Eastman BBB32 User Manual

EASTMAN LIGHT WEIGHT

ROUND KNIVES

TYPE

TYPE

BBB32

(PAGE 6)

CAUTION

MACHINE EQUIPPED

WITH

SHARP BLADE

TYPE D2H

(PAGE 8)

BBS32

(PAGE 4)

(PAGE 12)

TYPE D2

(PAGE 8)

INSTRUCTION BOOK AND PARTS LIST

779 WASHINGTON STREET

BUFFALO, NEW YORK 14203

AREA CODE: 716, 856-2200

EASTMAN DEPENDABILITY, EASTMAN QUALITY AND EASTMAN SERVICE ARE YOUR GUARANTEE

THAT EASTMAN CUTTERS CUT COSTS. THERE’S AN EASTMAN FOR EVERY CUTTING NEED.

Website: www.eastmancuts.com

Form C-1206

DESCRIPTION

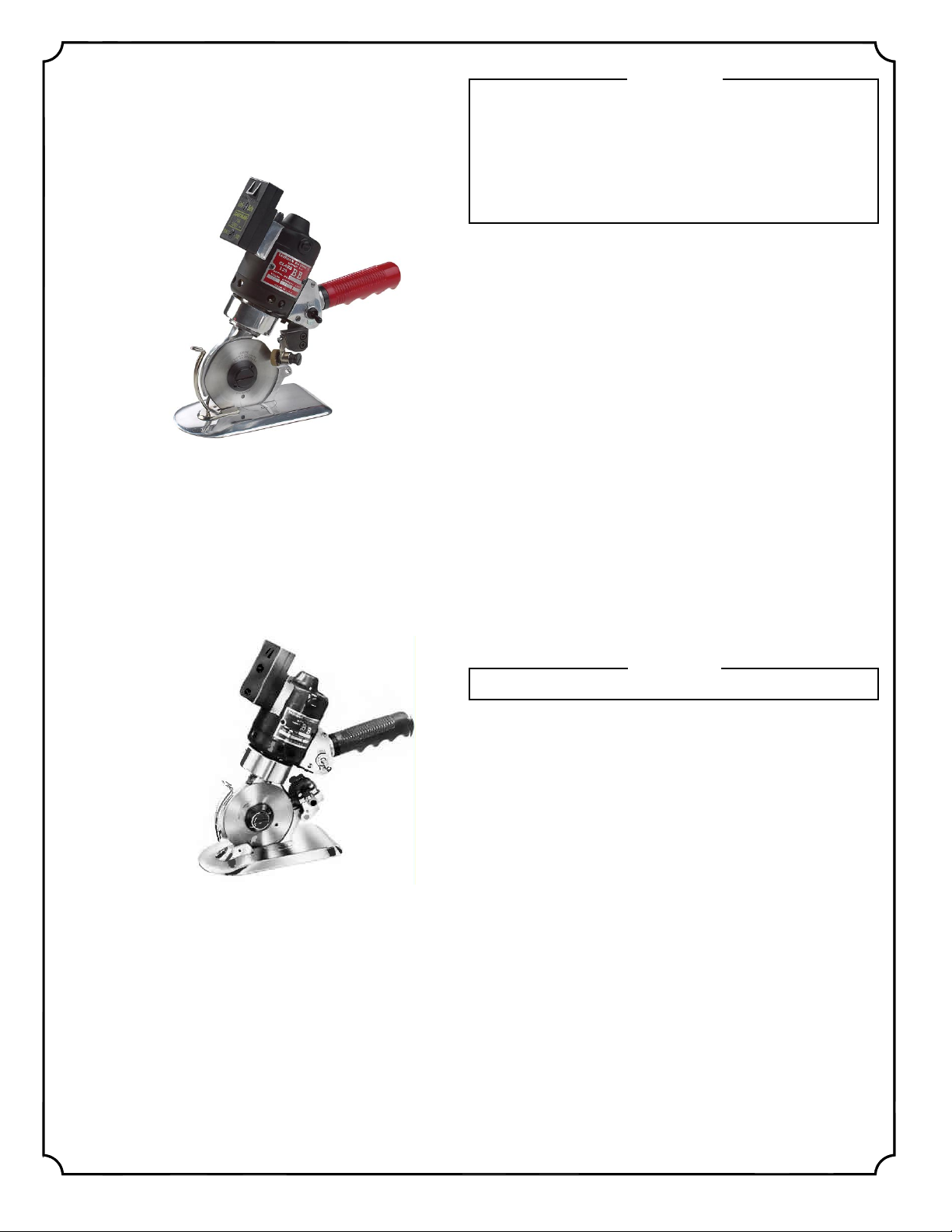

TYPE BBS32

(PAGE 4)

BBS – Equipped with single Sharpener and Shear Plate

where continuous honing of Knife is desired. 3 1/4”

Hexagon Knife.

CAUTION

Read instructions carefully before starting motor. Be sure

that voltage and current are the same as stamped on

nameplate. All Eastman machines shown in this catalogue

are equipped with sharp blades and extreme caution should

be used when this machine is put into use. When this equipment is not being utilized, the power supply should be

disconnected from the equipment.

TO OPERATE MACHINE

Turn machine to ON position; if cutter does not start immediately

return switch to OFF position. Check the line output and be sure

that the unit is plugged in properly and is making full contact. Do

not attempt to start this unit while it is in the material to be cut.

WARNING

Before performing any of the following procedures, make

sure that the attachment plug has been disconnected from

power source.

KNIFE REPLACEMENT

BBS32 (page 5) – To remove knife, lay machine on side and carefully insert blade of screwdriver into fan of the motor and using Spanner Wrench (95C1-19) inserted into Locknut (4C1-175) or (4C1-182),

turn counterclockwise and remove Locknut – replace knife making

sure the word “Eastman” faces outward.

BBB32 – To remove knife, line up hole in knife and hole in standard,

insert pin and use Spanner Wrench (95C1-21). Turn counterclockwise and remove. Replace knife with Eastman name facing outward.

