Page 1

INSTRUCTION MANUAL

(505)872-0037

idealvac.com

idealvac.com

MULTI-STAGE DRY VACUUM PUMP

A70W (A70W-S,A70W-C)

A30W (A30W-S, A30W-C)

A25S (A25S-S)

A10S (A10S-S)

A07V (A07V-S)

Page 2

Do not reproduce or reprint any portion of this manual without permission.

Manufacturer reserves the right to discontinue or change any specifications or designs

without notice and without incurring obligations.

All rights reserved, copyright EBARA Corporation.

Page 3

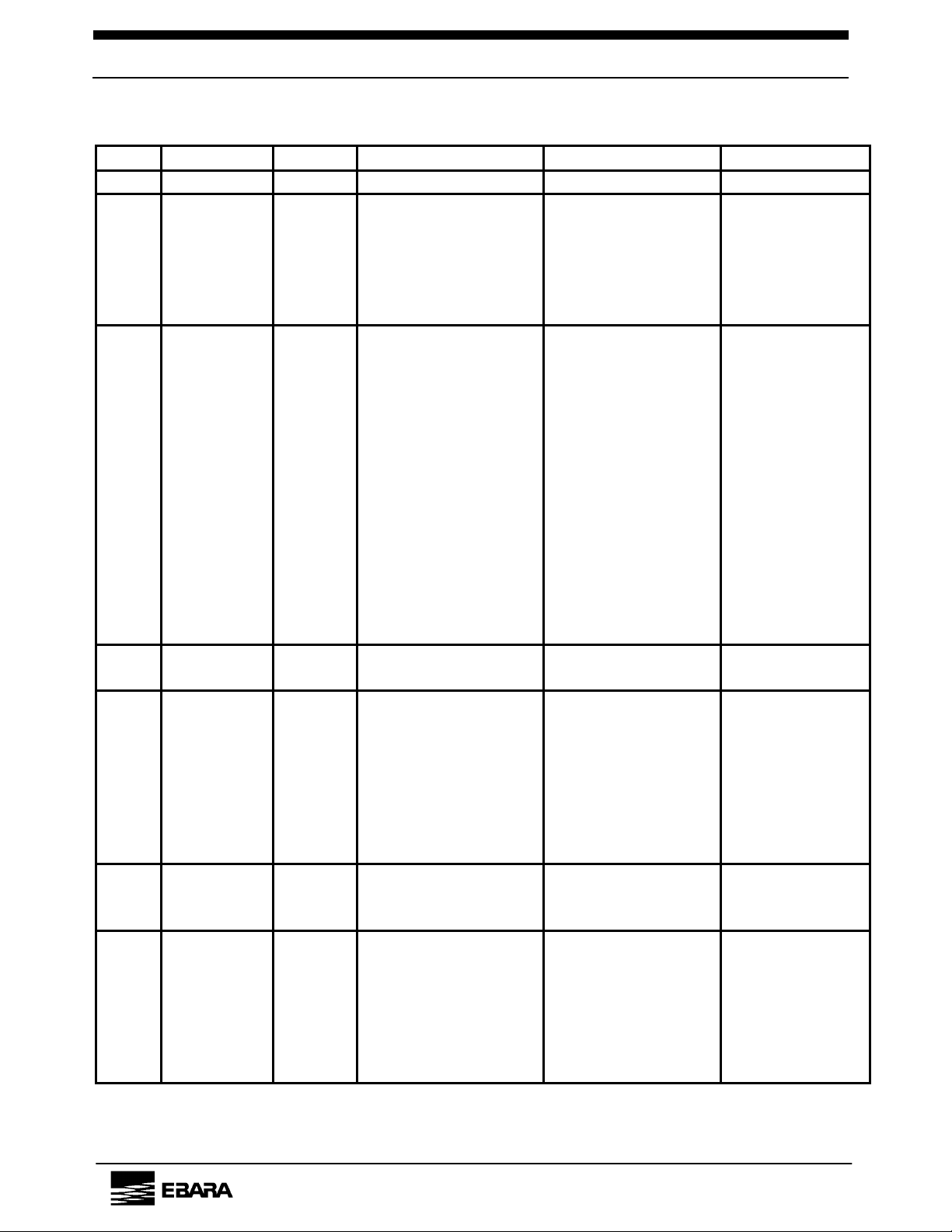

Record of Changes

Rev. Date Page Position Contents Reason

0 2-Jun-94 Newly issued

1 13-Jul-94 5

6-10

14

17

21

22

2 14-Nov-96

ⅲ ,ⅳ

ⅴ ,ⅵ ,ⅶ

4

21

25

26

33

35,36

37

44,45

A 12-Dec-97 New release

3 20-May-99 21

44,45

5,6,18,

27,28,

32

3A 27-Apr-01 ETI release of

3B June 2002 20

iv

Thruout

A07V Spec.

Outline Drawing

Fig. 3.4

Fig. 4.2

Fig. 4.6

Table 4.5

Fig. 1,2,3,4,5

Drawing

3.3 List

Dig. 4.4

Table 4.6

Fig. 4.7

Table 6.1

6.3

7 (8)

9

Tab. 4.2

9. Service Network

-----

Pumping Speed

Water Sup./Rtn

Sys. Flow

Coupler

Ctrl. Wiring

Pin Assign.

Safety warning

labels

Warning label

Location

Detailed

specifications

Power Sup. Rec

Dipswitch

S.W setting

Typical check

items

Spare Parts

Pump Lifting

Service Net.

Suitable wire

Japan, Taiwan

(Add., Phone, Fax)

The Unit was

changed in terms

of Domestic

regulation for

Measurement low.

Add UL grounding

note

Add LCD “hot

surface” note

Add appendices

Language Edit

Correction

Add NPT

Add Note

Add Drawing

Correction

Add note

Add

Add

Add List

Correction

Design Change

Design Change

Add Table

Add List

Add Note

Add List

per ECO 2905

Correction

Change

-----

EC Rev 3 per

ECO 5394.

Third-party

marking

Third-party

marking

SEMI S2

ECO 5771

(i)

EBARA Corporation

Page 4

(ii)

Safety Information

Anyone operating this pump must have the knowledge to identify and avoid hazardous

conditions associated with the pump.

Rash actions or improper operation may cause dangerous accidents and serious injuries.

Before installation and operation, the operator first should have a thorough knowledge of the

pump’s construction, operating procedures, and hazards.

The operator should read this instruction manual and other documents issued by EBARA.

If you have any questions on pump operation, safety, or maintenance, please do not hesitate

to contact EBARA directly.

Three terms in this manual designate different levels of hazard:

DANGER

WARNING

CAUTION

indicates an imminently hazardous situation that, if not avoided, will

result in death or serious injury.

indicates a potentially hazardous situation that, if not avoided, could

result in death or serious injury.

indicates an imminently hazardous situation that, if not avoided, may

result in minor or moderate injury.

This term may also indicate situations that might damage

equipment.

EBARA Corporation

Page 5

(iii)

Important Precautions

DANGER

WARNING

WARNING

WARNING

WARNING

WARNING

Keep out from under the pump when it is elevated.

Only qualified personnel should unload and lift the pump.

Be careful not to overturn the pump when pushing or pulling it

sideways. The pump is narrow in comparison to its height.

Only a qualified electrician, observing all national and local

regulations, should perform electrical work.

Cut and lock out electrical power before beginning wiring or

maintenance work.

Do not switch on the power supply to the pump until work is

completed and pump and piping are back in safe operating

condition.

Supply N2 gas to the exhaust piping when necessary to dilute

flammable or toxic gases down to a safe concentration.

Purge system with sufficient N2 gas before removing and cleaning

the vacuum lines and exhaust piping.

Prevent dispersal of flammable, toxic or dangerous materials and

guard against their contact with the human body.

Work only in locations with an emergency escape route.

WARNING

WARNING

WARNING

WARNING

WARNING

Do not convert the pump from one process to another without an

intervening overhaul. Gases or reaction products remaining in

the pump may react and lead to accidents or to the formation of

large amounts of byproduct.

Check Safety Interlock functions periodically (every 6 months) to

confirm correct operation. See Appendix 2 for a description of

these interlocks.

Connect exhaust from pumps handling process gases to an

appropriate exhaust abatement system that is equipped with

discharge quality monitors to provide warnings and to shut down

the process gas flow if concentrations exceed allowable limits.

Check for gas leaks after initial installation of the piping and after

reassembly following maintenance or, at least, annually. Gas

leaks can result in the discharge of harmful and dangerous

substances and in abnormal reactions due to the admission of air

into the pump. Replace o-rings as required to correct leaks.

See Appendix 4.

Do not modify the pump or any of its parts without EBARA's

approval.

EBARA Corporation

Page 6

(iv)

WARNING

Do not place the LCD controller on or near a surface with a

temperature exceeding 65ºC.

WARNING

The pump casing and exhaust piping become extremely hot

during operation and remain hot for some time after stopping.

Keep pump and exhaust piping away from contact with personnel

and flammable substances.

Do not remove pump enclosure panels during operation.

CAUTION

Disposal of process byproducts must be in strict accord with all

local and national environmental and safety regulations.

CAUTION

Dispose of printed circuit boards containing lithium batteries in

strict accord with all applicable local and national environmental

regulations.

CAUTION

The height of EBARA dry pumps may place the EMO button and

the LCD controller below the heights recommended in SEMI

S8-95. See Appendix 3.

