Eastman ETS-SLS-2 Parts List

®

Table of Contents

Safety Information .................................................................................... 3

INST ALLATION.........................................................................................4

T able Preparation ..................................................................................... 4

Place Machine on T able ........................................................................... 4

Guide Wheel Installation .......................................................................... 4

Safety Cam & Home/Limit Switch Installation .......................................... 4

Encoder Track Installation ........................................................................ 5

Encoder Assembly Installation ................................................................. 5

Cable Carrier Installation .......................................................................... 5

Machine Familiarization ........................................................................... 6

SLS 2 Stack Labeling System Familiarization.......................................... 6

Control Familiarization.............................................................................. 7

User Interface T erminal Familiarization ..................................................... 8

Zero Table (Machine Home Position) ........................................................ 9

Set Origin (location of first label)............................................................... 9

Labeling ................................................................................................... 9

Loading New Files for Labeling ................................................................. 9

Raising the Labeling T ool Head ................................................................ 9

Label Threading........................................................................................ 9

Operating Adjustments.............................................................................9

Label T ension Adjustment ........................................................................ 9

Label Air Pressure Adjustment................................................................. 9

Service and Maintenance ....................................................................... 10

Recommended Spare Parts List............................................................. 10

Easicut Software Section ...................................................................... 11

Software File Relationships .................................................................... 1 1

Machine Settings ................................................................................... 14

GLOSSARY........................................................................................... 22

Service Record....................................................................................... 27

TECHNICAL DA TA ................................................................................. 28

IMPORTANT

The purchaser must instruct all operators on the proper use of the equipment.

All standard industrial safety measures and equipment should be provided to

protect the operator. Operators must be cautioned that improper or careless

use of this equipment may cause personal injury. If you do not have qualified

operators to instruct new persons, contact your Eastman sales representative

or Eastman factory direct.

Disconnect electrical power form source before proceeding with any installation, adjustment or repair of the SLS 2 Stack Labeler.

Your Eastman SLS 2 Stack Labeler is designed to travel at high speed in both

directions. Equipment should be set up with a minimum 3 foot (1 meter) clear

path at front and rear of machine. All personnel should be instructed to wear

safety glasses and stand well clear of the SLS 2 Stack Labeler when in

operation.

2

Safety Information

Throughout this manual, safety information is presented by

the use of the terms WARNING, CAUTION, and NOTE

These terms have the following meanings:

WARNING

A warning contains critical information regarding

potential safety hazards that can occur during proper

use or misuse of the machine. Failure to follow these

procedures may result in serious personal injury to

the user.

CAUTION

A caution contains instructions for the use or maintenance of the machine. Failure to follow these procedures may result in damage to the machine.

Supplementary information may be given in a Note.

ELECTRICAL HAZARD

An electrical hazard calls attention to a procedure,

practice, or the like, which, if not correctly performed

or adhered to, could result in personal injury. Do

not proceed beyond a Electrical Hazard.

Safety and Indemnification

During the life of the machine, the purchaser agrees

.

to provide to all machine users (including its own

employees and independent contractors) all relevant

safety information, including warning labels and instruction manuals. The purchaser also agrees to

maintain the safety features and working condition

of the machine, and to adequately train all users in

the safe use and maintenance of the machine. The

purchaser agrees to defend, protect, indemnify , and

hold Eastman Machine Company and its subsidiaries harmless from and against all claims, losses,

expenses, damages, and liabilities to the extent

that they have been caused by the purchaser’s failure to comply with the terms and instructions of

this manual.

General Safety Precautions

WARNING

• This machine is equipped with fast moving labeler

head. Keep hands, arms, and hair away from the

labeling area and drive system at all times. Safety

gloves, glasses, and appropriate clothing may prevent serious personal injuries.

• Disconnect the power supply to the machine and

turn off battery back-up when it is not in use or during routine maintenance, including cleaning and lubrication.

• The purchaser must instruct all operators in the

proper use of the machine according to the instructions in this manual. This training must include instruction on the potential safety hazards arising from

the use or misuse of the machine. In addition to

such training, the purchaser should provide written

work instructions as necessary to ensure correct

use of the machine for specific cutting applications.

