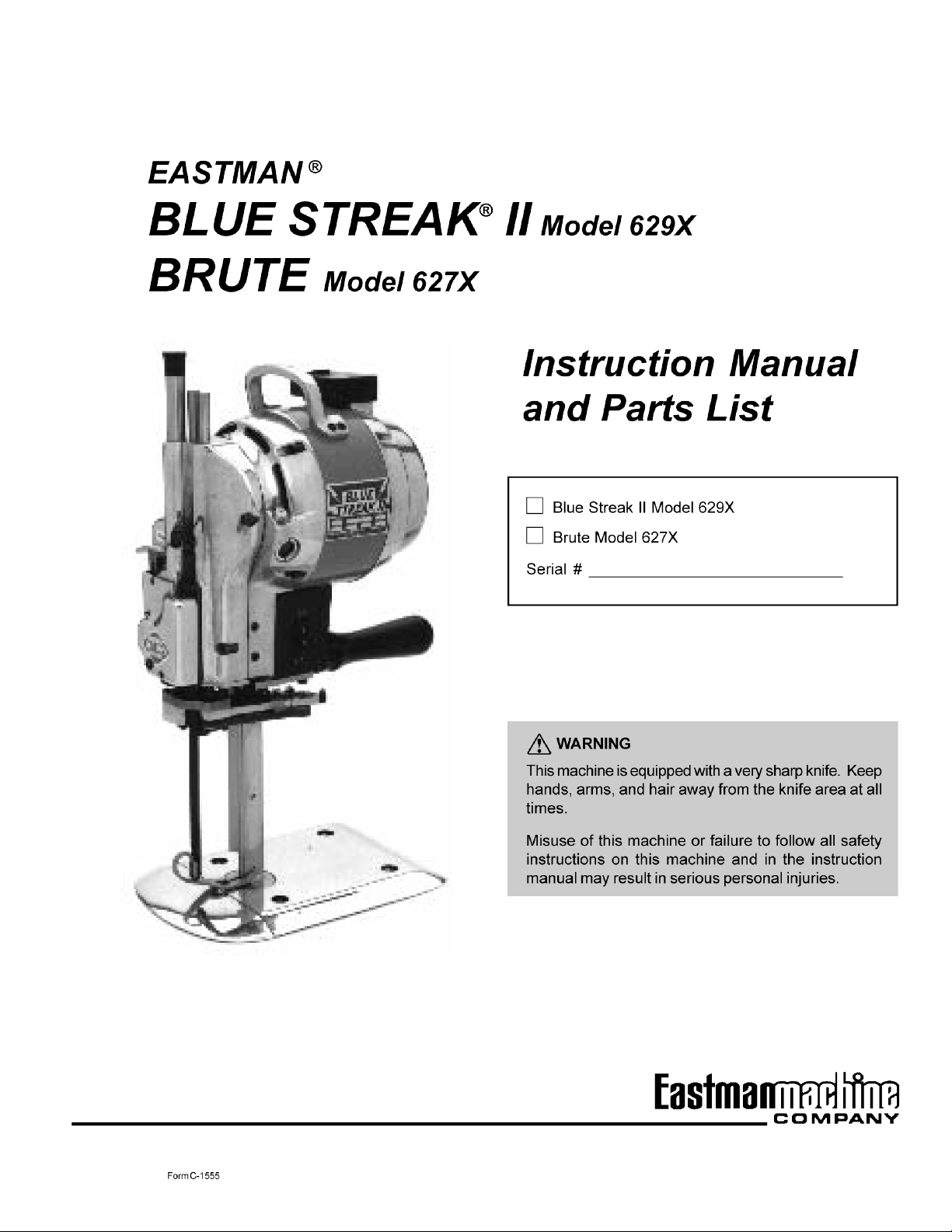

Eastman 629X, 627X Parts List

EASTMAN

Limited Warranty. Eastman warrants to the buyer that the Blue Streak II and Brute shall be free from

defects in materials or workmanship for a period of 180 days commencing on the date of invoice. Any

goods or parts claimed by the buyer to be defective must be returned to Eastman, freight charges prepaid,

within the 180–day warranty period. If Eastman determines that the goods or parts are defective in materials or workmanship, Eastman's sole obligation under this warranty shall be, at Eastman's sole option, to

repair or replace the defective goods or parts or to provide to the buyer a credit equal to the portion of the

purchase price allocable to the defective goods or parts. This warranty shall not apply if defects are

caused by product misuse or neglect, if the machine has been altered or modified by the buyer, or if other

than genuine Eastman belts, emery wheels, knives or parts are used in the machine. THIS WARRANTY

IS THE ONLY WARRANTY APPLICABLE TO THIS PURCHASE. SELLER DISCLAIMS ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Limitation of Liability. Eastman's liability to the buyer, and the buyer's remedies from Eastman, whether

in contract, negligence, tort, under any warranty or otherwise, shall be limited to the remedies provided in

the foregoing Limited Warranty. In no event shall Eastman have any responsibility or liability to the buyer

for (a) any special, indirect, incidental, or consequential damages, including, but not limited to, loss of use,

revenue, or profit, even if Eastman has been advised of the possibility of such damages, or (b) any claim

against the buyer by any third party. The price stated for the product sold is a consideration for limiting

Eastman's liability.

