual

Set Up

CONFIG

(Configuration)

XMTR

LCD

Output

Serial

Password

Graph

Label

4-20 mA

(1 or 2)

RELAY

Cal (more)

Fault (more)

Relay 1

Relay 2

Relay 3

Sensor

System Sensor 1 or 2

SIM

(Simulate)

Relays

4-20 mA

Sensor 1 or 2

2

Page 4

PREFACE

Purchasing products from Electro-Chemical Devices, Inc. provides you with the finest liquid analytical

instrumentation available. If this is your first purchase from ECD, please read the entire manual before installing

and commissioning your new equipment.

Manuals are accessible on the ECD website at http://www.ecdi.com/literature/manuals.html

If there are any questions concerning this equipment, please contact your local ECD representative, or the

factory directly at:

Electro-Chemical Devices, Inc.

1681 Kettering

Irvine, CA 92614 USA

Telephone: +1-949-336-6060

FAX: +1-949-336-6064

Website: www.ecdi.com

Email: sales@ecdi.com

.

Page 3 Model T80

Page 5

SYMBOLS USED IN MANUAL

This symbol is used to designate important information, warnings and cautions. Failure to follow

No operator serviceable parts, service by authorized service personnel only.

This symbol is used to designate a WARNING “Risk of Electrical Shock”

Disconnect supply before servicing

Equipment protected throughout by double insulation.

this information could lead to harm to the instrument or user.

Read the complete manual before installing or using the equipment.

Contents of this manual are believed to be correct at the time of printing and are subject to change without

notice. ECD is not responsible for damage to the instrument, poor performance of the instrument or losses

resulting from such, if the problems are caused by:

• Incorrect operation by the user.

• Use of the instrument in incorrect applications.

• Use of the instrument in an inappropriate environment or incorrect utility program (power supply).

• Repair or modification of the related instrument by anyone not authorized by ECD.

• There are no operator accessible parts. Service and maintenance to be done by authorized personnel only.

• If the equipment is used in a manner not specified by the manufacturer, the protection provided by the

equipment may be impaired.

© 2014 Electro-Chemical Devices, Inc. All rights reserved. No part of this manual may be used or reproduced in

any form or by any means, or stored in a database or retrieval system without prior written permission from

Electro-Chemical Devices, Inc. Making copies of any part of this manual for any purpose other than personal use

is a violation of United States copyright laws. Document printed in the United States of America.

4

Page 6

Table of Contents

Screen Map .................................................................................................................................................................2

TERMS AND CONDITIONS OF SALE .......................................................................................................................... 10

RETURN GOODS POLICY .......................................................................................................................................... 11

UNPACKING THE INSTRUMENT ............................................................................................................................... 12

INSTRUCTION MANUAL REVISION ........................................................................................................................... 12

1.0 GENERAL DESCRIPTION ..................................................................................................................................... 13

1.1 FEATURES ...................................................................................................................................................... 13

1.2 SPECIFICATIONS ............................................................................................................................................. 13

1.2.1 Input specification .................................................................................................................................. 13

1.2.2 Input Ranges ........................................................................................................................................... 13

1.2.3 Accuracy ................................................................................................................................................. 13

1.2.4 Output Signals ........................................................................................................................................ 14

1.2.5 Contact Relays ........................................................................................................................................ 14

1.2.6 Display .................................................................................................................................................... 14

1.2.7 Enclosure ................................................................................................................................................ 14

1.2.8 Power ...................................................................................................................................................... 14

1.2.9 Environmental Conditions ...................................................................................................................... 14

1.2.10 Shipping ................................................................................................................................................ 14

1.3 Model Codes .................................................................................................................................................. 15

2.0 INSTALLATION.................................................................................................................................................... 16

2.1 MOUNTING .................................................................................................................................................... 16

2.2 WIRING .......................................................................................................................................................... 17

2.2.1 Wiring, power ......................................................................................................................................... 18

2.2.2 Wiring, Sensor ........................................................................................................................................ 19

2.2.3 Wiring, 4-20 mA Outputs ........................................................................................................................ 19

2.2.4 Wiring, Contact Relay Outputs ............................................................................................................... 20

2.2.5 Wiring, Serial Output MODBUS RTU ...................................................................................................... 20

3.0 OPERATION ........................................................................................................................................................ 21

3.1 KEYS ............................................................................................................................................................... 21

3.1.1 Home/Exit Key ........................................................................................................................................ 21

3.1.2 Back/Hold Key ......................................................................................................................................... 21

Page 5 Model T80

Page 7

3.1.3 Selection Adjustment Keys ..................................................................................................................... 22

3.1.4 Alpha Numeric Entry............................................................................................................................... 22

3.2 MENU STRUCTURE ........................................................................................................................................ 22

3.2.1 HOLD (Output Hold) ............................................................................................................................... 22

3.2.2 CAL (Calibration Menu) .......................................................................................................................... 22

3.2.3 CONFIG (Configuration Menu) ............................................................................................................... 23

3.2.4 INFO (Information Menu) ....................................................................................................................... 25

3.2.5 SIM (Simulation Menu) ........................................................................................................................... 25

3.2.6 Fault Screens........................................................................................................................................... 25

3.2.7 SENTINEL® Screens ................................................................................................................................. 26

3.3 START UP GUIDE ............................................................................................................................................ 27

3.3.1 Configure 4-20 mA output range ............................................................................................................ 27

3.3.2 Configure 4-20 mA Fault Condition and Cal ........................................................................................... 27

3.3.3 Configure Alarm Relays (Relays Optional) .............................................................................................. 27

3.3.4 Exit Menus and Return to Main Display ................................................................................................. 28

3.3.5 Sensor Start Up ....................................................................................................................................... 28

3.4 USER SELECTABLE OPTIONS .......................................................................................................................... 29

3.4.1 Screen Lighting ....................................................................................................................................... 29

3.4.3 Graphical display .................................................................................................................................... 29

3.4.4 TAG Transmitter Name ........................................................................................................................... 29

3.4.5 SENSOR Name ........................................................................................................................................ 30

3.4.6 Password Protection ............................................................................................................................... 30

4.0 CALIBRATION ..................................................................................................................................................... 31

4.0.1 AUTO Calibration description ................................................................................................................. 31

4.0.2 STANDardize Calibration description ..................................................................................................... 31

4.0.3 MANUAL Calibration description............................................................................................................ 31

4.1 pH Calibration Procedures ............................................................................................................................. 33

4.1.1 AUTO Cal using pH 4.01, 7.00, 10.00 buffers ......................................................................................... 33

4.1.2 AUTO Cal using other pH buffers............................................................................................................ 33

4.1.3 Standardize ............................................................................................................................................. 33

4.2 ORP Calibration Procedures .......................................................................................................................... 34

4.2.1 Auto Cal with Quinhydrone .................................................................................................................... 34

4.1.2 Standardize ............................................................................................................................................. 34

6

Page 8

4.3 pION Calibration Procedures ......................................................................................................................... 35

4.3.1 AUTO Cal using 1, 10, 100 ppm solutions ............................................................................................... 35

4.3.2 AUTO Cal using non-decimal ppm solutions .......................................................................................... 35

4.3.3 Standardize ............................................................................................................................................. 35

4.4 S80/DO90 DISSOLVED OXYGEN Calibration Procedures ............................................................................... 36

4.4.1 AUTO Cal using zero ppm solution and Air............................................................................................. 37

4.4.2 Standardize ............................................................................................................................................. 38

4.4.3 Manual Cal .............................................................................................................................................. 38

4.5 TRITON® Dissolved Oxygen Calibration Procedures ...................................................................................... 38

4.5.1 AUTO Cal using zero ppm solution and Air............................................................................................. 39

4.5.2 Standardize ............................................................................................................................................. 40

4.6 TRITON® TR6 Turbidity/Suspended Solids Sensor ......................................................................................... 40

4.6.1 AUTO Cal ................................................................................................................................................. 41

4.6.2 Standardize ............................................................................................................................................. 41

4.6.3 MANUAL Cal ........................................................................................................................................... 42

4.7 Conductivity Sensors ..................................................................................................................................... 42

4.7.1 AUTO Cal using Air and Conductivity Standard ...................................................................................... 42

4.7.2 Standardize ............................................................................................................................................. 43

4.8 TDS Conductivity Sensors .............................................................................................................................. 43

4.8.1 Standardize ............................................................................................................................................. 44

4.9 Resistivity Sensors ......................................................................................................................................... 44

4.9.1 AUTO Cal using Air and Meg-Ohm process water .................................................................................. 44

4.9.2 Standardize ............................................................................................................................................. 44

5.0 MAINTENANCE .................................................................................................................................................. 46

5.1 CLEANING ...................................................................................................................................................... 46

6.0 TROUBLESHOOTING .......................................................................................................................................... 47

7.0 PARTS AND ACCESSORIES .................................................................................................................................. 48

7.1 Front Panel Control Board Exploded ............................................................................................................. 48

7.2 Front Panel Control Board Exploded, with Relays ......................................................................................... 48

7.3 Transmitter Case, back with Cable Glands .................................................................................................... 49

7.4 Replacement Parts......................................................................................................................................... 49

7.5 Accessories .................................................................................................................................................... 50

8.0 S80 SENSORS ..................................................................................................................................................... 51

Page 7 Model T80

Page 9

8.1 S80 Installation .............................................................................................................................................. 51

8.1.1 Insertion .................................................................................................................................................. 51

8.1.2 Immersion ............................................................................................................................................... 51

8.1.3 Flow through .......................................................................................................................................... 51

8.1.4 Valve Retractable .................................................................................................................................... 52

8.1.5 Flange fittings ......................................................................................................................................... 53

8.2 S80 Part Number Configurator ...................................................................................................................... 53

8.3 TRITON® DO80 Sensors ................................................................................................................................. 54

8.4 TRITON® TR6 Sensors .................................................................................................................................... 55

8.3 S80 Sensor Maintenance ............................................................................................................................... 56

8.3.1 Electrode Cartridge Installation .............................................................................................................. 56

8.3.2Electrode Cartridge Replacement ........................................................................................................... 56

8.3.3 Electrode Cleaning .................................................................................................................................. 56

8.3.4 pH Electrode Cartridge Cleaning ............................................................................................................ 57

8.3.5 ORP Electrode Cartridge Cleaning .......................................................................................................... 57

