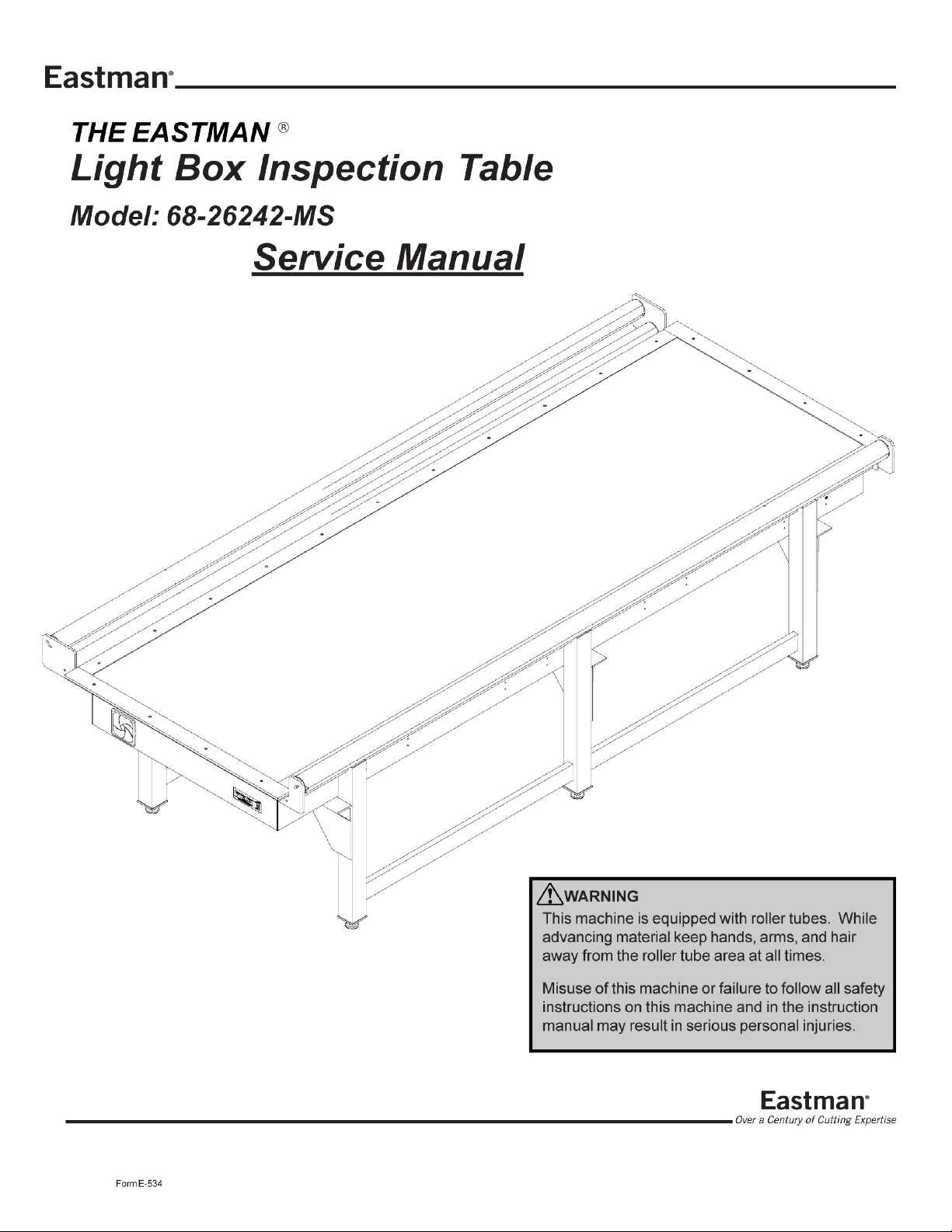

Eastman 68-26242-MS Parts List

Table of Contents

General Safety Precautions......................................... 3

Safety Information ....................................................... 3

Reference Manuals ..................................................... 4

Recommended Spare Parts List .................................. 4

Installation ................................................................... 4

Table Preparation ........................................................ 4

To Level Table .............................................................. 4

Electrical Connection .................................................. 4

Operation .................................................................... 4

Bulb Replacement ....................................................... 4

Light Box Inspection Table Familiarization ................... 5

Light Box Table ........................................................... 6

Light Box Rollers ......................................................... 8

Light Box Enclosure .................................................... 9

Light Box Electrical Diagram ..................................... 10

Blue Print No. (31-9000-32) ....................................... 10

Notes ........................................................................ 11

Technical Data .......................................................... 12

IMPORTANT

The purchaser must instruct all operators on the proper use of this equipment. All standard industrial safety measures

and equipment should be provided to protect the operator. Operators must be cautioned that improper or careless

use of this equipment may cause personal injury. If you do not have qualified operators to instruct new persons,

contact your EASTMAN sales representative or EASTMAN factory direct.

Electrical connections and servicing to this equipment should be made by a qualified electrician who is familiar with

applicable codes and regulations. Disconnect this equipment from electrical power source before proceeding with

any disassembly for adjustment or repair.