Form C-1555

Table of Contents

Safety Information ........................................ 1

General Safety Precautions ...................................... 1

Initial Set Up ............................................................. 2

Operation ...................................................... 2

Operating Procedure ................................................ 3

Safety Considerations ................................................. 3

Starting the Machine ................................................... 4

Making a Cut .............................................................. 4

Turning Off the Machine .............................................. 4

Routine Maintenance ................................... 4

Care of the Machine .................................................. 4

Daily ........................................................................... 4

Twice Weekly .............................................................. 5

Weekly ....................................................................... 5

Lubrication ................................................................ 5

Daily ........................................................................... 5

Weekly ....................................................................... 5

Monthly ....................................................................... 5

Sharpening the Knife ................................................ 5

Removing the Sharpener ............................................. 5

Replacing the Rubber Driver Pulley......................... 6

Adjusting the Belt Sharpener ................................... 7

Changing Sharpener Belts .......................................... 7

Adjusting Stabilizers for Central Alignment ................. 7

Checking the Sharpener Shoes ................................... 8

Checking the Extreme Down Position of the Sharpener 8

Checking the Stop Screw on the Sharpener Shoe ....... 9

Check the Width of the Bevel on the Knife .................. 9

Changing the Knife ..................................................... 9

Adjusting Bevel Bloc® Shoes ................................ 11

Adjusting Bevel Bloc® Shoes (continued) ............ 12

Troubleshooting...................................................... 14

Freeing Frozen Guides ........................................... 16

Accessories ................................................ 16

Stainless Steel Mesh Gloves .................................. 16

Ordering Details ........................................................ 17

Genuine Eastman Abrasive Belts........................... 17

Ergo-Handle ............................................................ 18

Specialty Machines ................................................. 18

Plastic Master Model 627PM/629PM ........................ 18

Micro Fog Model 627MF/629MF ............................... 19

Illustrated Parts List ................................... 20

Motor Assemblies ..................................................... 20

Front Bearing Housing Assembly .............................. 20

Sharpener Housing Assembly ................................... 20

Lower Gear Bracket Assembly.................................. 20

Standard and Baseplate Assembly ........................... 20

Electrical Connections ............................... 36

IMPORTANT

This manual contains instructions and part numbers for

two different machines: Brute Model 627 and Blue Streak II

Model 629. If you contact Eastman Machine Company for

information or to order parts, always specify the machine

name and model number.

If you are ordering electrical components, specify the voltage, frequency (Hz), and speed (RPM) of your machine.

You can find this information on a label attached to your

machine.

Patents Statement

Some parts of this manual and the equipment it describes

are protected by the following U.S. patents: 5,178,232,

4,609,244, 5,111,582, 4,761,878, and D281,416. Other

patents pending.

Trademarks Statement

The names Eastman, Uni-Safe, Blue Streak, and Bevel

Bloc are registered trademarks of the Eastman Machine

Company.