8.3.6 pIon Electrode Cartridge Cleaning .......................................................................................................... 57

8.3.7 Dissolved Oxygen Cartridges .................................................................................................................. 58

8.3.8 TRITON DO80 Dissolved Oxygen ............................................................................................................ 58

8.3.9 TRITON TR6 Turbidity ............................................................................................................................. 60

8.3.10 Conductivity and Resistivity sensors .................................................................................................... 60

8.4 S80 Sensor Specifications .............................................................................................................................. 61

8.4.1 pH electrodes.......................................................................................................................................... 61

8.4.2 ORP Electrodes ....................................................................................................................................... 62

8.4.3 Dissolved Oxygen .................................................................................................................................... 62

8.4.4 Ammonium Electrode ............................................................................................................................. 62

8.4.5 Bromide Electrode .................................................................................................................................. 62

8.4.6 Calcium Electrode ................................................................................................................................... 62

8.4.7 Chloride Electrode .................................................................................................................................. 63

8.4.8Cupric Electrode ...................................................................................................................................... 63

8.4.9 Cyanide Electrode ................................................................................................................................... 63

8.4.10 Fluoride Electrode ................................................................................................................................ 63

8.4.11 Potassium Electrode ............................................................................................................................. 63

8.4.12 Silver Electrode ..................................................................................................................................... 64

8

Page 10

8.4.13 Sodium Electrode ................................................................................................................................. 64

8.4.14 Sulfide Electrode ................................................................................................................................... 64

8.4.15 TRITON® DO80 ...................................................................................................................................... 64

8.4.16 TRITON® TR6 ......................................................................................................................................... 65

APPENDIX ................................................................................................................................................................ 66

A. Auto Cal Buffer Tables ..................................................................................................................................... 66

B. T80 HART Menu ............................................................................................................................................... 66

D.MODBUS RTU Register Listing ......................................................................................................................... 68

03 (0x03) Read Holding Registers .................................................................................................................... 68

06 (0x06) Write Single Register ....................................................................................................................... 68

Registers .......................................................................................................................................................... 69

Fault Status ...................................................................................................................................................... 72

Warning Status ................................................................................................................................................ 72

Sensor Type ..................................................................................................................................................... 73

E. Resistivity Temperature Compensation .......................................................................................................... 74

F. SOFTWARE HISTORY ........................................................................................................................................ 74

Page 9 Model T80

Page 11

TERMS AND CONDITIONS OF SALE

1. ACCEPTANCE. If this writing differs in any way from the terms and c onditions of Buyer's order or if t his writing is construed as an acceptance or as a confirmation acting as an

acceptance, then Seller’s acceptance is EXPRESSLY MADE CONDITIONAL ON BUYER’S ASSENT TO ANY TERMS AND CONDITIONS CONTAINED HEREIN THAT ARE DIFFERENT

FROM OR ADDITIONAL TO THOSE CONTAINED IN BUYER'S WRITING. Further, this writing shall be deemed notice of objection to s uch terms and conditions of Buyer. If this

writing is cons trued as the offer, acceptance hereof is EXPRESSLY LIMITED TO THE TERMS AND CONDITIONS CONTAINED HEREIN. In any event, Buyer's acceptance of the

goods shall manifest Buyer's assent to Seller's terms and conditions. No addition to or modification of these terms will be effective, un less set forth i n writing and agreed to by

Seller.

2. WARRANTIES AND REMEDIES

a. Warranty. Seller warrants to Buyer that it holds and will pass marketable ti tle to the goo ds sold hereunder. Seller warrants to Buyer that the items and components

manufactured by Se ller will be free from defects in material a nd workmanship (subject, ho wever, to tolerances and varia nces permitte d by the trade hereunder) for a

period one (1) year for non-consumable products. Consumable electrodes and se nsors have a conditional warranty based shelf life and process condit ions and is

determined by Se ller.

b. Exclusion and Conditions. Seller’s obligations with respect to the express warranties an d remedies contained herein are conditioned on the fol lowing: (i) Buyer's return

of the non-con forming goods, if authorized by Seller: (ii) Buyer shall not assign its rights under these express warranties and any attempted assignment shall render

such warranties, but not any disclaimers or limitations, void and the g oods sold shall be sold AS IS; and (iii) all products shall be carefully inspecte d for damage by Buyer

upon receipt, be properly cali brated for Buyer's particular use, and be used, repaired, and maintai ned by Buyer in accordance with the instructions set forth in Seller’s

product literat ure. Repair and maintenance by non-qualified personne l, product subjected to misuse or negligence, and/or damage d during shipment will invalidate

the warranty, as w ill the use of non-approved consumables or spare parts. As with any other sophisticated product, it is essential, and a condition of Seller’s warranty,

that all personnel us ing the product be fully acquainted with its use, capabilities and limitations as set forth in t he applicable product literature.

3. DISCLAIMER OF IMPLIED WARRANTIES. Seller gives no warranties except those expressly contained herein. Seller disc laims all other warranties implie d by law usage of the

trade, course of dealing or course of performance inclu ding, but not limited to, th e Implied warranties of MERCHANTABILITY and fitness for a particular purpose.

4. LIMITATIONS OF LIABILITY. The following limitations of Seller's liability are acknowledged by the parties to be fair and reasonable and shall apply to any act or omission

hereunder, and t o any breach of this contract of which these terms and c onditions form a part:

a. Disclaimer of Damage. In no event shall Seller be liable for special, indirect, consequential or incidental damages whether arising under contract, warranty,

tort, strict liabil ity or any other theory of liability. Such damages include but are not limited to loss of profits, loss of use of go ods, damage to property, and

claims of third parties.

b. Suitability. Buyer acknowledges that it alone has deter mined the intended purpose a nd suitability of the goods sold hereunder. It is expressly agreed by the

parties that any technical or other advice given by the Seller with respect to the use of the goods or services is given without charge and at Buyer's risk;

therefore Seller assumes no obligation or liability for the advice given or results obtained.

c. Notice and Time of Claims.

i. Buyer agrees to c heck and inspect all products against shi pping papers and for damage or shortage up on receipt of goods at dest ination.

ii. Every claim for shortage, damage in tra nsit, or other cause visi ble upon ins pection shall be deemed waived by the Buyer, or the Buyer’s customer in

iii. The parties expressly waive the statute of limitations and agree that any legal proceeding for any breach of this contract shall be waived unless filed

5. FORCE MAJEURE. Seller shall not be liable for any delay in delivery, or failure to deliver, due to any cause beyond the Seller’s contr ol including but not lim ited to fires, floods, or

other forces of the elements; strikes, or other labor disputes; accidents to machinery; acts of sabotage; riots; precedence or priorities granted at the request or for the benefit,

directly or ind irectly of the federal or any state go vernment or any subdivision or agency thereof; delay in transportation or lack of transportation facilities; restrictions imposed

by federal, state or other governmental legislation or rules or regulations thereof. If Seller, in its sole discretion, determines that Seller’s performance hereunder w ould result in

a loss to Sel ler’s on this sale as computed under Seller’s normal accounting procedures because of causes beyond Seller's control, then the Seller may terminate this agreement

in whole or in part without liability for any delay in the delivery of, or failure to deliver, the goods sold here under

6. TAXES AND OTHER CHARGES. The Buyer will pay, or reimburse Seller if it pays, any and all taxes or tariffs or any other similar charges imposed upon this contract, the goods

covered hereby or the delivery or use or resale thereof.

7. FREIGHT CHARGES. If the sale hereunder is other than F.O.B. Seller's facility, this acknowledgement is based upon the freight charges now in effect. In the event of an increase

or decrease in applicable freight charges before the goods are shipped, such charge in freight will be for the Buyer's account.

8. PRICES AND DELIVERY. Prices quoted herein are F.O.B. shipping point. Deliveries specified are only our best estimate and are subject to change. This quotation is based upon

freight charges now in effect. Buyer w ill be invoiced at the freight charge prevailing at the date of shipment. Prices are firm for orders meet ing Seller's normal shipping

schedules. If shipments are held or postponed for any reason other than Seller's fault, and a price increase becomes effective during the period of such hold or postponement,

the increase wil l apply to all shipments that are held or postponed thirty (30) days or more from t he effective date of the increase.

9. PAYMENTS. If in the judgment of Seller the financial condition of Buyer at any time prior to shipment d oes not justify the terms of payment specified, Seller may cancel the

order, withhold shipment, a nd/or require full or part ial payment in advance. If payment is not made when due, Sel ler may suspend all future delivery or other performance with

respect to Buyer wit hout liabilit y or penalty and, in addition to all other sums payable hereunder, Bu yer shall pay to Seller (i) the reasonable costs and expenses incurred b y

Seller in connection with all actions taken to enforce collection or to preserve and protect Seller’s rights hereunder, whether by legal proceedin gs or otherwise, including

without limitat ion reasonable attorneys’ fees, court costs a nd other expenses and (ii) intere st on all a mounts unpaid after 30 days char ged at the monthly rate of 1-1/2% or the

highest rate permitted by law, whichever is lower.

10. CANCELLATION OR ALTERATION. Buyer may not alter or cancel any order without Seller’s written consent. For any order altered or ca ncelled with Seller's consent, Buyer must

pay for all expenses and labor incurred up to the time of Seller’s consent, plus a reasonable percentage for profit. Any order delayed or deferred by Buyer will be subject to price

escalation for increased costs of production, and any other expenses caused by the delay. Material on such orders will be stored at Buyer's risk. Seller reserves the right to

invoice Buyer an d require pay ment before s hipment of any delayed or deferred order.

11. TITLE AND RISK OF LOSS. Title and risk of loss shall pass to buyer at Irvine , California, unless otherwise specified in the contract. If delivery is made by common carrier, risk of

loss shall pass upon delivery to the carrier. Claims for loss or damage in transit must be made by Buyer to the carrier. Seller accepts no respons ibility for l oss or damage to

product in transit.

12. PATENT OR TRADEMARK INFRINGEMENT. If the goods sold hereunder are to be prepared for manufacture according to Buyers specification, Buyer shall indemnify Seller

against any claim or liability for patent, trademark, service mark or trade name infringement on account of preparation, manufacture and/or sale.

