Page 1

End Suction Centrifugal

EBARA Fluid Handling

EBARA International Corporation

Operating Instructions, Installation & Maintenance Manual

Models 3U / 3UB

Page 2

Page 3

EBARA End Suction Centrifugal 3U / 3UB

Operating, Installation, and Maintenance

EBARA Fluid Handling

www.pumpsebara.com

3

(t) 803 327-5005 • (f) 803 327-5097

rev. 02/09

IMPORTANT SAFETY INSTRUCTIONS

Rules for Safe Installation and Operation

Installation

Contents

Section Page

Safety Specifications and Installation 3

3U / 3UB Selection Chart 5

3U / 3UB Specifications 6

3U / 3UB Type 1 Sectional View and Parts List 7

3U(B) 65 Type 3 Sectional View and Parts List 8

Installation Instructions 9

Maintenance and Service 10

3U / 3UB Assembly – 3HP - 15HP 11

3U / 3UB Assembly – 20HP - 30HP 12

Troubleshooting Checklist and Maintenance Information 13

1. Read these rules and instructions carefully. Failure to follow them could cause serious bodily injury and/or property damage.

2. Check your local codes before installing. You must comply with their rules

3. For maximum safety, this product should be connected to a grounded circuit equipped with a ground fault interrupter device.

4. Before installing this product, have the electrical circuit checked by an electrician to make sure it is properly grounded.

5. Before installing or servicing your pump, BE CERTAIN pump power source is disconnected.

6. Make sure the line voltage and frequency of the electrical current supply agrees with the motor wiring. If motor is dual voltage

type, BE SURE it is wired correctly for your power supply.

7. Complete pump and piping system MUST be protected against below freezing temperature. Failure to do so could cause severe

damage

and voids the Warranty.

8. Avoid system pressures that may exceed one and a half times the operating point selected from the pump performance curve.

9. Do not run your pump dry. If it is, there will be damage to the pump seal.

PACKAGE CONTENTS

1. Be sure all parts have been furnished and that nothing has been damaged in shipment.

2. The catalog lists all parts included with package. A packing list packed with pump, also lists contents.

3. OPEN PACKAGES AND MAKE THIS CHECK BEFORE GOING ON JOB.

PIPING – Pipes must line up and not be forced into position by unions. Piping should be independently supported near

the

pump so that no strain will be placed on the pump casing. Where any noise is objectionable, pump should be insulated

from

the piping with rubber connections. Always keep pipe size as large as possible and use a minimum of fittings to reduce

friction losses.

SUCTION PIPING – Suction pipe should be direct and as short as possible. It should be at least one size larger than suction

inlet tapping and should have a minimum of elbows and fittings (5 to 6 pipe diameters of straight pipe before inlet is recommended).

The piping should be laid out so that it slopes upward to pump without dips or high points so that air pockets are eliminated.

The highest point in the suction piping should be the pump inlet except where liquid flows to the pump inlet under pressure.

The suction pipe must be tight and free of air leaks or pump will not operate properly.

WARNING

Page 4

EBARA End Suction Centrifugal 3U / 3UB

Operating, Installation, and Maintenance

EBARA Fluid Handling

www.pumpsebara.com

4

(t) 803 327-5005 • (f) 803 327-5097

rev. 02/09

DISCHARGE PIPING – Discharge piping should never be smaller than pump tapping and should preferably be one size

larger. A gate valve should always be installed in discharge line for throttling if capacity is not correct. To protect the pump

from water hammer and to prevent backflow, a check valve should be installed in the discharge line between the pump and

gate valve.

ELECTRICAL CONNECTIONS – Be sure motor wiring is connected for voltage being used. Unit should be connected to a

separate circuit. A fused disconnect switch or circuit breaker must be used in this circuit. Wire of sufficient size should be

used to keep voltage drop to a maximum of 5%.

Single phase motors have built-in overload protection. Flexible metallic conduit should be used to protect the motor leads.

PRIMING – The pump must be primed before starting. The pump casing and suction piping must be filled with water before

starting motor. When water is poured into pump to prime, remove all air before starting motor.

