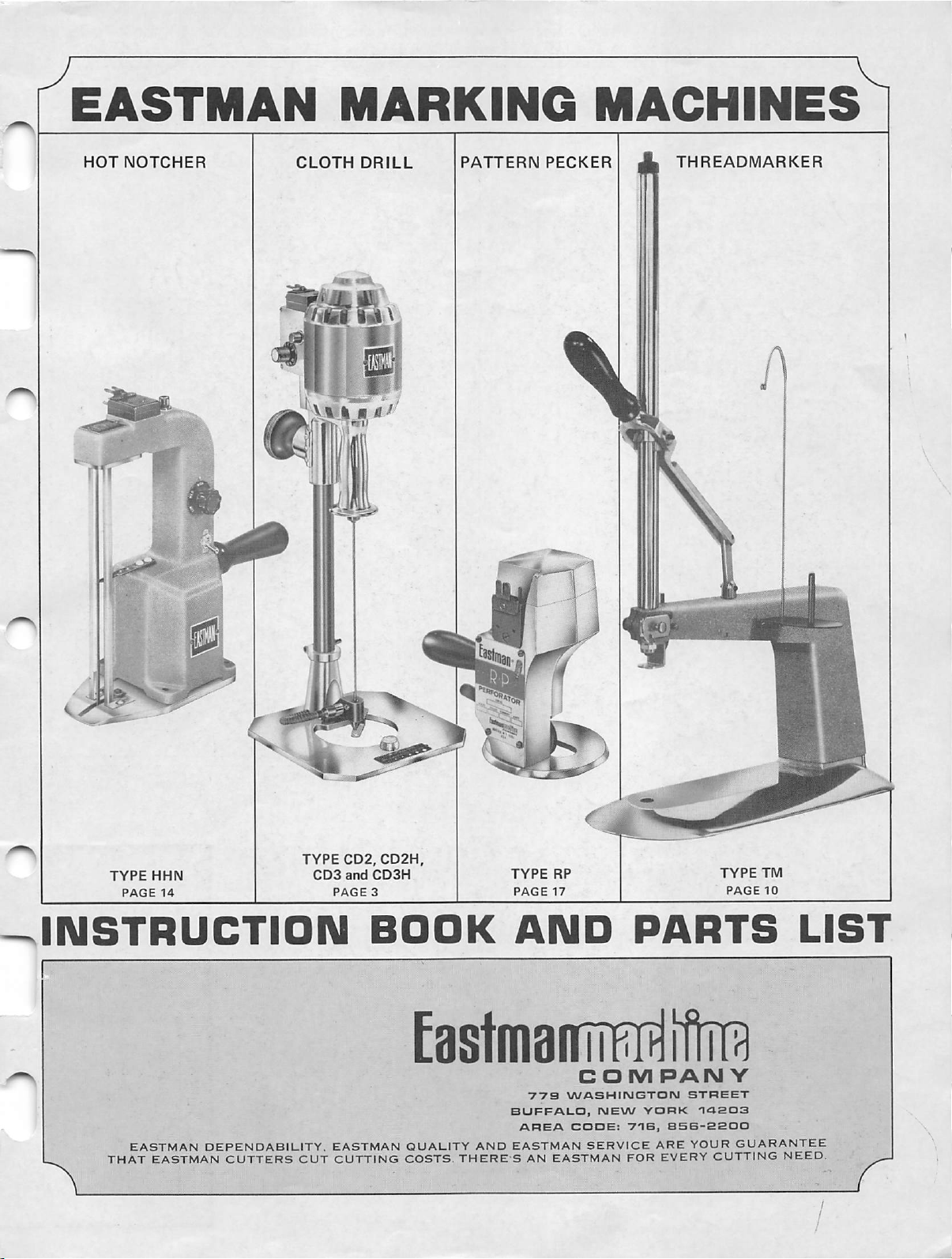

Eastman HHN, CD2, CD2H, CD3, CD3H User Manual

...

EASTMAN

HOTNOTCHER

MARKING

MACHINES

TYPE

CD2,

and

CD2H,

CD3H

CD3

I

INSTRUCTION

EASTMAN

THAT

EASTMAN

DEPENDABILITY.

CUTTERS

CUT

BOOK

EASTMAN

CUTTING

EastmairmiifjiftiR

QUALITY

COSTS,

THERE'S

AND

TYPE

RP

AND

779

AN

EASTMAN

WASHirOCTON

BUFFALO,

AREA

EASTMAN

COMPAN

NEW

CODE:

SERVICE

PARTS

STREET

YORK

71B,

FOR EVERY

BSS-SBOO

ARE

iaS03

YOUR

CUTTING

TYPE

TM

Y

GUARANTEE

LIST

NEED.

