Page 1

E

LECTRO-CHEMICAL DEVICES

Instruction Manual

Hydra Ammonium Analyzer

Rev: E - 07/11

Page 2

Page ii HYDRA NH

+

-N

4

Page 3

PREFACE

Purchasing products from Electro-Chemical Devices, Inc. provides you with the finest liquid analytical

instrumentation available. If this is your first purchase from ECD, please read this manual before

installing and commissioning your new equipment.

If there are any questions concerning this equipment, please contact your local ECD representative, or

the factory directly at:

Electro-Chemical Devices, Inc.

1681 Kettering St.

Irvine, CA 92614 USA

Telephone: +1-949-336-6060

FAX: +1-949-336-6064

Website: www.ecdi.com

Email: sales@ecdi.com

© 2010 Electro-Chemical Devices, Inc. All rights reserved. No part of this manual may be used or reproduced in any form or by any means, or

stored in a database or retrieval system without prior written permission from Electro-Chemical Devices, Inc. Making copies of any part of this

manual for any purpose other than personal use is a violation of United States copyright laws. Document printed in the United States of

America.

HYDRA NH

+

-N Page iii

4

Page 4

TABLE OF CONTENTS

PREFACE ....................................................................................................................................................... iii

TABLE OF CONTENTS .................................................................................................................................... iv

WARRANTY ................................................................................................................................................. vii

IMPORTANT SERVICE INFORMATION ......................................................................................................... vii

1.0 GENERAL DESCRIPTION ........................................................................................................................... 1

1.0.0 Description ................................................................................................................................... 1

1.0.1 Potassium Ion Compensation ...................................................................................................... 1

1.0.2 pH Compensation......................................................................................................................... 1

1.0.3 Temperature Compensation ........................................................................................................ 1

1.0.4 Cleaning and Maintenance .......................................................................................................... 1

1.1 FEATURES ............................................................................................................................................ 2

1.1.1 Features and Benefits .................................................................................................................. 2

1.2 Specifications ...................................................................................................................................... 2

1.2.1 Hydra Sensor ................................................................................................................................ 2

1.2.2 C22 Analyzer ................................................................................................................................ 3

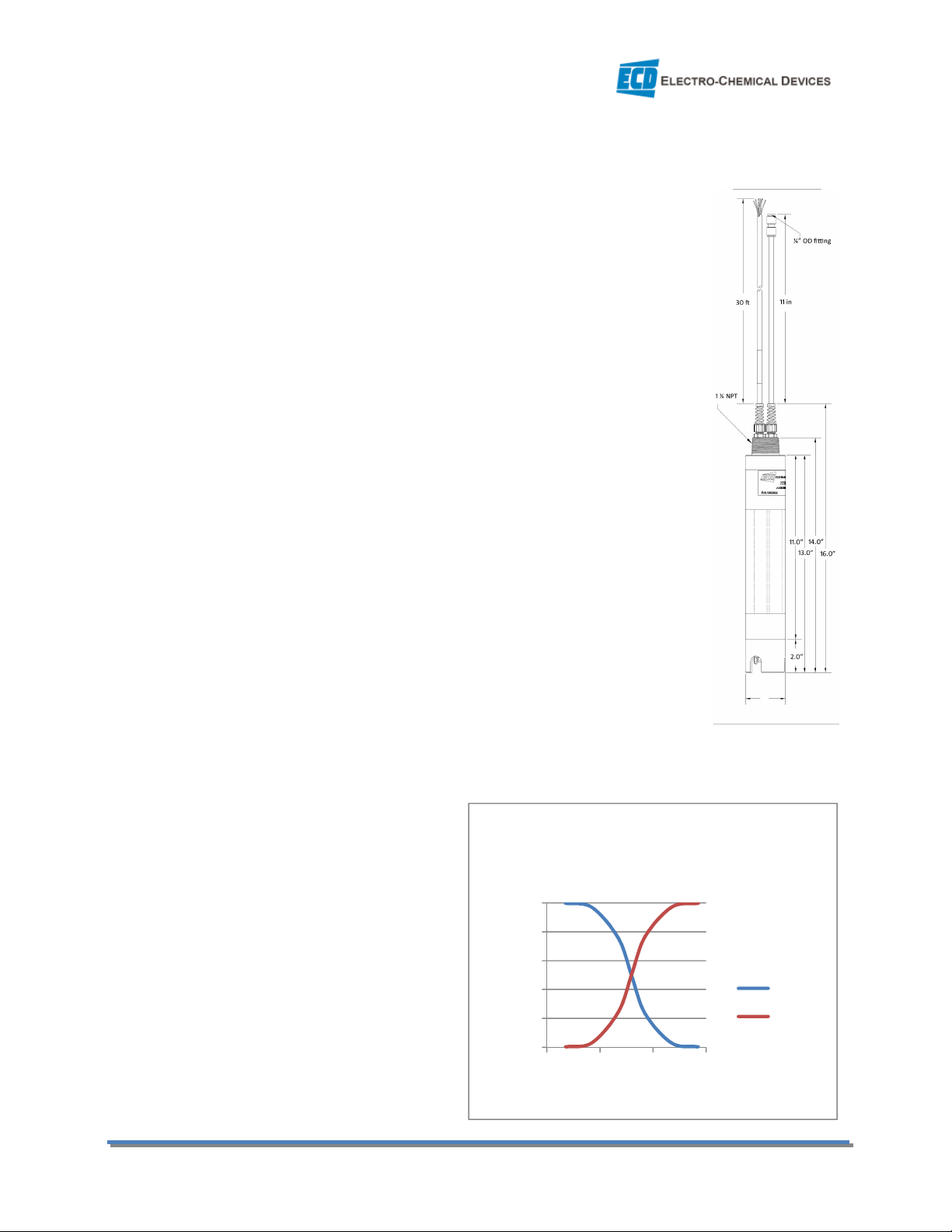

1.3 Hydra Dimensional Drawing ............................................................................................................... 4

1.3.1 Parts List: ...................................................................................................................................... 4

2.0 INSTALLATION ......................................................................................................................................... 5

2.1 UNPACKING ......................................................................................................................................... 5

2.2 ASSEMBLY ........................................................................................................................................... 5

2.2.1 Spray Cleaner ............................................................................................................................... 5

2.2.2 Immersion /Support Tube ............................................................................................................ 5

2.3 MOUNTING ......................................................................................................................................... 6

2.3.1 C-22 Analyzer ............................................................................................................................... 6

2.3.2 Hydra Sensor ................................................................................................................................ 6

2.4 WIRING ................................................................................................................................................ 6

2.4.1 Wiring, power .............................................................................................................................. 6

2.4.2 Wiring, Sensor .............................................................................................................................. 6

2.4.3 Wiring, 4-20 mA Outputs ............................................................................................................. 6

2.4.4 Wiring, Contact Relay Outputs ..................................................................................................... 7

Page iv HYDRA NH

+

-N

4

Page 5

3.0 OPERATION ............................................................................................................................................. 9

3.1 KEYS ..................................................................................................................................................... 9

3.2 MENUS .............................................................................................................................................. 10

3.2.1 Ammonium Ion Channel 1 Menu Structure ............................................................................... 10

3.2.2 Potassium Ion Channel 2 Menu Structure ................................................................................. 10

3.2.3 pH Channel 3 Menu Structure ................................................................................................... 10

3.2.4 Graphical Display Screen ............................................................................................................ 10

3.2.5 Buffer Menu ............................................................................................................................... 11

3.2.6 Set-Up Menu .............................................................................................................................. 11

3.2.7 Status Menu ............................................................................................................................... 14

3.2.8 Configuration and Trim Menu.................................................................................................... 14

3.3 OUTPUTS ........................................................................................................................................... 14

3.3.1 Manual Mode (4-20 mA Hold Function) .................................................................................... 15

3.4 CONTACTS-ALARM RELAYS ............................................................................................................... 15

3.4.1 Standard Configuration .............................................................................................................. 15

3.4.2 One AC10 with Two HYDRAs ...................................................................................................... 16

3.5 ION SELECTIVE FEATURES ................................................................................................................. 17

3.5.1 The Isopotential point ................................................................................................................ 17

3.5.2 Potassium Ion Interference Correction ...................................................................................... 17

3.5.3 pH Correction ............................................................................................................................. 17

4.0 START UP ............................................................................................................................................... 18

4.1 SET-UP AND CONFIGURATION .......................................................................................................... 18

4.1.1 Set Up Menus, Standard ............................................................................................................ 18

4.1.2 Set Up Menu, MASTER/SLAVE ................................................................................................... 19

4.1.3 Configure and Trim Menu, Standard ......................................................................................... 20

4.1.4 Configure and Trim Menu, MASTER/SLAVE ............................................................................... 21

4.2 CALIBRATION ..................................................................................................................................... 23

4.2.1 Recommended Materials ........................................................................................................... 23

4.2.2 Temperature Calibration ............................................................................................................ 24

4.2.3 Single point Calibration .............................................................................................................. 24

4.2.4 Two point Calibration ................................................................................................................. 25

4.2.5 Potassium Ion Compensation .................................................................................................... 25

HYDRA NH

+

-N Page v

4

Page 6

5.0 MAINTENANCE ...................................................................................................................................... 26

5.1 MAINTENANCE SCHEDULE ................................................................................................................ 26

5.2 CLEANING THE SENSOR ..................................................................................................................... 26

5.3 REPLACING THE ELECTRODES ........................................................................................................... 26

6.0 TROUBLESHOOTING .............................................................................................................................. 27

7.0 ENGINEERING DOCUMENTATION ......................................................................................................... 28

7.1 SPECIFICATIONS ................................................................................................................................ 28

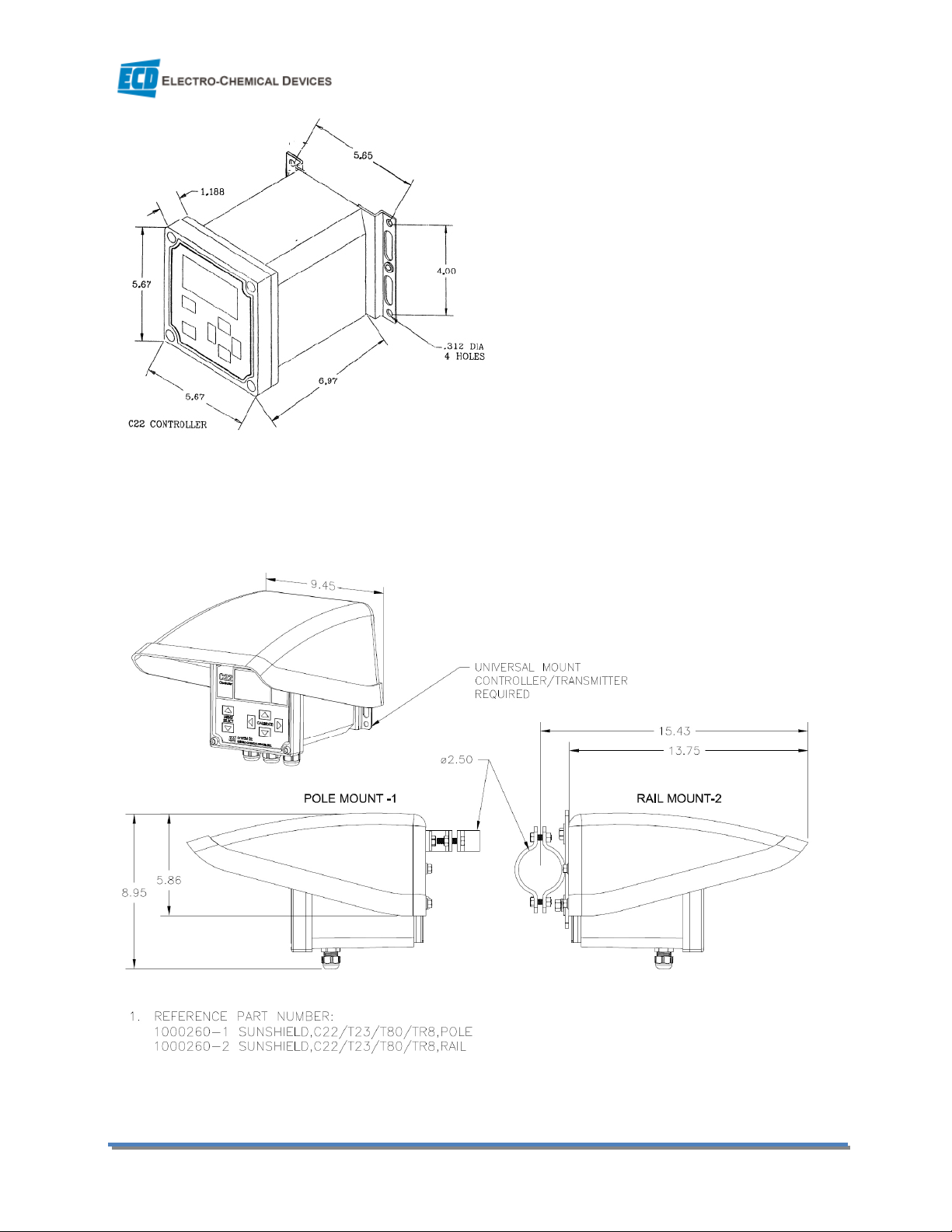

7.2 OUTLINE & DIMENSIONAL DRAWING ............................................................................................... 29

