Page 1

A

C

O

U

S

T

I

C

A

L

P

E

R

F

O

R

M

A

N

C

E

P

A

R

T

N

E

R

S

H

I

P

TECHNICAL SPECIFICATIONS KF400a

DESCRIPTION

The KF400a Powered Virtual Array™ Loudspeaker System

optimizes performance and reliability for a wide range of

portable and permanently-installed sound reinforcement

applications. The internal Close Coupled Power Module

provides ample distortion-free amplification as well as

sophisticated, tran sparent driver/amplifier pr otection circuitry

and signal processing.

EAW’s VA™ loudspeaker system design philosophy sets the

world standard for arrayabilty and performance by applying

advanced horn-loading con cepts to the three-way loudspeaker

configuration. Th e cone-loaded mid range h orn’s flare follows

a complex mathem atical fun cti on (n ot str ai ght lin es) allowing for smooth expansion of the wavefront. The newly

designed phase plug – the first example of EAW’s next

generation of phase plug designs – ensures coherent summation of th e wavefron t in the h orn throat, enhan cin g both

the smooth sound character and arrayability of the system.

CLOSE COUPLED POWER

™

The Close Coupled Power concept integrates amplification

with the loudspeaker system to maximize performance,

reliability and efficiency. Precisely matching the amplifier

design to the specific system’s driver/horn/enclosure

characteristics provides a substantial amount of headroom

without compromising r eliability . State-of-the-art protecti on

systems - actuated by real-time current and voltage

monitors – apply complex compressor/limiters and soft

clipping circuitry for virtu ally transparen t protection o f both

the amplifier and the drivers, even when driven to the

highest output levels. M odular input design allows f or future

system upgrades.

Authorized service professionals can access many elements

of the Close Coupled Power Module simply by removing the

back panel. When necessary the CCPM can be removed as a

self-contained unit.

APPLICATIONS

The KF400a provides the greatest user-benefit to sound

reinforcement applications utilizing the distributed loudspeaker system approach. Distributed amplifier/processor

racks and their associ ated logistical/compatibility pr oblems

are eliminated from the design. Determine the appropriate

loudspeaker system placemen t to meet your application’s SPL

and coverage r equir ements, d eliver audio and A C feeds , and

enjoy the results. The loop-through audio chain allows for

the immediate creation of arrays from a single audio feed.

The KF400a features a six year warranty on loudspeaker

enclosure and compon ents , four years on active electr oni cs.

Applications include:

Corporate Events Convention Centers

Ballroom Events Band PA

Small Worship Spaces Live Music Club

DESCRIPTIVE DATA

Configuration 3-way, Full Range

Powering Internal/Biamplified (passive LF/

MF crossover)

LF Subsystem 1x 15-in, Vented

MF Subsystem 1x 8-in Cone, Horn-Loaded

HF Subsystem 1x 1.4-in exit/75mm voice coil

Compression Driver on Constant

Directivity Horn

Coverage Angles 65° (h) x 45° (v)

Cabinet Type (shape) Trapezoidal

Enclosure Materials Baltic Birch Plywood

Finish Black Polyurethane

Connectors 1x Neutrik PowerCon (AC mains);

XLR female (audio input); XLR male

(audio output) Pin 2 Hot

Suspension Hardware (5) 3-Position Flytracks with

Integral 3/8"-16 Threaded

Mounting/Suspension Points

(2 top and 3 bottom)

Grill Vinyl Coated Perforated Steel

Options Flyclip w/Ring (179001)

Flyclip w/Hook (179002)

Dimensions inches millimeters

Height 36.50 927

Width (Front) 19.75 502

Width (Rear) 12.79 325

Depth 19.75 502

Trapezoid Angle 10° per side

Weights pounds kilograms

Net Weight 160 72.7

Shipping Weight 168 76.4

EASTERN ACOUSTIC WORKS

Acoustic Performance Partnership Eastern Acoustic Works KF400a

One Main Street, Whitinsville MA, 0158 8 USA • Phone 508/234-6158 • Toll Free 800/992-5013 • Fax 508/234-8251 • Web http://www.eaw.com • email info@eaw.com

One Main Street, Whitinsville, MA 01588 • (508) 234 - 6158 • FAX (508) 234 - 8251 • Email info@eaw.com • Web http://www.eaw.com

EAW products are continually improved. All specifications are therefore subject to change without notice. • PUB# KF400a-888045 (A)/4 pp/1/29/99 • Printed In USA