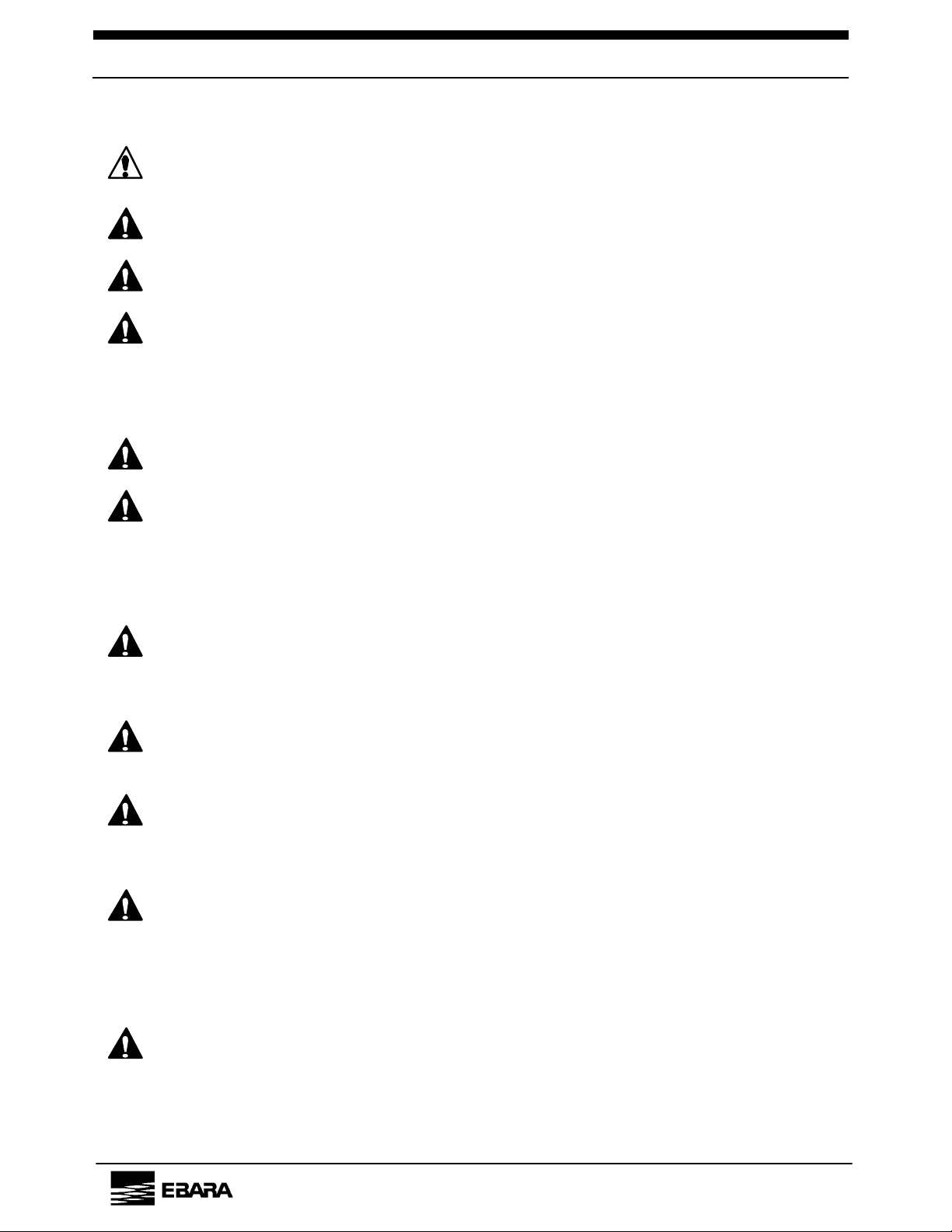

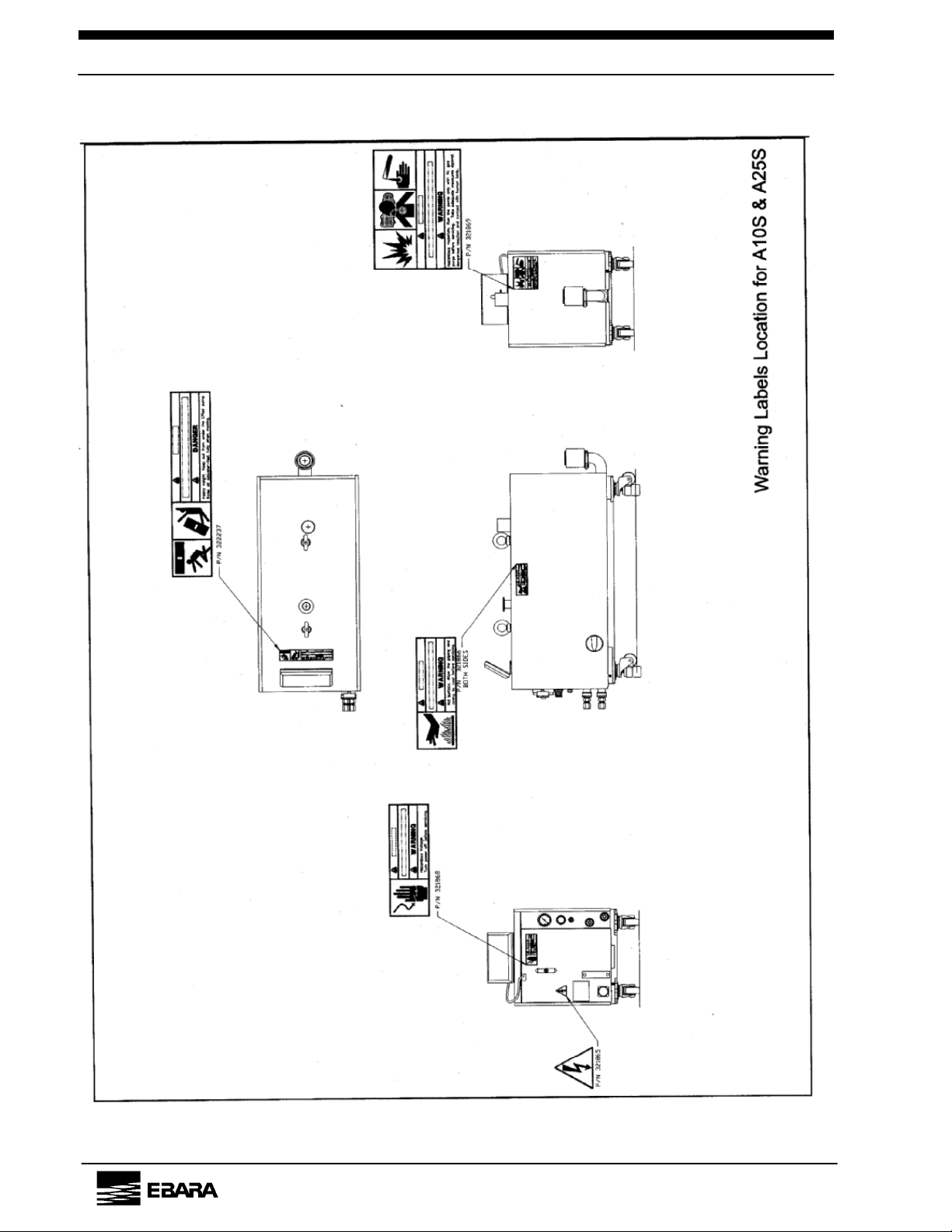

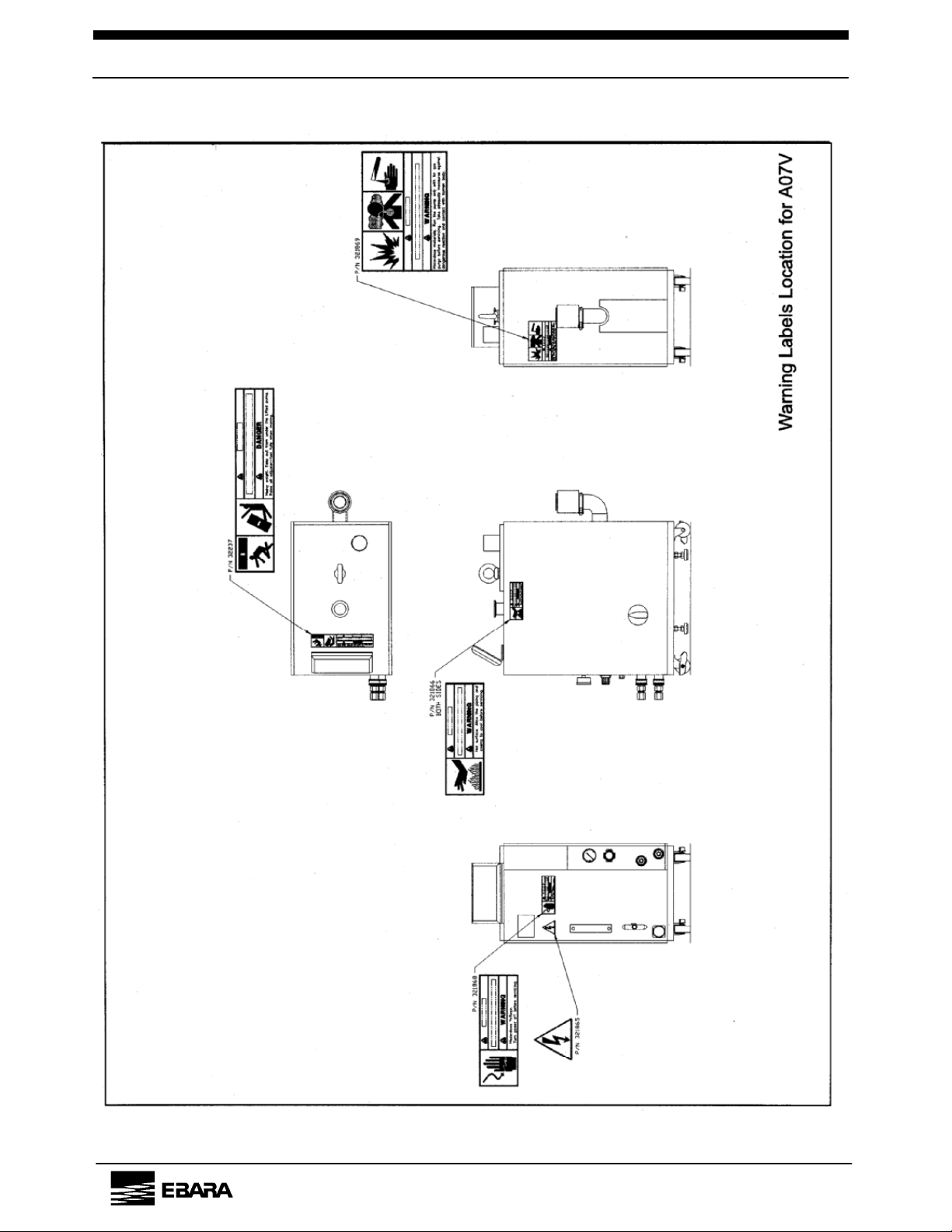

The following safety warning labels appear on the pump covers:

High temperature warning

Hazardous voltage warning

Hazardous materials warning

Electric charge mark

Hazardous weight danger

High temperature warning

Hot surface may burn or cause injury.

Allow the piping and casing to cool before servicing.

EBARA Corporation

Page 7

Hazardous voltage warning

Hazardous Voltage may shock, burn, or cause death.

Turn power off and lockout before servicing.

Hazardous materials warning

(Applies only when pumping hazardous materials)

Run the pump only with N

Take adequate measures against dangerous reaction and contact with human body.

Electric charge mark

gas purge before servicing.

2

(v)

EBARA Corporation

Page 8

(vi)

Hazardous weight danger

Heavy weight may cause severe injury or death due to overturning or falling pump.

Keep out from under the lifted pump.

Raise all adjuster feet fully when moving.

EBARA Corporation

Page 9

(vii)

EBARA Corporation

Page 10

(viii)

EBARA Corporation

Page 11

(ix)

EBARA Corporation

Page 12

(x)

Contents

Record of Changes.........................................................................................................i

Safety Information.........................................................................................................ii

Important Precautions..................................................................................................iii

Contents.........................................................................................................................x

1 Foreword..................................................................................................................1

2 Introduction.............................................................................................................1

3 Product Description................................................................................................2

3.1 Summary........................................................................................................2

3.1.1 Pump Module....................................................................................2

3.1.2 N2 Gas ...............................................................................................2

3.1.3 Cooling Water...................................................................................2

3.1.4 Exhaust .............................................................................................2

3.2 Control System..............................................................................................2

3.2.1 Warning.............................................................................................3

3.2.2 Operation Status Control.................................................................3

3.3 Moving the Pump...........................................................................................3

3.3.1 Preparation .......................................................................................3

3.3.2 Moving Method.................................................................................4

3.4 Detailed Specifications .................................................................................4

4 Installation.............................................................................................................16

4.1 Location .......................................................................................................16

4.2 Piping ...........................................................................................................17

4.2.1 Vacuum and Exhaust Piping.........................................................17

4.2.2 Cooling Water Piping.....................................................................17

4.2.3 N2 Gas Piping..................................................................................19

4.2.4 Ventilation Duct..............................................................................19

4.3 Electrical Wiring ..........................................................................................20

4.3.1 Power Supply Wiring .....................................................................20

4.3.2 Control Signal Wiring.....................................................................21

4.4 Operation Mode...........................................................................................24

5 Operation...............................................................................................................26

5.1 Before Starting.............................................................................................26

5.2 Operation .....................................................................................................30

5.2.1 Local (Pump side) Operation ........................................................31

5.2.2 Remote (Distant) Operation...........................................................31

6 Maintenance and Overhaul...................................................................................32

6.1 Routine Inspection ......................................................................................32

6.2 Piping Maintenance.....................................................................................33

6.3 Lubricant Oil ................................................................................................33

6.4 Spare (Maintenance) Parts List..................................................................34

6.5 Overhaul.......................................................................................................35

EBARA Corporation

Page 13

7 Removal and Transportation................................................................................36

8 Troubleshooting....................................................................................................38

8.1 Troubleshooting (1) Basic Trouble ............................................................38

8.2 Troubleshooting (2) ALARM.......................................................................39

8.3 Troubleshooting (3) TRIP............................................................................41

8.4 Troubleshooting (4) TRIP [Options]...........................................................42

9 Inquiries ................................................................................................................. 43

9.1 North America..............................................................................................43

9.2 Asia...............................................................................................................44

9.3 Europe ..........................................................................................................45

Appendices

1. Material Safety Data Sheet – Vacuum Pump Oil.................................................I

(xi)

2. Safety Interlocks ..............................................................................................III

3. Ebara Dry Pumps and SEMI S2-93A (S2-0200)................................................V

4. Leak Check Procedure..................................................................................... VI

5. Returning pumps for Rebuild in U.S................................................................VII

EBARA Corporation

Page 14

(xii)

[Blank page]

EBARA Corporation

Page 15

(1)

1 Foreword

We appreciate your selection of an EBARA A Series dry vacuum pump. EBARA has

manufactured this pump with much care and attention to permit safe and satisfactory

operation.

Incorrect operation will result in lack of performance and may cause accidents and injuries to

personnel.

[NOTE] This instruction manual contains necessary information on operation and

maintenance of the pump.

Operate the pump correctly in accordance with these instructions to ensure a long

service life.

Keep this instruction manual in a suitable place for immediate reference whenever

needed.

2 Introduction

Check the following items on receipt of the pump package.

Check the nameplate affixed to the outer cover of the pump to confirm that the pump

supplied agrees with your order.

Check the accessories against the packing list and the previously submitted drawings and

documents to confirm that the all ordered accessories have arrived.

Check for damage and for screws/bolts that have worked loose in transit.

CAUTION

Notify EBARA without delay when there is damage or when

components are missing.

