Page 1

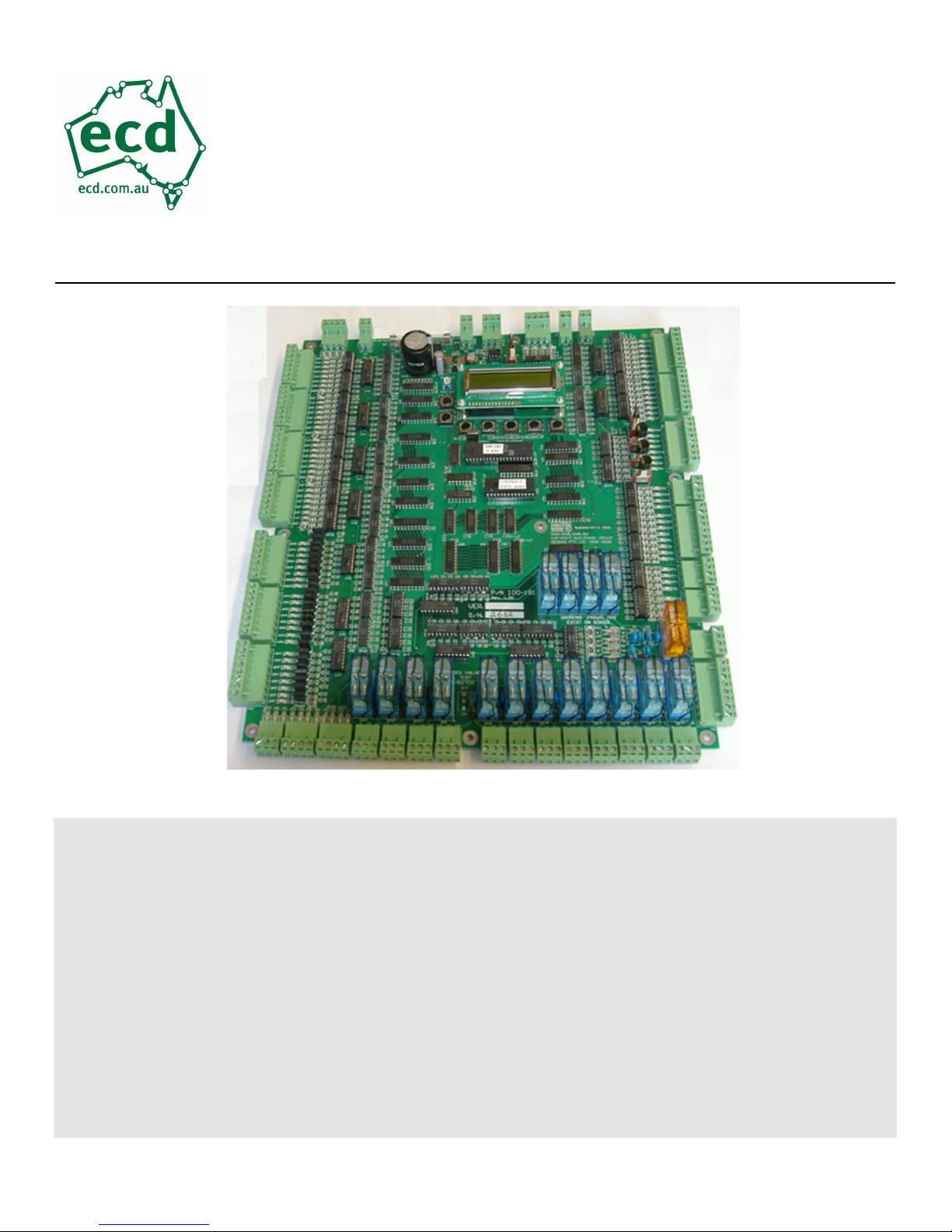

100-181 Controller Manual

Revision Date: Feb 22, 2017

ECD System

Manual

Page 2

E L E C T R O N I C C I R C U I T D E S I G N S P T Y . L T D .

Operation Guide

This manual covers all versions of 100-181 hardware

and software. Some features and operative descriptions

mentioned in this manual may differ or not be available on

earlier 100-181 versions

Electronic Circuit Designs Pty. Ltd.

Factory 11/30 Perry Street • Matraville • NSW • Australia • 2036

Phone 61 2 9316 6909 • Fax 61 2 9316 6797

Email sales@ecd.com.au Web www.ecd.com.au

Page 3

Table of Contents

Table of Contents............................................................................................ i

Section 1: Safety Regulations & Introduction .............................................. 4

1.2.1 Following operating instructions. ............................................ 4

1.2.2 Obligations of operator............................................................. 4

1.2.3 Obligations of personnel........................................................... 4

1.2.4 Hazards associated with the equipment. ................................. 5

1.2.5 Warranty and liability.............................................................. 5

1.2.6 Organizational measures.......................................................... 5

1.2.7 Protective equipment................................................................ 6

1.2.8 Informal safety measures. ........................................................ 6

1.2.9 Training of personnel. .............................................................. 6

1.2.10 Machine controls....................................................................... 6

1.2.11 Safety measures during normal operation.............................. 6

1.2.12 Hazards caused by electric power............................................ 6

1.2.13 Hazards caused by hydraulic power........................................ 7

1.2.14 Special danger areas (examples).............................................. 7

1.2.15 Controller Installation Environmental Requirements.............. 7

1.2.16 Introduction ................................................................................. 8

Section 2: EEProm Settings .......................................................................... 9

EEProm Version 4.02 Summary................................................................. 10

EEProm Definitions (Full description)....................................................... 13

ADO - Advanced Door Opening setup.................................................. 13

ALP – Auxiliary Leveling Pump operation setup ................................ 13

ANS - Anti Nuisance setup..................................................................... 13

BCC - Bottom Car Call setup................................................................ 13

BOT - Bottom floor setup ...................................................................... 13

BST – Brake Switch Time...................................................................... 14

CCMF - Car Call Mask (Front doors) setup........................................ 14

CCMR - Car Call Mask (Rear doors) setup......................................... 14

CNT - CNT Input setup ......................................................................... 14

COD – Parameter lockout function....................................................... 15

DCMF - Down Call Mask (Front doors) setup..................................... 15

DCMR - Down Call Mask (Rear doors) setup...................................... 15

DLI - Door Limit Invert setup............................................................... 15

DLM - Door Limit setup ........................................................................ 16

DRV - Drive type setup .......................................................................... 16

DT - Door Time Close setup .................................................................. 16

DTCF - Door Time Car call (Front doors) close setup ........................ 16

DTCR - Door Time Car call (Rear doors) close setup ......................... 16

DTHF - Door Time Hall call (Front doors) close setup........................ 17

DTHR - Door Time Hall call (Rear doors) close setup ........................ 17

DTL - Door Time Lobby call close setup .............................................. 17

DTRF - Door Time Recall Front setup ................................................. 17

DTRR - Door Time Recall Rear setup .................................................. 17

EQK......................................................................................................... 18

FS - Fire Service type ............................................................................. 18

HFAF - Hall Fire Alternate (Front doors) floor setup .........................18

HFAR - Hall Fire Alternate (Rear doors) floor setup .......................... 18

HFSF - Hall Fire Service (Front doors) return floor setup..................18

HFSR - Hall Fire Service (Rear doors) Return floor setup.................. 19

HRF – Hospital / Hall Recall Front doors............................................. 19

HRR – Hospital / Hall Recall Rear doors.............................................. 19

LCK – Parameter lockout function .......................................................19

LOB - Lobby floor setup ........................................................................ 19

L.# - Lift Number setup..........................................................................19

MOD - MODE Inputs setup...................................................................20

MSL - Magnet Slowing type................................................................... 20

NR - Door Nudging setup ....................................................................... 20

PRK - Park/Zone with doors open......................................................... 20

PRV - Proving required setup................................................................ 20

RLV - Re-Leveling setup ........................................................................ 20

RPT - Run Protection Timer setup ...................................................21

RTM – Run Time short floor run setup ................................................ 21

SDX - Star Delta Exchange Time setup................................................. 21

SDX - VF Drive setting 06,07,08 brake drop time................................ 21

SFR - Short Floor Run setup.................................................................. 21

Spares....................................................................................................... 22

StF - Start Fast ........................................................................................ 22

StM - Start Medium................................................................................22

SlF - Slow Fast......................................................................................... 22

SlM - Slow Medium ................................................................................22

ST2 - Star Delta Changeover Time setup.............................................. 22

ST2 - VF Drive setting 06,07,08 end run time....................................... 22

TCC - Top Car Call setup ...................................................................... 22

TOP - Top floor setup.............................................................................23

UCMF - Up Call Mask (Front doors) setup.......................................... 23

UCMR - Up Call Mask (Rear doors) setup........................................... 23

XTM - Extend run time short floor run ................................................ 23