7.2.1 Hydra Sensor Dimensions .......................................................................................................... 29

7.2.2 C-22 Dimensions ........................................................................................................................ 29

7.2.3 Sun Shield Mounting .................................................................................................................. 30

7.3 WIRING DIAGRAM ............................................................................................................................. 31

7.3.1 Sensor Color Coded Diagram ..................................................................................................... 31

7.3.2 Instrument – Terminal Layout/Connections .............................................................................. 31

8.0 ORDERING INFORMATION .................................................................................................................... 33

8.1 PART NUMBERS/MODEL NUMBERS ................................................................................................. 33

8.2 ACCESSORIES ..................................................................................................................................... 33

8.3 SPARE PARTS ..................................................................................................................................... 33

Page vi HYDRA NH

+

-N

4

Page 7

WARRANTY

Electro-Chemical Devices, Inc. (ECD) warrants all products it manufactures to be free from defect in materials and factory

workmanship, and agrees to repair or replace any product that fails to perform, as specified, within one (1) year after date of

shipment. This warranty shall not apply to any product that has been:

1. Subjected to misuse, negligence or accident;

2. Connected, installed, adjusted or otherwise used not in accordance with the instructions furnished by ECD;

3. Repaired, modified or altered by persons not authorized by ECD, resulting in injury to the performance, stability or

reliability of the product.

This warranty is in lieu of any other warranty, expressed or implied. ECD reserves the right to make changes in the design or

construction of its products at any time, without prior notification, and without incurring any obligation to make any changes in

previously delivered products.

Seller’s sole liabilities and the buyer’s sole remedies under this agreement shall be limited to a refund in the purchase price, or

at ECD’s discretion, to the repair or replacement of any product that proves, upon ECD’s examination, to be defective, when

returned to the factory, transportation prepaid by the buyer, within one (1) year of the product’s original shipment date. Seller

shall not be liable for damages consequential or incidental to defects in any product, for failure of delivery in whole or in part,

for injuries resulting from its use, or for any other cause.

This warranty and the writing attached constitute the full understanding of seller and the buyer, and no terms, conditions,

understanding, or agreement purporting to modify or vary the terms hereof shall be binding unless hereafter made in writing

and signed by an authorized official of Electro-Chemical Devices, Inc.

This warranty does not cover pH, ORP or Specific Ion measurement, reference or combination electrodes or electrode

cartridges that have been commissioned in service.

IMPORTANT SERVICE INFORMATION

Use only factory authorized components for repair. Tampering or unauthorized substitution of components may

adversely affect the operation of this product and may void the warranty.

If service or repair is required, please obtain the serial number(s) or sales order number of the product(s) in

question and contact ECD’s Service Department at:

+1-800-729-1333 (USA/Canada) or +1-949-336-6060

or email Service@ecdi.com

A Return Material Authorization (RMA) number must be obtained from the service department before returning

any material to ECD. All material returned to ECD shall be shipped prepaid to the factory.

HYDRA NH

+

-N Page vii

4

Page 8

UNPACKING THE INSTRUMENT

Your Electro-Chemical Devices instrument has been carefully packaged to protect it from damage during

shipment and dry storage. Upon receipt please follow the procedure outlined below.

1. Before unpacking, inspect the condition of the shipping container to verify proper handling by

the carrier. If damage is noted, save the shipping container as proof of mishandling for the

carrier.

2. Check the contents of the shipping container with the items and quantities shown on the

packing list. Immediately report any discrepancies to ECD.

3. Save the original packing material until you are satisfied with the contents. In the event the

product(s) must be returned to ECD, the packing material will allow you to properly ship it to

ECD.

4. Familiarize yourself with the instrument before installation, and follow proper installation and

wiring procedures.

Page viii HYDRA NH

+

-N

4

Page 9

1.0 GENERAL DESCRIPTION

1.0.0 Description

The HYDRA Ammonium Analyzer measures the concentration of dissolved

ammonium as nitrogen (NH

determine the NH

+

-N concentration, an Ammonium Ion Electrode, a Potassium Ion

4

Electrode and a pH electrode. It is designed for use in all kinds of water. Typical

applications include monitoring environmental waters, lakes, streams and wells as

well as wastewater treatment in aeration basins and effluent.

1.0.1 Potassium Ion Compensation

The Ammonium Ion Electrode provides the primary measurement. Any potassium

ion in the sample, due to its similar size and charge to the ammonium ion, causes a

positive interference in the measurement. A Potassium Ion Electrode measures the

amount of potassium ion present in the sample and HYDRA C22 Analyzer subtracts

the appropriate amount of signal from the Ammonium Measurement.

+

-N) in water. The sensor uses three electrodes to

4

1.0.2 pH Compensation

The Ammonium Ion Electrode only measures the ammonium ion (NH

+

) not

4

ammonia (NH3). Ammonium ion and ammonia coexist in a pH dependent ratio in

solution. At pH 9.2 the ratio is 1:1, at pH 7 nearly all of the ammonia is in the

ammonium state and at pH 11 it is nearly all ammonia which is invisible to the

sensor. The more acidic values favor the NH

+

and the more basic values favor

4

ammonia gas, NH3. The pH Electrode measures the pH and the HYDRA C22 Analyzer

calculates the total NH

+

-N concentration based on the pH vs. concentration profile.

4

1.0.3 Temperature Compensation

Temperature is also measured and used to compensate each of the three electrode measurements.

While the pH electrode response is well defined with respect to temperature the ion electrodes tend to

be less well behaved. For the best results

calibrate the sensors near the process

temperature.

1.0.4 Cleaning and Maintenance

The HYDRA Ammonium Analyzer is configured to

NH3/NH

% concentration vs pH

100

80

+

4

periodically actuate a cleaning cycle using the

integral spray cleaner in the sensor. The period

and duration of the cleaning cycle is user

configurable. The 4-20 mA output is held at

either the last value or a preset value during the

cleaning. This minimizes the formation biofilms

60

%

40

20

0

6 8 10 12

pH

% NH4+

% NH3

HYDRA NH

+

-N Page 1

4

Page 10

or other coatings on the electrodes keeping maintenance to a minimum.

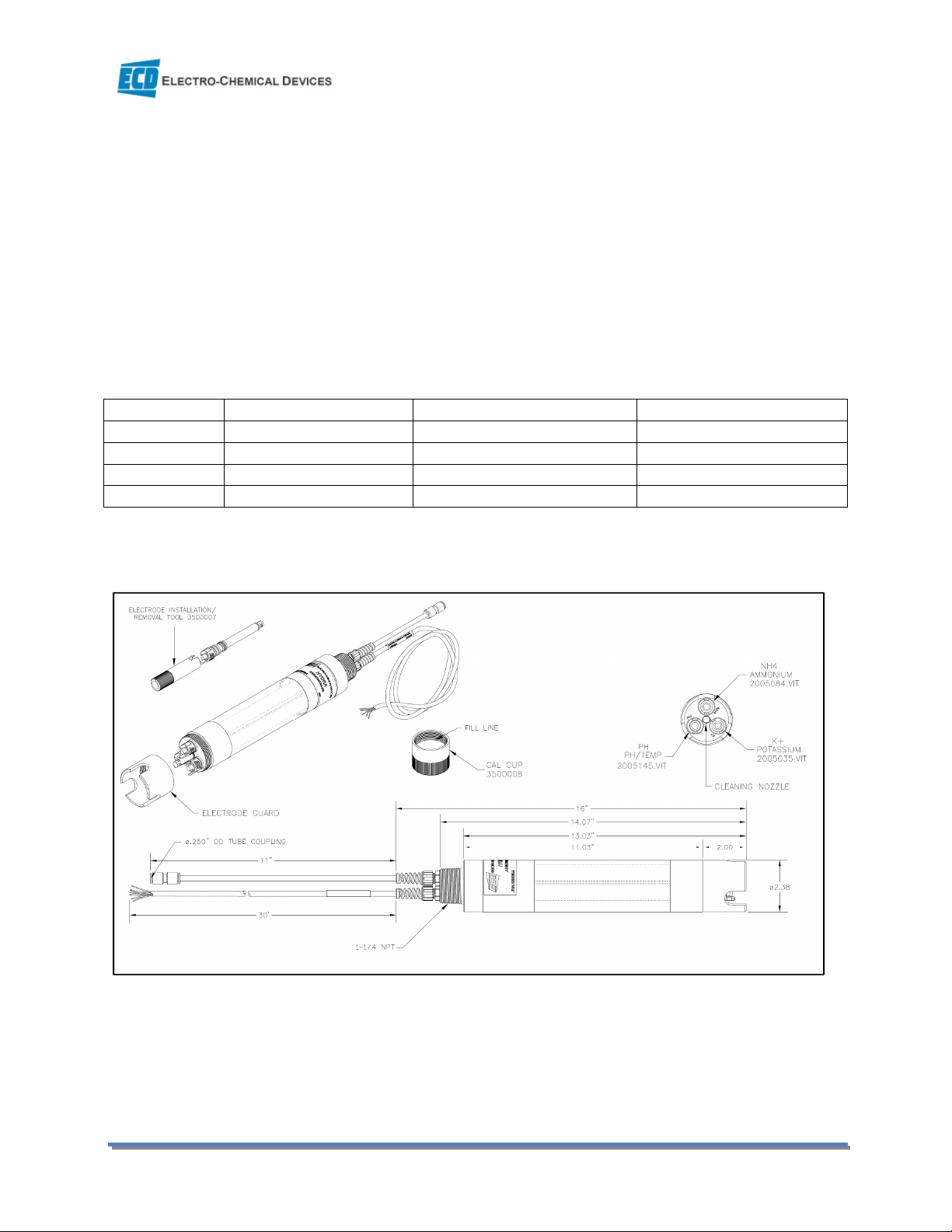

The rugged HYDRA sensor has a 1 ¼” NPT rear facing thread for attaching an extension/immersion tube

for easy installation from catwalks or handrails. The HYDRA sensor is submersible with an IP68 degree of

ingress protection. A removable electrode guard facilitates easy electrode replacement when necessary.

The HYDRA sensor features internal signal conditioning that allows the sensor to be mounted up to 200

meters from the analyzer.

1.1 FEATURES

1.1.1 Features and Benefits

• Separate, economical, easily replaceable Ammonium, Potassium and pH electrodes

• Fast and Accurate Ammonium Measurement NH4+ or NH4+-N

• pH and temperature compensated NH4+-N measurement

• Automatic compensation for K+ interference

• Rugged PVC design with removable electrode guard for easy maintenance

• Integral Spray Head Cleaner

Cleans sensor in situ with pressurized air

• Internal Signal Conditioning allows up to 200 meters between Sensor and Analyzer

1.2 Specifications

1.2.1 Hydra Sensor

• Three Electrode System with spray cleaner

• Ammonium ISE (NH4+- N) is the primary measurement

• Potassium ISE and pH glass electrodes are used for compensation of the NH4+ signal.

