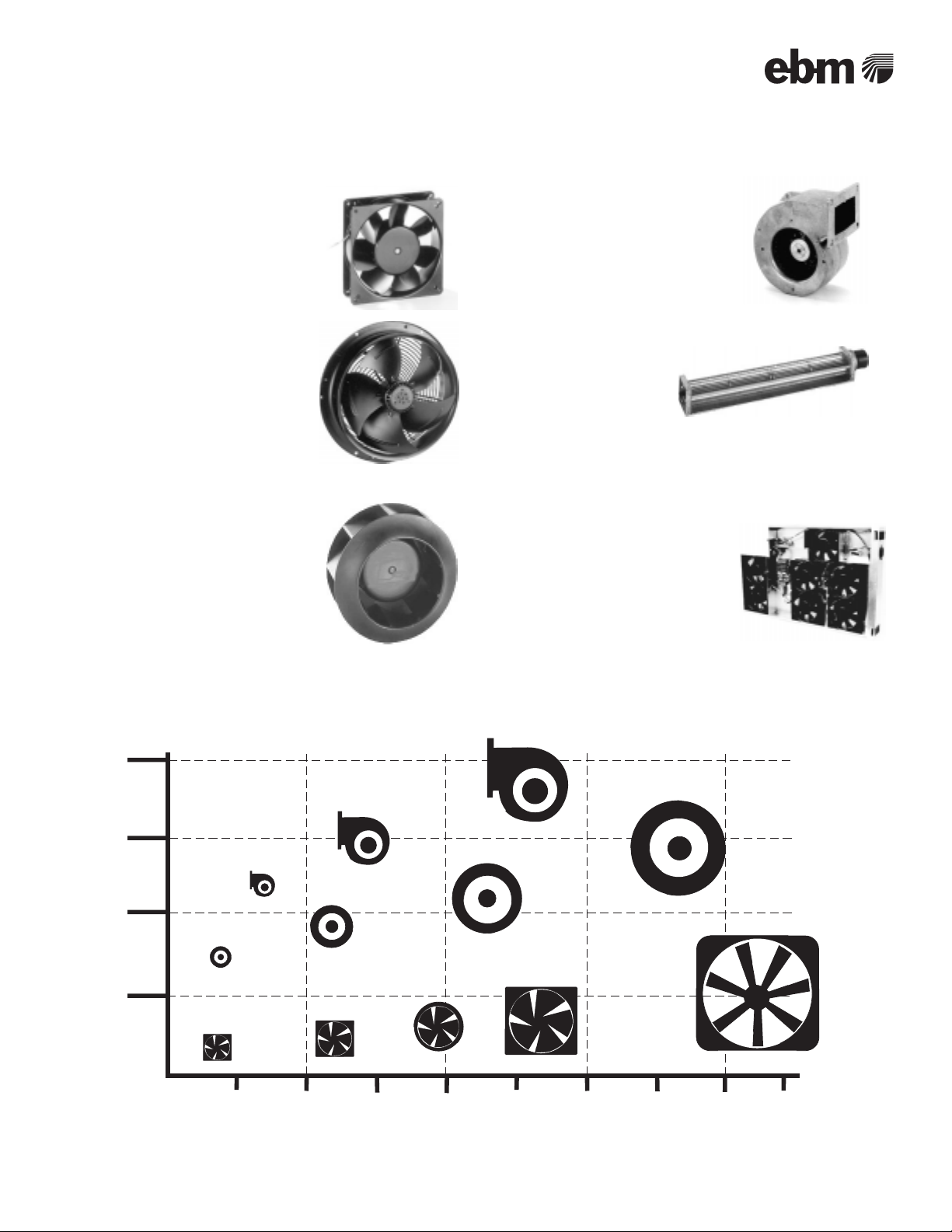

ebm-papst Fans Impellers and Blowers General Product Line Information

Understanding the Differences

in Fans, Impellers and Blowers

Select either AC or Brushless DC models:

