Eastman Ultronic 625 User Manual

INSTRUCTION

BOOK

AND

PARTS

LIST

[Jj}[b1f!X]@[i[)il@

DPERATION

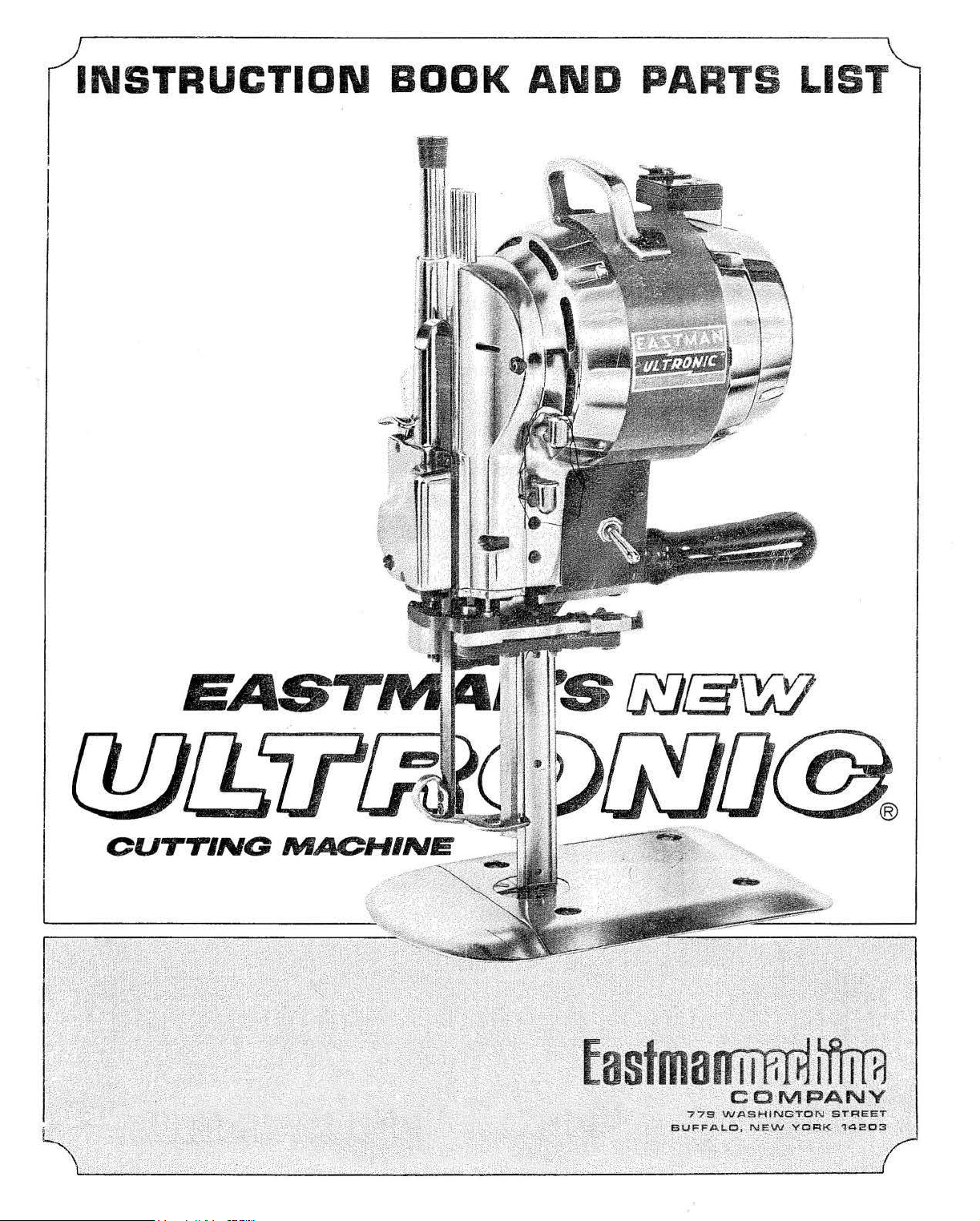

LUBRICATION

Read

AND

this

page before

CARE

operating

this machine

1

®

.

BEFORE

IN

PLEASE KEEP MACHINE

Fill oil

Make

Push in

a few revolutions

mo

sharpener

Use bell

to

Proceed

switch

to

With left

with

to

With right hand

allow

and

This will

to

STARTING

COLD

WEATHER,

cups

A,

B

and

C.

sure

sharpener

turning

ves easily.

is probably

crank

return

sharpener

as

follows:-Check

is

in

off position.

terminal

dis-engage

then

locked position. Knife

block on

hand

fingers

and

sharpener

motor

to

release lever

automatically

is

in

knob F and

by

hand

If

kni

fc

does

in

release lever H (see

to

locked

machine.

straddle

gather

thumb

turn

front

on

full

H.

return

an

Connect

· Press in release lever H

mechanism

motor

WARNIN

F

or

3-phase

must be

on t

urning

3-

phase

machines

as

indicated

knob

F. See tag attached

machines for

IN

WARM PLACE.

locked

posi

turn

the

to

see

if

not

move easily,

unlocke

photo,

position.

to

see

that

attachment

of

sharpener

switch,

speed

sharpener

must

be

in

G

direction

by

arrow

instructions.

tion

.

machine

knife

d position.