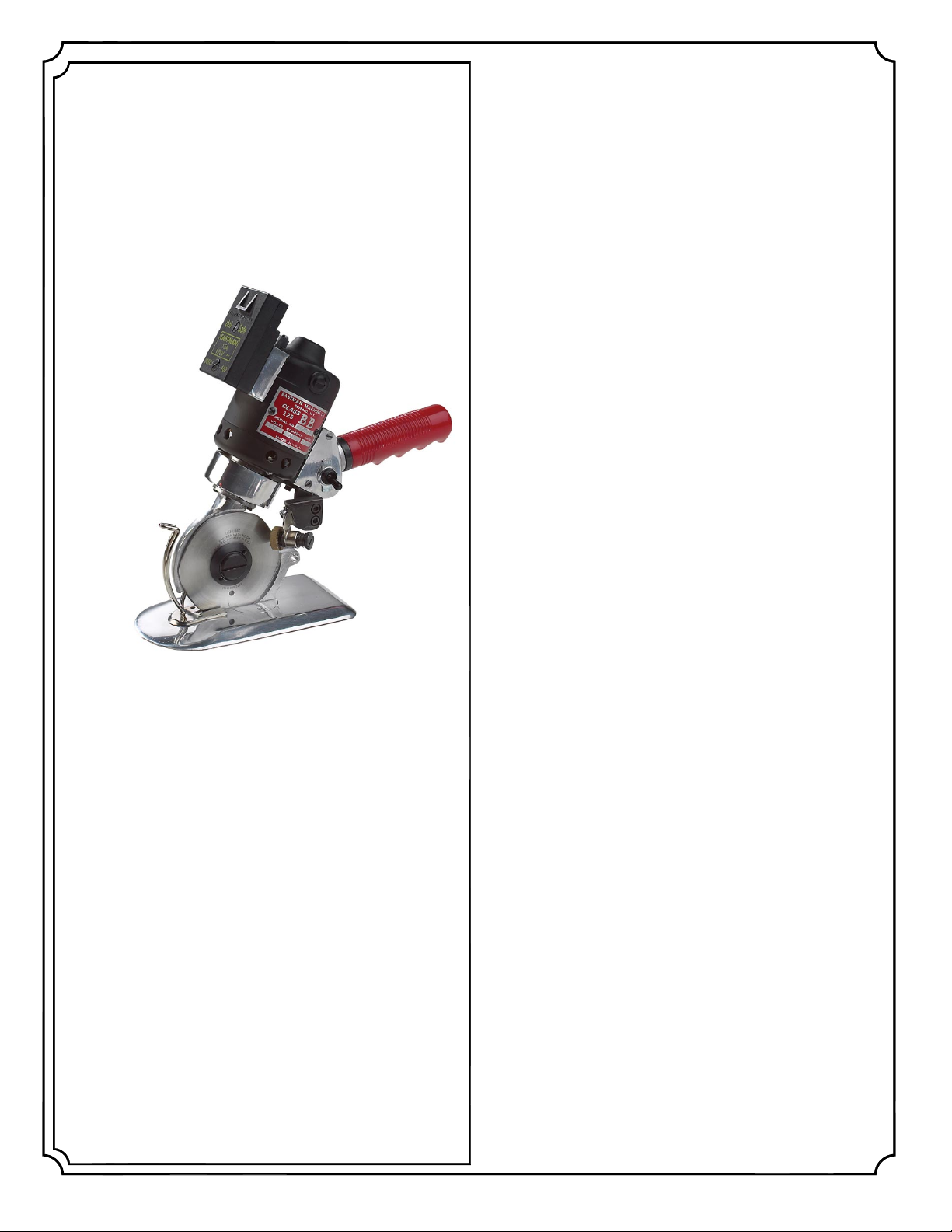

TYPE

BBB32

(PAGE 6)

BBB32 – Has a 3 1/4” Knife for increased capacity and an

adjustable Throat Plate.

CAUTION

Discard used sharp knives with care.

THROA T PLATE ADJUSTMENT

BBB32 (Page 7) – These machines are equipped with an adjustable Throat Plate (79C5-249) and it is important that the edge of

the knife be as close as possible without touching edge of knife

and equally straddling the blade. Two (2) Screws located on bottom of base can be loosened and tightened for this adjustment.

SHEAR PLA TE ADJUSTMENT

BBB (Page 5) – When adjusting the shear plate on the Model BBB,

adjusting screw (20C6-26) in a clockwise manner will increase the

spring tension on the shear plate; adjusting the screw in a counterclockwise manner will reduce the spring tension.

LUBRICATION

BBB32 – BBS32

OIL – Fill oil cup (72C4-2) daily and a small drop of SAE 30 nondetergent motor oil at each end of Sharpener Adjusting Bushing.

GREASE – To lubricate, remove Plug (54C4-35) page 5 or p age 7

and inject small quantity of Eastman Gear Lubricant Special Formula (242C2) at 90 day intervals for intermittent use. Every six

months the (20C12-145) (BBB32) and (20C12-165) (BBS32)

screws that retain the knife gear should be removed and the knife

gear taken out and inspected thoroughly to insure that no thread

or lint build-up is in or around the gear area.

2

Form C-1206

CAUTION

Do not use sewing machine oil or detergent oil. It is entirely too

light for cutting machine lubrication. For best results use specially compounded Eastman Oil or at least a good grade SAE 30

motor oil. Do not oil base plate rollers.

Do not overload with grease as machine will run hot at gear assembly.

Remove knife and gear and remove excessive grease.

MAINTENANCE PROCEDURES

1. Keep rollers of the base plate free of lint. Motor should be

blown clear of lint and dust weekly using air hose at 90

P.S.I.