STARTING – When the pump is up to operating speed, open the discharge valve to obtain desired capacity or pressure.

WARNING! DO NOT ALLOW THE PUMP TO RUN WITH THE DISCHARGE VALVE TIGHTLY CLOSED. IF THE PUMP

RUNS FOR AN EXTENDED PERIOD OF TIME WITHOUT LIQUID BEING DISCHARGED, THE LIQUID IN THE PUMP

CASE CAN GET EXTREMELY HOT CAUSING SEVERE DAMAGE TO THE PUMP AND POSSIBLY CAUSE INJURY TO

PEOPLE.

ROTATION – All single phase motors are single rotation and leave factory with proper rotation. Three phase motors should

be checked to ensure proper rotation

FREEZING – Care should be taken to prevent the pump from freezing during cold weather. It may be necessary, when

there

is any possibility of this, to drain the pump casing when not in operation. Drain by removing the pipe plug in the bottom

of the

casing.

ROTARY SEAL – PRO STEEL pumps are fitted only with rotary seal. This seal is recommended for LIQUIDS free from abrasives.

LOCATION OF UNIT – The pump should be installed as near to the liquid source as is practical so that the static suction

head (vertical distance from the center line of the pump to water level) is maximized, and so that a short, direct suction pipe

may be used. The capacity of a centrifugal pump is reduced when the unit is operated under a high suction lift. The piping

should be as free from turns and bends as possible, as elbows and fittings greatly increase friction loss. Place the unit so that

it is readily accessible for service and maintenance and on a solid foundation, which provides a rigid and vibration-free support. Protect the pump against flooding and excess moisture.

Rules for Safe Installation and Operation

(continued)