ZON - Zoning/Parking floor setup......................................................... 23

ZTM - Zoning Time setup...................................................................... 24

#.L - Number of Lifts setup .................................................................... 24

Section 3. Group .......................................................................................... 25

Group Connections and Communication.............................................. 25

Group Checks..........................................................................................26

Group/Duplex Faults ........................................................................... 26

Section 4. Inputs – Outputs.......................................................................... 27

BRK - Brake relay output ......................................................................27

BSL – Bottom SLowing input ................................................................ 27

CBSF - Hall Button Stop (Front doors) output..................................... 27

CBSR - Hall Button Stop (Rear doors) output......................................27

CC - Car Call inputs/Darlington outputs.............................................. 27

CFS - Car Fire Service input.................................................................. 28

Page 4

CFSS - Car Fire Service Start input...................................................... 28

DCBF - Door Close Button (Front doors) input................................... 28

DCBR - Door Close Button (Rear doors) input.................................... 28

DCF - Door Close (Front doors) relay output ...................................... 28

DCR - Door Close (Rear doors) relay output ....................................... 28

DDN - Direction Down output............................................................... 28

DDO - Door Open Disable input / Toggle Switch................................. 28

DF - Down Fast relay output ................................................................. 29

DFCF - Door Fully Closed (Front doors) input.................................... 29

DFCR - Door Fully Closed (Rear doors) input..................................... 29

DFOF - Door Fully Open (Front doors) input...................................... 31

DFOR - Door Fully Open (Rear doors) input....................................... 31

DHC - Down Hall Call inputs/Darlington outputs............................... 32

DN - Down Relay output........................................................................ 33

DOBF - Door Open Button (Front doors) input................................... 33

DOBR - Door Open Button (Rear doors) input.................................... 33

DOF - Door Open (Front doors) relay output...................................... 33

DOR - Door Open (Rear doors) relay output....................................... 33

DS - Down Slow relay output................................................................. 33

DUP - Direction Up output .................................................................... 33

DZ - Door Zone input............................................................................. 33

DZ – Door Zone relay output ................................................................ 33

EDPF - Electronic Door Protection (Front doors) input ..................... 33

EDPR - Electronic Door Protection (Rear doors) input...................... 34

EP - Emergency Power input................................................................. 34

EQK – Earthquake Detection input...................................................... 34

HCB – Hall Call Bypass Input............................................................... 34

HFA - Hall Fire Alternate input............................................................ 34

HFL - Hall Fire Light output................................................................. 34

HFM Hall Fire Machine room/Hoist way input................................... 34

HFR - Hall Fire Reset Input .................................................................. 34

HFS - Hall Fire Service input ................................................................ 35

HFV - Hall Fire Visual signal output .................................................... 35

HV2 - High Voltage input ...................................................................... 35

IDN - Inspection Down input................................................................. 35

IND - Independent Service input........................................................... 35

INSP - Inspection Control input............................................................ 35

IUP - Inspection Up input...................................................................... 35

LEV - Leveling relay output .................................................................. 36

LR – Lock Relay input. ......................................................................... 36

LR – Lock Relay output......................................................................... 36

LRX – Aux LR input.............................................................................. 36

M3 - Door Locks input........................................................................... 36

MSD – Magnetic Switch Down input.................................................... 36

MSU - Magnetic Switch Up input.......................................................... 36

NDGF - Nudging Buzzer output front doors........................................ 37

NDGR - Nudging Buzzer output rear doors......................................... 37

NRF - Nudging output front doors ........................................................37

NRR - Nudging output rear doors......................................................... 37

OS - Out of Service output ..................................................................... 37

PI - Position Indicator output ................................................................ 37

PRK - Parking function input................................................................ 38

PRV - Proving Circuit input .................................................................. 38

PULSE – Pulse Counting input..............................................................38

SAF - Safety Circuit input...................................................................... 38

Sin1 - BKSW - Brake Switch Input .......................................................39

SIn3 – HR Input...................................................................................... 39

SO1 – Inspection Relay Output/Correction Run Output.....................39

SO2 – HR Output....................................................................................39

SP1 - Multi Purpose output 1................................................................. 39

SP2 - Multi Purpose output 2................................................................. 39

SP3 - Multi Purpose Output 3................................................................ 40

SP4 - Multi Purpose output 4................................................................. 40

TSL – Top SLowing input...................................................................... 40

UD - Up/Dn relay output ........................................................................40

UF - Up Fast relay output....................................................................... 40

UHC - Up Hall Call inputs / outputs...................................................... 40

UP - Up relay output...............................................................................40

US - Up Slow relay output......................................................................41

Section 5. Liquid Crystal Display................................................................. 42

LCD Status Line...........................................................................................42

LCD Position & Direction ...................................................................... 42

LCD Modes..............................................................................................42

LCD Lift Status....................................................................................... 43

LCD Door Modes....................................................................................43

LCD Control Buttons .............................................................................44

LCD Display Options.............................................................................. 44

Section 6. Motion ......................................................................................... 46

Motion Control Outputs.........................................................................46

Drive settings and their output status.................................................... 46

Counting Method “00” - Magnet Counting........................................... 54

Counting Method “01” - Pulse Counting. ............................................. 56

Counting Method “02” - Pulse Counting. ............................................. 65

Section 7: Faults – Fault finding................................................................. 67

Upgrade Controller software. ................................................................ 67

Group/Duplex Faults .............................................................................. 67

Leveling inhibit. LEV ............................................................................. 67

Run protection timer. RPT..................................................................... 67

Lift won’t re-level with doors open........................................................ 67

On board fuse blows ............................................................................... 68

Testing 24Vdc.......................................................................................... 68

Doors do not open ................................................................................... 68

Doors close on park................................................................................. 68

Doors don’t open at terminal floors....................................................... 68

Page 5

Lift gets out of step ................................................................................. 68

Lift does not answer car calls................................................................. 68

Lift does not answer hall calls................................................................ 68

Lift misses hall calls................................................................................ 68

Re-leveling won’t operate....................................................................... 69

Red3 LED is not blinking....................................................................... 69

Processor errors/Lockup: ...................................................................... 69

Section 8. Upgrades, Changes & Technical Information........................... 70

Controller ID. .............................................................................................. 71

Terminal Screw Torque Settings................................................................. 72

Page 6

S A F E T Y R E G U L A T I O N S & I N T R O D U C T I O N

Section

1

Section 1: Safety Regulations & Introduction

Section 1.1 Safety Regulations

Elevator controllers and other electrical components can cause serious harm or death if installation guides are not

met. It is the responsibility of the installer of our equipment to ensure that once installed, the equipment does not

pose any threat, danger or hazard.

Installation of this equipment shall be done in accordance with AS1735 for Australia and with all applicable local

codes and NFPA 70 (National Electric Code) for the U.S.A. and C22.1-02 Canadian Electrical Code Part 1 for

Canada as well as ASME A17.1, CAN/CSA-B44.1.

Section 1.2 Obligations and Liability

1.2.1 Following operating instructions.

• In order to ensure safe handling and problem free operation of this equipment, it is absolutely

essential for the relevant personal to be fully acquainted with the relevant safety regulations.

• These operating instructions contain the most important information for operating the machine correctly

and safely.

• These operating instructions, in particular the safety regulations, must be observed by all those persons

who work on the equipment.

• Furthermore, all locally applicable rules and regulations relating to accident prevention and installation

must be observed.

1.2.2 Obligations of operator.

The operator undertakes to allow only those persons to work on the equipment who

• Are fully acquainted with the basic regulations relating to safety in the workplace and accident prevention

and to have been trained in handling the equipment.

• Have read the safety regulations and the warning notices contained in these the operating instructions.

• Regular checks are conducted to ensure that personnel perform their duties with safety considerations

foremost in their minds.

1.2.3 Obligations of personnel.

All personnel charged with working on the machine undertake prior to starting work to

• Observe the basic regulations relating to safety in the workplace and accident prevention.

• Read the operating instructions, in particular the safety regulations, and confirm by way of their signature

that they have understood them.

Page 7

S A F E T Y R E G U L A T I O N S & I N T R O D U C T I O N

1.2.4 Hazards associated with the equipment.

The equipment is built with state-of-the-art technology and recognized safety regulations. Nevertheless, use of the

equipment can result in dangers to life and limb for the installer, user or a third party and in impairments to the

equipment or to other material property. The equipment must only be used

• For its intended purpose.

• In perfect condition in terms of safety requirements.

Operate the equipment in technically perfect condition and for its intended use only while bearing in mind all

safety and hazard considerations and following the operating instructions. In particular, faults which restrict safety

must be rectified immediately after they have been identified and at the latest before the equipment is started up.

Compliance Testing for AS/NZS CISPR 22:2002 Class A

WARNING !

This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

Compliance Testing for FCC Title 47 Part 15, Subpart B Class A

FCC PART 15

This device complies with part 15 of the FCC rules. Operation is subject to the

following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference that

may cause undesired operation.