13. NON-WAIVER. If Government Contract Regulations require the addition, deletion, or mo dification of these terms a nd conditi ons upon prior notification to Seller and Seller's

written acceptance thereof, such changes shall beco me a part o f these terms and conditions. Seller shall not be bound by a ny Governm ent Contract Regulations applicable to

Buyer’s contracts with the U.S. Governme nt unless Buyer has expressly acknowledged, on the face of th is document, the applica bility of suc h Regulations to the transaction

between Buyer and Seller c ontemplated herein. Absent such acknowledgement, Seller is mak ing the assumption in issuing this document that no such Regulations apply.

the case of resale, unless delivered in writing to Seller by Buyer thirty (30) da ys from the ten der of delivery of the goods to Buyer, provided, however,

that claims for shortage must be made with in seven (7) days of receipt.

within one (1) year after the accrual of the cause of action thereof.

10

Page 12

14. JURISDICTION. All such disputes shall be resolve d in a court of compete nt jurisdict ion in Orange County, California. Buyer hereby consents to the jurisdiction of the State and

Federal Courts sitting in Orange County. Not withstanding the above, should either party c ontest the jurisdiction of such courts, the other party may institute its suit in any court

of competent jurisdiction.

15. APPLICABLE LAW. All questions arising hereunder or in connection with the quotations or any order submitted in connection therewith and/or the performance of the parties

hereunder shal l be interpreted and resolved in acc ordance with the laws of the state of Californ ia without regard to its conflict of law provisio ns and excluding the Uni ted

Nations Convention on the International Sa le of Goods.

RETURN GOODS POLICY

All requests for returned goods must be initiated through our Customer Service Department. Please call our

phone number (949) 336-6060 with the specifics of your request. The following conditions must be satisfied for

consideration of applicable credit for the return of products purchased from Electro-Chemical Devices:

1) The item is unused and in the original package.

2) The item was shipped directly from Electro-Chemical Devices.

3) The item has not been damaged in shipment to Electro-Chemical Devices.

4) Items containing date-sensitive parts such as electrodes, must be returned within 1 month of the

invoiced date.

5) Items without date-sensitive parts must be returned within 3 months of the invoiced date.

A Return Merchandize Authorization Number must be obtained from Customer Service and be provided on all

paperwork and packaging. To obtain a Return Merchandize Authorization Number, please provide the reason

for return, the date of purchase, your original purchase order number, and either our order number or our

invoice number. The issuance of a Return Merchandize Authorization Number is a verbal approval for return

only and does not guarantee credit or allowance. Returned goods must be received within 30 days of the

issuance date of the Return Merchandize Authorization Number or it will become null and void.

Necessary physical and mechanical inspection is completed upon receipt of the item. Applicable credit or

equivalent allowance is determined after inspection of the returned item. If all of the above conditions are met,

and the item has been approved to return to our stock, a restocking charge of 25% of the purchase price is

deducted from the applicable credit.

Page 11 Model T80

Page 13

UNPACKING THE INSTRUMENT

WARNING Electrical installation must be in accordance with the National Electrical Code

codes.

Your Electro-Chemical Devices instrument has been carefully packaged to protect it from damage during

shipment and dry storage. Upon receipt please follow the procedure outlined below.

1. Before unpacking, inspect the condition of the shipping container to verify proper handling by the

carrier. If damage is noted, save the shipping container as proof of mishandling for the carrier.

2. Check the contents of the shipping container with the items and quantities shown on the packing list.

Immediately report any discrepancies to ECD.

3. Save the original packing material until you are satisfied with the contents. In the event the product(s)

must be returned to ECD, the packing material will allow you to properly ship it to ECD.

4. Familiarize yourself with the instrument before installation, and follow proper installation and wiring

procedures.

(ANSI/NFPA-70), Canadian Electrical Code and/or any other applicable national or local

5.

Installation and wiring

Failure to follow the proper instructions may cause damage to this instrument and warranty invalidation.

Use only qualified personnel to install, operate and maintain the product.

The Model T80 transmitter should only be used with equipment that meets the relevant IEC, American or

Canadian standards. ECD accepts no responsibility for the misuse of this unit.

Basic Parts List

1. Model T80 Transmitter

2. Mounting Hardware

3. Instruction Manual

INSTRUCTION MANUAL REVISION

Revision Date Remarks

A 07/12 Initial release

B 03/13 Added Sensors and Conductivity Data

C 03/13 Updated Symbols

D 07/13 MODBUS Update

E 07/13 Turbidity, Conductivity, Cal Menu

F 05/14 Two Channels, MODBUS Update,

12

Page 14

GENERAL DESCRIPTION

1.0

The ECD Model T80 transmitter is a single or dual channel, intelligent, multiparameter transmitter designed for the online continuous measurement of pH, ORP,

pION, dissolved oxygen, conductivity, resistivity and turbidity in a general purpose

industrial environment. The Model T80 transmitter digitally communicates with any

ECD S80 digital sensor, automatically configuring the transmitter’s menus and

display screens to the measured parameter.

The Model T80 transmitter can be loop powered, 24 VDC powered or 100-240 VAC line powered. The standard

configuration has a 4-20 mA output and a RS485 serial communication port with MODBUS®RTU output. A HART®

communication version (single channel version only) is also available. Alarm relays are optionally available on

either line powered transmitter.

1.1 FEATURES

• Multi-Parameter, pH, ORP, Specific Ion, Dissolved Oxygen, Conductivity, Resistivity

• Simple, user friendly menu structure

• Noise free digital communication with sensors

• Reads and writes calibration data to sensor

• Dual Channel option has interactive channels, pH compensated readings, interfering ion corrections…

• Isolated 4-20 mA output and MODBUS® RTU standard, optional HART®

1.2 SPECIFICATIONS

1.2.1 INPUT SPECIFICATION

Digital protocol, all ECD S80 sensors

Optional analog to digital converter, 5 inputs [mV+, mV-, solution ground, temp + temp - (100 K-ohm)]

1.2.2 INPUT RANGES

pH -1.00 - 15.00 pH

ORP -1500 - +1500 mV

pION 000.1 - 999.9, Auto Ranging: ppb ↔ ppm ↔ ppT (thousand)

Dissolved Oxygen 000.1 - 999.9, Auto Ranging: ppb ↔ 20.00 ppm, % SAT, mg/L

Conductivity 0.000 - 2.000, Auto Ranging: µS ↔ mS ↔ S

TDS 0.00 - 9999 ppm

Resistivity 0.00 - 50.00 MΩ

Turbidity 0 - 4000 NTU/FNU, 0 – 9999 ppm, mg/l, 0 - 100% % solids

Temperature 100 K-ohm TC, -30°C - 140°C

1.2.3 ACCURACY

pH 0.02 pH

ORP ± 1 mV

pION Specific to electrode type

Dissolved Oxygen 2% of range

Conductivity 2% of range

Page 13 Model T80

Page 15

Resistivity 2% of range

Turbidity 2% of reading

Temperature ± 0.3°C

1.2.4 OUTPUT SIGNALS

4-20 mA output (standard, one per Channel), Fault Condition: 3.5 mA, 22 mA or none

Modbus RTU (standard)

HART® (optional)

1.2.5 CONTACT RELAYS

(Optional) Three (3) SPDT, 1 form C, 250 VAC, 10 Amp resistive maximum, relays, user configurable as Hi/Lo

alarms with expiration timer, Periodic Timers or Fault alarms

1.2.6 DISPLAY

128 x 64 pixels (2.75” x 1.5”) LCD, Black on Grey background on loop powered instruments, Blue on White

background with LED backlight on 100-250 VAC and 24 VDC powered instruments, English or icon based

menus, numeric and graphical displays

1.2.7 ENCLOSURE

Beige Polycarbonate, IP65, weatherproof, ½ DIN, (L x W x D) 5.7” X 5.7” X 3.5” (14.4cm X 14.4cm X 9.0cm)

1.2.8 POWER

Code -0 Loop powered, 24 VDC 600 Ω maximum load (18-36VDC @ 35 mW minimum)

Code -1 24 VDC (18-36 VDC @ 250 mW minimum)

Code -2 100-240 VAC, 50/60 Hz, 4W, protected with 250V, 1A, Slow Blow fuse

1.2.9 ENVIRONMENTAL CONDITIONS

Outdoor use (IP65)

Ambient Temperature -20°C - 70°C (24 VDC Models)

-20°C - 60°C (100-240 VAC Models)

Storage Temperature -30°C - 85°C

Relative Humidity 0 – 80%, up to 31°C

Decreasing linearly to 50% RH a 40°C

Altitude Up to 2000 m (6500 ft)

Mains Supply Voltage Fluctuations up to ±10% of the nominal voltage

Transient over voltages: CAT II

Pollution Degree: 2

1.2.10 SHIPPING

Size 8” x 8” x 5” (20.5 cm x 20.5 cm x 12.7 cm)

Weight 1.6 lbs. (0.75 kg)

14

Page 16

1.3 MODEL CODES

Model T80-

1 (S80) S80 Digital Sensor, pH, ORP, pION, DO, DO90 ppb DO, Conductivity, Resistivity

2 Triton® DO80 Optical DO

3 Internal Preamp, Digital to S10/S17 pH, ORP, pION (+mV, -mV, 100K TC, SG)

4 Internal Preamp, Digital to SGTC Conductivity/Resistivity (CSX2 or 2 electrode contacting )

5 Internal Preamp, Digital to SGTC Dissolved Oxygen, (Steam Sterilizable Products)

6 Triton® TR6 Turbidity

0 No Second Channel

1 (S80) S80 Digital Sensor, pH, ORP, pION, DO, Conductivity, Resistivity

2 (ODO) Triton® DO80 Optical DO

-0 Loop Powered Transmitter

-1 24 VDC Powered Transmitter

-2 100-240 VAC powered Transmitter

0 No Relays

1 (3) form 1C 250 V 3A relays

0 4-20 mA output and MODBUS

1 HART®

2 2 x 4-20 mA & MODBUS

00 No Mounting

01 Universal

02 Panel Mount

03 Handrail Mount

04 Sunshield Pole

05 Sunshield Rail

Model T80-

1 1 -2 1 2

01

1st Channel

2nd Channel

Power Supply

Relay Option

Outputs

Mounting

Hardware

Example above shows part# T80-11-212-01, a two channel T80 transmitter for use with two S80 sensors,

110/220 VAC powered with two 4-20 mA outputs and MODBUS RTU and a universal mounting bracket.

