EAW KF755 Series, SB750 Series, KF750 Series Owner's Manual

KF700 SERIES

OWNER’S MANUAL

KF750 | KF755 | SB750

i

KF700 Series Owner’s Manual

TABLE OF CONTENTS

Section 1 Read This First.................................................................................................................................................ii

1.1 Safety Precautions ..............................................................................................................................ii

1.2 General Precautions...........................................................................................................................ii

1.3 Important Information for Professional Riggers ......................................................................ii

Section 2 Unpacking .......................................................................................................................................................iii

2.1 Shipping Damage..............................................................................................................................iii

2.2 Returning Products to EAW ............................................................................................................iii

Section 3 Quick Start .......................................................................................................................................................iv

3.1 Important Safety and Rigging Information ..............................................................................iv

3.2 Audio Signal Connections ..............................................................................................................iv

Section 4 Description ......................................................................................................................................................1

4.1 Overview................................................................................................................................................1

Section 5 Operation..........................................................................................................................................................2

5.1 KF700 Series Products.......................................................................................................................2

5.2 Input Connections..............................................................................................................................3

5.3 Mechanical Characteristics and Accessories .............................................................................3

5.4 Electrical Characteristics and Accessories..................................................................................5

5.5 Array Design .........................................................................................................................................6

5.6 System Truck-Pack..............................................................................................................................7

Section 6 Maintenance and Service ......................................................................................................................8

6.1 Warranty ................................................................................................................................................8

6.2 How to Contact EAW..........................................................................................................................8

6.3 System Maintenance and Repair Tips..........................................................................................9

6.3.1 KF750F..................................................................................................................................9

6.3.2 KF750P...............................................................................................................................12

6.3.3 KF750P-WP.......................................................................................................................14

6.3.4 KF755F...............................................................................................................................16

6.3.5 KF755P...............................................................................................................................19

6.3.6 KF755P-WP.......................................................................................................................21

6.3.7 SB750F...............................................................................................................................22

6.3.8 SB750P...............................................................................................................................23

6.3.9 SB750P-WP.......................................................................................................................24

Section 7 Specifications ..............................................................................................................................................25

Congratulations on purchasing the latest sound reinforcement innovation from Eastern Acoustic Works. The KF700

Series is built upon the same fundamental design principles that EAW has upheld since the introduction of the

KF850 Series of loudspeakers in the 1980’s. This new product line draws elements from Virtual Array Technology™

and PhasedPoint Source Technology™, combining these with new patented advances in transducer design and system

integration. The KF700 Series centers on a design approach that optimizes building arrays in the three dimensions of

physical space while also addressing the key acoustical issues that reside in the fourth dimension of time.

ii

Section 1 Read this first

The terms “Caution,” “Warning” and “Danger” are used throughout this manual to alert

the reader to important safety considerations. If you have any questions about any

aspects of these cautions, contact your local dealer, distributor or EAW.

CAUTION: describes an operating condition or user action that may expose the equipment

or user to potential damage or danger.

WARNING: describes an operating condition or user action that will cause damage to the

equipment or injure the user.

DANGER: describes an operating condition or user action that will immediately damage

the equipment or be extremely dangerous or possibly life-threatening to the user.

1.1 Safety Precautions

Rigging (flying) must be performed only by a professional rigger. See Section 1.3 for

information for professional riggers.

1.2 General Precautions

WARNING: Some aspects of rigging and other related fields for which EAW manufactures,

sells or distributes equipment are potentially hazardous. Any person using this equipment

is personally responsible for his own safety. EAW transactions are made with the assumption

that the purchaser is a qualified individual or will have only qualified individuals perform

work with the equipment. EAW will not be liable for any damages arising from the use of

equipment sold to purchaser.

1.3 Important Information about Rigging

Prior to suspending any EAW loudspeaker enclosures overhead, it is essential that the

user

be familiar with the load ratings, rigging techniques and special safety considera

tions

appropriate to suspending loudspeakers overhead. The user must determine the load

requirements, dynamic loading and any other contributing factors affecting the flown

loudspeakers. The user must determine the proper safety factor for specific applications

and the required load rating of the connection points. EAW strongly recommends that all

rigging be done in accordance with and in compliance with all federal, state and local

regulations, relative to properly securing suspended loads prior to usage. The user

assumes liability for proper design, installation and use of rigging systems.