HOT

NOTCHER

CLOTH

DRILL

PATTERN

PECKER

THREADMARKER

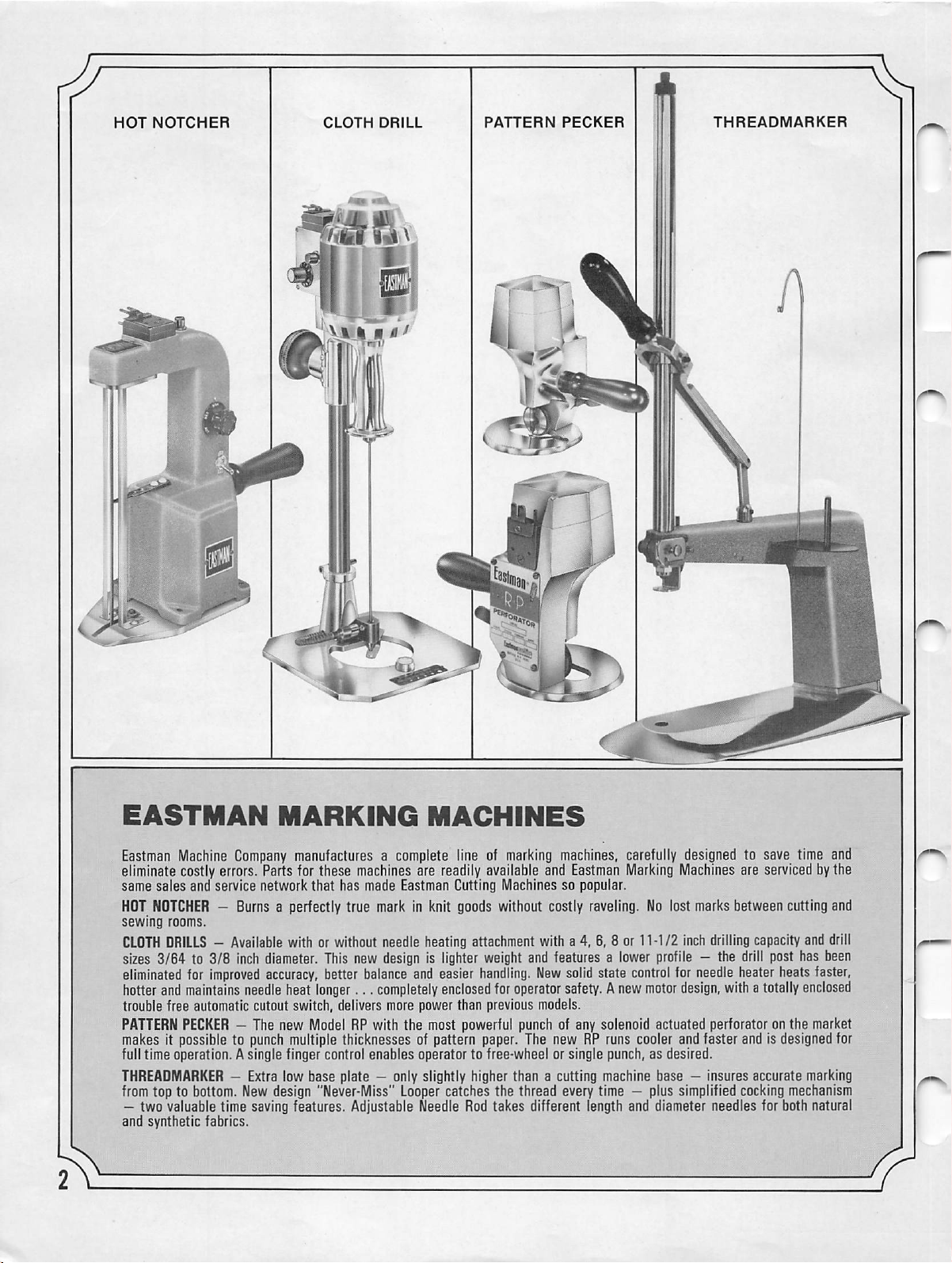

EASTMAN

Eastman

eliminate

same sales and service network that has made Eastman Cutting Machines so popular.

HOT

sewing rooms.

CLOTH

sizes

eliminated

hotter

trouble free automatic cutout switch, delivers

PATTERN

makesitpossibletopunch

full

THREADMARKER-Extra

from

- two

and synthetic fabrics.

Machine

costly

errors.

NOTCHER-Burns

DRILLS—Available

3/64 to 3/8

for

improved

and

maintains

PECKER

timeoperation. Asingle

top to

bottom.

valuable

time

MARKING

Company

inch

needle

- Thenew

New

manufacturesacomplete

Parts

a perfectly true

withorwithout

diameter.

accuracy,

heat

multiple

finger

lowbase plate -

design

saving

features.

MACHINES

for

these

machines

markinknit

needle

This

new

better

longer...

