Eastman L9E000MS Parts List

EASTMAN

Table of Contents

Safety Information ....................................................... 3

INSTALLATION ............................................................. 4

Conveyor Preparation .................................................. 4

Place Machine on Table .............................................. 4

Cables and Airline Installation ..................................... 4

Machine Familiarization .............................................. 5

EasiLabel Labeler Familiarization ................................ 6

Touch Screen Display Terminal (UIT) Familiarization ... 7

OPERATION .................................................................. 9

Zero Table (Machine Home Position) ........................... 9

Loading New Files for Cutting/Labeling ........................ 9

Load Material .............................................................. 9

Label Threading ........................................................... 9

OPERATING ADJUSTMENTS ..................................... 10

Label Tension Adjustment ......................................... 10

Label Air Pressure Adjustment .................................. 10

Machine Options: System Tab .................................. 10

Machine Options: Labeler Tab ................................... 10

SERVICE AND MAINTENANCE .................................... 11

Recommended Spare Parts List .................................11

LABELER v1.2 LABEL PRINTING SOFTWARE .......... 12

GLOSSARY ................................................................. 16

Pictorial Index, Eagle Labeler ....................................... 18

Labeler Gantry ............................................................. 19

Gantry Assembly ......................................................... 20

Main Tube Assembly.................................................... 22

Y-Car Assembly ........................................................... 24

Y-Car Assembly, Fiber Labeler ..................................... 26

Labeler Head Common Parts ....................................... 28

2" Labeler Head Assembly ........................................... 30

4" Labeler Head Assembly ........................................... 32

2" Labeler Head Assembly with Fiber Option ................ 34

4" Labeler Head Assembly with Fiber Option ................ 36

Labeler Diagnostic Cabinet ........................................... 38

Wiring Diagram Blue Print No. (31-9000-13, 1 of 7) ... 41

Wiring Diagram Blue Print No. (31-9000-13, 2 of 7) ... 42

Wiring Diagram Blue Print No. (31-9000-13, 3 of 7) ... 43

Wiring Diagram Blue Print No. (31-9000-13, 4 of 7) ... 44

Wiring Diagram Blue Print No. (31-9000-13, 5 of 7) ... 45

Wiring Diagram Blue Print No. (31-9000-13, 6 of 7) ... 46

Wiring Diagram Blue Print No. (31-9000-13, 7 of 7) ... 47

Pnuematic Diagram Print No. 31-9000-28 ................. 48

Trouble Shooting Guide ................................................ 49

TECHNICAL DATA ....................................................... 50

IMPORTANT

The purchaser must instruct all operators on the proper use of the equipment.

All standard industrial safety measures and equipment should be provided to

protect the operator. Operators must be cautioned that improper or careless

use of this equipment may cause personal injury. If you do not have qualified

operators to instruct new persons, contact your Eastman sales representative

or Eastman factory direct.

Disconnect electrical power from source before proceeding with any installation, adjustment or repair of the EasiLabel Labeler.

Your Eastman EasiLabel Labeler Print Head is designed to travel at high speed

in both directions. Equipment should be set up with a minimum 3 foot (1 meter)

clear path at front and rear of machine. All personnel should be instructed to

wear safety glasses and stand well clear of the EasiLabel Labeler when in

operation.

2

Form E-533

Safety Information

Throughout this manual, safety information is presented by

the use of the terms WARNING, CAUTION, and NOTE.

These terms have the following meanings:

WARNING

A warning contains critical information regarding

potential safety hazards that can occur during proper

use or misuse of the machine. Failure to follow these

procedures may result in serious personal injury to

the user.

CAUTION

A caution contains instructions for the use or maintenance of the machine. Failure to follow these procedures may result in damage to the machine.

Supplementary information may be given in a Note.

ELECTRICAL HAZARD

An electrical hazard calls attention to a procedure,

practice, or the like, which, if not correctly performed

or adhered to, could result in personal injury. Do

not proceed beyond a Electrical Hazard.

Safety and Indemnification

During the life of the machine, the purchaser agrees

to provide to all machine users (including its own

employees and independent contractors) all relevant

safety information, including warning labels and instruction manuals. The purchaser also agrees to

maintain the safety features and working condition

of the machine, and to adequately train all users in

the safe use and maintenance of the machine. The

purchaser agrees to defend, protect, indemnify, and

hold Eastman Machine Company and its subsidiaries harmless from and against all claims, losses,

expenses, damages, and liabilities to the extent

that they have been caused by the purchaser’s failure to comply with the terms and instructions of

this manual.

General Safety Precautions

WARNING

• This machine is equipped with fast moving labeler

head. Keep hands, arms, and hair away from the

labeling area and drive system at all times. Safety

gloves, glasses, and appropriate clothing may prevent serious personal injuries.

• Disconnect the power supply to the machine when

it is not in use or during routine maintenance, including cleaning and lubrication.

• The purchaser must instruct all operators in the

proper use of the machine according to the instructions in this manual. This training must include instruction on the potential safety hazards arising from

the use or misuse of the machine. In addition to

such training, the purchaser should provide written

work instructions as necessary to ensure correct

use of the machine for specific cutting applications.

• Do not modify this machine or disable safety features. Unauthorized modification may result in serious personal injuries to the user. Electrical connections to this machine must be made by a qualified electrician familiar with applicable codes and

regulations.

• Safety labels must be kept clean and legible at

all times. Call the Eastman Machine factory to

order replacement labels.

Form E-533

3

EASTMAN

The Eastman EasiLabel Labeler is shipped partially disassembled with all the necessary parts for proper setup and

operation. To get the best performance, familiarize yourself

with all the functions and adjustments of this equipment.

Before any operation can take place, it is important that you

carefully read and follow the instructions in this manual in the

same sequence in which they are presented.

INSTALLATION

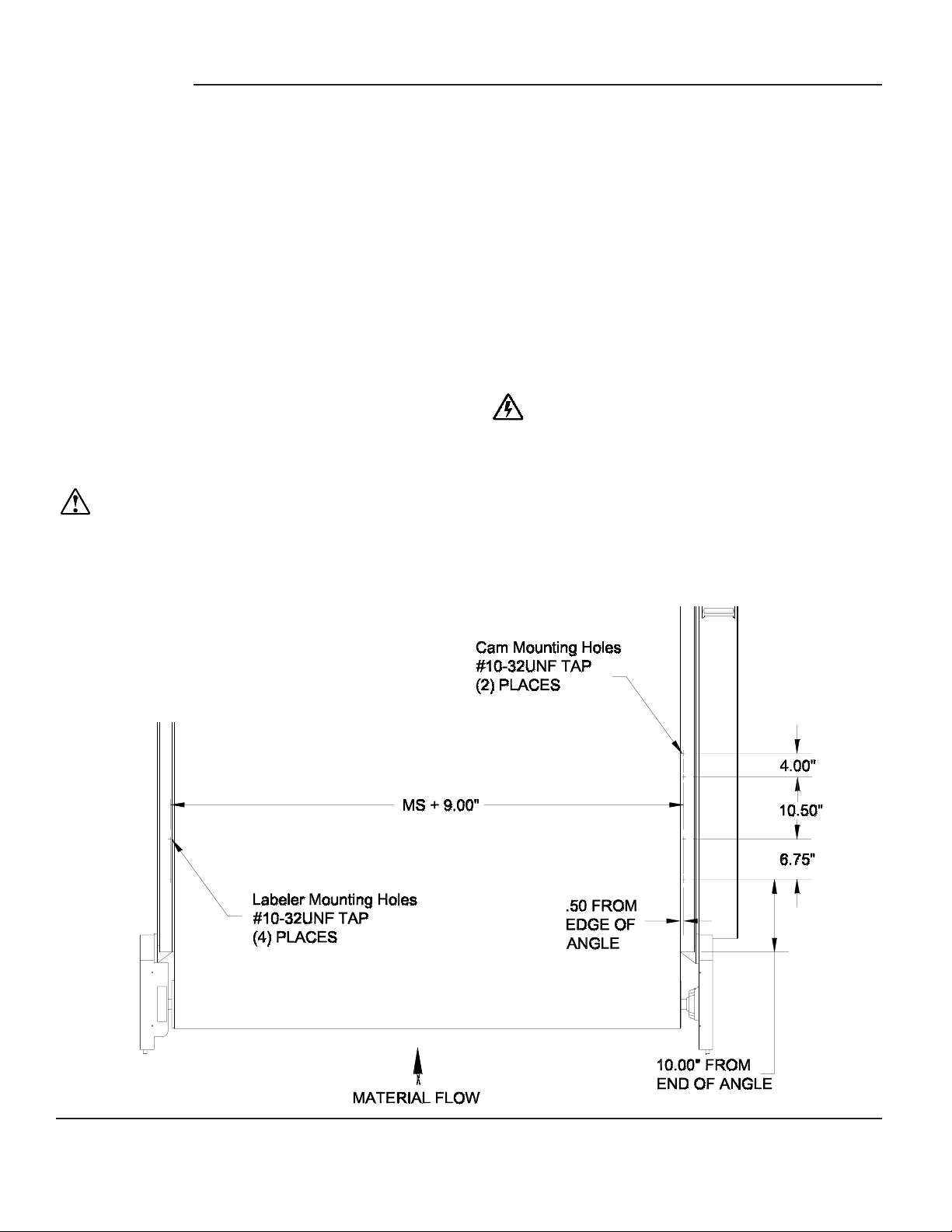

Conveyor Preparation

The Eagle Conveyor should be completely installed before

the EasiLabel labeler is mounted on the conveyor. If the

conveyor is not installed, Install it at this time.