EAW strongly recommends the following rigging system practices:

1.

Documentation: Thoroughly document the rigging design with detailed drawings

and parts lists.

2.

Analysis: Have a licensed structural engineer, registered architect or other qualified

professional review and approve the rigging design before its implementation.

3. Installation: Have a qualified professional rigger install and inspect the rigging

system.

iii

DANGER: Loudspeakers should be suspended overhead only by persons with a knowledge of the proper hardware and rigging techniques. When stacking or pole-mounting

loudspeakers, be sure they are stabilized and secured from falling over or being accidentally

pushed over. Failure to follow these precautions may result in damage to the equipment,

personal injury, or death.

EAW strongly recommends the following rigging system practices:

1. DOCUMENTATION:

Thoroughly document the rigging system design with

drawings and detailed parts lists.

2. PROFESSIONAL REVIEW:

Have a licensed structural engineer, registered

architect or other qualified professional review and officially approve the

rigging design before its implementation.

3. PROFESSIONAL INSTALLATION:

Have the rigging system installed and

inspected by a qualified professional rigger.

Section 2 Unpacking

2.1 Shipping Damage

You should have already visually inspected the outside of the shipping carton and noted

any damage on the shipping bill you signed. After unpacking, if you find concealed damage

to the loudspeaker, save the packing materials for the carrier’s inspection, notify the carrier

immediately and file a shipping damage claim.

Although EAW will help in any way possible,

it is always the responsibility of the receiving

party to file any shipping damage claim.

The carrier will help prepare and file this claim.

2.2 Returning Products to EAW

If this loudspeaker must be returned to EAW, contact EAW for a Return Authorization. Use

the original shipping carton and packing materials. If the shipping carton is damaged,

contact EAW for a new carton. EAW will not be responsible for damage caused by

inadequate packing.

iv

Section 3 Quick Start

NOTE: This section is intended only for qualified professional installers.

3.1 Important Safety and Rigging Information

CAUTION: Read all of Section 1, "Read This First", for important general, safety and

rigging precautions.

3.2 Audio Signal Connections

The audio signal connections are via Neutrik NL8 connectors or barrier strips. The two

NL8s are wired in parallel.

KF750F - 2 x NL8

LF1: pins 1 (+/-)

LF2: pins 2 (+/-)

MF: pins 3 (+/-)

HF: pins 4 (+/-)

KF750P and KF750P-WP - 2 x 4-terminal Barrier Strips

LF1: bottom strip terminals 1 (-) and 2 (+)

LF2: bottom strip terminals 3 (-) and 4 (+)

MF: top strip terminals 1 (-) and 2 (+)

HF: top strip terminals 3 (-) and 4 (+)

KF755F - 2 x NL8

Pins 1 (+/-) not used

LF: pins 2 (+/-)

MF: pins 3 (+/-)

HF: pins 4 (+/-)

KF755P and KF755P-WP - 1 x 2-terminal + 1 x 4-terminal Barrier Strips:

LF: bottom strip terminals 1 (-) and 2 (+)

MF: top strip terminals 1 (-) and 2 (+)

HF top strip terminals 3 (-) and 4 (+)

SB750 - 2 x NL8

Left driver*: pins 1 (+/1)

Right driver*: pins 2 (+/-)

Not used: pins 3 (+/-)

Not used: pins 4 (+/-)

*Note: Driver position is looking from front.

1

Section 4 Description

4.1 Overview

Professional loudspeaker systems are designed to optimize spectral, spatial, temporal and

usability performance attributes. Quite often optimization in one area compromises

performance in another. Thus, loudspeaker design is the art of balancing these goals while

minimizing compromise. In order to achieve these goals for the KF700 Series, key developments allowed for performance enhancement in each area without compromise in others.

4.1.1 SPECTRAL

The KF700 Series are true three-way designs. The goal was to develop

systems with greater

low frequency extension and greater overall mid frequency bandwidth. Traditionally these

goals required increased physical size. This was not an option. The

KF700 Series loudspeak-

ers were designed as uni-axial enclosures in which all the transducers

(woofer, mid-range,

and high frequency) share a common acoustic axis. This

permitted using larger horns for a

more consistent coverage pattern over a wider frequency

range and provided more available

enclosure volume for deeper bass response while

actually reducing physical size. A new,

patented mid frequency phase plug was also

developed that allows for improved upper

mid frequency response from a cone transducer

through a large format horn.