Page 15 Model T80

Page 17

2.0 INSTALLATION

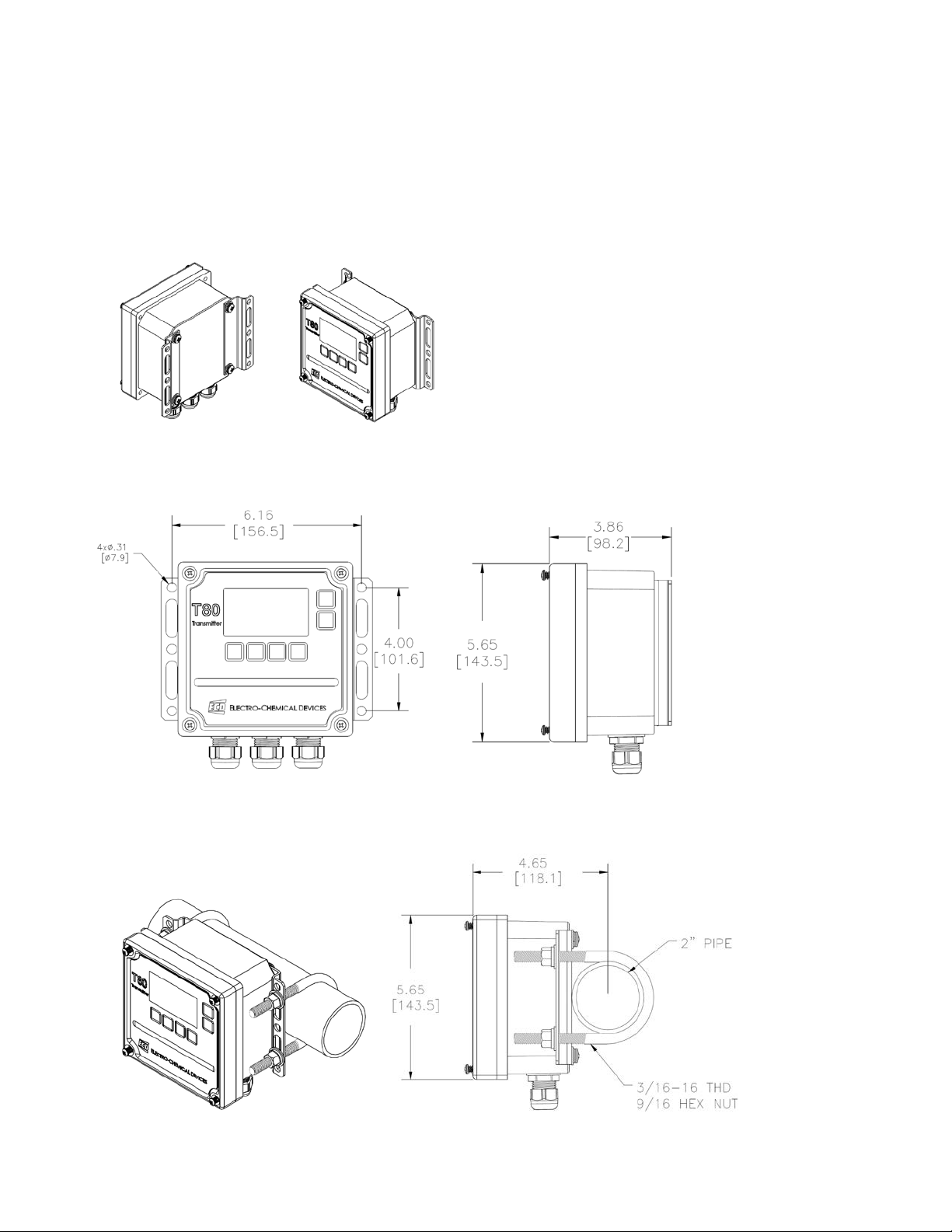

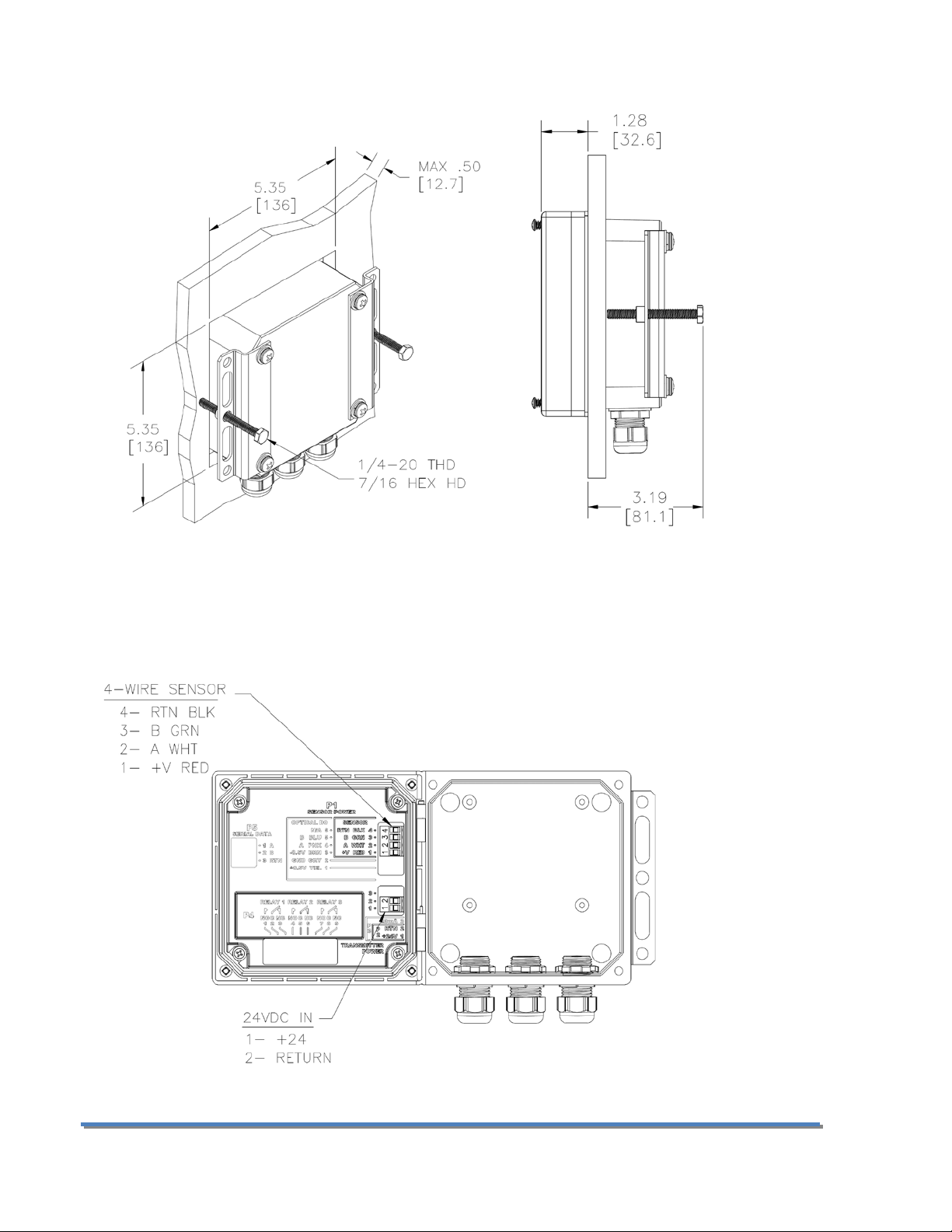

2.1 MOUNTING

Mount the T80 in a location where there is easy access to the analyzer and sensors. Install the system in an area

where vibrations, electromagnetic and radio frequency interference are minimized or absent. Do not mount in

direct sunlight or areas of extreme heat (temperature > 120°F). The IP65 T80 is suitable for outdoor use but it is

best to mount it with a protective cover or sunshield to prevent discoloring over the years.

Universal Mounting Brackets

Rail Mounting

16

Page 18

Panel Mounting

Cut Out: 5.35” x 5.35” (13.6 cm x 13.6cm)