Place Machine on Table

The EasiLabel Labeler weighs approx. 200 lbs. (90 Kg.)

uncrated for a 72" machine. Wooden braces are strapped

across the underside of its cross tube and the forklift arms

should be raised to those braces when machine is lifted.

CAUTION

When placing forklift arms under cross tube, use care

not to damage tube or cover.

Cables and Airline Installation

Locate five (5) labeler wiring cables and one (1) air line.

Secure the wiring cables and air line to the non-operator side

of the labeler. The cable ends are labeled for proper installation.

Feed the cable and air line under the conveyor and through

the yellow/black floor cable protector. Match the cable the to

mating connector and secure cables in place.

1 cable to computer.

1 cable to a power supply.

3 Cables to the Diagnostic Cabinet.

Note: Voltage varying more than 10% (11V for 110V ma-

chine, 22V for 220V machine) may damage your

system’s electronics.

The EasiLabeler requires 20 - 30 PSI compressed air.

Connect air line to air supply.

Locate the labeler mounting holes on each side of the

conveyor. If the holes are not predrilled, use the diagram

below to drill and tap holes as shown. Place the EasiLabel

Labeler on the conveyor. Secure the labeler to the conveyor

with mounting hardware provided.

4

Form E-533

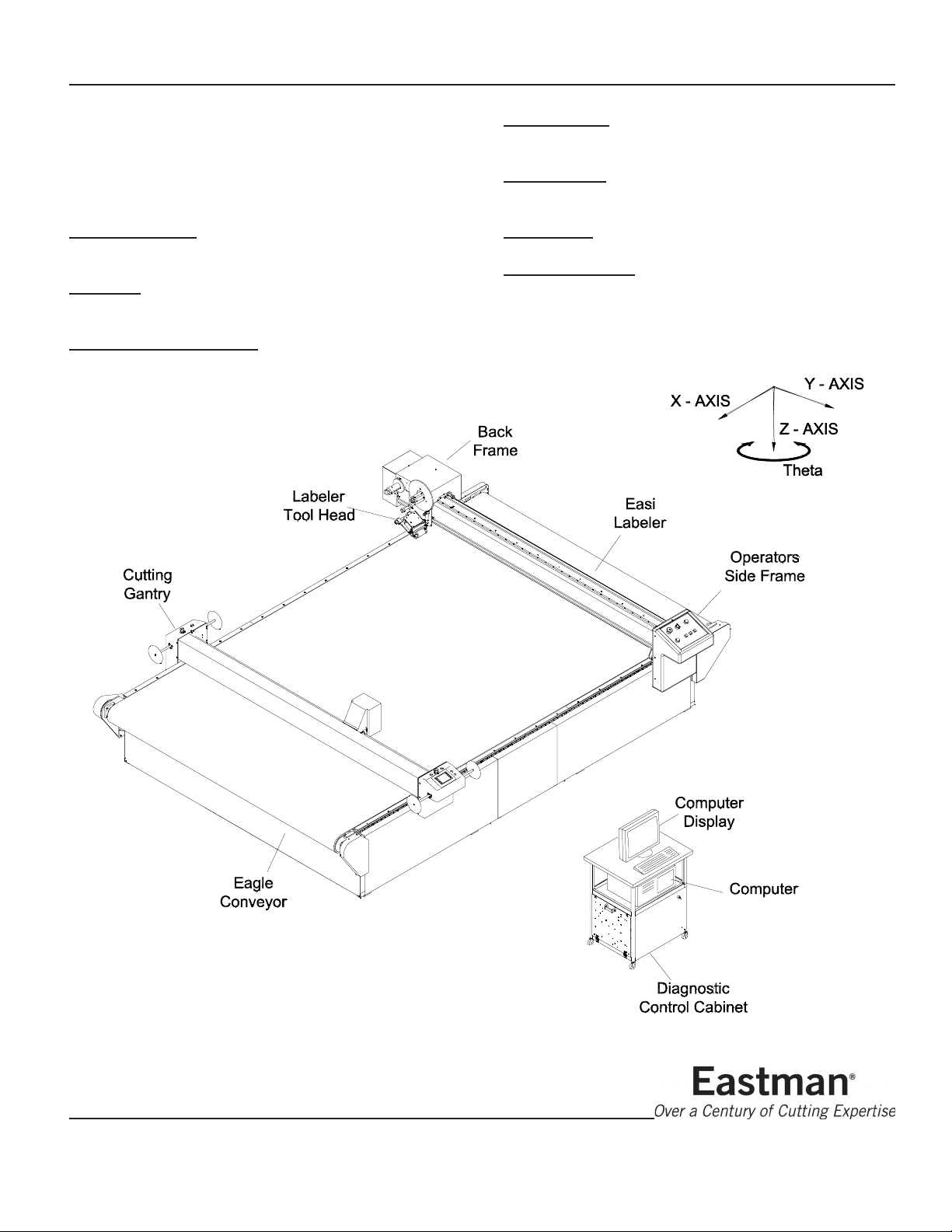

Machine Familiarization

The EasiLabel Labeler is controlled automatically through

the computer software. Manual controls are located on the

labeler front control panel and used in conjunction with the

controls on the cutting gantry control panel.

Eagle Conveyor: Machine used to advance material. Equipped

with cutting surface drive belt.

Cutting Gantry: Machine used to carry the cutting tool head

and manually control the EasiLabel Labeler.

Computer Display: Display used for setup and run of your

Gantry, conveyor and labeling system.

Computer: Stores running programs and user labeling files.

Disk drive available for loading labeling files.

Diagnostic Control Cabinet: Electronic controls for gantry,

conveyor, and Labeler.

Easi Labeler: Machine used to carry the labeler tool head.

Labeler Tool Head: Tool used to apply labels to material.

Available in various label sizes.