Do not use when a leak is present as this may result in an accident.

Store the pump in a dry and clean place until installation.

Temperature

: 5 – 40 °C

Humidity : 80 % or less

Do not stack the pump. Place it in an upright position.

EBARA Corporation

Page 16

(2)

3 Product Description

3.1 Summary

The A Series dry vacuum pump has a compact design and includes various sensors and

controls to enhance reliability and operation.

3.1.1 Pump Module

The pump is a roots-type vacuum pump that rotates a pair of non-contact, multi-stage rotors

synchronized by timing gears. High-capacity units have a Booster Pump (BP) connected in

series with the Main Pump (MP).

A compartment, isolated from the pump casing, encloses the timing gears and bearings,

which require lubrication with Perfluoro-Polyether (PFPE) oil and grease.

The pumps of this series are factory-filled with lubricating oil. Replenish or replace only with

the recommended oil grades shown in Specification Tables 3.1 and 3.2.

3.1.2 N2 Gas

Pressurized nitrogen, supplied to the labyrinth seal section, isolates the vapor stream from

the lubricated components, enabling the pump to draw a clean vacuum without admitting

lubricant oil to the pump casing.

Additional N2 gas, injected in various pump stages, reduces corrosion due to process gas

and retards the accumulation of reaction byproducts. For processes that do not produce

corrosion or reaction byproducts, the selector valve can stop completely the dilution N2 flow.

Adjusting the regulation pressure to the specified value supplies the correct amount of N2

gas for these two types of purge operation.

The pumps of this series are equipped with a dilution N2 gas control valve. Consult EBARA

before adjusting the N2 gas supply to the appropriate level for specific conditions of use.

(Maximum dilution N2 flow rate: 76 Pam3/s.)

3.1.3 Cooling Water

Compressing gas from vacuum to atmospheric pressure generates heat. Therefore, cool

motors and casings with cooling water.

Quick-connect cooling water couplers make connection and disconnection easy.

3.1.4 Exhaust

The exhaust check valve, a standard accessory, prevents reverse flow of gas from the

exhaust back through the pump to the vacuum chamber when pump stops. A silencer

(optional) reduces exhaust noise.

3.2 Control System

A Series dry vacuum pumps have a built-in sensing unit consisting of an Earth Leakage

Breaker (ELB), an electro-magnetic switch and a control circuit or an overcurrent circuit

breaker (CB). To improve reliability and safety, sensors monitor the condition of each utility

EBARA Corporation

Page 17

(3)

and pump section.

During pump operation the central processing unit monitors all operating conditions, including

power supply, cooling water flow, N

gas flow, lubrication oil level, casing and motor coil

2

temperature, motor current and suction pressure.

Pump operation “rides through” a transient power outage up to 500 milliseconds long.

(Two-second ride through is available as an option.)

3.2.1 Warning

To improve the reliability of the vacuum exhaust system, the pump control scheme generates

two levels of trouble warning: ALARM and TRIP.

An ALARM signal draws attention to an operating parameter value that has exceeded the

normal operating range; it does not signify that danger is imminent. The pump will continue to

operate in this condition, which enables the operator to complete the wafer cycle before

checking the pump.

The pump will stop automatically and generate a TRIP signal output if a parameter

approaches a mechanical safety limit.

Contact EBARA Corporation for details on checking the ALARM and TRIP setting conditions.

3.2.2 Operation Status Control

To facilitate operation status control and daily inspection, the LCD controller displays the

sensor data.

The LCD controller displays all ALARM and TRIP signals. For remote operation and

monitoring, the signals are available individually and as collective outputs.

3.3 Moving the Pump

3.3.1 Preparation

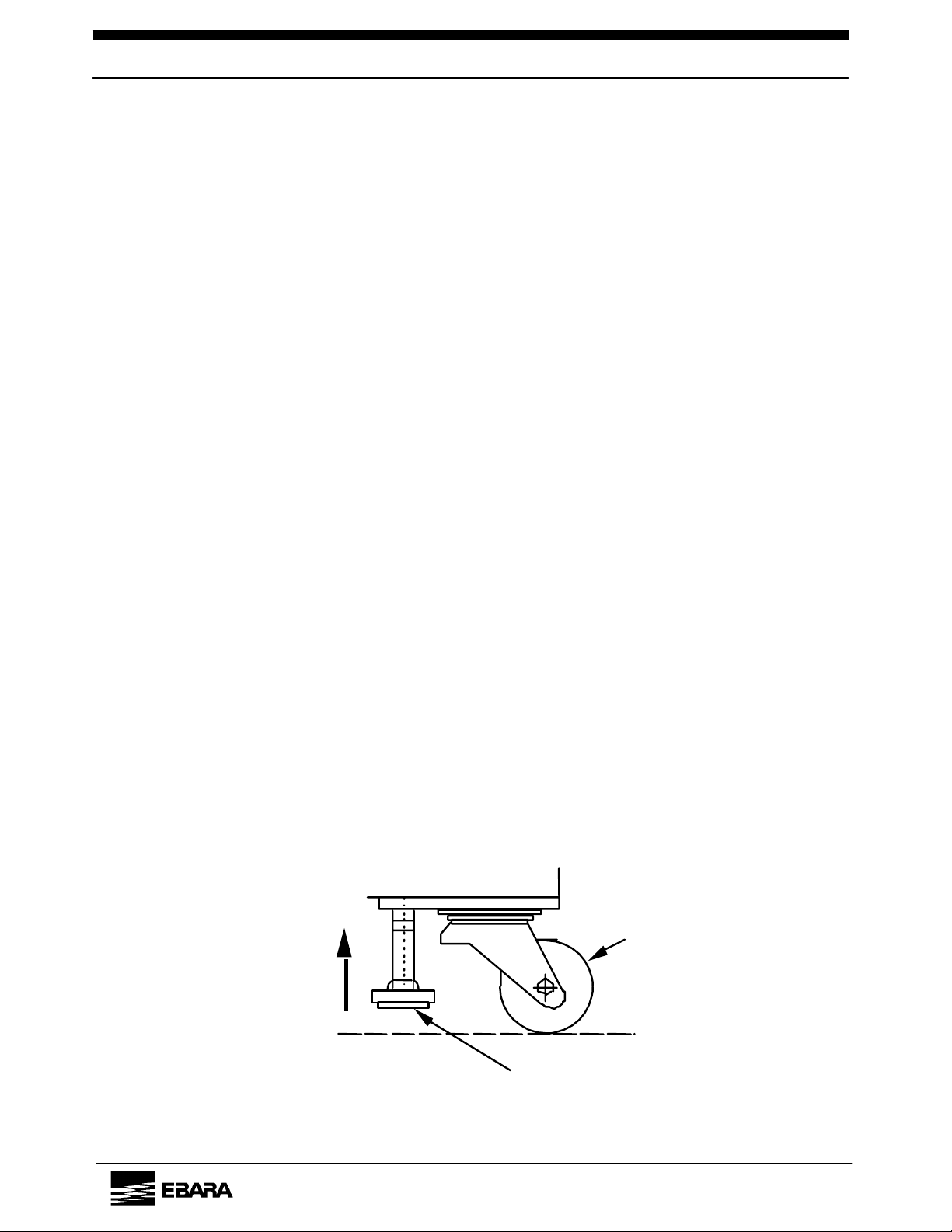

Raise all four adjuster feet fully before moving the pump; otherwise, an obstacle on the floor

may cause the moving pump to tip over.

Caster

fully

raised

Adjuster

f

EBARA Corporation

Page 18

(4)

3.3.2 Moving Method

Move pump slowly by pushing eyebolt along the long axis of the pump (Direction A). Keep

toes and fingers away from moving wheels. If placing the pump in a corner or narrow space

requires moving it along the short axis (Direction B), two persons should “walk” the pump

over by alternately pushing the ends as shown below.

B

A

To move the pump across cracks or joints in the floor, spread a steel plate or similar device,

which can sustain the pump’s weight, over the discontinuity. At least two persons, using

great caution, should move the pump.

Steel Plate

DANGER

If, when moving a pump, it loses balance and starts to tip over, do

not attempt to stop it. Get away from the pump immediately and

let it fall.

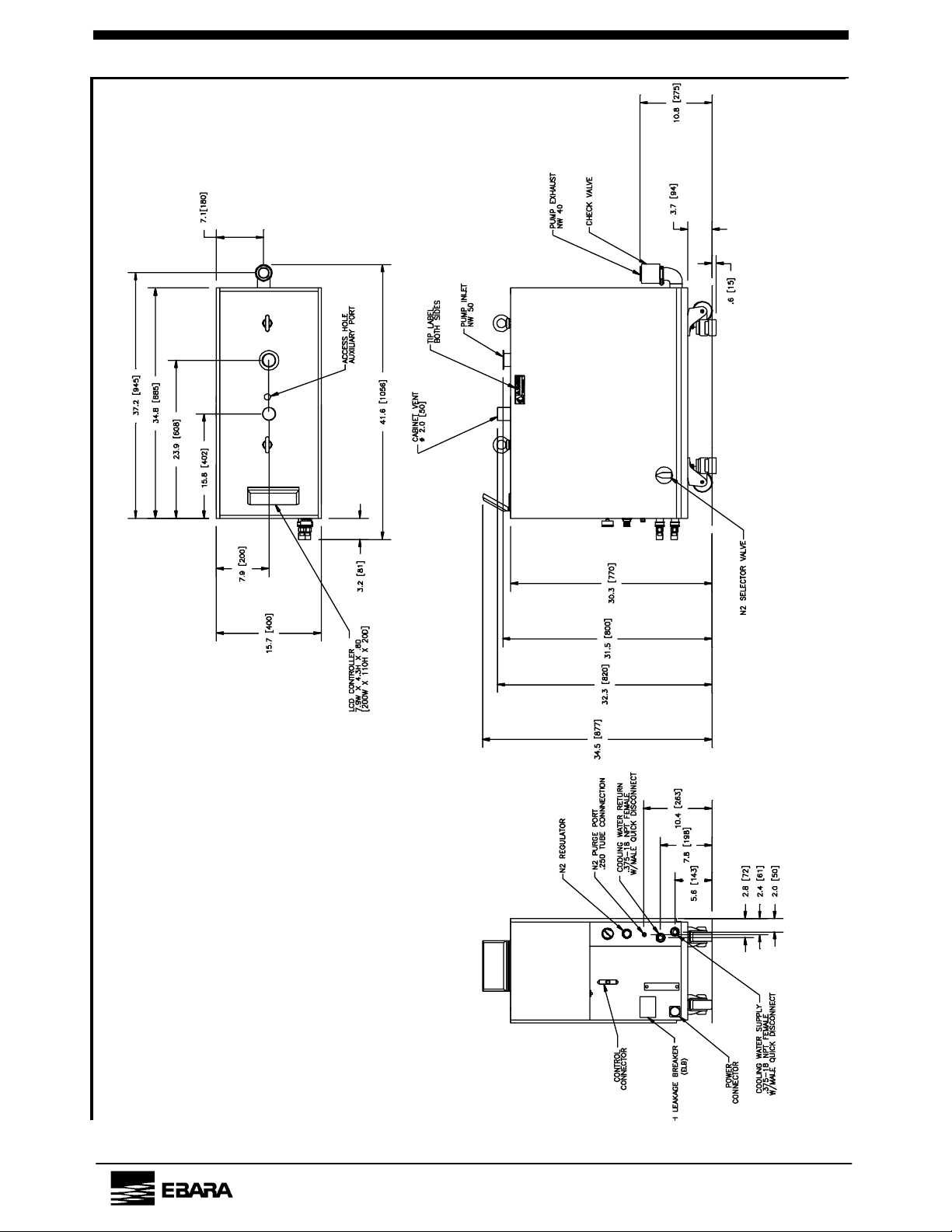

3.4 Detailed Specifications

Refer to the following tables and figures for detailed specifications, size, and pump

performance.

