Eaton MTVXKDA20225WRU Instruction Booklet

O & M Manual for 30-1000 Amperes

Manual Transfer Switch

Instruction Booklet

Description Page

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Receiving, Handling, and Storage . . . . . . . . . . . . . . . . . 5

Equipment Description. . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation and Wiring . . . . . . . . . . . . . . . . . . . . . . . . 10

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Testing and Problem Solving . . . . . . . . . . . . . . . . . . . . 18

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

IB140058EN For more information visit: www.eaton.com

Instructional Booklet

Page 2 Effective: March 2016

O&M Manual for 30-1000 Amperes

Manual Transfer Switch

Section 1: Introduction

WARNING

READ AND UNDERSTAND THE INSTRUCTIONS CONTAINED HEREINAFTER BEFORE ATTEMPTING TO UNPACK, ASSEMBLE, OPERATE, OR

MAINTAIN THIS EQUIPMENT.

HAZARDOUS VOLTAGES ARE PRESENT INSIDE TRANSFER SWITCH

ENCLOSURES THAT CAN CAUSE DEATH OR SEVERE PERSONAL

INJURY. FOLLOW PROPER INSTALLATION, OPERATION, AND MAINTENANCE PROCEDURES TO AVOID THESE VOLTAGES.

TRANSFER SWITCH EQUIPMENT COVERED BY THIS INSTRUCTION

BOOK IS DESIGNED AND TESTED TO OPERATE WITHIN ITS NAMEPLATE RATINGS. OPERATION OUTSIDE OF THESE RATINGS MAY

CAUSE THE EQUIPMENT TO FAIL RESULTING IN DEATH, SERIOUS

BODILY INJURY, AND/OR PROPERTY DAMAGE. ALL RESPONSIBLE

PERSONNEL SHOULD LOCATE THE DOOR MOUNTED EQUIPMENT

NAMEPLATE AND BE FAMILIAR WITH THE INFORMATION PROVIDED

ON THE NAMEPLATE. A TYPICAL EQUIPMENT NAMEPLATE IS

SHOWN IN FIGURE 1.

1.1 Preliminary Comments and Safety Precautions

This technical document is intended to cover most aspects associated with the installation, application, operation, and maintenance

of the Automatic Transfer Controller (ATC-300) Controlled ATS

with ratings from 30 through 1000 amperes (A). It is provided as

a guide for authorized and qualified personnel only. Please refer to

the specific WARNING and CAUTION in Section 1.1.2 before proceeding. If further information is required by the purchaser regarding a particular installation, application, or maintenance activity,

an Eaton representative should be contacted.

1.1.1 Warranty and Liability Information

No warranties, expressed or implied, including warranties of fitness for a particular purpose of merchantability, or warranties arising from course of dealing or usage of trade, are made regarding

the information, recommendations and descriptions contained

herein. In no event will Eaton be responsible to the purchaser or

user in contract, in tort (including negligence), strict liability or

otherwise for any special, indirect, incidental or consequential

damage or loss whatsoever, including but not limited to damage or

loss of use of equipment, plant or power system, cost of capital,

loss of power, additional expenses in the use of existing power

facilities, or claims against the purchaser or user by its customers

resulting from the use of the information and descriptions contained herein.

1.1.2 Safety Precautions

All safety codes, safety standards, and/or regulations must be

strictly observed in the installation, operation, and maintenance of

this device.

Figure 1. Typical Manual Transfer Switch Equipment Nameplate.

Note: All possible contingencies which may arise during installation, opera-

tion or maintenance, and all details and variations of this equipment do no

purport to be covered by these instructions. If further information is desired

by purchaser regard- ing the particular installation, operation or maintenance of particular equipment, contact a Eaton representative.

WARNING

THE WARNINGS AND CAUTIONS INCLUDED AS PART OF THE PROCEDURAL STEPS IN THIS DOCUMENT ARE FOR PERSONNEL

SAFETY AND PROTECTION OF EQUIPMENT FROM DAMAGE. AN

EXAMPLE OF A TYPICAL WARNING LABEL HEADING IS SHOWN

ABOVE TO FAMILIARIZE PERSONNEL WITH THE STYLE OF PRESENTATION. THIS WILL HELP TO INSURE THAT PERSONNEL ARE ALERT

TO WARNINGS, WHICH APPEAR THROUGHOUT THE DOCUMENT.

IN ADDITION, WARNINGS AND CAUTIONS ARE ALL UPPER CASE

AND BOLDFACE.