Form E-533

5

EASTMAN

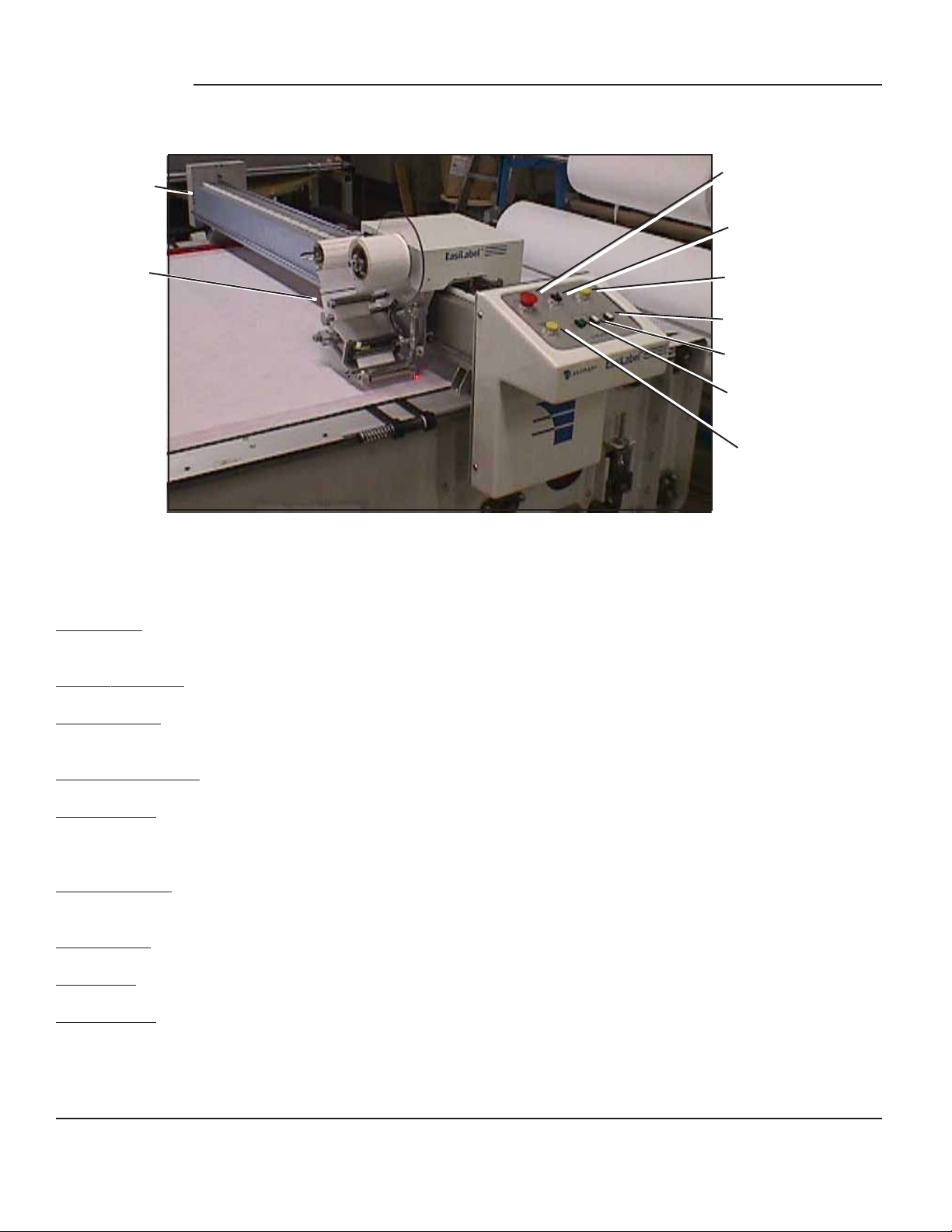

Back

Frame

Labeler

Tool

Head

EasiLabel Labeler Familiarization

Back Frame: Non-operator side of labeler. The air pressure

regulator is located under back cover.

Emergency

Off

Main Power

Off

System

Pause

Take-up Roller

On/Off

Label Feed

On/Off

Labeler

On/Off

Labeler

Reset

Labeler Tool Head: Tool used to apply labels to material.

Emergency Off: Activates power to all drive circuits. Pull on,

push off.

Main Power On/OFF: Activates power labeler gantry.

System Pause: Push to pause (stop) complete system when

in automatic labeling/cutting mode. Press NEXT on UIT to

resume.

Labeler Take-up: Press to activate power to label take-up

spool.

Labeler Feed: Press to manually feed label.

Labeler On: Press to activate labeler tool head.

Labeler Reset: Press to Initialize printer.

6

Form E-533

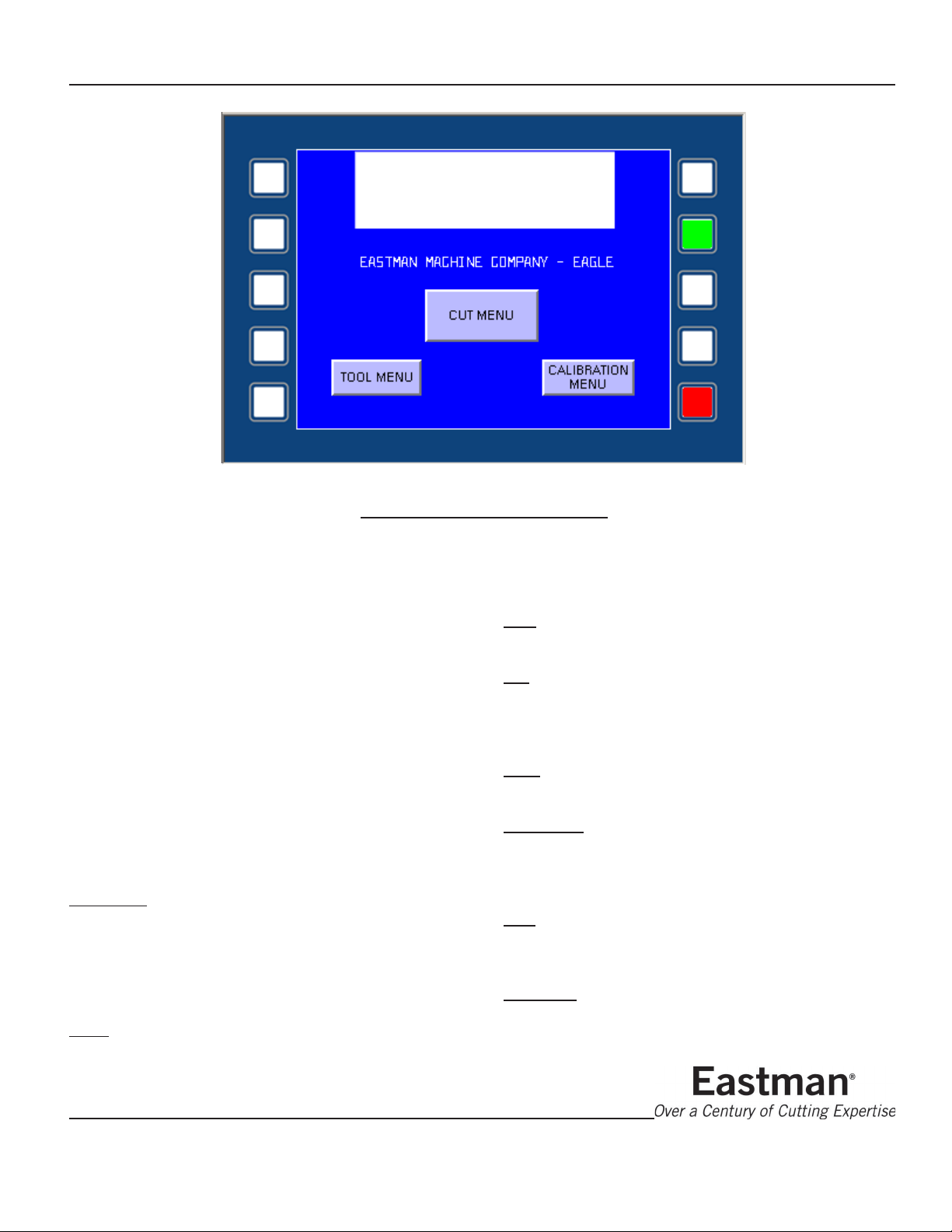

Main

Zero

Panel

Key

Board

Cut

Menu

Tool

Menu

Option

Touch Screen Display Terminal (UIT)

Touch Screen Display Terminal (UIT) Familiarization

(Located on the cutting gantry)

The Touch Screen Display Terminal features a user friendly

graphic display touch screen panel with 10 hard coded buttons and many soft coded buttons. Commands are issued

via the touch screen and communicated back to the computer, conveyor and labeler. Through the touch screen the

operator may position the gantry tool head, move the conveyor belt, enable automated movement, and manually cut

and mark.

Commands are sent to the computer by pressing buttons

and graphic commands shown on the display. Following the

visual instructions will allow access to the desired menu

and command. A description of the command are as follows:

Zero Table: Pressing the ZERO TABLE key activates the

zeroing function. The carriage will move to the home limit

switches in X, Y and Z and then move the distance of the X

Y and Z home offset values in the Machine Setting menu in

EasiCut. This point is set as table home. The Labeler tool

head will move to the home position.

Scan: Pressing SCAN allows the user to scan to a specific

panel within the current cut file . Press SCAN and the UIT

will prompt for a panel number . The UIT will automatically

go into Alt Left mode and allow the user to select a panel

number. Press ENTER to load the file.

Next

Enter

Zero

Table

Abort

Jog : Pressing JOG toggles the gantry manual move speed

to the VELOCITY value in Machine Setting.

UP: Pressing UP causes the gantry carriage to move in the

positive direction of the Y axis. The carriage will move as

long as the key is pressed down ( or until the carriage encounters an end stop).

Next: Pressing NEXT causes the gantry to cut and or draw

the active panel in the current cut file.

Zero Panel: Pressing the ZERO PANEL key resets the internal counters so that the local home position is set to the

current gantry position. The Z-axis is rotated and reset to

0_.

Pen: Pressing the PEN key toggles the gantry pen device

to change its current state of either up or down causing the

pen to drop or lift. The default pen device state is up.

Cut Down: Pressing the CUT DOWN key causes the primary cutter to drop to the cutting surface.

Form E-533

7

EASTMAN

Down: Pressing DOWN causes the gantry carriage to move

in the negative direction of the Y-axis. See UP for more

information.

Panel Home: Pressing the PANEL HOME key causes the

gantry carriage to move to the current panel home position

set either by the most recent panel zero or as set in the

current cut file.

Table Home: Pressing the TABLE HOME key causes the

gantry carriage to move to the table home position.