• The Sensor is waterproof with an ingress rating of IP 68.

Measurement Range

• NH4+- N: 0.1 to 1000 ppm

• K+: 0.1 to 10,000 ppm

• pH: 4-12 pH

Operating Temperature

• 0° C to 40° C (32° F to 104° F)

Min/Max Flow Rate by the sensor

• Minimum 0.1 m/s

• Maximum 3.0 m/s

Wetted Materials

• PVC, PES, PVDF, PTFE, Viton, Glass, 316 SS

Page 2 HYDRA NH

+

-N

4

Page 11

Accuracy

• ± 3% of reading, dependent on Calibra0on

Response Time

• T90 approximately 1 minute

Electrode Life

• ISEs: 4- 6 months, typical

• pH electrode: 6-12 months, typical

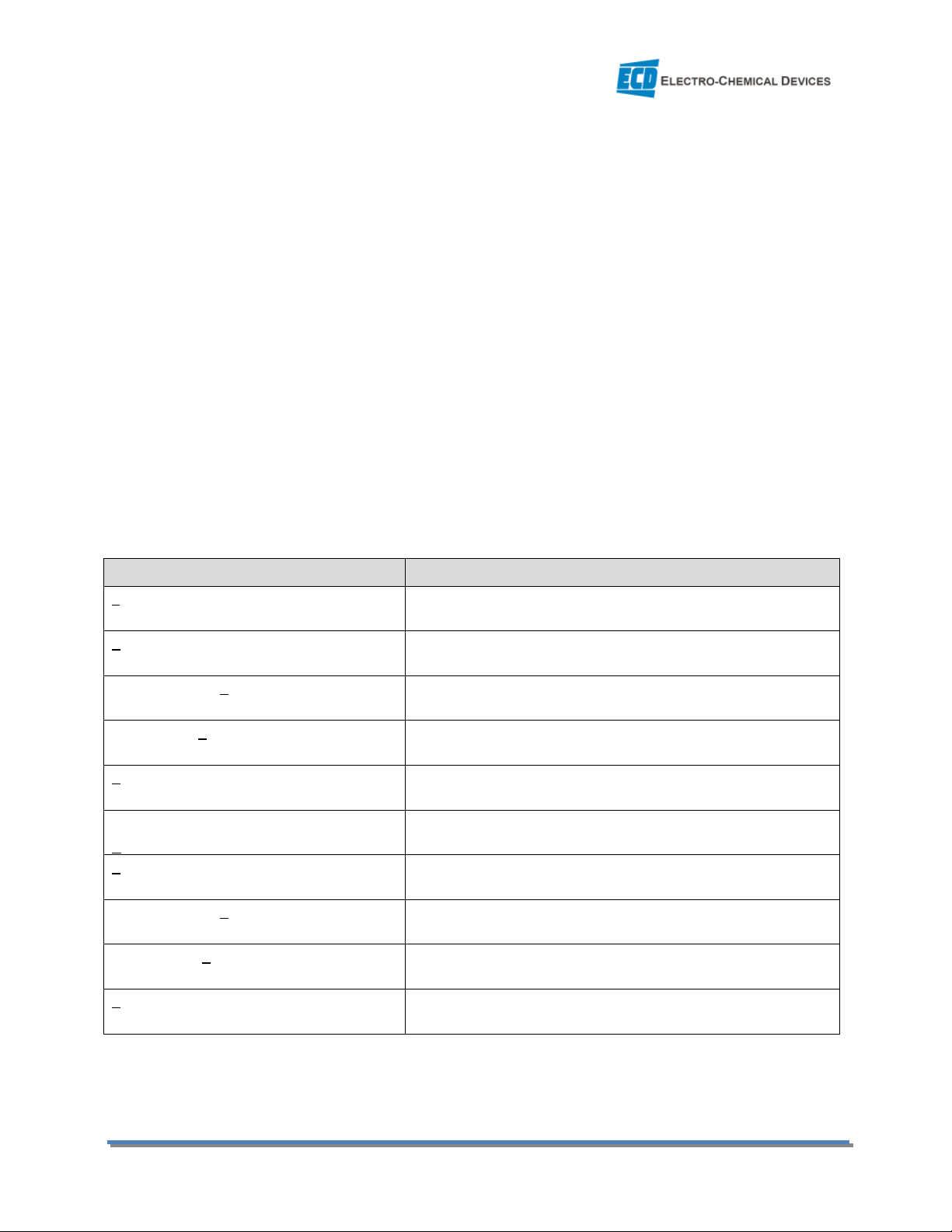

1.2.2 C22 Analyzer

Measurements

• Ammonium: 0.1 ppb to 1000 ppm as NH4+- N

• Potassium: 0.1 ppb to 1000 ppm

• pH: 0 to 14 pH

• Temperature: 0° C to 100° C (32° F to 212° F)

Compensation

• pH 4 - 12 pH

• Potassium: 0.1 to 1000 ppm

• 0° - 50°C

Display

• 2.5” X 1.75” backlit LCD

• 4 lines of Text

• Graphical display, NH4+-N vs. Time

Enclosure

• NEMA 4X, LxWxD: 5.7” x 5.7” x 7”

HYDRA NH

+

-N Page 3

4

Page 12

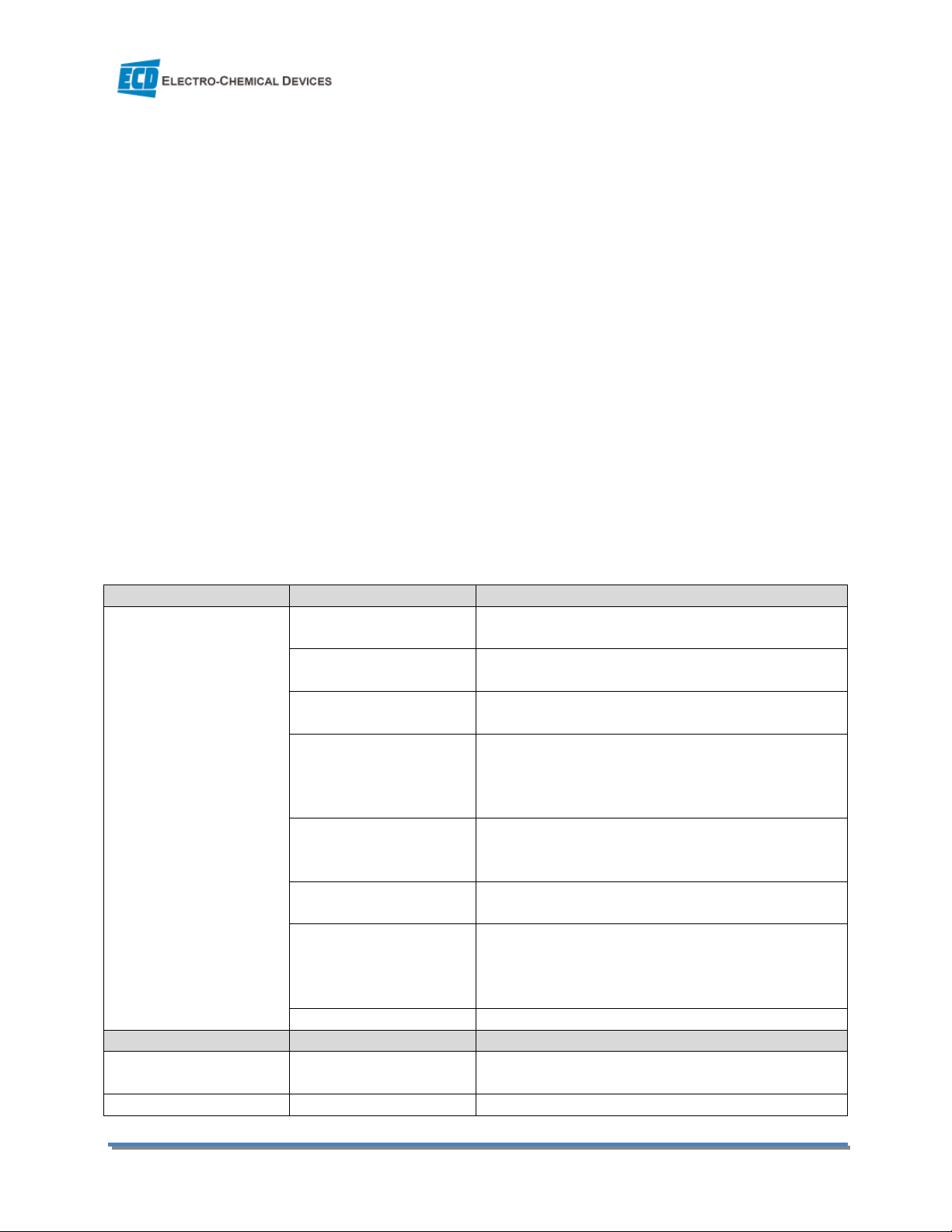

Relay

Standard Configuration

Master

Configuration

Slave Configuration

1 Spray Cleaner

(NO)

PV 1 Alarm

(NO)

NH4-N Alarm

(NO)

2 NH4-N Alarm

(NO)

Digital Input to Slave

(NO)

pH Alarm

(NO)

3

Spray Cleaner

(NO)

4

Diverter Valve

(NO)

Outputs

• (2) 4-20 mA maximum load 800 ohms @ 24 VDC

• mA #1: 0.1 to 50 mg/l NH4+- N (User Configurable)

• mA #2: 2 - 12 pH (User Configurable)

• Optionally up to (4) 4-20 mA outputs*

Input Power

• 110/220 VAC @ 50/60 Hz

Alarm Relay Ratings

• SPDT 230 VAC/5A or 30 VDC/5A resistive max. (NO) Normally Open

1.3 Hydra Dimensional Drawing

Figure 1.3

1.3.1 Parts List:

Page 4 HYDRA NH

o HYDRA Sensor with Electrodes, Calibration Cap,

o 30’ of ¼” air tubing, Electrode Removal Tool

+

-N

4

Page 13

2.0 INSTALLATION

2.1 UNPACKING

Carefully remove the HYDRA sensor from its shipping container. Inspect the sensor for damage. Verify

the electrodes, Ammonium, Potassium and pH and the Spray Cleaner Nozzle are installed in the sensor

housing. The electrodes should be hand tightened into place so that the sealing o-rings are not visible.

The electrodes are supplied with protective caps that must be removed before start up. Do not remove

the caps until ready to use.

### NEVER SUPPORT THE HYDRA SENSOR BY THE CABLE, IRREPAIRABLE DAMAGE WILL OCCUR ###

2.2 ASSEMBLY

The HYDRA Sensor is shipped completely assembled, before use it must be connected to the analyzer

and an air supply. Connect the spray cleaner feed tube to a compressed air supply controlled by a

solenoid valve (not supplied). Attach an immersion/support tube (not supplied). Finally connect the

sensor wires and 110 VAC power to the analyzer as shown on the wiring diagram. Connect the Cleaner

Relay to the solenoid and connect the 4-20 mA Output(s) and Alarm Relay to the Control System, (PLC or

DCS). The HYDRA is then ready to use.

2.2.1 Spray Cleaner

The Spray Cleaner uses compressed air to create turbulence around the electrodes which removes dirt

and films from the measurement surfaces. Depending on the process being measured the cleaner

should be actuated for 15-30 seconds every 0.25 -2 hour period. The spray cleaner connection is a ¼”

compression fitting and requires between 25-75 psi air pressure. The air supply is controlled with a user

supplied solenoid valve through Relay 1 in the C-22 analyzer. The solenoid valve should be a 110 AC

powered, <10 watt device. Wire the solenoid to Relay 1 as described in Section 2.4.4 below.

If no air supply is available use the ECD Model AC10 Air Blast Spray Cleaner compressor. The AC10 uses

redundant intake air filters and redundant fuses on both the relays and the compressor. A highly reliable

high current contactor assures years of trouble free service. The 115 VAC 3.0 Amp or 220 VAC 1.3 Amp

Air Compressor is housed in a rugged, corrosion resistant, hot compression molded, fiberglass

reinforced, polyester enclosure with a stainless steel piano hinge to secure the cover to the base. The

AC10 can be wall mounted or use the optional 2” handrail mounting system that uses stainless steel

support rails with two 2” galvanized pipe clamps.