at

left)

motor

from

motor.

machine.

of

rotation

to all

over

plug

For

the

first w

eek

or

two, or

machine

the

a few times before allowing

to

This

into

CARE

Use

and sharp

clean

sha

knife slides with

To

do

remove from

TO SHARPEN

Take

Drop

lever R

Press lever E

to

Too

If this occurs, lift lever D

After

correct

has

been

idle for

motor

should

be

run

continuously.

permits

the

air

rpe n

prevent

not

engage sharpening mechanism.

fast lever action may cause lever

the

oil

closely fit moving

OF

MACHI NE

bose

or

bellows

ener

twice a week. Remove cover Q

out

lint

around

er

once

a week. Remove knife

slot

undue accumulation

oil

plate

rollers.

plate

THE

the

machine

pressure foot

located

a few tries

operating

out

next

downward

you

pressure.

turned

to

warm

screw

cleaner

and

KNIFE

of

by

means

to

will feel

any

and

If

rollers stick,

wash

the

machine

with

and

WARNIN

Do

not

operate sharpener

in

machine

will

wh

ile

or the sharpener

be damaged.

sharpener

is

Do

in

after

the

length

of

time,

on

and

off

it

up

and

flow easily

parts.

blow

lint

out

of

mechanism

at

least

in

cleaning solvent.

lay.

of

a slow, firm pressure

start

in

and

once

of

lint,

pressure

operating

to

lock.

over.

clean

a day.

foot

handle.

G

not

shut

motion

without

.

oH

knif

motor

motor

and

e

LUBRICATION

EVERY 2 HOURS-

Fill

oil

cups

A-B-C.

bearing

rod

conn

Use can

with

shaft

G.

and

turn

ecting

with

machine

an.d

To

rod

oil.

Oil

oil,

drop

crank

unt

shaft through

small

spout

.)

Insert spout

DAILY

connecting

pressure

il

you

see

hole

(furnished

in

hole

foot

G.

rod

in

ONCE A

Oi] 2 places

use

can

spout (furnished

with

DAY

at

with

sma

machine.)

DO

M -

ll

NOT

ONCE A WEEK

One

Tubes

Tu

at

Pulley

Belt

USE

AN

CAUTION

Do

not

use sewing

It

is

entirely

lubrication.

compounded

of

No

. 30

motor

For

too

machine

light

for

oil

cutting

best results use speci

Eastman

oil.

Do

oil

or

at

not

oil Base Plate

or

detergent

machine

least a

ally

good

oil.

grade

Rollers

~astmanTiTmJ

.

drop

at

rning

F

Shaft

Pull

EXCESS

only

to:

K & L

Knob

N

eys

0

AMOUNT

779

BUFFAL.O, NEW

WASHINGTON

ONCE A

Remove plug

and insert

tube.

amou

to

the

i

nto

OF

Squeeze

nt

about

size

opening.