• Do not modify this machine or disable safety features. Unauthorized modification may result in serious personal injuries to the user. Electrical connections to this machine must be made by a qualified electrician familiar with applicable codes and

regulations.

• Safety labels must be kept clean and legible at

all times. Call the Eastman Machine factory to

order replacement labels.

ELECTRICAL HAZARD

• This machine is equipped with a battery pack power

supply . Disconnect main power & turn of f (O) UIT

Power Supply (battery backup) before performing

service or maintenance to this machine.

®

3

®

The Eastman

SLS 2 Stack Labeler

is shipped partially

disassembled with all the necessary parts for proper setup

and operation. To get the best performance, familiarize

yourself with all the functions and adjustments of this

equipment. Before any operation can take place, it is

important that you carefully read and follow the instructions

in this manual in the same sequence in which they are

presented.

INSTALLATION

Table Preparation

The spreading table required to operate your SLS 2 Stack

Labeler must be smooth and level. A minimum clearance of

24 inches (61 cm) is required from the table surface to the

floor and a minimum 3 feet (1 m) around the machine. If

Magna or Z-Track is required, install track at this time.

To Level Table

Use carpenter’s level to check spreading table. Be especially careful to make sure table joints mate closely. Adjust

table feet as necessary to level table.

Tracking Installation

The SLS 2 Stack Labeler requires Magna Track, Z-Track or

Guide Wheels to guide the machine.

Magna Track or Z- Track Installation

Place track sections along table top, end to end, on the

operator’s side of the table as they will be mounted. Mount

the track as shown. Make sure the joints in track are even

and DO NOT align with seams in table. Be sure track is

mounted firmly to table.

Place the

SLS 2 Stack Labeler

on table between end

markers (marks designating left and right end of spread).

Machines equipped with grooved wheels must be placed

on the lip of Magna or Z- Track.

Locking

Screw

Guide Wheel

Assembly

Adjusting

Nut

Guide Wheel Installation

Before installation can take place the covers must be

removed for access to the mounting holes. Remove the

mounting screws on the covers. Carefully remove the covers.

Mount the guide wheel assemblies as shown. To Adjust

Guide Wheels, Loosen the locking screw and turn the

adjusting nut until guide wheel makes contact with table. Do

not over tighten. If more adjustment is required, relocate

guide wheel in next hole. Tighten locking screw when

adjustment is complete.

Limit

Switch

Actuating

Arm

Place Machine on Table

The

SLS 2 Stack Labeler

weighs approx. 400 lbs. (180 Kg.)

uncrated for a 60" machine. Wooden braces are

strapped across the underside of its cross channels and

the forklift arms should be raised to those braces when

machine is lifted.

CAUTION

When placing forklift arms under cross channels, use

care not to damage tension rods or cover.

When the

SLS 2 Stack Labeler

is shipped the Stop Wands,

Stop Cams, Cable Carrier Kit and Guide Wheel Assemblies

are removed and must be installed upon installation.

4

Safety Cam

Assembly

Safety Cam & Home/Limit Switch Installation

The Safety Cams, Limit Switch, and Home Limit Switch

Assemblies should now be installed for safety. Mount the

Safety Cams as shown at each end of the spreading area.

Loosen the limit switch actuating arm and swing into position. Secure actuating arm. Loosen the limit switch adjustment plate and lower assembly to allow the actuating arm to

make contact with safety cam. If actuating arm does not

make contact with safety cam replace arm with longer arm

provided. Replace covers and secure the flat head screws.