### NEVER SUPPORT THE HYDRA SENSOR BY THE CABLE, IRREPAIRABLE DAMAGE WILL OCCUR ###

2.2.2 Immersion /Support Tube

Feed the cable and compressed air line through the immersion/support tube (not supplied). Connect a

support tube to the 1 ¼” MNPT thread at the rear of the sensor. The Hydra sensor weighs approximately

5.3 lbs. The support tube must be able to support the weight of the HYDRA sensor in the user’s

installation, whether vertical or angled. The recommended material for the immersion tube is 1.5”

Schedule 80 PVC pipe with a reducer fitting to 1 ¼” FNPT.

HYDRA NH

+

-N Page 5

4

Page 14

2.3 MOUNTING

2.3.1 C-22 Analyzer

Mount the C-22 in a location where there is easy access to the analyzer and sensors. Install the system

in an area where vibrations, electromagnetic and radio frequency interference are minimized or absent.

Do not mount in direct sunlight or areas of extreme heat (temperature > 120°F). The NEMA 4X C-22 is

suitable for outdoor use but it is best to mount it with a protective cover or sunshield.

There are three basic installation methods for the C-22, Wall Mount (UM), Panel Mount (PM) and Pipe

Mount (HM). The Pipe Mounting hardware includes 2” “U” bolts for attaching to standard 2” handrails.

(See the installation drawings in Section 9.3 at the rear of the manual)

2.3.2 Hydra Sensor

Install the sensor where the measured sample is representative of the entire process. Although the

sensor will function in a quiescent sample, flow improves the measurement. The recommended

minimum flow is 0.1 m/sec.

Securely mount the HYDRA sensor with the measuring end at least 6”away from the tank wall and

bottom. Ensure that the sensor is immersed at least 6” at all times.

Use care when servicing the sensor to ensure that the sensor does not hit the tank wall or bottom which

could break the sensing electrodes.

2.4 WIRING

Electrical wiring should only be conducted by qualified personnel. See the wiring color code for the

Hydra Sensor and the C-22 wiring diagram in Section 7.3 below.

2.4.1 Wiring, power

Attach power cable as shown in the diagram in Section 7.3 or the inside of the C22 cover. Feed the cable

through the gland fitting on the right hand side of the C-22. Tighten the cable gland to provide a good

seal to the cable. The instrument can be powered up at this point with no harm to the analyzer but it is

best to wait until the sensors are installed.

2.4.2 Wiring, Sensor

Attach the sensor wires as described on the diagram inside the C22 cover. Feed the sensor cable

through the gland fitting on the left hand side of the C-22. Do not use the same gland fitting for the AC

power or Alarm/Relays. The green terminal strip connectors are detachable from the circuit boards.

Remove the connector by pulling straight back from the circuit board.

2.4.3 Wiring, 4-20 mA Outputs

The 4-20 mA output is an unpowered output, 24V can be supplied from an external source, the PLC or

DCS receiving the signal or from the internal PS2 power supply.

If the internal PS2 Power Supply is used, first connect a jumper wire between Terminal #1 (RTN) on the

PS2 Power Supply Board and Terminal #2 of the 4-20 mA 1 output connector, the two slot connector on

Page 6 HYDRA NH

+

4

-N

Page 15

the top of the Channel 2 input card. (See diagram in Section 7.3) Then connect a shielded 22 gauge

twisted pair communication cable to Terminal #2 (+24V) on the PS2 power supply board and Terminal

#1 of the 4-20 mA 1 connector.

If a second mA output is supplied connect it in the same manner, jumper Terminal #1 of the PS2 board

to Terminal #2 of the 4-20 mA 2 output terminal strip then connect the two wire communication cable

to PS2 Terminal #2 and mA 2 Terminal #1.

If the 4-20 mA loop is powered from an external source then simply connect a shielded 22 gauge twisted

pair communication wire to Terminals #1 and #2 of the 4-20 mA terminal on the Channel 2 input card.

The standard Hydra C-22 is configured with the NH4+-N on mA 1 and pH on mA 2.

2.4.4 Wiring, Contact Relay Outputs

The standard configuration has two SPDT 230V 5 A relays that can be wired either normally open (NO)

or normally closed (NC). The default configuration is set to use the relays as normally open. Relay 1

actuates the solenoid for the air blast spray cleaner and Relay 2 is an NH

+

-N alarm relay, either a High or

4

Low Alarm.

Relay 1

Connect the Line terminal of the 110VAC power to the C (common) terminal of Relay 1. Connect the

Cleaner solenoid wires to the neutral terminal of the 110 VAC power and the NO (normally open)

terminal of Relay 1. (See Section 7.3)

Relay 2

Wire Relay 2 as a NO relay. Relay 2 is an alarm relay and should be connected to the Control System or

an external alarm.

Do not run the cable through the same cable gland fitting as the electrodes or the 4-20 mA signals.

The MASTER configuration has (4) SPDT 230V 5A relays that are wired as normally open (NO) relays.

Relay 1

Wire Relay 1 as a NO relay. Relay 1 is an alarm relay and should be connected to the Control System or

an external alarm.

Do not run the cable through the same cable gland fitting as the electrodes or the 4-20 mA signals.

Relays 2 (NO), 3 (NO), 4 (NO)

Connect to AC10 per wiring diagram in AC10 Air Blast Spray Cleaner

The SLAVE configuration has (2) SPDT 230V 5 A relays that are wired as normally open (NO) relays.

Relays 1, 2

Wire Relays 1 and 2 as a NO relays. Relays 1 and 2 are alarm relays and should be connected to the

Control System or an external alarm.

HYDRA NH

+

-N Page 7

4

Page 16

Do not run the cable through the same cable gland fitting as the electrodes or the 4-20 mA signals.

Page 8 HYDRA NH

+

-N

4

Page 17

3.0 OPERATION

This section will provide a basic overview of the C22 Analyzer/Controller. It covers the basic Menu

structure, the function of the MENU SELECT keys and the CALIBRATE keys.

The C-22 HYDRA analyzer has three measurement channels:

Channel 1, Ammonium as Nitrogen, NH

Channel 2, Potassium, K+ and

Channel 3, pH

+

4

-N,

3.1 KEYS

The blinking cursor indicates the active point where menus can be selected or numerical values

adjusted. There are two sets of keys on the C22 analyzer, the MENU SELECT keys and the CALIBRATE

keys.

The MENU SELECT keys are used to move the cursor vertically changing the displayed menu. These keys

are also used to Save/Accept the calibration data and exit the calibration menu.

The CALIBRATE keys are used to enter menus, change numerical values and move the cursor.

***To enter a calibration menu or parameter adjustment line simultaneously press both of the

Horizontal CALIBRATE keys, ◄CALIBRATE►***

Pressing either of the Horizontal CALIBRATE keys separately will move the cursor horizontally to the

point under the digit to be adjusted. The Vertical CALIBRATE keys are used to adjust numeric values.

Pressing the upper key will increase the value and pressing the lower key will decrease the value. When

the cursor is on a menu line, not in the menu, pressing the down CALIBRATE key will return the cursor to

the HOME Screen from any menu.

HYDRA NH

+

-N Page 9

4

Page 18

Screen Displayed

Button Pressed

Home Screen

MENU SELECT

Graphical display

MENU SELECT

Parameter Selection Screen (

Ch 1 Buffer

) MENU SELECT

Parameter Selection Screen

(Ch 1 Set

-Up) MENU SELECT

Parameter

Selection Screen (

Ch 1 Status

) MENU SELECT

Configure/ Trim Menu

MENU SELECT

..... To return to the Home screen

Screen Displayed

Button Pressed

Home Screen

MENU SELECT

pH Manual Mode Screen

MENU SELECT

Parameter Selection Screen (

Ch 2 Status

) MENU SELECT

Parameter Selection Screen (

Ch 2 Set

-Up) MENU SELECT

Parameter Selection Screen (

Ch 2 Buffer

) MENU SELECT

To channel 3

MENU SELECT

….. To return to the Home screen

Screen Displayed

Button Pressed

Parameter Selection Screen (

Ch 2 Buffer

) MENU SELECT

Parameter Selection Screen (

Ch 3

Status

) MENU SELECT

Parameter Selection Screen (

Ch 3

Set-Up)

MENU SELECT

Parameter Selection Screen (

Ch 3

Buffer

) MENU SELECT

Contrast

(adjustment screen)

MENU SELECT

….. To return to the Home screen

3.2 MENUS

There are three sets of menus on the Model C-22. The Channel 1 menus (PV1) the Ammonium Ion

channel (NH

the pH channel. Pressing the MENU SELECT UP key will first access the Potassium channel and then the

pH channel, pressing the MENU SELECT DOWN key will access the Ammonium channel. See the guide

below for the general menu structure.

3.2.1 Ammonium Ion Channel 1 Menu Structure

3.2.2 Potassium Ion Channel 2 Menu Structure

+

-N), the Channel 2 menus (PV2) the Potassium Ion channel and the Channel 3 menus (PV3)

4

▼

▼

▼

▼

▼

▲

▲

▲

▲

▲

▲

▼

3.2.3 pH Channel 3 Menu Structure

▲

▲

▲

▲

▼

3.2.4 Graphical Display Screen

This Graphical Display is only available in the Channel 1 menu. It is located one screen down from the

Home Screen. It displays a user assigned output value, for example, 4-20 mA1 vs. time. The Graphical

Page 10 HYDRA NH

+

-N

4

Page 19

Screen

Displayed

Button Pressed

Ch1 Buffer

CALIBRATE

(enter

the calibration menu by pressing

both

◄►

simultaneously

)

1 NH4-N

4.0

0 ppm

Cal

.0 mV

CALIBRATE

(enter line

, zero pt. Cal 1)

Sensor should be in the Cal 1 solution.

1

NH4-N

4.00

ppm

Cal

393.5 mV

To set Calibration Sol. Value use the CALIBRATE

or ►

to

move cursor. Use the

to adjust the integer value.

1

NH4-N

5.00 ppm

Cal

393.5 mV

MENU SELECT

(accept Calibration)

1 NH4-N

5.00 ppm

Cal

393.5 mV

MENU SELECT

(move to Cal line)

1

NH4-N

5.00

ppm

C

al

393.5 mV

MENU SELECT

(move to Cal 2, Slope)

Remove sensor, rinse and place in Cal 2 solution

2 NH4-N

00.0 ppm

Cal

29.6 mV/dec

CALIBR

ATE ►

(enter screen)

2

NH4-N

00.0

ppm

Cal

29.6 mV/dec

To set Calibration Sol. Value use the CALIBRATE

or ►

to

move cursor. Use the

to adjust the integer value.

2

NH4-N

5

0.0 ppm

Cal

29.6 mV/dec

MENU SELECT

(accept Calibration)

2 NH4-N

5

0.0 ppm

Cal

29.2 mV/dec

CALIBRATE

(return to Home Screen)

Display variables; which Output to display and which Time interval is used are configured in the Channel

1 Set-Up Menu. See Section 3.2.6, below, for more information on the Set-Up Menu.

3.2.5 Buffer Menu

The Buffer Menus are Calibration Menus. To access the Buffer Menu the cursor must be flashing in front

of the “Ch X Buffer” line. Simultaneously press both of the Horizontal CALIBRATE keys to enter the

Calibration screens. The calibration is structured for a two point calibration.

The first calibration “1 NH4-N” is the “zero point” calibration. This sets a base millivolt value to a specific

ion concentration. The concentration is adjustable to suit the measurement range, see procedure

below. When adjusting a value first move the cursor to the largest integer to be adjusted, perform the

adjustment and then move to the next lower value. When a calibration is performed the Cal line will

display the millivolt value associated with calibration standard solution. The Cal value can be reset to the

Factory default setting by “entering” the Cal line.