Tubeaxial Fans

• Readily available and inexpensive

• Many sizes and performances

• Good to excellent efficiency

• Axial air flow pattern

Axial & Propeller Fans

• Very high air flows

• Good efficiency

• Many sizes and performances

• Axial air flow pattern

Backward Curved Impellers

• Compact package size

• Excellent efficiency

• Quietest performance

• Many airflow options

• Even, tangential air flow

Centrifugal Blowers

• Excellent pressure performance

• Very good efficiencies

• Air in axially – out tangentially

• Single or Dual inlet options

Crossflow Blowers

• Fair to good efficiency

• Narrow, controlled air

flow direction

• Good for air curtains and paper/

converting transfer

Fan Trays & Flo-Thru Modules

• Compact, custom-fit package sizes

• Built-in redundancy, if needed

• Simple, space-saving designs

• Efficient, cost-effective solutions

STATIC

PRESSURE

(inches of water)

2.0

1.5

1.0

0.5

50

Air Mover Selection

100 200

400

800

1600 3200

6400

AIR FLOW (CFM)

12800

14

Call ebm Industries at 860-674-1515 • Fax 860-674-8536 • E-mail: sales@ebm.com for Technical Assistance

© ebm Industries, Inc. 1995,1996, 1997, 1999. ebm Industries, Inc. reserves the right to change any specifications or data without notice.

Motor Design, Quality and Performance are

Critical to Reliable Operation of Fans & Blowers

Most electronic systems create heat which needs

to be removed. Blowers and fans are the most reliable,

efficient way to control heat rise in electronic equipment.

Although blower selection relies on a variety of design

parameters, including air flow, system impedance, package

size, electrical characteristics and acoustics, the motor

which powers the impeller or fan is critical to safe and

reliable operation and protection of valuable system

components.

In most applications, the fan/blower motor

operates continuously when

the system in on and in

operation. Although speed

control is possible with most

motors, it is rarely a major

factor when selecting major

features of the motor. Similarly,

many of the common motor

evaluation criteria are not major

factors when choosing a fan or

blower. Typical speed/torque

curves are not important.

Acceleration, deceleration are

not critical. What is important?

Long-life operation, maintenance-free performance, size,

weight, efficiency and power

compatibility with other

components which are being

assembled into one integrated

system. The external rotor

motor which is available in both

AC and brushless DC versions

provides the best performance and most reliable operation

for most applications.

THE ADVANTAGES OF EXTERNAL

ROTOR CONSTRUCTION

Since most motor heat is produced in the rotor, making

it the rotating element and keeping the stator stationary (see

Photo ) have several very important effects on performance:

• More effective cooling improves reliability and

extends the life of the motor

• Motor efficiency and size/output relationships

are better than with induction-type motors.

Even if the external rotor motors operate at low speeds

which in turn increases heat, current (amps) increases only

slightly (in many internal rotor motors current often rises

30% to 40%). Superior cooling and heat dissipation from the

motor still occurs because the air flow passes over the rotor.

Speed control is very easy with external rotor motors by

voltage reduction using fixed or variable resistors, autotransformers, or electronic speed controllers. Speed control

has better linearity, too.

Because motors are

totally enclosed they run

clean and stay clean for

long life operation. Shorter

lamination stacks reduce

copper losses. Less

induction is required to

reach equivalent torque.

The operating temperature

range for most blowers or

fans is commonly – 22° F to

+ 300° F (-30° C to + 150°

C) but varies with motor

type and power selection.

Most AC motors include

built-in overload protection

by impedance or thermal

cutout.

Many options can be

added depending on user

needs. They include: Hall

Effect sensors, a choice of different alarms, different

windings, dual voltage, constant speed back up if a speed

controller fails, adaptation to substantial load changes,

impeller attachment and a choice of bearing systems.