CAUTION

COMPLETELY READ AND UNDERSTAND THE MATERIAL PRESENTED IN THIS DOCUMENT BEFORE ATTEMPTING INSTALLATION,

OPERATION, OR APPLICATION OF THE EQUIPMENT. IN ADDITION,

ONLY QUALIFIED PERSONS SHOULD BE PERMITTED TO PERFORM

ANY WORK ASSOCIATED WITH THIS EQUIPMENT. ANY WIRING

INSTRUCTIONS PRESENTED IN THIS DOCUMENT MUST BE FOLLOWED PRECISELY. FAILURE TO DO SO COULD CAUSE PERMANENT EQUIPMENT DAMAGE.

For more information visit: www.eaton.com IB140058EN

O&M Manual for 30-1000 Amperes

Emergency Source

Normal Source

Load

Manual Transfer Switch

Instructional Booklet

Effective: March 2016 Page 3

1.2 General Information

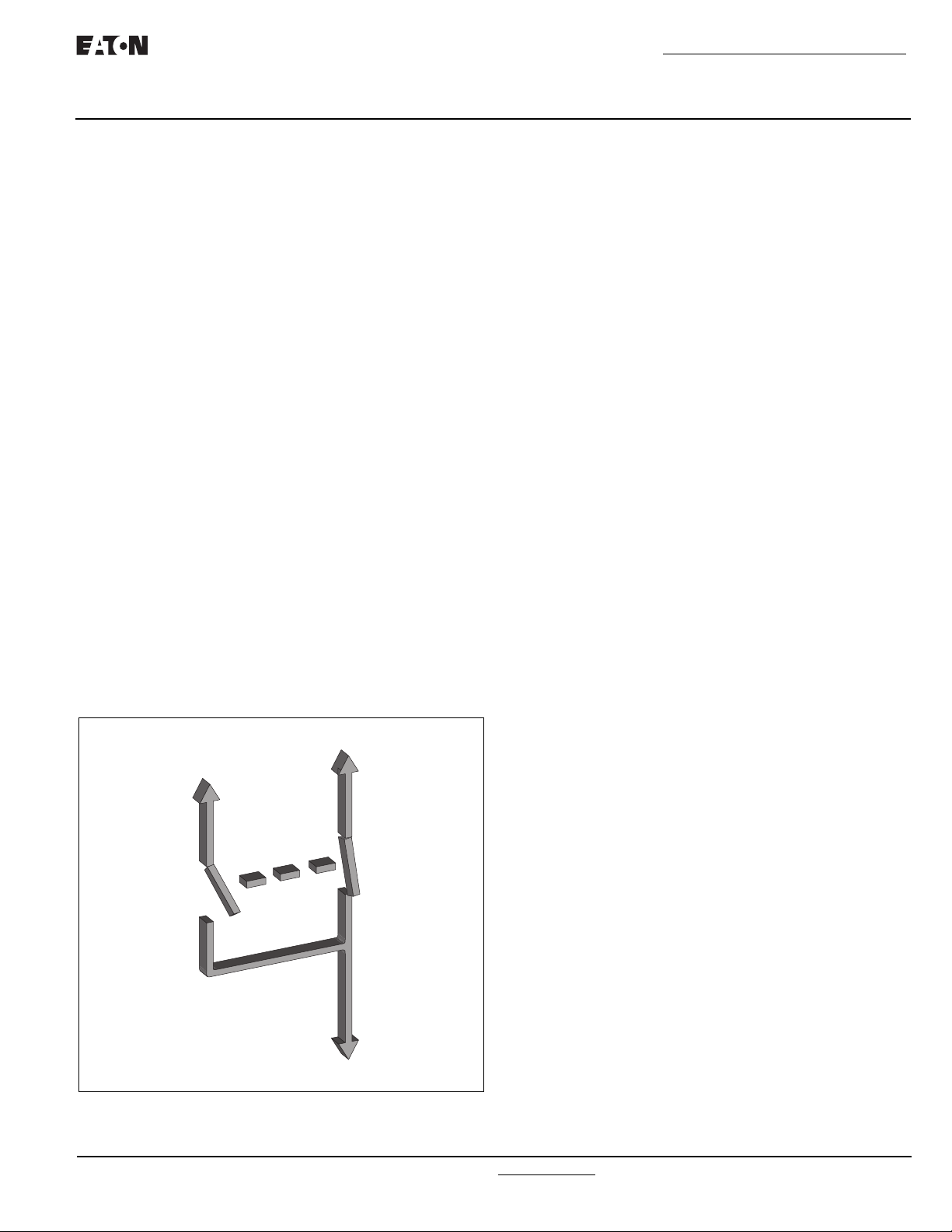

Transfer switches are used to protect critical electrical loads

against loss of power. The load's normal power source is backed

up by a secondary (emergency) power source. A transfer switch is

connected to both the normal and emer- gency power sources and

supplies the load with power from one of these two sources. In

the event that power is lost from the normal power source, the

transfer switch transfers the load to the secondary (emergency)

