Page 1

The information and technical data disclosed in this document may be used and disseminated only for the purpos es and to the

ELECTRO-CHEMICAL DEVICES

Instruction Manual

Model CA-6 Analyzer

Hardness

extent specifically authorized in writing by Electro-Chemical Devices. Electro-Chemical Devices reserves the right to change

published specifications and designs without prior notice.

Rev: B– 10/14

Page 2

PREFACE

Purchasing products from Electro-Chemical Devices, Inc. provides you with the finest liquid analytical

instrumentation available. If this is your first purchase from ECD, please read this manual before

installing and commissioning your new equipment.

If there are any questions concerning this equipment, please contact your local ECD representative, or

the factory directly at:

Electro-Chemical Devices, Inc.

1681 Kettering

Irvine, CA 92887 USA

Telephone: +1-949-336-6060

FAX: +1-949-336-6064

Website: www.ecdi.com

Email: sales@ecdi.com

© 2014 Electro-Chemical Devices, Inc. All rights reserved. No part of this manual may be used or reproduced in any form or by any means, or

stored in a database or retrieval system without prior written permission from Electro-Chemical Devices, Inc. Making copies of any part of this

manual for any purpose other than personal use is a violation of United States copyright laws. Document printed in the United States of

America.

CA-6 Analyzers Page ii

Page 3

TABLE OF CONTENTS

PREFACE ........................................................................................................................................................ ii

TABLE OF CONTENTS .................................................................................................................................... iii

TERMS AND CONDITIONS OF SALE ............................................................................................................. vii

RETURNED GOODS POLICY ........................................................................................................................... x

IMPORTANT SERVICE INFORMATION .......................................................................................................... xi

UNPACKING THE INSTRUMENT.................................................................................................................... xi

1.0 OVERVIEW ............................................................................................................................................... 1

CONTENTS: ................................................................................................................................................ 1

1.0.1 CA-6 Technical Specifications ....................................................................................................... 2

1.1 Safety Precautions, Instructions and Hazards .................................................................................... 3

1.1.1 General information ..................................................................................................................... 3

1.1.2 List of warnings and potential dangers ........................................................................................ 3

1.1.3 Reagents ....................................................................................................................................... 4

1.1.4 Sample Stream ............................................................................................................................. 5

1.1.5 Waste disposal of the liquid reagents for the colorimetric reaction ........................................... 5

1.1.6 Analyzer General Hazards ............................................................................................................ 5

2.0 INTRODUCTION – Analyzer Description .................................................................................................. 7

2.1 Applications ........................................................................................................................................ 7

2.2 Working principle: Lambert-Beer law ................................................................................................. 7

2.2.1 Absorption photometry (Colorimetry): ........................................................................................ 8

2.3 Analysis Cycle ...................................................................................................................................... 9

2.3.1 Typical Run Sequence: ................................................................................................................. 9

2.3.2 Settings ....................................................................................................................................... 10

2.3.3 Programmable Functions ........................................................................................................... 11

2.4 Components ...................................................................................................................................... 15

2.4.1 Fast-loop reservoir ..................................................................................................................... 15

2.4.2 Sampling Pump .......................................................................................................................... 16

2.4.3 3 Way Valve ................................................................................................................................ 16

2.4.4 Micro Peristaltic Pumps ............................................................................................................. 16

2.4.5 Mixing Pump .............................................................................................................................. 16

CA-6 Analyzers Page iii

Page 4

2.4.6 Pinch Valve ................................................................................................................................. 16

2.4.7 Colorimetric Reaction Cell .......................................................................................................... 17

2.4.8 Sample Drain .............................................................................................................................. 17

2.4.9 Electronic Components .............................................................................................................. 17

3.0 OPTIONS ................................................................................................................................................ 18

3.1 Dilution Module ................................................................................................................................ 18

3.2 Oxidation/Digestion Module ............................................................................................................. 19

4.0 INSTALLATION ........................................................................................................................................ 21

4.1 Unpacking and Inspecting ................................................................................................................. 21

4.2 Analyzer Handling ............................................................................................................................. 21

4.3 Location and Mounting Instructions ................................................................................................. 21

4.4 Pre-Installation .................................................................................................................................. 21

4.5 Electrical Connections ....................................................................................................................... 22

4.5.1 General information ................................................................................................................... 22

4.5.2 AC Power Connections ............................................................................................................... 23

4.5.3 Signal Output Connections – TB (4-20 mA, alarm, aux, RS232) ................................................. 23

5.0 REAGENTS PREPARATION ..................................................................................................................... 23

5.1 Method of Analysis ........................................................................................................................... 25

6.0 ANALYZER INITIAL START-UP ................................................................................................................. 26

6.1 Sample and Drain Tubing Connections ............................................................................................. 26

6.2 Powering, Priming and Starting the Analyzer ................................................................................... 27

7.0 CALIBRATION ......................................................................................................................................... 29

7.1 Blank Calibration (Zero Point) ........................................................................................................... 29

7.2 Slope Calibration (Factor) ................................................................................................................. 30

7.3 Step by Step Manual Calibration ...................................................................................................... 30

8.0 USER INTERFACE ................................................................................................................................... 32

8.1 Touch Screen Display ........................................................................................................................ 32

8.2 Passwords (****) .............................................................................................................................. 32

8.3 Main Screen .................................................................................................................................... 33

8.3.1 Status Modes ............................................................................................................................. 34

8.3.2 Menu Buttons ............................................................................................................................ 34

8.4 RUN MENU ........................................................................................................................................ 35

CA-6 Analyzers Page iv

Page 5

8.4.1 START ON-LINE? ......................................................................................................................... 35

8.4.2 CYCLE Ch1 / CYCLE Ch2 / Cycle Extra ......................................................................................... 35

8.4.3 EMERGENCY STOP ...................................................................................................................... 35

8.5 DISPLAY MENU .................................................................................................................................. 36

8.5.1 Display Process Values ............................................................................................................... 36

8.5.2 Chart ........................................................................................................................................... 36

8.5.3 Manual Step ............................................................................................................................... 36

8.6 PROGRAM MENU .............................................................................................................................. 37

8.6.1 Analysis Cycle ............................................................................................................................. 37

8.6.2 Extra Cycle .................................................................................................................................. 38

8.6.3 Settings Menu ............................................................................................................................ 38

8.6.2 Calibration Menu ....................................................................................................................... 38

8.7 SERVICE MENU .................................................................................................................................. 39

8.7.1 Method of Operation ................................................................................................................. 40

8.8 ? HELP MENU ................................................................................................................................... 41

8.8.1 Analyzer Installation................................................................................................................... 42

8.8.2 Analyzer Start Up ....................................................................................................................... 45

8.8.3 Start/Stop Commands ................................................................................................................ 47

8.8.4 Calibrations ................................................................................................................................ 48

8.8.5 Program / Modify Cycles ............................................................................................................ 50

8.8.6 Functions List ............................................................................................................................. 51

8.8.7 Shut Down Procedure ................................................................................................................ 55

8.8.8 Maintenance .............................................................................................................................. 56

8.8.9 Troubleshooting ......................................................................................................................... 57

9.0 MAINTENANCE ...................................................................................................................................... 58

9.0.1 Visual check ................................................................................................................................ 58

9.0.2 Monthly ...................................................................................................................................... 58

9.0.3 Every 4-6 months ....................................................................................................................... 59

9.0.4 Annual ........................................................................................................................................ 59

9.1 Sample Pump tubing replacement ................................................................................................... 59

9.2 Micro Peristaltic Tubing Replacement .............................................................................................. 60

9.3 Accessories and Spare Parts ............................................................................................................. 61

CA-6 Analyzers Page v

Page 6

10.0 ANALYZER SHUT DOWN ...................................................................................................................... 63

11.0 REAGENT RECIPE and PROGRAM SEQUENCE ..................................................................................... 64

METHOD DESCRIPTION ........................................................................................................................... 64

FIRST START-UP PROCEDURE .................................................................................................................. 64

11.1 Analysis Cycle .................................................................................................................................. 65

11.2 Extra Cycle ....................................................................................................................................... 66

11.3 TEST DATA ....................................................................................................................................... 67

11.4 Reagents .......................................................................................................................................... 69

11.4.1 REAGENT 1 ............................................................................................................................... 69

11.4.2 REAGENT 2 ............................................................................................................................... 69

11.4.3 Standard Solution..................................................................................................................... 70

CA-6 Analyzers Page vi

Page 7

TERMS AND CONDITIONS OF SALE

1. ACCEPTANCE.

If this writing differs in any way from the terms and conditions of Buyer's order or if this writing is

construed as an acceptance or as a confirmation acting as an acceptance, then Seller’s acceptance is

EXPRESSLY MADE CONDITIONAL ON BUYER’S ASSENT TO ANY TERMS AND CONDITIONS CONTAINED

HEREIN THAT ARE DIFFERENT FROM OR ADDITIONAL TO THOSE CONTAINED IN BUYER'S WRITING.

Further, this writing shall be deemed notice of objection to such terms and conditions of Buyer. If this

writing is construed as the offer, acceptance hereof is EXPRESSLY LIMITED TO THE TERMS AND

CONDITIONS CONTAINED HEREIN. In any event, Buyer's acceptance of the goods shall manifest Buyer's

assent to Seller's terms and conditions. No addition to or modification of these terms will be effective,

unless set forth in writing and agreed to by Seller.

2. WARRANTIES AND REMEDIES

a. Warranty. Seller warrants to Buyer that it holds and will pass marketable title to the goods sold

hereunder. Seller warrants to Buyer that the items and components manufactured by Seller will be free

from defects in material and workmanship (subject, however, to tolerances and variances permitted by

the trade hereunder) for a period one (1) year for non-consumable products. Consumable electrodes

and sensors have a conditional warranty based shelf life and process conditions and is determined by

Seller.

b. Exclusion and Conditions. Seller’s obligations with respect to the express warranties and remedies

contained herein are conditioned on the following: (i) Buyer's return of the non-conforming goods, if

authorized by Seller: (ii) Buyer shall not assign its rights under these express warranties and any

attempted assignment shall render such warranties, but not any disclaimers or limitations, void and the

goods sold shall be sold AS IS; and (iii) all products shall be carefully inspected for damage by Buyer

upon receipt, be properly calibrated for Buyer's particular use, and be used, repaired, and maintained by

Buyer in accordance with the instructions set forth in Seller’s product literature. Repair and

maintenance by non-qualified personnel, product subjected to misuse or negligence, and/or damaged

during shipment will invalidate the warranty, as will the use of non-approved consumables or spare

parts. As with any other sophisticated product, it is essential, and a condition of Seller’s warranty, that

all personnel using the product be fully acquainted with its use, capabilities and limitations as set forth

in the applicable product literature.

3. DISCLAIMER OF IMPLIED WARRANTIES. Seller gives no warranties except those expressly contained

herein. Seller disclaims all other warranties implied by law usage of the trade, course of dealing or

course of performance including, but not limited to, the Implied warranties of MERCHANTABILITY and

fitness for a particular purpose.

4. LIMITATIONS OF LIABILITY. The following limitations of Seller's liability are acknowledged by the

parties to be fair and reasonable and shall apply to any act or omission hereunder, and to any breach of

this contract of which these terms and conditions form a part:

CA-6 Analyzers Page vii

Page 8

a. Disclaimer of Damage. In no event shall Seller be liable for special, indirect, consequential or

incidental damages whether arising under contract, warranty, tort, strict liability or any other theory

of liability. Such damages include but are not limited to loss of profits, loss of use of goods, damage to

property, and claims of third parties.

b. Suitability. Buyer acknowledges that it alone has determined the intended purpose and suitability of

the goods sold hereunder. It is expressly agreed by the parties that any technical or other advice given

by the Seller with respect to the use of the goods or services is given without charge and at Buyer's risk;

therefore Seller assumes no obligation or liability for the advice given or results obtained.

c. Notice and Time of Claims.

i. Buyer agrees to check and inspect all products against shipping papers and for damage or shortage

upon receipt of goods at destination.

ii. Every claim for shortage, damage in transit, or other cause visible upon inspection shall be deemed

waived by the Buyer, or the Buyer’s customer in the case of resale, unless delivered in writing to Seller

by Buyer thirty (30) days from the tender of delivery of the goods to Buyer, provided, however, that

claims for shortage must be made within seven (7) days of receipt.

iii. The parties expressly waive the statute of limitations and agree that any legal proceeding for any

breach of this contract shall be waived unless filed within one (1) year after the accrual of the cause of

action thereof.

