EasyHeat Installation and Operation Manual: SR, TSR, HSR and HW Series Heating Cables, 14030-001 Manuals & Guides

SELF-REGULATING PIPE TRACING

HEATER CABLE

Installation & Operation Manual

For SR, TSR, HSR and HW Series Heating Cables

©2020 EasyHeat www.easyheat.com 14030-001 Rev. 6

TABLE OF CONTENTS

GENERAL INFORMATION .......................................................................................................... 1

How Heating Systems Work .................................................................................................. 1

PRODUCT SELECTION ................................................................................................................ 1

RECEIPT & STORAGE .................................................................................................................. 1

Receipt ..................................................................................................................................... 1

Storage ..................................................................................................................................... 1

Withdrawal from Storage .....................................................................................................1

INSTALLATION ............................................................................................................................. 2

Warnings ....................................................................................................................................... 2

Scheduling ............................................................................................................................... 2

Pre-Installation Check ...........................................................................................................2

Heater Handling .....................................................................................................................2

Heater Cable Placement on Pipe ......................................................................................2

Straight Tracing .......................................................................................................................2

Spiraling .................................................................................................................................... 3

Attachment ............................................................................................................................. 4

Cutting the Heater Cable ....................................................................................................5

Installation Details ..................................................................................................................5

Power Connections, Splices and Terminations ....................................................................7

THERMAL INSULATION ............................................................................................................... 7

Pre-Installation Checks .........................................................................................................7

Installation ...............................................................................................................................7

Marking ....................................................................................................................................8

Thermostats & Sensors .............................................................................................................. 8

Electrical Requirements ........................................................................................................... 9

Voltage Rating ............................................................................................................................ 9

Electrical Loading ..................................................................................................................9

Ground Fault Protection .......................................................................................................9

Waterproong .........................................................................................................................9

Testing ........................................................................................................................................... 9

Recommendations ................................................................................................................ 9

Procedure ................................................................................................................................ 9

Periodic inspection record form ................................................................................... 10 – 11

Start-up .......................................................................................................................................12

Heat-up Time .............................................................................................................................12

Diversity Factor .........................................................................................................................12

OPERATION & MAINTENANCE ................................................................................................12

System Design, Installation & Documentation ...................................................................12

Preventive Maintenance ........................................................................................................12

Visual Inspections .....................................................................................................................12

Frequency ..................................................................................................................................12

Personnel Training ....................................................................................................................12

Maintenance.............................................................................................................................12

Piping Repairs ............................................................................................................................13

Damaged products .................................................................................................................13

TROUBLESHOOTING ................................................................................................................. 14

Heat Trace Installation Record ..............................................................................................15

1

GENERAL INFORMATION

This manual is designed for use with Easy Heat self-regulating pipe tracing heater cable

products. Applications include freeze protection and temperature maintenance, includ-

ing hot water supply. For applications not specically addressed, please contact your local

representative.

How Heating Systems Work

An electric heating cable system uses the electric heater cable to replace the heat that

is lost through the thermal insulation system. Replacing the lost heat allows the pipe and

uid inside the pipe to be maintained at a constant temperature. This will keep water from

freezing and bursting a pipe, or a liquid from setting up (congealing) and plugging the pipe.

Simple systems may turn the entire system on with a contactor or switch, while others will use

a thermostat with each heater cable to control the temperature.

INSULATION

HEATER CABLE

PIPE

Figure 1

PRODUCT SELECTION

Check and verify that the proper heater cables are being installed on each pipe and vessel.

If no design/installation documents exist, check the appropriate Easy Heat Heat Application

Guide to determine the proper equipment for the application.

RECEIPT & STORAGE

Receipt

• Compare the materials against the shipping bill to verify receipt of proper materials.

• Inspect heating cable and components for transit damage. Insulation resistance tests

on each spool of cable are recommended.

• If design documents (line lists or per circuit bills of material) exist, check the received

materials against the lists to verify all needed materials. If no design documents exists,

keep a receipt log of all materials received.

Storage

Cables and system components should be stored in a clean, dry area. The equipment should

be protected from mechanical damage during storage. The storage temperature range is

-40 °F to 140 °F (-40 °C to 60 °C).

Withdrawal from Storage

It is recommended that a check out record be kept (in conjunction with the receipt records)

on equipment as it is removed from storage. This will serve to identify developing material

shortages before they happen - since project additions often cause the use of material for

other than designated piping.

2

INSTALLATION

Warnings!

While there are many acceptable ways of installing Easy Heat electric heating equipment,

certain actions can be dangerous to personnel and your installations. Please take care

to avoid the following problems:

• DO NOT TWIST THE BUS WIRES TOGETHER AT EITHER END OF THE CABLE. Each of these

wires has either voltage or neutral applied to it; twisting them together will cause a

short circuit.

• INSULATE BLACK POLYMER SURROUNDING BUS WIRES. The black compound extruded

around the bus wires is electrically conductive and should be treated as a conductor.

Follow connection kit installation instructions carefully.

• ALL ELECTRICAL CONNECTIONS IN THE SYSTEM SHOULD BE SEALED AGAINST MOISTURE.