4.1.2 SPATIAL

The KF700 Series have 35° x 35° coverage patterns. This enhances building arrays and

increases overall system output capability. Conventional phase plugs create beam-width

narrowing in the upper portion of the mid-range. The patented KF700 Series mid

frequency phase plug provides upper mid-range extension without creating this narrowing.

The uni-axial approach minimizes the impact of “apparent apex error”. This occurs when

the separation between physically misaligned transducers changes as the listening point

changes. The KF750 horn designs draw heavily from the SimplePhase™ horns used in the

KF900 Series in order to achieve more seamless coverage between arrayed enclosures.

The low frequency section uses multiple woofers in a dipole configuration to reduce off

axis low frequency energy and thus increase directivity. Research showed that the directivity

of the low frequency section could be smoothly matched to that of the mid frequency section.

This is done by optimizing the ratio between the woofer spacing within the mid frequency

horn and the dimensions of the mid frequency horn mouth. This configuration with its

dimensional ratio is patented.

4.1.3 TEMPORAL

The temporal focus is once again on the mid-range section. A mid frequency cone transducer tends to provide better tonality and lower distortion than standard compression

drivers, but can smear events in the time domain. This was resolved through a redesign of

the mid-range transducer geometry. The multi-axis approach and its subsequent impact

on apparent apex error also serves to minimize temporal inconsistencies from transducer

to transducer within the enclosure.

4.1.4 USABILITY

Usability goals were satisfied by making the enclosures small. The uni-axial approach

met all the performance goals while allowing for a reduction in overall package size. For

the most consistent coverage pattern through the low to mid frequency crossover region,

the optimal spacing of woofers is smaller than the optimal height of the mid frequency

horn. This allows the woofers to reside within the mid frequency horn, once again

resulting in a small overall package size.

In order to provide simple rigging, the standard KF850 flytrack was chosen. The KF750

utilizes these tracks on the front and back of the enclosure, eliminating the need for putting

fingers between cabinets during array assembly or disassembly. Finally, some internal

parts have been molded of lightweight materials in order to meet the desired enclosure

weight of less than 200 pounds.

4.1.5 VA4DEFINED

The system overview illustrates that the KF700 Series development was driven by enhancing

the acoustical performance of the loudspeaker systems as it relates to its arrayability. Each

loudspeaker must therefore array effectively both horizontally and vertically. Consistent

controlled coverage patterns in three dimensions guarantees predictable array results

from venue to venue.

The development goals also dictated that the KF700 Series improve upon the time

domain behavior, particularly in the vocal region. The ability of a loudspeaker to main

tain

the temporal integrity of the original input signal is easily as important as the frequency

response in determining the quality of the sound reproduction. Therefore, if harmonics

lead or lag fundamentals in the reproduction, then the original signal, and perhaps even

the intent of the performer, will be distorted. The ability to maintain the input signal’s

temporal integrity while delivering smooth frequency response to a well-defined coverage

area is ultimately the goal of any loudspeaker.

Consistently achieving the desired coverage from a loudspeaker array for a given venue

is governed by performance in the three dimensions of space. Maintaining temporal

coherence is governed by the fourth dimension of time. Meeting all of these criteria truly

addresses system performance in four dimensions. This four-dimensional design

approach is VA

4

technology.

4.1.6

WEATHER-PROTECTED (WP MODELS)

The KF700P-WP and SB750P-WP models are weather-protected for permanent

install

ations. The exterior of the enclosure is laminated with a water-resistant fiberglass

coating. A 2-layer grille is used to prevent water from entering the front of the enclosure.

The outside layer is powder-coated perforated steel for physical protection. The rear layer

is a 1/8 inch thick foam to break up driven water droplets. Behind the grille assembly, a

layer of 100 x 100 wires per inch stainless steel mesh is affixed to the enclosure to prevent

any water spray from entering the front of the enclosure. The input panel and back

doghouse are weather-sealed with rubber strips to prevent water intrusion.

