Eaton MTL83*C Modbus, Crouse-Hinds Series, MTL838C, MTL831C Software Manual

DRAFT - 06 January 2019

MTL83xC Modbus

PC software manual

January 2019

INM MTL83xC PC Modbus Rev 1

Instruction manual

MTL fieldbus networks

ii

INM MTL83xC PC Modbus Rev 1

DRAFT - 06 January 2019

This page left intentionally blank

iii

INM MTL83xC PC Modbus Rev 1

DRAFT - 06 January 2019

CONTENTS

1 INTRODUCTION ............................................................1

1.1 PC Requirements ........................................................................1

2 QUICKSTART GUIDE ........................................................2

3 BACKGROUND TO THE MTL838C .............................................2

3.1 The analog-input multiplexer system .......................................................3

3.2 Configuring the MTL838C .................................................................3

3.3 On-line Configuration .....................................................................4

3.4 Off-line Configuration ....................................................................4

3.5 The PC software .........................................................................4

3.6 Interconnection of the MTL838C ...........................................................5

3.7 Initialization mode .......................................................................5

3.8 Slave, Transmitter and Input addressing .....................................................5

3.8.1 Addressing MTL838C slaves ..............................................................5

3.8.2 Addressing the transmitters of each MTL838C ...............................................6

4 PC SOFTWARE INSTALLATION ........................................................7

5 SOFTWARE OPERATION .............................................................8

5.1 Configuration Overview ...................................................................9

5.2 The MTL838C Tab .......................................................................10

5.2.1 Communication Protocol ................................................................10

5.2.2 Data Format ..........................................................................10

5.2.3 Tag Name ............................................................................11

5.2.4 RS485 Link 1 Address ..................................................................11

5.2.5 RS485 Link 2 Address ..................................................................11

5.2.6 Transmitters Connected ................................................................11

5.2.7 Temperature Units .....................................................................12

5.2.8 Baud Rate ............................................................................12

5.2.9 Line Frequency ........................................................................12

5.2.10 Parity ................................................................................12

5.2.11 Alarm Relay 1 .........................................................................13

5.2.12 Alarm Relay 2 .........................................................................14

5.2.13 Action Buttons ........................................................................14

5.3 The MTL831C #1 Tab ....................................................................14

5.3.1 Input Type ............................................................................15

5.3.2 Safety Drive ..........................................................................15

5.3.3 High Alarm ...........................................................................15

5.3.4 Low Alarm ............................................................................15

5.3.5 Input Zero, Output Zero, Gain ............................................................16

5.3.6 Reading ..............................................................................16

5.3.7 The CJ Channel .......................................................................16

5.3.8 Moving around the Channel List: .........................................................16

5.4 Action Buttons ...................................................................... 17- 18

5.5 Input Calculator ........................................................................19

5.6 The MTL831C #2 Tab ....................................................................20

6 THE MENU .......................................................................21

6.1 File ...................................................................................21

6.2 Edit ...................................................................................22

6.3 Devices ............................................................................23-25

6.4 Help ...............................................................................26-29

iv

INM MTL83xC PC Modbus Rev 1

DRAFT - 06 January 2019

This page left intentionally blank

1

INM MTL83xC PC Modbus Rev 1

DRAFT - 06 January 2019

1 INTRODUCTION

The MTL83xC is a temperature (and mV) measuring system. It consists of an

MTL838C and one or two MTL831C modules. See the datasheet EPS830C

and installation manuals INM838C and INM831C for these modules for further

details. The main interface on the MTL838C which concentrates the data from the

MTL831Cs is Modbus

®

RTU (RS485). A separate document covers the MTL838C

Modbus

®

implementation (INM MTL838C-MBF).

This document covers the operation of the PC software that is used to configure

and monitor the system.

1.1 PC Requirements:

The MTL83xC PC software will run on a Windows® 7, 8, or 10 computer.

This is a small application that doesn’t require a lot of space, memory, or processor

speed. A USB cable is used to connect to the MTL838C (USB-C) – not part of the

MTL838C – purchase separately.

Modbus is a trademark of Schneider Automation Inc., North Andover, MA.

2

INM MTL83xC PC Modbus Rev 1

DRAFT - 06 January 2019

2 QUICKSTART GUIDE

This quickstart guide is written for an MTL83xC system based on an MTL831C

temperature input multiplexer transmitter with an MTL838C multiplexer receiver.