Page 2

A

C

O

U

S

T

I

C

A

L

P

E

R

F

O

R

M

A

N

C

E

P

A

R

T

N

E

R

S

H

I

P

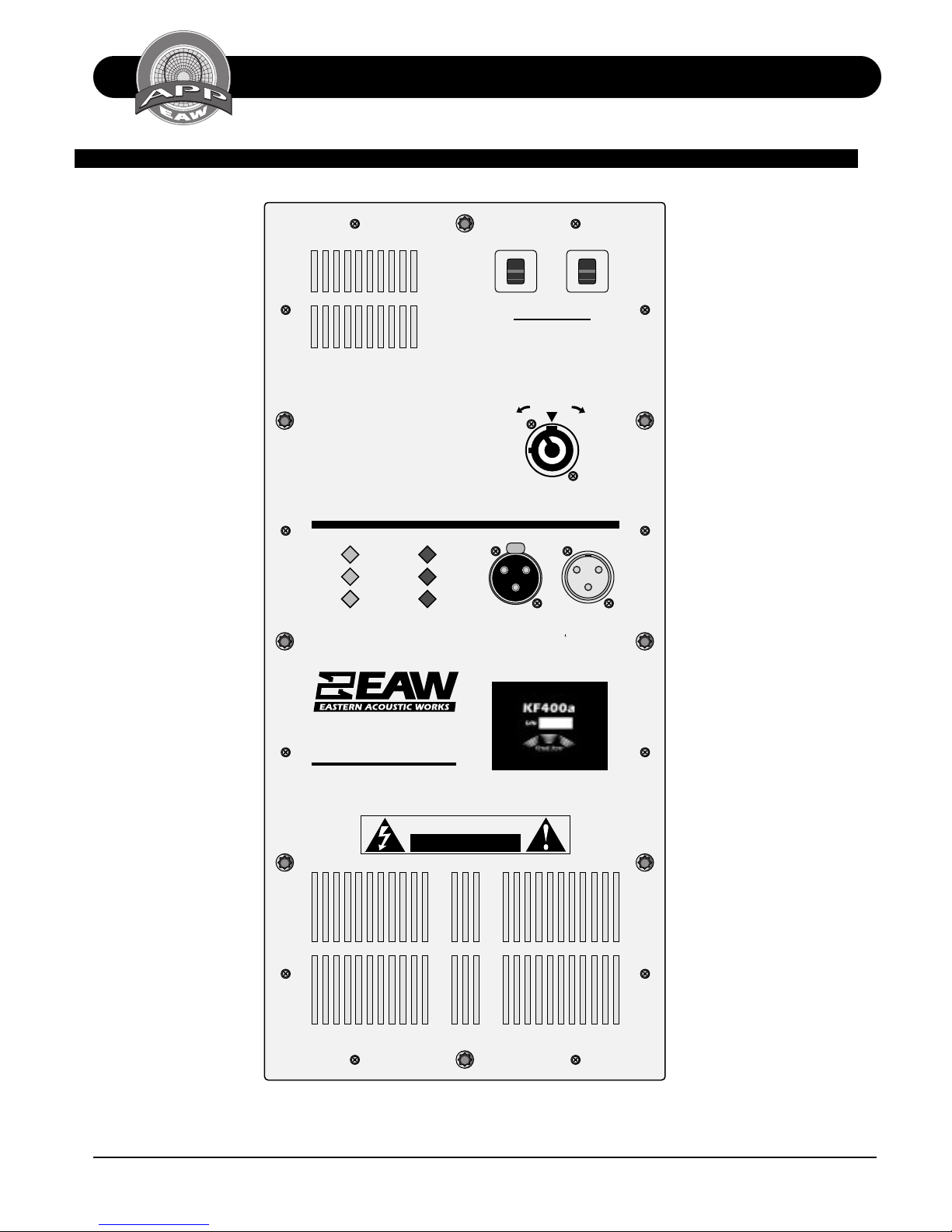

CLOSE COUPLED POWER™ MODULE

TECHNICAL SPECIFICATIONS KF400a

Fault LED

Indicates that protection

circuitry has shut down the

unit to avoid damage to

drivers or electronic d evices.

Power ON LED

Indicates that the unit is

powered and ready for

operation.

HF/LF Output Current LEDs

Indicates output curren t f or

both the high and low

amplifier channels.

HF/LF Limit LEDs

Indicates that protection

circuitry is actively limiting

output to protect the

drivers or electronic

components.

CIRCUIT BREAKERS

7

I

A

M

P

S

O

MAINS SUPPLY

Operating voltage range:

WARNINGS:

TO REDUCE THE RISK OF FIRE OR ELECTRIC

SHOCK DO NOT EXPOSE THIS EQUIPMENT

TO RAIN OR MOISTURE.

THIS SURFACE MAY BECOME HOT WHILE

THE UNIT IS OPERATING. ALLOW AT LEAST 6

INCHES CLEARANCE FROM THIS SURFACE

AND ADEQUATE VENTILATION TO ENSURE

RELIABLE OPERATION.