OIL

MONTH

grease

of a pea

tfnTB

COMPANY

YORK

at

an

equal

STREET

1420:;j

P

3

G!J[17?fXi@[i!Jil@®

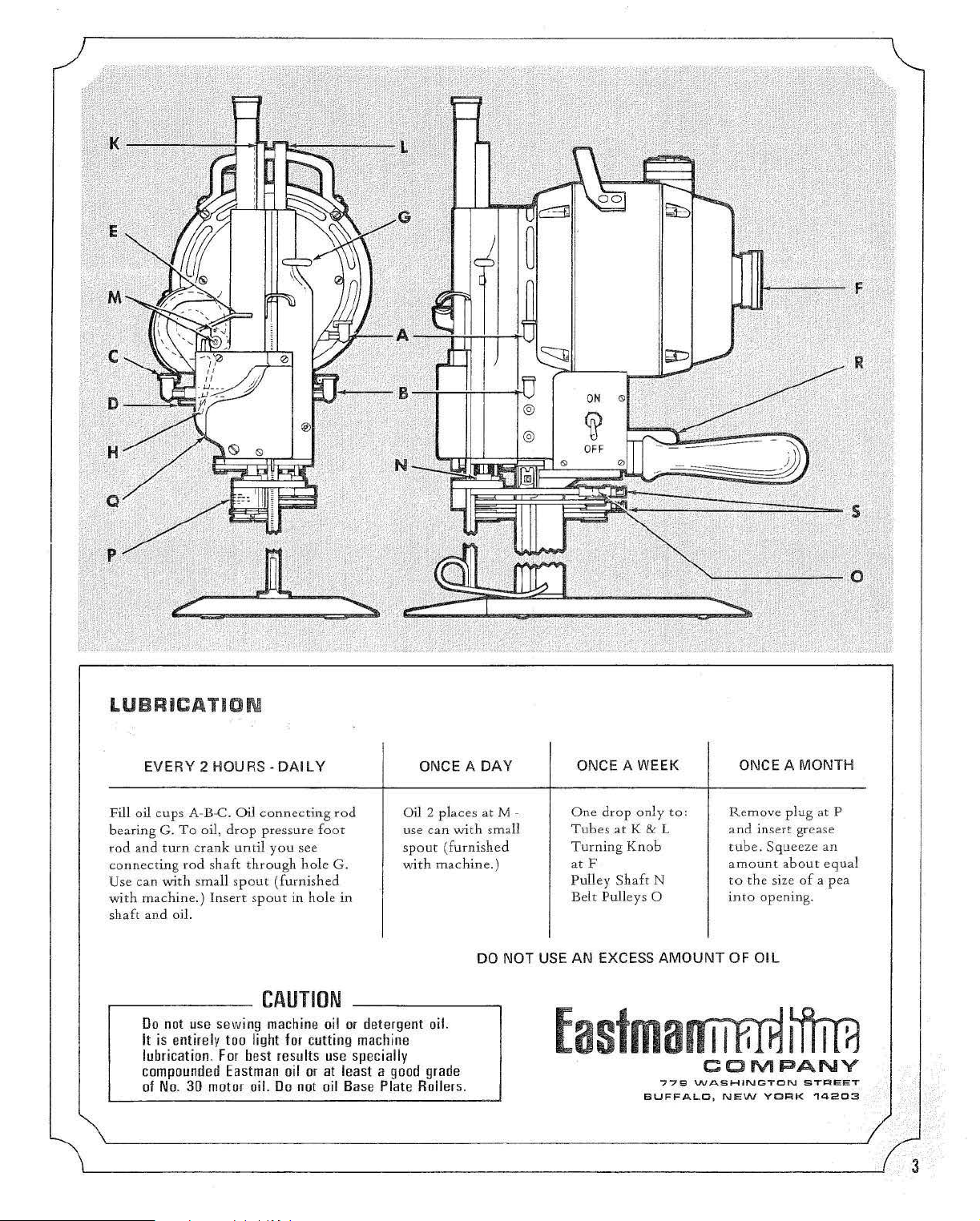

TO

CHANGE

Push

brackets

sion

and

belt

over

sharpener

rear

over

available in 4 gri t

Medium

SHARPENER BELT

S inward

remove worn belts. Place new

front

pulley T, th

shoe U and

pull

ey

0.

and

Fine.

to

knife

Sharpener

s:

Roug

S

release

ten

en

between

and

then

belts are

h, Coarse,

BE

LT

SHARPENER

-

ADJUSTMENT

INSTRUCTIONS

ADJUST ST A

FO

R CENTR

Disengage attachment plug. Depress

sharpener lever

belt carrier

tion

. (See page 3)

and

disengage back guide ( 6)

contact

( 2)

and

(5). Remove l

#G189

p

ivo~

screw

againsc side

position, engage

ftrmly against side

tighten

#G 189, press

against side o standard, fasten opposite

stabilizer

standard. Replace

engage

with back of

CHECK

SHOES

Shoes

without

If

adjustment

nuts

(3), tighten screws (7)

quired.

Check Clamping Arm

belt carrier in the

position

ward position. Clamping Arm

hold

shoe

do

so, s

worn or shoe

should

BILIZERS

AL

ALIGNME

(E) haJ.fway

to

extreme

with

standard.

disengage stabilizers (

ocknut

on exposed

(7) and press end

of

standard.

opposi

screws

/ositione

back

guide (6) in l

standard

SHARPENEfl

AND

CLAMPING

shou

ld swing in

excessive up

is

necess

and

the

kni

from

errations

be rep

moving in.

on

(11)

laced.

bottom

Loosen

Loosen

(

3).

threaded

te Stabilizer ( 4)

of

standard

(2). Remove

d stabilizer ( 4)

(5} firmly against

locknut

.

/ -

and out freely

and

ary

(10)

most

fe

in

clamping

is

NT

and

lower

posi-

screws ( 1)

from

screws

4)

Install Gauge

oose

ARM

down

, loosen lock-

the

If

worn

and

end

of

gauge

Hold

this

and

too

(7). Re-

contact

play.

as

re-

with the

downward

most up-

should

it

fails to

arm

are

. Parts

of

the most

knife

[f

the belts are

point

l

the

poi

nt

sively.

If

adjustmenr

carrier to

cap

from

th

rough

spacer (

nut

(15).

wrench

tion

position.

When spacer

hold spacer in

and

plastic cap.

CHECK ST

(8)

ON

With new belts on

feel

er

downward

is

in the

of

the

knife will

belts

are

of

the

knife will

up

position.

tu be for

hole

in

14

)

from

Turn

#6153

and

cou

nter clockwise

One

is

tighten l

SHARPENER

gauge

OP

#14

ocknut

SCREW

position

most upward

too

hig

too

low,

round

is

necessary , raise belt

screw

tube

(13)

turning, remove

spacer clockwise

to

raise

turn

adjusted

position,

SHOE

carrie

~Cl-

27

and

posi

h, the

not

Remove plastic

adjusts

(

bottom

sharpen,

the

bottom

off

shaft. Use

to

prevent

bottom

to

use pin to

re-assemble

15

).

Re

r, insert .010

between

the

tion

exces-

pin

lock

with

posi-

lower

1/32".

place

stop

screw

.

clamping

from

if

-

Sharpener

should

an

d knife.

loosen

proper spacing and r

CHECK

OF

BEVEL

Bevel should

on

b

oth

new

belts.

cil.

Run

era

l times.

for

Flex-Pad

over

the belt

end of

bevel,

bevel.