ModelRPwith

control

"Never-Miss"

designIslighter

balance

completely

more

the most

thicknesses of pattern paper. The newRPruns

enables operatorto

only

Looper

Adjustable

lineofmarking

are

readily

goods

heating

and

easier

enclosed

powerthan previous

powerful

slightly

catches the thread

Needle

available

without

attachment

weight

handling.

for

free-wheel

higher

Rod

takes different

machines,

and

Eastman

costly

with

a 4, 6, 8 or11-1/2

and

featuresalower

New

solid

operator

than a

safety.Anew

models.

punch

of any solenoid actuated perforator onthe

orsingle

cutting

every

carefully

Marking

raveling.Nolost

designed

Machines

inch

profile

state

control

for

motor

design,

cooler

punch,

machine

time — plus

length

and diameter needles for

andfaster and is designed for

as desired.

base - insuresaccurate

simplified

marks

- the

needle

to save

are

between

drilling

capacity

drill

heater

withatotally

cocking

time

and

servicedbythe

cutting

and

and

drill

post

has

been

heats

faster,

enclosed

market

marking

mechanism

both

natural

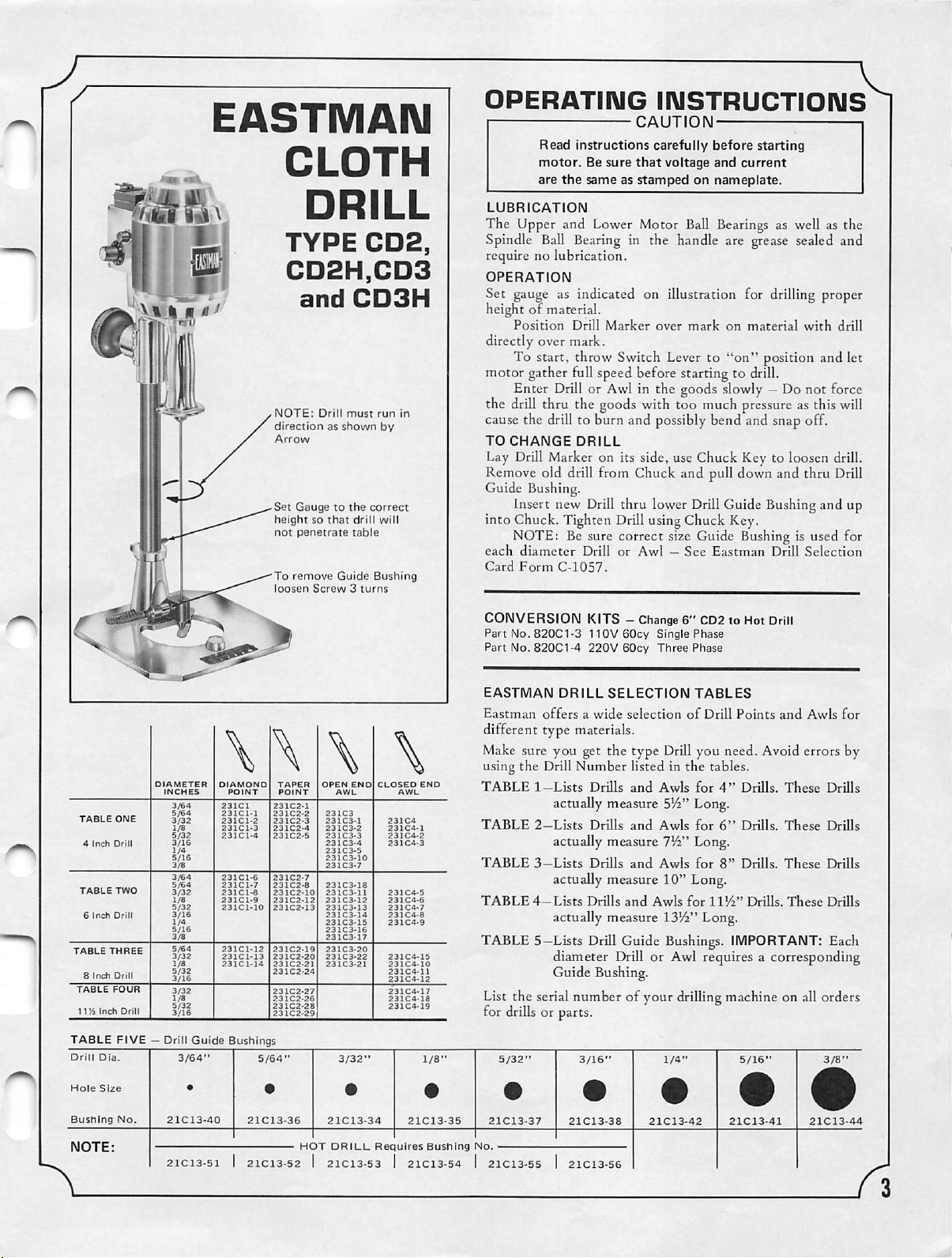

EASTMAIM

CLOTH

OPERATIiUG

Read

instructions

motor.Besure

are

the

same as

IIUSTRUCTIOIMS

CAUTION

carefully

that

voltage

stampedonnameplate.

before

and

starting

current

mm

,V|

11

DRILL

A TYPE CD2,

4 CD2H,CD3

and

-nil

NOTE:

Drill

directionasshown

Arrow

Set

Gaugetothe

heightsothat

not

penetrate

To

remove

loosen

Guide

Screw3turns

CD3H

must

run

by

correct

drill

will

table

Bushing

LUBRICATION

The Upper and Lower Motor

Spindle

Ball

Bearing

in the handle are

Bali

Bearings

grease

as well as the

sealed and

require no lubrication.