To prevent electrical arcing and re hazard, all cable connections and electrical

wiring connections should be sealed against moisture. This includes the use of proper

cablesealingkitsand the moisture proong of all wire connections. Use only Easy

Heat connection kits.

• DO NOT EXPOSE HEATER CABLES TO TEMPERATURES ABOVE THEIR MAXIMUM RATINGS.

Higher temperatures can greatly shorten the life of a heater.

• IMMEDIATELY REPLACE ANY DAMAGED HEATER CABLE OR COMPONENTS. Failure to replace

any damaged components (heater cable, components, or thermal insulation) will

result in system failure.

• CLASSIFIED AREAS (EXPLOSIVE DUST OR GAS) REQUIRE THE USE OF SPECIAL ELECTRICAL

COMPONENTS. Any area having explosive gases (such as chemical/petrochemical

installations) or explosive dusts (such as coal handling or graineries) require special

cable, connection components and control components that are approved for use

intheseareas.Installationofnon-approvedproductscanresultinresorexplosions.

• INSTALLATION ON PLASTIC PIPE REQUIRES SPECIAL CONSIDERATIONS IN SELECTION AND

INSTALLATION. Refer to cable Application Guide for details in design and selection.

• MINIMUMINSTALLATIONTEMPERATURE-40°C(-40°F).

Scheduling

The installation of the electric heat tracing must be coordinated with the piping, insulation,

electrical and instrument installers. Cable installation should begin only after the majority

of mechanical construction is complete. Pressure testing of the pipe and installation of the

instruments should be complete prior to the start of the heater cable installation.

Pre-Installation Check

Walk the piping system and plan the routing of the heater cable. Use this check to verify

completion of instrumentation and mechanical work. All coatings (paint, etc.) must be

dry before attempting the heater cable installation.

Heater Handling

• Use a reel holder to roll out the heater cable.

• Keep the cable strung loosely, but close to the pipe being traced. This will avoid interfer-

ence with supports and other equipment.

• Leave an extra 12-18" (305-457mm) of heater cable at all power connections, tee splices

and end seal connections to facilitate easy completion of connections.

• ADDITIONAL HEATER CABLE IS REQUIRED ON VALVES, PIPE SUPPORTS AND OTHER EQUIPMENT.

See the installation detail section for exact lengths and method of installation.

• When handling the heater cable, avoid pulling it over or installing against sharp edges.

• Do not kink or crush the cable, including walking on it or driving over it with equipment.

Heater Cable Placement on Pipe

The heating cable may be installed either straight along the pipe or spiraled around the

pipe. Due to the increased labor and space requirements associated with spiraling cable

on pipe, spiraling is not normally recommended. Spiraling does, however, enable the pipe

heat loss to be very closely matched by the cable. Spiraling may thus reduce the amount

of cable required on a pipe. Spiraling also limits the ability to service pipe system components. If spiraling is necessary, appropriate information is provided herein.

Install heating cable at

8o’clockor4o’clock

positions

Figure 2

Straight Tracing

When straight tracing is used, install the heater cable in the lower half of the pipe. This helps

prevent physical damage to the heater cable from falling objects and being stepped on by

service personnel.

3

Spiraling

Spiraling increases the length of heater cable installed per foot of pipe.

Installed cable length = Pipe Length X Spiral Factor.

The following example and table will allow you to determine the correct pitch for each

pipe size and spiral factor:

Example: If 140' of cable are to be installed on 100' of 4" IPS pipe (spiral factor of 1.4), the

Pitch (P) would be 356mm (14”).

PITCH (P)

IN INCHES

Figure 3

4

Table 1

Spiral Pitch Table (Inches)

Pipe Spiral Factor

Size (feetofheatercableperfootofpipe)

(IPS) 1.1 1.2 1.3 1.4 1.5

1.0 NR NR NR NR NR

1.5 NR NR NR NR NR

2.0 17 NR NR NR NR

2.5 20 14 NR NR NR

3.0 24 17 13 NR NR

3.5 28 19 15 13 NR

4.0 31 21 17 14 NR

4.5 35 24 19 16 14

5.0 39 26 21 18 15

6.0 46 31 25 21 18

8.0 59 41 33 28 24

1inch=25mm

Attachment

For regular installations, the heater cable may be attached with berglass tape. Plastic wire

ties may also be used, provided the plastic has a maximum temperature rating equal to or

greater than the system requirements. The cable should t snugly against the pipe and be

secured at 305mm (12") intervals, as shown in Figure 5.

Figure 4

ALUMINUM

FOIL TAPE

INTERVALS

Figure 5

Notes

1) To prevent possible damage to the heater cable, do not fasten with metal straps, wire,

vinyl electrical tape or duct tape.

2) Aluminum foil tape should only be used if specied by design. The foil is most often

used on plastic pipe to offset the insulation effect of the plastic. See the Easy Heat Pipe

Tracing Systems’ Design Guide for details.