2. Periodically check terminal pins on the terminal block and

the terminal in the attachment plug to insure full contact.

3. When replacing the knife on your cutting unit be sure to

clean out any lint build up between knife and standard.

4. If the cutting unit seems to lag or run hot when not cutting, run machine with knife removed to check for overgreasing or any obstructions.

5. When changing knife or cleaning machine check all screws

and nuts for tightness.

6. Carefully remove spring loaded brushes – replace brushes

when worn to less than .165 inches (4.2mm) or if springs

are less than .350 inches (9.00mm).

TO REPLACE EMERY WHEELS

BBS32

1. Remove left hand cap – 2 screws (300C8-2)

– lift out emery wheel with bushing.

2. Remove screw (20C13-30).

3. Coat new emery wheel spindle with oil and

re-assemble to arm (620C1-21).

4. Repeat above steps for right hand emery wheel.

NOTE

Left and Right caps must be replaced in the same manner that they were removed.

BBB32

1. Remove cap (35C5-45) and lift out emery

wheel and bushing. Then remove screw

(304C10-3) from left hand emery wheel and

pull out emery wheel (541C1-10). Replace

wheels and re-assemble.

2. Adjust wheels as outlined for BBR.

BBS32

Remove sharpener (637C1-23) from machine and disassemble as shown in diagram page 5 – replace emery wheel

(541C1-22). Lubricate – re-assemble – re-install.

7. When your machine performance does not appear to be

up to par, contact your Eastman Machine authorized

dealer.

MOTOR BRUSH REPLACEMENT

When replacing brushes (36C1-13) in the motor, carefully remove the

(54C4-43) brush caps, remove the (34C1-58) brush with springs and replace brushes accordingly .

KNIFE SHARPENING

BBB32R – BBS32 – Connect power cord and switch motor on. To

obtain a fine, keen edge on the blade, press lightly on sharpener lever

or button with a constant pressure.

KNIFE SHARPENER REPLACEMENT

BBB32 – BBS32

CAUTION

Disconnect from electric power source when servicing.

As the emery wheels wear away and become farther apart, they must

be adjusted. Proceed as follows:

1. Slightly loosen four (4) slotted screws (300C8-2) holding

adjusting bushings in place.

2. With fingers, turn adjusting bushings (20C6-23) until emery wheels are as close together as possible without touching and centered over knife. Both wheels should grind at

the same time when pressed lightly against knife with a

maximum 1/32 inch clearance between wheels. The sharpened edge (bevel) should be no more than 1/16 inch.

220 VOL T MACHINES

When using the 220 volt machine on three phase outlets,

use adaptor (509C1-54) by simply mounting this adaptor

on the (25C5-49) single phase attachment plug. The two

live leads of the (615C1-5) three phase attachment plug

can be utilized for the power this machine requires.

KNIFE GUARD ADJUSTMENT

Knife guards (25C4-144) and (25C4-106) should be regulated in a manner that only allows the material to pass

through the material to be cut.

REPLACEMENT BLADES

Machine Part Number Blade

T ype Size Carbon High Speed Type

BBS32 2 1/2"

BBB32 3 1/4" 80C1-84*80C1-84HS Round

D2

D2H 80C1-149HS Hex

BUZZ 2-1/32" —

*

Standard Blade

2 1/4" —

80C1-114 80C1-114HS Round

80C1-138* — Hex

80C1-147HS

80C1-123HS*Semi Square

80C1-133HS Octagon

*

Round

3. Tighten four (4) screws.

PLEASE SPECIFY MACHINE NAME AND SERIAL NUMBER WHEN ORDERING P ARTS.