The second calibration screen is the “slope, mV/decade” calibration. This calibration should use a

standard solution that is at least 10X the concentration of the solution used in the first calibration. Scroll

down to the “2 NH4-N” line and enter the value of the standard solution and the Cal line will display the

new slope, mV/decade. Follow the same procedure for calibration of Channels 2 & 3.

◄

◄

◄

►

►

◄

▲or▼

▼

▼

▼

◄

▲or▼

▼

▼

3.2.6 Set-Up Menu

The Setup menu allows the various parameters to be configured for the user’s requirements. Each

Channel has a Set-Up Menu that includes the parameters associated with that specific Channel. The

HYDRA NH

+

-N Page 11

4

Page 20

Screen Displayed

Button Pressed

Ch1 Setup

◄

CALIBRATE

►

(enter screen)

P

lot 4-

20 1

MENU SELECT

Plot

4-20 1

MENU SELECT

4mA1

.0 ppt

OUTPUT SET

-UP

CALIBRATE

►

(enter 4mA line)

4mA1

.0 ppt

To adjust the value

use the CALIBRATE

or ►

to move

4mA1 00.1 ppb

MENU SELECT

(accept the Value)

4mA1

00.1

ppb

MENU SELECT

4mA1

00.1

ppb

CALIBRATE

►

(enter 20mA line)

4mA1

00.1

ppb

To adjust the value

use the CALIBRATE

or ►

to move

4mA1

00.1

ppb

MENU SELECT

(accept the Value)

4mA1

00.1

ppb

MENU SELECT

2 On

> .0 ppt

RELAY SET

-UP

CALIBRATE

►

(enter Relay Set Point)

2 On > .

0

ppt

To adjust the value

use the CALIBRATE

or ►

to move

2

On >

10.00

ppm

MENU SELECT

(save

the Value)

2 On >

1

00.0

ppm

MENU SELECT

2

On >

10.00

ppm

CALIBRATE

►

(enter Relay Hysteresis Point)

2 On

> 10.00

ppm

To adjust the value

use the CALIBRATE

or ►

to move

2 On

< 10.00

ppm

MENU SELECT

(save

the Value)

** Whether the relay is a

2

On

< 10.00

ppm

(Low Alarm

MENU SELECT

(If the NH

+

-

N drops below 10

.

0 ppm the

Graphical Display, 4-20 mA Outputs, Alarm Relays and Timers are all configured in the Setup Menu. Ion

selective electrodes have unique Iso-Potential points, the mV value for the concentration where changes

in temperature have no effect. This value is supplied with each specific ion electrode and must be

entered in the “isopot” entry line below. This provides the analyzer with the base point for temperature

compensation.

▼

Sample .1 m

(the “4-20 1” indicates the displayed value, variable)

▼

Sample .1 m

(the Sample time is 0.1 minutes, variable)

◄

20mA1 999.9 ppt

◄

20mA1 999.9 ppt

cursor. Use the ▲or▼ to adjust the integer value.

▼

20mA1 999.9 ppt

▼

20mA1 999.9 ppt

◄

20mA1 999.9 ppt

◄

20mA1 999.9 ppt

cursor. Use the ▲or▼ to adjust the integer value.

▼

20mA1 100 ppm

▼

20mA1 100 ppm

(4-20 is set to 00.1 ppb to 1000 ppm)

◄

2 Off < .0 ppt

◄

2 Off < .0 ppt

cursor. Use the ▲or▼ to adjust the integer value.

▼

2 Off < .0 ppt

▼

2 Off < .0 ppt

◄

2 Off < .0 ppt

◄

2 Off < .0 ppt

cursor. Use the ▲or▼ to adjust the integer value.

▼

2 Off > 11.00 ppm

2 Off > 11.00 ppm example)

2 On > 10.00 ppm (High Alarm

2 Off < 9.500 ppm example)

High or Low Alarm is determined by the Off value **

▼

4

contact closes until it is higher than 11 ppm. If the Off value

is set to 9.5 ppm then the contact will switch to a High

Alarm, closing at 10.0 ppm and re-opening below 9.5 ppm.)

Page 12 HYDRA NH

+

-N

4

Page 21

T

imer 1: periodic

CALIBRATE

►

P

er 0d00 :00 :00

Cleaning Timer

CALIBRATE

►

Per 0d0

0 :15 :00

To adjust the value

use the CALIBRATE

or ►

to move

Per 0d0

0 :15

:00

CALIBRATE

►

(enter the

Off line, the duration of the

Timer 2: oneshot

↑

CALIBRATE

►

N

ow 0 00 :00 :00

Manual Mode Timer

MENU SELECT

, MENU SELECT

CALIBRATE

►

Ks

.120

MENU SELECT

NH4

electrode selectivity ratio for K

+

Ks

.120

MENU SELECT

K+ compensation should be

Off for

T

C .333 %/

°C

MENU SELECT

T

C .333 %/

°C

CALIBRATE

►

(Enter Iso

-

Potential Entry line)

T

C .333 %/

°C

To adjust the value

use the CALIBRATE

or ►

to move

T

C .333 %/

°C

MENU SELECT

(accept the Value)

T

C .333 %/

°C

MENU SELECT

Noise Filter 5

CALIBRATE

(return to Home Screen)

◄

←Clock

◄

Now 0 00 :00 :00 (Per sets the time

On 0 00 :00 :00 between cleaning

Off 0 00 :00 :00 cycles)

(Set the Period to 15 minutes then every ¼ hour the Now

Clock will reset to 0:00:00 and trigger the On Timer which is

set at 0:00:00, starting the cleaning cycle.)

◄

Now 0 00 :00 :00

On 0 00 :00 :00

Off 0 00 :00 :00

cursor. Use the ▲or▼ to adjust the integer value, then

MENU SELECT ▼ (save the Value)

MENU SELECT ▼, MENU SELECT ▼, MENU SELECT ▼

◄

Now 0 00 :00 :00 (Set the Off time

On 0 00 :00 :00 at 30 seconds)

Off 0 00 :00 :30

cleaning cycle) To adjust the value use the CALIBRATE ◄ or

► to move cursor. Use the ▲or▼ to adjust the integer

value, then MENU SELECT ▼ (save the Value)

◄

←timer 1←clock

On 0 00 :00 :00 (Hold Function)

Off 0 00 :01 :30 (Set at 1 min 30 sec)

4-20 mA hold time after cleaning cycle, (CT + 1 minute)

▼

▼, ◄

To adjust the value use the CALIBRATE ◄ or ► to move

cursor. Use the ▲or▼ to adjust the integer value.

▼

K+ comp Off

NH4 reading – 0.120 (K+ reading) = NH4 concentration

▼

K+ comp Off

Calibration and On for Measurement

▼

Isopot 20.0 mV

Temperature Compensation (no adjustments needed)

Equilib 9.24 pH

Dissoc 1.000 Off

◄

Isopot .0 mV ** Mandatory **

Equilib 9.24 pH ** Input **

**Iso-Potential value supplied with each electrode**

Dissoc 1.000 Off

◄

Isopot 20.0 mV

cursor. Use the ▲or▼ to adjust the integer value.

Equilib 9.24 pH

Dissoc 1.000 Off

▼

Isopot 187.0 mV

Equilib 9.24 pH

Dissoc 1.000 Off

MENU SELECT ▼ Equilibrium value, No Input Needed

(Equilib= pH value equal to the pKa, the acid dissociation

constant, where [NH4 = NH3 + H+])

▼

Isopot 187.0mV

Equilib 9.24 pH

Dissoc 1.000 On

Dissoc = the pH correction factor for the [NH4 ↔ NH3 + H+]

dissociation , (the Measured NH4)/Dissoc = Total NH4-N

(should be on at all times)

▼

HYDRA NH

+

-N Page 13

4

Page 22

Screen Displayed

Button Pressed

C

h1 Status

◄

CALIBRATE

►

(enter screen)

Fri 09:11:28

MENU SELECT

Input 364.2 mV

CALIBRATE

(return to Home Screen)

Screen Displayed

Button Pressed

Co

nfigure/Trim

◄

CALIBRATE

►

(enter screen)

Passwords

MENU SELECT

(allows menus to be

password protected)

Default Display

MENU SELECT

(defines Home Screen)

4-20 assign

MENU SELECT

(Assigns parameter/function to mA output)

Manual Mode

MENU SELECT

(Allows manual control of mA outputs)

Relay assign/Test

MENU SELECT

(Assigns triggering

parameter to a relay)

PID Assign

MENU SELECT

(Assigns PID to a PV)

PWM Assign

MENU SELECT

(Assigns Pulse Width Modulation to a PV)

Clock and timers

MENU SELECT

(Sets Clock function, assigns Timers)

Logic Gates

MENU SELECT

(assigns AND/OR gates)

Ion Species

MENU SELECT

(Sets Ion Measured)

General

MENU SELECT

( Not Used)

°C/°F & Temp Cal

MENU SELECT

( allows temperature trim/cal, choose °C/°F)

4-20 Trim/Test

MENU SELECT

(allows mA trim)

Millivolt Trim

CALIBRATE

(return to Home Screen)

3.2.7 Status Menu

The Status menu displays the actual uncompensated millivolt value from the sensor, very handy

information for troubleshooting. The day and time, hours: minutes: seconds, are also displayed.

▼

▼

3.2.8 Configuration and Trim Menu

The Configure/Trim menu provides access to the menus used to assign parameters, define functions and

trim input and output signals. This group of menus should rarely be needed as the instrument was

configured at the factory before testing and shipment. The basic structure is as follows. See the “System

22 Configuration Manual” for details about these menus, available at www.ecdi.com.

▼

▼

▼

▼

▼

▼

▼

▼

▼

▼

▼

▼

▼

▼

3.3 OUTPUTS

The Standard C-22 HYDRA Analyzer has two 4-20 mA outputs. The default configuration has “mA 1”

configured for NH4-N, 4-20 mA = 00.1 ppb to 50 ppm and “mA 2” is configured for pH, 4-20 mA = 2-12

pH. To reconfigure the outputs see Section 3.2.6, Set-Up Menu, above.

Page 14 HYDRA NH

+

-N

4

Page 23

The Outputs, mA 1 and mA 2, are held at the “Last Value” by Timer 2 during the Air Blast Cleaning Cycle.

The Outputs return to live readings one minute after the cleaning cycle ends. Timer 2 is a “one-shot”

timer triggered by Timer 1. When Timer 1 triggers, it starts Timer 2 which is set to run for a period of

time equal to the cleaning time plus one minute.

3.3.1 Manual Mode (4-20 mA Hold Function)

The % Output is displayed on the Home Screen for the NH4-N output, mA 1, and one screen above the

Home Screen for the pH % Output, mA 2.

The outputs can be set for manual control by simultaneously pressing both horizontal CALIBRATE keys

when the cursor is in front of the % Output line. An “M” will be displayed in front of the % Output value.

The Output will remain frozen at the last value until the Manual Mode is turned off. The Manual Mode

hold function is commonly used to freeze the outputs during maintenance and calibration cycles. While

in Manual Mode the Output can be adjusted between 0 and 99.9% using the CALIBRATE keys, very

useful for troubleshooting loop communication problems.

To exit Manual Mode press the left CALIBRATE arrow, ◄, three times and the “M” will disappear, the

Output will return to a live reading.

3.4 CONTACTS-ALARM RELAYS

3.4.1 Standard Configuration

Relay 1 is configured to control the Air Blast Spray Cleaner. It is triggered by Timer 1. Timer 1 is

configured as a periodic timer. The default setting for the period is 15 minutes with the duration set at

30 seconds. The period and duration of the cleaning cycle is user configurable and dependent on the

application. For water going to the clarifier an adequate cleaning cycle may be, every two hours for 15

seconds, where incoming water to an aeration basin may require a 30 second cleaning cycle every 15

minutes.

The Now clock is an arbitrary timer. The Period determines the amount of time that must pass before

the Now clock resets to 00 hours, 00 minutes and 00 seconds, 00: 00: 00. The On time is the start time

and it is set at 00: 00: 00, so every time the clock resets Relay 1 is triggered. The Off time sets the

duration of Timer 1 and is set at 00: 00: 30, thirty seconds. (See Section 3.2.6 above)

To Change how often the Spray Cleaner actuates, change the Per line to the desired period. The display

is set for days, hours: minutes: seconds, 0d00: 00: 00.