List of Tables and Figures

Category Contents Page

Table 3.1, 3.2 Specification 5,6

Outline Drawing 1 A70W 7

Outline Drawing 2 A30W 8

Outline Drawing 3 A25S 9

Outline Drawing 4 A10S 10

Outline Drawing 5 A07V 11

Figure 3.1 Performance Curve (A70W, A30W) 12

Figure 3.2 Performance Curve (A25S, A10S) 13

Figure 3.3 Performance Curve (A07V) 14

Figure 3.4 System Flow 15

EBARA Corporation

Page 19

A

A

[

(5)

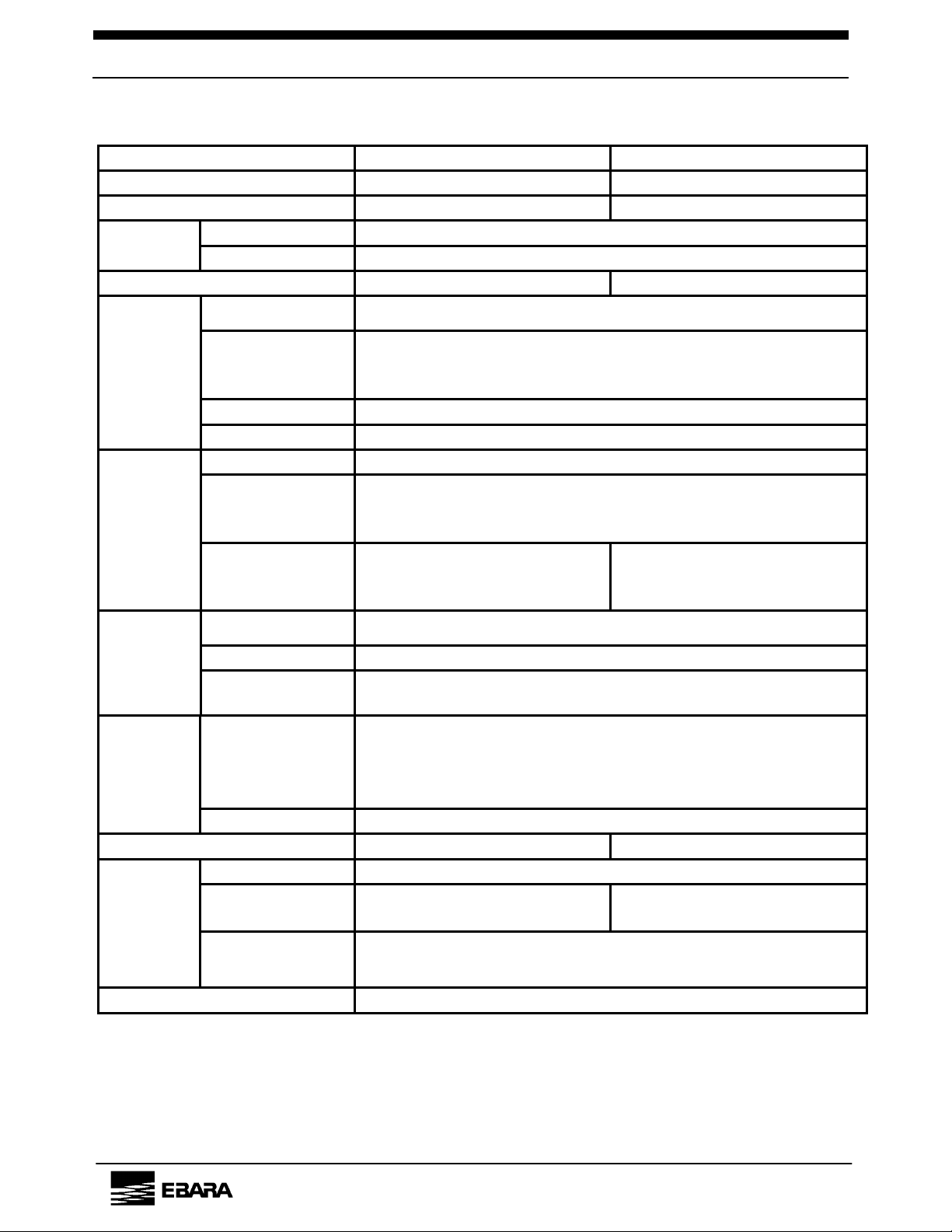

Table 3.1 Specification (A70W, A30W)

Model

70W

30W

Pumping Speed (50 / 60Hz) 7000 / 8400 L/min 3000 / 3600 L/min

Ultimate Pressure (50 / 60Hz) 0.27 / 0.13 Pa 0.4 / 0.27 Pa

Connection

Gas Inlet NW50

Gas Outlet NW40

Motor 2P 2.2 kW + 3.7 kW 2P 1.5 kW + 2.2 kW

Cooling

Water

Connection

Pressure

[Gauge Press.]

Differential Press. : 0.1 MPa

Coupler (Rc 3/8)

Supply : Max 0.4 MPa

Flow Rate Min. 3.5 L/min

Temperature Max. 30 deg C

Connection 1/4” Tube Fitting (Same as Swagelok®)

Pressure

Supply : 0.1-0.7 MPa

[Gauge Press.]

N2 Gas

Approx. Flow

Rate

Dilution 0 Mode]

24-27 Pa m3/s

[3.4 Pa m

Setting : 0.04-0.07 MPa

17-22 Pa m

3

/s]

[3.4 Pa m

3

3

/s

/s]

Duct

Ventilation

Connection

Pressure -196 Pa

Approx. Flow

d50 mm×L50 mm

3

0.5 m

/min

Rate

FOMBLIN Y-L VAC 25/6

Lubrication

Oil

Brand

BARRIERTA J100

DEMNUM S-65

KRYTOX VPF 1525

Quantity 0.8 L

Approximate Weight 380 kg 330 kg

Phase/Volt/Freq. 3 Phase, 200V (50 Hz), 200-220 V (60Hz)

Power

Current Rating

(50 / 60 Hz)

29.5 / 28.1 A 19.7 / 18.5 A

Supply

Connection

(Japan Aviation Electronics Industry)

MS Series 22-22

Control Signal 57 Series 50 (DDK. Ltd)

[Note] Approximate flow rate of N2 gas shows a necessary total amount for seal N2 and

dilution N2.

LCD controller displays only the flow rate of dilution N2.

EBARA Corporation

Page 20

A

A

A

[

/s]

[

/s]

[

/s]

y

(

(Jap

(6)

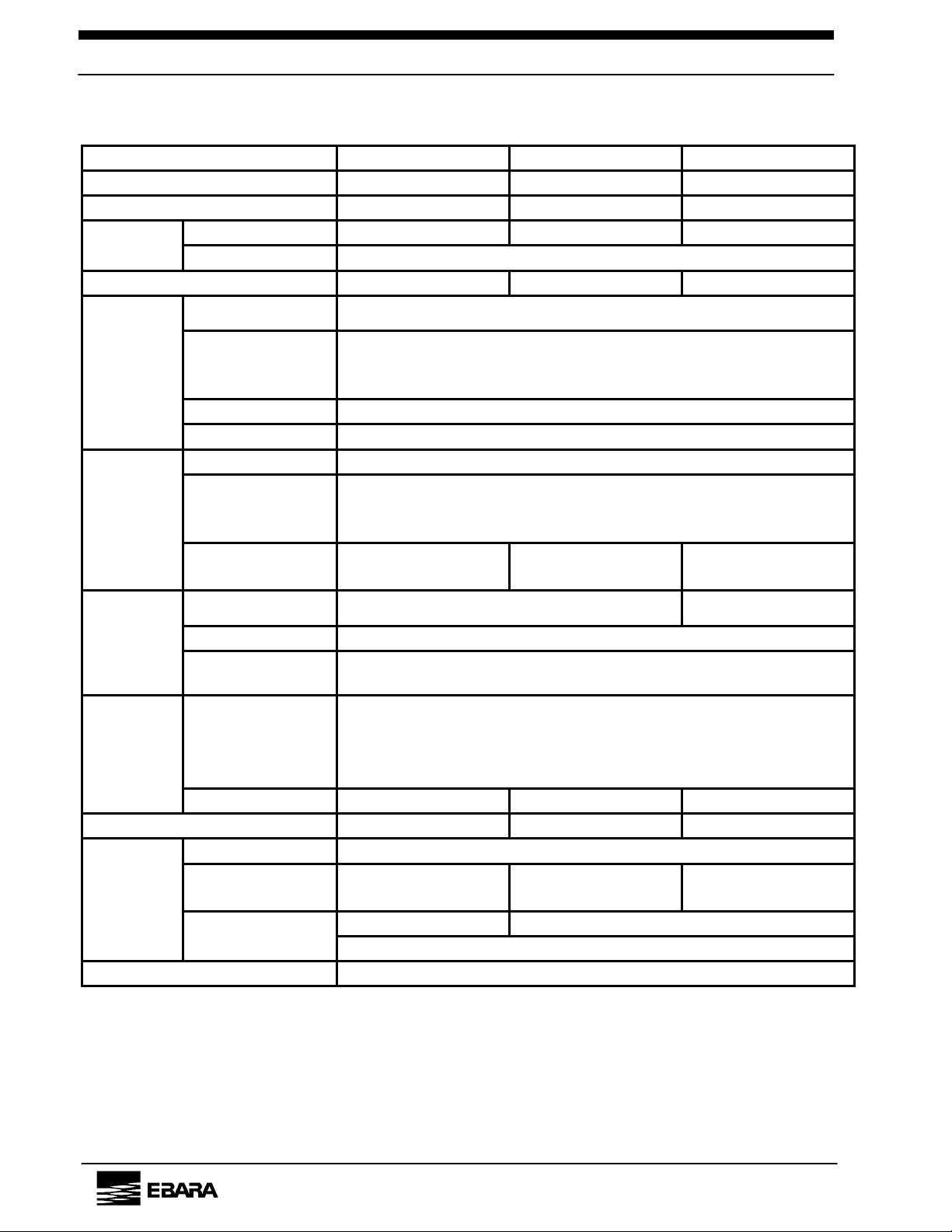

Table 3.2 Specification (A25S, A10S, A07V)

Model

25S

10S

07V

Pumping Speed (50 / 60 Hz) 2500 / 3000 L/min 1000 / 1200 L/min 700 / 840 L/min

Ultimate Pressure (50 / 60 Hz) 5.3 / 4.0Pa 5.3 / 4.0Pa 1.1 / 1.0 Pa

Connection

Gas Inlet NW50 NW40 NW40

Gas Outlet NW40

Motor 2P 3.7 kW 2P 2.2 kW 2P 1.5 kW

Cooling

Water

Connection

Pressure

[Gauge Press.]

Coupler (Rc 3/8)

Supply :Max. 0.4MPa

Differential Press.:Min. 0.1MPa

Flow Rate Min. 3.5 L/min

Temperature Max. 30 deg C

Connection 1/4” Tube Fitting (Same as Swagelok®)

N

Gas

2

Duct

Ventilation

Pressure

[Gauge Press.]

Approx.

Flow Rate**

Connection

17-20 Pa m

3.4 Pa m

d50 mm×L50 mm d50 mm×L60 mm

3

Pressure -196 Pa

Approx. Flow

Rate

Supply:0.1-0.7 MPa

[Setting:0.04-0.07 MPa]

3

/s

17-20 Pa m3/s

3

/min

3

3.4 Pa m

0.5 m

15-19 Pa m3/s

3.4 Pa m

FOMBLIN Y-L VAC 25/6

Lubrication

Oil

Brand

Quantit

0.4 L 0.4 L 0.5 L

BARRIERTA J100

DEMNUM S-65

KRYTOX VPF 1525

Approx. Weight 240 kg 220 kg 150 kg

Phase/Volt/Freq. 3 Phase, 200V (50 Hz), 200-220 V (60Hz)

Power

Supply

Current Rating

50 / 60 Hz)

Connection

18.3 / 17.5 A 11.7 / 11.1 A 8.4 / 8.6 A

MS Series 22-22 MS Series 20-4

an Aviation Electronics Industry)

Control Signal 57 Series 50 (DDK. Ltd)

3

** Numerals in brackets [ ] are flow rate in dilution-0 mode.

[Note] Approximate flow rate of N2 gas shows a necessary total amount for seal N2 and

dilution N2.

LCD controller displays only the flow rate of dilution N2.