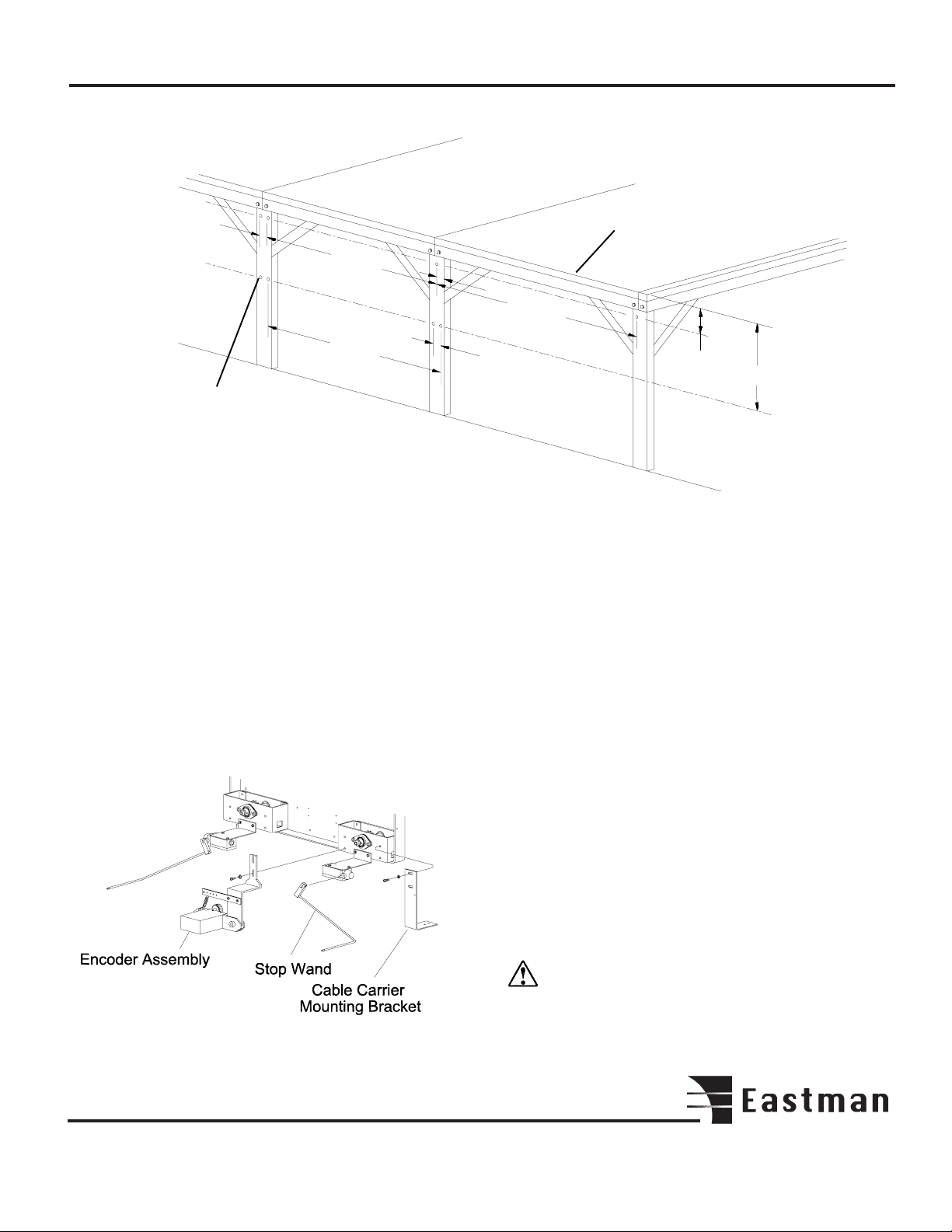

.94"

Spreading

Table

Non-Operator

Side

47.53"

1.50"

47.53"

48.00"

.219 (7/32) Drill

For Encoder Track

& Cable Carrier

Encoder Track Installation

Proper installation of the encoder rail is very important for

accurate machine performance. The encoder track must be

level along its entire length. Drill (3) 7/32" diameter holes for

each 8' section of track, as shown. Mount encoder track to

table legs. When ALL sections of track are mounted, the

rubber encoder gear belt is then adhered IN ONE PIECE to

underside of track. Belt must be undamaged along its entire

length. If belt must be spliced, make sure that ribs of belt

remain at consistent spacing, otherwise microprocessor will

not function properly.