To Change the duration of the Cleaning cycle change the Off line. If the duration is changed from the

default value of 30 seconds then the Manual Mode Timer should be adjusted to allow the sensor to

stabilize after the cleaning cycle. Adjust Timer 2; Off line; to the new Clean Time (CT) + 1 minute.

Relay 2 is configured as a high alarm triggering at 10.0 ppm NH

+

-N. The value can be changed in the Set-

4

Up Menu as shown in Section 3.2.6. Changing the > sign to a < sign in the On line changes the set point

from a high to a low alarm. This can also be accomplished by setting the Off value higher than the On

HYDRA NH

+

-N Page 15

4

Page 24

value which forces an automatic sign change. The Off value is the hysteresis point that the PV has to

correct to before the relay disengages.

3.4.2 One AC10 with Two HYDRAs

When two HYDRA Analyzers are connected to one AC10 Air Blast Spray Cleaning System then one C22

Analyzer becomes the MASTER and the other C22 Analyzer is a SLAVE.

3.4.2.1 Master Configuration

Relay 1 is configured as a high alarm triggering at 10.0 ppm NH

+

-N. The value can be changed in the Set-

4

Up Menu as shown in Section 3.2.6. Changing the > sign to a < sign in the On line changes the set point

from a high to a low alarm. This can also be accomplished by setting the Off value higher than the On

value which forces an automatic sign change. The Off value is the hysteresis point that the PV has to

correct to before the relay disengages.

Relay 2 is configured to trigger the Digital Input (Aux In) of the SLAVE analyzer. This initiates the Manual

Mode function of the SLAVE analyzer, placing the mA outputs in a Last Value Hold (Bumpless).

Relay 3 is configured to control the Air Blast Spray Cleaner. It is triggered by Timer 1. Timer 1 is

configured as a periodic timer. The default setting (Set Up Menu) for the period is 15 minutes with the

duration set at 30 seconds. This triggers a cleaning cycle every 15 minutes alternating between the

MASTER and the SLAVE units, so each HYDRA sensor is cleaned every 30 minutes. (see Relay 4

below)The period and duration of the cleaning cycle is user configurable and dependent on the

application. For water going to the clarifier an adequate cleaning cycle may be, every two hours for 15

seconds, where incoming water to an aeration basin may require a 30 second cleaning cycle every 15

minutes.

The Now clock is an arbitrary timer. The Period determines the amount of time that must pass before

the Now clock resets to 00 hours, 00 minutes and 00 seconds, 00: 00: 00. The On time is the start time

and it is set at 00: 00: 00, so every time the clock resets Relay 1 is triggered. The Off time sets the

duration of Timer 1 and is set at 00: 00: 30, thirty seconds. (See Section 3.2.6 above)

To Change how often the Spray Cleaner actuates, change the Per line to ½ the desired period. The

display is set for days, hours: minutes: seconds, 0d00: 00: 00.

To Change the duration of the Cleaning cycle change the Off line. If the duration is changed from the

default value of 30 seconds then the Manual Mode Timer should be adjusted to allow the sensor to

stabilize after the cleaning cycle. Adjust Timer 2; Off line; to the new Clean Time (CT) + 1 minute.

Relay 4 is configured to control the diverter valve which alternates the Air Blast between the two

sensors. It is triggered by Timer 2. Timer 2 is configured as a periodic timer. The default setting (Set Up

Menu) for the period is 30 minutes with the duration set at 30 seconds. The Period of Timer 2 must be

twice the Period of Timer 1 and have the same duration.

Page 16 HYDRA NH

+

-N

4

Page 25

% NH4+

% NH3

3.5 ION SELECTIVE FEATURES

The Hydra C22 analyzer has several features unique to Ion Selective Electrode measurements,

Isopotential, Interfering Ion Correction and pH Correction. The measurement range of the sensors is

from some ppb level to some ppm level, XXX ppb – XXX ppm, not the traditional 0 – XXX common to

most measurements, there is no zero value. This is most evident when configuring the 4-20 mA outputs.

3.5.1 The Isopotential point

Isopot in the menu is the mV value of the specific sensor where changes in the temperature of the

solution do not change the output of the sensor. This is the base point for temperature compensation

correction. Most pH electrodes have an isopotential near pH 7, but each type of Ion Selective electrode

has a unique isopotential value. Each NH4+ and K+ electrode is supplied with an Isopot that must be

entered in the respective Set-Up Menu.

3.5.2 Potassium Ion Interference Correction

Potassium ions and Ammonium ions have a similar ionic size and the same electrical charge. If

Potassium ions are present in the measured solution then they will cause a positive Interference on the

Ammonium Ion Measurement. The corrections for the Interfering Ions are in the Ks and K+ comp screen

in the Set-Up menu. The Ks, potassium ion selectivity, is the correction factor, ppm NH

+

/ppm K+;

4

Example: (50 ppm K+) x (0.10 ppm NH

With the Ks set at 0.10 (10 K+/ NH

+

) then 50 ppm potassium ion would cause the ammonium

4

+

/ ppm K+) = 5 ppm NH

4

+

interference

4

measurement to read 5 ppm high. When the K+ comp line is On the C22 Analyzer uses the potassium

ion concentration from the Potassium Ion Electrode and the Ks factor to calculate the amount of

interference on the Ammonium Ion Electrode and subtracts it from the measured ammonium value

before displaying the NH4-N value.

3.5.3 pH Correction

The Ammonium Ion Electrode only measures the ammonium ion (NH

+

) not ammonia (NH3). Ammonium

4

ion and ammonia coexist in a pH dependent ratio in

solution. At pH 9.24 the ratio is 1:1, at pH 7 nearly all of the

ammonia is in the ammonium state and at pH 11 it is nearly

all ammonia which is invisible to the sensor. The more acidic

values favor the NH

+

and the more basic values favor

4

ammonia gas, NH3. The pH Electrode measures the pH and

the HYDRA C22 Analyzer calculates the total NH

+

-N

4

concentration based on the pH vs. concentration profile.

The Dissociation should be On at all times.

% concentration vs pH

100

80

60

%

40

NH3/NH

+

4

HYDRA NH

20

0

6 8 10 12

pH

+

-N Page 17

4

Page 26

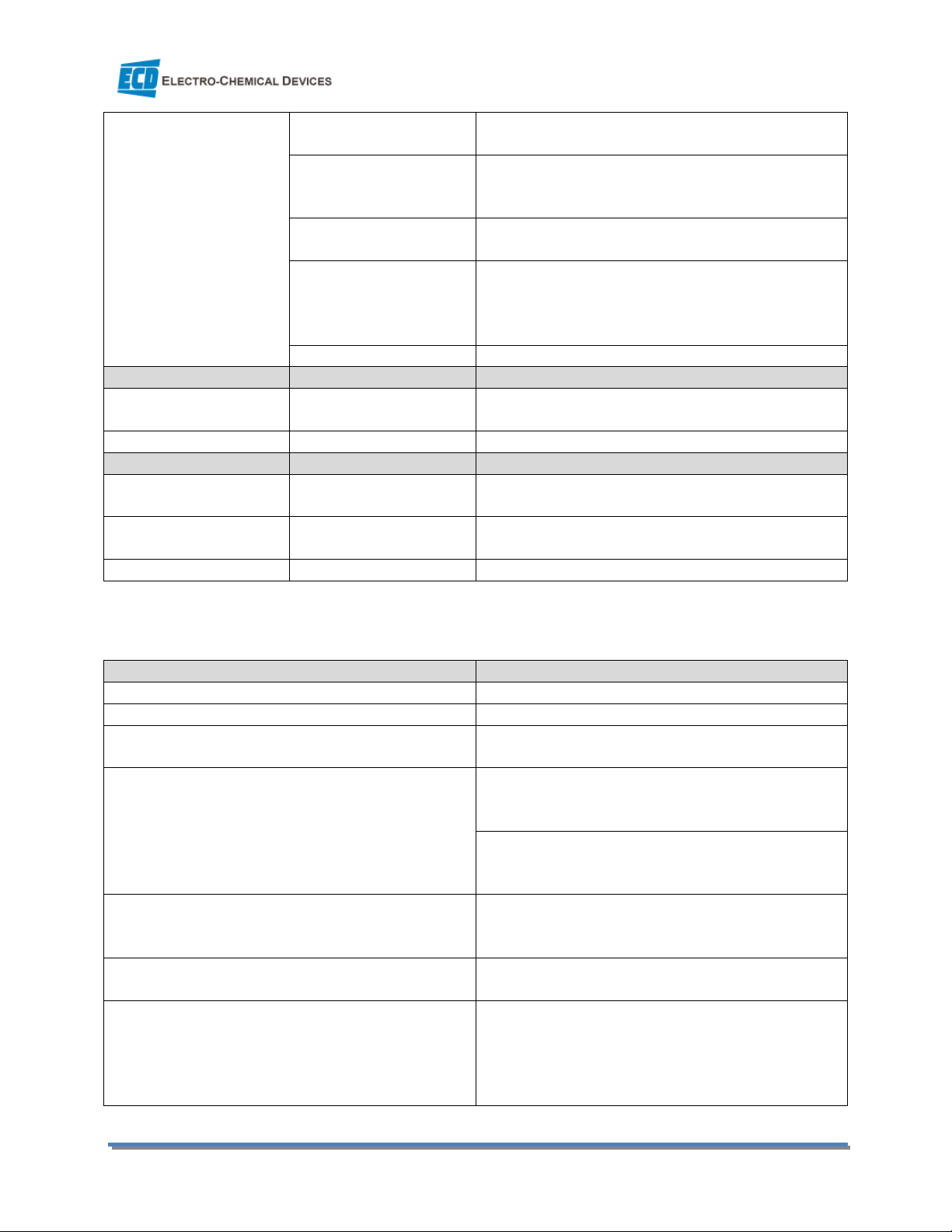

Ch 1 Setup Menu

Settings

Settings

Plot 4

-

20 1

4mA1

0.1 ppb

2 On > 10.00 ppm

Timer 1 : periodic

Per 0d0

0 :15

:00

Timer 2 :

oneshot

↑ Now 0 00 :00 :00

Ks 0.10

TC .333 %/°C

Noise filter 5

Ch 2

Setup Menu

Settings

Settings

TC .333 %/°C

Noise filter 5

4.0 START UP

The HYDRA Analyzer and Sensor was assembled and tested at the factory before shipment. The sensor

was then disconnected from the analyzer, cleaned and packaged for shipment. The HYDRA C22 analyzer

is configured as shown below and should be ready to use aside from any changes the user may wish to

make to the Outputs, Cleaning Timers and Alarm Set points.

Complete all of the steps in Section 2 INSTALLATION (above) before proceeding further. These steps

include:

1. Install the Analyzer in a suitable environment.

2. Determine an installation method and representative sample point for the sensor.

3. Connect the Air Blast Spray Cleaner tube to a solenoid controlled air supply, 1-4 bar (15-60 psig).

4. Wire the Power, Outputs, Contact Relays and the HYDRA Sensor to the HYDRA C22 Analyzer.

Familiarize yourself with the MENU Structure of the HYDRA C22 Analyzer, Section 3 (above).

4.1 SET-UP AND CONFIGURATION

The HYDRA C22 analyzer is configured as shown below. Changes to the default configuration can be

easily made as described in Section 3 above.