EBARA Corporation

Page 21

(7)

Outline Drawing A70W

EBARA Corporation

Page 22

(8)

Outline Drawing A30W

EBARA Corporation

Page 23

(9)

Outline Drawing A25S

EBARA Corporation

Page 24

(10)

Outline Drawing A10S

EBARA Corporation

Page 25

(11)

Outline Drawing A07V

EBARA Corporation

Page 26

(12)

100000

[50H z]

10000

1000

[l/min]

100

10

1

-2

10

10

-1

10

A70W

A30W

0

101 102 1 03 104 10

A70W

A30W

5

[Pa]

100000

10000

1000

[l/min]

100

10

1

-2

10

10

-1

10

A70W

A30W

0

101 102 103 104 10

[60Hz]

A70W

A30W

5

[Pa]

Figure 3.1 Performance Curve (A70W, A30W)

EBARA Corporation

Page 27

(13)

100000

10000

1000

[l/min]

100

10

1

10

-2

10

-1

10

A25S

A10S

0

101 102 103 104 10

[50Hz]

5

[Pa]

100000

10000

1000

[l/min]

100

10

1

-2

10

10

-1

10

A25S

A10S

0

101 102 103 104 10

[60Hz]

5

[Pa]

Figure 3.2 Performance Curve (A25S, A10S)

EBARA Corporation

Page 28

(14)

100000

10000

1000

[l/min]

100

10

1

-2

10

10

-1

10

A07V

0

101 102 103 104 10

[50Hz]

5

[Pa]

100000

10000

1000

[l/min]

100

10

1

10

-2

10

-1

10

A07V

0

101 102 103 104 10

[60Hz]

5

[Pa]

Figure 3.3 Performance Curve (A07V)

EBARA Corporation

Page 29

(15)

Power

N2 Gas

Water

Regulator

LCD Controller

Circuit Breaker

(ELB)

Pressure Gauge

P

Seal N2 Gas Flow Sensor

FT1

FT2

Dilluting N2 Gas Flow Sensor

FT3

Cooling Water Flow Sensor

Control Circuit

Motor Starter 1

Motor Starter 2

Selector Valve

Gas Inlet

Connector

Booster Pump

(BP)

Main Pump

(MP)

Motor 2

Gas Outlet

Motor 1

Check

Valve

[NOTE] A25S, A10S and A07V do not have a booster pump.

Figure 3.4 System Flow

EBARA Corporation

Page 30

(16)

4 Installation

Observe the following precautions and instructions when installing the pump.

4.1 Location

This pump is suitable for indoor installation. To install the pump, select a place not exposed

to dust or humidity and not subject to dew condensation. Also, allow sufficient space to

ensure easy pump installation and disassembly for maintenance. If the pump has an

interface box, locate it within 3m of the pump.

CAUTION

Install pump in a location where ambient temperature does not exceed

30℃. Exercise extra caution when operating the pump in an enclosed

room.

CAUTION

Leave a gap of at least 50mm between the pump cover and adjacent

equipment for ventilation.

Four integral mobile support units, each consisting of a caster and a height-adjustment foot,

support the pump base. To move the pump, raise the four adjustment feet by turning the

holding nuts in the counterclockwise direction.

Figure 4.1 Caster

Be careful not to overturn the pump when pushing or pulling it

WARNING

CAUTION

sideways. The pump is narrow in comparison to its height.

The neck portion of the casters will vibrate when the caster is moving.

Keep fingers and feet away.

CAUTION

Do not step on the pump or place objects upon it.

Turn the holding nuts in the clockwise direction to lower the height-adjustment feet and

secure the pump.

Adjust the height of the feet evenly to level the pump base.

The difference in height between the two sides of the pump base shall not exceed

1mm. The adjustment allowance is approximately 15 mm.

[NOTE]

[NOTE]

An unleveled pump may generate an OIL LEVEL LOW ALARM.

Failure to use adjustment feet will increase floor vibrations.

EBARA Corporation

Page 31

(17)

4.2 Piping

4.2.1 Vacuum and Exhaust Piping

Connect the vacuum and exhaust pipes to the suction and exhaust flanges respectively.

Because of the narrow clearance between pump rotors, ingested foreign objects will prevent

the pump from operating. Observe the following cautions when making the flange

connections:

a) Remove all foreign matter from inside the piping.

b) When connecting flanges, ensure that no dirt or dust particles adhere to the flange

surfaces and that the flange surfaces are undamaged.

c) Prevent the ingestion of wafer fragments and of reaction byproducts that may adhere to

the APC valve. For this purpose, a filter or screen may be advisable.

d) The weight of the pipes attached to the pump can cause misalignment and leaks from

the flange connections. Support the piping properly and do not apply excessive force to

align flange faces.

e) EBARA recommends the insertion of a flexible bellows between the piping and the

suction and exhaust flanges of the pump.

f) Length of the flexible bellows on the suction side will vary according to the vacuum

drawn. Connect without applying undue force to the flexible bellows.

DANGER

Check for leaks after installing the pump. A leak may lead to the

dangerous discharge of hazardous substances or to unpredictable

reactions with air admitted into the pump.

4.2.2 Cooling Water Piping

Connect the cooling water pipes to the correct inlet and outlet ports.

The water ports are quick-connect couplers. Seat the plug firmly in the socket. The socket

sleeve will return to the front (Figure 4.2).

Do not connect the supply/return plugs in reverse. The diameters are slightly different, and

there are In/Out markings on the plugs.

Disconnection automatically blocks water flow.

Use cooling water corresponding to the specifications of Table 4.1.

EBARA Corporation

Page 32

(18)

Table 4.1 Industrial Water Supply Quality Specifications

(Japan Industrial Water Association, Industrial Water Quality Standards Committee)

Turbidity

pH

Alkalinity(CaCO3)

Hardness(CaCO3)

Evaporation residue

Chlorine ion

Iron

Manganese

(ppm)

(ppm)

(ppm)

(ppm)

(ppm)

(ppm)

(ppm)

20

6.5-8.0

75

120

250

80

0.3

0.2

Co rre c t

Wrong

Socket

Sleeve

Figure 4.2 Coupler

In / Ou t

Marking

Plug

DANGER

CAUTION

CAUTION

CAUTION

When disconnecting water, first close the supply valve and then

remove the supply coupler.

When connecting, insert the return coupler first.

Connecting or disconnecting in the wrong order may cause a

rapid pressure rise—leading to a water leak.

Even if the cooling water flow rate drops, the pump will continue

to operate until the casing temperature reaches the TRIP limit.

Select facility water piping rated for at least 70℃ at the

operating pressure.

Do not connect pump cooling water loops in series. Select

piping to ensure sufficient flow through each pump.

Connect supply and return couplers correctly to avoid reverse

flow. Reverse flow will read incorrectly on the LCD, will not

cool the pump properly, and may lead to an accident.

CAUTION

In humid locations, allowing the cooling water to run when the

pump is stopped will lead to condensation on parts of the

pump. If droplets appear on the outside of the water tubes

when the pump is not running, cut off water flow.

EBARA Corporation

Page 33

(19)

4.2.3 N

Gas Piping

2

Cut tube at right angles and make the end-face perfectly smooth. Then connect the tube to

the tube fitting assembly of the N2 gas purge port. The tube will push fit onto the shoulder of

the tube fitting assembly.

Secure the tube fitting assembly properly and tighten the retaining nut by hand. Then use a

tool to tighten the nut an additional 1¼ turns.

To reconnect the tube again after subsequent removal, install the tube already fitted to the

ferrule and retighten the retaining nut slightly (about ¼ turn) beyond hand tight.

Body

Front

Ferrule

Back

Ferrule

Nut

1 + 1/4

R o ta tion

Figure 4.3 Tube Fitting Assembly

4.2.4 Ventilation Duct

Exhaust hot air from the pump enclosure through the ventilating duct port in the top cover.

Without proper ventilation, the temperature inside the cover may rise, causing an ALARM.

The pump does not have a gas leak detector. For hazardous gases, EBARA recommends

installing a gas leak detector, interlocked to gas flow, in the ventilation duct piping.

Use an exhaust duct material that resists corrosion from the gas(es) pumped.

CAUTION

For safety, ventilate through the enclosure exhaust duct when the

pump application is toxic and/or flammable gases. Do not

combine the ventilation duct with the pump exhaust piping.

[NOTE]

Even when pumping process gases that are not toxic or

flammable, do not combine the ventilation duct with the pump

exhaust piping. The exhaust noise of the pump may cause

acoustic resonance inside the pump unit and result in abnormal

noise.

EBARA Corporation

Page 34

(20)

4.3 Electrical Wiring

WARNING

Keep the power supply to the pump turned off and locked out until

you have finished the wiring and connecting work. Interrupt the

Earth Leakage Breaker (ELB) or circuit breaker (CB).

4.3.1 Power Supply Wiring

CAUTION

Ensure that the grounding wire is connected. Connect this

product to a grounded, metallic, permanent wiring system.

CAUTION

Match the wiring size and material to the power consumption and

ambient air temperature of the pump.

CAUTION

Use the threaded-coupling power connector provided with the

pump. At the power source size connect direct to distribution

panel wiring terminals or use a twist-lock, Hubbel-type connector.

Wire the connector for the main power supply (200V AC at 3-phase and 50Hz, 200-220V AC

at 3-phase and 60Hz). See figure and tables below for connector pin assignments and

specifications.

Table 4.2 Pin Assignments

Power Supply Receptacle

No. Phase

D A

A R

C B

Figure 4.4 Power Supply Receptacle

(As seen from connecting side)

B S

C T

D Ground

Table 4.3 Receptacle Specifications

Pump Model A70W A30W A25S A10S A07V

Receptacle

Japan Aviation Electronics Industry Co., Ltd.

manufacturer

Receptacle type MS3102A 22-22P MS3102A 20-4P

Current A (50/60 Hz) 29.5 / 28.1 19.7 / 18.5 18.3 / 17.5 11.7 / 18.5 8.4 / 8.6

Adapted plug type MS3106B 22-22S MS3106B 20-4S

Suitable wire AWG #8 - #10 AWG #12 - #14

EBARA Corporation

Page 35

4.3.2 Control Signal Wiring

Connect wires to the control connector for remote operation and remote monitoring.

Tables 4.4 and 4.5 and Figures 4.5 and 4.6 show the pin assignments.

Table 4.4 Receptacle Specifications

(Identical for all types)

Receptacle type 57FE-40500

Receptacle manufacturer DDK. Ltd.

Adapted plug type 57-30500

Suitable wire size AWG #24

Applied voltage for input *1 12V DC 20 mA

Contact capacity of output *2 50V DC/Maximum. 50 mA

*1. Apply voltage through pump.

*2. Apply voltage through equipment.

(21)

1

26

5025

Figure 4.5 Control Signal Receptacle

(As seen from connecting side)

CAUTION

CAUTION

Do not wire vacant pins.

Apply 12V DC power for input signals on the pump side. Do

not apply this voltage on the equipment side.

The output signals are generated from an open collector

output. Apply a voltage not exceeding 50V DC on the

equipment side.

CAUTION

Wire all signals with the correct polarity

(SIGNAL/COMMON).

CAUTION

When output signals energize an inductive load, such as a

relay, insert a diode (100V. 1A class) to absorb the back

electromotive force from surge currents.

EBARA Corporation

Page 36

(22)

1. Input signal

MP Start

BP Start

Reset

MP Stop

BP Stop

Connector

1 kOHM

Control

(+)

1

(+)

2

3

(+)

4

(+)

5

(+)

Dry

contact

Open

collector

2. Output Signal

MP Run

BP Run

Remote / Local

Casing Temp. (TRIP)

+

DC12V

11

12

14

26

27

50

6

(-)

Resistance

load

+

DC50V

Ma x. 50mA

+

DC50V

Ma x. 50mA

Inductive

load

+

DC50V

Max. 50mA

+

DC50V

Max. 50mA

Emergency Stop

Switch [ OPTION ]

8

[ NOTE ]

1. Insert a diode (100V / 1A class) when

9

connecting inductive load by output signal.

2. Do not conn ect wiring to opened pins.

It may cause malfunction.

Figure 4.6 Control Signal Wiring

EBARA Corporation

Page 37

(23)

Table 4.5 Pin Assignment (Do not connect wires to unassigned pins.)

No Signal name I/O Signal type No Signal name I/O Signal type

1 MP start IN N.O., Alternate *1 26 REMOTE/LOCAL OUT N.O., Alternate

2 BP start *6 IN N.O., Alternate *1 27 Casing Temp. (TRIP) OUT N.O., Alternate

3 ALARM/TRIP Reset IN N.O., Momentary *2 28 MP Motor Temp. (TRIP) OUT N.O., Alternate

4 MP Stop IN N.O., Momentary *1 29 BP Motor Temp. (TRIP) *6 OUT N.O., Alternate

5 BP Stop *6 IN N.O., Momentary *1 30 MP Overload (TRIP) OUT N.O., Alternate

6 COM of 1-5 IN 31 BP Overload (TIRP) *6 OUT N.O., Alternate

7 32 Phase Error (T RIP) OUT N.O., Alternate

8 Emergency Stop *3 OUT N.C., Alternate 33

9 COM of 8 OUT 34 Water Leak (TRIP) *3 OUT N.O., Alternate

10 35 Exhaust Press. (TRIP) *3 OUT N.O., Alternate

11 MP Operation OUT N.O., Alternate 36

12 BP Operation *6 OUT N.O., Alternate 37 Water Flow (ALARM) *4 OUT N.O., Alternate

13 38 Sealing N2 Flow (ALARM) *4 OUT N.O., Alternate

14 COM of 11-12 OUT 39

15 40 Casing Temp. (ALARM) OUT N.O., Alternate

16 41 MP Current (ALARM) OUT N.O., Alternate

17 42 BP Current (ALARM) *6 OUT N.O., Alternate

18 43 Oil Level (ALARM) OUT N.O., Alternate

19 TRIP/Collective OUT N.C., Alternate 44

20 COM of 19 OUT 45 Bearing Temp. (ALARM) *6 OUT N.O., Alternate

21 46

22 ALARM/Collective OUT N.C., Alternate 47

23 COM of 22 OUT 48

24 49

25 50 COM of 26-45 OUT

Dilut. N

Flow (ALARM) *4 *5

2

OUT N.O., Alternate

MP = Main Pump, BP = Booster Pump.