5. FORCE MAJEURE. Seller shall not be liable for any delay in delivery, or failure to deliver, due to any

cause beyond the Seller’s control including but not limited to fires, floods, or other forces of the

elements; strikes, or other labor disputes; accidents to machinery; acts of sabotage; riots; precedence or

priorities granted at the request or for the benefit, directly or indirectly of the federal or any state

government or any subdivision or agency thereof; delay in transportation or lack of transportation

facilities; restrictions imposed by federal, state or other governmental legislation or rules or regulations

thereof. If Seller, in its sole discretion, determines that Seller’s performance hereunder would result in a

loss to Seller’s on this sale as computed under Seller’s normal accounting procedures because of causes

beyond Seller's control, then the Seller may terminate this agreement in whole or in part without

liability for any delay in the delivery of, or failure to deliver, the goods sold hereunder

6. TAXES AND OTHER CHARGES. The Buyer will pay, or reimburse Seller if it pays, any and all taxes or

tariffs or any other similar charges imposed upon this contract, the goods covered hereby or the delivery

or use or resale thereof.

7. FREIGHT CHARGES. If the sale hereunder is other than F.O.B. Seller's facility, this acknowledgement is

based upon the freight charges now in effect. In the event of an increase or decrease in applicable

freight charges before the goods are shipped, such charge in freight will be for the Buyer's account.

8. PRICES AND DELIVERY. Prices quoted herein are F.O.B. shipping point. Deliveries specified are only

our best estimate and are subject to change. This quotation is based upon freight charges now in effect.

Buyer will be invoiced at the freight charge prevailing at the date of shipment. Prices are firm for orders

meeting Seller's normal shipping schedules. If shipments are held or postponed for any reason other

CA-6 Analyzers Page viii

Page 9

than Seller's fault, and a price increase becomes effective during the period of such hold or

postponement, the increase will apply to all shipments that are held or postponed thirty (30) days or

more from the effective date of the increase.

9. PAYMENTS. If in the judgment of Seller the financial condition of Buyer at any time prior to shipment

does not justify the terms of payment specified, Seller may cancel the order, withhold shipment, and/or

require full or partial payment in advance. If payment is not made when due, Seller may suspend all

future delivery or other performance with respect to Buyer without liability or penalty and, in addition

to all other sums payable hereunder, Buyer shall pay to Seller (i) the reasonable costs and expenses

incurred by Seller in connection with all actions taken to enforce collection or to preserve and protect

Seller’s rights hereunder, whether by legal proceedings or otherwise, including without limitation

reasonable attorneys’ fees, court costs and other expenses and (ii) interest on all amounts unpaid after

30 days charged at the monthly rate of 1-1/2% or the highest rate permitted by law, whichever is lower.

10. CANCELLATION OR ALTERATION. Buyer may not alter or cancel any order without Seller’s written

consent. For any order altered or cancelled with Seller's consent, Buyer must pay for all expenses and

labor incurred up to the time of Seller’s consent, plus a reasonable percentage for profit. Any order

delayed or deferred by Buyer will be subject to price escalation for increased costs of production, and

any other expenses caused by the delay. Material on such orders will be stored at Buyer's risk. Seller

reserves the right to invoice Buyer and require payment before shipment of any delayed or deferred

order.

11. TITLE AND RISK OF LOSS. Title and risk of loss shall pass to buyer at Irvine, California, unless

otherwise specified in the contract. If delivery is made by common carrier, risk of loss shall pass upon

delivery to the carrier. Claims for loss or damage in transit must be made by Buyer to the carrier. Seller

accepts no responsibility for loss or damage to product in transit.

12. PATENT OR TRADEMARK INFRINGEMENT. If the goods sold hereunder are to be prepared for

manufacture according to Buyers specification, Buyer shall indemnify Seller against any claim or liability

for patent, trademark, service mark or trade name infringement on account of preparation,

manufacture and/or sale.

13. NON-WAIVER. If Government Contract Regulations require the addition, deletion, or modification of

these terms and conditions upon prior notification to Seller and Seller's written acceptance thereof,

such changes shall become a part of these terms and conditions. Seller shall not be bound by any

Government Contract Regulations applicable to Buyer’s contracts with the U.S. Government unless

Buyer has expressly acknowledged, on the face of this document, the applicability of such Regulations to

the transaction between Buyer and Seller contemplated herein. Absent such acknowledgement, Seller is

making the assumption in issuing this document that no such Regulations apply.

14. JURISDICTION. All such disputes shall be resolved in a court of competent jurisdiction in Orange

County, California. Buyer hereby consents to the jurisdiction of the State and Federal Courts sitting in

Orange County. Not withstanding the above, should either party contest the jurisdiction of such courts,

the other party may institute its suit in any court of competent jurisdiction.

CA-6 Analyzers Page ix

Page 10

15. APPLICABLE LAW. All questions arising hereunder or in connection with the quotations or any order

submitted in connection therewith and/or the performance of the parties hereunder shall be

interpreted and resolved in accordance with the laws of the state of California without regard to its

conflict of law provisions and excluding the United Nations Convention on the International Sale of

Goods.

Revision A

RETURNED GOODS POLICY

All requests for returned goods must be initiated through our Customer Service Department. Please call

our phone number (949) 336-6060 with the specifics of your request. The following conditions must be

satisfied for consideration of applicable credit for the return of products purchased from ElectroChemical Devices:

1) The item is unused and in the original package.

2) The item was shipped directly from Electro-Chemical Devices.

3) The item has not been damaged in shipment to Electro-Chemical Devices.

4) The item is saleable;

a) Items containing date-sensitive parts such as electrodes, must be returned

within 1 month of the invoiced date.

b) Items without date-sensitive parts must be returned within 3 months of the

invoiced date.

A Return Authorization Number must be obtained from Customer Service and provided on all

paperwork and packaging. To obtain a Return Authorization Number, please provide the reason for

return, the date of purchase, your original purchase order number, and either our order number (on the

packing slip or invoice) or our invoice number. The issuance of a Return Authorization Number is a

verbal approval for return only and does not guarantee credit or allowance. Returned goods must be

received within 30 days of the issuance date of the Return Authorization Number or it will become null

and void.

Necessary physical and mechanical inspection is completed upon receipt of the item. Applicable credit

or equivalent allowance is determined after inspection of the returned item. If all of the above

conditions are met, and the item has been approved to return to our stock, a restocking charge of 25%

of the purchase price is deducted from the applicable credit.

CA-6 Analyzers Page x

Page 11

IMPORTANT SERVICE INFORMATION

Use only factory authorized components for repair. Tampering or unauthorized substitution of components may

adversely affect the operation of this product and may void the warranty.

If service or repair is required, please obtain the serial number(s) or sales order number of the product(s) in

question and contact ECD’s Service Department at:

+1-800-729-1333 (USA/Canada) or +1-949-336-6060

or email Service@ecdi.com

A Return Material Authorization (RMA) number must be obtained from the service department before returning

any material to ECD. All material returned to ECD shall be shipped prepaid to the factory.

UNPACKING THE INSTRUMENT

Your Electro-Chemical Devices instrument has been carefully packaged to protect it from damage during

shipment and dry storage. Upon receipt please follow the procedure outlined below.

1. Before unpacking, inspect the condition of the shipping container to verify proper handling by

the carrier. If damage is noted, save the shipping container as proof of mishandling for the

carrier.

2. Check the contents of the shipping container with the items and quantities shown on the

packing list. Immediately report any discrepancies to ECD.

3. Save the original packing material until you are satisfied with the contents. In the event the

product(s) must be returned to ECD, the packing material will allow you to properly ship it to

ECD.

4. Familiarize yourself with the instrument before installation, and follow proper installation and

wiring procedures.

CA-6 Analyzers Page xi

Page 12

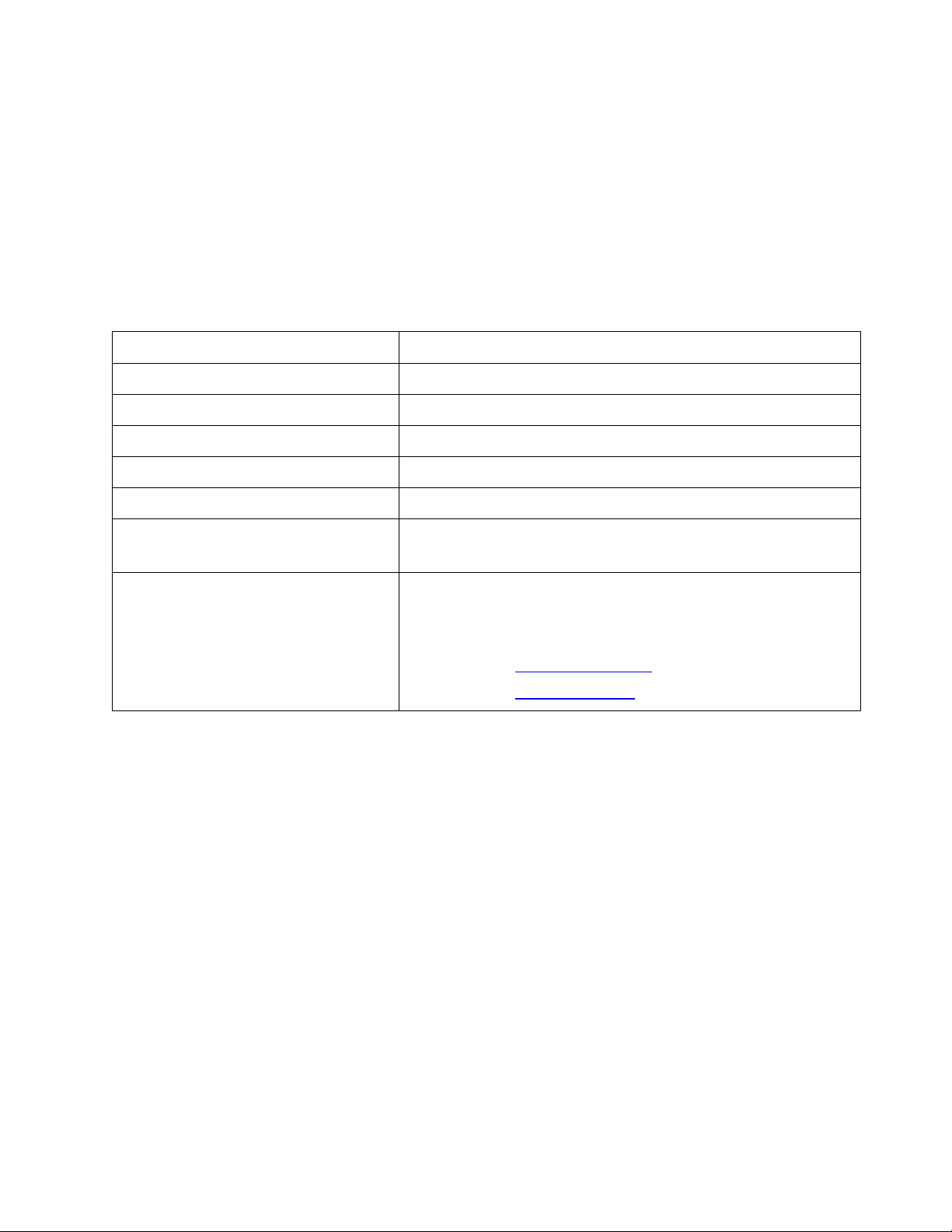

Product Name

CA-6 Analyzer

Product Model

CA-6 Colorimeter, Hardness, 0-1000 ppb as CaCO3

Purchase Date

October 2014

Serial No

CL428,

Warranty Period, Begin-End Dates

1 year from date of shipment

Password

Service 1111, Admin 6699

Contact Details,

Contact Details

1.0 OVERVIEW

Thank you for purchasing our Model CA-6 Analyzer.

The CA-6-Analyzer was designed and manufactured to be an easy-to-use, high-sensitivity and low-cost

measuring instrument. This Analyzer should give you many years of reliable and hassle-free operation

with regular care and maintenance.

This document is the Operating Manual for the Analyzer. We recommend that you enter the information

below the first opportunity you get.