1.75"

5.06"

15.00"

Encoder Assembly Installation

Mount Encoder Assembly on the rear frame as shown. The

encoder gear wheel must roll smoothly along encoder gear

belt. Fasten bracket with hardware provided. Adjust tension

so gear wheel remains in continuous contact with gear belt

as the SLS 2 moves.

Cable Carrier Installation

Before the Cable Carrier Kit can be installed the table legs on

the non-operator side must be modified. Drill two (2) 7/32

diameter holes in each table leg as shown. Locate the cable

carrier, trough, mounting brackets and mounting screws.

Assemble each section and mount to the table legs.

Mount the cable carrier between the two middle trough

sections. The SLS 2 requires 25 - 30 PSI compressed air.

Locate the air line on the cable carrier. Connect air line to

pressure regulator located on the non-operator side frame

and air supply.

Once the cable carrier is secured, connect the power plug

to the socket on the back frame. Check voltage rating with

electrical rating stamped on serial number plate. If compatible, connect cable carrier cord to wall outlet.

Note: Voltage varying more than 10% (11V for 110V

machine, 22V for 220V machine) may damage your

system’s electronics.

®

5

®

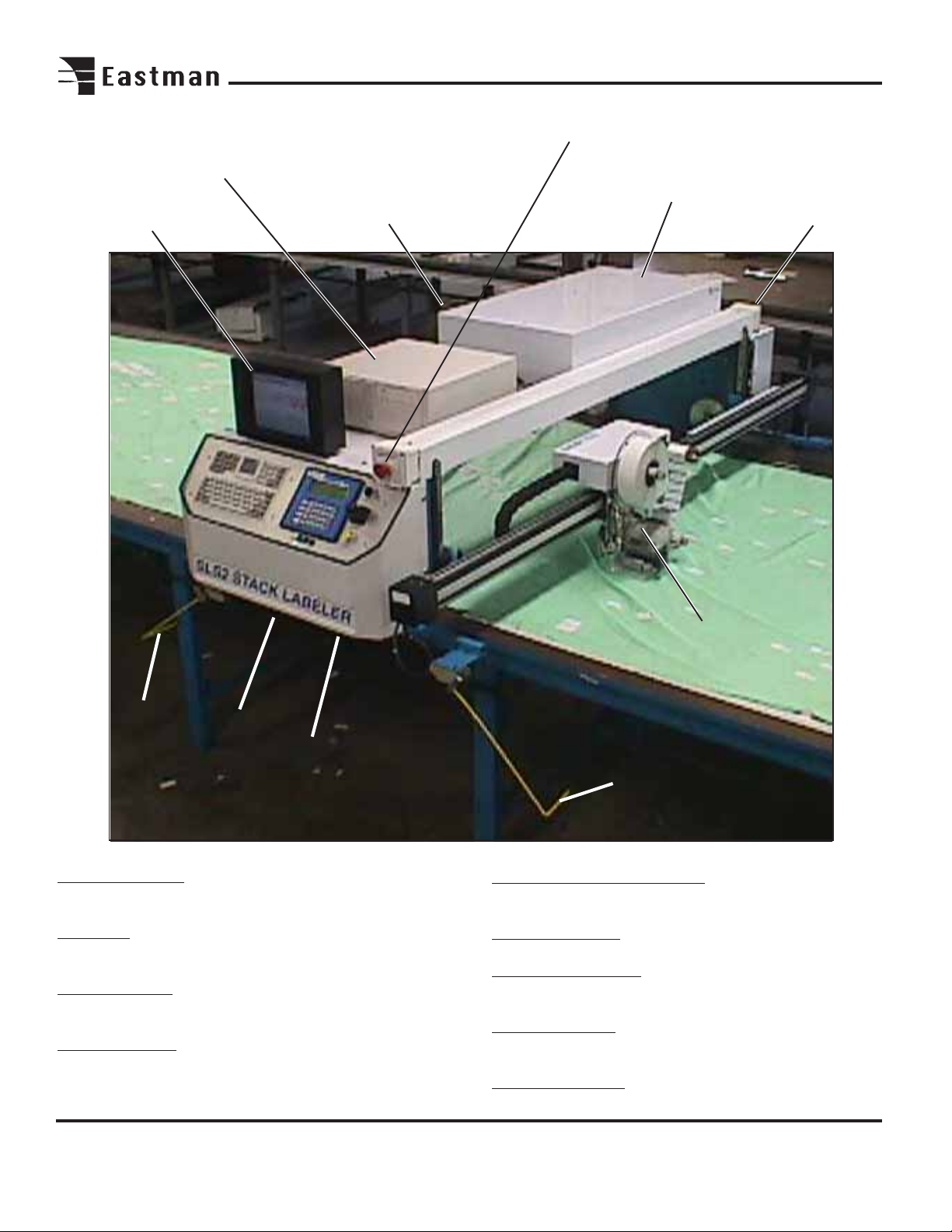

SLS 2 Stack Labeling System Familiarization

Computer

Battery

Computer Display

Back-up

Emergency Stop

On Board Control

Components

Emergency Stop

Machine

Stop

Wand

Home Limit

Switch

Stop Limit

Switch

Machine Familiarization

Computer Display: Display used for setup and run of your

SLS 2 labeling system.

Computer: Stores running programs and user labeling

files. Disk drive available for loading labeling files.

Battery Back-Up: Reserve power in the event main power

is interrupted (10 minute minimum supply).

Emergency Stop: Activates power to all drive circuits. Pull

on, push off.

Labeler T ool Head

Machine

Stop

Wand

On Board Control Components: Electrical components

used to control the SLS 2 labeling system.

Labeler T ool Head: Tool used to apply labels to material.

Machine Stop Wands: Deactivates power to all drive

circuits when wand strikes object in its path.

Stop Limit Switch: Switch is activated by cams located

near each end of labeling area.

Home Limit Switch: Switch is activated by cam to set

zero location on table.