2.2 WIRING

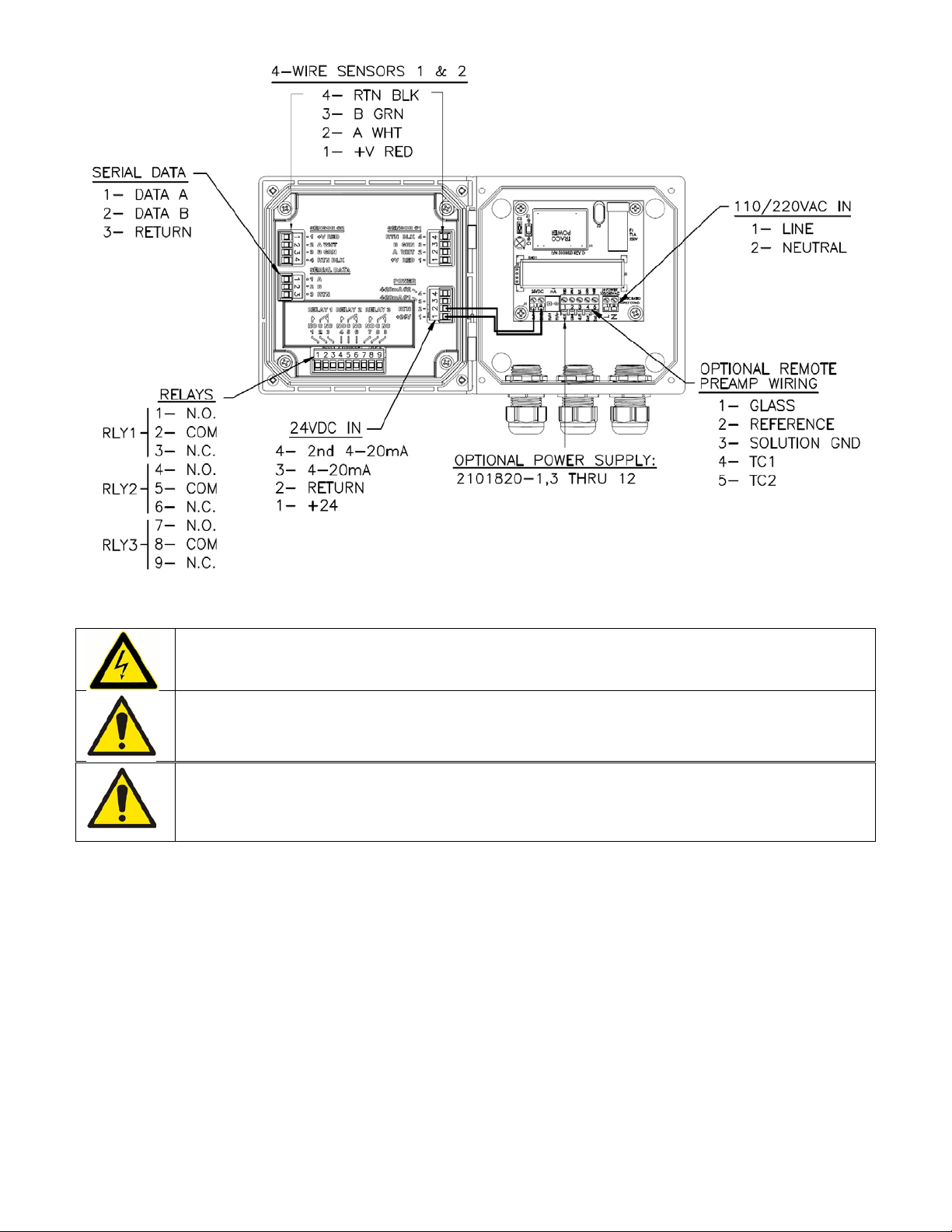

Electrical wiring should only be conducted by qualified personnel. See the T80 wiring diagram in Figure 2.2.X

Figure 2.2.1 Loop Powered Transmitter

Page 17 Model T80

Page 19

Figure 2.2.2 4-Wire Transmitter, 24VDC or /110/22 VAC, MODBUS, Relays/Optional Digital Preamp

codes.

Warning: RISK OF ELECTRICAL SHOCK

Disconnect Power before opening instrument.

WARNING Electrical installation must be in accordance with the National Electrical Code

(ANSI/NFPA-70), Canadian Electrical Code and/or any other applicable national or local

2.2.1 WIRING, POWER

ECD recommends using a thermoplastic, outdoor sunlight resistant jacketed cable, wet location rated and ½”

flexible conduit. The power should be hard wired with a switch or breaker to disconnect the analyzer from the

main power supply. Install the switch or breaker near the analyzer and label it as the Power Switch for the

analyzer.

Loop Powered (2 wire configuration)

Attach the 24VDC signal cable to terminals #1 and #2 as shown in Figure 2.2.1 and on the diagram inside of the

T80 cover. Feed the cable through the gland fitting on the right hand side of the T80. Tighten the cable gland to

18

Page 20

provide a good seal to the cable. The instrument can be powered up at this point with no harm to the analyzer

but it is best to wait until the sensor is installed.

24VDC (4 wire configuration)

Attach the 24VDC power cable to terminals #1 and #2 as shown in Figure 2.2.2 and on the diagram inside of the

T80 cover. Attach the 4-20 mA1 cable to terminals #3 (out) and #2 (return)single channel unit and attach the 420 mA2 cable to terminals #4 (out) and #2 (return) for a two channel instrument. Feed the cables through the

gland fitting on the right hand side of the T80. Tighten the cable gland to provide a good seal to the cable. The

instrument can be powered up at this point with no harm to the analyzer but it is best to wait until the sensor is

installed.

110/220 VAC (4 wire configuration)

Attach power cable as shown in Figure 2.2.2 or as on the diagram inside of the T80 cover. Feed the cable

through the gland fitting on the right hand side of the T80. Tighten the cable gland to provide a good seal to the

cable. The instrument can be powered up at this point with no harm to the analyzer but it is best to wait until

the sensor is installed.

2.2.2 WIRING, SENSOR

Attach the sensor wires as described on the diagram inside the T80 cover. Feed the sensor cable through the

gland fitting on the left hand side of the T80. Do not use the same gland fitting for the AC power or

Alarm/Relays. The green terminal strip connectors are detachable from the circuit boards. Remove the

connector by pulling straight back from the circuit board.

2.2.3 WIRING, 4-20 MA OUTPUTS

Loop Powered Instruments:

Connect the 4-20 mA cable to terminals #1 (+24V) and #2 (-24V), Model T80-XX-0 X-XX.

24 VDC or 110/220 VAC powered instruments:

For instruments powered with 24VDC or the internal power supply, Model T80-XX-1X-XX (24VDC) and T80-XX2X-XX (110/220 VAC), connect the 4-20 mA cable(s) to terminals #3 (out) for channel 1 and #2 (return) and to

terminals #4 (out) for channel 2 and #2 (return).

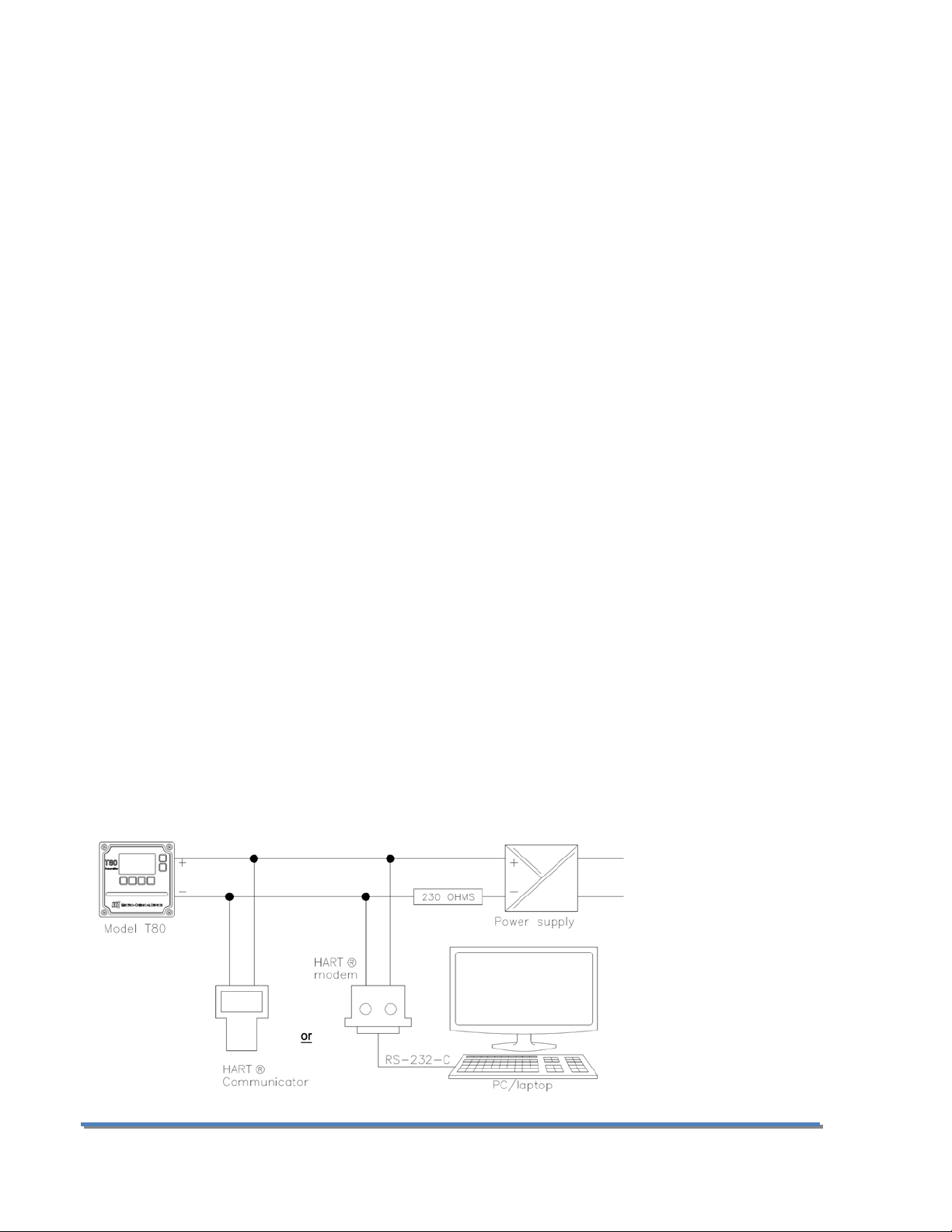

Transmitters with HART® Communication can be wired as shown below. See HART® Communication menu in

Appendix 9.2:

Page 19 Model T80

Page 21

2.2.4 WIRING, CONTACT RELAY OUTPUTS

The standard configuration has three SPDT 230V 5 A relays that can be wired either normally open (NO) or

normally closed (NC). The default configuration is set to use the relays as normally open.

2.2.5 WIRING, SERIAL OUTPUT MODBUS RTU

Attach the sensor wires as shown in Figure 2.2.2 or as described on the diagram inside the T80 cover. Feed the

sensor cable through the gland fitting on the left hand side of the T80. Do not use the same gland fitting for the

AC power or Alarm/Relays. See MODBUS command register in Appendix D

.

20

Page 22

3.0 OPERATION

The ECD Model T80 transmitter is an intelligent, single or dual

channel multi-parameter transmitter designed for the online

continuous measurement of pH, ORP, pION, conductivity, resistivity

or Dissolved Oxygen in a general purpose industrial environment.

The Model T80 transmitter digitally communicates with any ECD S80

digital sensor. The measurement identity is contained in the

sensor’s memory. When an S80 sensor is connected to the

transmitter it automatically configures the transmitter’s menus and

display screens to the measured parameter.