OPERATION

Set

gauge

as indicated on illustration for drilling proper

height of material.

Position

Drill

Marker

over

mark

on

material

with

drill

directly over mark.

To start, throw Switch

motor gather fullspeed

Enter Drill or Awl in the goods

in

the drill thru the goods with too much pressure as this will

causethe drillto burn and possiblybend and snap off.

TO

CHANGE

DRILL

before

Lever

to "on" position and let

startingto

drill.

slowly

—Do not force

Lay Drill Marker on its side, useChuck Key to loosen drill.

Remove

old drill from Chuck and pull down and thru Drill

Guide Bushing.

Insert new Drill thru lowerDrillGuide Bushing and up

into Chuck. Tighten DrillusingChuck Key.

NOTE: Be sure correct size Guide

each

diameter

Card

Form

CONVERSION

Part

NO.820C1-3

Part

No.

820C1-4

DrillorAwl—See

C-1057.

KITS - Change6" CD2to Hot Drill

110V

60cy

60cy

Single Phase

Three

220V

Phase

Bushing

Eastman

is used for

Drill

Selection

TABLE

TABLE

8

TABLE

11'A

TABLE

Bushing

NOTE

Inch

Inch

TWO

THREE

Drill

POUR

Drill

FIVE

No.

DIAMETER

INCHES

Drill

Guide

3/64"

\\

231C1-6

231C1-7

231Cl-e

231C1-9

231CMO

231C1-12 231C2-19

23IC1

231CI-14

13

Bushings

231C2-7

231C2-S

231C2-10

231C2-12

231C2-13

231C2-20

231C2-21

231C2-24

231C2-27

231C2-26

231C2-28

231C2-29

\l\

231C3

231C3-1

231C3-2

231C3-3

231C3-4

231C3-5

231C3-10

231C3-7

231C3-18

231C3-11

231C3-12

231C3-13

231C3-I4

231C3-1S

231C3-I6

231C317

231C3-20

231C3-22

231C3-21

21C13-34 21C13-35

I I I

HOT

DRILL

231C4-1S

231C4.10

231C4-11

23104-12

231C4-17

231C418

231C4-19

Requires

Bushing

EASTMAN

Eastman

DRILL

offersawide

SELECTION

selectionofDrill

TABLES

different type materials.

Make

sure you get the type Drillyou need.Avoiderrors by

using the Drill Number listed in the tables.

TABLE

TABLE

TABLE

1—Lists

Drills

actually measure

2—Lists

Drills

actually measure

3—Lists

Drills

and

and

and

Awls

5^"

Awls

7V2"

Awls

for4"Drills.

Long.

for6"Drills.

Long.

for8"Drills.

actually measure 10" Long.

TABLE4—Lists

TABLE

5—Lists

Drills

and

Awls

for

IIV2"

actually measure

ISVi"

Long.

Drill Guide Bushings. IMPORTANT: Each

diameter Drill or Awl requires a corresponding

Guide

Bushing.

List the

serial

numberof your

drilling

for drills or parts.

•mm

No.

Points

Drills.