Rotate CCW: Pressing the ROTATE CCW key causes the

Z-axis shaft to rotate counter clockwise. The shaft will rotate as long as the key is pressed down. If toggled into limp

mode the shaft will rotate slowly.

Left: Pressing LEFT causes the gantry carriage to move in

the negative direction of the X-axis. See UP for more information.

Abort: Pressing the ABORT key will cause the gantry carriage to come to an immediate and controlled stop. Once

stopped the UIT will prompt you to either press ABORT or

NEXT. Pressing ABORT will exit from the current panel or

motion. Pressing NEXT will continue the current panel or

motion.

Offset: Pressing the OFFSET key will cause the gantry car-

riage to move from its current position to the offset position

of the primary cutter. This effectively moves the primary cutter into position over the reference point (usually the pen

device or a laser pointer).

Rotate 90_: Pressing the ROTATE 90_ key causes the Z

shaft to rotate 90_ counter clockwise from its current position.

Y Z: The Y Z key has no function value and works during

data entry in either ALT RIGHT or ALT LEFT mode to allow

input of alphanumeric characters.

Back Space: Pressing the BACKSPACE key will cause the

cursor to move one position to the left when in data entry

mode.

Alt: Pressing the ALT key toggles the current mode of the

UIT. The ALT key is only active during data entry. Pressing

the ALT key will toggle the UIT between ALT RIGHT and ALT

LEFT to allow the user to access all alphanumeric characters on each of the keys. A left or right arrow in the upper

right of the display shows the current mode.

Enter: Pressing the Enter key causes the contents of the

command line to be sent to the computer. This key is only

active during data entry mode.

Main: Pressing the Main key changes the display to the

top level menu as shown. Choose required menu from here.

Key Board: Pressing the Key Board key changes the display to show a touch screen key board. The touch display

acts as a key board to enter required characters.

Cut Menu: Pressing the Cut Menu key changes the display

to show the Cut Menu screen. This is a short cut to the cut

menu.

Rescan: Pressing the RESCAN key causes the gantry pro-

gram to reset to the top of the current panel in the current

cut file.

Rotate CW: Pressing the ROTATE CW key causes the Zaxis shaft to rotate clockwise. The shaft will rotate as long

as the key is pressed down.

Right: Pressing RIGHT causes the gantry carriage to move

in the positive direction of the X-axis. See UP for more information.

V: The V key has no function value and only works during

data entry when the UIT is set to ALT RIGHT mode to allow

input of alphanumeric characters.

. W: The W key has no function value and works during data

entry in either ALT RIGHT or ALT LEFT mode to allow input

of alphanumeric characters.

8

Tool Menu: Pressing the Tool Menu key changes the display to show the Tool Menu screen. This is a short cut to

the Tool menu.

Option: Pressing the Option key changes the display to

show the Option Menu screen.

Form E-533

OPERATION

After setup is complete and the power and airline is connected, the EasiLabel Labeler is now ready for Initialization.

Important

To stop the cutting/labeling system at any point during

operation, either:

-Press any Emergency Stop button (Red).

-Press Machine Pause button (yellow) on main control

panel.

WARNING: Machine Cut Zone should always be

cleared before any automatic cutting/labeling takes

place.

1) Turn ON diagnostic cabinet main power (yellow/red

located on the back panel of the diagnostic cabinet). This

will enable main power to diagnostic cabinet.

2) Power up the computer and display by pressing the ON (I)

buttons. The computer display will run through the computer start-up program.

The UIT display will show "Check Table Limits?.

Press Enter to override and continue or press KeyBoard, Y

(for yes) and Enter on the keyboard to check table limits

(When checking table limits the gantry with verify the active

cutting area is available).

The UIT display will show "Ready" or "Table Limits OK" when

task is complete.

Loading New Files for Cutting/Labeling

Load a file by opening the file menu and clicking on the

desired file. See label design software section for label design details. Select the "PLOT" icon on the computer display to load design.

Note: Files are organized by type and are displayed on the

menu according to which type is selected. For example,

if you wish to use a file generated in CMD format, open

the list files of type menu and select CMD. The file

menu will then display all files with a CMD extension.

3) Enable power to the Gantry/Labeler by turning the ON (I)

button (green), located on the front panel of the diagnostic

cabinet.

4) Pull the Emergency Stop buttons for the cutting gantry and

the labeler to activate power to the drive circuit.

5) Turn On labeler main power by turning the ON (I) button

(black), located on the front panel of the labeler.

6) Press the labeler ON button (green) to the on position

(in).

7) Press the labeler Take-up button (red) to the on position

(in).

Start the EasiCut software by double clicking the EasiCut

software icon on the computer display. The log in screen

will appear. Enter the user name and password. Select OK

when complete. This will load the default test.cmd file. The

touch screen terminal display will show DESIGN LOADED.

Zero Table (Machine Home Position)

Press ZERO TABLE on UIT Terminal to locate the “cutting

machine home position”. This will accelerate gantry to the

end limit switches and back to “machine home position”.

The labeler print head will move to locate the "label home

position".

Load Material

Load material onto conveyor and under labeler. The labeler

laser pointer is the location of the first cut pattern.

Move the labeler laser pointer in/out to locate the start/cut

position on the material. Press "Zero Panel" to accept.

Turn on the cutting tool switch and the conveyor vacuum.

Press the "Next" button on the UIT terminal to begin cutting.

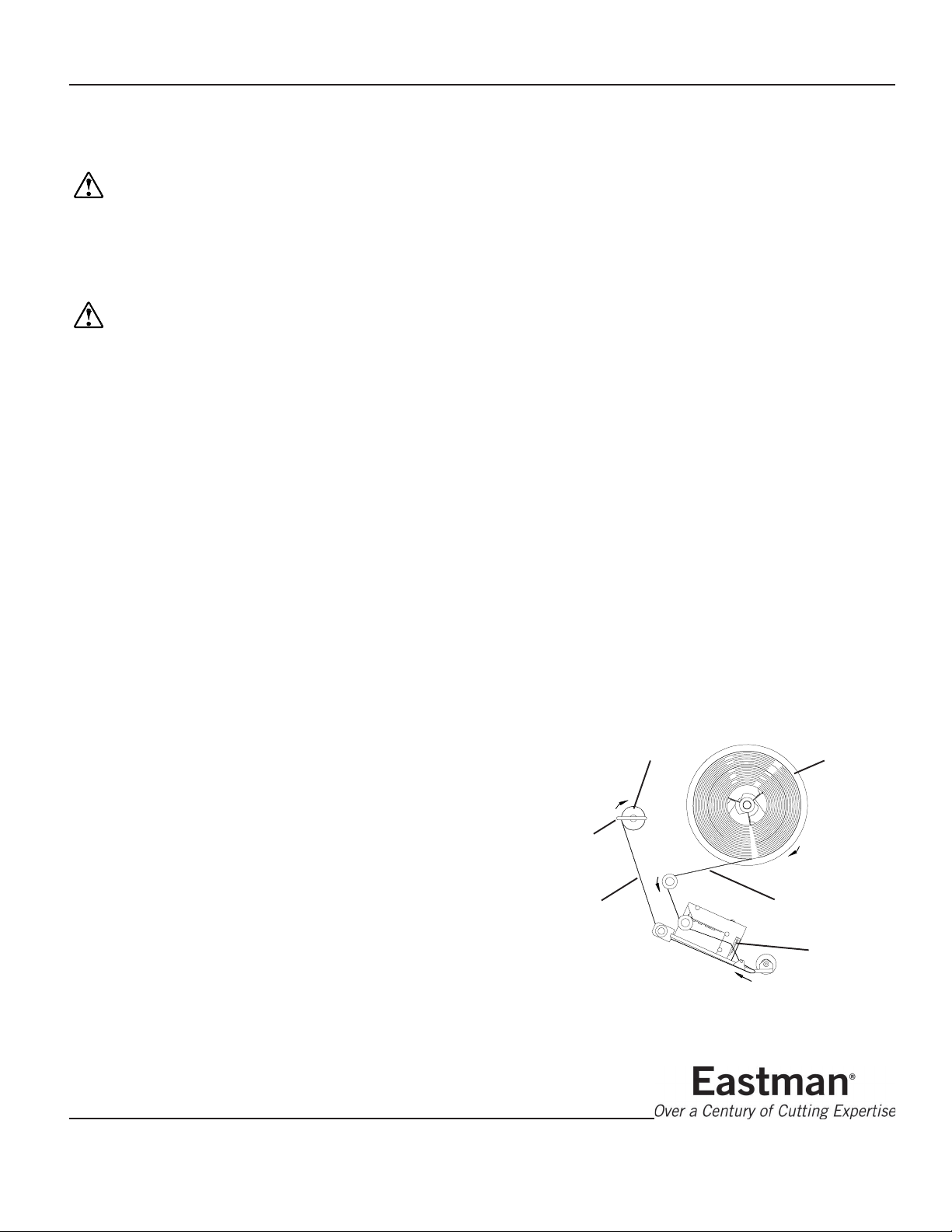

Take-up

spool

Label roll

Take-up

spool clip

Labels

Label Web

on this

side

Roller

Lever

Label Threading

Press Labeler ON (green) button to turn off printer. Press

Labeler TAKE-UP (red) button to turn off printer take-up

motor. Remove take-up spool clip. Lift the roller lever to

Form E-533

9

EASTMAN

separate the printer rollers. Discard used label web material

and label roll core. Load new label roll as shown. Release

roller lever. Press Labeler ON button to continue.