FIBERGLASS

TAPE

1 FOOT

Cutting the Heater Cable

Do not cut the cable until it is attached to the pipe. Conrm the allowances for terminations,

connections and heat sinks (valves, support, etc.) before cutting the cable. Heater cable

power is not affected by cutting to length. Protect all heater cable ends from moisture or

mechanical damage if exposed for long periods of time.

Installation Details

Heater cables should be applied in a manner to facilitate cable servicing and the easy

removal of valves and small in-line devices without the need to remove excessive thermal

insulation or having to cut the heater cable. The best way to accomplish this is to loop the

cable in the area of power connections, splices and piping devices. See diagram. The

amount of heater cable installed on each valve, hanger, etc. varies with the pipe size and

type of device. Table 2 gives the correct additional cable to be installed on each device.

Table 2—Extra Cable at Devices, Feet

PIPE FITTING TYPE

Pipe Flange Vent & Pipe Globe, Ball & Gate

Size(in) Pair Drain Support ButteryValves Valve

.50 .30 1.0 1.0 1.0 1.0

.75 .30 1.0 1.5 1.0 1.5

1.00 .30 1.0 1.5 1.0 2.0

1.50 .30 1.0 2.0 1.5 2.5

2.00 .30 1.0 2.0 2.0 2.5

3.00 .30 1.0 2.0 2.5 3.0

4.00 .50 1.0 2.5 3.0 4.0

6.00 .80 1.0 2.5 3.5 5.0

8.00 .80 1.0 2.5 4.0 7.0

10.00 .80 1.0 3.0 4.5 8.0

12.00 .80 1.0 3.0 5.0 9.0

14.00 1.0 1.0 3.0 5.5 10.0

16.00 1.0 1.0 3.5 6.0 11.0

18.00 1.0 1.0 3.5 7.0 12.0

20.00 1.0 1.0 3.5 7.5 13.0

24.00 1.0 1.0 4.0 8.0 15.0

5

Notes

1) Nominal cable length in feet. Extra cable is minimum required for various in-line pipe

ttings to compensate for greater areas of heat loss and to allow servicing of device.

2) Values above are based on area average of various ttings available, with the assumption that tting insulation will be equivalent to pipe insulation. The nominal length

of tracer to be applied to a particular tting would be the value shown in this chart plus

the ange-to-ange length of the tting.

3) For a Flanged Valve Adder choose Valve Type then add one Flange Pair for total adder

length.

6

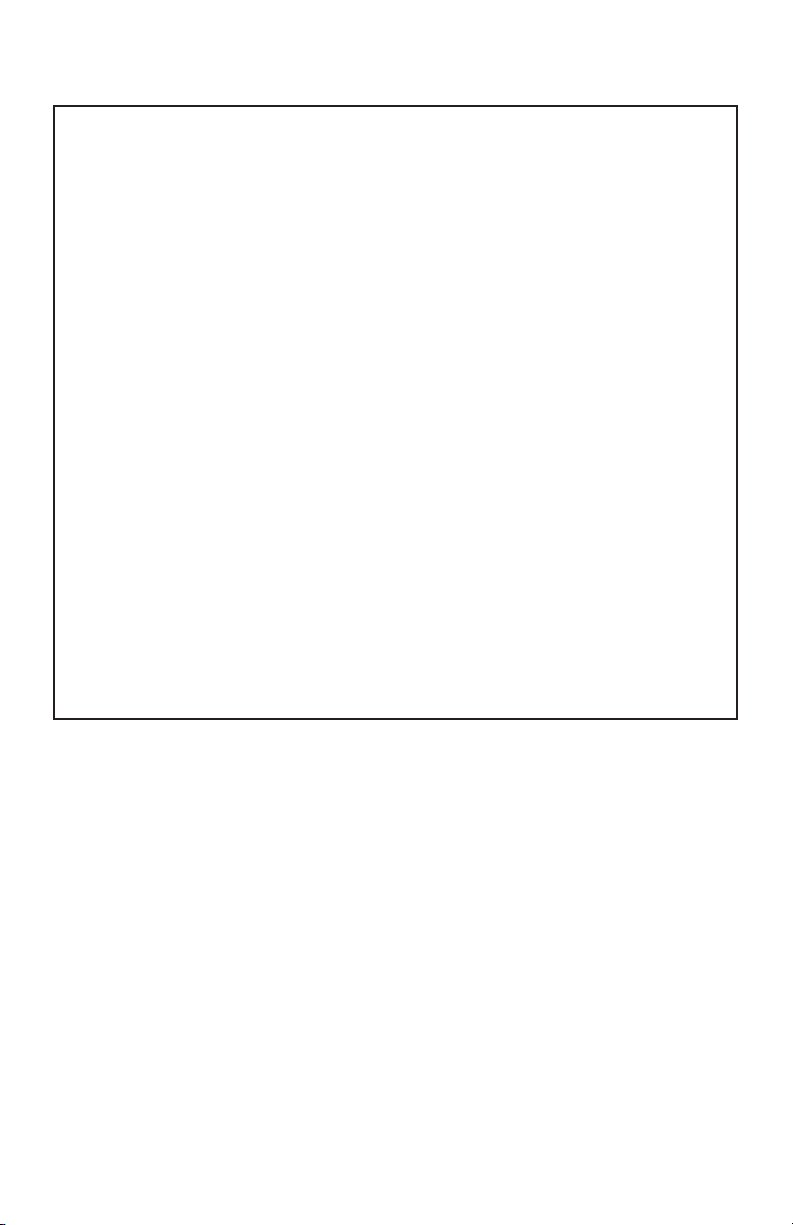

The following gures show installation details for various typical situations:

Figure 6

Figure 7

Heater cable should

be positioned on

the outside radius of

all elbows on pipes

2" in diameter and

larger.