ALL SP

ENER ADJUS

TAINED BY ORDE

#82

0C2.

and

knife and be sure th

arm

(10) has

just

locknut

WID

sides. lnstall new knife

sharpener

tool

to

ECIAL

shoe

fill

space

If

adjustment

(9)

TH

ON

KNIFE

be

approximately

Color

If

adjustme

shoes

guide pad

to

the

the

front

TOOLS

TMENT CAN

been

(11). The gauge

between screw

is necessary,

adjust

set

etighten locknut

bevel

with

up and

nt is required:

insert

T

and

rear

to

increase

to

decrease

FOR SHARP-

RING TOOL

released

screw

1/16"

and

blue

pen-

down

sev-

ool

#6226

move free

the

the

BE OB-

KIT

at

to

.

CHECK

DOWN POSITION

Correct

of

on

EXTREME

down

the knife

shoe (

12

OF

position

at

the

center

) when the

SHARPENER

is

having the

of

the belt

belt

carrier

is

fastma

rip

in

4

IITiliT8

COMPAN

775!1

BUFFALO,

WASHINGT

NEW

ON

YC~I(

hiir8

Y

ST'~EET

14203

FOR

BEST

RESULTS

USE

ONLY

EASTMAN

KNIVES

Th

e guarantee

covering

your

Ultronic

St

raight

knife

is

not

valid

if

knives other

than

those

manufactured

by

Eastman

are u

sed

.

KNIFE I TYPE

S

IZE STEEL

Carbon

5"

5"

High Speed

Special Alloy

5"

6"

Carbon

6"

High Speed

6"

High

6"

7"

7"

7"

8"

8"

8"

9"

9"

9"

1

0"

10"

10"

1 1Y."Carbon

11Y." High Speed

1

3"

1

3"