Your Eastman Light Box Inspection Table is designed to operate with the M9000 Cutting system. Material may

advance at a high rate speed. All personnel should be instructed to wear safety glasses and stand well clear of the

Light Box Inspection Table when in operation.

2

Form E-534

Safety Information

Throughout this manual, safety information is presented by

the use of the terms WARNING, CAUTION, ELECTRICAL

HAZARD, and NOTE. These terms have the following meanings:

WARNING

A warning contains critical information regarding

potential safety hazards that can occur during proper

use or misuse of the machine. Failure to follow these

procedures may result in serious personal injury to

the user.

CAUTION

A caution contains instructions for the use or maintenance of the machine. Failure to follow these procedures may result in damage to the machine.

ELECTRICAL HAZARD

An electrical hazard calls attention to a procedure,

practice, or the like, which, if not correctly performed

or adhered to, could result in personal injury. Do

not proceed beyond an Electrical Hazard.

Supplementary information may be given in a Note.

Safety and Indemnification

During the life of the machine, the purchaser agrees

to provide to all machine users (including its own

employees and independent contractors) all relevant

safety information, including warning labels and instruction manuals. The purchaser also agrees to

maintain the safety features and working condition

of the machine, and to adequately train all users in

the safe use and maintenance of the machine. The

purchaser agrees to defend, protect, indemnify, and

hold Eastman Machine Company and its subsidiaries harmless from and against all claims, losses,

expenses, damages, and liabilities to the extent

that they have been caused by the purchaser’s failure to comply with the terms and instructions of

this manual.

General Safety Precautions

WARNING

• This machine is equipped with roller tubes. While

advancing material keep hands, arms, and hair away

from the roller tube area at all times. Safety gloves,

glasses, and appropriate clothing may prevent serious personal injuries.

• Disconnect the power supply to the machine when

it is not in use or during routine maintenance, including cleaning and lubrication.

• The purchaser must instruct all operators in the

proper use of the machine according to the instructions in this manual. This training must include instruction on the potential safety hazards arising from

the use or misuse of the machine. In addition to

such training, the purchaser should provide written

work instructions as necessary to ensure correct

use of the machine for specific cutting and spreading applications.

• Do not modify this machine or disable safety features. Unauthorized modification may result in serious personal injuries to the user. Electrical connections to this machine must be made by a qualified electrician familiar with applicable codes and

regulations.

• Safety labels must be kept clean and legible at

all times. Call the Eastman Machine factory to

order replacement labels.

Form E-534

3

The Eastman Light Box Inspection Table has been inspected and tested at the factory prior to shipment. The

Light Box Table may be shipped partially disassembled and

require some assembly and setup before operation can take

place. Refer to this service manual as an installation guide

during installation. To get the best performance, familiarize

yourself and all operators with all functions and adjustments

of this equipment. Before any operation takes place it is

important to carefully read and follow the instructions in this

reference manual.

The Illustrated Parts List is a comprehensive list of the components used in the machine. When ordering replacement

parts, please include machine name, machine voltage and

serial number. Some machine configuration may require additional components not shown, please consult factory for

part numbers.

The following list of recommended spare parts may be included with your machine or purchased at a later date.

Reference Manuals

E-534 ..................... Light Box Table Service Manual

Recommended Spare Parts List

Part Number Description

11-1302 Fuse, 5 amp.

31-26260-1 Lamp, 36" T8

31-26261 Ballast, 110 volt

Connect power cord plug to table inlet at back under side of

the table. Check voltage rating with electrical rating stamped

on serial number plate. If compatible, connect cord to main

power.

Note: Voltage varying more than 10% (11v for 110 volt

machine, 22v for 220 volt machine) may damage

your system's electronics.

Operation

The Light Box Inspection Table is designed to aid the

operator in detecting material flaws by emitting light through

material to show material flaws.

The light switch is located at the table front. Press the light

switch ON to turn on the light box and OFF to turn off the light

box.

Bulb Replacement

CAUTION

Disconnect power before proceeding with bulb replacement.

Only Eastman bulbs should be used when replacing

bulbs. Damage to your machine may result and will

void your warrantee.

1) Disconnect main power.

2) Remove (4) screws holding the side dress plate.

3) Slide table surface out to gain access to the bulbs.

Installation

The Light Box Inspection Table weighs approx. 450 lbs. ( 204

kg.) uncrated for a 126" machine.

CAUTION

Do not place forklift arms under light box enclosure.

When lifting, places forklift arms under table leg

cross tubes.

Use care not to damage table legs and leg levelers.

Table Preparation

Place light box table approx. 12" [30.5 cm] from desired end

of table and even with the operators side of the existing table.

The table must be square and level along its entire length. A

minimum 3 feet (1M) clearance along each side of the table

is required for safe operation. Refer to familiarization section

before placing machine in the final location.

To Level Table

Use carpenter's level to check table. Adjust table feet as

necessary to level table.

Electrical Connection

Always allow bulbs to cool before replacing.

4) Replace bulbs as required. It is always recommended to

replace all the bulbs at the same time to ensure even light

disbursement.

5) Replace table surface and side dress plate.

It is the owners responsibility to properly dispose of used

bulbs according to the codes and regulations in your town.

4

Form E-534

Loading...

Loading...