Your Distributor

ECD Direct

Electro-Chemical Devices

Phone: +1-949-336-6060

Fax: +1-949-336-6064

Email:

Internet: www.ecdi.com

sales@ecdi.com

We recommend that you make a copy of your Analyzer TEST CERTIFICATE (chapter 11), record the

Analyzer's Passwords on it and store the copy somewhere safe.

CONTENTS:

1. CA-6 Colorimeter

2. Tubing Kit, Door Key

3. 2 Reagent Bottles

4. CA-6 Instruction Manual

5. Final Test document (See Chapter 11)

1

Page 13

1 liter each reagent in 30 days of continuous operation with no wait time

Sample flow for the fast loop

reservoir:

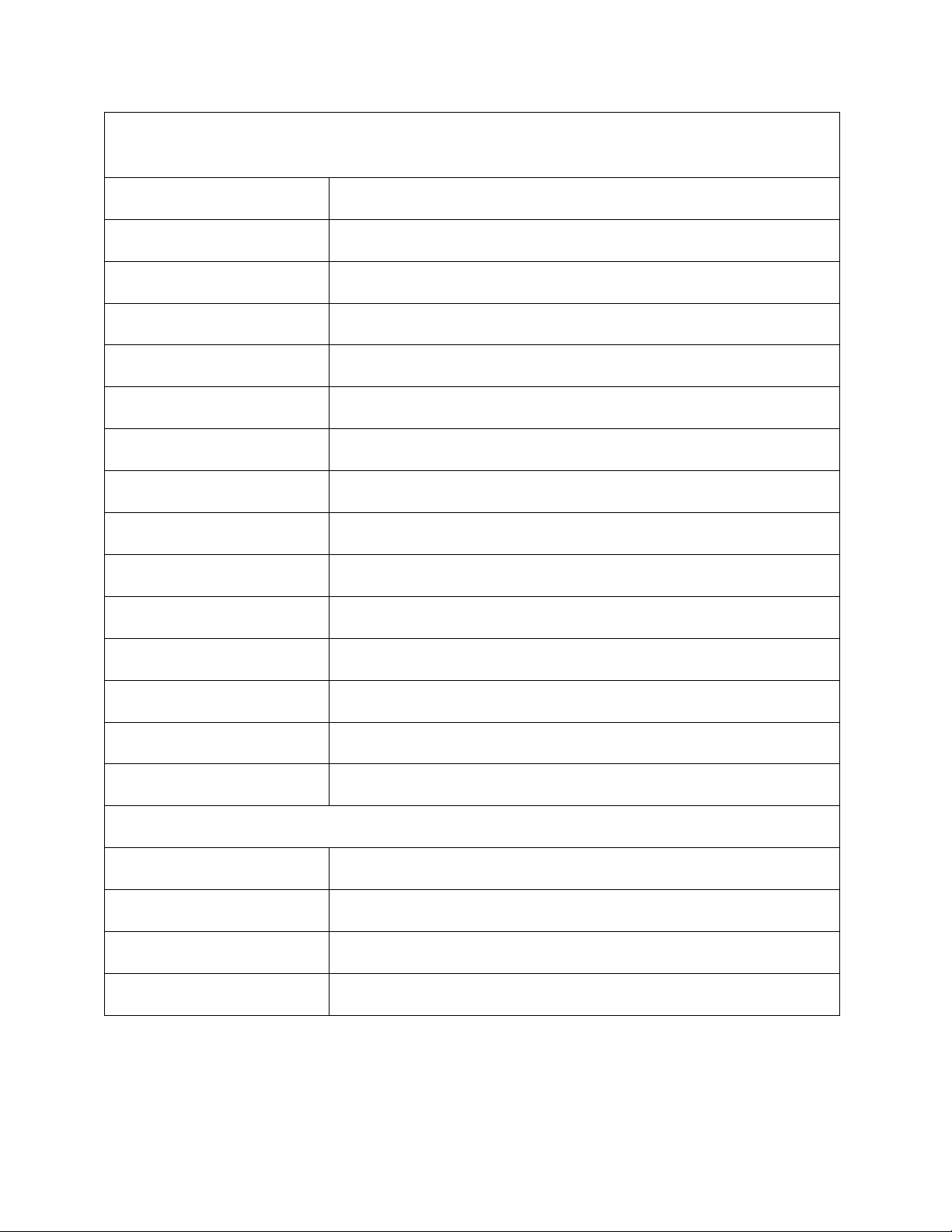

1.0.1 CA-6 Technical Specifications

Analysis:

Method:

Measuring range:

Response time:

Repeatability:

Drift:

Power supply:

Mounting:

Operating temperature:

Cabinet:

Dimensions:

Colorimetric parameters

Photometric differential absorbance

0.00 – 1.00 ppm configured 000 – 1000 ppb

6 minute 10 second cycle plus wait time

+/- 2% on absorbance value with turbidity < 80 NTU

+/- 2% per month on the absorbance measurement

110-220Vac, 50-60 Hz 80 VA

Wall mounting or with optional bench support

5°C to 50°C

Stainless steel, epoxy powder coated

15”W x 24”H x 8.25”D (380mm W x 600mm H x 210mm D)

Weight:

Reagent consumption:

Analog output:

Alarms:

Sample

Inlet sample pressure:

Outlet sample pressure: Atmospheric, waste tubing ⅜” O.D. x ¼” I.D.

Connections:

Approx. 38 lbs (17 kg)

between cycles

4-20 mA

4 configurable relays

Atmospheric

100-500 ml / min

To the fast loop reservoir with flexible tubing ¼”O.D. x ⅛” I.D.

2

Page 14

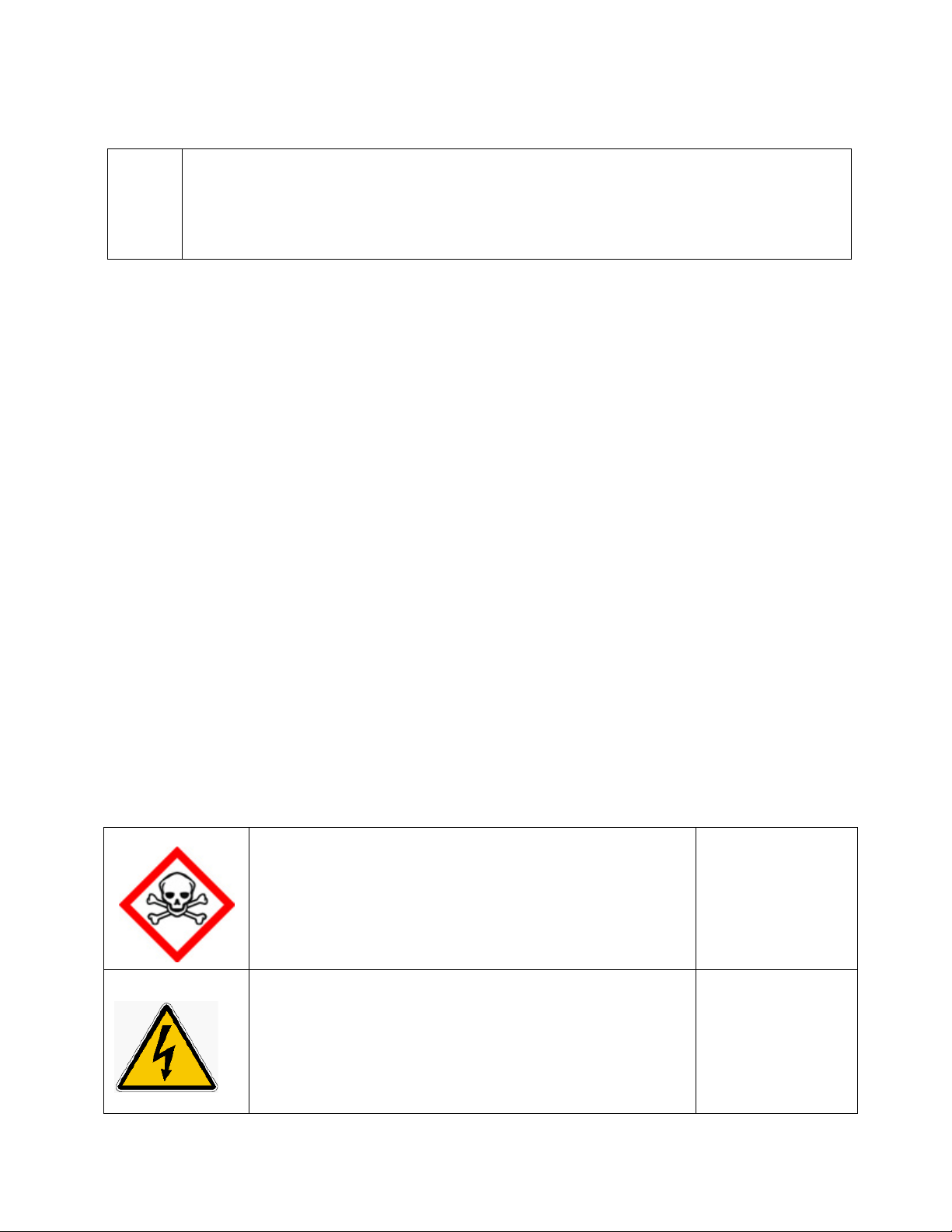

Poisonous Substances:

Very hazardous to health when inhaled, swallowed or when they

Avoid contact with the human body and immediately contact a

Involved parts:

Hazard of electrical shock

s and maintenance on electrical

with this symbol should be made by qualified

accordance with national or local regulations.

Involved parts:

!

1.1 Safety Precautions, Instructions and Hazards

This Manual contains important information required to install, start up and operate the

Model CA-6 Analyzer. Please read the entire manual carefully before installing or placing the

analyzer into service!

1.1.1 General information

Pay attention to all Caution and Danger labels present on the analyzer and all Caution and Danger

statements written in this manual.

Electro-Chemical Devices shall not be liable for errors contained herein and/or for the incorrect use of

the analyzer. The analyzer’s users must read the User’s Manual before placing the CA6 analyzer into

service. Observe the instructions and follow all national and local regulations and laws regarding

workers health and safety.

The use, maintenance and service of this analyzer is restricted to qualified personnel, fully trained in the

analyzer’s operations. These personnel are intended to be physically and mentally fit and not under the

influence of drugs or alcohol.

When the analyzer is not in use, it should be protected from intentional or unintentional powering up,

using a proper power switch.

Failure to do so or non-observance of hazards or dangers warnings could result in death or serious injury

to the operators or damage to the analyzer.

Before using the analyzer it is necessary to visually check for damage to the safety devices and to report

them to your supervisor even if they don’t cause analyzer stop or malfunction.

All of the analyzer’s components are installed inside a metallic enclosure; a special key is required to

open the door, only qualified maintenance personnel should have access to the key.

1.1.2 List of warnings and potential dangers

The table below is a list of Hazard and Danger Warning Labels found on the analyzer and/or in this

manual. Damaged or illegible labels should be replaced with new ones by the analyzer owner.

Table 1-1: List of Hazards and Dangers

come in contact with the skin. May even lead to death. Danger!

physician in case of contact.