Section 5 Operation

5.1 KF700 Series Products

5.1.1 KF700 MODELS

Model Name Description Primary Application

KF750F Three-way Concert touring

KF750P Three-way Permanent installation

KF750P-WP Three-way Outdoor installation

KF755F Three-way Concert touring downfill

KF755P Three-way Permanent installation downfill

KF755P-WP Three-way Outdoor installation downfill

SB750F Dual 18-in. Concert touring subwoofer

5.1.2 KF700 SERIES PRODUCT WEIGHTS

System Net (lb / kg) Shipping (lb / kg)

KF750F 198 / 90.0 230 / 104.6

KF750P 187 / 85.0 201 / 91.4

KF750P-WP 205 / 93.2 221 / 100.5

KF755F 198 / 90.0 232 / 105.5

KF755P 180 / 81.8 203 / 92.3

KF755P-WP 205 / 93.2 223 / 101.4

SB750F 193 / 87.7 202 / 91.8

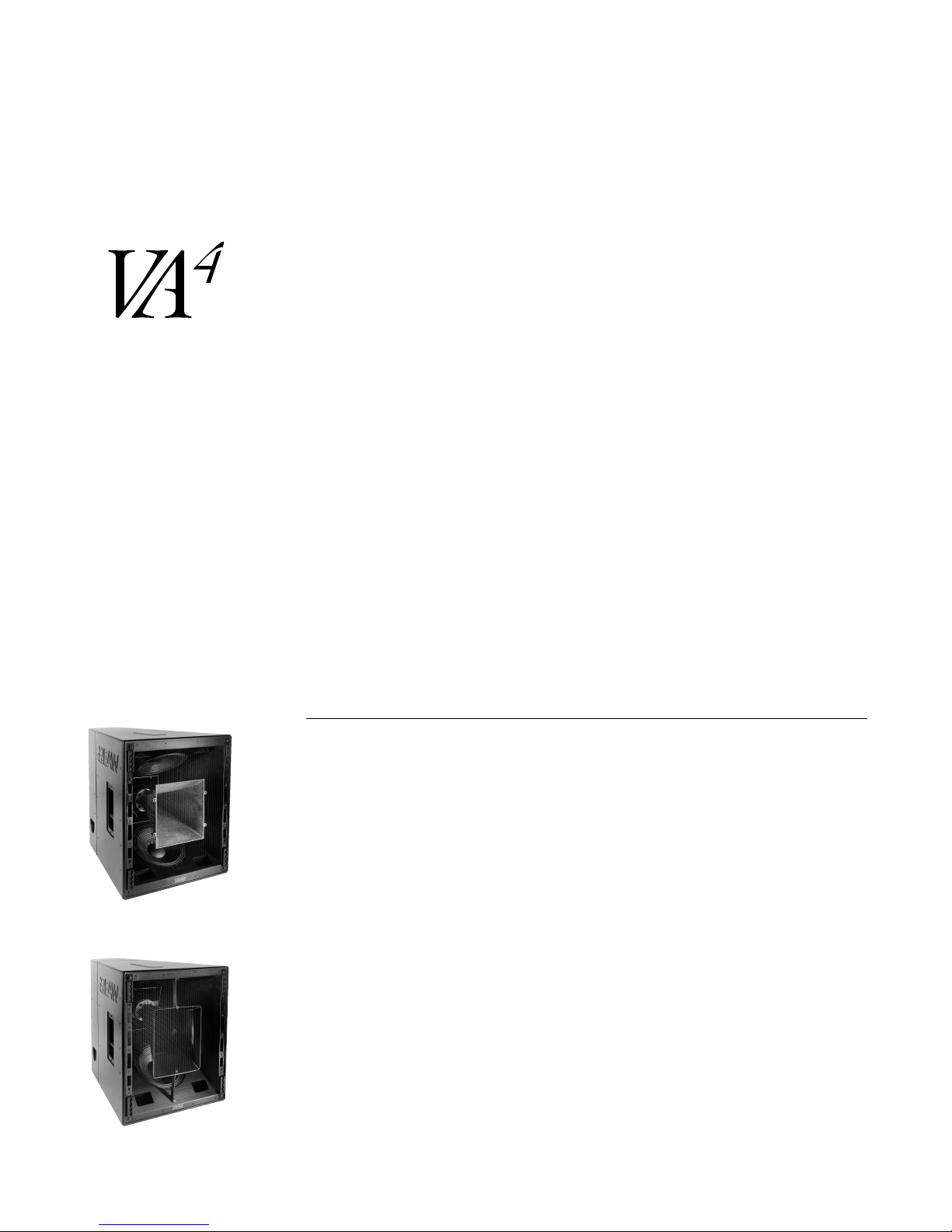

KF750

KF755

2

3

5.1.3

EQUIPMENT SUPPLIED

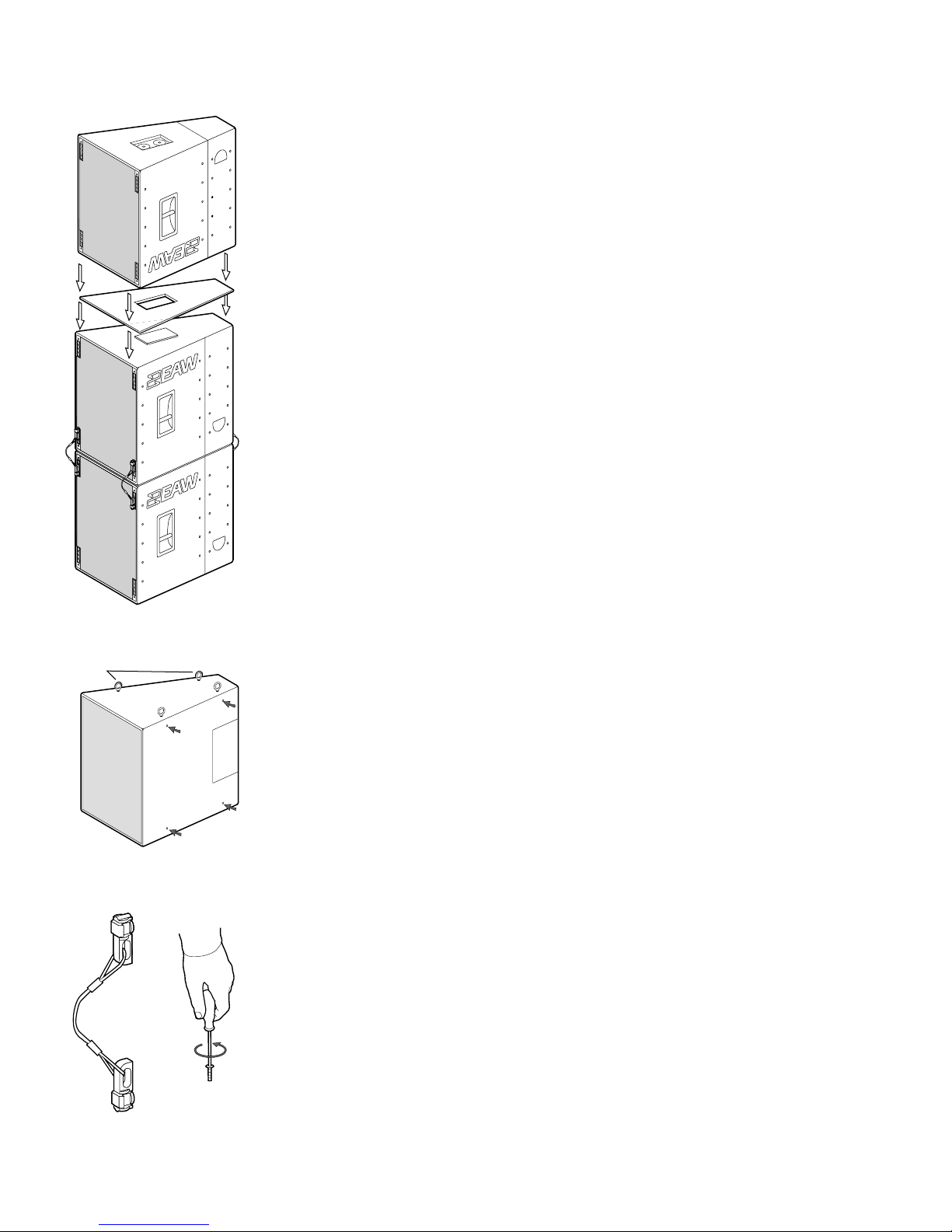

Each model is shipped individually boxed, two of which fit on one shipping pallet.

Concert touring versions include four cable links, which comprise two fly clips and a

load-rated cable whose length is optimized for creating flown arrays.

5.1.4

ARRAYS

Flying one row of downfill is recommended when more than one row of KF750 loudspeakers is flown. At least one SB750F subwoofer is recommended for every two KF750s

or KF755s.