Page 5

EBARA End Suction Centrifugal 3U / 3UB

Operating, Installation, and Maintenance

EBARA Fluid Handling

www.pumpsebara.com

5

(t) 803 327-5005 • (f) 803 327-5097

rev. 02/09

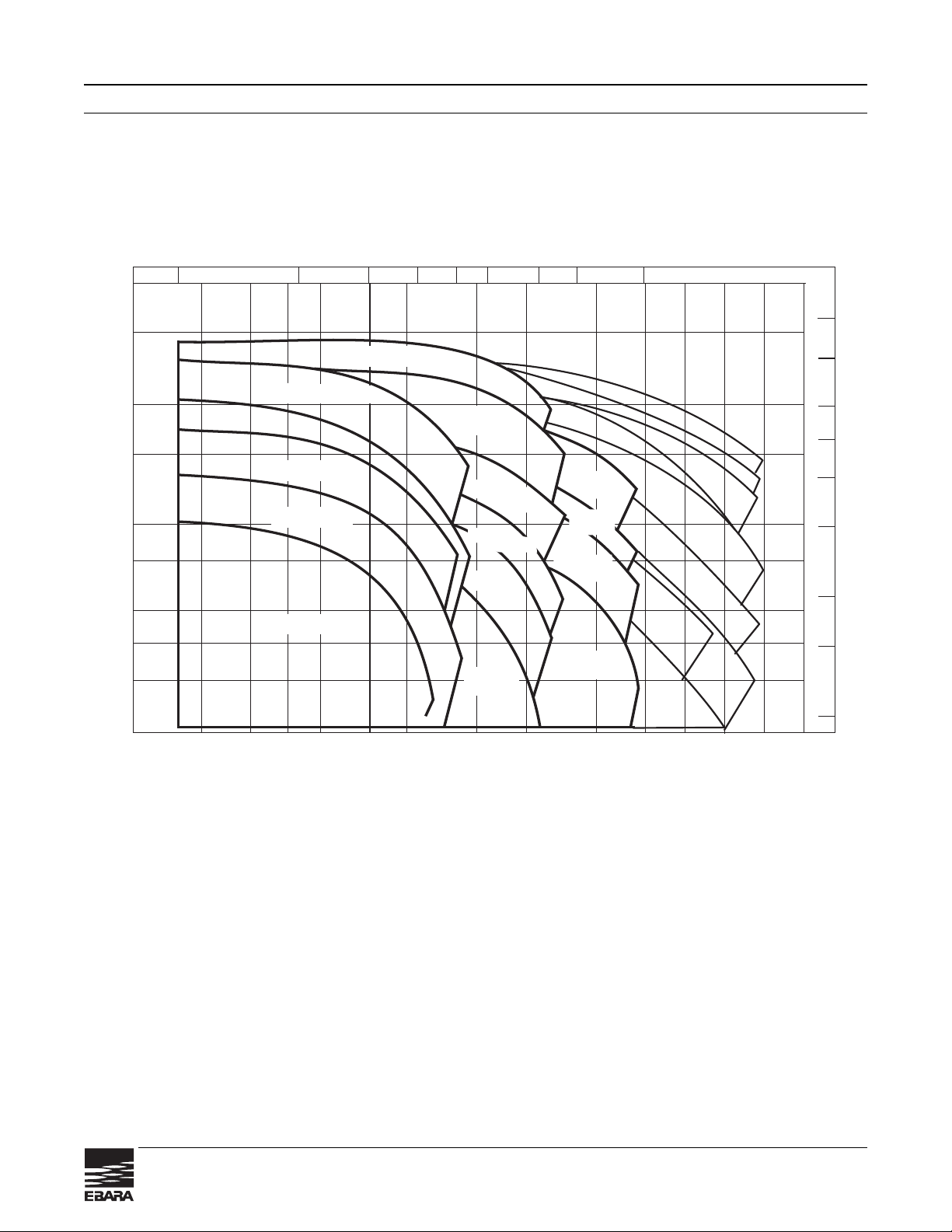

Model 3U / 3UB Selection chart Synchronous Speed 3450 RPM

0.1 0.2 0.3 0.4 0.5 0.6 0.8 1.0 1.5

100M

80

60

50

40

30

20

15

10

Ft

300

200

150

100

80

60

50

20 30 40 50 60 80 100 150 200 300 400 600 700

M

3

/MIN

CAPACITY IN GPM

TOTAL HEAD

*

Three phase motor only

50-160 10HP

40-160 7½HP

32-200 7½HP

32-200 7½HP

32-125-3HP

50-125

7½HP

40-125A 5HP

50-125-1

10HP

40-125B 5HP

*50-160-1

15HP

*40-200A 15HP

40-160-1 10HP

50-160 10HP

32-160A-5HP

32-160B-5HP

32-200-1-10HP

*40-200B-15HP

40-160 7½HP

1. 3U65-125-7.5HP

1

2. 3U65-125-10HP

2

3. 3U65-160-10HP

3

4. 3U65-160-15HP*

4

5. 3U65-160-20

HP*

5

40

30

6. 3U65-160-25

HP*

6

7. 3U65-200-20HP*

7

8. 3U65-200-25

HP*

8

9. 3U65-200-30HP*

9

Page 6

EBARA End Suction Centrifugal 3U / 3UB

Operating, Installation, and Maintenance

EBARA Fluid Handling

www.pumpsebara.com

6

(t) 803 327-5005 • (f) 803 327-5097

rev. 02/09

Standard Optional

Size

Suction 3U32 – 2'' ANSI Equivalent Companion Flange kit

(150 lb. ANSI R.F. equivalent) 3U40 – 2

1

/2

'' ANSI Equivalent 150 Lb. ANSI, Female NPT

3U50 – 2

1

/2'' ANSI Equivalent

3UB65 – 3'' ANSI Equivalent

Discharge 3U32 – 1

1

/4'' ANSI Equivalent

(150 lb. ANSI R.F. equivalent) 3U40 – 1

1

/

2'' ANSI Equivalent

3U50 – 2'' ANSI Equivalent

3UB65 – 2

1

/2'' ANSI Equivalent

Range of HP 3U – 3 HP to 15 HP

3UB – 7

1

/2 HP to 30 HP

Range of Performance

Capacity 13 to 750 GPM at 3450 RPM

Head 33 to 250 feet at 3450 RPM

Liquid handled

Type of liquid Clean water

Temperature 212°F (100°C) Max. 250°F (121°C) with optional

high temperature seal

Max. working pressure 230 PSI (15 Bar)

Materials 3U 3UB

Casing 304L Stainless Steel 304L Stainless Steel

Impeller (closed type) 304L Stainless Steel Bronze

Stainless steel option for 3UB models

Shaft Sleeve 304L Stainless Steel 304L Stainless Steel

Bracket Cast iron Cast iron

Shaft Seal

Mechanical Seal – Type 21

Seal Material Carbon/Ceramic/Viton Consult factory for additional

Carbon/Ceramic/Buna optional seal availability

Hot water – Carbon/Ni-Resist/Viton, 250°F (121°C) max.