Models A25S, A10S, A07V do not have a BP.

[NOTE]

*1 Dipswitch No. 5 selects external start / stop signal type.

Off : Alternate signal (Use only Pins 1 and 2.)

On : Pulse signal (Use Pins 1 and 2 for start and Pins 4 and 5 for stop,

Change Pins 1 and 2 to momentary signals with Dipswitch No. 5.)

In remote mode, select pump operation “accord ing to signal” or “automatically stop” with

Dipswitch No.4.

Use Dipswitch No.8 to configure remote BP operation as “automatic” or “according to

signal.”

*2 Input signal duration for Pin No. 3 (ALARM / TRIP Reset) and Pins No. 1, 2, 4, and 5

(Momentary Start / Stop) is 200ms.

*3 Pins No. 8 (Emergency Stop Switch), 34 (Water Leakage), and 35 (Exhaust Pressure)

are for options. Pin No. 8 (Emergency Stop Switch) output remains OFF until the switch

is closed and a RESET signal is entered.

*4 Dipswitch No.2 selects observation of cooling water and N

gas flow as “always” or

2

“operating period only.”

EBARA Corporation

Page 38

(24)

*5 When Dipswitch No. 7 is OFF (Normal Mode), a decrease in dilution N

flow will cause

2

an output on Pin No. 39. When Dipswitch No. 7 is ON (Dilution 0 Mode), this same

output on Pin 39 indicates that the dilution N2 selector valve is open.

*6 Pins No. 2 (BP Start), 5 (BP Stop), 12 (BP Operation), 29 (BP Motor Temp.),

31 (BP Overload), 42 (BP Current) apply to Models A70W and A30W.

Only Model A07V uses Pin No. 45 (Bearing Temperature).

CAUTION

CAUTION

Do not wire vacant pins.

Apply 12V DC power for input signals on the pump side. Do

not apply this voltage on the equipment side.

The output signals are generated from an open collector

output. Apply a voltage not exceeding 50V DC on the

equipment side.

CAUTION

Wire all signals with the correct polarity

(SIGNAL/COMMON).

CAUTION

When output signals energize an inductive load, such as a

relay, insert a diode (100V. 1A class) to absorb the back

electromotive force from surge currents.

4.4 Operation Mode

Set the dipswitches on the control panel in accordance with the conditions (Table 4.6).

Table 4.6 Dipswitch Settings

No. Mode Off On

1 RS232C Data Length 7bit 8bit

2 Service observation Always Operating period only

3 Buzzer Not used Used

4 Operation switched to remote According to signal Automatically stop

5 Remote start signal Alternating Momentary (Pulse)

6 ----- ----- ----7 Dilution N2 With dilution Without dilution

8 BP operation Automatic According to signal

When using the RS232C communication port to monitor pump status, select a Data Length

of either 7 bits or 8 bits.

Dipswitch No. 2 configures observation of cooling water and N

gas flow as either "always" or

2

"operating period only." Even when "operating period only" is selected, observation of

cooling water flow continues for 15 minutes after pump stops.

Dipswitch No. 3 selects Buzzer usage in ALARM / TRIP condition.

In remote mode, select pump operation “according to signal” or “automatically stop” with

Dipswitch No.4.

EBARA Corporation

Page 39

(25)

Dipswitch No. 5 sets configuration for remote START / STOP signals as either "alternate

(maintained) signal" or "pulse (momentary) signal."

Pins 1, 2, 4, and 5 pins become momentary signal ports when Dipswitch No. 5 is ON.

Dipswitch No. 7 sets dilution N2 usage.

For applications that neither deposit byproducts nor corrode the pump (e.g. load lock,

sputtering, SEM) the user may reduce nitrogen consumption by closing the dilution N

2

selector valve located on the side of the pump and turning on Dipswitch No. 7,

In dilution mode, the pump outputs a Dilution N2 Flow ALARM when dilution N2 flow

decreases; in zero dilution mode, the pump outputs a Dilution N2 Flow ALARM when

dilution N2 selector valve is open.

[NOTE] Select compatible settings for the dilution N2 selector valve and Dipswitch No. 7

together.

Set Dipswitch No. 8 ON to start and stop BP automatically based on inlet vacuum; set

Dipswitch No. 8 OFF to start and stop BP with a remote signal.

[NOTE] The user may toggle remote / local switch and use of the buzzer at any time. The

pump stores the setting of other switches at start up. Turn power OFF to change

the settings.

Default factory settings at time of shipment are: Data Length = 8 bits, always observation,

buzzer in use, according to signal, alternating signal, with dilution mode, BP automatic

operation, and Local operation. Refer to Figure 4.7.

Figure 4.7 Switch Settings

1

ON

Dip

Switch

8

Rotary

Switch

Toggle

LOCAL

Switch

REMOTE

Power

LED

RS232C

Port

EBARA Corporation

Page 40

(26)

5 Operation

WARNING

Following an Emergency Stop or TRIP (auto shut down), troubleshoot

the pump as described in Section 8 before restarting.

[NOTE]

These pumps are factory filled with lubrication oil.

5.1 Before Starting

Turn on the cooling water flow and check piping for water leaks.

CAUTION

Without sufficient cooling water, the pump temperature will rise,

which may cause rotor contact or other problems.

[NOTE] The pump unit has no cooling water valve.

Turn on the N

gas supply.

2

Check that the regulator attached to the pump is closed, i.e. the pressure adjustment knob is

fully counterclockwise. Open the main valve and check that there are no N

gas leaks from

2

the pipe connections.

Slowly turn the pressure adjustment knob clockwise to set the pressure (gauge pressure) to

0.05 MPa. Then press the red stopper to lock the knob in position.

WARNING

CAUTION

Operate dilution N

dilution N

mode setting of dipswitch.

2

Dipswitch No. 7

Selector Valve

[NOTE]

[NOTE]

Supply N2 gas to the exhaust piping when it is necessary to dilute

flammable or toxic gases down to safe concentration.

Set N2 flow rate appropriately to avoid problems such as oil

carryover, corrosion inside the pump and deposition of byproducts.

selector valve, located on the side face of pump cover, in accord with the

2

ON OFF

CLOSED OPEN

N2 gas flow requires several seconds to stabilize after opening valve.

During regular operation, open dilution N2 gas selector valve except

for processes that are non-corrosive and do not produce reaction

byproducts.

EBARA Corporation

Page 41

(27)

Turn on power.

Turn on the ELB and ensure that the yellow LED (beside the dipswitches) lights. The LCD

controller counts down 10 seconds. Refer to Table 5.2 and Figure 5.1.

[NOTE] After turning on power, the instruments warm up for 10 seconds before the pump

will start.

Ensure cooling water flow is 3.5 L/min or more.

Readjust regulator so that dilution N

gas is within the range described below.

2

Table 5.1 Dilution N2 gas flow

A70W 20-24 Pa m3/s

A30W 15-19 Pa m3/s

A25S 14-17 Pa m3/s

A10S 14-17 Pa m3/s

A07V 12-15 Pa m3/s

Then ensure that pressure gauge indicates 0.04-0.07 MPa.

After setting, push the red stopper of knob to lock.

Under this condition, shaft seal N2 flow rate is 2.7-3.4 Pa m3/s. (Shaft seal N2 flow rate is

not shown on LCD.)

Check that LCD displays no ALARM/TRIP signal.

The motor current is indicated as "00.0 A" on LCD.

When LCD indicates an ALARM/TRIP signal or an abnormal symptom appears, take

necessary measures in accordance with Section 8.

[NOTE] ALARM/TRIP signal persists until entry of a RESET signal even if the causes are

remedied.

After taking necessary measures, either press the RESET switch on the LCD

controller or input RESET signal through the control connector.

When buzzer is in use, pressing BUZZER OFF mutes the buzzer despite an

ALARM/TRIP condition.

Open the valve on the exhaust piping before starting the pump.

If the system has an exhaust gas scrubber, open its inlet and outlet valves.

CAUTION

Operating pump with these valves closed will pressurize the

exhaust and overload the pump.

EBARA Corporation

Page 42

(28)

LED ( Green )

LED ( Red )

LED ( Orange )

Buzzer

B.P.RUN

M.P.RUN

LOCAL

( Liquid Crystal Display )

STOPSTART

LCD

DISP.

SELECT

RESET

Figure 5.1 LCD Controller

[Buttons] START: Start MP and BP

STOP: Start of MP and BP

DISP. SELECT: Change LCD indication

RESET: Reset ALARM and TRIP

BUZZER OFF: Mute buzzer in ALARM / TRIP

ALARM

TRIP

ERROR

BUZZER

OFF

Push Button

[LED] B.P. RUN: BP running

M.P. RUN: MP running

LOCAL: LOCAL mode

ALARM: ALARM condition

TRIP: TRIP condition

ERROR: Microprocessor malfunction

EBARA Corporation

Page 43

(29)

Table 5.2 LCD Controller Indication

No

ITEM INDICATION

1.1 Operating mode selection 1

(10 second count down)

1.2 Operating mode selection 2

(10 sec count down)

2 Motor current

& & & & & & & %

U T Y : S T D R E M : S I G

& & & & & & & R U N : A L T %

D I L : S T D B P : A T @

B P : # # . # A

@

%

M P : # # . # A

3 Cooling water flow W A T E R F L O

W %

i n

4 Dilution N2 gas flow

(with dilution mode)

5 Dilution N2 gas flow

(without dilution mode)

6 Pump casing temperature

# # . # L / m

D I L . N 2 F L O W %

# # . # P a m 3 / s

%

W / O D I L . N 2 M O D E

P U M P C A S I N G %

# # # * C

7 Total operation time

O P E . T I M E %

# # # # # h

8 ALARM / TRIP

$ $ $ $ $ : $ $ $ $ $ $ $ %

$ $ $ $ $ $ $ $ $ $ $ $ $ $

" &&&&&&& " shows pump serial number.

" % " shows present number of ALARM / TRIP.

" @ " shows 10 second countdown after turning on power.

Mode selection contains items below.

UTY : Service observation REM : Operation switched to remote

RUN : Remote start signal DIL : Dilution N

2

BP : BP operation

Dilution N2 gas flow displays the amount of N2 gas excluding seal N2; therefore, it differs

from the N2 approximate flow rate in Table 3.1.

Total operation time displays the hours of operation after initialization at factory.

Upper row " $$$$$$ " describes cause of ALARM / TRIP.

Lower row " $$$$$$ " shows value of parameter that caused ALARM / TRIP.

Display defaults to No. 2 (Motor Current) when buttons on LCD controller are not operated

for one minute.

"DISP. SELECT" scrolls the display in order. It will display progressively all present

ALARM/TRIP’s.

EBARA Corporation

Page 44

(30)

5.2 Operation

REMOTE / LOCAL and USE OF BUZZER can be toggled at any time. Select properly

according to the working conditions.

If Dipswitch No. 4 is ON, pump automatically stops when changed to remote mode.

WARNING

CAUTION

WARNING

CAUTION

[NOTE]

The pump casing and exhaust piping become extremely hot during

operation and for some time after stopping.

Keep pump and exhaust piping away from contact with personnel and

flammable substances.

Do not remove the pump cover during operation.

When the production process leads to reaction byproducts in the

pump or when the process handles corrosive gases, do not stop the

pump until after at least 30 minutes after stopping the flow of process

gases.

Purge with N2 gas for one (1) hour or more after the pump stops to

remove the residual process gas inside the pump.

The pump will remain at a very high temperature even after it has

stopped. Leave the cooling water running for about one (1) hour after

shutdown.

Shutting off cooling water immediately after the pump stops causes a

pressure rise in the cooling water piping, which may cause a water

leak.

Do not pump process gases until the pump has run at least one hour.

If possible, wait four hours for the pump casing temperature to

stabilize before pumping process gases.

[NOTE]

In service observation mode “Always,” cooling water and dilution N2

ALARMs can occur when the pump is stopped.