Speed

Special

Alloy

Carbon

Hig

h Speed

Special

Alloy

C"arbon

High Speed

Special

Alloy

Carbon

High Speed

Special

Alloy

Carbon

High Speed

Special

Alloy

Carbon

Hig

h Speed

OF

STRAIGHT

KNIFE

80C5

80C5HS

80C5SA

80C6

80C6HS

80C6SA

80C7

80C.7HS

80C7SA

80C8

80C8HS

80C8SA

80C9

80C9HS

80C9SA

80C 10

80C 1

0HS

80C10SA

80C11Y,

80C

11

Y.HS

80C 13

80C13HS

WAVE

KN

I FE

80C5

-

19

80C5-1

9HS

80C6-19

80C6-19HS

9HS

80C6-1

80C7-

19

80C7-19HS

80C8

-19

80C8-19HS

80C9-19

80C9-

19H

S

80C 10-19

80C10-19HS

%-19HS

80C11

-G*

*-

Grooved

G

Wave

5

v

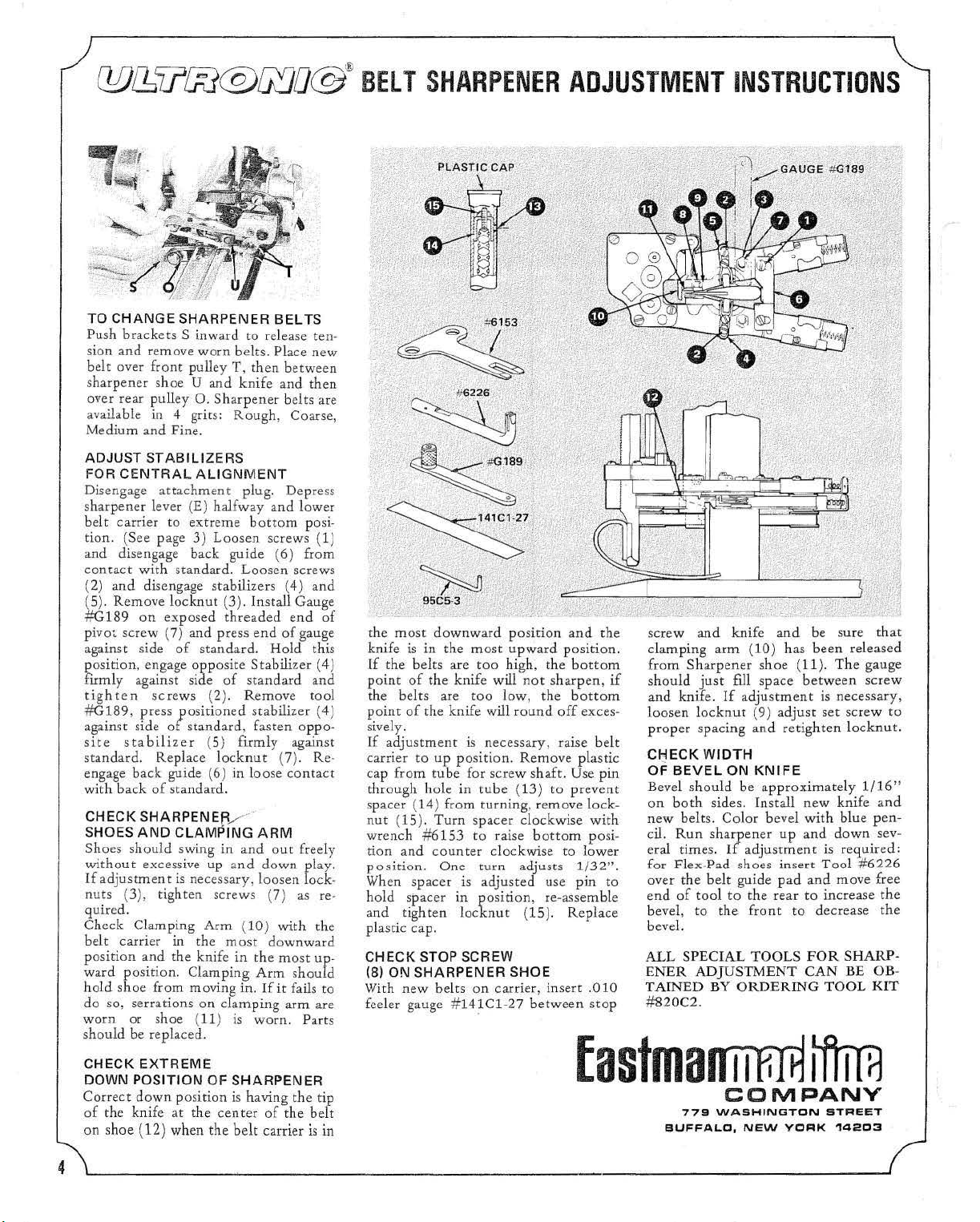

TO REMOVE SHARPENER

Pre~s

lever E

down

approximately

to neutral

sharpener

.--

v

E

----

If

lever

neutral pos

brack

et.

by

E is

To

position

hand.

--

pressed

ition) it

releas

NOTE----------,

will lo

e,

and

too

far

ck

lift lever

halfway

low

er

down

(beyond

the

sharpene

D an d s

the

tart

r

over.

0 -

--

V

--~~

=<:::::t

~

v

Remove guid

to

a n

eutral

to

original

hold

(top)

down

e bracket. Press lever E

position

and

raise sharpener

position. Remove four

nuts V and

remove

sharpener

.

:

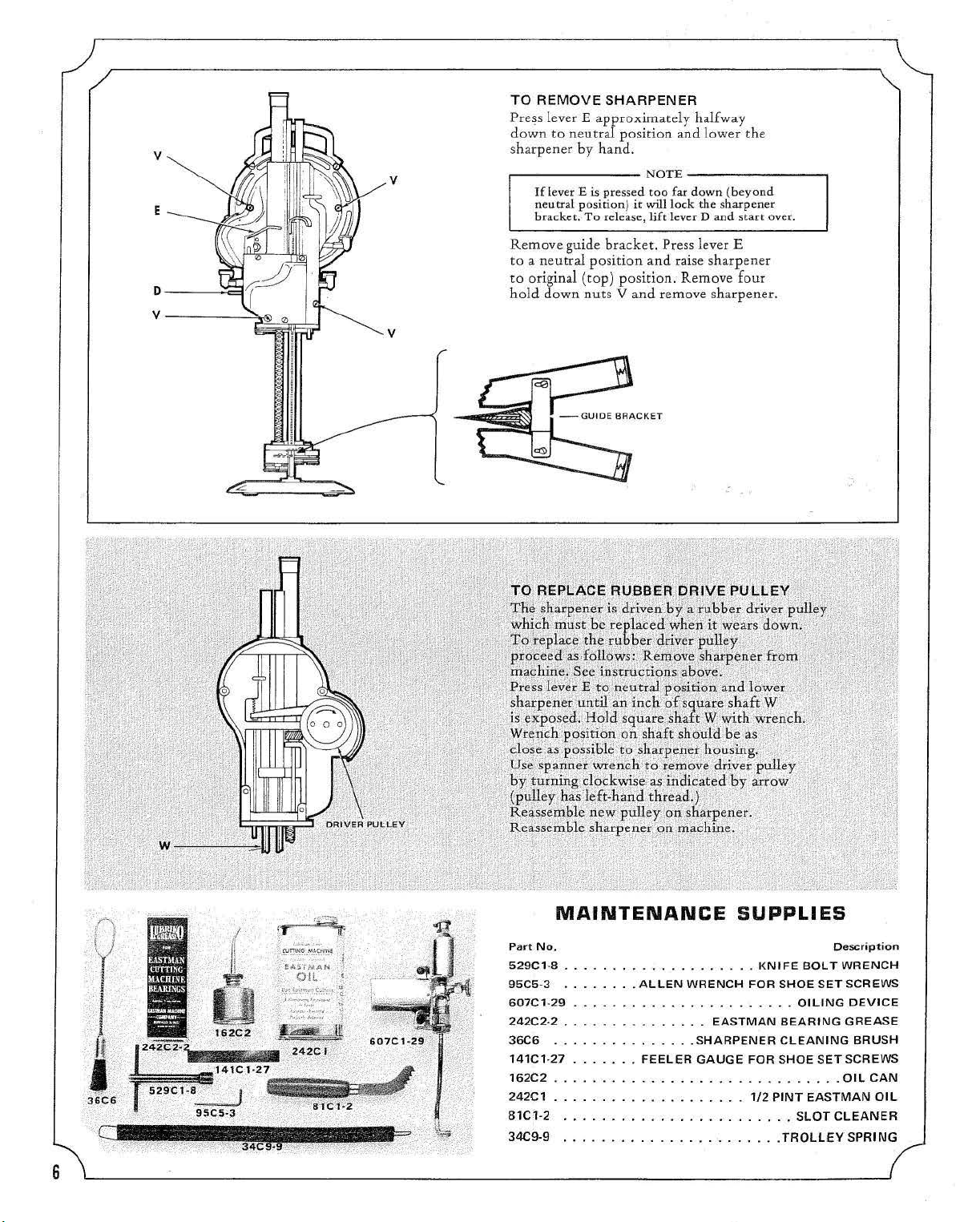

MAINTENANCE

Pa

rt No.