This symbol is used to represent a hazard of severe electric shock or

electrocution. All adjustment

devices labeled

personnel in

Qualified Personnel means a person who has been fully trained and

· fluids section

· reagent containers

·main power supply

·peristaltic pump motor

·input terminal

3

Page 15

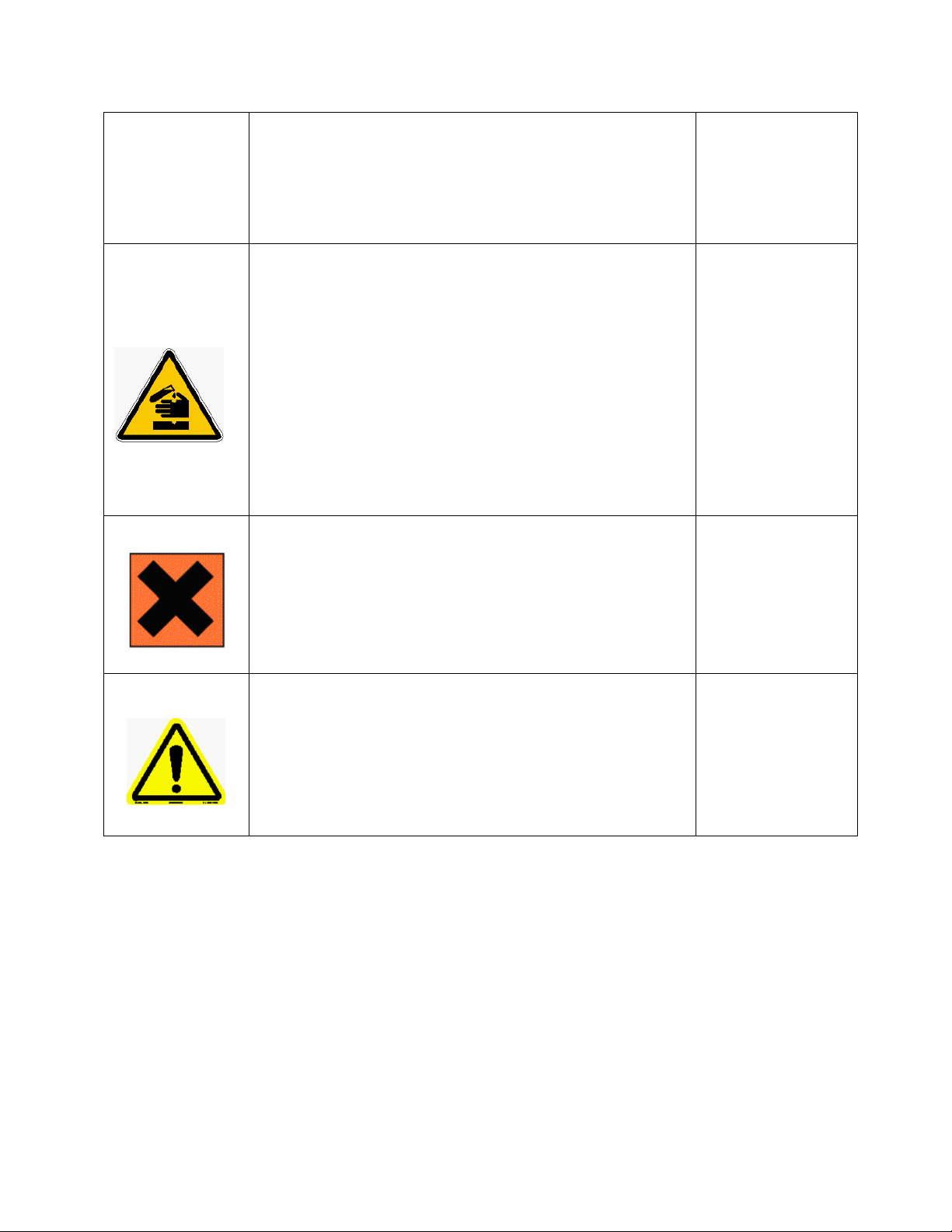

has professional experience to avoid electrical hazards and dangers.

Hazard of chemical burns

Warning of general hazard

To avoid potentially fatal electrical shock and/or analyzer damage

always disconnect input power to analyzer before servicing.

This symbol is used to represent a hazard of severe burns or injury

due to handling of dangerous chemicals. All handling, maintenance

and filling operations of chemicals labeled with this symbol should

be made by qualified personnel in accordance with national or local

regulations. Qualified Personnel means a person who has been fully

trained and has the professional experience to avoid chemical

hazards and dangers. Before handling the chemicals or proceeding

with service operations, read the material safety data sheets

supplied with each chemical and follow all necessary precautions

when handling.

Harmful

Involved parts:

· Fluids section

· reagent containers

Involved parts:

Specific warning depending on the parameter analyzed and the

chemical colorimetric method used. See appendix of the manual.

This symbol means that is necessary read the manual before

proceeding to any service operation in order to properly perform

the operation. Only qualified personnel, fully trained on the

analyzers use and maintenance are allowed to proceed with service

operations on the unit.

1.1.3 Reagents

The Model CA-6 Analyzer is based on colorimetric analysis methods, using chemical solutions. For the

dangers and hazards regarding the chemicals used for the analysis, refer to the Chapter 5 Reagents

Preparation.

Make sure that proper safety precautions are taken (e.g. using safety gloves and glasses) during handling

the chemical solutions and the reagents containers / bottles.

Read carefully the Material Safety Data Sheets of each chemical.

All bottles of the reagents must be labeled with the specific hazards and dangers labels.

· Fluids section

· Reagent containers

4

Page 16

1.1.4 Sample Stream

Take appropriate precautions to avoid direct contact with sample stream. It is the responsibility of the

user to collect all the information and take all the precautions regarding physical, chemical, radiation

and/or biological hazards and dangers coming from sample stream and/or sample vapors. It is also

responsibility of the user to collect all the information and potential hazards regarding the chemical and

physical compatibility of sample stream with the analyzer materials.

Table 1-2: List of materials used in the Model CA-6 Analyzer

Pump tubing Silicon or Norprene®

Fittings PP

Connection tubing Norprene® / Si lic o n

Colorimetric cell Quartz Glass

Micro perista ltic Pump Norprene® / PP

Mixing membrane pump PP / EPDM

Pinch valve Norprene® / Silico n tubing

1.1.5 Waste disposal of the liquid reagents for the colorimetric reaction

The liquid from the drain of the colorimetric cell may need to be collected in a separate canister. For

guidelines on disposal consult the requirements of the Local Authority for chemical waste regulation.

Arrange removal by a Disposal Company.

1.1.6 Analyzer General Hazards

1.1.6.1 Electrical precautions and hazards

Power to the CA-6 Analyzer must be routed through an ON/OFF power switch.

Mind the electrical shock and/or electrocution labels placed on the analyzer.

All electrical devices powered by 110/220 VAC present the hazard of electrical shock or electrocution.

The analyzer enclosure is equipped with a door that requires a special key for opening to protect all the

personnel involved in analyzer use and maintenance.

Only Qualified Service Personnel should have access to the key that opens the analyzer.

Before servicing the analyzer or any parts that are electrically powered, turn off the power to avoid the

risk of electrocution.

Inside the analyzer’s lower level, the electrical protection is IP2X. Analyzer’s enclosure is IP54.

Protection against electrical shock is guaranteed by the grounding of all isolated metal surfaces.

Grounding terminal/screw is located inside the electrical enclosure, in Upper Left position.

It is the user’s responsibility to periodically check the efficacy of analyzer’s electrical ground.

In case of loss of power, the analyzer stops and automatically restarts as soon as power is returned.

5

Page 17

1.1.6.2 Operating precautions and hazards

HAZARD: Mechanical hazards caused by moving parts such as the peristaltic pump, the motor...

PREVENTIVE ACTIONS:

To avoid risks the analyzer’s moving parts have been designed, built and located in an enclosure with a

special key. When present inside the enclosure, these parts have protection covers to avoid any contact

and physical injuries to users.

HAZARD: Hazard of burns and poisoning caused by contact with dangerous chemicals

PREVENTIVE ACTIONS:

To avoid risks, the analyzer’s parts that can cause contact with chemicals have been designed, built and

located in closed enclosure with a special opening key. Before servicing the liquids section, read the

material safety data sheets supplied with each chemical to take all the necessary precautions when

handling. Wear eye protections, gloves, mask and protective clothing if necessary.

HAZARD: Hazard of poisoning caused by waste gas leaking from the hydraulic parts or waste collector.

PREVENTIVE ACTIONS:

Install the analyzer in location of adequate dimensions and in a well ventilated area.

HAZARD: Hazard of electric shock and/or electrocution inside the electrical enclosure.

PREVENTIVE ACTIONS:

The analyzer’s electric equipment complies with EN 60204 requirements.

To avoid risks, the analyzer’s parts that can cause hazard of electric shock and/or electrocution have

been designed, built and located in an enclosure with a special key. When working inside the enclosure,

these parts have protective covers and warning labels to avoid any contact and serious injuries or death

to users.

Note:

Electrical equipment, input power and grounding must comply with all national and local regulations

and laws.

Check that the source voltage to be used corresponds with that requested by the analyzer.

Check periodically the power cord as well as the analyzer grounding.

1.1.6.3 Chemical and waste gas hazards

The analyzer has been designed, built and equipped to avoid risks caused by physical and chemical

factors such as noise, vibrations, radiations, dust, waste gas etc.

6

Page 18

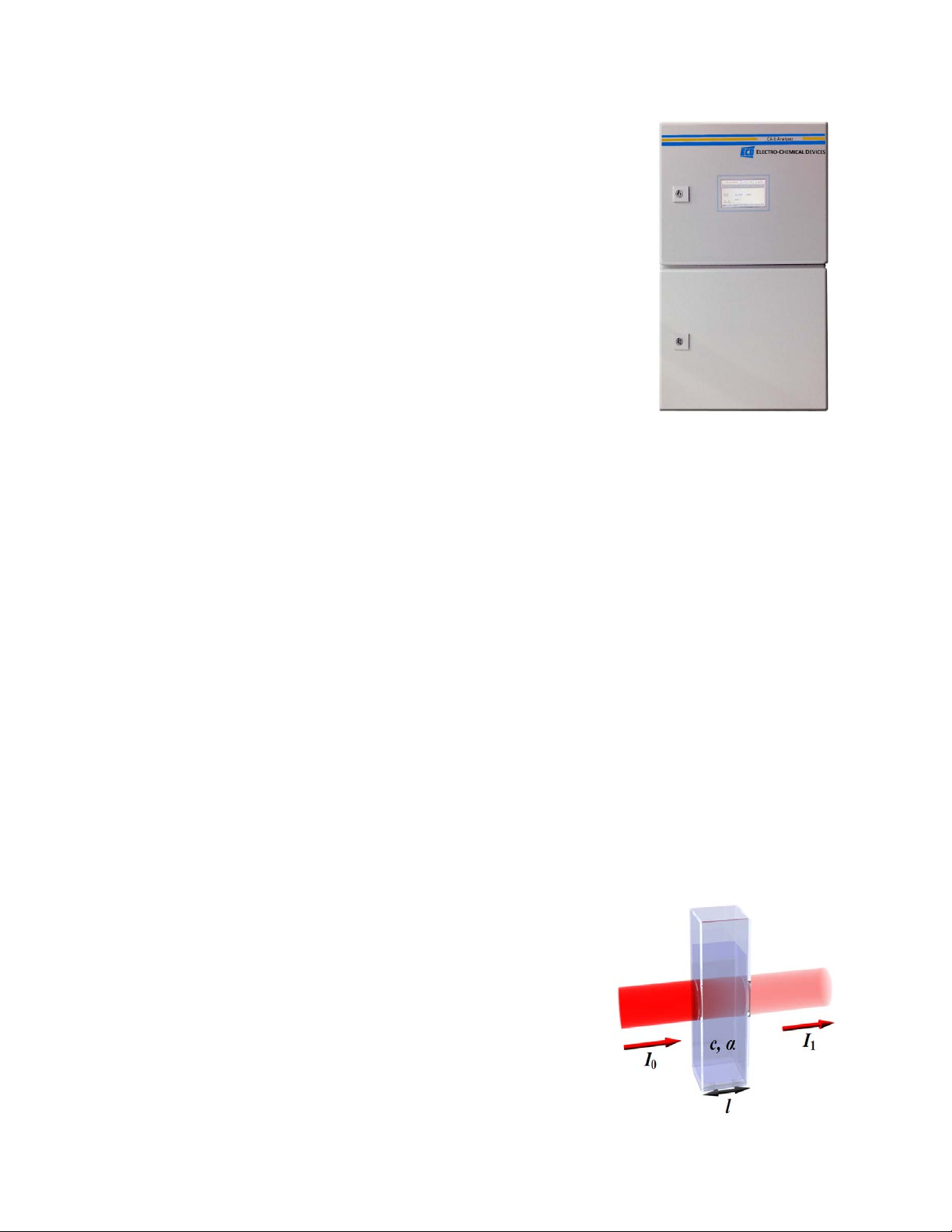

2.0 INTRODUCTION – Analyzer Description

This manual provides general information regarding the principles of

operation, the proper installation and operation of the CA-6 Analyzer.

The Model CA-6 is an on-line sequential sampling analyzer (a sequence of

sampling, analysis and result processing), using colorimetric methods.

The analyzer is assembled with two separated sections with two lockable

doors. The bottom section is the LIQUIDS section. It includes all of the

components involved in the flow, mixing and reaction stages of the sample

and reagents (sampling pump, colorimetric reaction cell, reagents micro

pumps,..). Numerous analysis configurations can be programmed,

depending on accessories and of the number of micro pumps mounted in

the Liquid Section. The top section is the ELECTRICAL enclosure. It includes

the main power supply, the controller PCB assembly and the touch screen

interface.