[NOTE]

The pump will not start while an ALARM/TRIP signal remains active.

Pressing START button will bring STARTFAIL to the display.

EBARA Corporation

Page 45

5.2.1 Local (Pump side) Operation

Start

Press controller START button.

MP (Main Pump) starts and MP RUN LED lights.

BP (Booster Pump) starts automatically, and BP RUN LED lights.

While pump is running, the default LCD display is motor current(s).

For other indications of pump condition, refer to Table 5.2.

(31)

[NOTE]

The pump will not start while an ALARM/TRIP signal remains active.

Pressing START button will bring STARTFAIL to the display.

Stop

Press controller STOP button.

Both MP and BP stop and both RUN LED go out.

Motor current is indicated as "00.0 A.”

5.2.2 Remote (Distant) Operation

Start

[NOTE] External signal type must comply with dipswitch settings.

Input external MP START signal from control connector.

MP starts.

In BP automatic operation mode, BP starts and stops automatically based on the

pump inlet vacuum.

When operating BP by remote signal, input external BP START signal from control

connector only when inlet pressure is less than or equal to 4000 Pa.

Stop

[Alternating signal mode]

Turn MP START signal off, both MP and BP stop.

[Momentary (Pulse) signal mode]

Input external MP STOP signal, both MP and BP stop.

EBARA Corporation

Page 46

(32)

6 Maintenance and Overhaul

6.1 Routine Inspection

Check periodically that there is no ALARM signal on the LCD controller or remote output.

Any ALARM indicates that the pump is operating in abnormal condition.

Table 6.1 Typical Check Items

No. Item Sensor Interval(recommended)

1

Motor Current CT

2 N2 Gas Flow Flow sensor

3 Vibration / Noise -----

1 time/week

4 Lubrication oil Quantity Level switch

5 Cooling water flow Flow sensor

6 Pump casing Temp. T/C

7 Color of lubrication oil ----- 1 time/month

If any ALARM/TRIP occurs, take necessary measures according to Section 8.

WARNING

Switch off the power supply to the pump; interrupt the ELB or CB

and lockout power before you start maintenance.

WARNING

The pump and exhaust piping will remain at a high temperature

during operation and for a short time after the pump has stopped.

Avoid contact and keep flammable substances out of reach.

Do not remove the outer cover during operation.

[NOTE]

Even after clearing the cause of the ALARM/TRIP signal, the

display will persist until the RESET signal is entered. After you

have taken the remedial action, press the RESET button on the

controller or enter the RESET signal from the control signal

connector to reset the ALARM/TRIP status.

CAUTION

An ALARM signal will not stop the pump.

However, continuing pump operation in this condition may lead to a

TRIP signal or a serious breakdown. After completion of the next

wafer cycle, check the pump in accordance with the instructions of

Section 8.

CAUTION

In the REMOTE operating mode, when a TRIP signal has occurred,

interrupt the external start signal before beginning maintenance. If

the external ALTERNATE start signal is present, the pump will start

as soon as the TRIP is RESET.

EBARA Corporation

Page 47

6.2 Piping Maintenance

(33)

WARNING

Purge system with sufficient N2 gas before removing and cleaning the

vacuum lines and exhaust piping.

Prevent dispersal of flammable, toxic or dangerous materials and

guard against their contact with the human body.

Work only in locations with an emergency escape route.

WARNING

Check for gas leaks after installing and maintaining the piping.

Gas leaks will result in the discharge of harmful and dangerous

substances and in abnormal reactions due to the admission of air into

the pump

CAUTION

Dispose of process byproducts in strict accord with all local and

national environmental and safety regulations.

Follow the instructions below when carrying out maintenance work on the vacuum and

exhaust piping of the pump.

Before you remove and wash the piping, purge with a sufficient volume of N

On systems with an exhaust gas scrubber, interrupt N

purge and close the inlet valve of the

2

gas.

2

scrubber before removing the piping.

Switch off the power supply.

After cleaning the piping, do not reconnect until it has dried completely.

6.3 Lubricant Oil

CAUTION

Do not start filling oil until the pump interior reaches atmospheric

pressure. During pump operation, the chamber containing the oil is

under vacuum. Removing the oil fill plug while the pump is running

will cause oil carryover and damage the pump.

CAUTION

A licensed industrial waste disposal dealer should dispose of waste

oil in accordance with Material Safety Data Sheet (Appendix 1).

Upon an OIL LEVEL LOW ALARM or whenever the lubricant oil needs replenishing, fill the oil

chamber and drain the oil that has collected in the secondary reservoir.

EBARA Corporation

Page 48

(34)

6.4 Spare (Maintenance) Parts List

Pump maintenance requires the following parts at customer site.

Table 6.2

1. Standard Consumable

Item Type EC Part No. ETI Part

FOMBLIN Y-L VAC 25/6

No.

PFPE oil

2. Parts Recommended for Safe Operation

Item Type EC Part No. ETI Part

O-ring (Viton A)

3. Parts Recommended for Quick Maintenance

Item Type EC Part No. ETI Part

Exhaust check valve 32X80L CER01-4402 980083

4. Recommended Spare Parts (not needed for each pump)

BARRIERTA J100

DEMNUM S-65

KRYTOX VPF 1525

NW25 CER01-4746 980928

NW40 CER01-4747 980927

G55 (For exhaust check

valve)

CER01-4002 927009

CER01-4402-2 923111

No.

No.

Item Type EC Part No. ETI Part

No.

Oil level switch NOR. CLOSE CER90-6515 ----Water flow sensor 20 L/min CER90-6018 942020

Pump gas flow sensor (seal) 3.4 Pam3/s CER90-6012

N2 flow sensor 84.4 Pam3/s CER90-6017 ----T/C bolt T TYPE, M8 CER90-6035 913046

N2 gas pressure regulator R31-200-C121 CER01-4420 980086

(EC: EBARA CORPORATION; ETI: EBARA TECHNOLOGIES INCORPORATED)

EBARA Corporation

Page 49

(35)

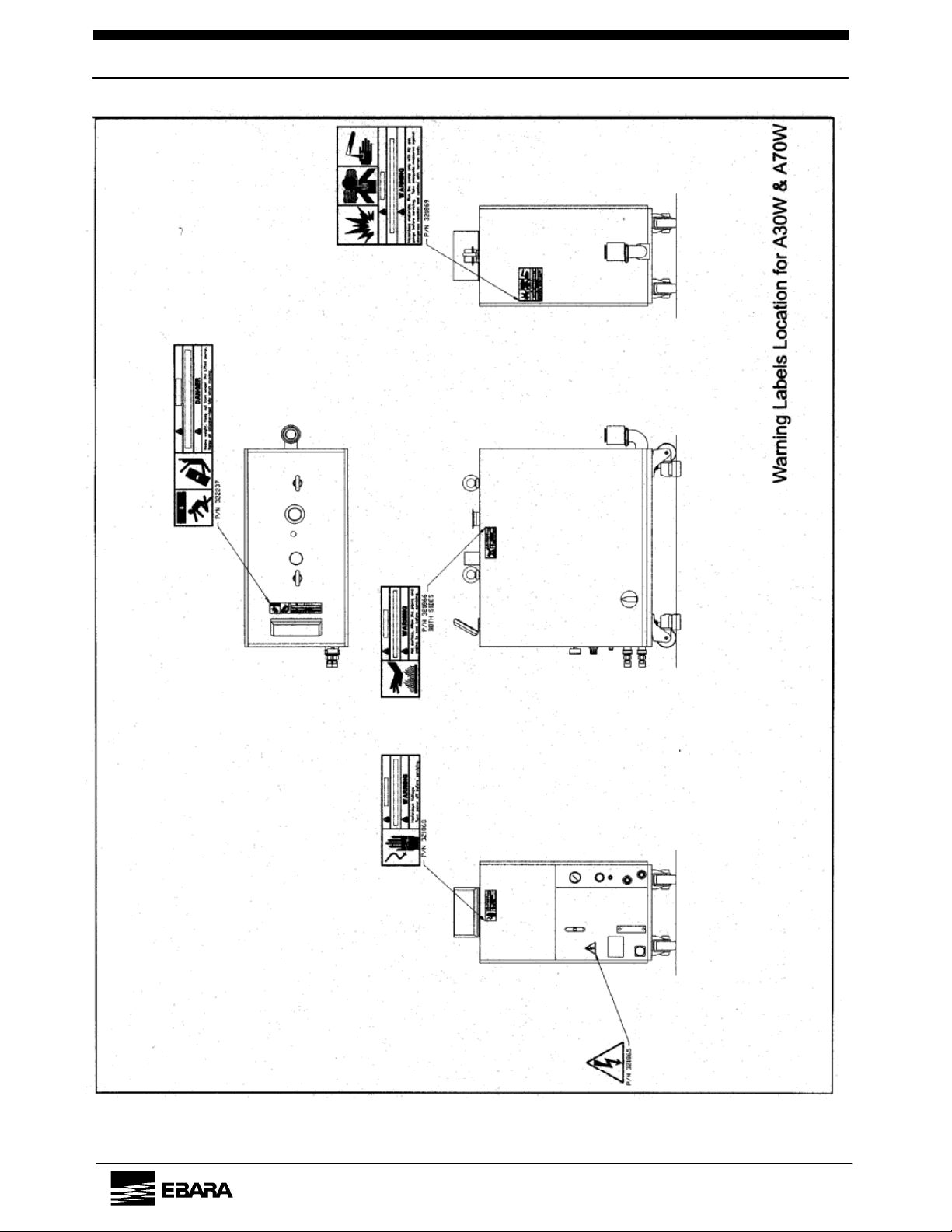

The pump enclosure panels carry the following labels. If a label should peel off or become

illegible, replace it as directed in the Warning Label Drawings.

Table 6.3 Labels

Label Name EC Part No. ETI Part No.

[DANGER] HAZARDOUS WEIGHT DANGER CER90-9193 322237

[WARNING] HAZARDOUS VOLTAGE WARNING CER90-9115 321868

[WARNING] HIGH TEMPERATURE WARNING CER90-9113 321866

[WARNING] HAZARDOUS MATERIAL WARNING CER90-9116 321869

[CAUTION] CHARGE MARK CER90-9112 321865

6.5 Overhaul

Properly trained personnel should perform overhaul work. Contact EBARA sales office or

overhaul service center.

EBARA Corporation

Page 50

(36)

7 Removal and Transportation

WARNING

When a pump exhausts highly toxic gases such as arsenic and

mercury compounds, contact EBARA Corporation before you return

the pump.

CAUTION

In the interest of safety during the transportation, disassembly and

cleaning of the pump, take note of the gases that it has pumped.

[NOTE]

In the U.S., Department of Transportation regulations may apply to

the shipment of your pump. See Appendix 5.

To disconnect and transport the pump, proceed as follows.

Stop the pump and replace all gases inside the pump by purging them with N

gas.

2

Switch off the power supply to the pump; remove the power and signal wires.

After fully closing the N

regulator and removing the N2 pipe, seal off the N2 purge port with a

2

sealing flange.

Remove the cooling water pipes.

Remove the vacuum and exhaust pipes and completely seal off the suction and exhaust

ports of the pump with a blind flange or similar seal. Seal off other process gas connection

points, such as the differential port, with a blind flange.

Tape the LCD controller, face down, to the pump‘s top cover.

Wrap the pump in a vinyl sheet.

Use the eyebolts provided on the pump for slinging the pump to load and unload. Fasten

eyebolts completely; turn in until flush with the seating surface. For sling, use a wire with a

length so that the slinging angle (that is, the angled subtended by the two wires) is 60° or

less.

[NOTE]: A07V has only one eyebolt.

DANGER

WARNING

Do not enter the zone underneath the suspended pump.

Only qualified personnel should lift the pump.

Ensure that the wire rope and crane used for lifting the pump are in

proper order and match the weight of the pump.

To prevent unequal weight distribution, suspend the pump with

symmetrically centered slinging angle.

CAUTION

To avoid oil leaks when lifting or transporting the pump, do not keep

it more than 10° off the horizontal longer than five minutes.

EBARA Corporation

Page 51

(37)

60° or less

LCD Controller

Figure 7.1

Route the sling to avoid damaging any options, such as an interface box, mounted on the

pump.

To transport an uncrated pump, lower the adjustment feet. Place a protective cloth around

the pump and use protective members between the outer cover and the tie down straps to

distribute the strap load.

EBARA Corporation

Page 52

(38)

8 Troubleshooting

8.1 Troubleshooting (1) Basic Trouble

Abnormal symptom Check Item Corrective Action

Circuit breaker is activated.