Form C-1206

3

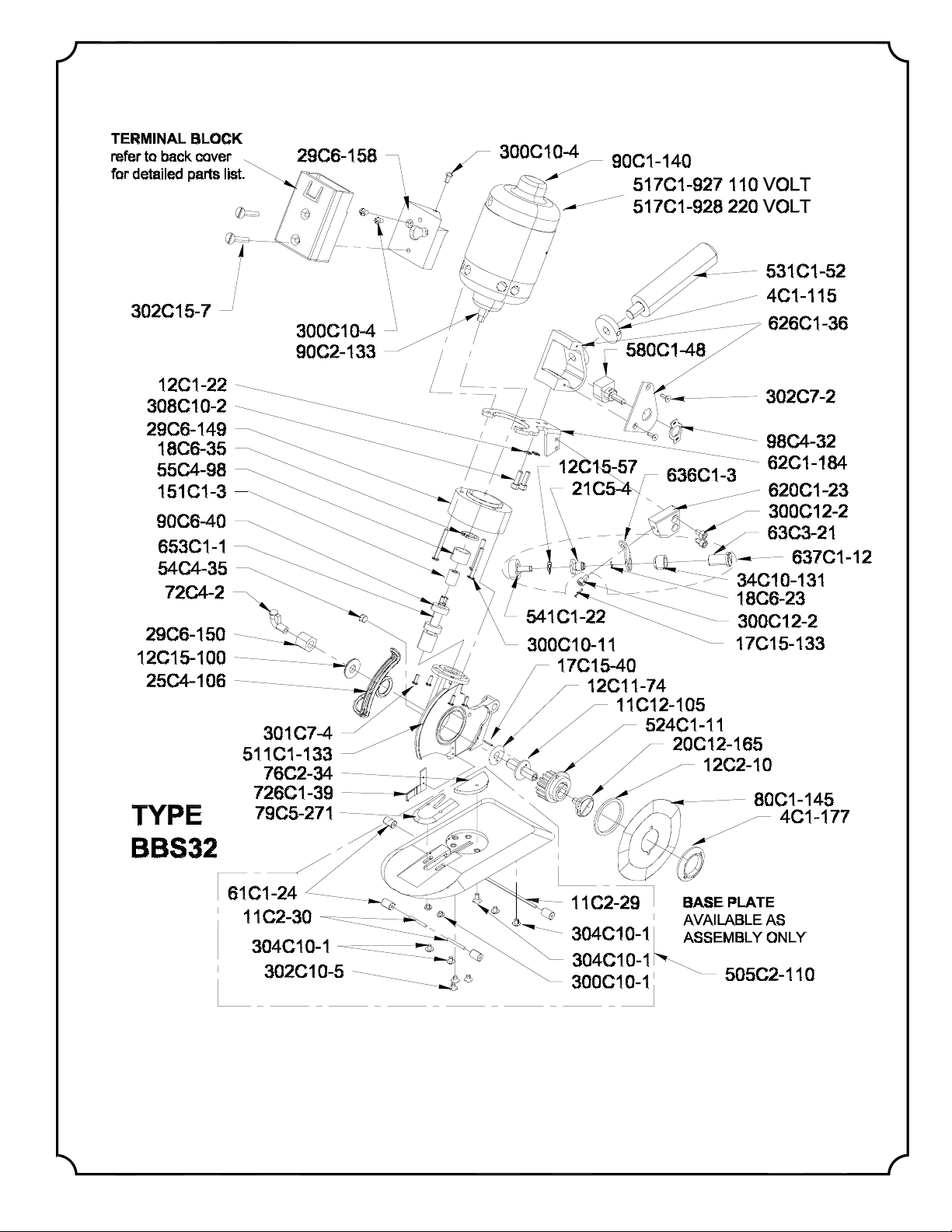

ILLUSTRATED PARTS

LIST

TYPE BBS32

Note: Please specify model and serial num-

ber of machine when ordering parts.