Before the actual installation, it is recommended that new users initially set up a

simple system on the bench to become familiar with the MTL83xC system. The

minimum hardware required for a test system is as follows:

MTL831C Analog transmitter

MTL838C Receiver

MTL5553 Isolator (for hazardous area installations only).

In order to run a test the following equipment will be required:

A PC loaded with MTL83xC Configuration software, Power supply 20 - 35V @

500mA, together with suitable cabling for the following requirements:

Data highway connections (see INM831C / INM838C)

Power supply connections

USB cable

The user will also need the following documentation for wiring information:

INM831C MTL831C installation manual

INM838C MTL838C installation manual

Connect at least one sensor to an MTL831C.

Refer to chapter 5 to configure and test the system.

3

INM MTL83xC PC Modbus Rev 1

DRAFT - 06 January 2019

3 BACKGROUND TO THE MTL838C

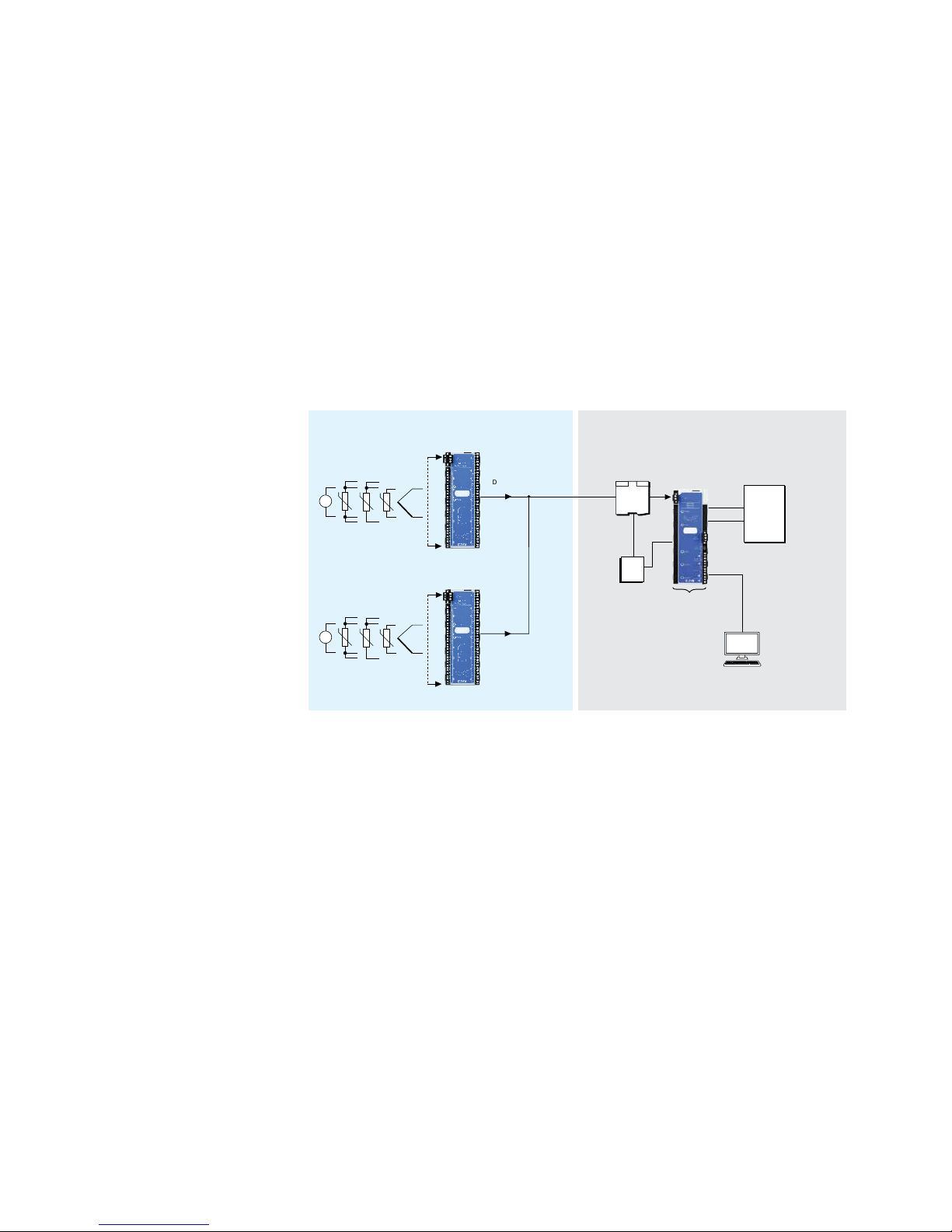

3.1 The analog-input multiplexer system

The MTL838C is an analog multiplexer receiver that is used with the MTL831C

hazardous area millivolt input multiplexer transmitter. The status of up to 32 analog

inputs may be communicated from the hazardous area to the safe area via a data

highway, comprised of a simple twisted pair - over distances up to 2000m.

Each data highway must be protected by an MTL5553/5053 digital isolator when

the inputs are located in a Zone 0,1 hazardous area. The MTL831C is typically used

with thermocouple and RTD inputs and is intrinsically safe. It can be mounted in a

Zone 0,1 hazardous area and will accept 16 inputs. For systems that do not require

Zone 0 or Zone 1 installation, the MTL5553/5053 can be eliminated.

Up to two MTL831C transmitters can be combined on a single MTL838C receiver

input - up to a total of 32 analog inputs - as shown in Figure 1.

Figure 1 - MTL838C/MTL831C System Diagram

The MTL838C acts as a Modbus slave. It may be connected into any standard

Modbus network, with up to 31 MTL838C slaves on each network. If each unit has

its full complement of 32 analog inputs, the status of a total of 992 analog inputs

may be passed to a Modbus master using a single RS485 network.

3.2 Configuring the MTL838C

The MTL838C must first be configured using software on a PC and the USB

connection. This configures things such as the slave address and communication

parameters. After the initial configuration, the MTL838C is ready to communicate

with the Modbus host. At this point, the remaining configuration may be done in

one of two ways:

• on-line via the Modbus link, direct from the host