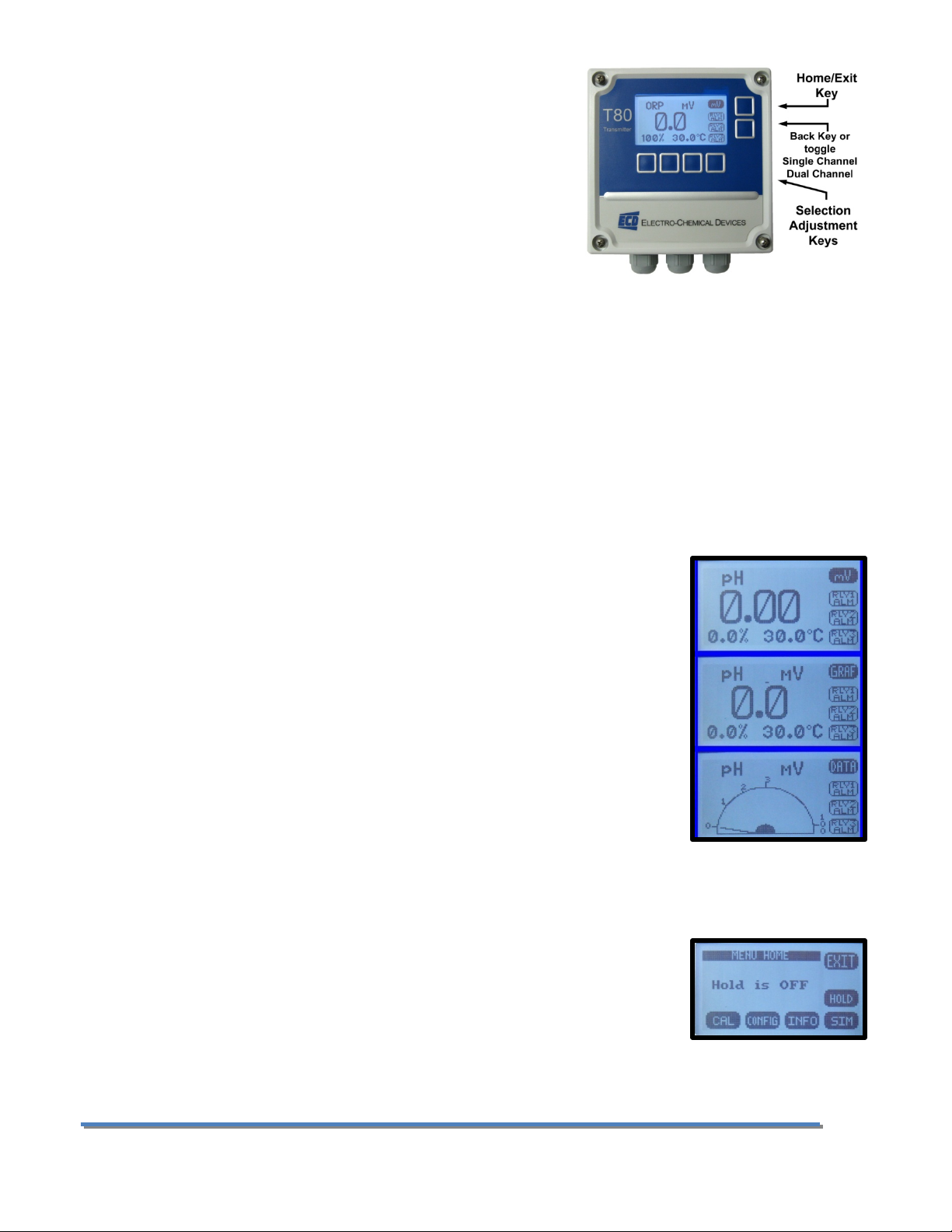

3.1 KEYS

The functions associated with each key are displayed on the screen, above the key for the Selection Adjustment

Keys and to the left of the key for the HOME and BACK keys. Press any Selection Adjustment key twice within

one second to enter the HOME Menu Screen.

3.1.1 HOME/EXIT KEY

The HOME key performs two functions, it selects which Home Screen is displayed and it returns the active

screen to the HOME Menu Screen from anywhere inside the menu structure.

Three Display screens are available:

1. DATA SCREEN: Displays the measurement type, numerical value,

engineering Units, % Output of the 4-20 mA channel and temperature.

2. mV SCREEN: Displays the measurement type, the sensor’s raw millivolt

Value, % Output of the 4-20 mA channel and temperature.

3. GRAF SCREEN: Displays a Graphical representation of the 4-20 mA channel

% Output, the measurement type, the engineering units, and temperature.

Only one of the three graphical display styles is available through the HOME

key, either the Bar, Gauge or Line display. Choose which style will be

displayed in the Graph Menu. (pathway to Graph Menu: CONFIG → XMTR

→ LCD → Graph menu)

Each of the above screens also displays the condition of the optional Alarm Relays,

black if energized and white if de-energized.

The HOME key changes to the EXIT key in the HOME Menu Screen, pressing EXIT prompts the user to “Save

Changes” YES/NO when exiting the HOME Menu. YES applies any changes made in

the menus, NO exits the HOME Menu without applying any changes made in the

menus.

3.1.2 BACK/HOLD KEY

The BACK key changes the screen to the previously displayed screen when inside a

menu, it moves BACK one screen. On a dual channel transmitter it toggles between the PV1, PV2 and Dual

Channel Screens. The HOLD key toggles the output HOLD function ON/OFF in the MENU HOME screen.

Page 21 Model T80

Page 23

3.1.3 SELECTION ADJUSTMENT KEYS

The (4) Selection/Adjustment keys allow navigation and numerical adjustments to be made in the MENUs. To

enter the HOME Menu screen press any of the Selection/Adjustment keys twice within one second. The

various Menu choices and adjustment tools are displayed above the buttons once inside the MENU.

3.1.4 ALPHA NUMERIC ENTRY

The LABEL and PASSWORD (Caps and Numbers only) Menus allow alphanumeric entry. Entry is accomplished by

scrolling through the alphanumeric list with the ▲ (forward) and ▼ (backwards) arrows to the character of

choice and then moving to the NEXT digit. Pressing and holding the ▲ or ▼ keys will initiate two speed auto

scrolling. The character set is sequentially listed below. The first character in the set is an empty space.

! ” # $ % & ‘ ( ) * + , - . / 0 1 2 3 4 5 6 7 8 9 : ; < = > ? @ A B C D E F G H I J K L M N O P Q R S T U V W X Y Z [ ¥ ] ^ _

‘ a b c d e f g h I j k l m n o p q r s t u v w x y z { | } → ←

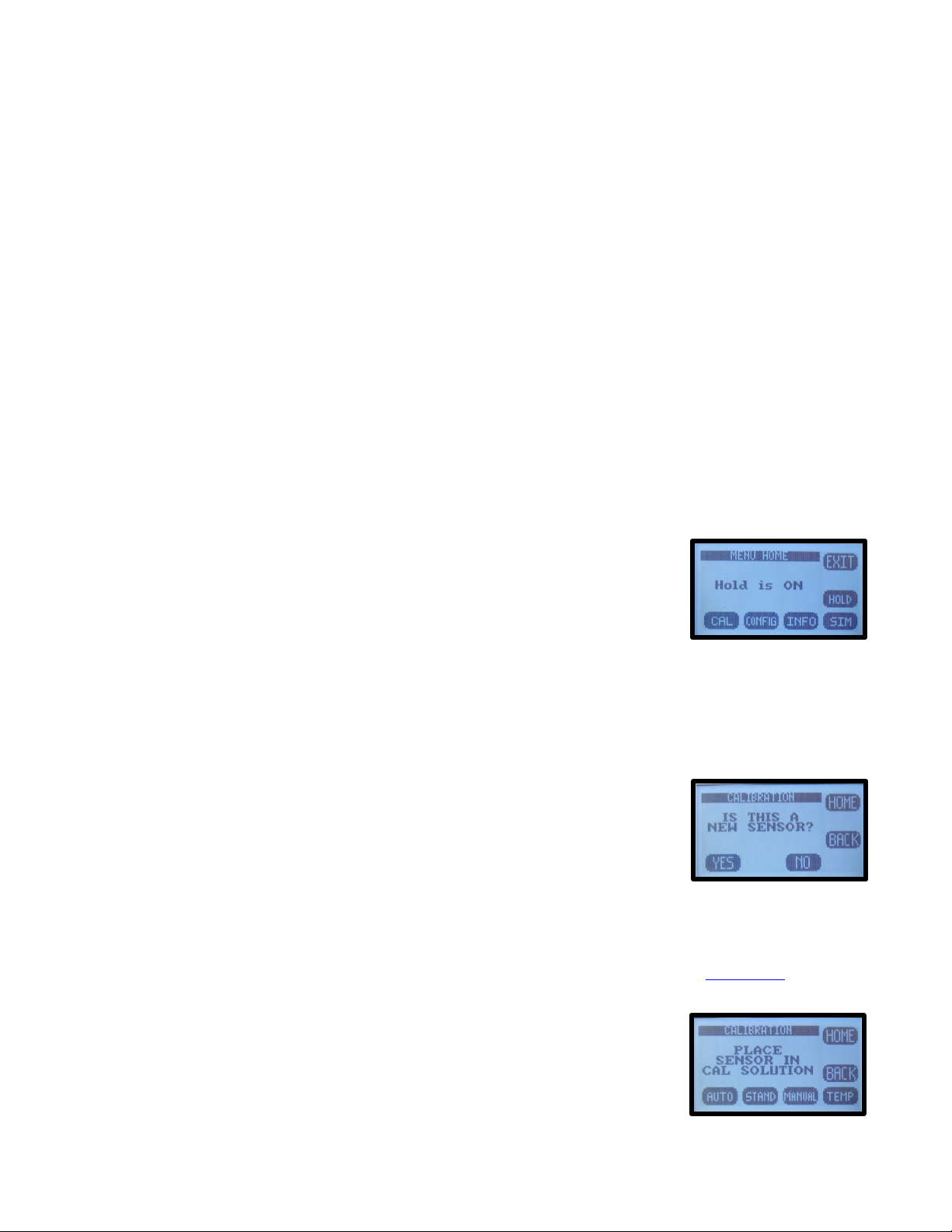

3.2 MENU STRUCTURE

Double tap any Selection/Adjustment key to enter the HOME Menu Screen. Five menu choices will appear, CAL,

CONFIG, INFO, SIM and HOLD. Each of the Menus is detailed below.

3.2.1 HOLD (OUTPUT HOLD)

Pressing the HOLD Key activates the HOLD function, HOLD is ON, displayed.

Freezes the 4-20 mA output at the last value prior to activation

Freezes optional Alarm Relays in the current state

While in the HOLD mode the % Output display toggles between the last

value and HOLD

Pressing HOLD again turns the hold function off, Hold is OFF, displayed. The HOLD function remains ON until it is

turned OFF. (See Time Out in CONFIG>XMTR>OUTPUT>HOLD)

3.2.2 CAL (CALIBRATION MENU)

Four options are available, AUTO, STAND, MANUAL and TEMP. On dual channel instruments choose Sensor 1 or

Sensor 2 when prompted.