1.2.5 Warranty and liability.

Our “Sales terms and conditions” apply. These terms and conditions will have been available to the purchaser at

time of sale. Warranty and liability shall be limited to repairs and replacement to the equipment purchased from

us. Warranty and liability claims shall not be entertained if they can be traced back to one or more of the following

causes.

• Equipment not used for its intended purpose.

• Improper installation, startup, operation and maintenance of the equipment.

• Operation of the equipment with faulty safety devices or improperly installed or non-operational safety

and protective equipment.

• Failure to observe the information, instructions and notices contained in the operating instructions

relating to transportation, storage, installation, startup, operation, maintenance and setting up of the

equipment.

• Inadequate monitoring of the equipment parts which are subject to wear.

• Improperly conducted repairs.

• Catastrophes caused by the influence of foreign bodies and force majeure.

1.2.6 Organizational measures.

• The installer and or maintainer shall provide the necessary protective equipment for the personnel

• All existing safety equipment must be checked at regular intervals.

Page 8

S A F E T Y R E G U L A T I O N S & I N T R O D U C T I O N

1.2.7 Protective equipment.

• At all times, prior to putting the machine into operation, all protective equipment must be correctly

installed and in proper working condition.

• Protective equipment may only be removed

- after the machine has come to a complete stop and the machine has been disabled to ensure it

cannot be started up again.

- if subcomponents are delivered, the operator must install the protective equipment in

accordance with regulations

1.2.8 Informal safety measures.

• Keep the operating instructions and circuit diagrams permanently at the site where the equipment is

installed.

• In addition to the operating instructions, the generally valid and local regulations relating to accident

prevention and environmental protection must be provided and observed.

• Maintain all safety and danger notices on/next to the machine in legible condition and comply with

them.

• If the equipment is sold or transferred, the operating instructions must be included with the equipment.

1.2.9 Training of personnel.

• Only personnel who have been trained and instructed are allowed to work on the machine.

• The responsibilities of the personnel must be clearly defined for the machine/controller installation,

startup, operation, setting-up, maintenance and repairs.

• Personnel still in the process of being trained are only permitted to work at the machine under the

supervision of an experienced person.

1.2.10 Machine controls.

• Under no circumstances carry out any program modifications to the software!

• Only properly instructed personnel are permitted to operate the controls.

• The machine must not be operated if potential electromagnetic interference sources are acting on the

machine. Interference sources are e.g. welding equipment, portable phones.

1.2.11 Safety measures during normal operation.

• Only operate the machine when all protective equipment is fully operational.

• Prior to switching on the machine, ensure that the startup can cause no harm to personnel.

• Regularly maintain and check machine for externally identifiable damage and check that all the safety

devices are operational.

1.2.12 Hazards caused by electric power.

• Ensure 0V and +24V are free from other voltages. High voltages may be superimposed on 0V

and 24Vdc lines as no reference to ground exists. See Warning 1.2.14

• Work on the electric power supply may only be carried out by a qualified electrician.

• Check the electrical equipment of the machine at regular intervals.

Repair loose connections and scorched cables immediately.

• Keep the control cabinet locked at all times. Access is only permitted to authorized personnel with a key

or tool.

Page 9

S A F E T Y R E G U L A T I O N S & I N T R O D U C T I O N

• If work has to be carried out on live parts, do this only in the presence of a second person who can

switch off the master switch in an emergency.

• The machine causes electromagnetic interference sources. For this reason, do not use any sensitive

equipment in its vicinity.

• For EMC reasons, the controller must not be modified.

1.2.13 Hazards caused by hydraulic power.

• Only personnel with special knowledge and experience in the field of hydraulics may work on hydraulic

equipment.

• Before beginning repairs, depressurize system sections and pressure lines which are to be opened.

1.2.14 Special danger areas (examples).

• When on inspection, always ensure either of the common or direction control buttons stops the lift.

• The common button shall break the safety line and the 0V up/down direction input.

• Never place yourself or any party in a position of danger where relying on any single safety measure.

• Automatic machines start without warning. Care must be taken at all times.

WARNING !

Always treat terminals and conductors as dangerous. High voltages may be

superimposed on 0V and 24Vdc lines as no reference to ground exists. Always

meter these points to ensure correct voltage exists.

1.2.15 Controller Installation Environmental Requirements

Controller cabinet must be installed in a location free from;

• Dust and dirt.

• Excessive heat and humidity. Ambient temperature should not exceed 40°C /104°F.

• Excessive vibrations.

• Mist or water

When mounting controller cabinet, ensure it is suitably supported.

Page 10

E E P R O M S E T T I N G S

T

1.2.16

he 100-181 controller enables independent control of the front and rear doors at each

floor.

The 100-181 controller can operate up to 8 floors.

The controllers can be grouped up to a 6 car group and may be inter-connected using 3 wire serial communication. A

separate group controller is therefore, not required.

Processor

Under normal operation;

When re-powering; ensure the lift is off for 10 seconds before turning back on.

On power up, a delay of approximately 2 seconds is given on start up to ensure voltages are stable prior to reading

and writing outputs.

Introduction

• The red Red3 LED blinks to confirm that the microprocessor is running.

• The yellow Yel3 LED comes on to confirm outputs are enabled.

• The green Grn3 LED comes on during power up and turns off during normal operation. It will

also flash once when a new value has been written in to EEPROM.

Page 11

E E P R O M S E T T I N G S

Section

2

Section 2: EEProm Settings

EEProm How to read and modify settings

This EEProm holds settings for the particular contract data including number of

floors, door type and drive types.

The EEPRom holds values for various contract settings which may be altered on site. Each setting has a definition

followed by its value in hex followed by its value in bit format.

To inspect the settings from the power up state,

press the forward “>” button located to the left

below the LCD until the EEPROM setting appears.

To inspect the settings from the power up state,

press the forward “>” button located to the left

below the LCD until the EEPROM setting appears.

Now you can use the up “∧” and down “∨”buttons

to scroll through the settings. If you want to change

a setting press the enter “ENT” button and a * shall

appear on the screen to indicate you are in edit mode.

Now use the up “∧” and down “∨” buttons to

change the setting. When you are at the required

value press the enter “ENT” button again and the *

shall disappear.

EEProm Security

A special write sequence has been added to ensure unauthorized writes to the EEProm are not made. Only

operates with EEProms with this capability. These EEproms are recommended and identified by a “contract data

secure” label.

01- NOR IDL ][

ECD Aust. V-4.02

01- NOR IDL ][

TOP: 08:00001000

01- NOR IDL ][

TOP:*08:00000010

01- NOR IDL ][

TOP: 06:00000010

Page 12

E E P R O M S E T T I N G S

EEProm Version 4.02 Summary

The EEProm holds values for various contract settings which may be altered on site. Each setting has a definition

followed by its value in hex and then its value in bit format.

Note: Refer to EEProm Definitions (Full description) for more information.

BOT Bottom floor number (VALUE)

Setting example:- BOT 01: 00000001 (Level 1)

TOP Top floor number (VALUE)

Setting example:- TOP 06: 00000110 (Level 6 is top floor)

BCC Bottom car call for “BOT CALL” button on the circuit board (MASK)

Setting example:- BCC 80: 10000000 (Bottom call Level 1)

TCC Top car call for “TOP CALL” button on the circuit board (MASK)

Setting example:-TCC 04: 00000100 (Top call to level 6)

CCMF Car call mask. Front doors floors allowed. (MASK)

Setting example:-CCMF FC: 11111100 (Front doors, levels 1-6)

CCMR Car call mask. Rear doors floors allowed. (MASK)

Setting example:-CCMR F8: 11111000 (Rear doors, levels 1-5)

UCMF Up call mask. Front doors floors allowed. (MASK)

Setting example:- UCMF F8: 11111000 (Front doors, levels 1U-5U)

UCMR Up call mask. Rear doors floors allowed. (MASK)

Setting example:- UCMR F0: 11110000 (Rear doors, levels 1U-4U)

DCMF Down call mask. Front doors floors allowed. (MASK)

Setting example:- DCMF 7C: 01111100 (Front doors, levels 2D-6D)

DCMR Down call mask. Rear doors floors allowed. (MASK)

Setting example:- DCMR 78: 01111000 (Rear doors, levels 2D-5D)

LOB Lobby floor. (MASK)

Setting example:- LOB 40: 01000000 (Level 2 is the master zoning floor)

ZON Zone floor. (MASK)

Setting example:-ZON 10: 00010000 (Zone to Level 4)

ZTM Zoning time. (VALUE)

Setting example:-ZTM 06: 00000110 (= 60seconds)

HFSF Hall fire service floor. Front doors floors (MASK)

Setting example:-HFSF 80: 10000000 (Front doors, level 1)

HFSR Hall fire service floor. Rear doors floors (MASK)

Setting example:-HFSR 00: 00000000 (Rear doors, no setting)

SFR Short Floor Run (MASK)

Setting example:- SFR 9F: 10011111 (Short floor between 2&3)

L.# Lift Number (VALUE)

Setting example:- L.# 02: 00000010 (Lift #2)

#.L Number of Lifts (VALUE)

Setting example:- #.L 03: 00000011 (3 Lifts in group)

MOD Mode inputs (MASK)

Setting example:- MOD 02: 00000010 (CFS input inverted)

CNT CNT inputs (MASK)

Setting example:- CNT 02: 00000010 (DOB input inverted)

HFAF Hall fire alternate floor. Front doors floors. US only (MASK)

Setting example:- HFAF 00: 00000000 (Front doors, no setting)

HFAR Hall fire alternate floor. Rear doors floors. US only (MASK)

Setting example:- HFAR 40: 01000000 (Rear doors, level 2 alt. fire floor)

PRV If set to "1" requires PRV on all DRV settings

Page 13

E E P R O M S E T T I N G S

RPT Run protection timer

Setting example:-RPT 01: 00000001 (25s)

DRV Drive control type.