• off-line using the PC software and USB connection

Using the PC software is required for initial configuration and recommended for

first time configuration of the measuring channels.

MTL831C

transmitter 1

MTL831C

transmitter 2

mV

Sensors can be in Zone 0

MTL5553/5053

isolator/PSU

mV

MTL838C

receiver

PLC

RS485

RS485

19-30Vdc

Power

PC

(MTL 83xC Configurator Software)

USB

2x SPST

relay

contacts

DATA HIGHWAY (BUS)

Up to 16 THC, RTD,

and mV inputs

potentiometer

Up to 16 THC, RTD,

and mV inputs

potentiometer

Zone 0, 1 or 2

Hazardous Area

Safe Area

4

INM MTL83xC PC Modbus Rev 1

DRAFT - 06 January 2019

3.3 On-line Configuration

Configuring the unit via the Modbus master and the network might seem to be the

simplest method at first sight, but there are a number of practical difficulties with this

configuration technique. This approach means that the user must deal with a number

of complex aspects which require a significant investment of the configurer’s time

before they are understood fully. A further difficulty may be a lack of the necessary

memory space within the Modbus master. If the configuration is likely to be changed

frequently it could even be necessary for the system designer to design specific ‘user

interface’ screens, such as those used by the PC software, to allow changes to be

made by operators. This would be a time consuming and costly task.

For most users, the attraction of being able to use the Modbus master to configure the

unit is that the configuration can be re-sent if the slave’s memory becomes corrupted.

Whilst this is true, it is not possible to avoid the difficulties (and costs) outlined earlier

and the decision to adopt a strategy of configuring via the Modbus master should be

arrived at only after due consideration.

A cost effective compromise would be to perform the initial configuration via the PC

software, and then read the configuration parameters stored in the MTL838C via the

host. The stored parameters could then be re-written to the MTL838C should the

configuration database ever become corrupt.

If a user intends to adopt the on-line configuration method, the calculation of

configuration parameters for storage in the master can be simplified, and the

possibility of ‘human error’ reduced, by using the PC software to input the required

data and data format, and then reading the stored values (encoded correctly in the

required data format) back from the MTL838C via Modbus. The user should still realize

that any subsequent alterations of the parameters will require further use of the PC

software.