(Leakage detector is on.)

Power LED does not come

on.

Display is abnormal.

MP does not start when

pressing START button.

MP does not start when

applying START signal.

BP does not start.

Abnormal noise.

Excessive vibration.

Vacuum pressure increase.

Interrupt Earth Leakage Breaker (ELB) or CB and lock out power

WARNING

before starting on wiring and maintenance work.

Do not switch on the power supply to the pump until work is

completed.

The pump casing and exhaust piping become extremely hot during

WARNING

operation and for some time after stopping.

Keep pump and exhaust piping away from contact with personnel and

flammable substances.

Do not remove the pump cover during operation.

Incorrect wiring Check wiring

Ground fault Replace or overhaul pump

Short circuit Replace or overhaul pump

No power supply to pump Check power supply

Connector is not connected Connect power connector

ELB is not mode ON Switch ELB ON

ELB is not mode ON Switch ELB ON Nothing appears on LCD.

Instruments are in failure Replace instruments

Mode is set in “Remote” Set switch to “Local” mode

Start-up conditions are not satisfied

(“STARTFAIL” is displayed)

Instruments are in failure Replace instruments

Mode is set in “Local” Set switch to “Remote” mode

Mode is set in “Alternate”

(Pump jogs)

Instruments are in failure Replace instruments

Leakage on vacuum piping Check piping

MP insufficient vacuum Replace or overhaul

BP start signal is not applied Apply BP start signal

Instrument failure Replace instruments

Adjuster foot is not lowered Properly set all adjuster feet

Cover is in contact with other items Remove objects from cover

Cover screws loose Tighten mounting screws

Pump part is damaged Replace or overhaul pump

Byproducts settled in piping Clean up piping

N2 pressure setting is high Set pressure for correct value

Leakage from vacuum piping Check piping

Byproducts settled in pump Replace or overhaul pump

Satisfy all start-up conditions

Apply “Alternate” start signal

Set to “Momentary” mode

WARNING

Gas leaks will result in the discharge of harmful and dangerous

substances and in abnormal reactions due to the admission of air into

the pump

EBARA Corporation

Check for gas leaks after installing and maintaining the piping.

Page 53

8.2 Troubleshooting (2) ALARM

Display Symptom Check Item Corrective Action

ALARM: WATER

FLOW LOW ##.#

ALARM: SEAL N2

FLOW LOW

ALARM: DIL. N2

FLOW LOW ##.#

[w/ dilution mode]

ALARM: DIL. N2.

VALVE OPEN

[w/o dilution mode]

ALARM: BP MOTOR

CURRENT HIGH##.#

ALARM: MP MOTOR

CURRENT HIGH##.#

ALARM: CASING

TEMP HIGH ##.#

ALARM: BP-GEAR

OIL LEVEL LOW

ALARM: BP-MOTOR

Water flow

decreases.

Shaft seal. N

flow

2

decreases.

Dilution N

. flow

2

decreases.

*1

[w/ dilution mode]

Dilution N

valve

2

open.

*2

[w/o dilution mode]

BP motor current

rises.

MP motor current

rises.

Casing temperature

rises.

BP gear side oil level

low

BP motor side oil

Coupler is disconnected Connect coupler

Pressure is not sufficient Apply sufficient pressure

Source valve is closed Open valve

Water piping is clogged Clean or replace piping

Water piping leaks Check the fittings

Instruments are in failure Replace instruments

Inlet/Outlet is reverse

Connect correctly

(Flow rate 0L/min)

N2 port is not connected Connect N2 pipe fitting

Primary pressure is

Apply sufficient pressure

insufficient

Regulator setting low Increase pressure setting

N2 piping is clogged Replace N2 piping

N2 piping leaks Check the fittings

Instruments are in failure Replace instruments

Selector valve is closed *1 Open the valve

Set to zero dilution mode”

Selector valve is open *2 Close the valve

Set to “standard mode”

Exhaust pressure rises Check exhaust piping

Rotor is in contact

(Byproducts)

(Substance plunge)

(Cooling water decrease)

(Gear or bearing damage)

Replace or overhaul pump

Replace or overhaul pump

Increase water slowly

Replace or overhaul pump

Instruments are in failure Replace instruments

Power supply failure Check power supply

Exhaust pressure rise Check exhaust piping

Duct ventilation is

Ventilate sufficiently

insufficient

Byproduct is clogged Replace or overhaul pump

Cooling water decrease Increase water slowly

Decrease of oil Fill the lubricating oil

Insufficient sealing N2 Check sealing N2 ALARM

Pump is inclined Level the pump with

adjuster feet

(39)

EBARA Corporation

Page 54

(40)

Display Symptom Check Item Corrective Action

OIL LEVEL LOW level low

ALARM: MP-GEAR

OIL LEVEL LOW

ALARM: MP-MOTOR

OIL LEVEL LOW

ALARM: OIL LEVEL

LOW

ALARM: DRV BRG

TEMP HIGH

ALARM: DRVN BRG

TEMP HIGH

TEMP HIGH

MP gear side oil

level low

MP motor side oil

level low

Oil level low in oil

pan.

[A07V only]

Driving shaft brg

temp. rises. [A07V]

Driven shaft brg

temp. rises. [A07V]

Temperature in

pump cover rises.

Instruments are in failure Replace instruments

Cooling water decrease Increase water slowly

Decrease of grease Change the grease

Bearing is damaged Replace or overhaul pump

Duct ventilation not sufficient Ventilate sufficiently ALARM: PUMP BOX

Cooling water decrease Increase water

After taking corrective action, input RESET signal or push RESET button. The pump will

not RESET while the cause of the ALARM remains.

WARNING

Interrupt Earth Leakage Breaker (ELB) or CB and lock out power

before starting on wiring and maintenance work.

Do not switch on the power supply to the pump until work is

completed.

WARNING

The pump casing and exhaust piping become extremely hot during

operation and for some time after stopping.

Keep pump and exhaust piping away from contact with personnel and

flammable substances.

Do not remove the pump cover during operation.

WARNING

Check for gas leaks after installing and maintaining the piping.

Gas leaks will result in the discharge of harmful and dangerous

substances and in abnormal reactions due to the admission of air into

the pump

EBARA Corporation

Page 55

(41)

8.3 Troubleshooting (3) TRIP

Display Symptom Check Item Corrective Action

TRIP: CASING

TEMP H.HIGH

TEMP HIGH

TRIP: MP MOTOR

TEMP HIGH

TRIP: BP MOTOR

OVERLOAD

TRIP: MP MOTOR

OVERLOAD

TRIP:

PHASE ERROR

TRIP: BP MOTOR

NO CURRENT

TRIP: MP MOTOR

NO CURRENT

TRIP: STARTFAIL

ALARM/TRIP EXIST

Pump casing temp.

rises.

BP motor temp.

rises.

MP motor temp.

rises.

BP current rises.

(thermal relay trip)

MP current rises.

(thermal relay trip)

Open phase Incorrect wiring Check power supply

BP motor current value

is 0.

MP motor current value

is 0.

Start fault

Exhaust pressure rise Check exhaust piping

Cooling water decrease Increase water slowly

Byproduct clog Replace or overhaul pump

Duct ventilation insufficient Ventilate sufficiently

Cooling water decrease Increase water slowly TRIP: BP MOTOR

Motor is in failure Replace or overhaul pump

Exhaust pressure rise Check exhaust piping

Byproduct clog Replace or overhaul pump

Object ingestion Replace or overhaul pump

Instruments are in failure Replace instruments

Power supply failure Check power supply

Incorrect wiring Wire R/S/T/E correctly Negative phase

Instruments are in failure Replace instruments

Instruments are in failure Replace instruments

Starting in ALARM / TRIP

condition

Instruments are in failure Replace instruments

Satisfy all starting

conditions

After taking corrective action, input RESET signal or push RESET button. The pump will

not RESET while the cause of the TRIP remains. In remote operation mode, interrupt

external START signal before resetting.

WARNING

Interrupt Earth Leakage Breaker (ELB) or CB and lock out power

before starting on wiring and maintenance work.

Do not switch on the power supply to the pump until work is

completed.

WARNING

The pump casing and exhaust piping become extremely hot during

operation and for some time after stopping.

Keep pump and exhaust piping away from contact with personnel and

flammable substances.

Do not remove the pump cover during operation.

WARNING

Check for gas leaks after installing and maintaining the piping.

Gas leaks will result in the discharge of harmful and dangerous

substances and in abnormal reactions due to the admission of air into

the pump.

EBARA Corporation

Page 56

(42)

8.4 Troubleshooting (4) TRIP [Options]

Display Symptom Check Item Corrective Action

Tube fitting loose Tighten fittings TRIP:

Instruments are in failure Replace instruments

Exhaust valve is closed Check exhaust piping TRIP:

Instruments are in failure Replace instruments

Stop by emergency stop

button

Check that pump can be

operated and turn the

button head to reset

WATER LEAKAGE

BACK PRESS. HIGH

TRIP:

EMG. STOP SWITCH

Water leakage

Exhaust pressure

rises.

(0.1 MPa)

Emergency stop

switch

After taking corrective action, input RESET signal or push RESET button. The pump will

not RESET while the cause of the TRIP remains. In remote operation mode, interrupt

external START signal before resetting.

WARNING

WARNING

WARNING

Interrupt Earth Leakage Breaker (ELB) or CB and lock out power

before starting on wiring and maintenance work.

Do not switch on the power supply to the pump until work is

completed.

The pump casing and exhaust piping become extremely hot during

operation and for some time after stopping.

Keep pump and exhaust piping away from contact with personnel and

flammable substances.

Do not remove the pump cover during operation.

Check for gas leaks after installing and maintaining the piping.

Gas leaks will result in the discharge of harmful and dangerous

substances and in abnormal reactions due to the admission of air into

the pump

EBARA Corporation

Page 57

(43)

9 Inquiries

For all inquiries and queries in connections with any of the details given in this Operating

Instruction Manual or the pump in general, please contact EBARA Corporation directly with

pump model and serial number.

9.1 North America

EBARA TECHNOLOGIES, INC.

(1) Western Region CALIFORNIA

Headquarters

51 Main Avenue

Sacramento, CA 95838, U.S.A.

Phone: (916) 920-5451 Fax: (916) 925-6654

Silicon Valley Operations

45 Plumeria

San Jose, CA 95134-2103, U.S.A.

Phone: (408) 934-2888 Fax: (408) 934-2801

(2) Eastern Region CONNECTICUT

1 Parklawn Drive

Bethel, CT, 06801, U.S.A.

Phone: (203) 790-1080 Fax: (203) 790-7404

(3) Southwest Region TEXAS

8201-6 E. Riverside Drive, Suite 600

Austin, TX 78744, U.S.A.

Phone: (512) 389-3993 Fax: (512) 389-3995

EBARA Corporation

Page 58

(44)

9.2 Asia

EBARA Corporation

(1) Japan Precision Machinery Group

Nissay Aroma Square 5-37-1 Kamata

Ohta-Ku, Tokyo 144-8721 Japan

Phone: 81-3-5714-6111

Fax: 81-3-5714-6081

(2) Korea EBARA Precision Machinery Korea, Inc.

15 FL, Kangnam Bldg.

1321 Seocho-Dong, Seocho-Ku, Seoul, Korea

Phone: 82-2-581-6901

Fax: 82-2-581-4211

(3) Taiwan EBARA Densan (TED)

No. 7 Nan Yuen 2nd Road

Chung Li City, Tao Yuen Hsien, Taiwan

Phone: 886-3-451-5881

Fax: 886-3-452-7904

EBARA Precision Machinery Taiwan, Inc.

EBARA Corporation, Taipei Office

Room 1402 Chia Hsin Bldg., No. 96, Sec. 2

Chung Shan N. RD., Taipei Taiwan

Phone: 886-2-2560-1166

Fax: 886-2-2560-1177

(4) Singapore EBARA Engineering Singapore (E.E.S.)

No. 1 Tuas Link #2

Singapore, 638550

Phone: 65-862-3536

Fax: 65-861-0589

EBARA Corporation

Page 59

9.3 Europe

(1) United Kingdom EBARA Corporation Scotland Branch

3 & 4 Adam Square-Brucefield Industrial Estate

Livingston, G-8West Lothian, EH54 9DE U.K.

Phone: 44-1509-460232

Fax: 44-1506-460222

(2) Germany EBARA Germany GmbH

Donaustabe 7, D-63452

Hanau, Germany

Phone: 49-16181-1876-0

Fax: 49-1618¥1-1876-40

(45)

EBARA Corporation

Page 60

(46)

[Blank Page]

EBARA Corporation

Page 61

Appendix 1