2.1 Applications

The measurement is a colorimetric analysis using an LED light source and a heated colorimetric cell

designed for measuring trace amounts of analyte in water.

2.2 Working principle: Lambert-Beer law

A colorimetric determination is based on the color formation of a solution after the addition of reagents.

The Absorbance of the solution is measured at a specific wavelength and is related to sample

concentration according to 'Beer's law'.

Lambert–Beer law is an empirical relationship relating the absorption of light to the properties of the

material through which the light is travelling.

The law states there is a logarithmic dependence between the transmission (transmissivity), T, of light

through a substance and the product of the absorption coefficient of the substance, α, and the distance

the light travels through the material (i.e. the path length), ℓ.

The transmission (or transmissivity) is expressed: T = I

Absorbance for liquids is defined as the negative logarithm of the transmittance:

A= - log

T =log101/T =log10I0/I

10

I0: light intensity through the sample before colorimetric reaction

I

: light intensity through the sample after colorimetric reaction

1

In most cases the absorbance has a linear correlation to sample

concentration so a calibration line just requires a zero and span value.

(Zero analyte concentration and the maximum expected

1

/ I

1

0

concentration) are needed. Multiple analysis of the standard are

averaged to gain a reliable calibration line. (See section 8.7)

7

Page 19

Typical absorbance values range from 0 to 1, but it can be greater than 1.

When the absorbance is 0 then none of the light passing through the sample is absorbed. The intensities

of the sample and reference beam are both the same, so the ratio Io/I

is 1. Log10 of 1 is zero.

1

An absorbance of 1 happens when 90% of the light at that wavelength has been absorbed - which

means that the intensity is 10% of the blank sample reading.

In that case, Io/ I

is 100/10 =10 and log10 (10) = 1.

1

2.2.1 Absorption photometry (Colorimetry):

The methods used are based on the formation of a colored complex of the analyte with a color reagent.

Light with a specific wavelength is transmitted through the reaction mixture. The absorbance of light by

the formed complex is measured by a photometer and related to the concentration of the analyte.

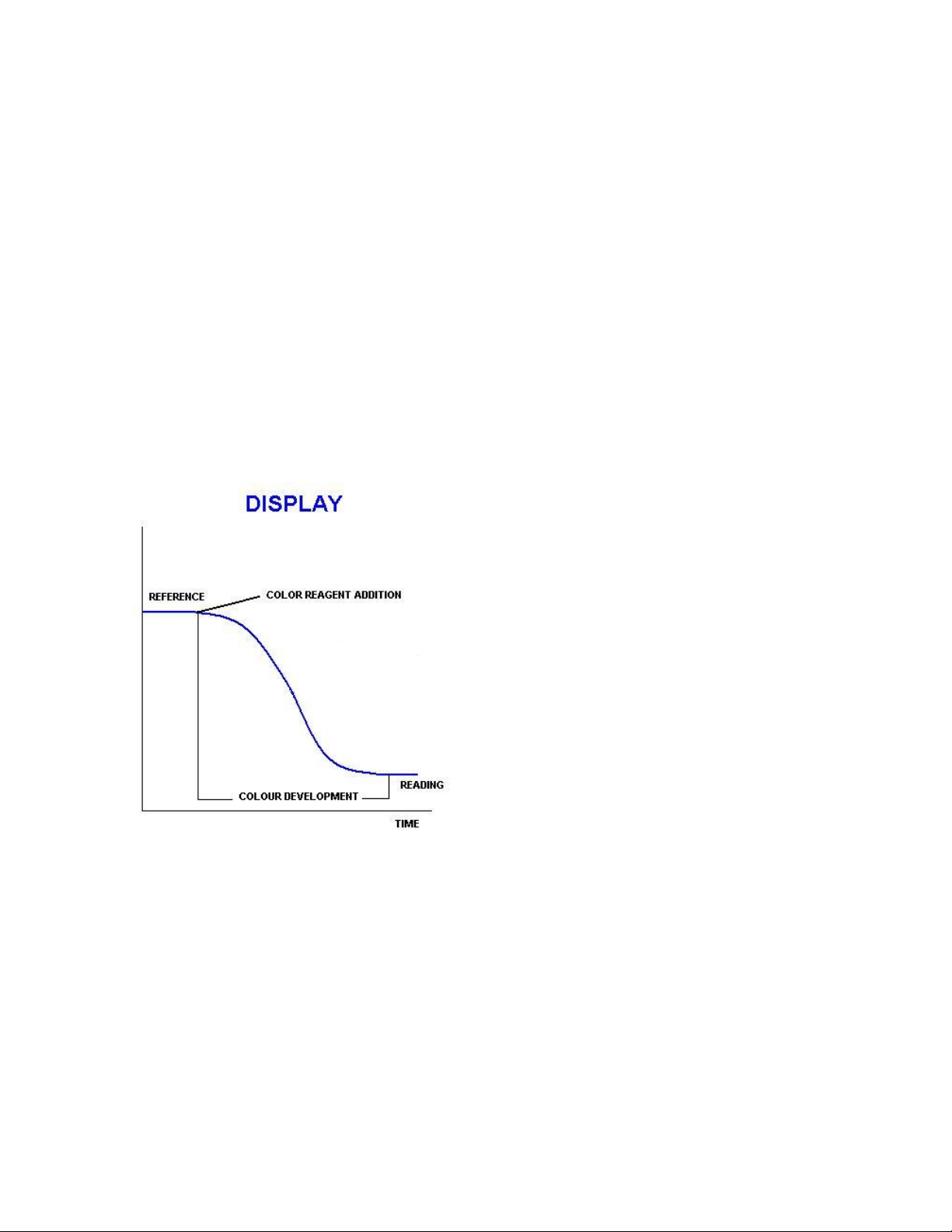

Fig. 2-2: Color development

Absorbance = log (reference / sensor readin g)

The DISPLAY screen of the CA6 displays the live Sensor reading, the recorded Reference reading, the

recorded sensor Reading, the Absorbance and the Blank (the absorbance through deionized water).

8

Page 20

Conditioning, rinsing and sampling

First the cuvette is drained and rinsed (these steps can also be

and the

Addition of reagent(s)

Depending on the method one or more reagents are added before

Mixing and wait

The mixing pump is activated and the liquid is pumped from the

lower part to the upper part of the colorimetric cell. The waiting

2.3 Analysis Cycle

A typical Analysis Program in the Model CA-6 would have the following structure: Rinse the colorimetric

reaction cell and take a sample, add one or more reagents like a buffer or masking agent and then make

the first measurement, the reference measurement. The reference measurement eliminates interfering

factors such as sample color and turbidity, miscellaneous color from the reagents and refractive index

variations.

After the reference reading, the color producing reagents are added. The sample is mixed and allowed

time to complete the color forming reactions before taking the second measurement, the Reading

measurement. The reference and reading values are used to calculate the concentration using the

calibration factor. The reaction cell is drained and rinsed several times before starting the next

measurement.

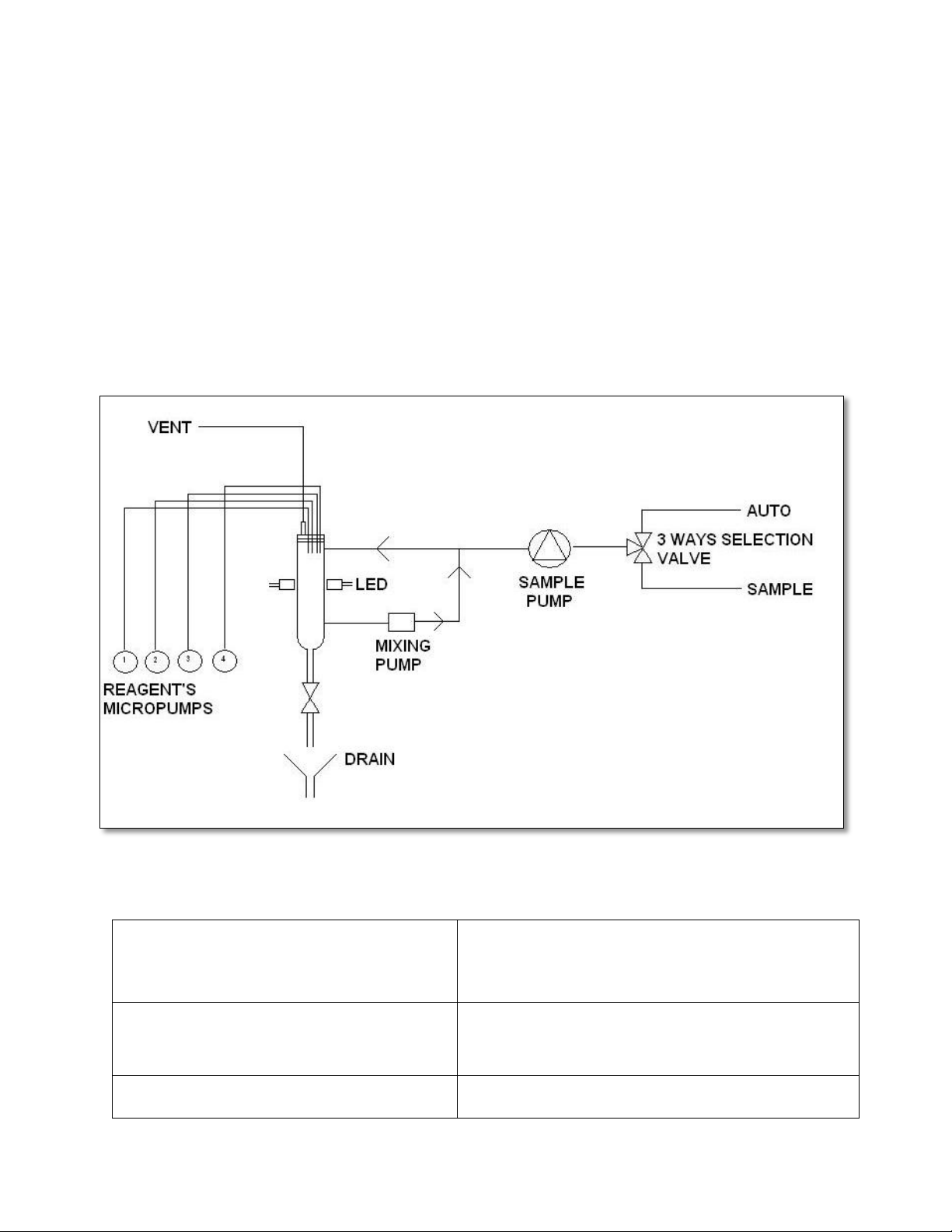

Fig. 2-3 Flow diagram

2.3.1 Typical Run Sequence:

Drain, rinse and sample functions

Add reag function

programmed at the end of the run). The hydraulic lines

colorimetric cell are rinsed prior to taking the actual sample. Then

the sample is taken.

the reference reading.

9

Page 21

time is programmed in order to eliminate bubbles and allow

First measurement

Measures the light intensity for the base reference value, in order to

start from a fixed reference point and eliminate interfering factors

Addition of color reagent(s)

Depending on the method one or more reagents may be added for

Mixing and wait

The mixing pump is activated and liquid is pumped from the lower

Reading, absorbance and concentration calculation

Reading of the light intensity after the colorimetric reaction,

Drain, conditioning, rinsing, sampling

Drain and rinse of the hydraulic lines and the colorimetric cell.

Waiting time (analysis frequency)

The wait function allows the frequency of the analysis to set.

Mix and wait functions

Reference function

Add reag function

Mix and wait functions

Absorbance and Calculation

Drain, rinse and sample functions

Wait function

suspensions to settle ...

(sample turbidity, color...).

the color development.

part to the upper part of the colorimetric cell; mixing the sample and

the reagent(s). The waiting time is programmed to provide adequate

time to complete the colorimetric reaction.

calculation of the absorbance and of the concentration.

2.3.2 Settings

Analysis cycle – Extra cycle (second level password, administration)

These menus list the sequence of programmable operations run by the analyzer. See actual program

sequences in Section 11 at the rear of the manual.

Both the Analysis Cycle and the Extra Cycle menus have 30 programmable steps. Each step has an

operation and a time associated with it. The time of the operation is in seconds and the maximum

programmable value is 900 seconds. See the list of operations on the following pages. The operations of

absorbance, calculation, calibration, validation, blank and print require only few seconds, 1-2 seconds

each.