3.4 Off-line Configuration

Off-line configuration requires the use of the PC software briefly described below.

Once configured, the configuration parameters are stored in non-volatile memory

within the unit.

3.5 The PC software

By far the simplest method of configuring the MTL838C is using the PC software. This

software has been specifically designed to perform all of the complex calculations that

must be carried out, in order to configure the unit. These calculations are transparent

to the user, and this method provides a convenient and time efficient method.

Alternatively, as explained before, the master could read the configured parameters

after initial off-line configuration and these may then be stored within the host for use

in the event of a database failure.

5

INM MTL83xC PC Modbus Rev 1

DRAFT - 06 January 2019

3.6 Interconnection of the MTL838C

The MTL838C may be connected to a Modbus host in a number of ways.

Two RS485 outputs, Link 1 and Link 2, are provided on the MTL838C. As there are

two outputs the unit can either be connected to a single Modbus master, with dual

redundancy, or connected to two separate Modbus hosts.

The MTL838C will respond on whichever RS485 connection the query is received,

and there is no restriction placed on the simultaneous use of both interfaces. The

Modbus addresses for each Link may only be set by using the PC software.

3.7 Initialization mode

The MTL838C has two distinct modes of operation - normal and initialization.

It will always enter initialization mode during power-up. It can also be triggered by

the detection of internal hardware or software faults, or after receiving an instruction

from the host to reset some or all of the configuration registers.

During initialization, the unit will ignore all commands from the master.

The initialization period will take several seconds to complete all the necessary

operations and calculations. Following successful initialization, the unit will

automatically enter, or return to, normal operation mode.

If a corrupted configuration database is detected during initialization the unit will

revert to a set of default values, and on entering normal operation mode, will issue

exception responses when requested by the host to read input values. Exception

responses will continue to be issued until the unit is re-configured. The need to reconfigure the unit will remain even if the MTL838C is powered down and back up.

If a corrupted configuration is detected, the slave address may be reset. If this

occurs, the user must use the PC software to set the slave address.

Also, when the PC software is communicating with the MTL838C, Modbus

communications are disabled. This is to prevent the possibility of writing to the

configuration database simultaneously from two sources.

3.8 Slave, Transmitter and Input addressing

The following discusses the allocation of addresses to the slaves on the Modbus

network - including the MTL838C - and the allocation of addresses for the

transmitters and inputs connected to each MTL838C.

3.8.1 Addressing MTL838C slaves

Modbus allows slave addresses in the range 1 to 247. JBUS allows slave addresses

in the range 1 to 255. This is the only difference between the two protocols. The

MTL838C will accept addresses in the range 1 to 255 for each Link. Care should be

taken when setting the addresses for each Link using the PC software. For example,

if both Links are connected to the same Host, the addresses should probably be

different.

The Modbus address for each MTL838C slave is set via the PC software. For

reasons of security, it is not possible to set the address of the slave via the

Modbus host.