Setting example:-DRV 02: 00000010 (3010/2CH/S block)

ST2 Star Delta time. (VALUE)

Setting example:-ST2 08: 00001000 (= 800ms)

SDX Star Delta Exchange time. (VALUE)

Setting example:-SDX 01: 00000001 (= 100ms)

MSL Magnet slowing type.

Setting example:- MSL 00: 00000000 (MSU/MSD slowing)

MSL 01: 00000001 (Pulse slowing)

RTM Extend run time. – If slowing is obtained less than this time, then add the value

of in XTM on before dropping high speed.

Setting example:-RTM 00: 00000000 (No extended run time.)

XTM Extend run time. – If a short floor determined by RTM then add this amount of

Time on before dropping high speed.

Setting example:-XTM 00: 00000000 (No extended run time.)

StF Start Fast. - Number of pulses it takes to reach fast speed.

StM Start Medium.- Number of pulses it takes to reach medium speed.

SlF Slow Fast. - Number of pulses it takes to slow from fast speed.

SlM Slow Medium.- Number of pulses it takes to slow from medium speed.

RLV Re-leveling. Turn re-leveling on/off.

Setting example:-RLV 00: 00000000 (No Re-level.)

RLV 01: 00000001 (Re-leveling on.)

DLM Door limit mask.

Setting example:-DLM 00: 00000000 (Single doors.)

DLM 01: 00000001 (Multi doors.)

DLM 02: 00000010 (Door cam.)

DLI Door limit invert. (MASK)

Setting example:-DLI 00: 00000000 (Limits not inverted.)

NR Nudging Relay for door nudging/Passing tone (MASK)

Setting example:-NR 00: 00000000 (Nudging off.)

ADO Advanced Door Opening.

Setting example:-ADO 00: 00000000 (Off )

DTCF Door time car call for front doors. (VALUE)

Setting example:-DTCF 32: 00110010 (= 5000ms, “5 seconds”)

DTCR Door time car call for rear doors. (VALUE)

Setting example:-DTCR 32: 00110010 (= 5000ms, “5 seconds”)

DTHF Door time hall call for front hall. (VALUE)

Setting example:-DTHF 32: 00110010 (= 5000ms, “5 seconds”)

DTHR Door time hall call for rear hall. (VALUE)

Setting example:-DTHR 32: 00110010 (= 5000ms, “5 seconds”)

DTL Door time lobby. (VALUE)

Setting example:-DTL 32: 00110010 (= 5000ms, “5 seconds”)

ANS Anti Nuisance EDP. (VALUE)

Set to the number of times a car call is answered without EDP activation before calls are cancelled.

PRK Park/Zone with doors closed/open. Set to 00 – doors closed.

FS Fire service type

Setting example:-FS 00: 00000000 (Australian fire service.)

FS 01: 00000001 (Code 17.1 U.S.A..)

DT Door Time Close Setup. Door Time Canceling Function

Setting example:-DT 01: 00000001 (Door Timing Canceling Activated)

BST Brake Switch Time

Setting example:-BST 03: 00000011 (3s)

Page 14

E E P R O M S E T T I N G S

DTRF Door time HR recall . (VALUE)

Setting example:-DTRF 32: 00110010 (= 5000ms, “5 seconds”)

DTRR Door time HRR recall . (VALUE)

Setting example:-DTRR 32: 00110010 (= 5000ms, “5 seconds”)

HRF Hosp / Hall recall mask.

Setting example:-HRF 40: 01000000

HRR Hosp / Hall recall mask.

Setting example:-HRR 40: 01000000

ALP Auxiliary Leveling Pump. Turns on Auxiliary Leveling Pump, for Up Re Level operation.

Setting example:- ALP FF:11111111 (No Auxiliary pump Re-level.)

ALP 01: 00000001 (Re-leveling with Auxiliary pump)

LCK EEProm Lock (Unlock default 67)

COD Lock code (Unlock default 89)

EQK N/A. Do not adjust

Page 15

E E P R O M S E T T I N G S

EEProm Definitions (Full description)

ADO - Advanced Door Opening setup

Sets the doors to open whilst traveling into the floor. The doors shall commence opening when the lift is within the

door zone and the MSU or MSD vane pending direction.

ADO EEPROM Advanced Door Opening.

00: 00000000 “Off – Default”

01: 00000001 ”On”

ALP – Auxiliary Leveling Pump operation setup

For hydraulic lifts, ALP can be set to control SP3 relay to allow Up Re-Leveling using the Auxiliary Pump motor.

For “SP3” relay to energise when performing an Up Re level set ALP to “01” and DRV to “00”, “02” or “05”.

The contacts of SP3 may also be used to stop a secondary pump starting when Up Re-Leveling

If ALP is set to “01”, SP3 shall NOT turn on for inspection.

ALP EEPROM Auxiliary Leveling Pump.

FF: 11111111 “Off”

01: 00000001 “On – operates SP3 for Up Re-Level or inspection”

ANS - Anti Nuisance setup

Set to the number of times a car call is answered without EDP (Electronic Doors Protection) activation before calls

are cancelled. Counter is reset to zero if either EDPF or EDPR is activated. If a hall call is present as well as a car

call, the counter will not increment.

ANS EEPROM Anti Nuisance.

00: 00000000 “Off”

03: 00000011 ”On – operates after 3 car calls of no EDP in a row.”

1e: 00011110 ”On – operates after 30 car calls of no EDP in a row - Default”

BCC - Bottom Car Call setup

BCC EEPROM Bottom car call for the “BOT CALL” button on the circuit board (MASK)

First floor served for this lift only.

The controller shall enter a car call to this setting when the “BOT CALL’ button on the circuit board is pressed.

80: 10000000 (Level 1)

40: 01000000 (Level 2)

20: 00100000 (Level 3)

10: 00010000 (Level 4)

08: 00001000 (Level 5)

BOT - Bottom floor setup

BOT EEPROM Bottom number (VALUE)

Set value to lowest floor served. (01 to 05 valid values)

Lift resets to “BOT” value when BSL limit is activated.

Page 16

E E P R O M S E T T I N G S

This signal can be used when a lift in the group doesn’t go all the way to the bottom.

01: 00000001 (Level 1)

02: 00000010 (Level 2)

03: 00000011 (Level 3)

04: 00000100 (Level 4)

05: 00000101 (Level 5)

BST – Brake Switch Time

For brake switch monitoring.

BST sets the time that the BKSW input must be turned on (to prove the brake has lifted) once the brake lift

command (BRK relay pulled in) has been initiated.

Setting example:

01: 00000001 = 1s

02: 00000010 = 2s

03: 00000011 = 3s

04: 00000100 = 4s

05: 00000101 = 5s

FF: 11111111 = OFF. BKSW not monitored.

Any other setting than 01-05 will turn the brake switch monitoring OFF.

BST is a fatal error. Reset is only via a processor POR.

See also Input - Output, Sin1- BKSW.

CCMF - Car Call Mask (Front doors) setup

CCMF EEPROM Car call mask. Front doors floors allowed. (MASK). For this lift only.

This setting lets you define the floors which the lift serves via the front doors.

Set bits to a “1” car call allowed or a “0” for not allowed.

C0: 11000000 (1c,2c)

E0: 11100000 (1c,2c,3c)

F0: 11110000 (1c,2c,3c,4c)

F8: 11111000 (1c,2c,3c,4c,5c)

FC: 11111100 (1c,2c,3c,4c,5c,6c)

Note: This masking feature shall not to be used as a means providing of floor security, as it shall disable the car

calls in Fire Service and other modes of operation.

CCMR - Car Call Mask (Rear doors) setup

CCMR EEPROM Car call mask. Rear doors floors allowed. (MASK). For this lift only.