power source. Transfer can be automatic or manual, depending

upon the type of transfer switch equipment being used. Once normal power is restored, the load is automatically or manually transferred back to the normal power source, again depending upon the

type of transfer equipment being used (Figure 2)

1.2.1 Transfer Switch Types

Four types of basic transfer switch equipment are available:

Automatic Transfer Switch

Automatic transfer switches automatically perform the transfer

function. They consist of three basic elements:

1. Main contacts to connect and disconnect the load to and from

the power source.

2. A mechanism to transfer the main contacts from source to

source.

3. Intelligence/supervisory circuits to constantly monitor the condition of the power sources and thus provide the intelligence

necessary for the switch and related circuit operation.

Basic Transfer Switch

The basic transfer switch is designed for use with customer furnished controls. It is similar in design to the automatic version

except the intelligence circuit (logic panel) and voltage selection

panel are omitted. All automatic sensing devices, relays or solidstate devices are the customer's responsibility.

Manual Transfer Switch (Manually Operated)

Manual transfer switches provide the main contacts and the transfer mechanism to effect the transfer of the main contacts from

source to source. Transfer of power, however, is accomplished by

true hand operation (not power assisted) of the transfer switch.

This switch is similar to the basic switch in that an intelligence circuit and a motor driven mechanism are not part of the design.

1.2.2 Design Configuration

The Eaton Transfer Switch is a rugged, compact design utilizing

molded case switches to effect the transfer of essential loads

from one power source to another (Figures 3, 4 and 5). Molded

case switches are interlocked to prevent both switches from being

closed at the same time. The versatile design, in addition to standard transfer functions, offers an optional integral thermal and

short circuit protection in either or both switching devices.

Molded case switches and the associated transfer mecha- nism

are usually mounted vertically in the assembly. The vertical configuration (225 - 1000 amperes) is accomplished by utilizing a positive, metallic transfer and interlocking system between the molded

case switches. A horizontally mounted transfer mechanism is utilized with transfer switches 30 - 150 amperes.

The Eaton Transfer Switch was designed with installation ease

and simplified maintenance in mind. Three main panels comprise

the automatic transfer switch design:

• Power Panel

• Voltage Selectin Panel

• Logic Panel

Each panel is independently mounted with interconnecting wiring

terminated in connector plugs to permit individual door or panel

removal without disturbing critical connec- tions. Enclosure

mounting is simplified by utilizing top and bottom mounting

flanges with elongated mounting holes.

For the vertical design, installed power panel positioning bolts,

elongated mounting holes and pre-tapped inserts insure proper

power panel mounting after initial enclosure installation or when

switching from top to bottom entry and vice versa. Refer to Section 4 for mounting and modification details.

1.3 Transfer Switch Catalog Number Identification

Transfer switch equipment catalog numbers provide a signifi- cant

amount of relevant information that pertains to a particu- lar piece

of equipment. The Catalog Number Identification Table (Table 1)

provides the required interpretation informa- tion. An example is

Figure 2. Typical Load Transfer Switch (Circuit Breaker Type)

Schematic.

IB140058EN For more information visit: www.eaton.com

offered to initially simplify the process.

Example: Catalog Number (bolded numbers correspond to position headings in Table 1)

Table 1.

1 to 2 3 4 5 6 7 8 9 to 12 13 14 15

MT V X KD A 3 0300 X S U

The catalog number MTVXKDA30300XSU describes a Manual

transfer switch with the switching devices mounted vertically in

the enclosure. The Eaton Series CT Type HKD is used as the

switching device and is in the form of a 3-pole molded case

switch on each source. The continuous current rating of this

equipment is 300 amperes and applicable at 480 Vac, 60 Hz. The

transfer switch equipment is enclosed in a NEMAT 1 enclosure

and is both UL and CSA listed.