The modular design and easily programmed operations make it possible to automate most any

colorimetric laboratory method with up to 4 reagents.

10

Page 22

2.3.3 Programmable Functions

Rinse #1

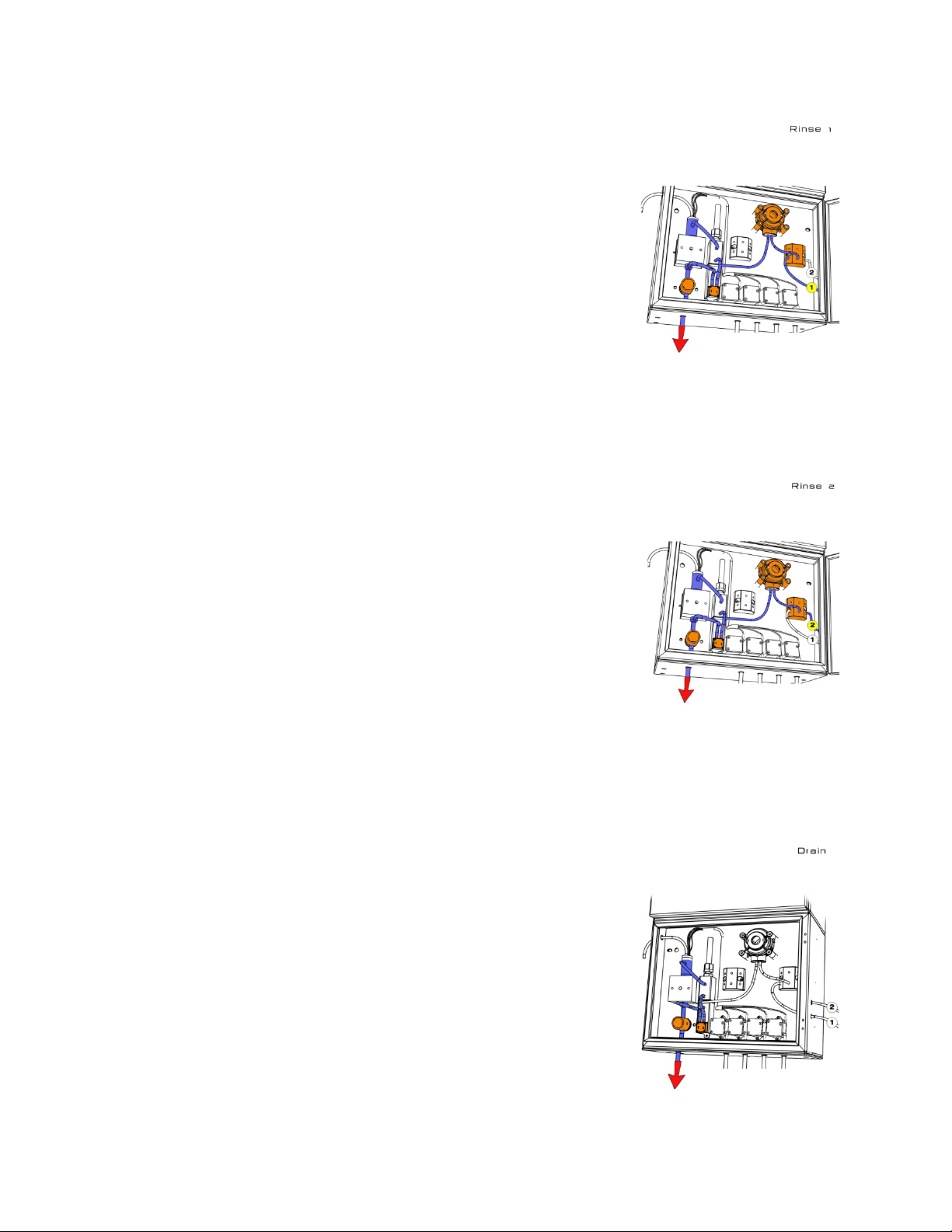

Rinse #1 opens the bottom pinch valve and Sample #1 flows directly to the

drain. The rinsing time is set in seconds.

RINSE #1 = left side of the selection valve

Rinse #2

Rinse #2 opens the bottom pinch valve and Sample #2 flows directly to the

drain. The rinsing time is set in seconds.

RINSE #2 = right side of the selection valve

Drain

Drain opens the bottom pinch valve, drains colorimetric cell and mixer. The

drain time is set in seconds.

11

Page 23

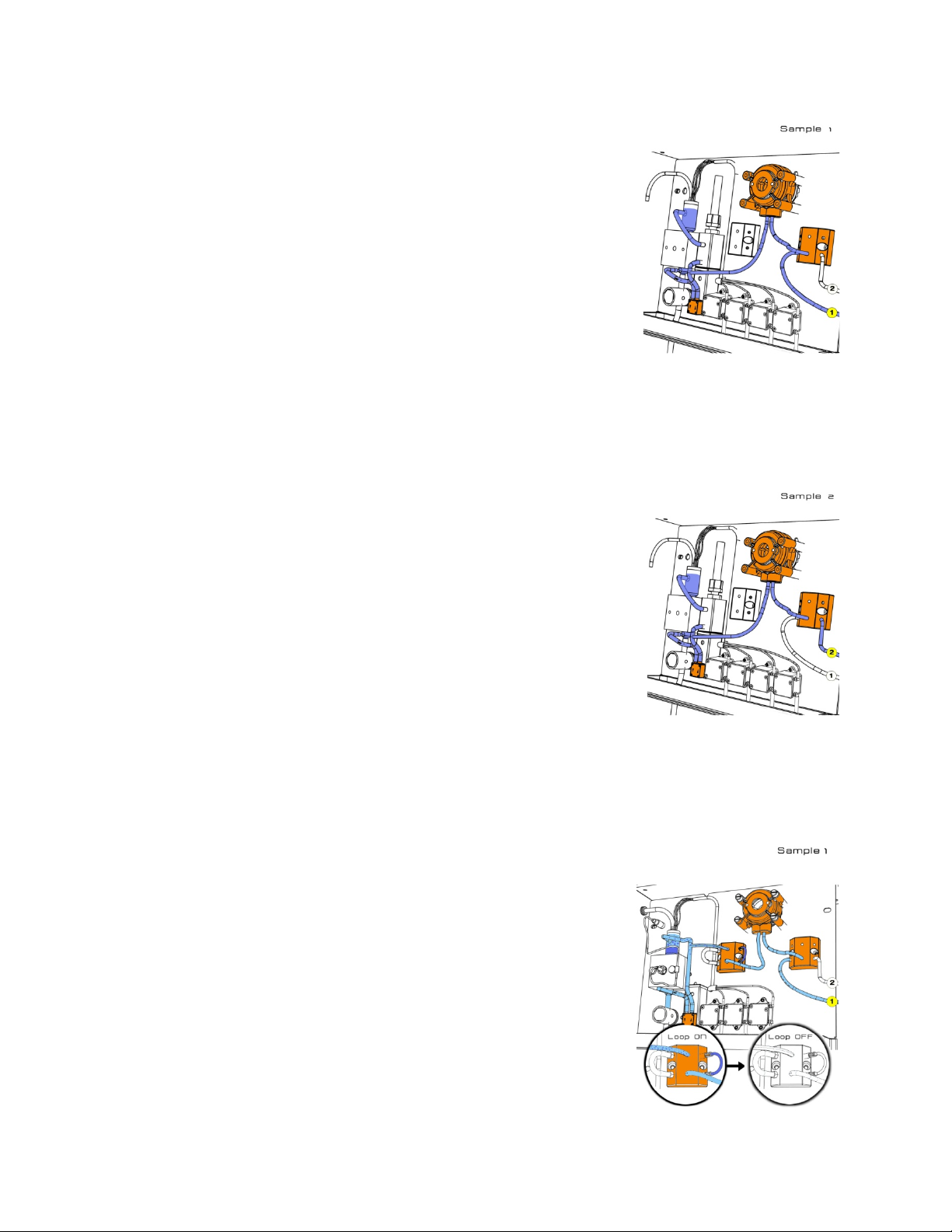

Sample #1

Sample #1 actuates the peristaltic pump with the bottom pinch valve closed

and the colorimetric cell fills with sample #1. The sample time is set in

seconds.

SAMPLE #1 = left side of the selection valve

Sample #2

Sample #2 actuates the peristaltic pump with the bottom pinch valve closed

and the colorimetric cell fills with sample #2. The sample time is set in

seconds.

SAMPLE #2 = right side of the selection valve

Dilution options

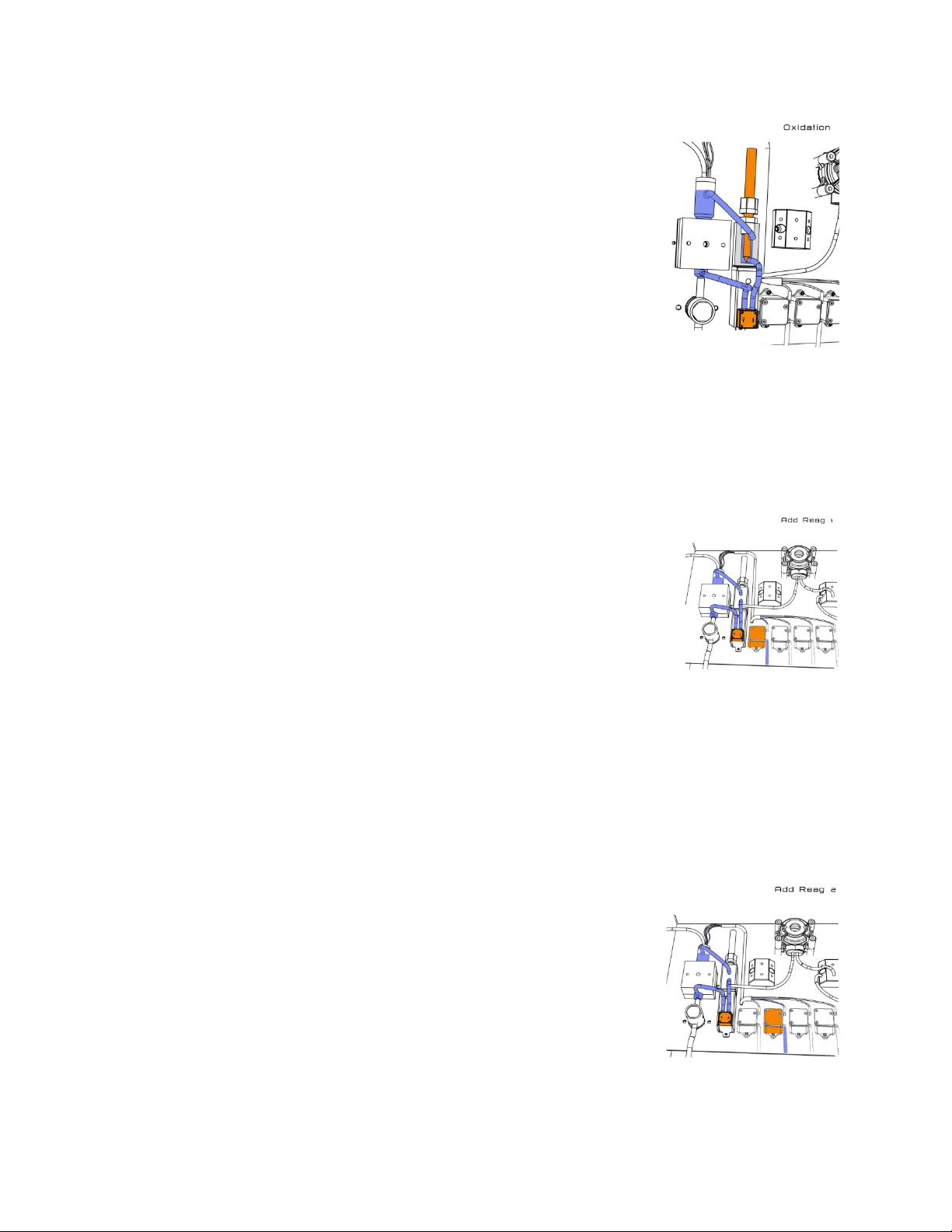

Loop On

Loop On allows the sample liquid (sample line #1) that is to be diluted to

flow through the Sample Loop. The Loop On time is set in seconds.