This setting lets you define the floors which the lift serves via the rear doors.

Set bits to a “1” car call allowed or a “0” for not allowed.

C0: 11000000 (1c,2c)

E0: 11100000 (1c,2c,3c)

F0: 11110000 (1c,2c,3c,4c)

F8: 11111000 (1c,2c,3c,4c,5c)

FC: 11111100 (1c,2c,3c,4c,5c,6c)

Note: This masking feature shall not to be used as a means providing of floor security, as it shall disable the car

calls in Fire Service and other modes of operation.

CNT - CNT Input setup

Enables the following CNT inputs to be inverted; DCBF, DOBF, EDPF, DCBR, DOBR, EDPR.

CNT EEPROM (MASK)

00: 00000000 No inputs inverted.

01: 00000001 DCBF. Door close front input inverted

02: 00000010 DOBF. Door open front input inverted

04: 00000100 EDPF. Light ray front input inverted

Page 17

E E P R O M S E T T I N G S

08: 00001000 Not used. Default to 0.

10: 00010000 Not used. Default to 0.

20: 00100000 DCBR. Door close rear input inverted

40: 01000000 DOBR. Door open rear input inverted

80: 10000000 EDPR. Light ray rear input inverted

eg. 42: 01000010 = Both DOBF and DOBR door open button inputs inverted.

COD – Parameter lockout function

To stop unauthorised adjustments to the EEprom parameters the COD and LCK parameters are used.

COD and LCK must both be set to default values to allow other parameters to be adjusted.

See also Eeprom setting LCK

COD default. 89: 10001001

LCK default. 67: 01100111

DCMF - Down Call Mask (Front doors) setup

DCMF EEPROM (MASK) Front doors down hall calls allowed for this lift only.

This setting lets you define the DOWN front doors floors which the lift can serve via DOWN HALL CALLS

Set bits to a “1” hall call allowed or a “0” for not allowed.

40: 01000000 (2d)

60: 01100000 (2d,3d)

70: 01110000 (2d,3d,4d)

78: 01111000 (2d,3d,4d,5d)

7C: 01111100 (2d,3d,4d,5d,6d)

DCMR - Down Call Mask (Rear doors) setup

DCMR EEPROM (MASK) Rear doors down hall calls allowed for this lift only.

This setting lets you define the DOWN rear doors floors which the lift can serve via DOWN HALL CALLS

Set bits to a “1” hall call allowed or a “0” for not allowed.

40: 01000000 (2d)

60: 01100000 (2d,3d)

70: 01110000 (2d,3d,4d)

78: 01111000 (2d,3d,4d,5d)

7C: 01111100 (2d,3d,4d,5d,6d)

DLI - Door Limit Invert setup

DLI is only valid when DLM is set to 00, 03 or 04. See also EEprom setting DLM.

DLI setting is used to invert the DFOF/DFOR and DFCF/DFCR inputs when normally open (n/o) door limit

contacts are used.

DLI EEPROM Door limit invert. (MASK)

DLI: 00 “Limits not inverted.”

DLI: 01 “ Limits inverted.” Any setting other than 00 shall default to inverted limits.

DLI set to 00 - Limits not inverted. Using n/c limits.

Doors fully open – DFCF/DFCR LED will be on. DFOF/DFOR LED will be off

Doors fully closed – DFCF/DFCR LED will be off. DFOF/DFOR LED will be on

Doors midway – DFCF/DFCR LED will be on. DFOF/DFOR LED will be on

DLI set to 01 - Limits inverted. Using n/o limits.

Doors fully open – DFCF/DFCR LED will be off. DFOF/DFOR LED will be on

Doors fully closed – DFCF/DFCR LED will be on. DFOF/DFOR LED will be off

Page 18

E E P R O M S E T T I N G S

Doors midway – DFCF/DFCR LED will be off. DFOF/DFOR LED will be off

DLM - Door Limit setup

This signal sets up the door limits inputs.

See also EEprom setting DLI, DFCF/DFCR, DFOF/DFOR.

DLM EEPROM Door limit mask.

Setting example:

DLM 00: 00000000 (Door open and close limits going to DFOF/DFOR, DFCF/DFCR

inputs which drop DOF/DOR and DCF/DCR relays).

DLM 01: 00000001 N/A

DLM 02: 00000010 (Door cam control) DC relay output used to control Cam operation.

Nb: 1 sec delay from DO picking up after DC has dropped. (to allow time for cam

to drop and locks to break, to avoid lock “snagging”).

See also Input - Output, DFCF/R.

DLM 03: 00000011 (As per setting “00” but DOF/DOR and DCF/DCR relays are held up)

DLM 04: 00000100 (As per setting “00” but DCF/DCR relay picks up whilst running).

DRV - Drive type setup

This sets the drive output type. Relay output configurations are changed to suit equipment installed.

Refer to operation section for motion outputs.

DRV…EEPROM…Drive control type.

00: 00000000 “Standard hyd. block valve. 3010EN”

01: 00000001 ”DA DynaHyd valve.”

02: 00000010 “Soft valve. 3010/2CH/S”

03: 00000011 “VF type 1; Keb VF drive, Zetadyn VF drive”

04: 00000100 “1,2 speed AC”

05: 00000101 “GMV 3010/S, Blain EV100”, Maxton, Bucher LRV, EECO

06: 00000110 “VF type 2”

07: 00000111 “VF type 3; ABB VF drive”

DT - Door Time Close setup

This setting allows the door fully open time NOT to be canceled when a car-call or door closed button

(DCBF/DCBR) is pressed.

Setting example:

DT 00: 00000000 (NOT ALLOW pressing a car-call or door close button to cancel door timing).

DT 01: 00000001 (ALLOW pressing a car-call or door close button to cancel door timing).

DTCF - Door Time Car call (Front doors) close setup

Sets the amount of time before the front doors close for a car call whilst on normal operation.

DTCF EEPROM Front doors time close. (VALUE)

Set value for front door close time.

The time is set in 100ms increments.

1e: 00011110 = 3000ms, “3 seconds”

32: 00110010 = 5000ms, “5 seconds”

90: 10010000 = 14400ms, “14.4 seconds”

(01 to FF valid values.)

DTCR - Door Time Car call (Rear doors) close setup

Sets the amount of time before the rear doors close for a car call whilst on normal operation.

DTCR EEPROM Rear door time close. (VALUE)

Set value for rear door close time.

The time is set in 100ms increments.

1e: 00011110 = 3000ms, “3 seconds”

Page 19

E E P R O M S E T T I N G S

32: 00110010 = 5000ms, “5 seconds”

90: 10010000 = 14400ms, “14.4 seconds”

(01 to FF valid values.)

DTHF - Door Time Hall call (Front doors) close setup

Sets the amount of time before the front doors close for a hall call whilst on normal operation.

Lobby time (DTL) overrides this setting when lift is at the lobby floor.

Recommend DTHF is set equal to or greater than DTCF.

DTHF EEPROM Front door hall call time close. (VALUE)

Set value for front door close time.

The time is set in 100ms increments.

1e: 00011110 = 3000ms, “3 seconds”

32: 00110010 = 5000ms, “5 seconds”

90: 10010000 = 14400ms, “14.4 seconds”

(01 to FF valid values.)

DTHR - Door Time Hall call (Rear doors) close setup

Sets the amount of time before the rear doors close for a hall call whilst on normal operation.

Lobby time (DTL) overrides this setting when lift is at the lobby floor.

Recommend DTHR is set equal to or greater than DTCR.

DTHR EEPROM Rear door hall call time close. (VALUE)

Set value for rear door close time.

The time is set in 100ms increments.

1e: 00011110 = 3000ms, “3 seconds”

32: 00110010 = 5000ms, “5 seconds”

90: 10010000 = 14400ms, “14.4 seconds”

(01 to FF valid values.)

DTL - Door Time Lobby call close setup

Sets the amount of time before the doors close after a lobby call is answered when on normal operation.

DTL value overrides DTHF/DTHR value when answering a hall call at the lobby floor.

Recommend DTL is set equal to or greater than DTHF/DTHR and DTCF/DTCR.

DTL EEPROM Door time close. (VALUE)

Set value for door close time.

The time is set in 100ms increments.

1e: 00011110 = 3000ms, “3 seconds”

32: 00110010 = 5000ms, “5 seconds”

90: 10010000 = 14400ms, “14.4 seconds”

(01 to FF valid values.)

DTRF - Door Time Recall Front setup

Sets the amount of time before the front doors close after returning to HR or HR1 floor and lift not being

switched to IND or CFS.

The time is set in 100ms increments.

Eg. 32: 00110010 = 5000ms, “5 seconds”

See also Inputs-Outputs SIN3

DTRR - Door Time Recall Rear setup

Sets the amount of time before the rear doors close after returning to HR or HR1 floor and lift not being switched

to IND or CFS.