FIBERGLASS

TAPE

HEATER

CABLE

ELBOW

VALVE: TYPICAL

INSTALLATION METHOD

(may vary for different valve shapes)

FIBERGLASS

TAPE

HEATER

CABLE

Figure 8

FLANGE

Figure 9

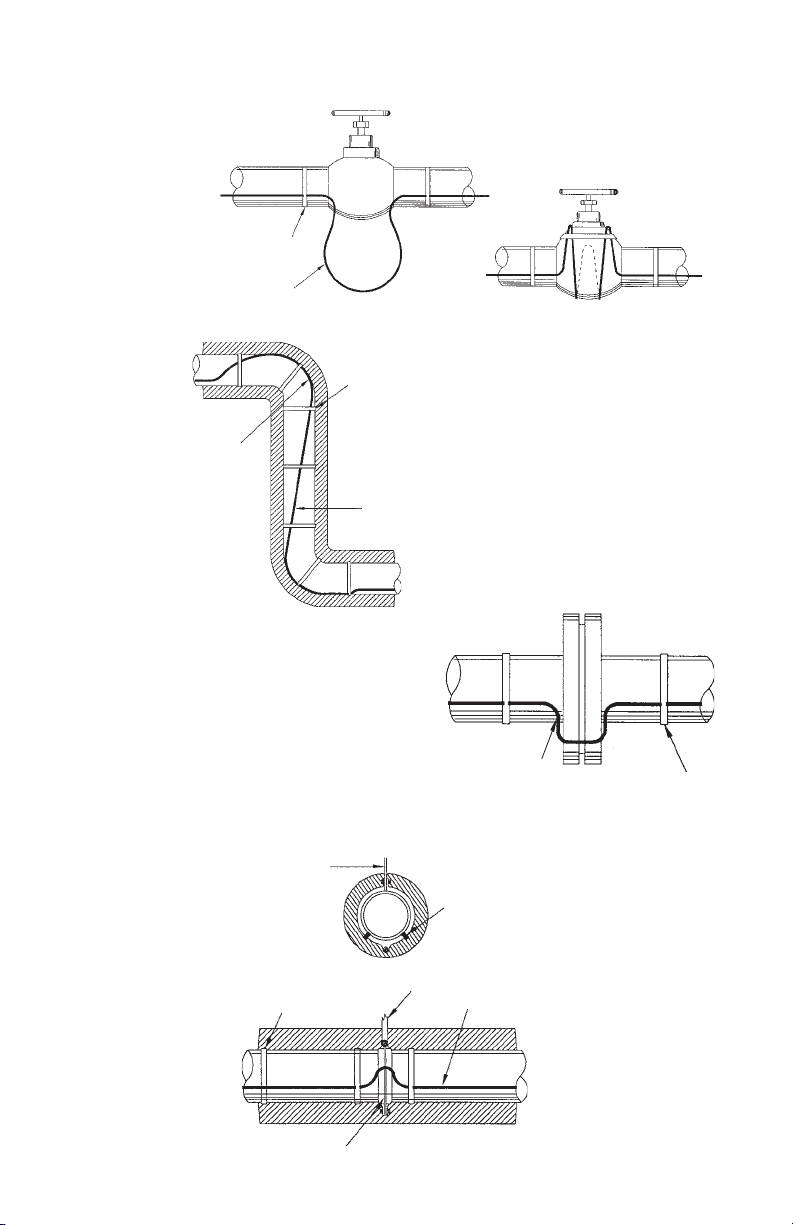

BAR HANGER

FIBERGLASS TAPE

Do not clamp heater

cable under hanger bracket.

HEATER

CABLE

FIBERGLASS

TAPE

HANGER SUPPORTBAR HANGER

HEATER

CABLE

HEATER CABLE

Figure 10

SHOE SUPPORT

7

Side

View

FIBERGLASS TAPE

PIPE SHOE SUPPORT

FIBERGLASS TAPE

Bottom

View

Power connections, splices and terminations

Only Easy Heat approved termination, connection and splice kits may be used. Failure

to do so will void warranties and agency approvals. Installation instructions in each

component kit must be followed regarding heater cable preparation and assembly.

Make end seals (terminations) and splice connections before making the power

connections. It is recommended that all heater cables be labeled as they are installed

with a discrete circuit number. This will facilitate identication, components needed

and electrical wiring during later phases of the installation. Power connection kits

utilize an adapter plate kit for installation on instrument tubing and tanks. Installation

instructions for mounting are included in each kit.