Part No. No. Req'd Description

4C1-115 1........................................................ HANDLE LOCKNUT

4C1-177 1............................................................ KNIFE LOCKNUT

4C2-101 2....................................................................... WIRE NUT

11C2-29 1................................................... REAR ROLLER SHAFT

11C2-30 2.................................................FRONT ROLLER SHAFT

12C1-22 2............................................. WASHER, SHAKE PROOF

12C2-10 1..........................................FELT WASHER FOR STAND

12C11-74 1........................................................ SPACING WASHER

12C15-57 1.......................................................... SPRING WASHER

12C15-100 1............................ WASHER FOR WORM GEAR SHAFT

17C15-40 1..........................................................PIN IN STANDARD

17C15-133 1...................................................... PIN, ROLL 1/16 X 3/8

18C6-23 1..................................................................... SNAP RING

18C6-35 1........................................................... RETAINING RING

20C12-165 1............................................................ THRUST SCREW

21C5-4 1............................................. EMERY WHEEL BUSHING

25C4-106 1................................................................ KNIFE GUARD

29C6-149 1......................................................... MOTOR ADAPTOR

29C6-150 1........................................................ OIL CUP ADAPTOR

29C6-158 1....................................... TERMINAL BLOCK ADAPTOR

34C1-58 2..............................................................BRUSH SPRING

34C10-131 1.................................................... SHARPENER SPRING

36C1-13 2............................................................................ BRUSH

54C4-35 1............................................................... GREASE PLUG

54C4-43 2..................................................................BRUSH PLUG

55C4-98 1......................................................... SPACER BEARING

61C1-24 4.................................................. PLATE ROLLER SHELL

62C1-184 1........................................................ HANDLE BRACKET

63C3-21 1................................................... SHARPENER BUTTON

72C4-2 1.......................................................................... OIL CUP

76C2-34 1................................................................ PLATE FILLER

79C5-271 1.............................................................. THROAT PLATE

80C1-145 1.............................................................................. KNIFE

90C1-140 1............................................ BEARING HOUSING REAR

90C2-133 1.......................................... BEARING HOUSING FRONT

90C6-40 2..................................... BALL BEARING, WORMSHAFT

98C4-32 1.................................................................. ON/OFF CLIP

151C1-3 1........................................................ COUPLING MOTOR

300C10-1 2.............................. SCREW, 6-32 X 3/16 ROUND HEAD

300C10-4 3................................ SCREW, 6-32 X 3/8 ROUND HEAD

300C10-11 3............................ SCREW, 6-32 X 11/16 ROUND HEAD

300C12-2 4................................ SCREW, 8-32 X 1/4 ROUND HEAD

301C7-4 4..........................SCREW, 4-36 X 5/16 FILLISTER HEAD

302C10-4 4...................................SCREW, 6-32 X 5/16 FLAT HEAD

302C10-5 3.................................... SCREW, 6-32 X 3/8 FLAT HEAD

302C7-2 2.................................... SCREW, 4-36 X 1/4 FLAT HEAD

302C15-7 2..................................... SCREW, 10-32 X 1 FLAT HEAD

304C10-1 4................................. SCREW, 6-32 X 1/8 TRUSS HEAD

308C10-2 2...............................SCREW, 6-32 X 1/2 SOCKET HEAD

505C2-110 1.................................................... FLAT PLATE ROLLER

511C1-133 1..................................................................... STANDARD

517C1-927 1............................................. MOTOR (120 VOLT ONLY)

517C1-928 1............................................. MOTOR (220 VOLT ONLY)

524C1-11 1................................................................... KNIFE GEAR

531C1-52 1.......................................................................... HANDLE

541C1-22 1.................................................... SHARPENING STONE

542C1-99 1.......................................ARMATURE (120 VOLT ONLY)

542C1-100 1.......................................ARMATURE (220 VOLT ONLY)

580C1-48 1.......................................................................... SWITCH

620C1-23 1..................................................... EMERY WHEEL ARM

626C1-36 1.......................SWITCH BASE & BRACKET ASSEMBLY

636C1-3 1.................................................SHARPENER BRACKET

637C1-12 1............................................. SHARPENER, COMPLETE

726C1-39 1............................................ SHEAR PLATE ASSEMBLY

4

Form C-1206

Form C-1206

5

Loading...

Loading...