6

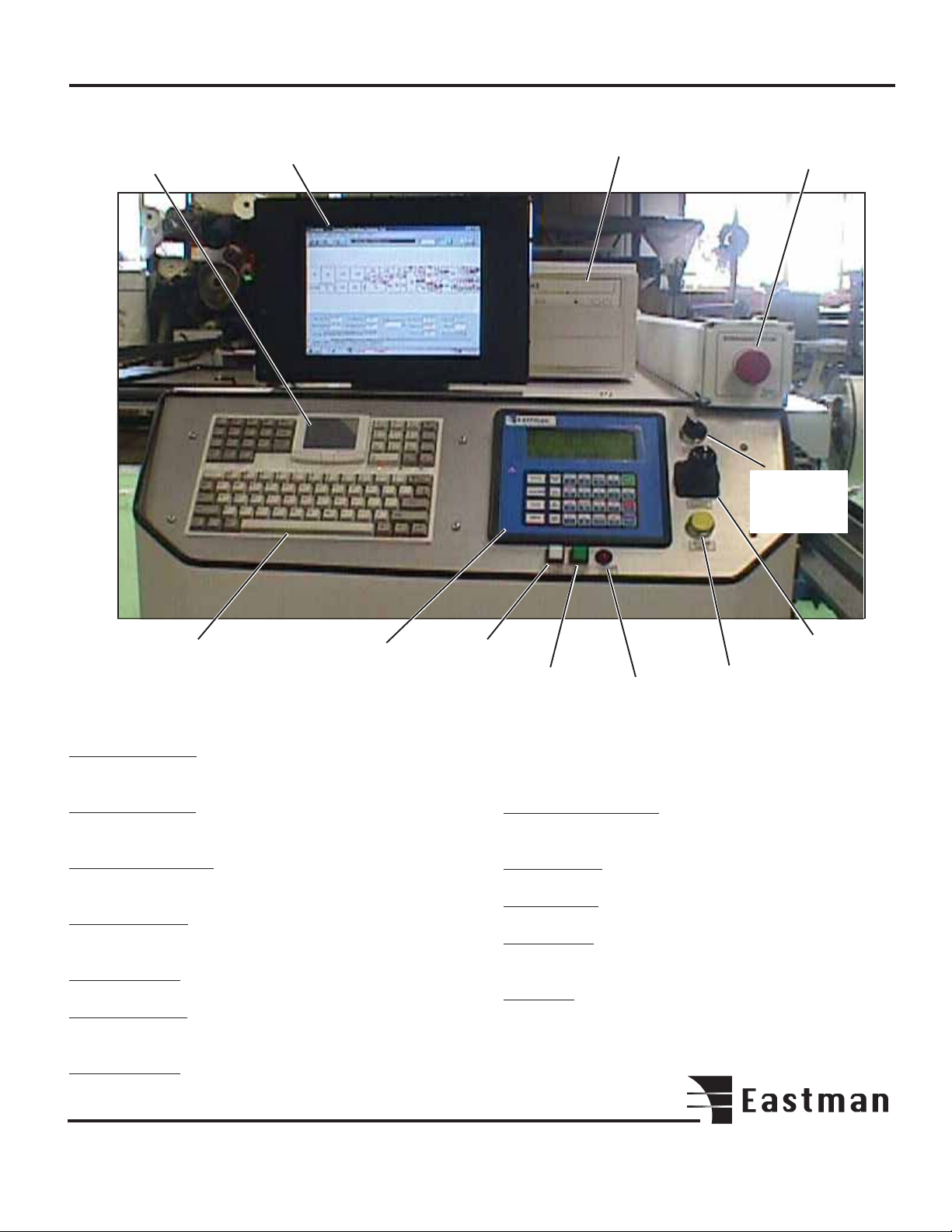

T ouch

Mouse Pad

Computer

Display

Computer

Disk Drive

Emergency

Stop

Auxiliary

Switch

(future use)

Keyboard

UIT T erminal

Control Familiarization

Touch Mouse Pad: Used to control the cursor on the

computer display .

Computer Display: Display used for setup and run of your

SLS 2 labeling system.

Computer Disk Drive: Disk drive used to down load

labeling files.

Emergency Stop: Activates power to all circuits. Pull on,

Push off.

Auxiliary Switch: Available for future use.

Joy Stick Control: For manual movement of machine and

labeling head.

Machine Pause: Push to stop machine when in automatic

labeling mode. Press NEXT on UIT to resume.

Label Feed

Labeler Error Indicator: Indicates error in label position.

Press label feed to reset.

Printer On/Off: Press to activate labeler tool head.

Labeler Feed: Press to manually feed label.

UIT T erminal: Used for operator interface of machine. See

operating instructions for more details.

Keyboard: Used to enter labeling data on the computer

display .

Printer

On/Off

Labeler

Error

Indicator

Machine

Pause

Joystick

Control

®

7

®

MOVE: Press to access menu.

Press 1 to send SLS 2 to home position.

Press 2 to send SLS 2 to label origin position.

UP: Pressing UP causes the elevator to move up.

DOWN: Pressing DOWN causes the elevator to move down.

LEFT : Pressing LEFT causes the SLS 2 Labeler to move to

the left.

Right:: Pressing RIGHT causes the SLS 2 Labeler to move

to the right.

ST ART : Press ST ART to begin automatic labeling mode.

UIT T erminal

User Interface Terminal Familiarization

The UIT (User Interface T erminal) features a 33 key membrane keypad and a four line display . Commands are issued

via the keypad and information is communicated back to

the user through the display . Through the UIT the operator

may position the plotter carriage, enable automated movement, and manually cut and mark.

Commands are sent to the computer by pressing specific

keys or key sequences on the UIT . Each key on the UIT can

have a function and characters related to that key (note that

not all keys have both a function and characters). Commands that require data entry following the pressing of a

FUNCTION key the UIT will automatically set itself in anticipation of the expected type of input.

Some commands require only one key to be pressed while

other commands require multiple keystrokes and may sometimes prompt the operator for input.

A description of commands follows:

SET ORIGIN: Press to set the first label position on the

table. The laser pointer marks the origin position. T o

adjust offset, see software section.