529C1·8 ...

95

C5·

3 •

.•.

607C1·

29

242C2

·2 ...

36C6

. .

......

141C1-27

162C2 ......

242C1

81C1

34Cg..9 .......•

. .

....

·2 .•....

6

. .

.

..

.. ..

.

...

.

.......

.

ALLEN

. . . ....

. .

......

.......

FEELER

..........

..•..

...

. . . ..•. .

..

. . . . • . .

SUPPLIES

..

... KNIFE

WRENCH

.....

SHARPENER

GAUGE

....... 1/2

FOR

. .

EASTMAN

FOR

.............

.......

...

. . .

BOLT

SHOE

.•.

OILING

BEARING

CLEANING

SHOE

PINT

EASTMAN

SLOT

TROLL

Descript

WRENCH

SET

SCREWS

DEVICE

GREASE

SET

SCREWS

OIL

CLEANER

EY

SPRING

ion

BRUSH

CAN

OIL

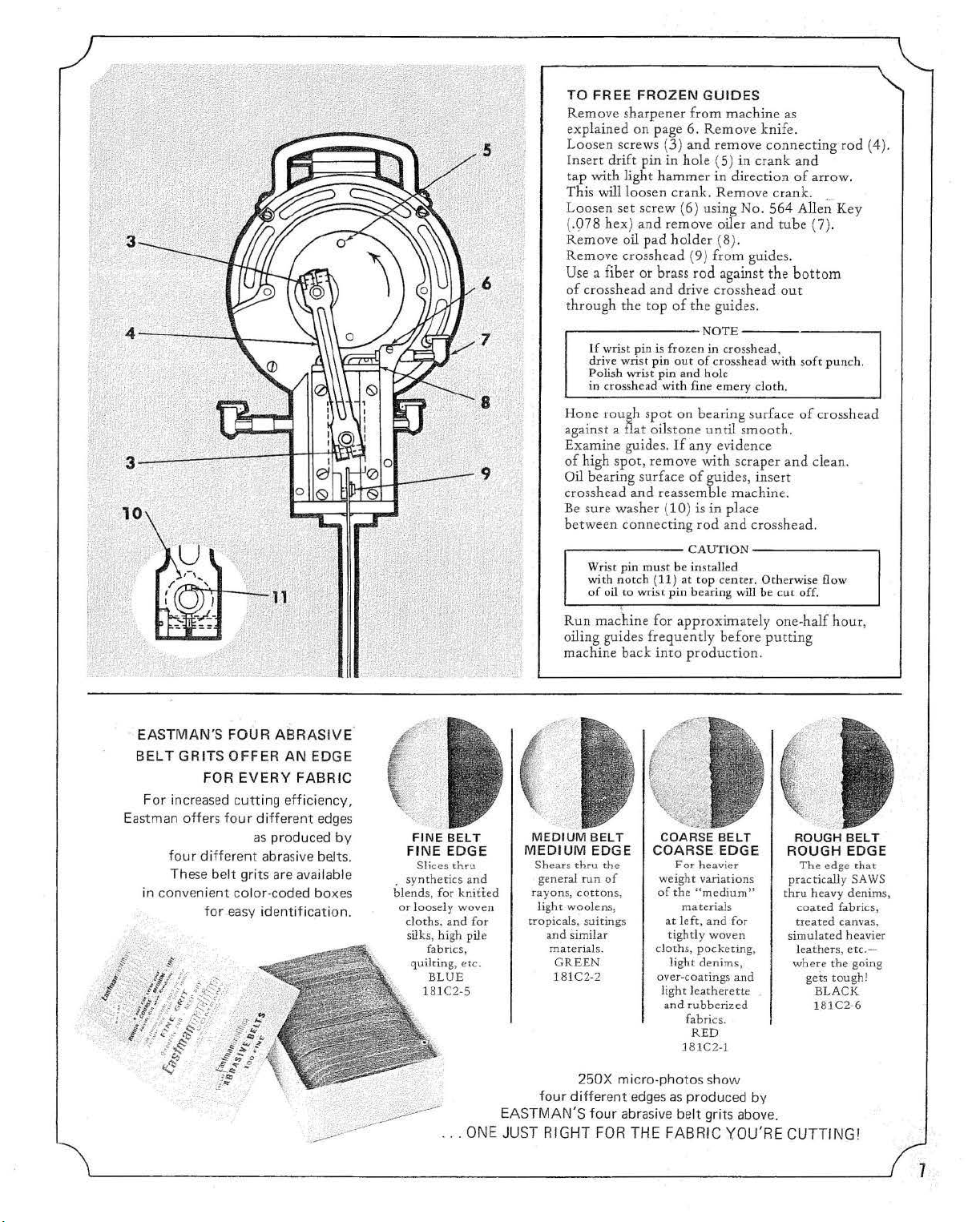

TO

FREE

Remove

sharpener from

explaine d

Loosen

Ins

ta

This

Loosen

ert

drift

p with

wil

screws (3)

light

l

loosen

set

(.978 hex)

Remove oil

FROZEN

on

page 6. Remove knife.

pin

screw

and remov

pad

GUIDES

mac hine

and

remove

in

ho

le ( 5)

in

hammer

in

crank. Re

direction

move

(6) using No. 564

e oil

er

holder

(8).

connecting

crank

crank.

and tube (7) .