OPERATING ADJUSTMENTS

This machine is adjusted and tuned at the factory for optimal performance. No Adjustments other than normal setup

are necessary. However, if after continued use the performance level becomes unacceptable, the following procedures should be carried out before repairs are considered.

Label Tension Adjustment

The label tension adjustment is located under the labeler tool

head cover. Remove the cover to access the take-up clutch.

Rotate the knurled adjusting knob clockwise to increase and

counterclockwise to decrease tension.

Label Air Pressure Adjustment

The labeler pressure regulator is located on the back side

frame. To adjust, remove back cover. Locate the regulator

valve. Pull the "Adjust" knob up and turn clockwise to

increase pressure and counter clockwise to decrease pressure. After adjustment is made, push knob down to lock in

place.

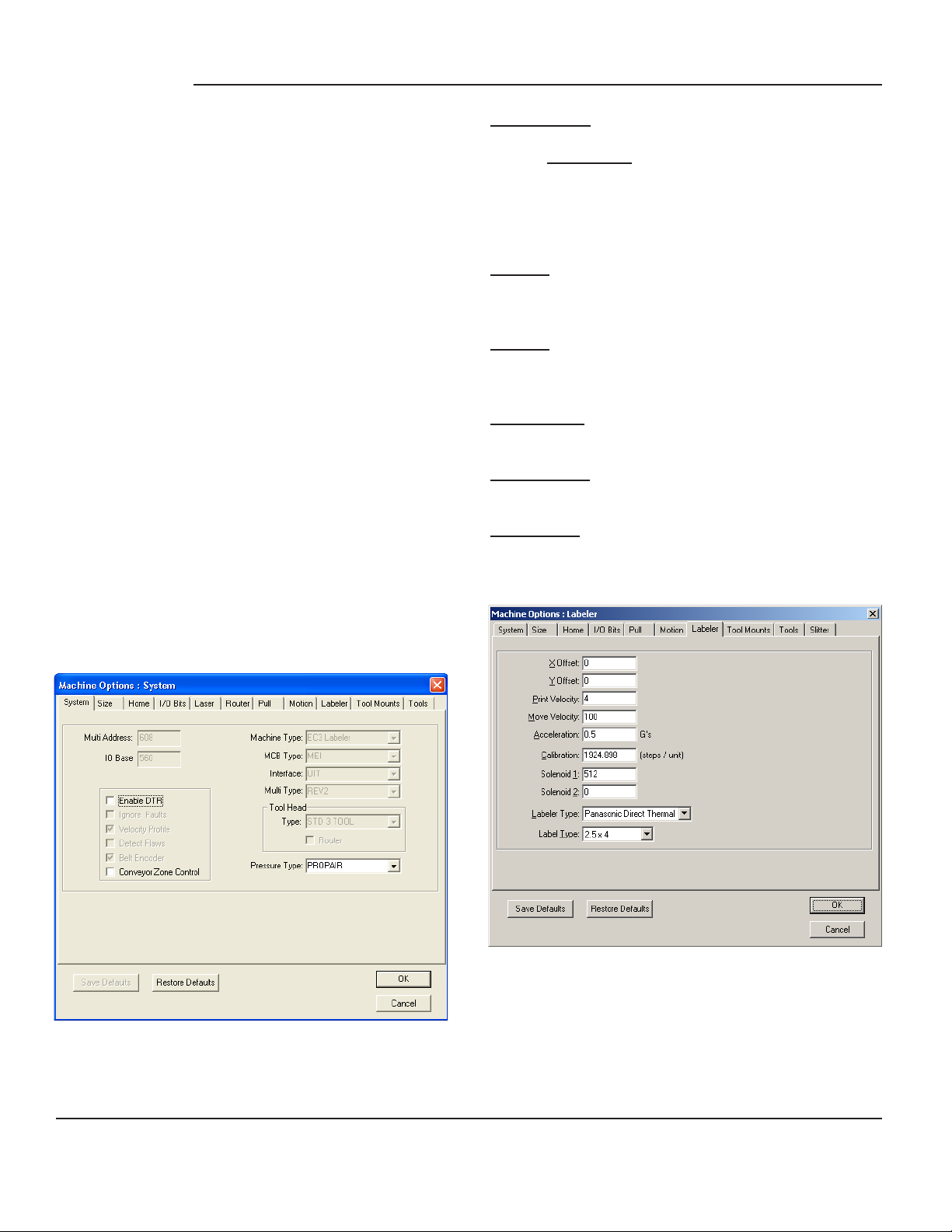

Machine Options: System Tab

The System tab is used in the initial system setup. The

system settings are factory set and no further adjustmens

are required. The labeler functions are as follows:

Machine Type: Machine Type is a setting to determine the

type and configuration of the system. The machine type

must be EC3 Labeler when equipped with a labeler.

Machine Options: Labeler Tab

The Labeler tab in used to setup and adjust the labeler

functions as follows:

X Offset: X Offset is a measure of distance from the labeler

laser pointer to the cutting gantry laser pointer in the X direction.

Y Offset: Y Offset is a measure of distance from the labeler

laser pointer to the cutting gantry laser pointer in the Y direction. Adjust as required to align laser pointer.

Print Velocity: This is the maximum velocity of the labeler

head while printing and applying a label.

Move Velocity: This is the maximum velocity of the labeler

head while moving across the gantry.

Acceleration: This is the base acceleration and deceleration number, controlling how fast the Labeler head gets up

to full speed and how fast it comes to a stop. Larger numbers increase acceleration and deceleration.

10

Form E-533

Calibration: Controls the accuracy of the Labeler head in

the Y axis relative to the cutter tool head. Expressed in

steps per unit, this variable will be preset from the factory

and should not need adjustment. A greater number will cause

the computer to output more steps to travel, causing more

movement in the Y axis length. The correct number for this

calibration may be determined by measuring the distance

the labeler head travels compared to the distance the cutter

head travels. This setting is normally the same as the cutter

Y Calibration setting.

SERVICE AND MAINTENANCE

Daily

-Blow off entire machine and Cable Carrier using low pressure

compressed air (required twice a day depending on material).

-Check safety cams for proper location.

-Lubricate Linear Bearing with oil cloth.

Weekly

-Check for unusual wear and determine why.

Solenoid 1: Bit setting for air solenoid used to apply labels.

Normal bit setting in 512. This is a Supervisor User Only

Setting.

Solenoid 2: Bit setting for air solenoid used to move down

labeler head. Normal bit setting in 1024. This is for FC style

labeler only. This is a Supervisor User Only Setting.

Labeler Type: Choose type of label. This is a Supervisor

User Only Setting.

Label Type: Choose size of label. This is a Supervisor User

Only Setting.

Save Defaults: Select to save setting as the labeler default

settings.

Restore Defaults: Select to restore settings to previously

saved settings.

Bi-Monthly

-Check entire machine for loose nuts and bolts.

Monthly

-Inspect Cable Carrier, Check for loose nuts, bolts or worn

parts.

Recommended Spare Parts List

Item Description Qty.

54-26214-4 Roller Quick Release Pin 1

54-26031-4 Spring Clip, Label Take-up Roller 1

*********** Printer (See Printer Parts List) 1

31-26165 Printer Controller Board 1

10-26043-1 Interface Board 1

10-00904-2 Labeler "Y" Board 1

10-26044-1 Labeler Power Supply Board 1

67-26069-4 Labels 4" x 2.5", 2300/Roll, 11/32 Index A/R

67-26069-4R

Labels 4" x 2.5", 2300/Roll, 11/32 Index

(Removable Adhesive) A/R

67-26069-5 Labels 4" x 1", 5500/Roll, 11/32 Index A/R

67-26069-6 Labels 1" x 2", 5500/Roll, 11/32 Index A/R

67-26069-6R

Labels 1" x 2", 5500/Roll, 11/32 Index

(Removable Adhesive) A/R

A/R -As Required

Form E-533

11

EASTMAN

LABELER v1.2 LABEL PRINTING SOFTWARE

This document provides instructions for the use of the Labeler

v1.2 label printing program (Labeler.exe). The program provides a very basic mechanism for designing and printing

sample labels. The Labeler v1.2 application is designed to

be used only with the Panasonic EPL-1700 label printer.

