Page 1

SPECIFICATIONS KF750F

DESCRIPTION

PERFORMANCE

One Main Street, Whitinsville, MA 01588 508 234 6158 Toll Free 800 992 5013 FAX 508 234 8251 info@eaw.com www.eaw.com

EAW products are continually improved. All specifications are therefore subject to change without notice. KF750F/2 pp October 2001 Printed in USA

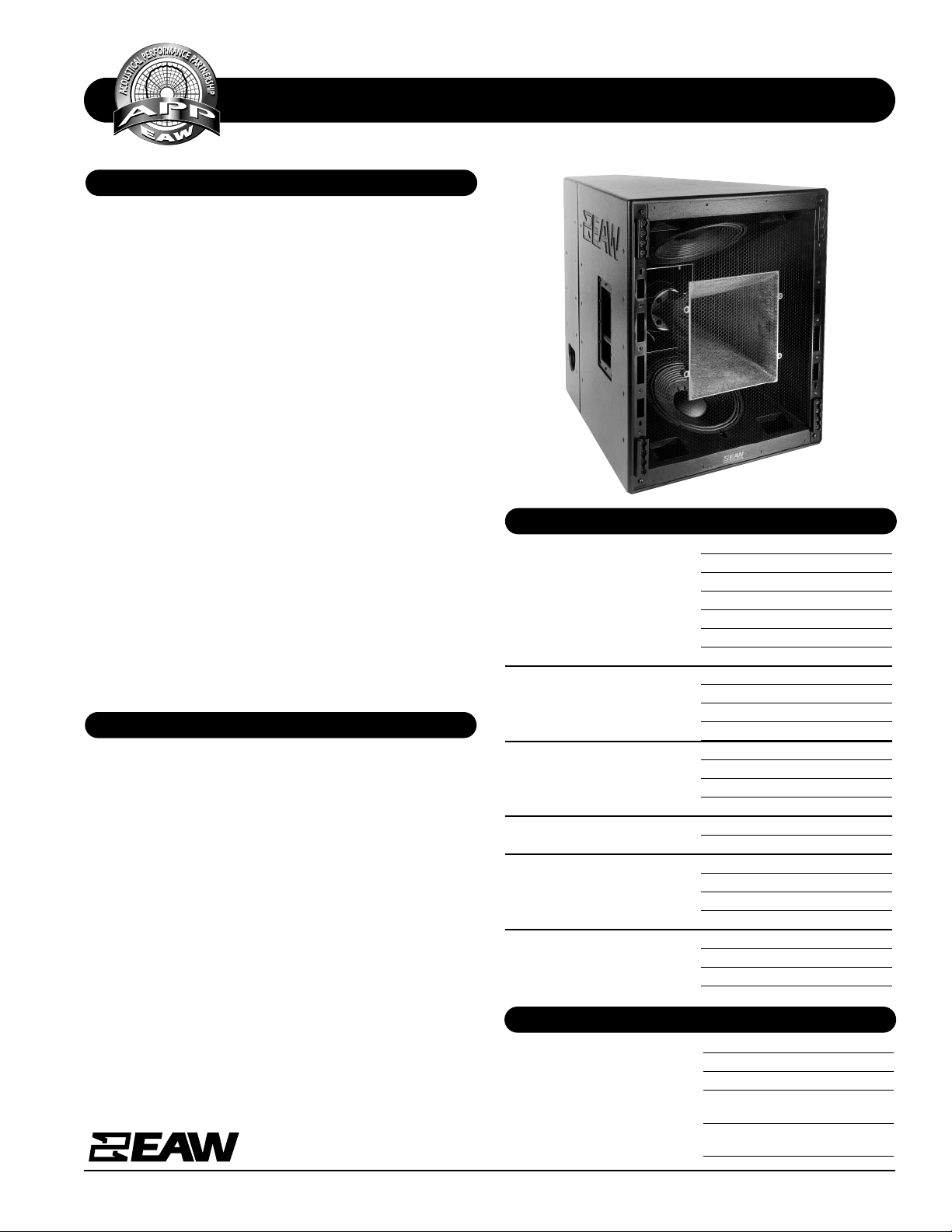

The KF750F 3-way tri-amplified full range system contains

many new EAW technologies that make it a powerful concert

touring sound reinforcement tool. Its Acoustic Singularity™

design aligns the three subsystems along a single axis so the

KF750 acts as a true point source, greatly reducing temporal

smearing of tr ansi en t even ts an d improvin g over all clarity an d

impact.

Since the large mid frequency horn contains both the high

and low frequency subsystems, the overall package is just

31-in high. Still, the KF750F provides consistent wideband

pattern control in both the vertical and horizontal planes.

The LF subsystem includes two vented 12-in woofers mounted in the MF horn’s upper and lower walls. This spaced configuration extends vertical directivity well into the LF passband to minimize midbass build up below the array.

The large MF horn loads a specially designed 10-in midrange

cone whose geometry exactly matches the rear of its phase

plug assembly. By developing the driver and phase plug as a

single unit, pathlength discontinuities within the MF passband have been eliminated without compromising the directional qualities of the source.

The 2-in exit/4-in voice coil HF compression driver is mounted on a 35° x 35° constant directivity horn mounted coaxially within the MF horn flare.

The KF750F’s 15°-per-side trapezoidal enclosure features

eight 4-position flytracks (four each front and rear) that

accept industry-standard flyclips.