ZERO T ABLE: Press to activate the zeroing function on

the carriage. The carriage will move to the home limit

switch cam. This point is set as home position.

SPEED: Press to set fast/slow machine movement.

/6: Press to move labeler head away from operator.

/9: Press to move Labeler head toward the operator.

NEXT: Press to resume automatic labeling when machine

pause is pressed.

ABORT: Press to abort command.

ENTER: Press ENTER to accept command.

Operation

After setup is complete and the power and airline is connected, the SLS 2 is now ready for Initialization.

Important

To stop the SLS 2 at any point during

operation, either:

-Press the Emergency Stop button (Red).

-Hit Machine Sop Wands.

-Press Machine Pause button (yellow) on main control

panel.

WARNING: Safety cams should always be checked

for proper operation with the SLS 2 before any automatic

labeling takes place.

Activate battery back-up to ON (I) position. Activate the

computer by pressing the ON (I) button. The computer

display will run through the computer start-up program.

Pull the Emergency Stop button to activate power to the

drive circuit. Start the EASICUT software by double clicking

the EASICUT software icon on the computer display. This

will load the default test.cmd file. Enter label text for the

required fields using the keyboard. Select OK.

The log in screen will appear. Enter the user name and password. Select OK when complete. The UIT Display will show

DESIGN LOADED. Press ENTER on UIT T erminal to continue.

8

Zero Table (Machine Home Position)

Press ZERO T ABLE on UIT T erminal to locate the “machine

home position” of the table. This will raise the elevator to the

top position and accelerate machine to the “machine home

position”.