Form C-1555

i

EASTMAN

List of Figures

Figure 1. Operating Features ....................................... 2

Figure 2. Controls and Adjustments ............................ 3

Figure 3. Removing the Sharpener ............................... 6

Figure 4. Replacing the Rubber Driver Pulley ............... 6

Figure 5. Changing the Sharpener Belts ...................... 7

Figure 6. Adjusting the Stabilizers ............................... 7

Figure 7. Changing the Knife ....................................... 9

Figure 8. Available Eastman Knife Types ................... 10

Figure 9. Adjusting Bevel Bloc Shoes ......................... 11

Figure 10. Bevel Bloc Shoe Assembly ........................ 12

Figure 11. Maintenance Supplies ................................ 13

Figure 12. Single-Phase Electrical Configuration ......... 15

Figure 13. Freeing Frozen Guides ............................... 16

Figure 14. Available Metal Mesh Glove Styles ............. 17

Figure 15. Eastman Abrasive Belts ............................. 17

Figure 16. Edges Produced by Different Belt Grits ...... 18

Figure 17. Ergo-Handle ............................................... 18

Figure 18. Plastic Master ............................................ 19

Figure 19. Micro Fog ................................................... 19

Figure 20. Standard and Baseplate Assembly

(Exploded View) ......................................... 21

Figure 21. Single-Phase Motor Assembly

(Assembled View) ...................................... 22

Figure 22. Single/Dual-Phase Motor Assembly

(Exploded View) ......................................... 23

Figure 23. Three-Phase Motor Assembly

(Assembled View) ...................................... 24

Figure 24. Three-Phase Motor Assembly

(Exploded View) ......................................... 25

Figure 25. Front Bearing Housing with Oiler

Assembly (Exploded View) ......................... 27

Figure 26. Sharpener Housing Assembly

(Assembled, Front View) ............................ 28

Figure 27. Sharpener Housing Assembly

(Exploded, Front View) ............................... 29

Figure 28. Sharpener Housing Assembly

(Assembled, Rear View) ............................. 30

Figure 29. Sharpener Housing Assembly

(Exploded, Rear View) ................................ 31

Figure 30. Lower Gear Bracket Assembly

(Assembled View) ...................................... 32

Figure 31. Lower Gear Bracket Assembly

(Exploded View) ......................................... 33

Figure 32. Standard and Baseplate Assembly

(Assembled View) ...................................... 34

Figure 33. Standard and Baseplate Assembly

(Exploded View) ......................................... 35

Figure 34. Removing a Worn Plate Roller Shell ........... 35

ii

Form C-1555

Safety Information

Throughout this manual, safety information is presented by

use of the terms Warning, Caution, and Note. These terms

have the following meanings:

WARNING

A warning contains critical information regarding potential safety hazards that can occur during proper use or

misuse of the machine. Failure to follow these procedures may result in serious personal injury to the user.

CAUTION

A caution contains instructions for the use or maintenance of the machine. Failure to follow these procedures

may result in damage to the machine.

General Safety Precautions

WARNING

• This machine is equipped with a very sharp and dangerous knife. Keep hands, arms, and hair away from

the knife area at all times. When the machine is not

in use, keep the pressure foot knife guard lowered

and locked at all times. Safety gloves and glasses

and appropriate clothing may prevent serious personal

injuries.

• Disconnect the power supply from the machine when

it is not in use or during routine maintenance, including lubrication.

• The purchaser must instruct all operators in the proper

use of the machine according to the instructions on

the machine and in this manual. This training must

include instruction on the potential safety hazards arising from the use or misuse of the machine. In addition to such training, the purchaser should provide

written work instructions as necessary to ensure correct use of the machine for specific cutting applications.

Safety and Indemnification

During the life of the machine, the purchaser agrees to provide to all machine users (including its own employees and

independent contractors) all relevant safety information, including warning labels and instruction manuals. The purchaser also agrees to maintain the safety features and working condition of the machine, and to adequately train all

users in the safe use and maintenance of the machine. The

purchaser agrees to defend, protect, indemnify, and hold

Eastman Machine Company harmless from and against all

claims, losses, expenses, damages, and liabilities to the

extent that they have been caused by the purchaser’s failure to comply with the terms and instructions of this manual.

• The purchaser must provide appropriate safety measures and equipment as recommended in this manual.

Observe all statutory requirements concerning the use

of hazardous machinery that apply to your location.

• Do not modify this machine or disable safety features. Unauthorized modification may result in serious personal injuries to the user. Electrical connections to this machine must be made by a qualified

electrician familiar with applicable codes and regulations. To prevent electrocution, a ground lead must

be connected to terminal “E” on the attachment plug.

• This machine is intended ONL Y for hand-held operation. Misuse of this machine or use of this machine

as part of another machine may result in serious personal injuries to the user.

• Safety labels must be kept clean and legible at all

times. Call the Eastman Machine factory to order

replacement labels.

Form C-1555

1

EASTMAN

Operation

Before operating the machine, read these instructions carefully . Familiarize yourself with all the functions and adjustments of the machine.