4.1.1 Set Up Menus, Standard

Sample .1 m

20mA1 50.00 ppm

2 Off < 9.500 ppm

K+ comp On

Isopot XXX.X mV

Equilib 9.24 pH

Dissoc 1.000 On

Now 0 00 :00 :00

On 0 00 :00 :00

Off 0 00 :00 :30

On 0 00 :00 :00

Off 0 00 :01 :30

Page 18 HYDRA NH

Isopot XXX.X mV

+

-N

4

Page 27

Ch 3 Setup Menu

Settings

Settings

4mA 2.00 pH

Noise filter 5

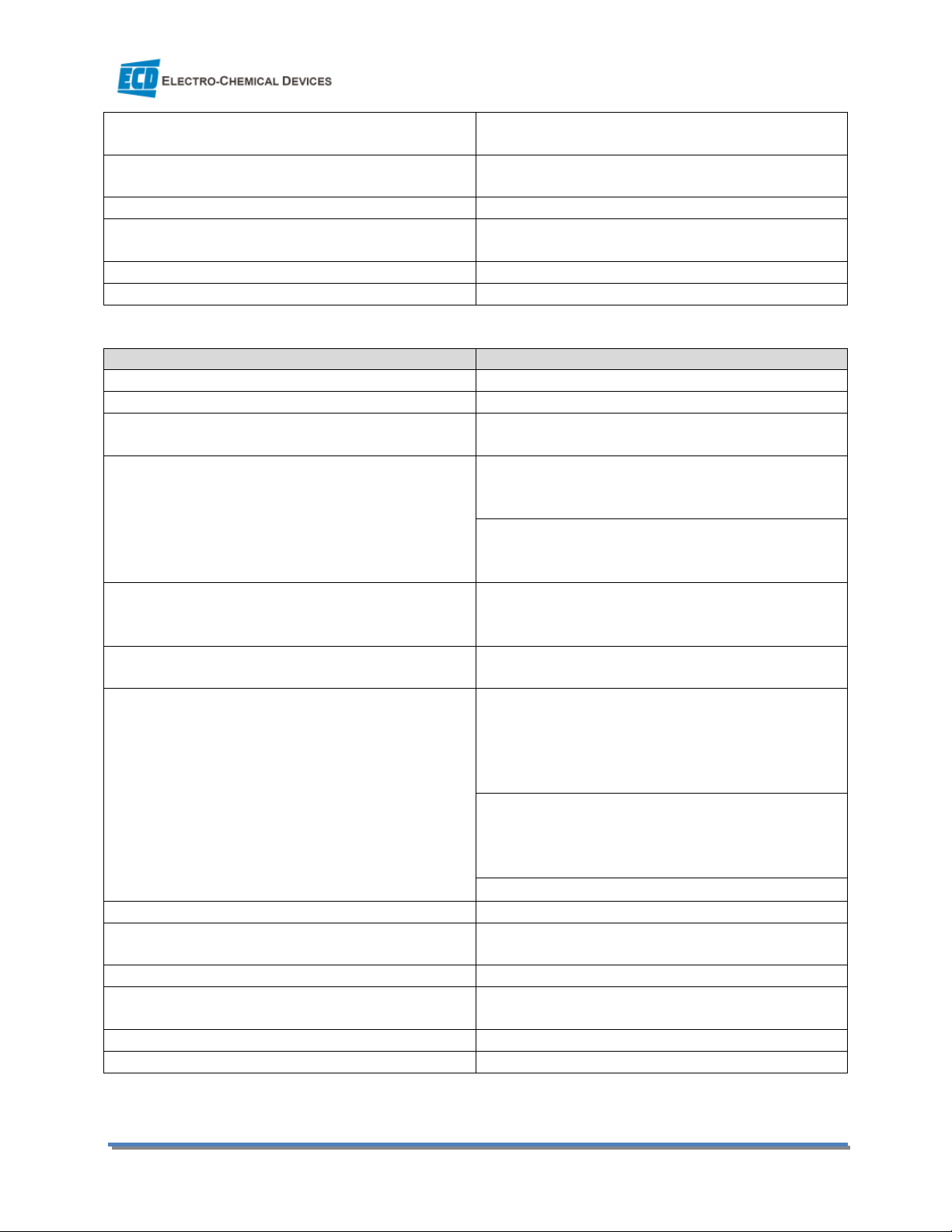

Ch 1

Setup Menu

Settings

Settings

Plot 4

-

20 1

4mA1 0.1 ppb

1 On > 10.00 ppm

Timer 1 : periodic

Per 0d00 :15 :00

Timer 2 : periodic

Per 0d00 :30 :00

Timer 3 : oneshot

↑ Now 0 00 :00 :00

Ks 0.10

TC .333 %/°C

Noise filter 5

Ch 2 Setup Menu

Settings

Settings

TC .333 %/°C

Noise filter 5

Ch 3 Setup Menu

Settings

Settings

4mA 2.00 pH

Noise filter 5

Ch 1 Setup Menu

Settings

Settings

Plot 4

-

20 1

4mA1 0.1 ppb

20mA 12.00 pH

4.1.2 Set Up Menu, MASTER/SLAVE

Master

Sample .1 m

20mA1 50.00 ppm

1 Off < 9.500 ppm

K+ comp On

Isopot XXX.X mV

Equilib 9.24 pH

Dissoc 1.000 On

Now 0 00 :00 :00

On 0 00 :00 :00

Off 0 00 :00 :30

Now 0 00 :00 :00

On 0 00 :00 :00

Off 0 00 :00 :30

On 0 00 :00 :00

Off 0 00 :01 :30

Slave

HYDRA NH

Isopot XXX.X mV

20mA 12.00 pH

Sample .1 m

20mA1 50.00 ppm

+

-N Page 19

4

Page 28

1 On > 10.00

ppm

Timer 1 : oneshot

↑ Now 0 00 :00 :00

Ks 0.10

TC .333 %/°C

Noise filter 5

Ch 2 Setup Menu

Settings

Settings

TC .333 %/°C

Noise filter 5

Ch 3 Setup Menu

Settings

Settings

4mA 2.00 pH

1 On > 7.50 pH

Noise filter 5

Menu

Settings

Passwords

No Pass Words (not configured)

Default display

0 (not configured)

4-20

assign

4-

20 1 : Ch1 PV

Manual Mode

Ch1 man mode on: 4

-

20 1

Ch2 man mode on:

4-20 2

Re

lay assign/test

Relay

1 timer 1

PID Assign

PID A unused

Clock and timers

Clock: Software

Ch 1 Setup Menu,

cont’d

1 Off < 9.500 ppm

On 0 00 :00 :00

Off 0 00 :01 :30

K+ comp On

Isopot XXX.X mV

Equilib 9.24 pH

Dissoc 1.000 On

Isopot XXX.X mV

20mA 12.00 pH

1 Off < 7.40 pH

4.1.3 Configure and Trim Menu, Standard

The Configure and Trim is configured as shown be and does not require any adjustments.

4-20 2 : Ch3 PV

Initial ch1 manual setting: Bumpless

Ch1 auto entry: timer 2

Initial ch2 manual setting: Bumpless

Ch2 auto entry: timer 2

Relay 2 Ch1 PV

(Relays 3-8 set to missing)

PID B unused

Hide Clock N

Hide Rate Y

Hide Flash N

Man trig OK Y

Page 20 HYDRA NH

+

-N

4

Page 29

Timer 1: periodic

Timer2:

oneshot

↑

Logic gates

All unused

Ion Species

Ch1 ion NH4

-N

General

No Menu

°C/°F & temp cal

1 Trim °C .0

4-20 Trim/Test

(not configured)

Millivolt trim

(not configured)

Menu

Settings

Passwords

No Pass Words (not configured)

Default display

0 (not configured)

4-20 assign

4-

20 1 : Ch1 PV

Manual Mode

Ch1 man mode on:

4-20 1

Ch2 man mode on: 4

-

20 2

Relay assign/test

Relay 1 Ch1 PV

PID

Assign

PID A

& B

unused

Clock and timers

Clock: Software

Timer 1: periodic

Timer 2: periodic

Timer

3: oneshot

↑

Logic gates

AND Gate A

Retriggerable N

Resettable N

Trig 2 timer 1

Ch2 ion K+

Unit 200.0 °C

4.1.4 Configure and Trim Menu, MASTER/SLAVE

MASTER

4-20 2 : Ch3 PV

Initial ch1 manual setting: Bumpless

Ch1 auto entry: timer 3

Initial ch2 manual setting: Bumpless

Ch2 auto entry: timer 3

Relay 2 timer 2

Relay 3 timer 1

Relay 4 timer 2

Hide Clock N

Hide Rate Y

Hide Flash N

Man trig OK Y

Retriggerable N

Resettable N

Trig 3 AND A

HYDRA NH

+

-N Page 21

4

In Timer 1

In Timer/2

Page 30

OR Gates A, B, C Not Used

Ion Species

Ch1 ion NH4

-N

General

No Menu

°C/°F & temp cal

1 Trim °C .0

4-20 Trim/Test

(not

configured)

Millivolt trim

(not configured)

SLAVE

Menu

Settings

Passwords

No Pass Words (not configured)

Default display

0 (not configured)

4-20 assign

4-

20 1 : Ch1 PV

Manual Mode

Ch1 man mode on: 4

-

20 1

Ch2

man mode on: 4

-

20 2

Relay assign/test

Relay 1

Ch 1 PV

PID Assign

PID A unused

Clock and timers

Clock: Software

Timer

1: oneshot

↑

(Timers 3

-

8 unused)

Logic gates

All unused

Ion

Species

Ch1 ion NH4

-N

General

No Menu

°C/°F & temp cal

1 Trim °C .0

4-20 Trim/Test

(not configured)

Millivolt trim

(not configured)

AND Gate B, C Not Used

Ch2 ion K+

Unit 200.0 °C

4-20 2 : Ch3 PV

Initial ch1 manual setting: Bumpless

Ch1 auto entry: timer 1

Initial ch2 manual setting: Bumpless

Ch2 auto entry: timer 1

Relay 2 Ch 2 PV

(Relays 3-8 set to missing)

PID B unused

Hide Clock N

Hide Rate Y

Hide Flash N

Man trig OK Y

Retriggerable N

Resettable N

Trig 1 Ext/1

Ch2 ion K+

Page 22 HYDRA NH

Unit 200.0 °C

+

-N

4

Page 31

4.2 CALIBRATION

The HYDRA Ammonium Analyzer was calibrated at the factory using the Two Point Calibration described

below. The sensor was assembled and placed beaker of equilibration solution for 8-12 hours before

starting the calibration. The Potassium Ion and Ammonium Ion electrodes sensing membranes require

several hours to properly hydrate/ equilibrate to the measured solution. The calibration sets the zero

potential and slope for each of the sensors into the analyzers memory.

Since the factory calibration characterizes the complete measurement system the initial user calibration

should only require a standardization of the Ammonium Ion Electrode once the HYDRA has equilibrated

to the process solution.

The Factory Calibration and all subsequent calibrations should be performed in the following sequence:

1. Temperature Calibration

2. pH Electrode calibration in pH 4.01 buffer and pH 7.00 buffer (2 point)

3. Potassium Electrode calibration in 1 ppm and 100 ppm solutions (2 point)

4. Ammonium Electrode calibration in 1 ppm and 100 ppm solutions (2 point)

Calibration checks should be performed weekly by comparison to a grab sample or immersing the

HYDRA sensor into a standard solution with known pH, K+ and NH4-N values. Performing a Single Point

Calibration will eliminate any offset found in the calibration check. Continuous drifting of the potassium

or ammonium ion reading may indicate the electrode needs to be replaced. (See Section 6 Trouble

Shooting below)

Two Point Calibration is required whenever an electrode is replaced, pH, Potassium or Ammonium. Two

Point Calibrations are also recommended every two months to verify the response of the electrodes is

greater than 50 mV/decade.