The time is set in 100ms increments.

Eg. 32: 00110010 = 5000ms, “5 seconds”

See also Inputs-Outputs SIN3

Page 20

E E P R O M S E T T I N G S

EQK

N/A. Do not adjust.

FS - Fire Service type

Australia: Set to 00: 00000000

USA Only. Fire Service Code 17.1. FS EEprom setting must be set to 01: 00000001

HFAF - Hall Fire Alternate (Front doors) floor setup

USA Only. Fire Service Code 17.1. FS EEprom setting must be set to 01

When the designated floor smoke alarm is activated, the lift shall return to the HFAF floor if there is a setting floor.

See also Inputs-Outputs HFAF

HFAF…EEPROM Hall Fire Alternate (Front doors) floor. (MASK)

00: 00000000 (No setting floor)

80: 10000000 (Level 1)

40: 01000000 (Level 2)

20: 00100000 (Level 3)

10: 00010000 (Level 4)

08: 00001000 (Level 5)

04: 00000100 (Level 6)

Note: Set either HFAF OR HFAR. DO NOT set both of them.

HFAR - Hall Fire Alternate (Rear doors) floor setup

USA Only. Fire Service Code 17.1. FS EEprom setting must be set to 01

When the designated floor smoke alarm is activated, the lift shall return to the HFAR floor if there is a setting

floor.

See also Inputs-Outputs HFAR

HFAR…EEPROM Hall Fire Alternate (Rear doors) floor. (MASK)

00: 00000000 (No setting floor)

80: 10000000 (Level 1)

40: 01000000 (Level 2)

20: 00100000 (Level 3)

10: 00010000 (Level 4)

08: 00001000 (Level 5)

04: 00000100 (Level 6)

Note: Set either HFAF OR HFAR. DO NOT set both of them.

HFSF - Hall Fire Service (Front doors) return floor setup

This sets the hall fire service return front doors floor activated when HFS input is active whilst in normal mode and

HFSF has a setting floor.

HFSF…EEPROM Hall Fire Service (Front doors) floor. (MASK)

00: 00000000 (No setting floor)

80: 10000000 (Level 1)

40: 01000000 (Level 2)

20: 00100000 (Level 3)

10: 00010000 (Level 4)

08: 00001000 (Level 5)

04: 00000100 (Level 6)

Note: Set either HFSF OR HFSR. DO NOT set both of them.

Page 21

E E P R O M S E T T I N G S

HFSR - Hall Fire Service (Rear doors) Return floor setup

This sets the hall fire service return rear doors floor activated when HFS input is active whilst in normal mode and

HFSR has a setting floor.

HFSR…EEPROM Hall Fire Service (Rear doors) floor. (MASK)

00: 00000000 (No setting floor)

80: 10000000 (Level 1)

40: 01000000 (Level 2)

20: 00100000 (Level 3)

10: 00010000 (Level 4)

08: 00001000 (Level 5)

04: 00000100 (Level 6)

Note: Set either HFSF OR HFSR. DO NOT set both of them.

HRF – Hospital / Hall Recall Front doors

This sets the Hospital Recall floor for the front doors when lift is in HR mode.

See also Inputs-Outputs SIN3 and Eeprom settings HRR

If HRF is set, HRR MUST be 00 or recall shall not operate.

eg. 40: 01000000 (Level 2)

HRR – Hospital / Hall Recall Rear doors

This sets the Hospital Recall floor for the rear doors when lift is in HR mode.

See also Inputs-Outputs SIN3 and Eeprom settings HRF

If HRR is set, HRF MUST be 00 or recall shall not operate.

eg. 20: 00100000 (Level 3)

LCK – Parameter lockout function

To stop unauthorised adjustments to the EEprom parameters the LCK and COD parameters are used.

LCK and COD must both be set to default values to allow other parameters to be adjusted.

See also Eeprom setting COD

LCK default. 67: 01100111

COD default. 89: 10001001

LOB - Lobby floor setup

This signal sets the master zoning floor. After the zone time period as defined by ZTM, a lift shall zone to floor

defined by LOB, if unoccupied. If LOB floor is occupied then the lift shall alternatively zone to ZON floor.

A lift shall zone to floor defined by LOB and ignore ZON, when working in simplex.

LOB EEPROM Lobby floor. (MASK) Master zoning floor.

LOB must be set to the same value in all lifts belong to the group.

00: 00000000 (No zoning). To disable zoning set “LOB” and “ZON” to “00”.

80: 10000000 (Level 1)

40: 01000000 (Level 2)

20: 00100000 (Level 3)

10: 00010000 (Level 4)

08: 00001000 (Level 5)

04: 00000100 (Level 6)

L.# - Lift Number setup

Lift number setup.

Example: In a 2 car group you must have one lift set to 01 and the other set to 02. It doesn’t matter which way

around they are as long as each lift is different.

Page 22

E E P R O M S E T T I N G S

L.#…EEPROM…Lift # (VALUE). Set value to lift number. (01 to 06 valid values.)

01: 00000001 (Lift 1)

02: 00000010 (Lift 2)

03: 00000011 (Lift 3)

04: 00000100 (Lift 4)

05: 00000101 (Lift 5)

06: 00000110 (Lift 6)

MOD - MODE Inputs setup

Enables the 3 MODE inputs to be inverted. CFS, HFS, IND

MOD EEPROM (MASK)

08: 00001000 CFS. Car fire service input inverted

20: 00100000 HFS. Hall fire service input inverted

40: 01000000 IND. Independent Operation input inverted

All other inputs default to 0.

MSL - Magnet Slowing type

Sets the slowing/counting type.

00: 00000000 MSU/MSD magnet slowing.

01: 00000001 Pulse slowing.

See also Section 6: Motion – EEprom MSL setting “00” and “01”

NR - Door Nudging setup

Sets the door nudging feature on or off. (Nudging time is preset).

See also output, NRF and NRR

See also output, NDGF and NDGR

Sets “NDGF and NDGR” output on or off to control the floor passing tone.

00: 00000000 No door nudging or passing tone

01: 00000001 Door nudging only

02: 00000010 Door nudging and passing tone

03: 00000011 Passing tone only

04: 00000100 Sets EDP/OS time to 180 secs. See also Input - Output, EDP

PRK - Park/Zone with doors open

This setting sets the lift to Zone with the doors open.

PRK EEPROM value.

00: 00000000 “Normal.”

01: 00000001 ”PRK doors open.”

PRV - Proving required setup

If set to "01" PRV input is required to be on prior to starting a run, irrelevant of DRV type selected.

See also Input - Output, PRV.

RLV - Re-Leveling setup

This sets the floor re-leveling function on/off

Setting example 00: 00000000 off. Lift will NOT re-level.

01: 00000000 on. Lift will re-level.

Note: Lift only re-levels if doors are either fully opened or closed.

Page 23

E E P R O M S E T T I N G S

RPT - Run Protection Timer setup

If the lift is given run signals from controller and lift does not move, (no MSU or MSD input received) the

controller turns off all run signals after a certain time, (e.g. 25s) depending on value of the RPT setting. If this

process is cycled 3 times, then the controller shall display RPT error message on the LCD screen.

RPT is a fatal error. Reset is only via a processor POR or Inspection on/off sequence.

Setting example 01: 00000001 = 25s

02: 00000010 = 50s

03: 00000011 = 75s

All other remaining settings including 00, will default to the value of 25s.

RPT does not operate on inspection or on DRV setting “01” (DA valve).

RTM – Run Time short floor run setup

If a short floor exists where the lift starts slowing prior to reaching full speed, a long creep into floor may occur.

RTM setting, in conjunction with XTM setting, can reduce this long creep time by holding in the fast speed relay

for a defined (XTM) time after the initial slowing point.

Setting RTM. – Look at Ram address R:72. (Motion Timer).

To access R:72 on the LCD see also Section 5: LCD

02- NOR IDL ][

R:70 00 OA 00 14

Display Options

R: 72 shown in red at left.

When performing the shortest floor run take note of the highest value R:72 reaches (in hex). Add approx. 5 (in hex)

to this value and set RTM to this value.

If slowing is obtained before the value in RTM is reached, the fast speed relay (UF or DF) will be held up for extra

time as defined by XTM. See XTM setting.

RTM and XTM may be used as above for both MSL=00 and MSL=01 (pulse counting) settings.

SDX - Star Delta Exchange Time setup

This sets the amount of time from Star dropping out and Delta picking up.

SDX EEPROM Star Delta Exchange time. (VALUE)

Set value for delay between star dropping and delta pulling in.

The time is set in 100ms increments.

08: 00001000 = 800ms

Set between 01 & 08

SDX - VF Drive setting 06,07,08 brake drop time

Valid only when Eeprom setting “DRV” is set to “06, 07, 08”.

This sets the amount of time after a run for the brake drop in 10ms increments.