Direction of Rotation Clockwise when viewed from motor end

Motor

Type NEMA JM, TC, TSC Frame

Speed 60 Hz, 3450 RPM (2 poles) 4 pole – consult factory as noted

Bearing Ball Bearing

Single Phase TEFC – 3 HP

ODP – 3 HP to 10 HP

Three Phase TEFC – 3 HP to 30 HP Explosion proof – consult factory

ODP – 3 HP to 30 HP for availability

208-230/460V Washdown duty – consult factory

Motor Protection Overload protection must be provided for availability

Standard Accessories Suction and Discharge Flange Gasket

Motor support

Specifications

Page 7

EBARA End Suction Centrifugal 3U / 3UB

Operating, Installation, and Maintenance

EBARA Fluid Handling

www.pumpsebara.com

7

(t) 803 327-5005 • (f) 803 327-5097

rev. 02/09

Sectional view – 3U / 3UB Type 1

001

011

018

021

021

039

041

111

115

117-1

117-2

117-3

125

160

212

800

Casing

Casing cover

Bracket

Impeller (3U)

Impeller (3UB)

Key

Shaft sleeve

Mechanical seal

O-Ring

Gasket

Gasket

Gasket

Impeller Bolt

Motor support (not shown)

Plug

Motor

Suction Flange Gasket

Discharge Flange Gasket

304L Stainless

304L Stainless

Cast Iron

304L Stainless

Bronze

304L Stainless

304L Stainless

–

Viton

Nylon

Nylon

Nylon

304L Stainless

Steel

304L Stainless

–

Viton

Viton

1

1

1

1

1

1

1

1

1

1

1

1

1

1 set

1

1

1

1

Part No. Part Name Material No. for 1 Unit

212

001

125

021

115

111

011

117-3

041

117-2

129

135-1

018

039

800

117-1

Page 8

EBARA End Suction Centrifugal 3U / 3UB

Operating, Installation, and Maintenance

EBARA Fluid Handling

www.pumpsebara.com

8

(t) 803 327-5005 • (f) 803 327-5097

rev. 02/09

001

003

003A

004

006

007

011

012

025

026

032

034

040

041

042

042A

044

234

Casing

Motor bracket

Adapter ring

Casing cover

Coupling

Impeller

Mechanical seal

Motor

Drain plug

O-ring

Key

Impeller nut

Flange Gasket

Flange Gasket

Motor support

Casing support (65-160 25HP only)

Coupling guard

Lip seal

304L Stainless

Cast iron

Cast iron

304L Stainless

Steel / Stainless steel

Bronze/optional Stainless Steel

304L Stainless

Viton

304L Stainless

Stainless / Nylon

EPDM

EPDM

Steel

Steel

Stainless Steel

304L Stainless

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

2

2

1

Part No. Part Name Material No. for 1 Unit

Sectional view – Model 3U 65 Type 3

3U 65-160/20

3U 65-160/25

3U 65-200/20

3U 65-200/25

3U 65-200/30

Page 9

EBARA End Suction Centrifugal 3U / 3UB

Operating, Installation, and Maintenance

EBARA Fluid Handling

www.pumpsebara.com

9

(t) 803 327-5005 • (f) 803 327-5097

rev. 02/09

3U / 3UB Installation Instructions

Mounting the Assembly

Do not operate the pump unless the assembly is securely and properly mounted.

Misalignment of the motor/pump assembly or not having the assembly reasonably level may cause pump vibration,

noisy operation, fluid leaks, or air leaks and air locks in the suction pipe.