The KF750F is designed to create arrays with optimized coverage in both the h orizontal an d vertical plan es to cover audience areas ranging from 200 to 80,000 people.

At just 31-in tall and 190 lb. per module, KF750F arrays are

smaller, lighter, more efficient and, therefore, more powerful

than those built with other systems. These smaller, lighter

arrays are easier to fly, require less truck space and permit

more open sight lines to cover any given venue.

The KF750F works with a companion downfill module, the

KF755F, to provide full range nearfield coverage below the

array. The KF750F’s smooth power response produces remarkably even SPL levels throughout the coverage area, allowing

it to be used for nearfield coverage when necessary.

Applications include:

Concert Tours Performing Arts Centers

Houses of Worship Theaters

APPLICATION

Frequency Response (Hz)

±3 db 48 Hz to 18 kHz

-10 dB 30 Hz

Axial Sensitivity (dB SPL, 1 Watt @ 1m)

LF 103

MF 109

HF 116

Impedance (Ohms)

LF 2x 8

MF 8

HF 8

Power Handling, (Watts Continuous)

LF 2x 600

MF 400

HF 200

Recommended High-Pass Frequency

24 dB/Octave 35 Hz

Calculated Maximum Output (dB SPL @ 1m)

LF Peak/Long Term 139/133

MF Peak/Long Term 141/135

HF Peak/Long Term 145/139

Nominal Coverage Angles, -6 dB points (degrees)

Horizontal 35

Vertical 35

PHYSICAL

Configuration 3-way, full range

Powering Tri-amplified

LF Subsystem 2x 12-in cones, vented

MF Subsystem 10-in cone, Radial Phase Plug™

horn-loaded

HF Subsystem 2-in exit/4-in voice coil

compression driver on CD horn

Page 2

SPECIFICATIONS KF750F

DIMENSIONAL DRAWING

A & E SPECIFICATIONS

One Main Street, Whitinsville, MA 01588 508 234 6158 Toll Free 800 992 5013 FAX 508 234 8251 info@eaw.com www.eaw.com

EAW products are continually improved. All specifications are therefore subject to change without notice. KF750F/2 pp October 2001 Printed in USA

Cabinet Type (shape) Trapezoidal

Enclosure Materials Baltic birch plywood

Finish Black polyurethane

Connectors 2x Neutrik NL8 Speakon

Suspension Hardware 8x 4-position flytrack

(4 each front and rear)

Grille Powder coated perforated steel,

foam backed

Dimensions inches millimeters

Height 31.0 787

Width (Front) 27.0 686

Width (Rear) 8.8 233

Depth 34.0 864

Trapezoid Angle 15 degrees per side

Weights pounds kilograms

Net Weight 190 86.5

Shipping Weight 200 91.0

Companion Systems

Sub Bass SB750F/SB1000e/KF940

Full Range Downfill KF755F

Accessories KF700 Series caster pallet

The three-way full ran ge loudspeaker system shall incorpor ate

2x 12-in LF transducers, a 10-in MF cone transducer and a 2in exit/4-in voice coil compression driver HF transducer.

The LF drivers shall be mounted in a vented enclosure tuned

for optimum low frequency response and separated vertically.

The MF driver shall be mounted on a large-format horn and

shall be coupled to a phase plug whose geometry exactly

matches that of the driver. The HF driver shall be loaded on a

constant directivity horn with a nominal coverage pattern of

35° (h) x 35° (v).

System frequency response shall vary no more than ±3 dB

from 48 Hz to 18 kHz measured on axis. The loudspeaker’s

subsystems (LF/MF/HF) shall produce a Sound Pressure Level

(SPL) of 103/109/116 dB SPL on axis at 1 meter with a power

input of 1 Watt, an d shall be capable of pr odu cing a peak output of 139/141/145 dB SPL on axis at 1 meter. The subsystems (LF/MF/HF) shall handle 2x 600/400/200 Watts of

amplifier power (continuous) and shall have nominal impedances of 2x 8/8/8 Ohms.

The loudspeaker enclosure shall be trapezoidal in shape. It

shall be constructed of multi-ply void-free cross-grain-laminated Baltic birch plywood and shall employ extensive internal bracing. It shall be finished in black catalyzed

polyurethane. Input connectors shall be a 2x Neutrik NL8

Speakon. A total of eight 4-position flytracks (4 each front

and rear) shall be provi d ed. The front of the loudspeaker shall

be covered with a powdercoated perforated steel grille.

The three-way full ran ge loudspeaker system shall be the EAW

model KF750F.

CABINET TO BE SYMMETRICAL ABOUT CENTERLINE DESIGNATIONS.

INDICATES CENTER OF BALANCE.

INDICATES FLY TRACK MOUNTING POINTS.

FRONT

DIMENSIONS APPLY

TO TOP AND BOTTOM

4X 18.88

8X 4.12

27.00

.38

C

L

GRILL PARTIALLY SHOWN

31.38

TOP/BOTTOM

(8.78)

4.00

4.44

15.25

22.90

9.25

9.81

STACK PAD

L

C

34.00

(8X.25)

30°

34.50

(8X 1.37)

7.75

27.80

4.50

3.00

7.28

6.44

10.87

SIDES

BACK

C

INPUT

6.63

3.63

L

15.50

4.00

510741 (1)

4/15/99

Manufacturing tolerances are +/- 0.13 and +/- 1°

PHYSICAL continued

Loading...

Loading...