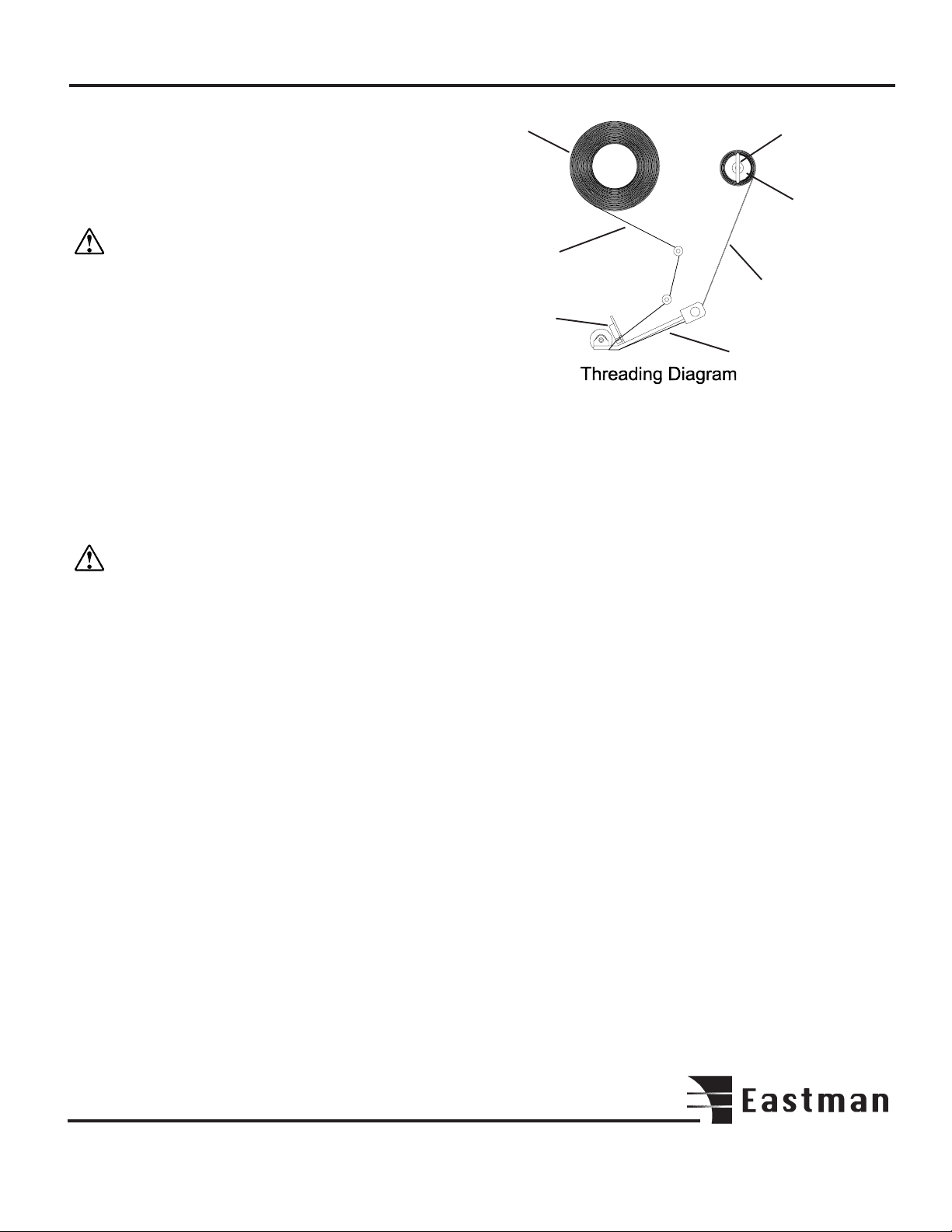

Label roll

T ake-up

spool clip

T ake-up

spool

Note: The “Machine Home Position” is created when

the Home Limit switch strikes the Stop Cam mounted

on the table.

The UIT display will show TABLE ZERO OK when task is

complete. Press enter on UIT terminal to except. The UIT

display will show ready .

Set Origin (location of first label)

Press the Printer ON/OFF (Green) button to activate labeler

tool head. Using the joystick, move the SLS 2 to the first

label position. The red laser should be in the center of the

first label. Press Set Origin to except. The elevator will lower

to locate the table surface. The SLS 2 Labeler is now ready

to begin labeling.

Note: Labeling area must be clear of all personnel and

objects before starting the labeling process.

Labeling

T o begin labeling press Start on the UIT T erminal. The SLS

2 will begin labelling. After the final label is applied the machine will return to the original label origin position.

Loading New Files for Labeling

Load a file by opening the file menu and clicking on the

desired file. Enter label text and press enter on the keyboard to accept. Select the "PLOT" icon on the computer

display to load design. Press ENTER on the UIT Terminal

to accept new design.

Note: Files are organized by type and are displayed on the

menu according to which type is selected. For example,

if you wish to use a file generated in CMD format, open

the list files of type menu and select CMD. The file

menu will then display all files with a CMD extension.