1. Place the motor/pump assembly in its intended operating position.

2. Level the pump through the centerline of the motor/pump assembly suction port.

Initial Operation

Make certain the motor is not connected to a power source until the motor is properly assembled and mounted.

Serious personal injury or damage to the motor/pump assembly could occur if the motor is activated improperly.

Only certified electricians should make electrical connections.

1. Prime the pump by adding fluid to the volute case through the top plug.To properly prime the pump, venting

may be required.

2. Check the nameplate on the motor to determine the correct wiring procedure for your intended power source

and if the motor is single or three phase. Connect the motor to a power source by following the wiring procedure

on the motor's nameplate.

Note:

a. Single phase motors are typically dual voltage. In some cases, three phase motors are tri-voltage. Check the

nameplate and follow the proper wiring procedure for the voltage you are using. Improperly wiring the motor

could result in damage to the motor.

b. Three phase motors require a control box. Install overload protection to help prevent motor damage.

c. Depending on the wiring, three phase motors may start in reverse. Interchange any two power leads to

change the starting direction and pump rotation.

• Always follow correct operating procedures.

• Always disconnect the motor/pump assembly from all power sources before servicing the pump or motor.

• Periodically check all power connections, bolts, screws, and the motor's mounting.

• Failure to properly follow assembly and operating instructions could result in damage to the pump and motor.

• Failure to properly install the impeller and impeller nut could result in damage to the pump and could cause

serious personal injury.

WARNING

Initial Operation

Make certain the motor is not connected to a power source until the motor is properly assembled and mounted.

Serious personal injury or damage to the motor/pump assembly could occur if the motor is activated improperly.

Only certified electricians should make electrical connections.

1. Prime the pump by adding fluid to the volute case through the top plug.To properly prime the pump, venting

may be required.

2. Check the nameplate on the motor to determine the correct wiring procedure for your intended power

source and if the motor is single or three phase. Connect the motor to a power source by following the wiring

procedure on the motor's nameplate.

Page 10

EBARA End Suction Centrifugal 3U / 3UB

Operating, Installation, and Maintenance

EBARA Fluid Handling

www.pumpsebara.com

10

(t) 803 327-5005 • (f) 803 327-5097

rev. 02/09

Service

Keep ventilation openings clear of extraneous objects which may hinder free flow of air thru motor. Motor bearings are lubricated

during manufacture. Additional lubrication is not required during their normal lifetime.

Maintenance

Disassembly Instructions

All pumping parts can be removed from case without disturbing the piping.

POWER SUPPLY – Open the power supply switch contacts and remove fuses. Disconnect the electrical wiring from the motor.

VOLUTE CASE

(a) Drain pump case by removing drain plugs.

(b) Remove the bolts securing volute case to pump bracket.

(c) Pry volute case from casing cover with a screwdriver.

IMPELLER

(a) Hold the motor shaft with a screwdriver in the shaft end slot. Grasp and turn the impeller counterclockwise (as viewed

from pump end).

SEAL

(a) Remove the rotating part of the seal by pulling it off the shaft.

(b) The stationary seat can be pressed from the casing cover.

CHECK LIST FOR EXAMINATION OF PUMP PARTS

IMPELLER - Replace the impeller if any vane is broken, excessive erosion shows, or if labyrinth surfaces are worn. Impeller

cap screw, washer and lockwasher should be replaced if damaged.

MECHANICAL SEAL - Seal face, O-ring and sealing members should be free of burrs and dirt. Complete seal assembly

should be replaced if not in perfect condition.

SHAFT- Shaft sleeve surface under seal or packing must be clean, smooth and without any grooves. It should be replaced if

necessary.

VOLUTE AND SEAL/PACKING PLATE LABYRINTH SURFACES (Wear Rings)- If worn, replace the necessary part. If furnished with pressed in wear rings, only the rings need be replaced.

GASKETS - Volute, suction pipe and discharge pipe gaskets should be checked for damage. Replace if necessary.