machine

and

These

These

These

These

on all

Awls

orders

for

Drills

Drills

Drills

Drills

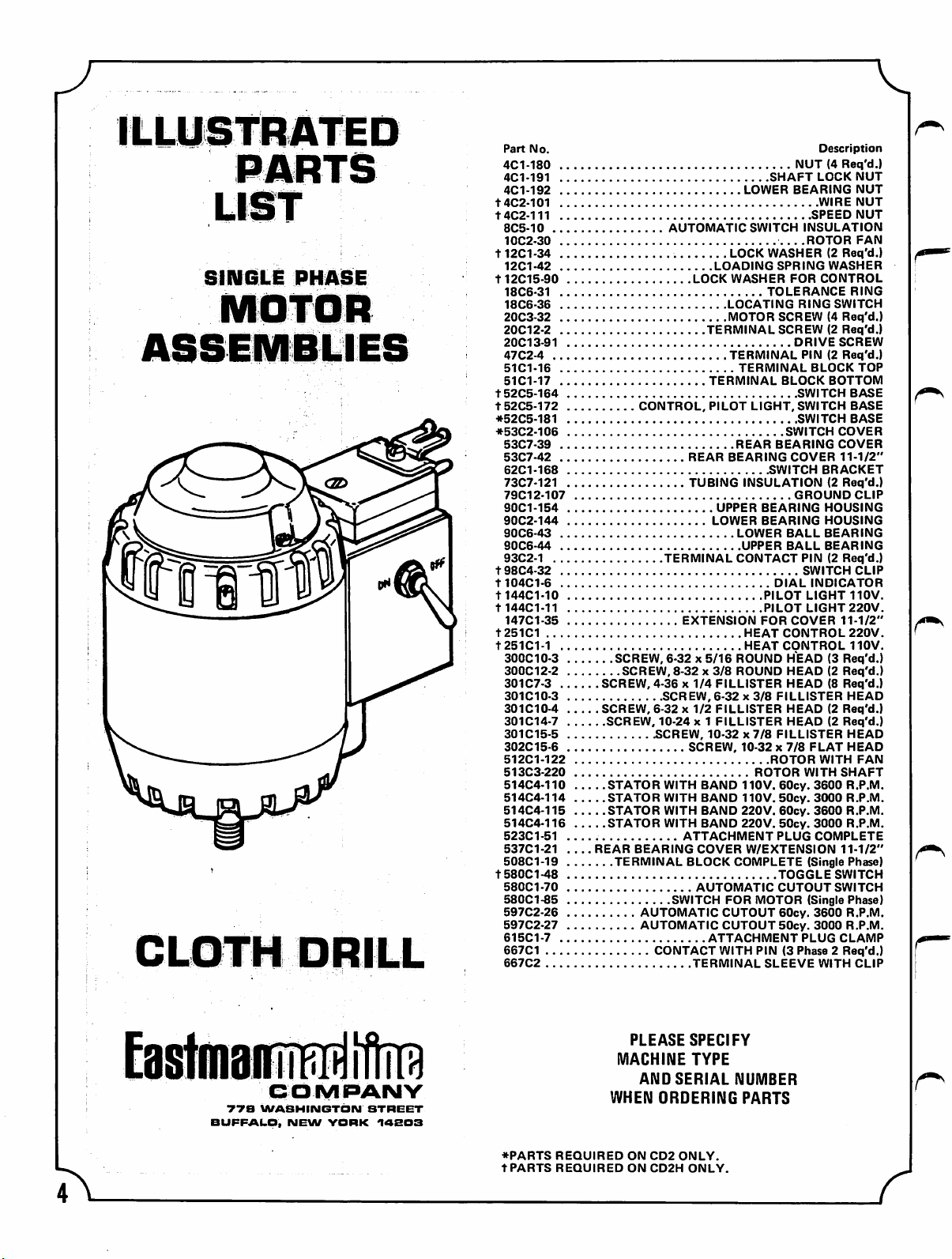

SINGLE

MOTOR

PHASE

1

Part

No.

4CM80

4C1-191

401-192

1402-101

1402-111

805-10

1002-30

11201-34

1201-42

112015-90

1806-31

1806-36

2003-32

20012-2

20013-91

4702-4

5101-16

5101-17

15205-164

15205-172

*5205-181

*5302-106

5307-39

5307-42

6201-168

7307-121

79012-107

9001-154

9002-144

9006-43

9006-44

9302-1

19804-32

110401-6

114401-10

114401-11

14701-35

125101

125101-1

300010-3

300012-2

30107-3

301010-3

301010-4

301014-7

301015-5

302015-6

51201-122

51303-220

51404-110

51404-114

51404-115

51404-116

52301-51

53701-21

50801-19

158001-48

58001-70

58001-85

59702-26

59702-27

61501-7

66701

66702

SCREW,

SCREW,

SCREW,

SCREW,

SCREW,

STATOR

STATOR

STATOR

STATOR

REAR

TERMINAL

AUTOMATIC

CONTROL,

REAR

TUBING

TERMINAL

EXTENSION

6-32x5/16

8-32x3/8

4-36x1/4

SCREW,

6-32x1/2

10-24

.SCREW,

SCREW,

WITH

WITH

WITH

WITH

BEARING

ATTACHMENT

BLOCK

SWITCH

AUTOMATIC

AUTOMATIC

CONTACT

LOOK

LOADING

LOOK

WASHER

LOCATING

MOTOR

TERMINAL

TERMINAL

TERMINAL

PILOT

REAR

BEARING

UPPER

LOWER

CONTACT

ROUND

ROUND

FILLISTER

6-32x3/8

FILLISTER

x 1

FILLISTER

10-32x7/8

BAND

BAND

BAND

BAND

COVER

COMPLETE

AUTOMATIC

FOR

CUTOUT

CUTOUT

ATTACHMENT

WITH

TERMINAL

Description

NUT(4Req'd.)

SHAFT

LOCK

LOWER

BEARING

SWITCH

INSULATION

ROTOR

WASHER(2Req'd.)

SPRING

FOR

TOLERANCE

RING

SCREW(4Req'd.)

SCREW(2Req'd.)

DRIVE

PIN (2

TERMINAL

BLOCK

SWITCH

LIGHT,

SWITCH

SWITCH

SWITCH

BEARING

COVER

.SWITCH

INSULATION(2Req'd.)