For more information on building arrays, please refer to the KF700 Touring Usage Guide

available at ftp://ftp.eaw.com/ProductGuides/KF700TouringUsageGuide.pdf. Most of

the basic array building concepts described in the Touring Usage Guide apply equally to

permanent installations.

5.2 Input ConnectIons

KF750F - 2 x NL8

LF1: pins 1 (+/-)

LF2: pins 2 (+/-)

MF: pins 3 (+/-)

HF: pins 4 (+/-)

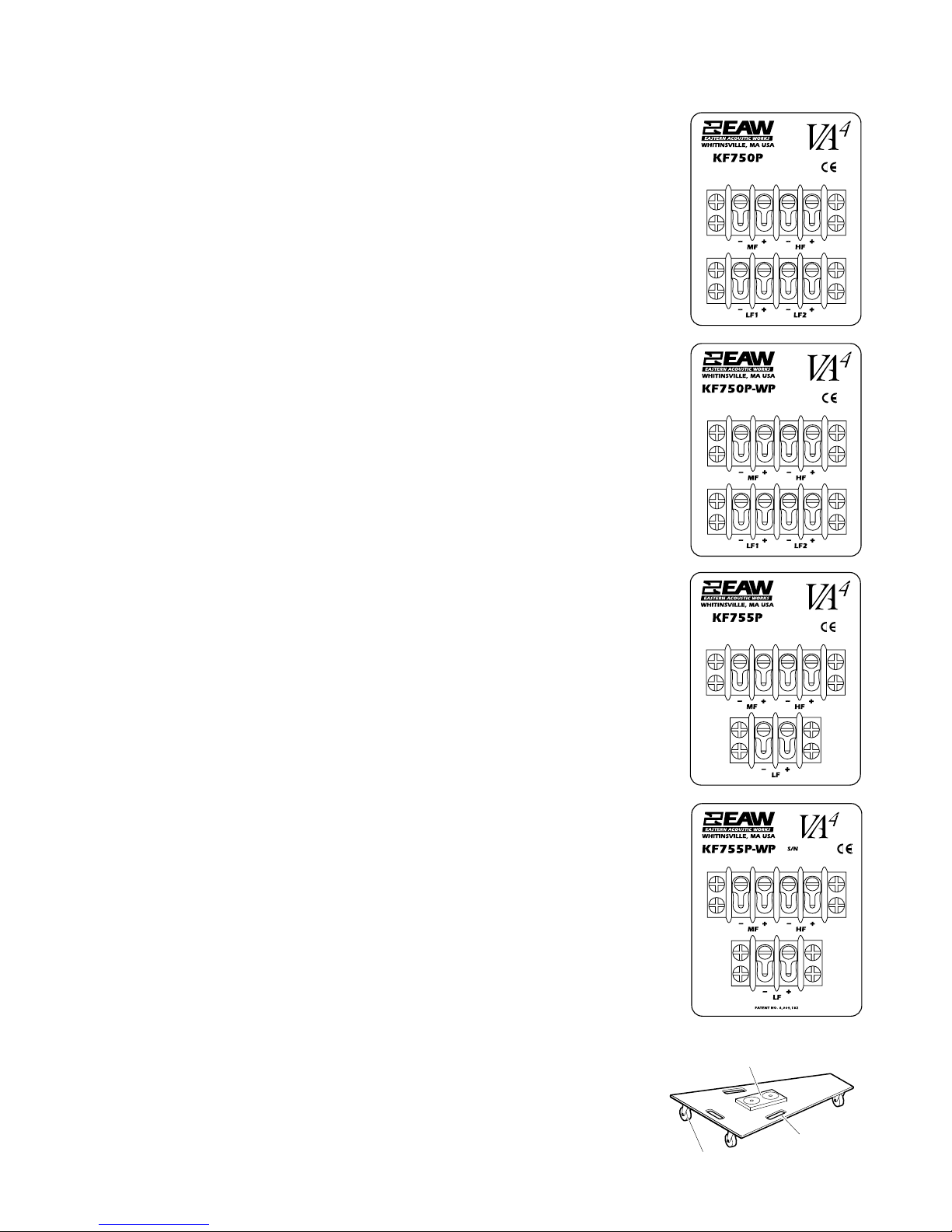

KF750P and KF750P-WP - 2 x 4-terminal Barrier Strips

LF1: bottom strip terminals 1 (-) and 2 (+)

LF2: bottom strip terminals 3 (-) and 4 (+)

MF: top strip terminals 1 (-) and 2 (+)