External rotor motors are also better when multiple motors

operate simultaneously in a system at a common frequency

or speed, for example, using several fans in a fan tray or fan

rack, or using one blower at an intake inlet and another at

an exhaust outlet.

Call ebm Industries at 860-674-1515 • Fax 860-674-8536 • E-mail: sales@ebm.com for Technical Assistance

© ebm Industries, Inc. 1995,1996, 1997, 1999. ebm Industries, Inc. reserves the right to change any specifications or data without notice.

15

A VARIETY OF MOTORS

The motors used in ebm blowers and motorized impellers

are either shaded-pole, permanent split capacitor or brushless

DC designs with Class "B" insulation. AC units operate at 115V

or 230V, 50/60Hz. Dual voltage (115/230 volt) motors, three

phase motors and other special AC models rated from 12 to 440V

are available on a special order basis. AC motors are thermally

protected in accordance with UL, CSA and VDE requirements.

Brushless DC models are available in 12, 24, 48 and special

voltages. Motors are up to 5 times as efficient as AC motors.

Voltage can deviate ±30% from the nominal voltage. DC motors

feature electronic locked rotor protection. Electronic features

such as Hall effect for failure monitoring or output for external

control, temperature sensing and control can be integrated in the

motor. Dimensions will vary with each motor. NEW brushless

DC motors and blower products are constantly being introduced.

Call us for complete and current information, 860-674-1515.

The motor ratings listed correspond to the maximum power

demand of the impeller occurring at zero static pressure.

SPEED CONTROL

All ebm external rotor motors are 100% speed controllable

by voltage reduction or other means and operate at very low

voltages without overheating or reducing reliability. The outstanding advantage of ebm/Papst motors, when speed controlled, is their STABILITY which permits proper balance between air flow and noise.

It is possible to make any ebm fan or blower with a PSC

motor a multi-speed blower by adding a second or third capacitor

on the load line (see wiring diagrams) at or near the value of the

motor run capacitor. Actual capacitor value and RPM achieved

are dependent on the uniqueness of the customer's application.

To maintain operating reliability of AC products, a reactive

filter (sine filter) should be used when controlling speed with a

variable frequency drive (VFD).