The Labeler v1.2 program is written as a Single Document

Interface (SDI) application. This means that only one label

file may be opened at a time. This is similar to other simple

Windows applications such as Notepad or Paint. All user

inputs are made through the options available on the main

menu bar. The application window shows an approximation

of the current label layout. There are no provisions in the

application for direct graphical manipulation of label components (e.g., drag and drop) within the label drawing.

The Labeler program saves the label design in a text file.

This text file is used by EasiCut to generate formatted label

text entities and by Plotterw to process label text and to

print labels. If the label design file is to be used by EasiCut

and Plotterw it must be named Plotter.LBL and must be in

the same folder as the EasiCut program file.

1.

Program Limitations

The Underline and Negative (white-on-black) font options in

the Label Fields dialog box do not produce the expected

printer output. These printer command codes were not properly interpreted by the printer when sent. Therefore, the Underline and Negative font options are currently not functional.

A line containing a barcode field may not contain any other

type of field. This appears to be a limitation of the printer.

Since the printer does allow feeding paper in the reverse

direction, fields on the same line may be printed in two or

more passes. However, this added complexity is not incorporated into this version of the Labeler application.

There are certain limitations that are imposed by the Labeler

software and by the Panasonic EPL-1700 printer. Some of

these limitations may just be a misunderstanding in the

way the printer functions and such limitations may be eliminated in future releases of the Labeler program.

The Page Feed option in the Label Options dialog box does

not work properly. The first label is printed correctly and the

printer feeds the amount specified in the Page Length edit

box but all subsequent printing is ignored. Printer power

must be cycled and the label paper reregistered before printing may resume. This problem may be due to the fact that

the printer’s photo sensor is detecting the registration bars

on the back of the label paper.

The Cut After Print option in the Label Options dialog box

has no effect since the Panasonic printer has no cutter

mechanism.

If the Marker Search option is selected in the Label Options

dialog box, the Feed Dist must be set to a value of 0.2 or

greater. A lower distance value causes the printer to hang

after the marker search operation has completed.

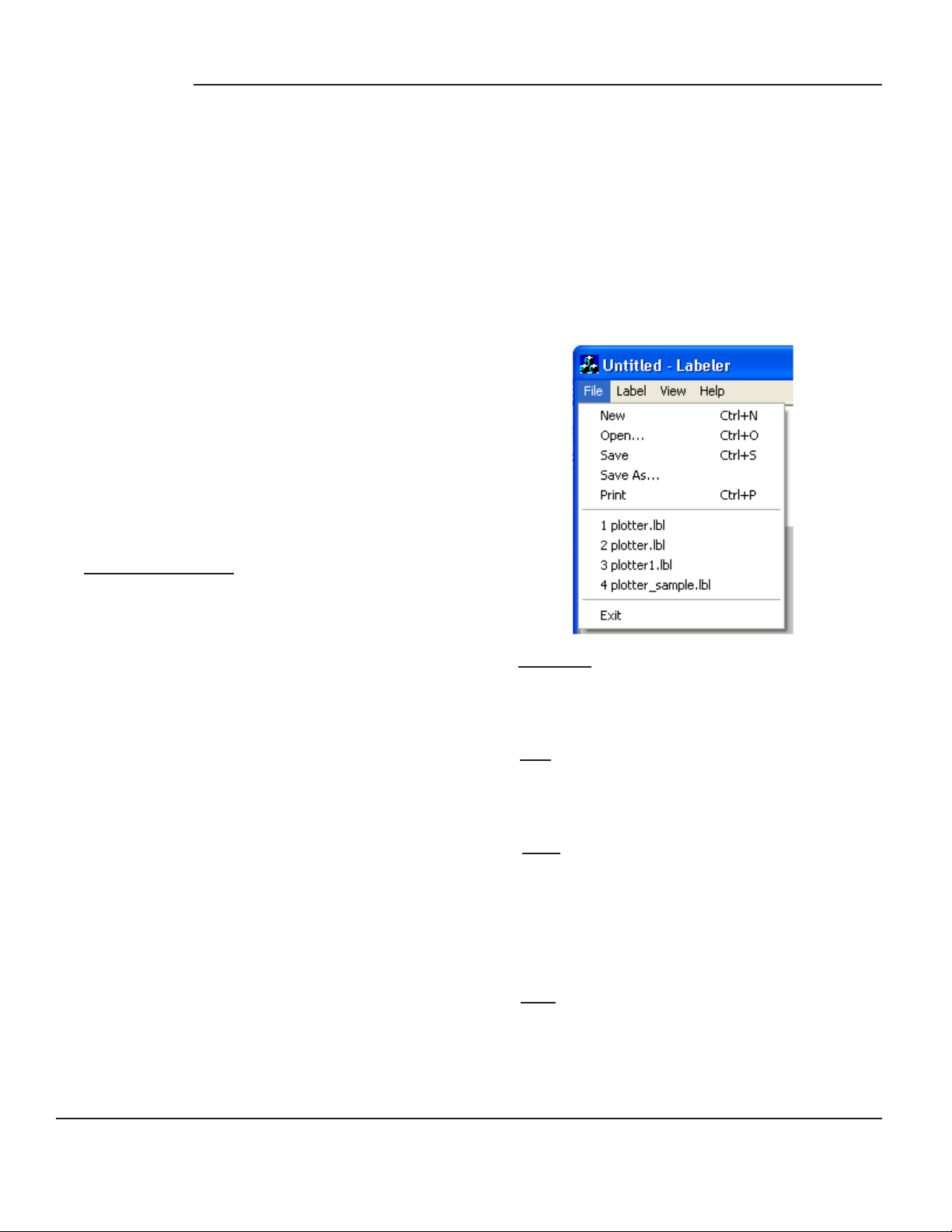

2. File Menu

The File menu includes basic options familiar to all users of

Windows based applications.

The New option erases the current label entity and creates

a new label entity with default parameter settings. If the

current label settings were not saved to a file, a message

reminds the user to do so.

The Open option displays the standard File Open dialog

box allowing the user to specify the name of an existing

label file. The default file name extension for label files is

LBL. The specified file is read into memory and the label

layout is displayed in the Labeler window. If the previous

label settings were not saved to a file, a message reminds

the user to do so.

The Save option is used to save the settings of the current

label to a file. If no file name is associated with the label

entity, the Save As dialog box is displayed to allow the user

to specify the name and location of the label file. The default

file name extension for label files is LBL.

12

Form E-533

The Save As option saves the settings of the current label

entity to a new file. The standard Save As dialog box is

displayed to allow the user to specify the name and location

of the new label file. The default file name extension for label

files is LBL.

The

Print option is used to output the label contents to the

Panasonic EPL-1700 printer. First, a dialog box is displayed

to allow selection of the printer serial port (COM port) and

baud rate. This dialog box also allows input of matching text

which is used to select label data from an external file and

allows selection of a master field for the label. The master

fields selection list is only available if two or more master

fields are included in the currently opened label file.

Click the Cancel button to cancel the label printing. To print

the label, select the correct port and baud rate, enter external file match text if applicable, select a master field if applicable and click OK. The Labeler program validates the position of label fields prior to printing. If an error is detected

(e.g., overlapping fields or fields extending beyond the edge

of the label), an error message is displayed and label printing is terminated.

If the printer is not powered up or not connected to the PC or

if the printer interface times out, a CTS HOLD error message is displayed.

The MRU List in the file menu includes the names of the

most recently accessed label files. These options are included in the File menu to provide for easy access to the

current working file or other frequently accessed label files.

The Exit option is used to terminate execution of the Labeler

program. If the current label settings have not been saved to

a file, a message reminds the user to do so before the program exits.