LOWER

UPPER

HEAT

HEAT

10-32x7/8

110V.

110V.

220V.

220V.

W/EXTENSION

GROUND

BEARING

BEARING

BALL

BALL

PIN (2

SWITCH

DIAL

PILOT

PILOT

FOR

COVER

CONTROL

CONTROL

HEAD(3Req'd.)

HEAD(2Req'd.)

HEAD(8Req'd.)

FILLISTER

HEAD(2Req'd.)

HEAD(2Req'd.)

FILLISTER

ROTOR

ROTOR

60cy.

50cy.

60cy.

50cy.

PLUG

LIGHT

LIGHT220V.

WITH

(Single

TOGGLE

CUTOUT

MOTOR

PIN(3Phase2Req'd.)

60cy.

50cy.

SLEEVE

(Single

PLUG

WIRE

SPEED

WASHER

CONTROL

RING

SWITCH

SCREW

Req'd.)

BLOCK

BOTTOM

BASE

BASE

BASE

COVER

COVER

11-1/2"

BRACKET

CLIP

HOUSING

HOUSING

BEARING

BEARING

Req'd.)

CLIP

INDICATOR

110V.

11-1/2"

220V.

110V.

HEAD

HEAD

FLAT

HEAD

WITH

SHAFT

3600

R.P.M.

3000

R.P.M.

3600

R.P.M.

3000

R.P.M.

COMPLETE

11-1/2"

Phase)

SWITCH

SWITCH

Phase)

3600

R.P.M.

3000

R.P.M.

CLAMP

WITH

CLIP

NUT

NUT

NUT

NUT

FAN

V

TOP

FAN

G O

lyi

778

BUFRAI.P,

WASHIIMBTOIM

NEW

PAIM

YORK

Y

STREET

laEOS

4\

*PARTS

t

PARTS

REQUIRED

REQUIRED

PLEASE

MACHINE

AND

WHEN

ON

002

ON

0D2H

SPECIFY

TYPE

SERIAL

ORDERING

ONLY,

ONLY.