CAUTION: TO PREVENT ELECTRIC SHOCK

DO NOT REMOVE COVERS. NO USER

SERVICEABLE PARTS INSIDE. RREFER TO

QUALIFIED SERVICE PERSONNEL.

DISCONNECT AC POWER BEFORE

ATTEMPTING SERVICE OR CONFIGURATION.

Power ON

HF Output Current

LF Output Current

Fault

HF Limit

LF Limit

Turn on 85VAC, turn off 260VAC

UNLOCK LOCK

AC INLET

PUSH

CLOSE COUPLED

POWER MODULE

Whitinsville, MA U.S.A.

PUSH

TO

RESET

95-250VAC

50-60Hz

8A RMS

16A Peak

PIN 2=POS (+),

PIN 3=NEG (-)

PIN 1=GND ( )

Circuit Breakers

7

I

A

M

P

S

O

The AC Circuit Breakers

protect the unit from power

line faults and electronics

failure.

AC Input

Neutrik PowerCon lockin g AC

connector provid es AC power

connection. Auto-sensing

power input operates from

95-125 VAC and 190-250

VAC.

Audio Signal Input

A balanced, 3-pin, female

XLR connector is provid ed for

LOOPINPUT

the audio signal input

connection.

Audio Signal Loop Output

A balanced, 3-pin, male XLR

connector provides a

hardwired loop out of the

input signal.

Rear Exhaust Grills

The fan exhaust grills ar e the

main exits for air dr awn into

the unit for cooling. Avoid

blocking air flow.

Acoustic Performance Partnership Eastern Acoustic Works KF400a

One Main Street, Whitinsville MA, 0158 8 USA • Phone 508/234-6158 • Toll Free 800/992-5013 • Fax 508/234-8251 • Web http://www.eaw.com • email info@eaw.com

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

MADE IN USA

Page 3

A

C

O

U

S

T

I

C

A

L

P

E

R

F

O

R

M

A

N

C

E

P

A

R

T

N

E

R

S

H

I

P

DIMENSIONAL DRAWING

V

i

INDICATES MOUNTING POINT, 1/4-20 THREADED HOLE.

KF400a

PARTIALY SHOWN GRILL

19.75

19.00

36.50

INDICATES CENTER OF BALANCE.

ALL DIMENSIONS ARE IN INCHES UNLESS OTHERWISE NOTED

1.97

32.56

2X HANDLES

10.99

TECHNICAL SPECIFICATIONS KF400a

9.77

8.75

LID

19.51

16.12

9.50

.89

C

L

7.88

7.74

510614

exp 2/2/99 dpm

FRONT

9.93

15.44

BOTTOM ONLY

SIDES

20°

12.51

C

L

7.74

12.79

TOP/BOTTOM

CCPM™ INPUT SECTION BLOCK DIAGRAM

XLR / Input PCB

RFI Attenuation /

Transient Protection

XLR-M

Signal

3

2

1

Input

XLR-M

Signal

3

2

1

Loop

Power On Fault

HF Output HF Limit

LF Output LF Limit

4th Order

High-Pass Filter

Analog Control Module

4th Order

Low-Pass Filter

High CMRR

Input Receiver

Voltage

Controlled

HF Parametric

Amplifer

HF Control Voltage

ACM PCB

Voltage

Controlled

LF Parametric

Amplifer

Low Control Voltage

+

Filter #1

Filter #1

HF Parametric

Filter #1

High Gain Set

LF Parametric

Filter #2

Low Gain Set

Low Mute

Alignment

High Mute

6.44

4.12

4.68

6.12

HF Driver

(delay)

∆t

LF Parametric

Filter #3

∑

Low Gain

Control

INPUT

BACK

A

19.75

A

CASTER PALLET MOUNT,

BOTTOM ONLY

2nd Order

Low Pass Filter

∑

High SOA

Control

Compress

HighClamp

Compress

LF Parametric

Filter #4

Low Sliding

Filter Control

CV

Low SOA

Compress

Low ClampCompress

High Gain

7.50

High SIG

High Driver

Multiplexer

+

LF Sliding

High -Pass Filter

Low Driver

Multiplexer

+

-

High O/P V

High O/P I

High SOA

High CLAMP CV

High SIG

Low S

Low O/P V

Low O/P I

Low SOA

Low CLAMP C

Low SIG

Acoustic Performance Partnership Eastern Acoustic Works KF400a

One Main Street, Whitinsville MA, 0158 8 USA • Phone 508/234-6158 • Toll Free 800/992-5013 • Fax 508/234-8251 • Web http://www.eaw.com • email info@eaw.com