SDX value must be less than ST2 value

Set between 01 & ff

SFR - Short Floor Run setup

Note: this setting only works on MSL 00

This signal sets a short floor between floors, i.e the controller will not set the fast speed relays (UF & DF).

SFR…EEPROM Must be FF: 11111111 unless stated.

A setting for a short floor between levels 2 & 3 would be as follows.

12345678

10011111

Page 24

E E P R O M S E T T I N G S

Spares

--1 EEPROM Spare

--2 EEPROM Spare

--3 EEPROM Spare

--4 EEPROM Spare

--5 EEPROM Spare

StF - Start Fast

Number of pulses (in hex) it takes to reach fast speed

StF EEPROM Start Fast pulses. (VALUE)

Eg. 30: 00110000 (30 pulses in hex or 48 in decimal)

See also Section 6: Motion – EEprom MSL setting “01”

StM - Start Medium

Number of pulses (in hex) it takes to reach medium speed.

StM EEPROM Start Medium pulses. (VALUE)

Eg. 20: 00100000 (20 pulses in hex or 32 in decimal)

See also Section 6: Motion – EEprom MSL setting “01”

SlF - Slow Fast

Number of pulses (in hex) it takes to slow from fast speed.

SlF EEPROM Slow Fast pulses. (VALUE)

Eg. 30: 00110000 (30 pulses in hex or 48 in decimal)

See also Section 6: Motion – EEprom MSL setting “01”

SlM - Slow Medium

Number of pulses (in hex) it takes to slow from medium speed.

SlM EEPROM Slow Medium pulses. (VALUE)

Eg. 20: 00100000 (20 pulses in hex or 32 in decimal)

See also Section 6: Motion – EEprom MSL setting “01”

ST2 - Star Delta Changeover Time setup

Star connected motor running time.

The amount of time the motor runs in Star, before changing to Delta.

ST2 EEPROM Star Delta time. (VALUE)

The time is set in 100ms increments.

08: 00001000 = 800ms

0a: 00001010 = 1000ms, “1 second”

12: 00010010 = 1800ms, “1.8 seconds”

ST2 - VF Drive setting 06,07,08 end run time

Valid only when Eeprom setting “DRV” is set to “06, 07, 08”.

This sets the amount of time after a run for the Up/Dn relays to drop in 10ms increments.

Set between 01 & ff .

ST2 value must be greater than SDX value

TCC - Top Car Call setup

TCC EEPROM Top car call for the “TOP CALL” button on the circuit board (MASK)

Top floor served for this lift only.

The controller shall enter a car call to this setting when the “TOP CALL’’ button on the circuit board is pressed.

40: 01000000 (Level 2)

Page 25

E E P R O M S E T T I N G S

20: 00100000 (Level 3)

10: 00010000 (Level 4)

08: 00001000 (Level 5)

04: 00000100 (Level 6)

TOP - Top floor setup

TOP EEPROM Top floor number (VALUE)

Set value to number floors served. (02 to 06 are valid values).

Lift resets to “TOP” value when TSL limit is activated.

02: 00000010 (Level 2)

03: 00000011 (Level 3)

04: 00000100 (Level 4)

05: 00000101 (Level 5)

06: 00000110 (Level 6)

UCMF - Up Call Mask (Front doors) setup

This setting lets you define the UP call(s) of front doors floors which the lift can serve.

With this setting you may disable UP hall calls to front doors floors not allowed.

UCMF EEPROM Up call mask. Front doors floors allowed. (MASK) Up calls allowed for this lift only.

80: 10000000 (Level 1u)

C0: 11000000 (Level 1u,2u)

E0: 11100000 (Level 1u,2u,3u)

F0: 11110000 (Level 1u,2u,3u,4u)

F8: 11111000 (Level 1u,2u,3u,4u,5u)

UCMR - Up Call Mask (Rear doors) setup

This setting lets you define the UP call(s) of rear doors floors which the lift can serve.

With this setting you may disable UP hall calls to rear doors floors not allowed.

UCMR EEPROM Up call mask. Rear doors floors allowed. (MASK) Up calls allowed for this lift only.

80: 10000000 (Level 1u)

C0: 11000000 (Level 1u,2u)

E0: 11100000 (Level 1u,2u,3u)

F0: 11110000 (Level 1u,2u,3u,4u)

F8: 11111000 (Level 1u,2u,3u,4u,5u)

XTM - Extend run time short floor run

If a short floor exists where the lift starts slowing prior to reaching full speed, a long creep into floor may occur.

RTM setting, in conjunction with XTM setting, can reduce this long creep time by holding in the fast speed relay

for a defined time after the initial slowing point.

Setting RTM. – Look at Ram address R:72. (Motion Timer). See RTM for access to R:72.

When performing the shortest floor run take note of the highest value reached (in hex). Add approx. 5 to this value

and set RTM to this value.

If slowing is obtained before the value in RTM is reached, the fast speed relay will be held up for extra time as

defined by XTM.

Set XTM to 20. If the lift fails to slow down to leveling speed before reaching the floor, (ie, fast speed relay is

being held up too long) reduce XTM value. If there is still too much creep (ie, fast speed relay is being held up not

long enough) increase XTM time. Continue until desired result is obtained.

ZON - Zoning/Parking floor setup

ZON is only used in duplex configurations.

After the zone time period as defined by ZTM, a lift shall zone to floor defined by LOB. If LOB floor is occupied

then the lift shall alternatively zone to ZON floor.

Page 26

E E P R O M S E T T I N G S

Recommend to set ZON to the same value in all lifts belong to the group.

A lift shall zone to floor defined by LOB and ignore ZON, when working in simplex.

ZON EEPROM Zone floor. (MASK) Zoning floors for other lifts.

00: 00000000 (No zoning). To disable zoning set “LOB” and “ZON” to “00”.

80: 10000000 (Level 1)

40: 01000000 (Level 2)

20: 00100000 (Level 3)

10: 00010000 (Level 4)

08: 00001000 (Level 5)

04: 00000100 (Level 6)

ZTM - Zoning Time setup

This sets the amount of time prior to zoning to the “LOB” or “ZON” setting.

To disable zoning set “LOB” and “ZON” to “00”.

ZTM EEPROM Zoning time. (VALUE)

The time is set in 10s increments.

06: 00001000 = 60s

0a: 00001010 = 100s, “1 minute 40 seconds”

12: 00010010 = 180s, “3 minutes”

#.L - Number of Lifts setup

This sets the number of lifts in the group.

All lifts within the group must be set to the same value.

#.L EEPROM Number of Lifts (VALUE)

01: 00000001 (1 Lift)

02: 00000010 (2 Lifts)

03: 00000011 (3 Lifts)

04: 00000100 (4 Lifts)

05: 00000101 (5 Lifts)

06: 00000110 (6 Lifts)

Set value to number of lifts. (01 to 06 valid values.)

Page 27

G R O U P

Section

3

Section 3. Group

Group Connections and Communication

• +24V and 0V, up and down hall calls, HFS and HFA (if USA) inputs MUST be looped between all

elevators in the group.

• Group serial communication uses RS485 3-wire system.

• Controllers in the group are linked at the Serial TX terminals, SX+, SX- and GND, using shielded 3 wire

serial cable.

• Install link JP1 on the last lift of the group only.

• The same version software (build date) must be used in all grouped controllers.

• See connection diagram below.

SHIELDED CABLE FOR

SERIAL CONNECTION.

SERIAL

JP1

TX

TERM.

24V

0V

HFS

1U

2U

3U

4U

11U

12D

11D

10D

9D

2D

24V

0V

HFS

1U

2U

3U

4U

11U

12D

11D

10D

9D

2D

JP1

TERM.

SERIAL

TX

SERIAL

JP1

TX

TERM.

24V

0V

HFS

1U

2U

3U

4U

11U

12D

11D

10D

9D

2D

SOFTWARE PARAMETERS FOR

3 CAR GROUP SHOWN LEFT:

LIFT 1

L# 01 #L 03

LIFT 2

L# 02 #L 03

LIFT 3

L# 03 #L 03

GROUP CONNECTIONS

FOR 2 - 6 LIFTS.

LOOP 0V, 24V, HFS, AND ALL HALL

CALLS BETWEEN ALL LIFTS IN THE GROUP.

LINK JP1 TERMINATOR ON THE

LAST LIFT IN THE GROUP.

LIFT #1 OF 3 LIFT #2 OF 3 LIFT #3 OF 3

100-181 100-181 100-181

Page 28

G R O U P

Group Checks

To ensure all the lifts in the group are communicating with each other, check the RAM address which shows the position

of each lift.

Each lift has its position shown at the following RAM addresses.

• Lift 1. - Ram location 81

• Lift 2. - Ram location 91

• Lift 3. - Ram location a1

• Lift 4. - Ram location b1

• Lift 5. - Ram location c1

• Lift 6. - Ram location d1

To obtain RAM (R) address see Section 5, LCD Controller Status Options.