NUMBER

PARTS

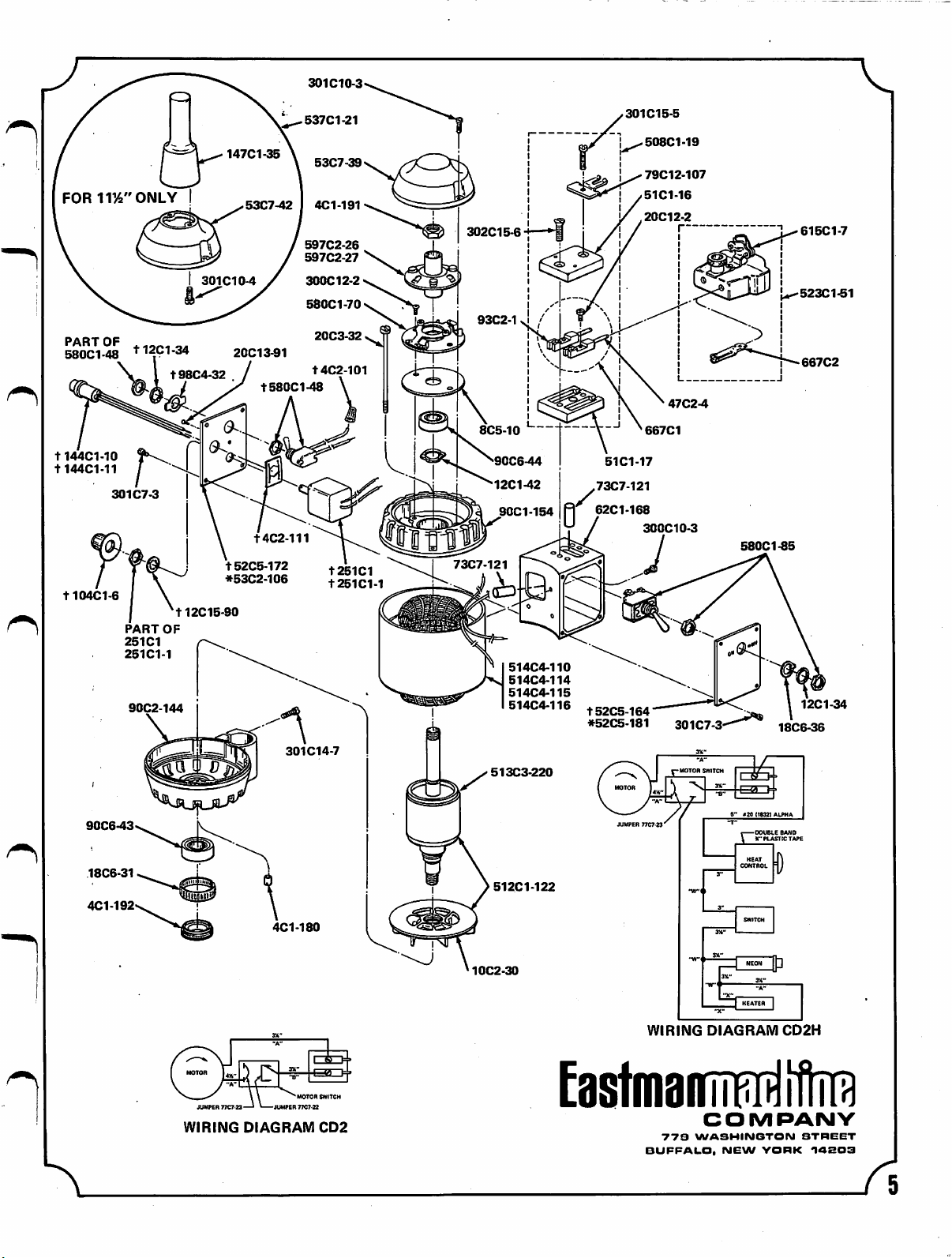

301C10-3

FOR

11%"ONLY

PARTOF.„ci34

580C1-48

1144C1-10

t144C1-11

110401-6

TlZCI-34

I

PART

25101

25101-1

9002-144

t98C4

112015-90

OF

147C1-35

301C10-4

15205-172

*5302-106

53C7-42

20C13-91

t580C1-48

1402-111

537C1-21

597C2-26

597C2-27

300C12-2

580C1-70

301014-7

53C7-39

4C1-191

t4C2-101

t25101

125101-1

302C15-6

93C2-1

7307-121

9006-44

1201-42

90C1-154

51404-110

51404-114

51404-115

51404-116

51303-220

301C15-5

51C1-17

7307-121

6201-168

t5205-164

*5205-181

508C1-19

79C12-107

51C1-16

20C12-2

47C2-4

667C1

300010-3

30107-3

•1^61501-7

U^523C1-51

667C2

58001-85

1201-34

1806-36

¥

1806-31

401-192

401-180

1

JUMPER

WIRING

77C7-23

-JUMPER

DIAGRAM

^ MOTOR SWITCH

77C7-22

CD2

51201-122

1002-30

WIRING

DIAGRAM

CD2H

EastmaiTiTFiijiflii^

COMPANY

773

BUFFAUO.