Page 4

A

C

O

U

S

T

I

C

A

L

P

E

R

F

O

R

M

A

N

C

E

P

A

R

T

N

E

R

S

H

I

P

TECHNICAL SPECIFICATIONS KF400a

NOMINAL DATA

DIMENSIONAL DRAWINGS

Frequency Response (1 Watt @ 1m)

±3 dB 62Hz to 20kHz

-10 dB 45 Hz

Calculated Maximum Output (dB SPL @ 1m)

Full Range Peak 126.0

Full Range Long Term 122.0

Nominal Coverage Angle/-6 dB points (degrees)

Horizontal 65

Vertical 45

Close Coupled Power™ Module

Topology Class H, linear power supply,

vertical N-channel MOSFET output

devices

AC mains voltage Auto-sensing, 95 – 250 VAC, 47/66

Hz

AC power

requirement (max) 1800 W peak, 950 W continuous

AC wiring Ground, plus two hot lines or hot

plus neutral

Input Sensitivity 0.775 V

Input Impedance (Ohms) 600

Protection Short Circuit, Latch-up, device Safe

Operating Area, overtemperature,

Soft Clip, soft turn-on, turn-off,

fault mute, driver thermal

protection, driver excursion

limiting. The KF400a must be

disconnected from the AC mains in

order for the Fault trip to reset.

CMRR 90 dB (typical)

LED Indicators Power On, LF Current, HF Current,

LF Limit, HF Limit, Fault

Maximum Ambient

Temperature For

Full Output 50° C

Altitude 6500 ft

Humidity 10% to 95%, non-condensing

SERVICE ITEMS

LF: Complete Cone Driver

EAW Part No. 804083

MF: Complete Cone Driver

EAW Part No. 804086

HF: Complete Compression Driver/Tweeter

EAW Part No. 803040

HF: Diaphragm Assembly

EAW Part No. 804023

Close Coupled Power™ Module: Complete Assembly

EAW Part No. 230002

ARCHITECTURAL SPECIFICATIONS

The self-powered, biamplified 3-way full range loudspeaker

systems shall incorporate a 15-in LF transducer, an 8-in MF

cone and a 1.4-in exit/75mm voi ce coil HF compression driver .

The LF driver shall be mounted in a vented enclosure tuned

for optimum low frequency response. The MF driver shall be

loaded into a midrange horn constructed of 3mm birch

plywood backed with high density polyurethane foam that

shall incorporate a conical/hexagonal displacement/phase

plug. The HF driver shall be loaded on a con stant dir ectivity

horn with a nominal coverage pattern of 65° (h) x 45° (v).

An internal passive filter network shall provide fourth order

acoustical crossover and system equalization between the

LF and MF subsystems.

System frequency response shall vary no more than ±3 dB

from 62 Hz to 20 kHz measured on axis . The system shall be

capable of produ cing a peak output o f 126.0 dB SPL on axis

at 1 meter.

The internal active si gnal processing shall provide complex,

asymmetrical LF/MF to HF crossover. The internal amplification module shall provide class H amplifier topology, linear

power supply and vertical N-channel M OSFET output devi ces

each of which is load-matched to the subsystem it powers.

Amplifier power shall provid e substantial head room such that

transien t peaks are reprod uced with the appropri ate dynamic

range.

Driver/amplifier protection systems shall be actuated by

sensors continu ously monitorin g Voltage and current in real

time. Driver/amplifi er protection systems shall grad ually apply

compressor/limiter-based soft clipping cir cuitry to minimize

changes to the output soun d characteristics when engaged.

The amplifier module shall be designed so that most

components shall be accessed by removing the rear panel.

The input circuitry shall be of a m odular design to allow for

future upgrades. The entire amplifier module shall be easily

removable as a discreet unit.

The loudspeaker enclosure shall be trapezoidal in shape. It

shall be constructed of 15mm thi ckness void-free cr oss-grainlaminated Baltic birch plywood and shall employ extensive

internal bracing. It shall be finished in black polyurethane.

The AC power input connector shall be Neutrik PowerCon.

Auto-sensing power input shall oper ate from 95-125 V AC and

190-250 VAC. The audio input connector shall be a female

XLR (pin 2 hot) chassis-mount conn ector. A complementary

male XLR chassis-mount connector (pin 2 hot) shall be

provided for audio output (loop through). Five (5)

3-position flytracks (2 top and 3 bottom) shall be installed

in the enclosure. The front of the loudspeaker shall be

covered with a powder-coated perforated steel grill.

The self-powered, biamplified 3-way full range loudspeaker

shall be the EAW model KF400a.

Acoustic Performance Partnership Eastern Acoustic Works KF400a

One Main Street, Whitinsville MA, 0158 8 USA • Phone 508/234-6158 • Toll Free 800/992-5013 • Fax 508/234-8251 • Web http://www.eaw.com • email info@eaw.com

Loading...

Loading...