NOTE

If replacement parts are ordered, please furnish the following information to your EBARA distributor:

1. Reference Numbers

2. Description of Pump Part

3. EBARA Model Number and Serial Number on the Nameplate.

WARNING

CAUTION

Draining

The pump and piping should always be protected against freezing temperatures. If there is any danger of freezing, the unit

should be drained. To drain the pump, remove the drain plug at the bottom of the volute, and remove the priming plug to

vent the pump. Drain all piping.

Page 11

EBARA End Suction Centrifugal 3U / 3UB

Operating, Installation, and Maintenance

EBARA Fluid Handling

www.pumpsebara.com

11

(t) 803 327-5005 • (f) 803 327-5097

rev. 02/09

Position the pump on its end with the shaft up. The work surface should be level, capable of supporting the motor.

Make certain the motor is not connected to a power source. Do not install or assemble the pump on a motor

connected to a power source. Serious injury could occur if the motor activates during pump assembly.

Assembling the Pump – Models 3HP - 15HP

(see page 7 for sectional view)

1. Position a Nylon gasket (117-3) over the motor shaft.

2. Carefully press the rotating seal assembly onto the shaft sleeve (041). The smooth face of the

rotating ring must make good contact with the seal seat and the seal retainer must seal against the shaft sleeve.

Note: Seal faces should be wiped clean with non-oil based solvent or alcohol.

3. Using finger pressure only, insert the seal seat into the casing cover (011). Press the seal until it evenly

bottoms out in the seal cavity.

4. Position the cast iron motor bracket (018) over the shaft. Fasten the bracket to the motor, tightening bolts

using a cross-tightening pattern. (Tighten the bolts to the factory recommended torque specifications of 8 ft. lbs.)

Overtightening may cause stripping of threads.

5. Carefully position the casing cover (011) and seal over the shaft. Be careful not to damage the stationary

seal seat.

6. Slide the stainless steel shaft sleeve, with rotating assembly, over the motor shaft.

7. Position the O-ring (115) around the casing cover (011). Do not cut, nick, or damage the O-ring during the

installation.

8. Install the impeller shaft key (

3

/16" x 3/16" x 1 3/16").

9. Place the seal spring assembly over the rotating piece of the seal in position to receive the impeller.

10. Place a Nylon gasket (117-2) on top of spring retainer.

11. Firmly press the impeller (021) into position by aligning the slot over the shaft key. Press the impeller down

the shaft until it bottoms and seats squarely against the Teflon gasket (117-2) and shaft sleeve (041).

12. Place a Nylon gasket (117-1) over the impeller hub and into the impeller eye. Install the impeller bolt (125) to

secure the impeller to the shaft. Do not overtighten the shaft bolt. (Use a thread compound or cement to

secure the shaft bolt and prevent it from working loose.)

13. Tighten the impeller bolt. (Tighten the bolts to the factory recommended torque specifications of 11 ft. lbs.)

14. Install the pump volute (001) over the seal plate. Rotate the volute to align with the bolt holes and secure it

with the bolts, washers, and nuts. Cross-tighten the bolts to the factory recommended torque specifications

(8 ft. lbs.).

15. With a socket wrench, rotate impeller to check for alignment. If rubbing against casing, loosen bolts on

casing and retighten.

3U / 3UB Assembly Instructions

WARNING

Page 12

EBARA End Suction Centrifugal 3U / 3UB

Operating, Installation, and Maintenance

EBARA Fluid Handling

www.pumpsebara.com

12

(t) 803 327-5005 • (f) 803 327-5097

rev. 02/09

Assembling the Pump – Models 20HP - 30HP

(see page 8 for sectional view)

1. Apply a coat of anti-seize lubricant to the inside of the coupling (005).

2. Insure that key is installed in motor shaft keyway, slide coupling (005) onto shaft. (

Tip:

To ease the installation

of the coupling tighten the set screw on the side of the coupling. Tightening this screw will cause the coupling

to open slightly allowing for easier installation. After the coupling is in place be sure to loosen the set screw

to release the pressure and allow the coupling to close down on the motor shaft.)

3. Secure the coupling to the motor shaft by tightening the socket head bolts in the side of the coupling. Torque

to 11ft. lbs.