WASHINGTON

NEW

YORK

STREET

laSOS

/5

wm

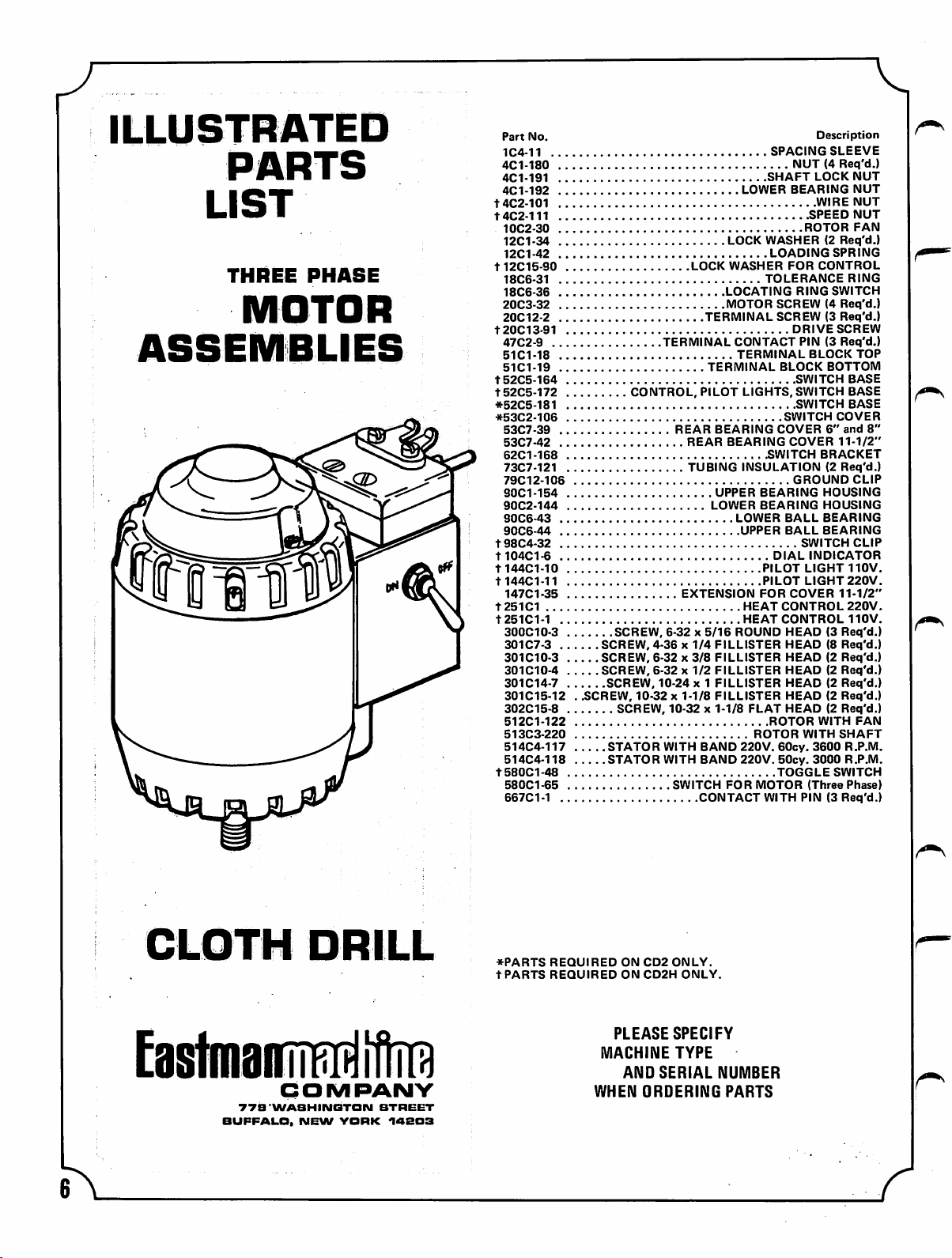

THREE

%

PHASE

1

Part

No.

1C4-11

4C1-180

401-191

401-192

1402-101

1402-111

1002-30

1201-34

1201-42

112015-90

1806-31

1806-36

2003-32

20012-2

t20013-91

4702-9

5101-18

5101-19

15205-164

15205-172

#5205-181

*5302-106

5307-39

5307-42

6201-168

7307-121

79012-106

9001-154

9002-144

9006-43

9006-44

19804-32

110401-6

114401-10

114401-11

14701-35

125101

125101-1

300010-3

30107-3

301010-3

301010-4

301014-

7

301015-12..SCREW,

302015-8

51201-122

51303-220

51404-117

51404-118

t58001-48

58001-65

66701-1

CONTROL,

SCREW,

SCREW,

SCREW,

SCREW,

SCREW.

10-32x1-1/8

SCREW,

STATOR

STATOR

LOOK

TERMINAL

REAR

REAR

TUBING

EXTENSION

6-32x5/16

4-36x1/4

6-32x3/8

6-32x1/2

10-24

x 1

10-32x1-1/8

WITH

WITH

SWITCH

SPACING

SHAFT

LOWER

LOOK

WASHER{2Req'd.)

LOADING

WASHER

TOLERANCE

LOCATING

MOTOR

TERMINAL

TERMINAL

PILOT

BEARING

BEARING

UPPER

LOWER

FILLISTER

FILLISTER

FILLISTER

FILLISTER

SCREW(4Req'd.)

SCREW(3Req'd.)

CONTACT

TERMINAL

BLOCK

LIGHTS,

COVER6"and

SWITCH

INSULATION(2Req'd.)

BEARING

BEARING

LOWER

UPPER

DIAL

PILOT

PILOT

FOR

HEAT

CONTROL

HEATCONTROL

ROUND

FILLISTER

FLAT

ROTOR

FOR

ROTOR

220V.

220V.

MOTOR

60cy.

50cy.

TOGGLE

WITH

BAND

BAND

CONTACT

Description

SLEEVE

NUT(4Req'd.)

LOCK

BEARING

ROTOR

FOR

RING

DRIVESOREW

PIN(3Req'd.)

SWITCH

SWITCH

SWITCH

SWITCH

COVER

GROUND

BALL

BALL

SWITCH

LIGHT

LIGHT

COVER

HEAD(3Req'd.)

HEAD(8Req'd.)

HEAD(2Req'd.)

HEAD(2Req'd.)

HEAD(2Req'd.)

NUT

NUT

WIRE

NUT

SPEED

NUT

FAN

SPRING

CONTROL

RING

SWITCH

BLOCK

BOTTOM

BASE

BASE

BASE

COVER

11-1/2"

BRACKET

CLIP

HOUSING

HOUSING

BEARING

BEARING

CLIP

INDICATOR

110V.

220V.

11-1/2"

220V.

110V.

TOP

HEAD(2Req'd.)

HEAD(2Req'd.)

WITH

3600

3000

FAN

SHAFT

R.P.M.

R.P.M.

SWITCH

Phase)

WITH

(Three

PIN(3Req'd.)

8"

CLOTH

DRILL

COMPANY

77e'WAaHiNGITaN

BUPPAUa.

NEW

YORK

STREET

lAEOS

6\

*PARTS

t

PARTS

REQUIRED

REQUIRED

ON

ON

PLEASE

MACHINE

AND

WHEN

0D2

ONLY,

0D2H

ONLY.

SPECIFY

TYPE

SERIAL

ORDERING

NUMBER

PARTS

Loading...

Loading...