Remove crosshead (9) from guides.

Use a fiber

of

crossh

through the

r---

Lf

drive wrist

Po

i.n

or

brass

ead

and

top

----------

wrist

pin

is frozen in

lish WTist

crosshead with

pin

pin

rod

agai

nst

drive crosshead

of

the guides.

--N

OTE

--------------~

cross

out

of

and hole

fme

h e

crosshead

emery cl

the bottom

ad,

with

ot

h.

as

and

of

arrow

Aile~

out

soft punc

rod

K

(4 ).

.

ey

h.

EASTMA

BELT

F

Ea

stman

in conveni

N'S

FOUR

GRITS

or

increased

four different abrasive belts.

These belt grit

offe

FOR

rs f

ent

for

OFFER

EVERY

cutting

our different

as

color-coded boxes

easy identi

ABRASIVE

AN

EDGE

FABRIC

eff

iciency ,

edges

produced

s are

available

fication

by

Hone rough

nst

agai

Examine

of

high

Oil

bearing surface

crosshead

Be su re washer

between

.-------

Wrist

with

of

Run

machine for

oiling guides

machine

.

.

: f.

'

(

FINE

BEL

ces

thru

for

hig

h pile

fabri cs,

BL

UE

T

and

kniti:ed

woven

for

etc.

FI

NE EDGE

Sli

.

synthetics

blends,

or l

.

oosely

cloths, and

silks,

qu

ilting,

181C2-5

MEDIUM BELT

MEDIUM

Shears

general

r

ayons, cott

light

trop

icals

and

m

thru

run

woolens

, suitings

similar

at

erials.

EDGE

GREEN

l81C2

-2

spot

on beari

a flat oilstone

guides.

spot,

If

remove

an

d reassemble machine.

(10) is in p

connect

pin

notch (11) at

oil to

'

ing

must

be installed

wri

st

pin

approximately

freque

back into

the

of

ons

t

,

production

COARSE

COARSE

For

weight

of

the

materials

at

left,

tightly

c

loths, pockering,

light

over-coat

li

ght lcarherette

and

rub

fabrics.

ng

sur

until

face

smooth.

any eyjdence

with

scraper

of guides, insert

]a.ce

rod

and

crosshead .

CAUTION

top

bearing

---------~

cen

ter.

Othe

will

be

cut

one-half

ntly

before

putting

.

BELT

EDGE

heavier

variations

"medium"

and

for

woven

denims,

ings

and

ber

ized

of

crosshead

and

clean.

rwise

flow

off.

ROUGH

ROUGH

The

edge

practically

th

ru

heavy

coated

treated

sim

ulated heav

lea

thers,

where

geis

BLACK

1

81C2

hour,

BELT

EDGE

chat

SAWS

denims,

fab rics,

canvas,

etc

the

going

tough

-6

ier

.-

!

RED

J81C2

-1

250X mic

four

different

EAS

TMAN'S

. . ONE JUST RIGH T

four

abrasive belt

FOR

ro-pho

edges as

THE

FABRIC

tos sh

ow

prod

uced

by

grit

s above .

Y.OU'RE CUTTING'