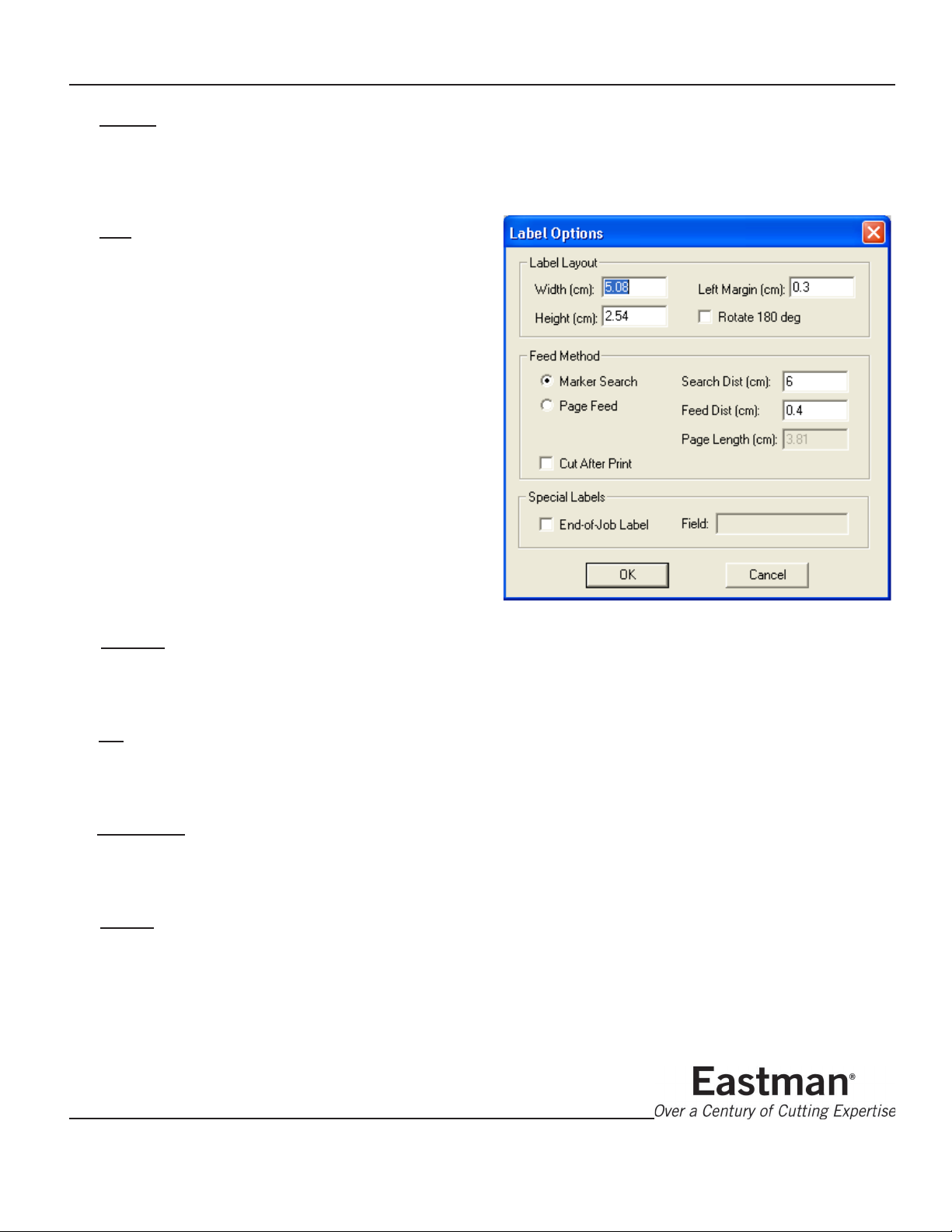

3. Label Menu

The Label menu contains the options used to modify the

contents and layout of the current label.

The Options option displays a dialog box within which the

user may specify general label layout and printing parameters. The label Width and Height are specified in centimeters. These settings should agree with the label paper currently loaded in the printer. Use the Left Margin setting to

move the left edge of any printed text away from the left

edge of the label paper. Of course, the actual location of the

left margin will depend on how close the left edge of the

label paper corresponds to where the printer thinks the left

edge of the paper is. If necessary, the Width value may be

increased to accommodate a label paper position which requires an artificially high left margin setting.

Check the Rotate 180 deg checkbox to print the label upside down.

The Panasonic printer supports two methods of feeding label paper. The Marker Search method utilizes a registration

mark on the paper roll. The Search Distance specifies the

maximum distance that the printer will feed paper in search

of this registration mark. The Feed Distance is the amount

that the printer will feed the paper after the registration mark

has been located. Be sure to set a Feed Distance of at

least 0.2 cm.

The Page Feed method of feeding label paper relies on a

fixed label spacing which must be specified in the Page

Length setting. Each time a form feed character is sent to

the printer, the printer feeds paper until the top of the next

page (as defined by the page length) is reached. This is

similar to the mechanism used in conventional printers using continuous form or fanfold paper.

Check the Cut After Print option to activate the printer’s

automatic cutter after the label has been printed.

Form E-533

13

EASTMAN

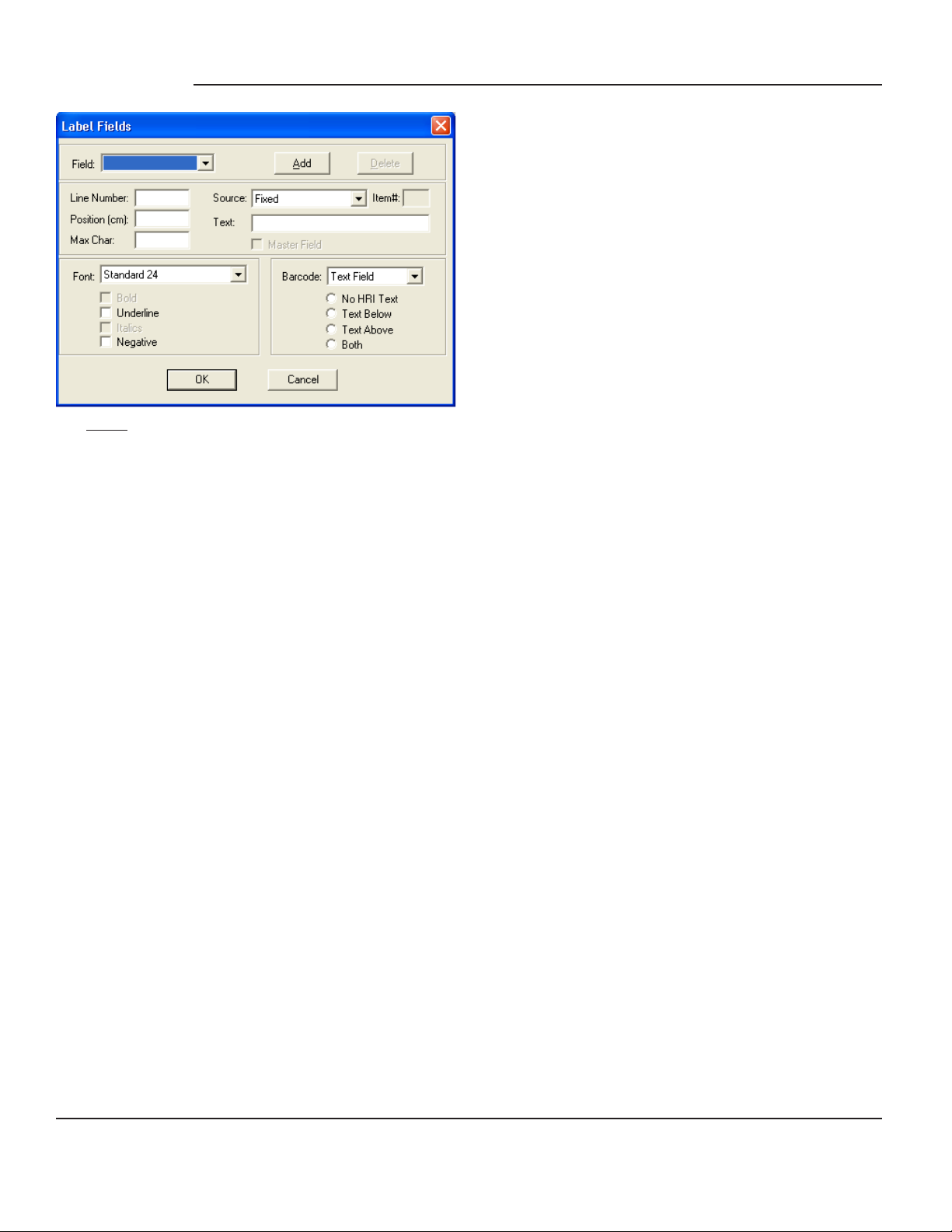

The Fields option displays a dialog box used to manipulate

the text and barcode fields within the current label. The currently selected label field is shown in the Field combobox

control in the upper left. All settings displayed in the dialog

box pertain to the currently selected field. Once all field

settings have been made, click the OK button to save the

settings. Click the Cancel button to cancel changes made

to all fields (not just the currently selected field).

Click the Add button to add a new field to the label. A dialog

box is displayed to allow entering the name of the field.

Duplicate names are not allowed. Also, the name may not

contain any spaces.

Click the Delete button to remove the currently selected

field from the label.