Figure 11

POWER

CONNECTION

KIT

CABLE LOOP

HEATER

CABLE

END SEAL

IN-LINE SPLICE

UNDER INSULATION

(SHOWN)

INSULATION

HEATER CABLE

PIPE SHOE

SUPPORT

HEATER

CABLE

HEATER

CABLE

LOOP

PIPE CLAMPS

Note

Heater cable power connections and end seals are required for each heater cable.

Heater cable splices, tees, and thermostats are used as needed.

FIBERGLASS

TAPE

TEE SPLICE UNDER

INSULATION (SHOWN)

THERMAL INSULATION

Pre-Installation Checks

Inspect the heater cable and components for correct installation and possible damage. In particular, verify that:

• The proper extra amount of heater cable has been installed at each valve, ange,

pipe support, etc. and that all cables are free from physical nicks, tears or gouging.

• Connections, splices and end seals are correctly installed, including cable seals at

power connection enclosures.

Installation

Check the thermal insulation type and thickness against the design criteria. Changes

in insulation type or thickness may require a different wattage heater cable. Verify that

all pipe work, including wall penetrations, ttings, etc. has been completely insulated.

8

Check the system to verify that:

• Insulation is not wet from rainfall or other moisture sources prior to the application of

waterproong.

• Lap joints on vertical piping are properly overlapped–higher piece lapped over the top

of lower piece.

• Band seals are used at lap joints to prevent the ingress of water.

• All penetrations of lagging (valve stems, hanger rods, etc.) are properly water proofed.

• Irregular shaped items (i.e. pumps, etc.) are properly waterproofed.

To minimize potential damage to the heater cable, install the insulation as soon as possible. It is recommended that another insulation resistance (megger) test be done after

the insulation has been installed to verify that the heater cable was not damaged during

the insulation installation.

Marking

Install “Electric Trace” signs on alternate sides of the piping at regular intervals, as a warning

to maintenance personnel. Permanently mark the outside of the insulation lagging with the

location of heater cable components. This will facilitate any future servicing requirements.

Thermostats & Sensors

Temperature sensitive applications will require the use of a thermostatic control. Selection

of the proper thermostat must consider voltage and amperage ratings of the device as

well as the suitability of housing for the environment (explosion proof, rain tight, corrosion resistance, etc.). Thermostat sensor bulb must be attached to the pipe at a location

representative of the entire length of pipe being protected by heating cable. If possible,

thermostat housing should be mounted as close as possible to the power connection kit.

It may be attached to the power connection kit provided code requirements are met with

regard to conduit connections seals, etc. To sense the coolest air temperature, ambient (air

sensing) thermostats should be mounted in the shade when possible. When using pipe-sensing

thermostats, the bulb (sensor) should be mounted on the opposite side of the pipe from the

heater, or at least 90° away from cable. This will allow the thermostat to sense the actual

pipe temperature and not be inuenced by the heater temperature. Mount the bulb at

least three (3) feet from the closest heat sink if possible.

Moisture inside thermostat enclosure will cause both corrosion and electrical shorting

problems. The potential for this type of problem, can be greatly reduced by:

• Proper sealing of all enclosures openings.

• Keeping enclosure cover closed and secured as much as possible during installation

sequence

• Proper closing and sealing of the cover to prevent leaking into the housing.

• Use of a moisture proong/electrical spray (aerosol) sealant on thermostat and electrical

connections (including all metal parts) at completion of installation.

• Connection and use of space heater if thermostat is so equipped. Do not de-energize

space heater during summer months.

Electrical Requirements

Voltage Rating

Verify that the heater cable voltage rating is suitable for the service being used. Refer to

Easy Heat Application Guide if further information is required.

Electrical Loading

Size over-current protective devices according to Easy Heat Application Guide. If devices

are other than standard thermal magnetic circuit breakers, consult Easy Heat.

Ground Fault Protection

Ground fault circuit breakers are required on all heater constructions per the National Electric

Code. Typically, 30mA trip devices are required due to the capacitive leakage of the heater

cable construction. Devices with lower trip levels can result in nuisance tripping. Consult Easy

Heat for further information.

Waterproong

Moisture penetration of the electrical system is the single largest source of problems in a heater

cable system installation. Therefore, particular care must be given to the proper sealing of all

electrical connections and splices. Heater cable connection kits will provide a proper seal

for the heater cable itself, when installed as per kit instructions. All other electrical connections (power wiring, thermostat connections, panel and breaker connections, etc.) must be

sealed or moisture proofed appropriately. Either mastic shrink tube or an aerosol electrical

insulative sealant should be used on all connections to reduce any moisture penetration.

The sealant will also reduce the potential for corrosion on exposed metal parts.

Testing

Recommendations

Electrical tests are recommended at specic points in the receipt and installation of the

heater cable. This periodical testing is designed to provide early warning in the event of

damage to the heater cable during installation. Installation costs of the cable and thermal

insulation can be signicant. Early identication of any heater cable damage is the most

economic approach to an installation. An insulation resistance test is recommended at

the following point of the installation process:

• UPON RECEIPT of the heater cable

• BEFORE thermal INSULATION installation

• IMMEDIATELY AFTER thermal insulation installation

• As part of a PERIODIC MAINTENANCE program

9

Procedure

The insulation resistance test is used to check for damage to extruded jackets. Connections

for the megger are made as shown in Figures 12 & 13.