7

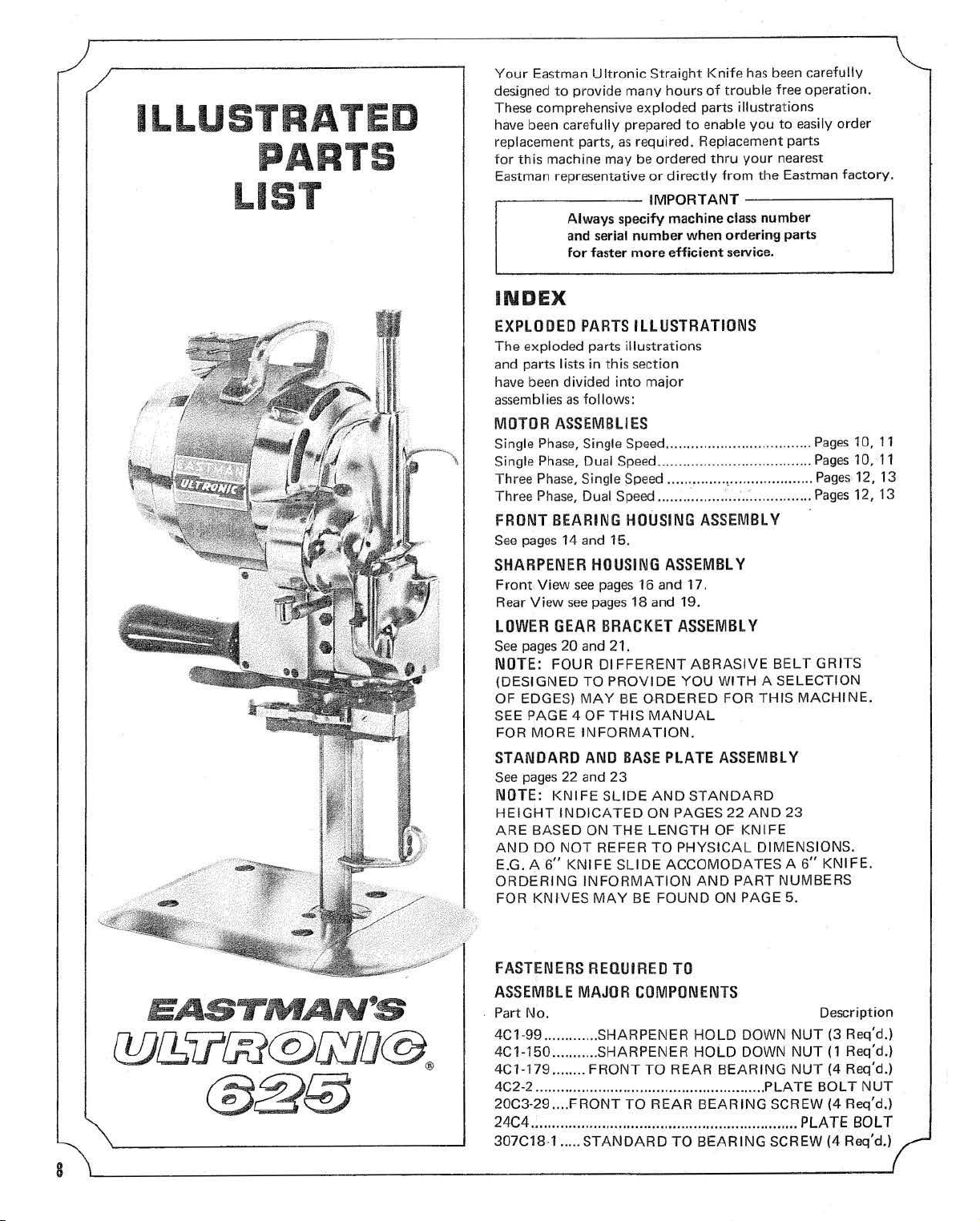

ILLUSTRATED

PARTS

LIST

You

r Eastman

designed

These comprehensive exploded parts illustrations

have been

re

placeme

for

this

Eastman repre

.--------I

Ult

ronic Straight

to

provide

carefully

nt

machine

Always specify machine

and

for

parts,

se

ntat

serial

faster

many

hours

prepared

as

required. Replacement parts

may

be ordered

ive or

directly

MPORTANT---

number

more

efficient

Knif

e has been caref

of

trouble

to

enable

thru

from the Eastman

class

when ordering parts

service.

free operation.

you

to

your

nearest

number

easily order

---

INDEX

EXPLODED

The exploded parts illustrations

and parts lists in

have been divided

assemblies

MOTOR

Single

Single

Three

Th

ree Phase, Dual Speed ................ : ....................

FRONT BEARING

See

pages

SHARPENER

Front

View see

Rear

LOWER

See

pages

NOTE:

(DESIGNED TO PROVIDE

OF EDGES)

SEE

PAGE

FOR

MORE

STANDARD

See

pages

NOTE:

HE

IGHT

ARE

BASED ON THE

AN

D DO

E.G. A

ORDERING

KNIVES

FOR

PARTS

as

follows :

ILLUSTRATIONS

this

section

into

major

ASSEMBLIES

Phase,

Single Speed ...................................

Phase,

Dual Speed ...................................

Phase, Single

14 and 15.

View

see

GEAR

20 and 21.

FOUR Dl

4 OF THIS M

22 and

KNIFE

INDICATED

NOT

6" KNIFE SLIDE

~peed

.............. , .................... Pages 12, 13

HOUSING

HOUSING

pages

pages

BRACKET

FFERENT

MAY

INFORMATION.

AND

23

SLIDE

REFER

INFORMATION

MAY

ASSEMBLY

16 and 17.

18 and 19.

ASSEMBLY

YOU

BE

ORDERED

ANUAL

BASE

PLATE

AND

ON PAGES

LENGTH

TO

PHYSICAL

ACCOMODATES A 6"

BE

FOUND

ASSEMBLY

ABRASIVE

STANDARD

AND

..

BELT GRIT

WITH A SELECTION

FOR T HIS

MACHINE.

ASSEMBLY

22

AND

23

OF

KNIFE

DIMENSIONS

PART

NUMBERS

ON PAGE 5.

ully

fact

Pages

Pages

Pages

KN IFE.

ory.

---..

10,

11

10,

11

12, 13

S

.

FASTENERS

EASTWIAN

C!!Jeb7?1X1@!1!JD@

9

S

®

®:td®

ASSEMBLE

Part

4C1

4C1-150 ...........

4C1

4C2-2 .................................................. .....

20C3·29 ....

No.

-99 ............. SHARPENER HOLD

-179 ........

MAJOR

FRONT

24C4 ...............

307C18-1 .....

8

REQUIRED

COMPONENTS

SHAR

PENER H

FRONT

....

STANDARD

TO

TO

REAR

........................

TO

REAR

BEAR

TO

BEARING

DOWN

OLD

DOWN N

BEARING

ING

......

..........

Description

NUT

(3 Req'd.)

UT

(1

Req'd.)

NUT

(4 R

eq'

PLATE

BOLT

NUT

SCREW (4 Req'd.)

.....

PLATE

SCREW (4 Req'd.)

BOLT

d.)

Loading...

Loading...