Raising the Labeling Tool Head

Press the UP or DOWN on the UIT terminal to raise or lower

the labeling tool head.

Labels

on this

side

Label Web

Roller

Lever

Skid Plate

Label Threading

Press Printer ON/OFF (green) button to turn off printer.

Remove take-up spool clip. Lift the roller lever to separate the

printer rollers. Discard used label web material and label roll

core. Load new label roll as shown. Release roller lever.

Press Printer ON/OFF button to continue.

Optional: Label web material may be threaded above the skid

plate as required to prevent pushing material or

interfering with take-up spool performance while

labeling.

Operating Adjustments

This machine is adjusted and tuned at the factory for optimal

performance. No Adjustments other than normal setup are

necessary. However, if after continued use the performance

level becomes unacceptable, the following procedures

should be carried out before repairs are considered.

Label T ension Adjustment

The label tension adjustment is located under the labeler tool

head cover. Remove the cover to access the take-up clutch.

Rotate the knurled adjusting knob clockwise to increase and

counterclockwise to decrease tension.

Label Air Pressure Adjustment

The labeler pressure regulator is located on the back side

frame. To adjust, remove back cover. Locate the regulator

valve. Pull the "Adjust" knob up and turn clockwise to

increase pressure and counter clockwise to decrease pressure. After adjustment is made, push knob down to lock in

place.

®

9

Loading...

Loading...