FOR HEATER CABLES WITH BRAID, TEST

FROM HEATING CABLE BUS TO BRAID

Note

Test should use at least a 500

VDC megger. Do not use a meg-

Figure 12

ger with an excess of 2500 VDC.

Minimum acceptable readings

should be 20 megohms per circuit, regardless of length.

10

Figure 13

A record should be kept of the readings taken from the time the cable is rst installed on

the pipe. A history of the insulation resistance reading can be helpful in spotting moisture

ingress into the electrical system (by seeing a gradual decline in the insulation resistance or

physical damage to the heater cable (sharp decline in the insulation resistance). A sample

record for this is shown in Figure 14.

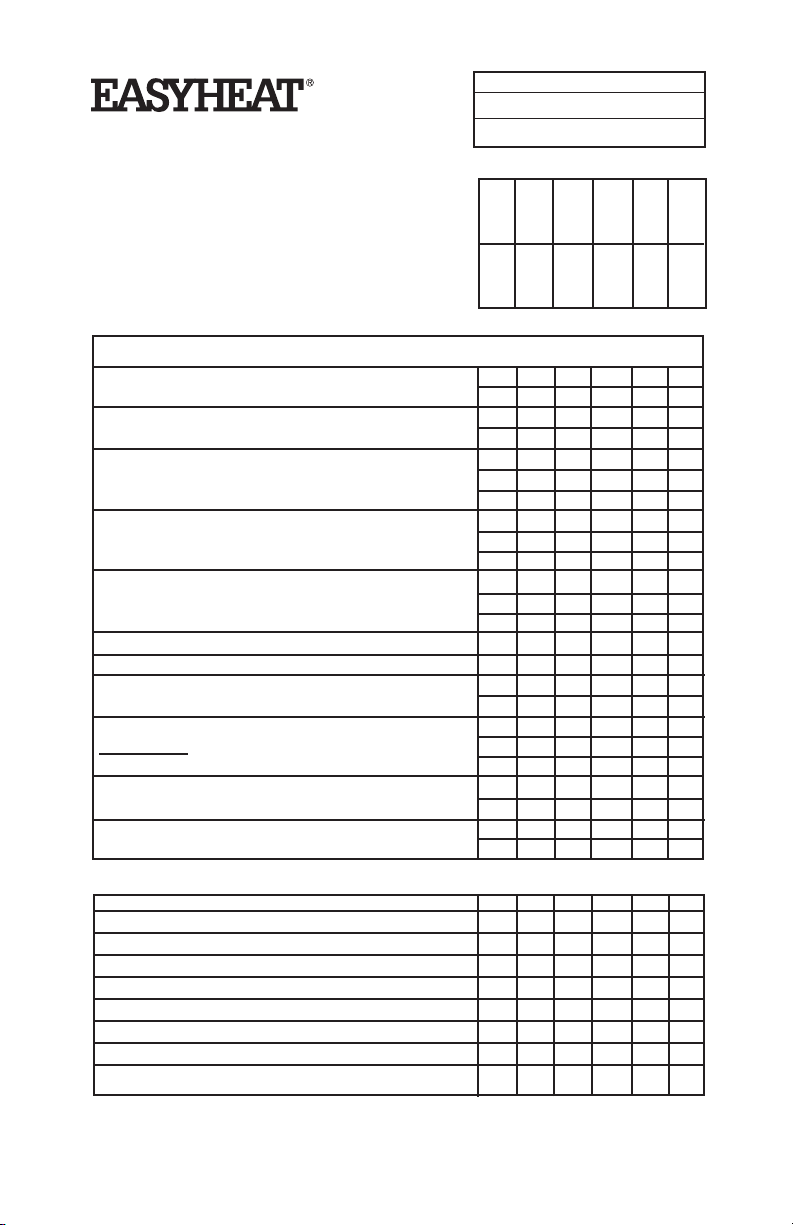

Periodic Inspection Record Form

The Periodic Inspection Record Form may be used in one of two ways:

1) One sheet per circuit. The results of periodic tests of a single circuit are posted in ver-

tical columns, beginning on the left and working toward the right. This allows easy

comparison of test values for up to seven test sequences on an individual circuit.

2) One circuit per column. Test data for a single test sequence on as many as seven

circuits can be recorded on a single sheet.

FOR HEATER CABLES WITH BRAID AND

OUTER JACKET

Test A – From heating cable bus wires

to braid

Test B – From braid to metal pipe

Circuit Number

Heater Type

Circuit Length

Periodic Inspection Record

Freeze Protection Circuits

Perform these checks as season requiring use

approaches.

Temperature Maintenance Controls

Perform these checks at least twice per year.

Maintenance Checks for ______________Month ____________Year _____

Visual inspection inside connection

box corrosion, moisture, etc.

Damage or cracks (leaks) in insulation

seals at valves, hangers, pumps, etc.