4. Fasten the adapter ring (003A) to the motor using a cross tightening pattern.

5. Fasten the motor bracket (003) to the adapter ring.

6. Apply a thin coat of non-petroleum based lubricant (i.e. dish soap) to the stationary seal seat in the casing

cover (004), using finger pressure only press the stationary seal into the seal seat. Wipe the seal face clean

with alcohol and a soft cloth.

7. Position the o-ring ( 026 ) around the casing cover.

8. Using hand pressure or a rubber mallet, press fit the casing cover ( 004 ) onto the motor bracket (003).

9. Apply a thin coat of non-petroleum based lubricant (i.e. dish soap) to the inside of the rubber boot on the

rotating seal. Slide the seal onto the coupling pushing it gently until it contacts the stationary seal that was

installed in step 6. Place the spring and spring retainer over the coupling and onto the rotating seal.

10. Place the stainless steel lip seal (234) onto the spring retainer insuring that the raised surface of the lip seal

seats into the spring retainer.

11. Install the impeller shaft key (032) into the coupling shaft.

12. Slide impeller (007) over the key and shaft.

13. Tighten the impeller nut (034) to secure the impeller in place. Tighten to 11 ft.lbs

14. Install Casing (001). Take care to align the bolt holes. Cross tighten the bolts to 8 ft. lbs.

15. With a socket wrench, rotate impeller to check for proper casing alignment. If rubbing against casing occurs

loosen casing bolts and retighten taking care to cross-tighten and use equal torque.

16. Install motor support (042) or casing support (042A) as required.

Page 13

EBARA End Suction Centrifugal 3U / 3UB

Operating, Installation, and Maintenance

EBARA Fluid Handling

www.pumpsebara.com

13

(t) 803 327-5005 • (f) 803 327-5097

rev. 02/09

TROUBLE

Pump does not run.

Pump does not pump water.

Inadequate quantity.

Overcurrent

Pump vibrates, excessive operating

noise

Pressurizing application.

Pump starts and soon stops

Pump does not stop

POSSIBLE CAUSE

Faulty connection of power supply circuit.

Wrong wiring of control circuit.

Bound shaft

Mechanical seal faces stuck together

Faulty motor

Damage to bearing

Considerable voltage drop.

Rotation direction reversed.

Lack of priming.

High discharge head.

Large piping loss.

Clogged foot valve.

Leakage from suction piping.

Too high suction lift.

Low water level.

Considerable fluctuation of power supply

voltage.

Considerable voltage drop.

Low head and overflow rate.

Damaged bearing.

Beyond rated capacity.

Cavitation.

Improper piping.

Damaged bearing.

Foreign matter clogging cooling fan.

Too limited pressure switch setting.

Leakage in system.

Too high pressure setting.

TROUBLESHOOTING

Check power supply circuit.

Correct control circuit.

Remove cause of obstruction.

Release seal by turning shaft.

Repair or replace motor.

Repair or replace any damaged bearing.

Correct rotation direction.

Re-prime the pump.

Re-examine the plan.

Re-examine the plan.

Clear foot valve suction.

Check and repair suction piping.

Re-install as per our instructions.

Foot valve in ample immersion.

Throttle flow rate at outlet.

Replace any damage bearing.

Reduce flow rate.

Consult distributor

Secure piping again.

Replace any damaged bearing.

Remove foreign matter.

Replace pressure switch to wider range.

Check and repair leaks.

Reduce max pressure setting to the

lower in pressure switch.

MAINTENANCE:

The pump does not require special maintenance.

The following rules must be observed for safe operation:

If the pump is not going to be used for a long period, the pump should be drained of water and flushed with clean water.

Where the pump is exposed to freezing temperatures, it should always be left drained when not in use.

*All specifications subject to change without notice.

Troubleshooting

Page 14

Page 15

Page 16

EBARA Fluid Handling

1651 Cedar Line Drive • Rock Hill, SC 29730

(t) 803 327 5005 • (f) 803 327 5097

www.pumpsebara.com

© 2005 EBARA International Corporation EFH 3U_3UB0209

Contact your dealer or supplier

for more information about other EBARA products

Loading...

Loading...