The first screen asks, “Is this a New Sensor, YES / NO”. If YES the calibration history

from the previous sensor is cleared from memory and a new register is started, if NO

then the calibration is written to the memory stack, (3) sets of data are stored.

AUTO is a two point calibration. The calibration proceeds in two steps, AutoCal 1 is an offset calibration

and AutoCal 2 is a slope calibration. Auto Cal provides automatic solution recognition of the calibration

solutions used for each measurement in accordance with the following list:

1. pH Calibration Buffers (US Standard), pH 4.01, pH 7.00 and pH 10.00 (see Appendix A

2. ORP Calibration Solutions: Quinhydrone saturated: pH 4.01= +89 mV, pH 7.00= +266 mV

3. pIon Calibration Solutions: 1.00, 10.00, 100.0 ppb, ppm, ppt

(thousand)

4. Dissolved Oxygen: Zero ppm (Sodium sulfite, Na

saturated water, 8.25 ppm

in water), Air

2SO3

)

22

Page 24

Any two solutions can be used for AUTO calibration however if solutions other than those listed above

are used for calibration then the calibration values must be entered manually.

STAND is standardization, a single point calibration. Standardizations are typically used to adjust the

process reading to agree with a laboratory determined “grab sample” reading.

MANUAL is a data entry screen. Manual calibration allows the user to enter a concentration with the

corresponding mV value and a slope for an electrode. Laboratory generated calibration data for an

electrode can be input to a remote analyzer where calibration is difficult or impractical.

TEMP allows the displayed temperature to be trimmed to agree with actual

process temperature.

3.2.3 CONFIG (CONFIGURATION MENU)

Four options are available in the Configure Menu, XMTR, SENSOR, LOAD DEFAULT

and Dampen.

XMTR enters the Transmitter Configuration menu.

o LCD access the Display Configuration Menu

SETUP adjust screen lighting characteristics

• Temp. Choose °C or °F

• CONT adjust Contrast

• BACK LIGHT adjust Backlight Timeout, from always ON to OFF after 10 minutes

GRAPH provides the choice of which Graph style is displayed on the Home screen.

• LINE , Moving average, vertical scale set to 0-100%

of the 4-20 mA output and user defined time scale

• GAUGE, Current reading 0-100% of 4-20 mA range

• BAR, Current reading 0-100% of 4-20 mA range

LABELS

• TAG, Enter up to 2 lines x 16 characters, example,

Name, tag #... Displayed in INFO screen

• TAG ON, Turn TAG ON/OFF, adds TAG to Main

Display Sequence, DATA → mV → GRAF → TAG →

DATA

• POP UP, Turns ON/OFF, the double tap HOME Screen pop up memo

• SENSOR, Enter up to 2 lines x 16 characters

o OUTPUT access the Output Configuration Menu

4-20 mA configure 4-20 mA output (PV or Temp or More)

• RANGE Enter 4 mA value and 20 mA value

• CAL Trim 4.00 mA output and 20.00 mA output

• FAULT Choose fault condition 3.5 mA, 22 mA, None

nd

Optional 2

RELAY

• RLY1,2,3 Choose relay type:

4-20 mA, same as above

o Alarm, enter the Set point ON, Set Point OFF,

Expiration time, Delay ON and Delay OFF

Page 23 Model T80

Page 25

times and the State, energize: changes state from de-energized to

energized on alarm.

o Timed, Enter Period, Duration times and Hold On/Off

o Fault, No input required, relay condition changes from energize to de-

energize.

o Disable, Inactivates relay and removes the relay 1 button from the

HOME Screen display.

HOLD, Freezes outputs at current value and locks relays in their current state.

• Hold Timeout, Removes HOLD after a certain period

of time, default setting: No Timeout, selections

include 15 minutes, ½ hour, 1 hour

o SERIAL MODBUS configure serial output,

ADDRESS, enter address: 001 to 247

BAUD, Choose baud rate, default 9600

FORMAT, set serial data format, default value: 8N1, 8 bit, no

parity bit, 1 stop bit

o SERIAL HART configure output,

ADDRESS, enter address: 01-63

BAUD, default 1200, no adjustment available

FORMAT, default value: 8O1, 8 bit, Odd parity bit, 1 stop bit,

no adjustment available

o PASSWD Enter 4 character password to protect access to MENU Level, CAL Menu, CONFIG

Menu and SIM Menu (simulate). Each level can be turned ON or OFF and can have a unique

password.

MENU ON/OFF _ _ _ _ Locks Main Menu

CAL ON/OFF _ _ _ _ Locks CAL and CONFIG

CONFIG ON/OFF _ _ _ _ Locks CONFIG

SIM ON/OFF _ _ _ _ Locks SIM and CONFIG

SENSOR enters the sensor configuration menu.

o Choose SENSOR 1 or 2

TYPE, Allows T80 transmitter to configure the S80 sensor.

For use only when switching the measurement electrode

type in an S80 sensor, i.e. for a pH electrode to a pION

electrode. Select Sensor Type: pH, ORP, DO

++

Ca

, Cl-, Conductivity, Resistivity, Cu++, CN-, F-, NO

+

Na

, S--

T COMP, Enter % temperature compensation per degree: pH, pION 0.33%, ORP 0.00%,

DO

4%, Conductivity 2%, Resistivity -5.4% (see Table Appendix D)

2

ISO PT, Enter Iso Potential value in mV. The Iso Potential is

the point where changes in the temperature do not cause

changes to the signal.

o COMP Dual Channel Only, Sets compensation type: Dissociation

(pKa), NH

+

, Free Chlorine, HF, S-2, Interference, X ppm Sensor 1 = 1

4

ppm Sensor 2, Percentage % change per pH.

, NH3, NH

2

-

3

+

, Br-,

4

, K+, Ag+,

24

Page 26

o Qty of SENSORS, Choose 1 or 2

Fault

Definition

Recommendation

AN ERROR WAS FOUND

THE MICROCONTROLLER

POWER IS OUT OF

TOLERANCE

CHECK WIRING TO

THE TRANSMITTER

ONBOARD 12V IS

OUT OF TOLERANCE

RETURN TO FACTORY

FOR SERVICE

ONBOARD 3.3V IS

OUT OF TOLERANCE

RETURN TO FACTORY

FOR SERVICE

COMMUNICATION WITH

THE SENSOR WAS LOST

CHECK WIRING TO

THE SENSOR

NO SENSOR WAS FOUND

AT START-UP

CHECK WIRING TO

THE SENSOR

1) CLEAN SENSING TIP

4) RE-CALIBRATE

1) CHECK SENSOR OP

B) TANKS

1) CHECK SENSOR OP

B) TANKS

1) CHECK SENSOR OP

B) TANKS

Load Default resets all Menus to factory default configuration.

3.2.4 INFO (INFORMATION MENU)

The Information Menu provides two choices,

Transmitter Screen, details the Name, Power type, Serial #, Firmware

version and the output configuration(s).

Sensor Screen, details the Name, Part #, Serial # and three sets of

Calibration data.

3.2.5 SIM (SIMULATION MENU)

The Simulation menu allows the Input or Output signals to be simulated.

SYSTEM allows the Input to be simulated. Two choices are available, FIXED is

a fixed value, RAMP varies the signal across the 4-20 mA range, from the

lowest value to the highest value and back, activating and deactivating relays

if present. The RAMP has two adjustments the Ramp period, 30 seconds to 2

minutes and Duration; 1 cycle, 5, 10, 20, 30 minutes.

RELAYS allows individual relays, #1, #2, and #3 to be activated and deactivated

4-20 mA allows the output to be simulated from 4.00 mA to 20.00 mA.

3.2.6 FAULT SCREENS

Memory Error

Input Voltage OOT

+12V OOT

+3.3V OOT

Loss of Comm

No Sensor

Cal Failed

Relay 1 Expired

Relay 2 Expired

WITH THE MEMORY OF

SENSOR CALIBRATION

FAILED

RELAY 1 TIME

ON EXPIRED

RELAY 2 TIME

ON EXPIRED

RETURN TO FACTORY

FOR SERVICE

2) VERIFY SOLUTIONS

3) DO NOT LEAVE

UNATTENDED

2) CHECK AUX EQUIP

A) PUMPS

2) CHECK AUX EQUIP

A) PUMPS

Relay 3 Expired

Page 25 Model T80

RELAY 3 TIME

ON EXPIRED

2) CHECK AUX EQUIP

A) PUMPS

Page 27

3.2.7 SENTINEL® SCREENS

The SENTINEL feature allows the Model T80 transmitter to provide Pre-pHault

diagnostic information about the accuracy of a pH, ORP or pIon measurement. The

SENTINEL displays a filled triangular gauge that decreases proportionally to the

degradation of the reference electrode. A filled gauge indicates a properly

functioning measurement while the emptying gauge indicates the remaining life of

the electrode. This Pre-pHault diagnostic alerts the user to potential problems and

provides a visual indicator of the sensor’s remaining life before the measurement

actually fails.

The Model T80 transmitter only displays the SENTINEL functions when a Model S80

SENTINEL sensor is connected. The Model S80 SENTINEL sensor uses Diagnostic

electrodes designated by Part#’s 20053XX, these electrodes use a triaxial connector with a, PV connection (pH,

ORP, Ion), Reference connection and Diagnostic connection.

On a dual channel instrument an asterisk *, will be displayed in the sensor name block, SENSOR 2 *. The

SENTINEL function will only be visible in the Single Screen mode, not in the Dual Screen mode. Toggle the BACK

Key from Dual → Sensor 1 → Sensor 2 to see the SENTINEL function.

Configure SENTINEL Function

The SENTINEL function is located in the Configure Sensor menu:

CONFIG → SENSOR → SENSOR 1 or 2 →MORE → SNTL

There are three values displayed:

= SENTINEL Voltage offset, The diagnostic voltage of a new electrode

V

o

V

= SENTINEL expiration Voltage, Vo + Range

e

RANGE = The shift in the diagnostic voltage required to trigger diagnostic fault.