The Line Number and Position settings specify the location

of the field within the label. Since the printer adjusts the

height of each printed line based on the height of the largest

font used within that line, the horizontal positioning of individual fields is somewhat limited. The top line of a label is

line 1. Any blank lines within a label are treated as standard

height 16-dot font lines and are equivalent to about 3mm of

blank space. The Position setting is the distance from the

left margin as specified in the Label Options dialog box. It is

equivalent to the distance from the left edge of the label only

if the left margin setting is zero.

The Source combo box contains a list of available text

sources for the field. The available text sources are: Fixed,

Panel Name, Panel Text, Operator, Operator/Panel Text,

and From External File. The last source option is only available if the Use External Data option is checked in the External Data dialog box (see below). The Fixed source uses the

text entered in the Text edit box when printing the label field.

This source option should be used for all fields when developing a test label; all other options are meant to be used

when developing a label file (*.lbl file) for use with the EasiCut

application. The Panel Name option causes the name of the

panel or part found in the drawing file to be printed in the

field. The Panel Text option prints the contents of a text

entity found in the panel. The text entity is identified by

entering its sequence number in the Item# edit box. The

Operator source indicates that the contents of the field will

be specified by the operator in the EasiCut application. The

Text edit box is used to enter the edit box label that is displayed in EasiCut. The Operator/Panel Text source identifies a label field for which the contents are specified by the

EasiCut operator as described above but the operator’s entry may be overridden by a text entity found in the drawing

panel. The overriding text entity is identified by entering its

sequence number in the Item# edit box.

If the From External File source is selected, the field’s contents are obtained from an external data file defined in the

External Data dialog box (see below). Use the Item# edit

box to specify the column or line item number of the field

text within the external file. This source option is only available if the Use External Data option is checked in the External Data dialog box (see below).

The Max Char setting is used to specify the extent of the

field in the label layout drawing and on the printed label. In

the case of a Fixed source field, the Text string is truncated

before printing if the string is longer than the Max Char setting. If the Text string is shorter than the Max Char setting,

it is padded with spaces prior to printing. For all other source

options, the name of the source is used as the field text.

The name is truncated or padded with spaces, as required.

The Master Field option is only available for Panel Text and

Operator/Panel Text fields. The Master Field option is used

in two ways. First, the master field in a label will be used to

determine the location of the printed label on the panel or

piece. Second, a separate label is printed for each master

field in a label definition. Each master field is only included

in its own unique label while all other fields are included in

all labels associated with a master field. If no master field is

selected for a label, the label position is based on the first

text entity found in the panel or, if none is found, the label is

positioned at the center of the panel.

For text fields, one of eight possible Font styles may be

selected. The text may also be underlined or printed in a

negative (white-on-black) format. Although the program allows both options to be selected, the Panasonic printer does

not support white underlining of negative text. The Bold and

14

Form E-533

Italics options are permanently disabled, and are included

for possible future use with other printers.

If a Barcode field is desired, one of seven available barcode

types may be selected. Select one of the available locations for the human readable interpretation (HRI) text associated with the barcode. Note that for UPC-A, UPC-E, JAN13

and JAN8 barcodes, the text is always printed below the

barcode. Remember to put each barcode field on its own

line.

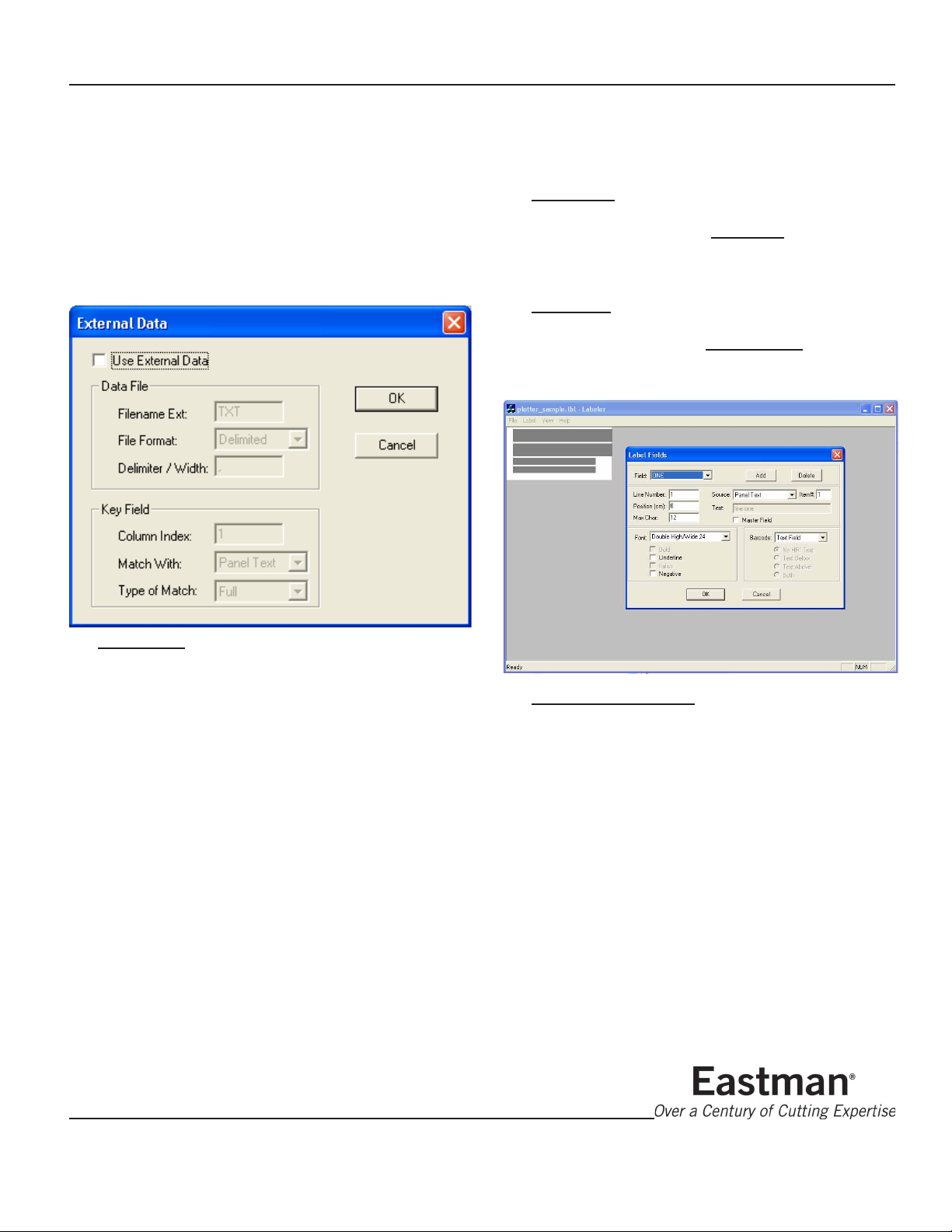

text specifies the drawing panel or part name and the Panel

Text option is used if the key field text matches the contents of the first text entity found in the drawing panel.

View Menu

4.

The View menu contains the

Status Bar option which is

used to make the status bar at the bottom of the application

window visible or invisible.

5. Help Menu

The Help menu contains the About Labeler option which

displays information about the Labeler application including

the version number.

The

External Data option displays a dialog box used to specify

the format of a text file which contains data for one or more

label fields. These fields must have their Source set to From

External File. The Use External Data option must be checked

to enable use of an external text file for label text.

Enter the file name extension of the external text file in the

File name Ext text box. The base file name of the external

text file must be the same as the name of the corresponding drawing file. The File Format combobox allows selection

of a Fixed Width or a Delimited option. If the external text

file consists of fixed width columns, enter the column width

in the Delimiter / Width text box. If the external text file

consists of variable length, delimited text, enter the delimiter character in the Delimiter / Width text box. The most

frequently used delimiter character is the comma.

The Key Field settings identify the entry within each line of

the external text file that contains the text which specifies

the drawing panel or part that corresponds to that line. The

Column Index specifies the sequential index of the text entry within a line of text in the external file. The Match With

combobox is used to select the source of the text which

must match the key field text (at Column Index) found in the

external file. The Panel Name option is used if the key field

6. Label Layout Drawing

The layout of the current label or labels is displayed in the

Labeler application window. This drawing shows the outline

of each label in white. The location of each field defined in

the Label Fields dialog box is indicated by a gray or yellow

rectangle. Text fields are shown in gray while barcode fields

are shown in yellow. The height and width of each rectangle

is meant to indicate the relative size of each field. In the

case of barcode fields, the height of the yellow rectangle

includes any human readable text included with the barcode

symbol itself.

If two or more fields within the label file have the Master

Field option checked, a separate label is displayed for each

master field. Each master field is displayed in only one of

these labels while other fields are displayed in all labels.

The current version of the Labeler application does not support mouse interactions with the label drawing.

Form E-533

15

Loading...

Loading...