Instructional Booklet

Page 4 Effective: March 2016

Table 2. Transfer Switch Catalog Number Explanation

O&M Manual for 30-1000 Amperes

Manual Transfer Switch

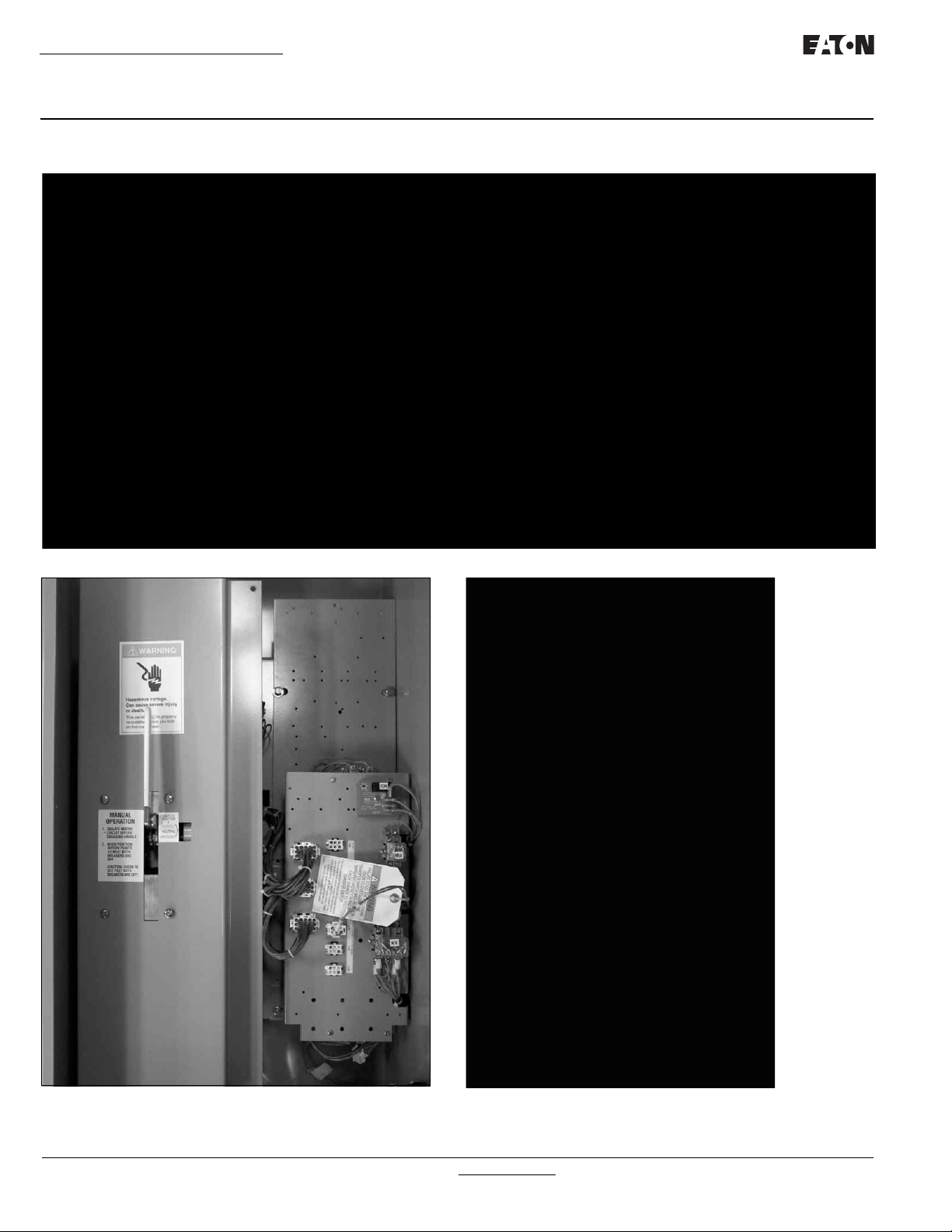

Figure 3. Vertical Design Automatic Transfer Switch Equipment

with Deadfront Cover in Place Over Power Panel (225 - 1000

Amperes)

For more information visit: www.eaton.com IB140058EN

Figure 4. Vertical Design Automatic Transfer Switch Equipment

Shown with Deadfront Cover Removed (225 - 1000 Amperes).

O&M Manual for 30-1000 Amperes

Manual Transfer Switch

Instructional Booklet

Effective: March 2016 Page 5

Section 2: Receiving, Handling, and Storage

2.1 Receiving

Every effort is made to ensure that the ATS equipment arrives at

its destination undamaged and ready for installation. Packing is

designed to protect internal components as well as the enclosure.

Care should be exercised, however, to protect the equipment from

impact at all times. Do not remove the protective packaging until

the equipment is ready for installation.