01- NOR IDL ][][

R:80 80 01 ff 03

02- NOR IDL ][][

R:90 80 02 ff 03

80 81 82 83 90 91 92 93

LIFT 1 LIFT 2

e.g. For a 2 car group. Lift 1 is on level 1. Lift 2 is on level 2.

From lift 1 controller look at RAM address 91. (lift 2 position). This should read a value of 02.

From lift 2 controller look at RAM address 81. (lift 1 position). This should read a value of 01.

This proves each controller knows the position of the other lift in the group, therefore indicating serial communication

established.

If controllers are not communicating correctly, a value of 00 will be shown.

Group/Duplex Faults

If group system is faulty check all wiring and connections as per Section 3.

Also, ensure EEprom settings L# and #L have been set correctly. See section 2.

NB: Due to looping of 24V and 0V between all boards in the group, 24VDC shall still exist on any board, even though it

may have been turned off at the main Circuit Breaker.

DO NOT remove the 0V or 24V from such boards as backfeeding shall occur which can false fire inputs.

Alternatively it is ok to remove ALL plugs from the board. (ie removal for repair)

Page 29

I N P U T S – O U T P U T S

Section

4

Section 4. Inputs – Outputs

All inputs except LR, SAF, HV1 and HV2 switch low to 0V in respect to +24V. The input shall draw approx

12mA. The input LED is in series with the input. All inputs are OPTO isolated to avoid noise-related problems.

Darlington outputs (ULN2803) switch low to 0V in respect to +24V. The output can switch a maximum

of 500mA. The output LED indicates the output status and shall be illuminated when the output has switched low.

All outputs are OPTO isolated to avoid noise-related problems.

Transistor outputs (BD682) switch high to +24V in respect to 0V. The output can switch a maximum of

1.5A. The output red LED indicates transistor output on, e.g. 1P, 2P, 3P, 4P.

BRK - Brake relay output

BRK RELAY OUTPUT Brake relay output

See Section 6: Motion, for more on the relay operation

BSL – Bottom SLowing input

Bottom floor position correction limit and forced slowdown limit for terminal floor.

BSL LED shall be off when BSL limit is activated.

BSL LED must remain off when lift is on the buffer

CBSF - Hall Button Stop (Front doors) output

CBSF TRANSISTOR OUTPUT

Hall button stop output. Activates when lift answers a front doors hall call.

CBSR - Hall Button Stop (Rear doors) output

CBSR TRANSISTOR OUTPUT

Hall button stop output. Activates when lift answers a rear doors hall call.

CC - Car Call inputs/Darlington outputs

inputs / outputs

Front doors:

1CF - I/O - 1st floor front car call/tell tale light

2CF - I/O - 2nd floor front car call/tell tale light

3CF - I/O - 3rd floor front car call/tell tale light

4CF - I/O - 4th floor front car call/tell tale light

5CF - I/O - 5th floor front car call/tell tale light

6CF - I/O - 6th floor front car call/tell tale light

Rear doors:

Page 30

I N P U T S – O U T P U T S

1CR - I/O - 1st floor rear car call/tell tale light

2CR - I/O - 2nd floor rear car call/tell tale light

3CR - I/O - 3rd floor rear car call/tell tale light

4CR - I/O - 4th floor rear car call/tell tale light

5CR - I/O - 5th floor rear car call/tell tale light

6CR - I/O - 6th floor rear car call/tell tale light

CFS - Car Fire Service input

Australia: CFS - Car Fire Service signal input.

LED on when keyed to CFS unless inverted with MOD setting.

CFS over rides HFS.

CFS shall allow only one car call to be entered and shall toggle to the latest pressed call.

When CFSS is pressed, CFS input must stay on.

USA: Fire Service Code 17.1. FS EEprom setting must be set to 01

CFS – Phase 2. In Car Fire Operation input.

CFSS - Car Fire Service Start input

Australia: CFSS – Car Fire Service Start signal input.

The CFSS LED is on when keyed to CFSS unless inverted with MOD setting.

The input is switched low to 0V.

When on CFS mode, CFSS input shall close the doors. The DOBF/DOBR and EDPF/EDPR shall be ignored.

CFSS must held on until the doors are closed. The lift shall then run to the floor selected.

USA: CFSS – Phase 2. In Car Call Cancel input.

DCBF - Door Close Button (Front doors) input

LED will turn on when front door close button is pressed unless inverted with CNT setting.

The front door close button closes the front doors on Independent Service.

DCBF cancels front doors timing on normal operation if DT is set to 01h.

Both the front doors detector EDPF and front door open button DOBF shall override the front door close button

DCBF.

DCBR - Door Close Button (Rear doors) input

LED will turn on when the rear door close button is pressed unless inverted with CNT setting.

The rear door close button closes the rear doors on Independent Service.

DCBR cancels rear doors timing on normal operation if DT is set to 01h.

Both the rear doors detector EDPR and rear door open button DOBR shall override the rear door close button

DCBR.

DCF - Door Close (Front doors) relay output

DCF RELAY OUTPUT Door Close (Front doors) relay output. See also DFCF Input.

DCR - Door Close (Rear doors) relay output

DCR RELAY OUTPUT Door Close (Rear doors) relay output. See also DFCR Input.

DDN - Direction Down output

DDN TRANSISTOR OUTPUT Down Direction indication output.

Output switches to +24V for indication of lift advanced down direction.

DDO - Door Open Disable input / Toggle Switch

Door Open Disable input

LED on when DDO input is activated.

Page 31

I N P U T S – O U T P U T S

Toggle switch also provided on board. When switch is on (down) DDO is activated.

Allows the lift to be sent to floors via car calls without the doors opening. Useful for testing/adjusting etc.

OS output shall be activated. Lift shall be taken out of the group.

DO button, Independent Service and Fire Service override DDO

DF - Down Fast relay output

DF RELAY OUTPUT Down Fast output

See Section 6: Motion, for more on the relay operation

DFCF - Door Fully Closed (Front doors) input

DFCF input must change state when the front doors reach the fully closed limit/position.

Single Front Door:

Input state can be inverted with DLI setting. See DLI in EEprom settings.

To close the lift front door, DCF relay shall pull up and stay up until the DFCF input is switched and the locks are

made. If DFCF input does NOT switch, DCPfail shall appear on the LCD after a period of 25 seconds and

drop DCF relay. After a further period of 15 seconds, the front door will re-open and display DCP (Door Close

Protection) on the LCD. This process is repeated until the fault has been cleared and the DFCF input switches.

While in DCPfail/DCP mode, the controller switches on the OS output. See Inputs - Outputs, OS.

Nb: When DLM = 02, DCPfail does not apply.

Alternatively, If DFCF input is switched and the door locks do not make, LCK-bad shall appear on the LCD.

DCF relay shall stay active for a period of 5 seconds to try to push the front door closed. If the door locks still fail

to make then the doors shall then re-open. This process will be repeated until the fault has been cleared and the

locks make.

Nb: When DLM = 02, LCK-bad does not apply, due to locks not making until a call is registered and cam lifting.

Dual Front Doors:

DLM EEprom setting must be set to 01 for dual doors.

DLI EEprom setting shall be ignored. . See DLI in EEprom settings.

DFCF input is switched via the external front door close relay n/o contacts.

The door close relays drop out via the door fully closed limit switches.

When the external front door close relay is in DFCF LED will be on.

See the following DC-DCPfail flow chart for more detail.

DFCR - Door Fully Closed (Rear doors) input

DFCR input must change state when the rear doors reach the fully closed limit/position.

Single Rear Door:

Input state can be inverted with DLI setting. See DLI in EEprom settings.

To close the lift rear door, DCR relay shall pull up and stay up until the DFCR input is switched and the locks are

made. If DFCR input does NOT switch, DCPfail shall appear on the LCD after a period of 25 seconds and

drop DCR relay. After a further period of 15 seconds, the rear door will re-open and display DCP (Door Close

Protection) on the LCD. This process is repeated until the fault has been cleared and the DFCF input switches.

While in DCPfail/DCP mode, the controller switches on the OS output. See Inputs - Outputs, OS.

Nb: When DLM = 02, DCPfail does not apply.

Alternatively, If DFCR input is switched and the rear door locks do not make, LCK-bad shall appear on the

LCD. DCR relay shall stay active for a period of 5 seconds to try to push the rear door closed. If the door locks still

fail to make then the doors shall then re-open. This process will be repeated until the fault has been cleared and the

locks make.

Nb: When DLM = 02, LCK-bad does not apply, due to locks not making until a call is registered and cam lifting.

Dual Rear Doors:

DLM EEprom setting must be set to 01 for dual doors.

Page 32

I N P U T S – O U T P U T S

DLI EEprom setting shall be ignored. . See DLI in EEprom settings.