The default values of V

= 0.0 mV and the Range = 60 mV are good for most

o

situations. The starting diagnostic voltage is typically near 0 mV on a new electrode

and if the readings have drifted 60 mV apart (a full pH unit) then electrode service is

required.

26

Page 28

3.3 START UP GUIDE

Install and wire the T80 Transmitter as described in Sections 2.1 and 2.2 above.

Connect the sensor to the transmitter as described in Section 2.2 above.

Supply power to the Model T80 transmitter.

Verify the proper measurement type is displayed, pH, ORP or Ion. The sensor automatically uploads the

measured parameter, the calibration data and the range of measurement to the transmitter. The default

configuration of the 4-20 mA output is the range of the sensor, 0-14 pH for pH sensors, -1500 - +1500 for ORP or

0-XXXX ppm for a pIon Sensor. To change the 4-20 mA range, follow the instructions in Section 3.3.1 below.

3.3.1 CONFIGURE 4-20 MA OUTPUT RANGE

Double press any key except the HOME key to enter the HOME Menu. Follow the path below to set the

4-20 mA range.

HOME Menu → Press CONFIG → XMTR → OUTPUT → 4-20 (1)(2) → PV or

TEMP

Press CHANGE to enter New Values.

Choose 4 mA value, press OK

Enter value using ▲ or ▼and NEXT to move to the next digit, press OK→Back

Choose 20 mA value, press OK,

Enter value using ▲ or ▼and NEXT to move to the next digit, press OK→Back

Press BACK to return to the CONFIGURE 4-20 mA screen or HOME to return to

the HOME Menu screen.

3.3.2 CONFIGURE 4-20 MA FAULT CONDITION AND CAL

In the CONFIGURE 4-20 mA screen, Press MORE → FAULT or

Choose Low Fault 3.5 mA or Hi Fault 22 mA or NONE, (default setting NONE),

Press OK

Press BACK → CAL, connect DVM to 4-20 mA line, Press 4.00 mA then adjust value to the DVM reading,

Press 20.00 mA and adjust value to the DVM reading. The 4-20 mA output is calibrated.

3.3.3 CONFIGURE ALARM RELAYS (RELAYS OPTIONAL)

HOME Menu → Press CONFIG → XMTR → OUTPUT → RELAYS→RLY1

Choose the ALARM, TIMER, FAULT or DISABLE mode for Relay 1

ALARM Displays:

o SET POINT ON: The Process Variable Value that activates the relay.

o EXPIRATION: Enter a time that should not be exceeded before the PV should have changed

enough to activate the OFF set point. At the Expiration time the relay is deactivated and a Fault

condition is initiated. Fault: Relay 1 Time expired: Cause: Loss of reagent, failed sensor ….

o Delay ON: The amount of time the PV must remain above/below the set point before the relay

activates.

o SET POINT OFF: The Value of the process variable that deactivates

the relay.

SET POINT OFF > Set Point → Low Set Point

SET POINT OFF < Set Point → Hi Set Point

Page 27 Model T80

Page 29

o Delay OFF: The amount of time the PV must remain above/below the hysteresis point before

the relay deactivates.

o STATE: Energize (relay is energized on activation)/De-energize (relay is de-energized on

activation)

TIMER activates the relay periodically for a specific duration, user configured period and duration

FAULT sets the relay condition to a de-energize state and NC relay closes in response to a Fault

condition.

DISABLE turns off the relay and removes it’s icon from the HOME screen

Setting up an Alarm Relay

Choose ALARM

Press CHANGE to enter new values

Choose ON Set Point, Press OK

Enter value using ▲ or ▼and NEXT to move to the next digit, press OK, press BACK (Min –Max values

indicate the range of acceptable values)

Choose Expiration, Press OK,

Choose time from drop down menu using ▲ or ▼, press OK, press BACK

Choose OFF Set Point, Press OK

Enter value using ▲ or ▼and NEXT to move to the next digit, press OK, press BACK

Choose Delay ON, Press OK

Enter value using ▲ or ▼and NEXT to move to the next digit, press OK, press BACK

Choose Delay OFF, Press OK

Enter value using ▲ or ▼and NEXT to move to the next digit, press OK, and press BACK when done to

exit Relay 1.

Repeat for Relay 2 and Relay 3.

3.3.4 EXIT MENUS AND RETURN TO MAIN DISPLAY

Press HOME Key to return to the Home Menu Screen

Press Hold to turn OFF Hold

Press EXIT Key to exit the menu

“Save Changes?” press YES

Choose Display Mode, DATA, mV or GRAF by pressing selection Key. The

selection key displays which screen will be displayed next.

o The type of graphical display used, Line, Bar or Gauge is selected in

CONFIG → XMTR → LCD → GRAPH → LINE, GAUGE, BAR

3.3.5 SENSOR START UP

All sensors are supplied with protective caps over the sensing end. Remove the

cap(s) from the sensor before installing in the process. All sensors were calibrated

at the factory before shipment, no calibration should be necessary before use.

Allow the sensor to equilibrate to the process solution conditions for ½ hour before

verifying the reading against a grab sample. If calibration is required follow the

instruction in Section 4.0 below.

28

Page 30

3.4 USER SELECTABLE OPTIONS

Full Screen Period

15 minutes

1 hour

12 hours

1 day

2 days

Sample Rate ( 1 point every)

10 seconds

40 seconds

8 minutes

15 minutes

30 minutes

3.4.1 SCREEN LIGHTING

LED back lighting is available on AC and DC powered instruments only, this feature is

inactive on loop powered instruments.

Contrast can be adjusted for optimal viewing. The Backlight can be adjusted to

timeout after a set period of time or remain on.

Location: CONFIG → XMTR → LCD → Set Up → CONT, BACK LIGHT

3.4.3 GRAPHICAL DISPLAY

There are three graphical display choices:

LINE, The Line graph is a moving average of the process variable with the 4-20 mA range as the

maximum/minimum values and a choice of time scales.

The Time scale is the amount of time displayed across the full screen. Choices include:

GAUGE, Live reading displaying 0-100% of 4-20 mA range. The Alarm Relay number(s), #1, #2 and#3

mark the respective set points on graph.

BAR, Live reading displaying 0-100% of 4-20 mA range. The Alarm Relay number(s), #1, #2 and#3 mark

the respective set points on graph.

Pressing OK after selecting a Graphical Display will exit the menu structure and return to the Main Display.

Location: CONFIG → XMTR → LCD → GRAPH

3.4.4 TAG TRANSMITTER NAME

Two 16 character lines are available for naming the transmitter, Upper and Lower case characters, Numbers and

Punctuation are available. The information entered will be displayed in the INFO

screen and optionally in the Main display sequence if activated in the TAG ON

menu. The character set is listed below sequentially; the first character in the set is

an empty space.

! ” # $ % & ‘ ( ) * + , - . / 0 1 2 3 4 5 6 7 8 9 : ; < = > ? @ A B C D E F G H I J K L M N O P Q R S T U V W X Y Z [ ¥ ] ^ _

‘ a b c d e f g h I j k l m n o p q r s t u v w x y z { | } → ←

Entry is accomplished by scrolling through the alphanumeric list with the ▲

(forward →) and ▼ (backwards ←) arrows to the character of choice and then

pressing NEXT to advance the cursor to the next digit. Pressing and holding the ▲

or ▼ keys will initiate two speed auto scrolling. Press BACK to exit the screen.

Location: CONFIG → XMTR → LCD → LABELS → TAG

Page 29 Model T80

Page 31

3.4.5 SENSOR NAME

Two 16 character lines are available for naming the Sensor, Upper and Lower case characters, Numbers and

Punctuation are available. The information entered will be displayed in the INFO screen. Entry is accomplished

by scrolling through the alphanumeric list with the ▲ (forward →) and ▼ (backwards ←) arrows to the

character of choice and then pressing NEXT to advance the cursor to the next digit. Pressing and holding the ▲

or ▼ keys will initiate two speed auto scrolling. Press BACK to exit the screen.

Location: CONFIG → XMTR → LCD → LABELS → SENSOR

3.4.6 PASSWORD PROTECTION

PASSWD Enter 4 character password to protect access to MENU Level, CAL Menu, CONFIG Menu and SIM Menu

(simulate). Each level can be turned ON or OFF and can have a unique password. Upper Case Characters and

Numbers are available for use.

Place the cursor in front of the level to be changed and Press OK. Move the cursor to

ON and press OK to change the password status from OFF to ON.

Entry is accomplished by scrolling through the alphanumeric list with the ▲ (forward

→) and ▼ (backwards ←) arrows to the character of choice and then pressing NEXT

to advance the cursor to the next digit. Pressing and holding the ▲ or ▼ keys will

initiate two speed auto scrolling.

o MENU ON/OFF _ _ _ _ Locks Main Menu

o CAL ON/OFF _ _ _ _ Locks CAL and

CONFIG

o CONFIG ON/OFF _ _ _ _ Locks CONFIG

o SIM ON/OFF _ _ _ _ Locks SIM and CONFIG

In the case of a Lost or Forgotten password enter MSTR to access the screen.

Location: CONFIG → XMTR → PSSWD

30

Page 32

4.0 CALIBRATION

The Model T80 transmitter provides three methods of calibration:

4.0.1 AUTO CALIBRATION DESCRIPTION

Auto calibration is the primary calibration method for all measurements. AUTO calibration automatically

recognizes the calibration solution the sensor is in and proposes the actual temperature compensated value for

acceptance. AUTO calibration can be a single point or two point calibration. A single point calibration sets the

zero point or offset value of the sensor. The second calibration sets the slope or span of the sensor.

When the AUTO key is pressed the transmitter displays the PV (Process Variable)

and the associated mV signal from the sensor. When the reading has stabilized a

calibration value is AUTOmatically proposed, i.e. 7.00 pH, 10 ppm Fluoride ion, 0.00

mg/L Dissolved Oxygen. The user is prompted to accept the proposed calibration

value or enter and accept another value. Once Cal 1 is accepted the user is ask to

continue to Cal 2, yes/no. If yes, then a second calibration value is proposed when the sensor has stabilized in

the second calibration solution. Accept the value and the calibration is complete.

At the end of each calibration the Offset and Slope are displayed in the respective units, pH, mV, ppm, mg/l.

4.0.2 STANDARDIZE CALIBRATION DESCRIPTION