6

INM MTL83xC PC Modbus Rev 1

DRAFT - 06 January 2019

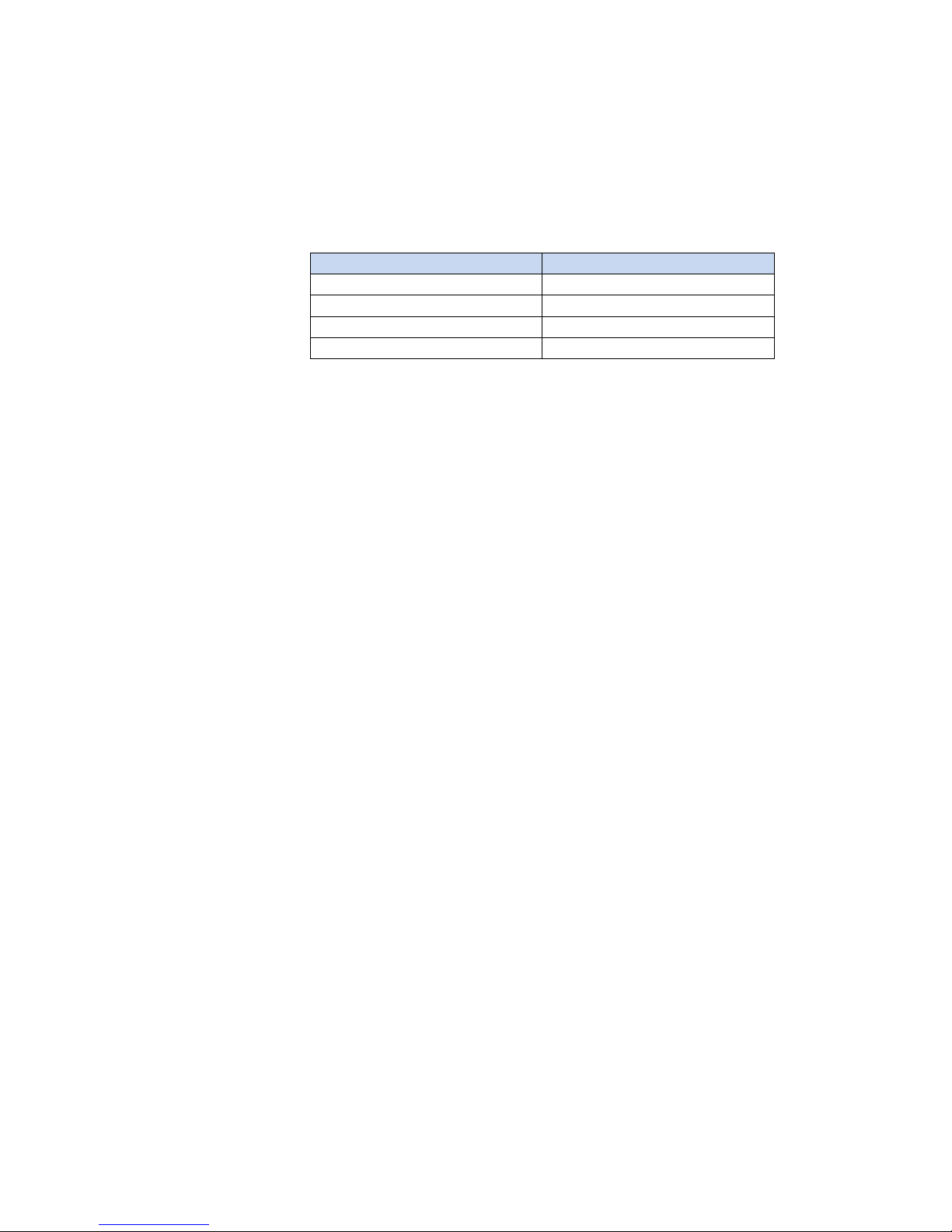

3.8.2 Addressing the transmitters of each MTL838C

Each MTL831C transmitter accepts up to 16 sensor inputs and there can be one

or two MTL831C transmitters connected to a single MTL838C. The address of

the MTL831C as seen by the MTL838C is determined by whether a jumper wire

is installed on the MTL831C. A jumper wire not installed gives the MTL831C an

address of ‘1’ and a jumper installed gives it an address of ‘2’. The following shows

the sensor numbers used by the MTL838C for a given MTL831C address.

MTL831C Address Sensor Numbers

1 0 - 15

1 32 CJC

2 16 - 31

2 33 CJC

Addressing of the MTL831C transmitters affects which sensor is given which

address in the MTL838C. For example, if only one MTL831C is connected to the

MTL838C but its address jumper is installed, it will be at transmitter address ‘2’ and

the sensor range will be 16 – 3, 1, 33.

It is also important that with two MTL831Cs connected to a single MTL838C, that

one and only one of them has the jumper installed. Otherwise they will both be at

the same address and communication between the MTL831s and the MTL838C

will fail. Likewise, there can be no more than two MTL831Cs connected to a single

MTL838C.

CJC stands for Cold Junction Compensation and reports the average temperature

of the MTL831C circuit board. This is an average of two temperature sensors

and should not be used by the Modbus Host to cold junction compensate

thermocouples. Instead the thermocouple channels should be compensated by the

MTL831C by selecting the correct Input Type.