Heater cable properly connected and

grounded. Heater cable and connections

insulated from connection box.

Thermostat checked for moisture,

corrosion, set point, switch operation,

and capillary damage.

Megger tests performed at power

connection with both bus wires

disconnected from power wiring

Circuit voltage at power connection.

Circuit amperage after 5 minutes.

Pipe temperature at time amps

were measured.

Watts/Ft.

Volts × Amps = w/ft.

feet

All connections, boxes, and thermostats

have been resealed.

End seals, covered splices and tees

marked on insulation cladding.

Initial

Date

Initial

Date

Initial

Date

Set Point

Initial

Date

Reading

Initial

Date

Reading

Reading

Reading

Initial

Date

Initial

Date

Initial

Date

11

Remarks & Comments

Periodic Inspection Record Form

Figure 14

12

Start-up

Heat-up Time

Heat-up capacity (the ability to heat the pipe and it’s contents rapidly) is not normally designed into the system. Cold start-ups should allow adequate time for the pipe to come up

to temperature.

Diversity Factor

If the electrical supply capability is limited, then a diversity factor may be used in a cold start

situation (trying to start the entire system up in very cold weather). This is accomplished by

staggering the initial turn on of the various heater cable circuits such that the inrush currents

occur in a sequential fashion rather than all at once.

OPERATION & MAINTENANCE

System Design, Installation & Documentation

The heater cable system must be properly designed, installed and documented. This docu-

mentation should at least included line lists and location identication documentation. As

built installation drawings provide the optimum maintenance tool. Test records should also

be considered as part of the system documentation requirements. See Figure 15.

Preventive Maintenance

A preventive maintenance program is needed which will encompass both visual and

electrical checks of the system. These should be done not only before initial operation

of the system, but also on a scheduled basis. The checks should also be done after any

maintenance has been performed.

Visual Inspections

• Thermal insulation. Check weatherproong for damage, missing seals, cracks or gaps in

caulking and mastic coatings, damaged or missing lagging. When damage does exist, the

insulation will need to be repaired or replaced, and then resealed. WET INSULATION HAS

POOR INSULATING PROPERTIES, THEREFORE THE INSULATION MUST BE KEPT DRY. If insulation

has been damaged, check the heater cable for damage– replace any damaged sections.

• Inspect junction boxes, connection boxes and thermostats for corrosion, moisture or foreign

matter.

• Tightness of electrical connections, proper electrical insulation of heater cable wires, adequacy of moisture seal on electrical connections and that a minimum of one (1) inch of

electrically insulated heater extends above the grounding connection. No strands of the

ground braid should extend above this connection.

• Check all thermostats or sensor capillary leads to verify they are tied back and shielded

from physical damage.

• Verify all enclosure, connection box, etc. covers are properly closed and that the thermostat is switching off and on by measuring current ow in the circuit when the unit switches

on. Reset the knob to the proper temperature after completion of the test.

Frequency

Inspections should be made prior to the start of the freeze season on freeze protection systems.

Process maintenance systems should be checked on a frequent base, at least twice a year.

Personnel Training

Qualied maintenance personnel must maintain the system. It is recommended that periodic training programs be utilized to assist in keeping maintenance personnel up to date

on equipment and procedures.

Maintenance

The heater cables will not require any maintenance. Mechanical temperature controls

should be sprayed with a moisture repellent/corrosion inhibitor once a year on all metal parts.

Piping Repairs

Disconnect the electrical connection for the heater cable and protect it from mechanical or thermal damage during the repair. Check the heater cable installation after the

repairs per established procedures. Replace and water seal the thermal insulation system.

Damaged Products

Do not attempt to repair a damaged heater cable; replace the entire section. Fault currents will often destroy the connection between the bus wires and the heater core material

from the fault location to the power supply end of the circuit.

Replace the damaged heater cable immediately. If cable core is left exposed, moisture

migration into the undamaged section of the heater cable may cause electrical shorting

in that cable after repair of the damaged section.

Any heater cable exposed to ame should be removed from service immediately and

replaced. Further re damage could result if energized.

Troubleshooting

SYMPTOMS PROBABLE CAUSE CORRECTION

A. Circuit Breaker

Trips (Standard)

B. Circuit Breaker

Trips (Ground

Leakage Type)

1. Circuit breaker undersized.

2. Circuit oversized.

3. Start-up at too low temp.

1, 2, 3. Re-establish what the current

loads are going to be and resize the

breakers.*

4. Defective circuit breaker. 4. Replace circuit breaker.

5. Connection and/or splices

may be shorting out.

6. Physical damage to the

heater cable may be

5, 6. Locate and repair incorrect

connections, splices, or damaged

sections of heater cable.** Megger

per installation instructions.

causing a short.

7. Wires connected at end

seal.

7. Disconnect wires and perform

a current check for possible other

damage.

1. All of section A. 1. All of section A.

2. Excessive moisture in connection boxes or splices. This

can usually be veried by

Megger test.

2. Dry out and re-seal connections

and splices. Megger per Installation Instructions (20 megohms min.).