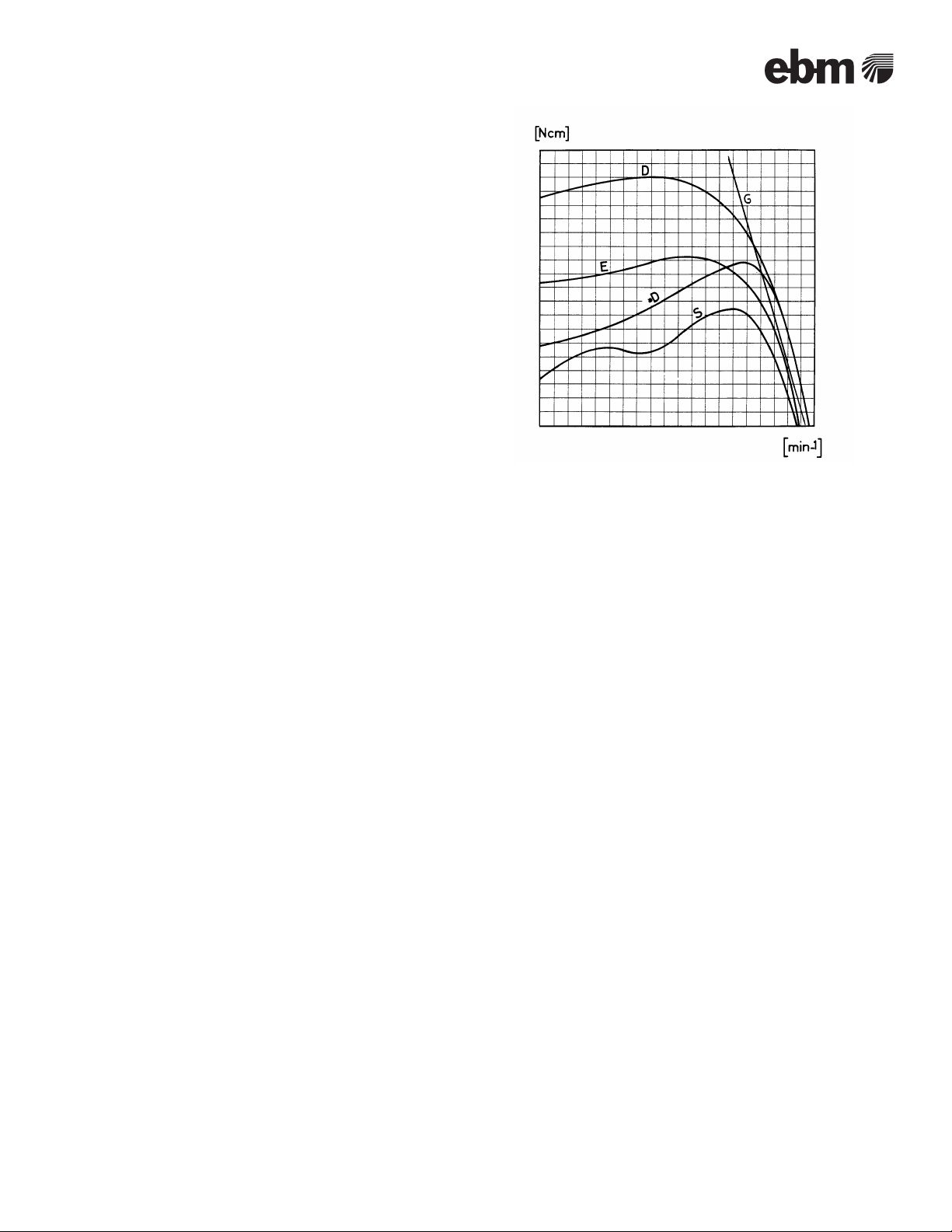

For brushless DC motors the speed/torque relationship is

more linear than that of most AC induction motors. Speed control

electronics can be built in to the DC motor assuring high quality

performance of the motor and the air mover.

S = Shaded pole motor: low starting torque, low efficiency

E = Single phase motor: high starting torque, good speed

control, fair efficiency

D* = 3Ø motor with capacitor: high pull out torque, high

efficiency, excellent speed stability

D = 3Ø motor: high starting torque, very high efficiency,

good speed control characteristics

G = DC, brushless motor: highest starting torque, exceptionally

high efficiency, 100% speed controllable.

HIGH QUALITY, SPACE-SAVING

DESIGN

Flexible air flow design, long life and structural stability are

inherent properties of all ebm fans, blowers and motorized

impellers. The external rotor motor, shaft and impeller blades

are each manufactured by ebm/Papst and assembled into a

single unit which is dynamically balanced in accordance with

DIN 1940.

The external rotor motor is mounted in the center of the fan

or impeller to save space, improve efficiency and minimize the

vibration that commonly occurs when the impeller is mechanically affixed to the motor shaft with set screw and hub.

GROUNDING

Grounding can be achieved through mounting to the metal

chassis. Additional ground connections on the blowers can

include an unpainted M4 tapped hole or separate ground wire to

meet VDE requirements.

Call ebm Industries at 860-674-1515 • Fax 860-674-8536 • E-mail: sales@ebm.com for Technical Assistance

© ebm Industries, Inc. 1995,1996, 1997, 1999. ebm Industries, Inc. reserves the right to change any specifications or data without notice.

16

ACOUSTICS

Sound measurements are made in an anechoic chamber

at nominal voltage with a microphone one meter from the air

inlet. Sound values are determined using a Bruel and Kjaer

sound level meter 2131. Low noise levels are achieved by

computer-aided-design of impeller blades and by precision

manufacturing and balancing.

Loading...

Loading...