7

INM MTL83xC PC Modbus Rev 1

DRAFT - 06 January 2019

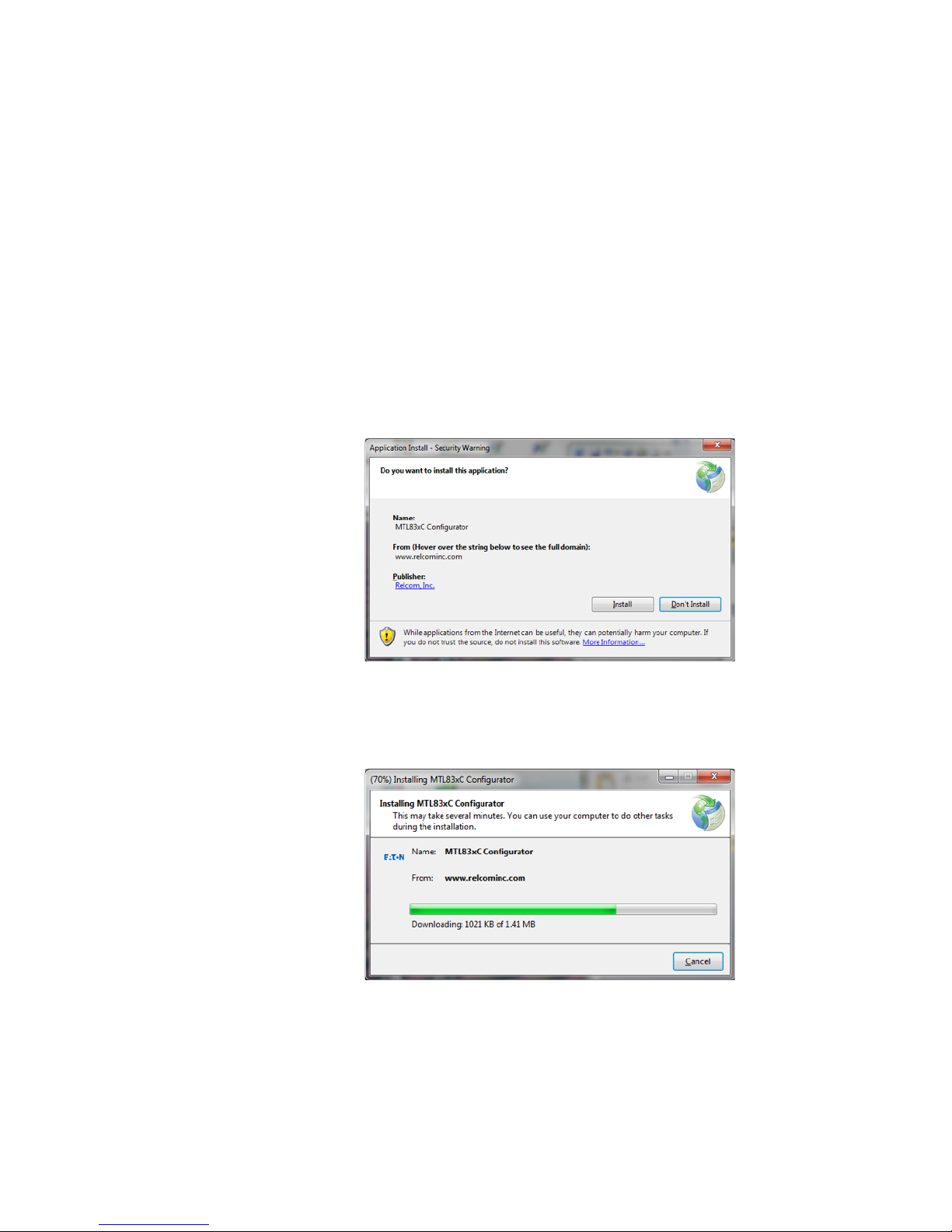

4 PC SOFTWARE INSTALLATION

The MTL83xC Configuration Software is only available from the Eaton (MTL)

website. Direct your browser to the following website and then locate the

MTL83xC product page. There will be a link on that page to download and install

the software:

www.mtl-inst.com

When you click on the link, your computer will likely warn about the file (setup.exe)

as it is an executable. Allow it to Run the file.

Anti-virus software on your computer may also complain about not knowing

whether the file is safe or not. Tell it to Allow the execution of the file.

Finally, Windows will want confirmation that you want to install the application. The

following is a sample screen shot of the warning. Notice that Relcom, Inc. is the

publisher of the software as they wrote it for Eaton (MTL).

Allow the installation to proceed.

The application will be downloaded, installed, and will start running.

Loading...

Loading...