Work on connections outside the

thermal insulation rst, going to the

the thermal insulation rst, going to

the below insulation connections

and seals after the others have been

eliminated.

3. Nick or cut in heater or

moisture present.

3. Locate and repair or replace damaged heater cable or power wire.**

13

* Check to see if existing power wire sizing is compatible with larger sized breakers.

** To locate shorting problems, follow these steps:

1) Visually inspect the power connections and splices that are outside of the thermal insulation for proper

installation.

2) Check around the valves, pumps, and any area where there may have been maintenance work done, for

visual indications of damage.

3) Look for crushed or damaged insulation lagging along the pipe.

4) Inspect heater cable splices under the thermal insulation.

5) If you have not located the problem by now, you will have to isolate one section of the heater cable at a

time until you determine the general area of damage. First, isolate by disconnecting any tees or splices then

remove insulation from that area until the specic damage is found. For long runs of cable, it may be neces

sary to cut the cable in half to isolate the shorted section.

-

14

Troubleshooting

SYMPTOMS PROBABLE CAUSE CORRECTION

C. Power output is

zeroorlowerthan

rated.***

D. Power output

appears correct

but pipe temps.

are below design

value.

1. Low or no input voltage. 1. Repair electrical supply lines

equipment.

2. Circuit is shorter than 2. Check routing and length

cable (use “as builts”),

power requirements.

a. splices or tees may not

a. connect and recheck the power.

have been connected.

b. Heater cable may have

been severed.

3. Improper crimping

b. Locate and repair the damaged

heater cable. Recheck the power.

3. Re-crimp using correct procedure.

causing a high resistance

connection.

4. Control thermostat is wired

in the opened position.

5. Pipe is at an elevated

temp.

6. Heater cable has been

Rewire in the normally closed

position.

5. Check pipe temperature and

recalculate the output.***

6, 7. Replace the heater

exposed to excessive

moisture.

7. Heater cable has been

exposed to excessive

temperatures.

1. Insulation is wet. 1. Remove and replace with dry

insulation and insure proper weather-

proong.

2. Insufcient heater cable

was used on valves,

supports, and other heat

Splice in additional heater cable

but do not go over maximum circuit

length.

sinks.

3. Thermostat was set

3. Reset the thermostat.

incorrectly.

4. There are thermal design

inconsistencies.

4. Check with the local or factory

representatives for design conditions.

Modify as recommended.

heater

and recalculate

*** The power output on lower resistance heater cables is temperature sensitive and requires a special procedure to determine its value.

1) Check the pipe temperature under the thermal insulation.

2) Allow heater cable to stabilize for 10 minutes and then measure the current.

3) Calculate the power (watts/ft) of the heater cable by multiplying the current by the input voltage and divid

ing by the actual circuit length, l × V / Ft = Watts/Ft.

4) Compare the measured value to the power output curves for the heater cable at the measured pipe

temperature. If the heater cable’s actual output is substantially below the theoretical output, the bus wire

interface with the core has been damaged by the fault current and the cable must be replaced. This is not

a highly accurate method of analysis, so use discretion in comparing theoretical and actual values.

-

Heat Trace Installation Record

1. Circuit No. ___________________________

2. Receiving Documentation Date____________________

Item DESIGN ACTUAL

A. Cable Type ________________ _________________

B. Cable Length ________________ _________________

3. Receiving Testing Date____________________

A. Check for physical damage.

O.K.____________ Damage____________

B. Continuity Check

Check for continuity between power leads.

O.K.____________ Damage____________

C. 500VDC min., 2500 VDC recommended, megger

check between leads and sheath, 20 megohms min.

Megohms____________________________

D. Lot No. No._________________________________

4. Post Installation Testing Date____________________

15

A. Check for continuity between cold leads.

O.K.____________ Open____________

B. 500VDC min., 2500 VDC recommended, megger

check between leads and sheath, 20 megohms min.

Check for continuity between power leads.

O.K.____________ Damage____________

C. Visually Check Cable Installation Prior to Release

for Thermal Insulation.

Megohms____________________________

D. Lot No. No._________________________________

16

5. Final Testing & Commissioning Date____________________

A. Circuit approved for testing by client.

Approved____________________________

B. 500VDC min., 2500 VDC recommended, megger

check between leads and sheath, 20 megohms min.

Megohms____________________________

C. Energized Testing DESIGN ACTUAL

(All test data to be within 10% of design data)

1. Circuit Voltage ________________ _________________

2. Initial Current ________________ _________________

3. Current after 15

mins. of operation ________________ _________________

4. Current after 30

mins. of operation ________________ _________________

5. Pipe temperature ________________ _________________

6. Circuit Acceptance

This circuit has been tested and documented in accordance with the above itemized

data. Ths circuit by:

Contractor __________________________________________________________

Date __________________________________________________________

Client __________________________________________________________

Date __________________________________________________________

The Heat Trace Installation Record can be used to monitor the initial installation

and check-out process. This form can be used in conjunction with the Periodic

Inspection Record Form shown in Figure 14.

Figure 15

©2020 EasyHeat www.easyheat.com 14030-001 Rev. 6

Loading...

Loading...