4.2.1 Recommended Materials

pH Calibration Solutions

1. pH 4.01, 500 ml (Part # 2010100)

2. pH 7.00, 500 ml (Part# 2010101)

pIon Calibration Solutions

1. 1 ppm K+, 500 ml (Part# 2010443)

2. 100 ppm K+, 500 ml (part# 2010444)

3. 1 ppm NH

4. 100 ppm NH

+

-N, 500 ml (Part# 2010445)

4

+

-N, 500 ml (part# 2010446)

4

Accessories

1. 1 liter plastic beakers

2. Distilled Water for rinsing

3. Calibrated thermometer with 0.1 °C graduations

4. Stir plate with magnetic stir bars.

HYDRA NH

+

-N Page 23

4

Page 32

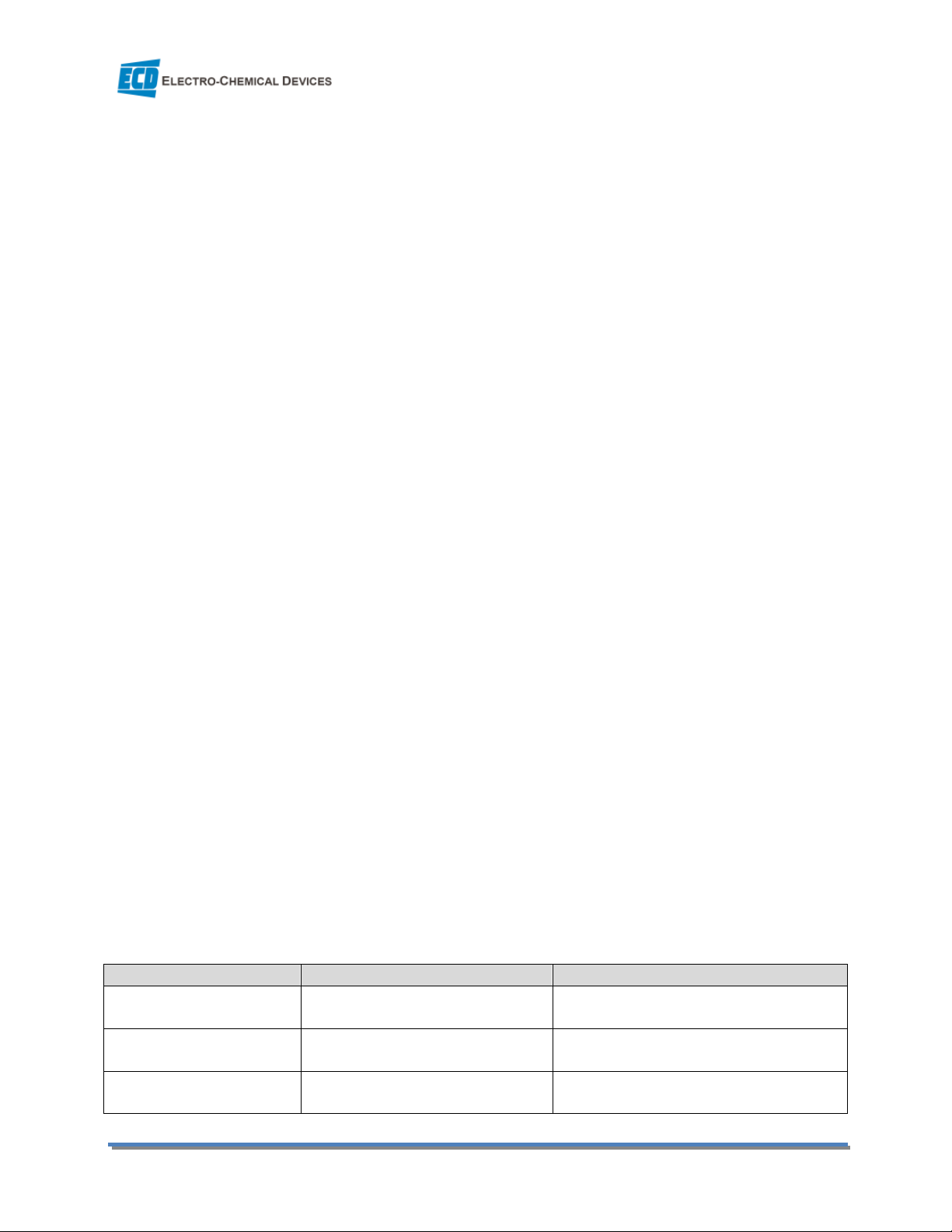

Channel

Screen

Recommended Solution

Ch1 Buffer (NH4

-N)

1NH4

-

N 1.000 ppm

1.0 ppm NH4

-

N (Part# 2010445)

Ch2 Buffer (K+)

1K+ 1.000 ppm

1.0 ppm K (Part# 2010443)

Ch3 Buffer (pH)

1 pH 7.00 pH

pH 7.0 Buffer (part# 2010101)

4.2.2 Temperature Calibration

Place the HYDRA sensor in a beaker of water so that the bottom 3 inches (7.6 cm) of the body is

immersed. Allow the sensor to equilibrate for 10 minutes. Verify the displayed temperature agrees with

the thermometer. If not, then adjust the temperature in the Configure/Trim > °C/°F & temp cal > 1 Trim

°C menu to agree with the thermometer. This calibration was performed in the factory calibration but it

is advisable to perform a temperature check every 2-3 months.

4.2.3 Single point Calibration

Single Point Calibrations are used to standardize the sensor’s reading to a known value typically to

eliminate errors caused by drift or large changes in the makeup of the measured solution. A Single Point

Calibration adjusts the base potential of the sensor by shifting the response curve to a higher or lower

level but it does not affect the slope (mV/ppm) of the curve.

Single point calibration is available for each of the measured parameters in the appropriate Buffer

Menu, Channel 1 Buffer for the NH

+

-N, Channel 2 Buffer for the K+ and Channel 3 Buffer for pH. (See the

4

Single Point Calibration Screen table below)

Immerse the front end of the sensor into a container of the calibration solution, enter the value of the

calibration solution or the value derived from a grab sample into the “1 (ion) xxx ppm” line of the

Buffer menu as described in Section 3.2.5 above. Accept the reading when stable by pressing either of

the MENU SELECT keys. The lower line in the menu, the Cal line will show the new mV value associated

with the entry.

***Important Note for Ammonium Calibrations*** When using the 1 ppm and 100 ppm NH

+

-N

4

calibration solutions to calibrate the HYDRA C22 analyzer the potassium ion compensation, the “K+

comp” line in the Channel 1 Setup menu should be turned on, it is on by default. These calibration

solutions contain no potassium ions but the ammonium ions interfere with the potassium ion electrode

and the potassium ion electrode registers a K+ reading, this value must be accounted for in the NH

+

-N

4

calibration.

If the Single Point Calibration is the first point in a Two Point Calibration it is customary to use the

solution with the lowest value for the single point calibration. There are no restrictions on the value

entered in the “1 (ion) xxx ppm” line of the Buffer menu; it can be higher or lower than the value in line

2 of the menu. For the pH calibration the zero point is set with pH 7.0 calibration buffer and the slope is

set with the pH 4.01 calibration buffer.

Single Point Calibration Screens

Cal 320.0 mV

Cal 165 mV

or Grab Sample value

or Grab Sample value

Page 24 HYDRA NH

Cal 3.1 mV

or Grab Sample value

+

-N

4

Page 33

4.2.4 Two point Calibration

The second point of a Two Point Calibration sets the slope of the sensor, the mV per decade. The slope is

calculated by comparing the millivolt values and ppm values in the “1NH4-N 1.00 ppm” line to the

values in the “2NH4-N 100 ppm” line of the Buffer Menu. The concentration of the solution used for

the second point should be at least 10 times higher than the value used in the first point of the

calibration. The recommended calibration standards for both the ammonium ion and potassium ion

calibrations are 1 ppm and 100 ppm. Perform a two point calibration whenever an electrode is replaced.

After completing the single point calibration, see section 4.2.3 above, rinse the sensor with distilled

water and gently dab it dry with a paper towel or soft tissue. Carefully cleaning the sensor prevents

errors in the calibration due to carryover from the first solution. Place the sensor in the second solution,

either the pH 4.01 buffer or one of the 100 ppm solutions and wait for the reading to stabilize before

accepting the value. See section 3.2.5 above for further instruction.

4.2.5 Potassium Ion Compensation

Potassium ions have a positive interference on the Ammonium Ion Electrode, i.e. the ammonium

reading is higher than the actual value. The Potassium Ion Compensation, K+ comp, adjusts the

measured potassium ion concentration using the interference ratio value, the Ks value, and subtracts

the resulting amount from the Ammonium Ion Signal. The Ks value in the NH4-N Set Up screen allows

the interference ratio to be adjusted as needed. The default setting is Ks = .100 which is 10 potassium

ions produce the same signal as 1 ammonium ion, Ks = 0.04 would change the correction to 25:1. The

0.100 correction factor is good for most solutions with low levels of potassium, less than 20 ppm.

Each Potassium Ion Electrode should have similar characteristics but adjustments are necessary when

the potassium electrode is replaced or when high levels of potassium are present in the solution. If the

ammonium ion concentration is less than expected when compared to a grab sample measurement

then adjust the Ks value to a smaller value. Adjusting from 0.100 > 0.082 for example would increase the

potassium to ammonium ion ratio from 10:1 to 12:1 thereby slightly increasing the displayed

ammonium ion concentration by subtracting less in the compensation.

HYDRA NH

+

-N Page 25

4

Page 34

5.0 MAINTENANCE

5.1 MAINTENANCE SCHEDULE

The HYDRA sensor requires little maintenance since most of the required cleaning is accomplished by

the Air Blast Spray Cleaner. Determining the proper cleaning cycle and duration for the application will

keep the front end of the sensor clean for extended periods but weekly inspection of the sensing end is

recommended.

Weekly calibration checks versus a grab sample are recommended to minimize any drift in the sensor.

Once the stability of the sensor has been established in the process, the time between calibration

checks can be adjusted. A calibration check must occur at least once per month.

The HYDRA should be checked monthly in calibration solutions for proper span of both the ammonium

and potassium electrodes. The electrodes start life with a span in the 55 mV/decade range and drop off

into the 40 mV/decade range as they age. Readings below 40 mV/decade indicate the electrode should

be replaced. Depending on the characteristics of the water being measured the Ion Selective electrodes

should last 3-6 months.

5.2 CLEANING THE SENSOR

The HYDRA sensor can be rinsed with water and wiped with a soft brush or cloth to remove most

coatings. DO NOT clean the potassium or ammonium ion electrodes with a stiff brush or vigorous wiping

as the sensing membrane is easily torn. DO NOT use strong detergent solutions or Spray Glass cleaners

to clean the sensor, the potassium and ammonium electrodes will be irreparably harmed. The sensor

can be soaked in dilute HCl, 2-3%, for 15 minutes to help remove stubborn coatings. Use a weak

detergent solution, a couple of drops detergent per liter of water, to remove any oily coatings. The pH

electrode and HYDRA housing can be cleaned in a more rigorous manner since the plastic body and glass

membrane are more durable than the Ion Selective Electrodes.

5.3 REPLACING THE ELECTRODES

The three electrodes, Ammonium, Potassium and pH are easily replaceable by simply removing the

electrode guard, screwing out the old sensor and screwing in the new one using the supplied installation

tool. Make sure no water gets inside the sensor when removing the electrodes. Water will cause the

internal electronics to fail. If the electronics are compromised the HYDRA sensor must be replaced.

The potassium and ammonium electrodes are PVC membrane combination electrodes (indicator

electrode and reference electrode in one body) and the pH electrode is a glass membrane combination

electrode.

Apply a thin film of o-ring lubricant to the o-rings on the electrode before installing it into the sensor

housing. Use the supplied electrode installation tool to remove or install electrodes into the sensor. The

use of pliers or other tools is not recommended as they may crack the electrode housing.

Page 26 HYDRA NH

+

-N

4

Page 35

Problem

Possible Cause

Remedy

NH

+

-

N Reading Low

Dirty Coated electrode

Clean sensor:

Old Expired

NH4 ISE Perform two point calibration,

Inaccurate

Potassium

Verify

Potassium

ISE reading

NH

+

-N Reading High

Ammonium

Sensor has drifted

Perform a single point

Low or No

Potassium

ion

Verify

K

comp

is ON

Interfering Ions Present in

Influx of interfering ions causing

No Response to Changing

Bad Electrode

Visually inspect membrane for

Bad Sensor

Switch out old electrode with a

6.0 TROUBLESHOOTING

4

Soak in 2% HCl for 5 minutes to

remove algae or

Rinse with weak detergent 10-15

seconds solution to remove oils

Soak in tap water for 30 minutes

after either cleaning method.

Increase frequency of the air

blast cleaner, See Section 3.4

the slope > 40 mV/decade if not

replace NH4 Sensor

4

Ammonium