HF: top strip terminals 3 (-) and 4 (+)

KF755F - 2 x NL8

Pins 1 (+/-) not used

LF: pins 2 (+/-)

MF: pins 3 (+/-)

HF: pins 4 (+/-)

KF755P and KF755P-WP - 1 x 2-terminal + 1 x 4-terminal Barrier Strips:

LF: bottom strip terminals 1 (-) and 2 (+)

MF: top strip terminals 1 (-) and 2 (+)

HF top strip terminals 3 (-) and 4 (+)

SB750 - 2 x NL8

Left driver*: pins 1 (+/1)

Right driver*: pins 2 (+/-)

Not used: pins 3 (+/-)

Not used: pins 4 (+/-)

*Note: Driver position is looking from front.

Note: All models can be special ordered with AP or EP 4, 6 and 8-conductor connectors.

5.3 Mechanical Characteristics and Accessories

5.3.1 CASTER PALL E T S

The KF700 Series includes an optional rugged caster pallet (EAW P/N 255049) designed

for years of reliable service in concert touring applications. Caster pallets can be

ordered separately in quantities suitable to particular truck packing strategies.

CENTRAL RAISED PLATFORM WITH TWO MAGNETS

THREE HANDLES

FOUR WHEEL CASTERS

4

KF700 Series caster pallets are constructed of 15 mm Baltic birch plywood with four

mounted wheel-casters. The caster pallet shares a common footprint with KF700F

enclosures. The pallet incorporates a central raised platform that keys into a recess on the

bottom of any enclosure. Magnets on the platform register to steel plates in the recess,

attaching the pallet to the enclosure. The caster pallet has three handles for easy transport

when not connected to a KF700 Series enclosure.

5.3.2 GROUND STACKING

All KF700(F) Series enclosures are equipped with a UHMW (Ultra High Molecular

Weight) plastic stacking pad that keys into the recess in the bottom of another enclosure

when stacked. This pad provides for a more secure stack. EAW recommends that fly hardware be used to provide additional stability. A crossed configuration of the cable links

allows for minimal slack, improving safety and stability. Stacked clusters should

also be strapped together to provide even greater stability.

In many venues, most notably theaters that do not permit flown arrays, inverted KF755s

will be used to provide upfill when stacked. This scenario forces enclosures to touch topto-top and, therefore, pad-to-pad. In order to prevent slippage and provide a more secure

stack, EAW has created a stacking plate (EAW P/N 980031)constructed of painted birch

plywood. The stacking

plate shares the KF700 Series footprint and provides a central

cutout that locks into pads on both adjoining enclosures.

5.3.3 SUSPENSION HARDWARE

WARNING: See Section 1.3 for information regarding rigging and suspending KF700

Series loudspeakers.

KF700(P and P-WP) Series installation versions utilize internal steel angles to provide a

total of sixteen (16) 3/8”-16 threaded mounting points (four each on the top, bottom

and sides). The enclosures ship with undercut 3/8-16 hardware that sits flush with the

enclosure walls. Replacement of factory-installed hardware with Grade 8 forged shoulder

eyebolts provides appropriate suspension points on an enclosure. The eyebolt manufacturer should be consulted for eyebolt working load limit specifications.

CAUTION: All four points on any given side should be utilized when hanging an

enclosure. Failure to use all four points can result in damage to the equipment, personal

injury, or death.

KF700(F) Series touring versions are equipped with two-position industry standard flytracks located in the front and rear corners. The aircraft grade aluminum track is attached

to the Baltic birch enclosure via internal angled steel that runs the full height of the enclosure. This construction is such that the enclosure bears no weight when flown. Each

KF700(F) Series touring version loudspeaker is shipped with four cable links described

above. These can be used for attaching the enclosures to fly bars as well as for attaching

vertically adjacent enclosures to each other. Enclosures should be connected using all

four available points (two front and two back) as depicted in the illustration.

Available fly bar manufacturer information can be obtained by contacting EAW.

FOUR EYE BOLTS INSTALLED INTO

TOP THREADED HANG POINTS

ARROWS INDICATE

SIDE HANG POINTS

FLY

CLIP/CABLE

INTERCONNECT

ASSEMBLIES

3/8-16 HARDWARE

WITH A 7/32 ALLEN WRENCH

REMOVING

THE

UNDERCUT

Loading...

Loading...