Loop off

Loop Off traps the sample inside the loop tubing while the sample fluid is

flushed from the lines with the dilution water. The Loop off time is set in

seconds.

Loop On

Loop On for the dilution fluid, DI water (sample line #2), dilutes the sample

in the loop tube and fills the Colorimetric Cell.

12

Page 24

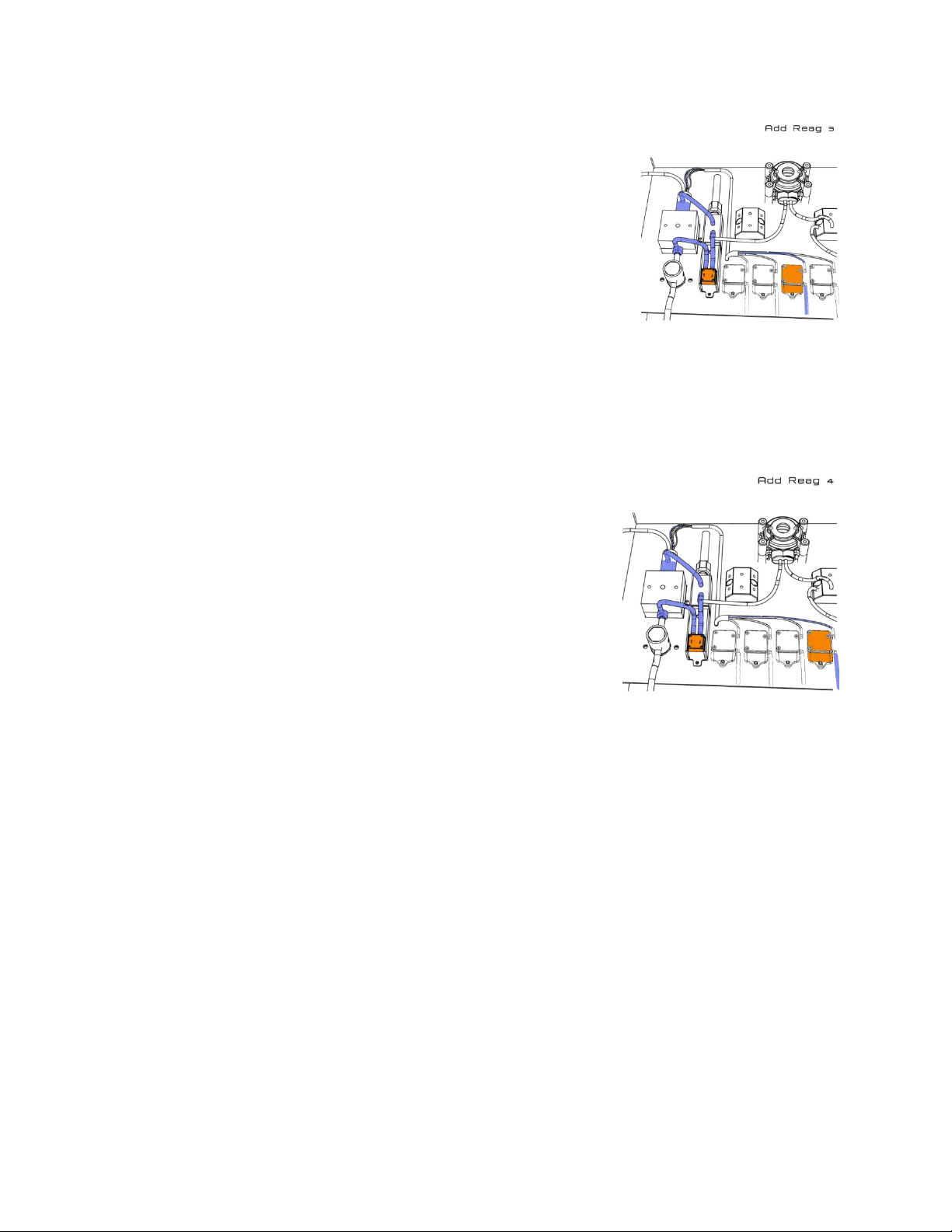

Aux on

Aux On activates an optional auxiliary operation (a digestion, oxidation or

auto-function for a dilution configuration). The picture shows the oxidation

option (On switches the UV lamp on).

Aux off

Aux Off stops the optional auxiliary operation.

Add rea #1

Add rea #1 turns on the micro peristaltic pump for the addition of reagent #1. The

mixing pump is circulating the sample as the reagent is being added. The Add Rea

#1 time is set in seconds.

Add rea #2

Add rea #2 turns on the micro peristaltic pump for the addition of reagent #2.

The mixing pump is circulating the sample as the reagent is being added. The

Add Rea #2 time is set in seconds.

13

Page 25

Add rea #3

Add rea #3 turns on the micro peristaltic pump for the addition of reagent

#3. The mixing pump is circulating the sample as the reagent is being

added. The Add Rea #3 time is set in seconds.

Add rea #4

Add rea #4 turns on the micro peristaltic pump for the addition of

reagent #4. The mixing pump is circulating the sample as the reagent is

being added. The Add Rea #4 time is set in seconds

.

Wait

The waiting time is set in seconds. Wait puts the CA6 in Stand By mode.

Mix

The mixing time is set in seconds.

Reference

The reference measurement is the first point for the calculation of the absorbance, I

. Reference sets the

0

time, in seconds, of when to take the base intensity measurement.

Absorbance

Absorbance sets the time, in seconds, of when to take the colored intensity measurement, the Reading,

I

, and calculate the absorbance, I0/ I1. Typically 1 – 2 seconds

1

Calculation

Calculation sets the time in seconds to convert the absorbance reading into a concentration reading and

sends the calculated value to the main display. Calculation uses the absorbance reading and the

calibration factor. Typically 1 – 2 seconds

14

Page 26

Calibration

Calibration sets the time in seconds, to calculate and record a new calibration factor after a calibration

extra cycle, Auto Calibration. Typically 1 – 2 seconds

Validation

Validation sets the time, in seconds, to calculate and display % Validation of a Known Standard in the

display screen using the current calibration factor as a calibration check. A 5 ppm sample reading 4.8

ppm, displays 96% after the validation extra cycle. Typically 1 – 2 seconds

Blank

The Blank function sets the time, in seconds, to enter a new blank calibration, calculating and recording

the new blank value in the calibration screen after a Blank extra cycle. Typically 1 – 2 seconds

Save Dtlog

Allows the measurement's reading to be saved in the internal Data logger, Typically 1 – 2 seconds, the

data log register is only written to after the internal 24 hour clock resets to 00:00:00

Relay #1

The Rele #1 setting allows a time, in seconds, to be assigned to the activation of relay 1. The relay

configuration is set in the Service Menu.

Relay #2

The Rele #2 setting allows a time, in seconds, to be assigned to the activation of relay 2. The relay

configuration is set in the Service Menu.

2.4 Components

The CA-6 Analyzer has three distinct sections:

1. The Liquids Section which includes all of the liquid

handling equipment. This is located in the Lower

Compartment, (pictured right, with Dilution Module).

2. The Electrical Section including power supply,

microprocessor controller, I/O and touch screen

interface are located in the Upper Compartment.

3. Reagents Section, the CA-6 can use up to 4 reagents,

these containers are typically stored below or beside

the analyzer.

2.4.1 Fast-loop reservoir

The external Fast-Loop Reservoir is a sample collection and

conditioning chamber for a sample coming from a pressurized

line or from the optional filtration unit. The overflow design

removes variations in sample line pressure as well as eliminating

any air bubbles from the sample line or bubbles generated by

the cleaning cycle of the optional filtration unit. Inside the fast-

15

Page 27

loop reservoir the sample is at atmospheric pressure and this allows the sample pump to provide a

consistent sample delivery to the colorimetric cell. In addition, the fast-loop reservoir provides an extra

quantity of sample in case of an interruption in the sample flow.

The stainless steel drain tubing keeps a constant sample level inside the container. The sample flow

should be adjusted for a continuous sample overflow through the stainless steel drain tube thereby

providing ample circulation to avoid suspended solids accumulation in the reservoir. A small hole at the

top of the stainless steel drain tubing allows the fast-loop reservoir to be easily emptied for cleaning

purposes.

The Fast-Loop reservoir uses a level sensor to verify sample volume. The loss of sample triggers the level

switch which places the analyzer in stand-by mode at the end of the current measurement cycle. When

the sample flow returns and refills the reservoir, the analyzer will automatically start a new cycle.

2.4.2 Sampling Pump

Model CA-6 uses a Masterflex® peristaltic pump for sampling. The Model # of the pump is printed on the

cover and the Model # includes the two digit tubing size

designator. Proper diameter and material of the tubing must

be used for proper functioning of the CA-6 Analyzer, use only

ECD replacement tubing and parts. The pump is located in the

liquid enclosure.

2.4.3 3 Way Valve

The use of 3 Way Valves allows the CA-6 to perform automatic

operations. An operator can set up auto-calibration, autovalidation or auto-cleaning functions. The valve is located in

the liquid enclosure.

2.4.4 Micro Peristaltic Pumps

The reagents are dispensed with “Micro Peristaltic Pumps“. Up to 4 pumps can be installed in the

analyzer, allowing the use of up to 4 different reagents. Every 1 second pulse of the pump allows a 0.05

ml dose of reagent. The pumps are located in the liquid enclosure.

2.4.5 Mixing Pump

The sample and reagents are mixed with a diaphragm pump. The liquids are pumped from the lower

part of the colorimetric cell to the upper part for a specified period of time. Flow direction (inlet / outlet)

of the pump is indicated with the symbols (V) and (Λ) on the pump body. The mixing pump is located in

the liquid enclosure.

2.4.6 Pinch Valve

The normally-closed pinch valve is used to control the draining or rinsing of the colorimetric cell. When

the valve is actuated it opens and drains the cell. The valve can be manually actuated by pressing the

black plastic face. The pinching jaws are sized for ⅜” O.D. Silicon or Viton tubing. The size and material of

the tubing is VERY IMPORTANT, use only ECD spares. The pinch valve is located in the liquid enclosure.

This tubing should be checked regularly for proper sealing.

16

Page 28

2.4.7 Colorimetric Reaction Cell

The colorimetric reaction cell is made of Quartz glass with a diameter of 16 or 25 mm, depending on the

measured parameter. The cell is located inside a thermostatic block held in place with 2 thumb screws.

The block can be easily removed to allow the cleaning of the glass cell.

2.4.8 Sample Drain

Tubing for the sample drain maintains a constant level of few cm of liquid in the colorimetric cell.

2.4.9 Electronic Components

The microprocessor based controller and its PCB assembly are located in the electronic section. The

cover and touch screen interface have been removed to show the internal construction. The controller

handles all analyzer operations. It collects all the information and data coming from the different

analyzer devices and controls all I/O dialogue with the user touch screen interface and data transfer

equipment. Remove the cover to adjust the REFERENCE LED voltage. This adjustment should only be

made when a CLEAN reaction cell filled with deionized water reads below 8. Turn the potentiometer

clockwise to increase the REFERENCE value to 9.00 ± 05.

17

Page 29

3.0 OPTIONS

Two popular options are the Dilution Module, allowing over range

samples to be diluted into the proper measurement range and the

Oxidation Module, used to break down complex molecules into

measurable constituents.

3.1 Dilution Module

For high range samples a dilution module is added to the hydraulic

configuration. A second 3-way valve is added to the flow train. The Loop

On and Loop Off functions are used to program the steps of the dilution.

Below is a description of the steps of the dilution.

Sample and DI water must be connected to the correct position, verify:

#1 (sample) connected to the left side of the selection valve and #2

(deionized water) to the right side of the selection valve.

1) Drain function

The first step of every measurement cycle is a drain cycle. This function opens the pinch valve to

empty the colorimetric cell.

2) Rinse Function #1 or #2 Loop On/Loop Off

With Loop On, the loop pathway is open and the sample passes through the loop and the hydraulic

lines to drain.

With Loop Off, the loop pathway is closed trapping a small sample in the loop while the sample

passes through the other side of the valve to drain.

This function also allows the loop to be filled with the sample and then to trap and hold the exact

quantity of sample to be diluted.

The “Rinse 1” picture shows rinse function with sample connected to #1 and loop on.

The “Rinse 2” picture shows rinse function with DI water connected to #2 and loop on.