When the ATS equipment reaches its destination, the customer

should inspect the shipping container for any obvious signs of

rough handling and/or external damage that occurred during transportation. Record any external and internal damage for reporting

to the transportation carrier and Eaton, once a thorough inspection

is complete. All claims should be as specific as possible and

include the Shop Order and General Order numbers.

CAUTION

MAKE NOTE OF THE WARNING LABEL ATTACHED TO THE TOP OF

THE SHIPPING CONTAINER THAT WARNS AGAINST DOUBLE

STACKING TRANSFER SWITCH EQUIPMENT.

Figure 5. Horizontal Design Automatic Transfer Switch Equipment

(30 - 100 Amperes)

1.4 Environmental Conditions

Seismic

With proper installation and by including the appropriate option

which includes specially designed cleats, transfer switches have a

seismic capability which exceeds the worst case Zone 4 required

levels per both the Uniform Building CodeT and the California

Building Code.

Operational Conditions

Normally, a transfer switch is applied indoors in an electrical

equipment room. In the appropriate enclosure, it can be used for

outdoor applications where the equipment is sub- ject to falling

rain, freezing temperatures and 95% humidity (non-condensing).

The ambient temperature range for operation is between -20 and

+70°C.

A shipping label is affixed to the top of the shipping container

which includes a variety of equipment and customer information,

such as General Order Number (GO#) and Catalog Number (Cat#).

Make certain that this information matches other shipping paper

information.

Each transfer switch enclosure is bolted through its top and bottom mounting flanges to a rigid wooden pallet. The pallet is open

at two ends for movement by a fork lift. Heavy duty cardboard

sides surround the enclosure and are further supported with reinforced cardboard corner posts. An egg crate design cardboard protector covers the entire top of the enclosure with additional

cardboard protectors over the indicating light panel and operating

handle. A heavy duty cardboard lid covers the entire opening. The

shipment is secured and further protected with shrink wrap. Do

not discard the packing material until the equipment is ready for

installation.

Once the top packaging is removed from the shipment, the enclosure door can be opened. A plastic bag of docu- ments will be

found within the enclosure, usually attached to the inside of the

door. Important documents, such as test reports, wiring diagrams,

appropriate instruction leaflets and a warranty registration card,

are enclosed within the bag and should be filed in a safe place.

2.2 Handling

As previously mentioned, ATS equipment is packaged for forklift

movement. Protect the equipment from impact at all times and DO

NOT double stack.

Once the equipment is at the installation location and ready to be

installed, packaging material can be removed and discarded. Once

the enclosure is unbolted from the wooden pallet, it can be hand

moved to its installation position. Be careful not to damage the top

or bottom enclosure mounting flanges. Refer to Section 4 of this

manual for specific installation instructions.

IB140058EN For more information visit: www.eaton.com

Instructional Booklet

Page 6 Effective: March 2016

O&M Manual for 30-1000 Amperes

Manual Transfer Switch

2.3 Storage

Although well packaged, this equipment is not suitable for

outdoor storage. The equipment warranty will not be applicable if there is evidence of outdoor storage. If the equipment

is to be stored indoors for any period of time, it should be

stored with its protective packaging material in place. Protect the equipment at all times from excessive moisture, construction dirt, corrosive conditions, and other contaminants.

It is strongly suggested that the package-protected equipment be stored in a climate-controlled environment with temperatures from -20 to 85°C (-22 to 185°F) and with a

relative humidity of 80% or less. DO NOT, under any circumstance, stack other equipment on top of a transfer switch

equipment enclosure, whether packaged or not.

Section 3: Equipment Description

3.1 General

Eaton transfer switch equipment is available in four different

configurations:

• Automatic Transfer Switch

• Maintenance Bypass Transfer Switch

• Manual Transfer Switch (Manually Operated)

• Non-automatic Transfer Switch (Electrically Operated)

Refer to Section 1 for a discussion of the four types. Each

transfer switch is usually supplied in an enclosure, although

un-mounted sub-assemblies can be supplied for mounting by

the customer. Since the enclosed automatic transfer switch

encompasses all transfer switch equipment possibilities, it is

the only specific type that will be discussed in this section.

Figure 6. Typical Vertical Design Power Panel (Unmounted).

The enclosed automatic transfer switch consists of three

basic panels interconnected through connector plugs and

mounted in an enclosure (Figures 4, 5, 15 and 16):

1. Power Panel

2. Voltage Selection Panel

3. Logic Panel.

For more information visit: www.eaton.com IB140058EN

Loading...

Loading...