18

Page 30

3) Sample Function #1 or #2 Loop Off / Loop On

With the Sampling function, the sample pump is activated and the pinch valve (to drain) is closed.

De-Ionized water (#2) is used to fill the colorimetric cell after passing through the loop.

Loop On, the loop pathway is open. This releases the sample contained inside the loop to mix with

the DI water (#2) passing through the loop, In this way the sample quantity trapped in the loop

during the Rinse Cycle is mixed with DI water and transferred to the colorimetric cell for the

colorimetric analysis.

Loop Off, the loop pathway is closed and liquid does not pass through the loop. Sample 1 picture

shows the sample function with sample connected to #1 and loop on or off.

After the dilution, the colorimetric reaction is performed.

3.2 Oxidation/Digestion Module

For the detection of some parameters (for example TP, TN, NO3...) it is necessary to perform a

photochemical oxidation or digestion before the colorimetric reaction. In these cases the Oxidation

Module option is added to the Liquids section.

To ensure a complete oxidation of the sample, the oxidation can be performed using sulfuric acid, heat,

UV irradiation and/or a chemical oxidizer.

DANGER!

Below is a list of possible hazards to be considered when the oxidation / digestion module is included

in a CA-6 analyzer:

19

Page 31

Hazard of chemical burns

operations on

with this symbol should be made by qualified personnel in

avoid chemical

all the necessary precautions when handling.

Hazard of UV radiation

with this

This symbol is used to repr esent the hazard of severe burns and serio us injury from

handling dangerous chemicals. All handling and maintenance

chemicals labeled

accordance with nat ional or local regulations. Qua lified Personnel means a person

who has been fully trained and has professional experience to

hazards an d dangers. Before handling t hese chemicals or proceeding with servic e

operations, read the m aterial saf ety data sheets supplied with each chemical t o take

This symbol is used to represents a hazard from ultravi olet rad iation . It is mandatory

to wear eye protection when operating or servicing UV lamps labeled

symbol.

Never look directly at a l ighted UV lamp. UV radiation exposure ca n cause severe

and permanent damage to skin and eyes.

Hazard of hot surface

This symbol is used to present a hazard from hot surfaces.

Do not touch the oxidation / digestion module during operation.

Method Description:

After rinsing the hydraulic line, the sample is pumped with the peristaltic pump into the reaction cell.

The oxidation can be performed with:

• the addition of a chemical oxidizer (for example sodium

persulfate or potassium peroxodisulfate) using the Micro

Peristaltic Pump

• the addition of sulfuric acid, using a Micro Peristaltic Pump

• UV irradiation (photochemical)

• heating the cell

The sample and reagents are mixed using the diaphragm pump

until the oxidation cycle is complete.

After the oxidation, the colorimetric reaction is performed to

measure the concentration of the specific parameter present in

the sample.

20

Page 32

4.0 INSTALLATION

4.1 Unpacking and Inspecting

The CA-6 Analyzer is fully assembled and was tested for proper performance at the factory before

packaging and shipping. Before proceeding with installation of the analyzer, it is recommended that you

carefully inspect the box and analyzer for damage that may have occurred during shipping.

Use care when unpacking and moving the analyzer. Refer to the Packing List when unpacking the CA-6

Analyzer and be careful not to misplace any of the accessories.

4.2 Analyzer Handling

Use extreme care when lifting or moving the analyzer. If the analyzer has been in service, empty all

liquids from the hydraulic parts before moving the analyzer.

4.3 Location and Mounting Instructions

Install the CA-6 Analyzer in a clean, dry and dust free environment or in an enclosure with good

ventilation.

Environmental Operating conditions are:

• Temperature: 5° to 50°C (41° - 121°F)

• Relative humidity: 80% maximum

If the temperature is below 5°C (41°F), the analyzer should be installed in a heated cabinet.

Due to the possible generation of chemical or waste gases, choose a well ventilated location for the

analyzer.

The Model CA-6 analyzer is supplied with four mounting brackets for wall mounting or stainless steel

support rack installation. To Wall or Rack mount the CA6 analyzer use (4) ¼-20 screws or larger.

The Reagent bottles are supplied with the analyzer. The relative position of the reagent bottle(s) to the

reagent pump(s) is very important. The maximum distance between the bottom of the reagent bottle(s)

and the lowest edge of the analyzer panel shall be no more than 40 cm (15.75”).

4.4 Pre-Installation

Considerations for the proper Location of the CA-6 Analyzer:

• Place the analyzer close to the sample point in order to minimize the response time.

• The sample point should provide a homogenous and representative sample to the CA6.

• Plumb sample line to analyzer. If the sample line is under pressure use an adjustable shut-off

valve (needle or ball valve) to feed the Fast Flow Reservoir. If drawing from a tank or pond then

minimize the tubing length. If longer than 10 feet add time to the initial Rinse times in the

Analysis Cycle and the Extra Cycle. (+5 seconds per 10 ft section)

• Position the CA-6 Analyzer near a suitable drain, with sufficient capacity to handle the gravity

fed waste discharge and the bypass overflow from the Fast Loop Reservoir (if used).

21

Page 33

DANGER:

• WARNING: The sample drain from the analyzer must drain at ambient pressure with no

restrictions or counter pressure.

• Clearance requirements for the analyzer should be 8 inches (20 cm) on either side of the

analyzer and 40 inches (100 cm) on the front.

• Sufficient space for the reagent containers should be provided beside or beneath the analyzer.

• The reagent containers should be placed in a suitable collection basin in case of spills.

Note: 15.75” maximum height between the reagent's bottle(s) and the reagent's pump(s).

4.5 Electrical Connections

4.5.1 General information

The electrical installation should be carried out by qualified personnel in accordance with all national

and local regulations. Qualified Personnel refers to a person who has the professional training and

experience to avoid electrical hazards and dangers.

Only Qualified Personnel should have access to the key that opens the analyzer enclosure.

Power to the CA-6 Analyzer should be routed through an ON/OFF switch.

Turn off the power before beginning any service on the CA-6 Analyzer.

The CA-6 must be properly grounded to prevent the possibility of electrical shock. All metal surfaces are

connected to the Ground terminal. The Grounding Terminal/Screw is located inside the electrical

enclosure in the upper left position.

It is the user’s responsibility to periodically check the efficacy of analyzer’s

electrical ground.

The analyzer stops when power is lost or disrupted and automatically restarts when

the power is restored.

Users and qualified maintenance personnel must proceed as follows:

• Always turn off the power before servicing the analyzer

• Take notice of all Electrical Shock and/or Electrocutions labels placed on the analyzer

No Service should be carried out on the instrument without first switching off the

power.

22

Page 34

4.5.2 AC Power Connections

The CA-6 Analyzer is designed for operation with 110-220Vac, 50-60 Hz power. The supplied AC power

cord exits through a port on the top side of the electrical compartment. All the connections must be

made in accordance with national or local regulations. The analyzer is equipped with a thermal switch

(main power switch). It is recommended that the CA-6 analyzer is connected to power via a circuit

breaker or an ON/OFF switch installed near the unit.

4.5.3 Signal Output Connections – TB (4-20 mA, alarm, aux, RS232)

CA-6 Analyzer provides various output signals all from the TB terminal pictured below.

• Digital Input (- Input; + Input) for an external device (start extra cycle)

• (1) 4-20 mA output (-signal 1 / + signal 1)

• (2) configurable relays (Normally Open Relays 1 2)

23

Page 35

Name

Quantity

2.83 ml/L

o-Cresolphthalein Complexone

CAS Number: 2411-89-4

0.075 g/l

Name

Quantity

200 ml/L

Deionized Water

800 ml

5.0 REAGENTS PREPARATION

Each analyte uses its own set of reagents to develop the distinctive color for measurement. The recipes

for the specific reagents required for this measurement are listed in Section 11.4 at the end of the

manual.

Each recipe details the chemicals used and the procedures used to produce the reagent.

Read all MSDS data sheets before preparing the reagents.

Use good laboratory technique. Wear safety goggles, gloves and protective clothing when preparing the

reagents, calibration solutions or cleaning solutions.

Mind all Hazard and Poison labels

Pre-made reagents and solutions are available from ECD. The part #s for the reagents can be found in

the recipe next to the reagent name and in section

reagents are listed as Hazardous Shipping Materials; these materials are only available for shipment

domestically inside the USA.

Reagent 1

Cresolphthalein Solution

9.3 Accessories and Spare Parts. Several of the

Part Number# 2010037-1

For 1 Liter preparation:

Hydrochloric Acid 37%, ACS Reagent

CAS Number: 7647-01-0

Clean all equipment with DI water before use.

Dissolve o-cresolphthalein in 2.83 ml of the concentrated hydrochloric acid. It may take a minute or so.

Fill a 1 liter volumetric flask to 2/3rds capacity with DI water. When dissolved slowly add the

Cresolphthalein HCl solution to the water while stirring the solution. Fill the volumetric flask to the

gauge line (1 liter). Transfer to the reagent 1 container provided with the analyzer.

Reagent 2

Ethanolamine solution

Part Number# 2010038-1

For 1 Liter preparation:

Ethanolamine, ACS Reagent

CAS Number: 141-43-5

24

Page 36

Fill a 1 liter volumetric flask to 2/3rds capacity with DI water. Add 200 ml of ethanolamine while stirring

the solution. Fill the volumetric flask to the gauge line (1 liter). Transfer to the reagent 2 container

provided with the analyzer.

5.1 Method of Analysis

The Hardness determination is a colorimetric analysis using a 572 nm LED and a heated colorimetric cell

of 16 mm diameter. After rinsing the hydraulic lines, the sample is pumped with the peristaltic pump

into the colorimetric cell. The reference measurement of the initial color is taken. Reagent 1, the

Cresolphthalein solution, is added using Micro Pump 1 and Reagent 2, the ethanolamine solution, is

added with Micro Pump 2. The solutions are mixed and a violet color develops proportionally to the

calcium and magnesium ions present. Absorbance is measured at the end of the reaction and the result

is displayed as Hardness as CaCO

Wavelenght: 572 nm led

ppb/ppm.

3

Before proceeding with the analyzer Start-Up, check that all installation (Section 4.0) and

reagent preparation (Section 11.0) operations have been properly completed. Please

verify that all suggestions and recommendations have been followed.

25

Page 37

6.0 ANALYZER INITIAL START-UP

• Open The Liquids Compartment

• Disconnect LED Cable from upper left

corner of the back panel, twist ¼ turn

counter clockwise then pull back.

• Remove the protective paper

surrounding the colorimetric cell by

unscrewing the two (2) thumbscrews

and carefully removing the

heater/LED block, remove the paper,

replace the block and gently retighten the thumbscrews. Reconnect LED.

• Remove the block from the Drain Pinch Valve by pressing the black button. Save for future use.

It removes compression from the drain tube when the CA6 is not in use.

• Install the Fast Loop Reservoir(s) close to the right side of

the CA-6 Analyzer. Samples and Dilution water must be

drawn from atmospheric pressure.

6.1 Sample and Drain Tubing Connections

After double checking Sections 4.0 & 5.0, proceed as follows:

• Connect the overflow drain of the Fast-Loop Reservoir to

the drain with 12 mm OD tubing.

• Connect the sample feed line (or the outlet of the optional

filtering unit) to the bottom of the Fast-Loop Reservoir

previously installed on the right side of the analyzer.

• SEE SECTION 11, ANALYSIS CYCLE, FOR ACTUAL TUBING

CONNECTIONS

• Connect the sample inlet tubing from the analyzer, Sample

#1, to the “Sample to Analyzer” port fitting on top of the Fast-loop Reservoir. The John Guest

fitting accepts 1/8” I.D. flexible tubing (Tygon, Pharmed or Norprene are recommended). The

sample will now be taken from atmospheric pressure by the sample peristaltic pump.

• Connect the reagents tubing (coming from the

reagent bottle) to the corresponding

REAGENT port fitting (Reagent 1 to Port 1)

using 1/16” I.D. flexible tubing (Tygon,

Pharmed or Norprene are recommended).

The reagents will be delivered to the optical

cell by the internal reagent peristaltic pumps.

Note the maximum height of 15.75” (40 cm)

between the bottom of the bottle(s) and the

bottom edge of the analyzer panel.

26

Page 38

• Connect the analyzer drains (CELL and VENT DRAINS) to a waste line using 3/8” flexible tubing.

WARNING: the drain from the analyzer must be at atmospheric pressure with no restrictions.