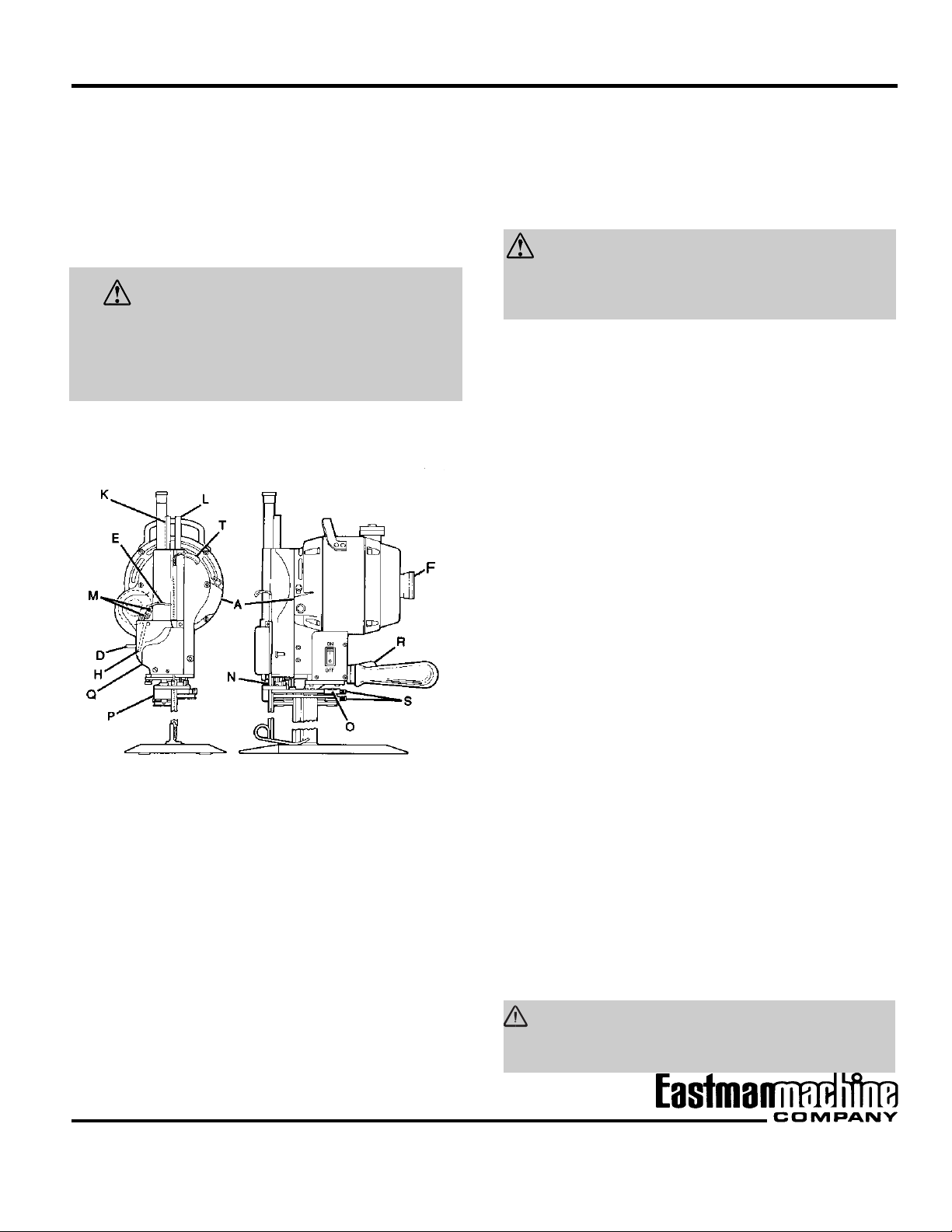

Carrying Handle

Operating Handle

Knife GuardPressure Foot

CAUTION

Operating this machine from an incorrect electrical

supply may damage it.

2. Check that the machine has been lubricated according

to the schedule listed in Routine Maintenance–Lubrica-

tion on page 5.

Note: At this time, carry out the full monthly lubrication

schedule on page 5.

3. Make sure that the sharpener is in the locked position.

To do this, push in the turning knob (Figure 2, F). While

depressing the turning knob, turn the machine over a few

revolutions by hand to see if the knife reciprocates

easily. If the knife does not move easily, the sharpener

may be in the unlocked position.

4. To lock the sharpener in place, lift the release lever

(Figure 2, D) and press the sharpener lever (Figure 2, E)

to release the sharpener. Raise the sharpener bracket

(Figure 2, S) by hand to lock it in place. Once the

sharpener is locked in place, you may disengage the

release lever and sharpener lever. Repeat step 3 to

ensure that the sharpener is now locked. If not, repeat

this step.

5. Visually inspect the blade to ensure that the top of the

knife is flush with the knife lockbolt (Figure 7, 1 on page

9) and that the knife is perpendicular to the baseplate. If

you need to adjust the alignment of the blade, see

section Changing the Knife on page 9.

Figure 1. Operating Features

Initial Set Up

After the machine has been installed and before you use it

for the first time:

1. Check that the electrical supply current and voltage that

the machine is connected to are the same as stamped

on its name plate. For three-phase machines, also

check that the direction of rotation is correctly set by the

turning knob (Figure 2, F). Refer to the tag attached to

all three-phase machines for detailed instructions.

2

Form C-1555

6. Check that the motor switch is in the OFF position. Then

connect the attachment plug to the terminal block on the

machine.

7. Hold the operating handle and turn on the machine.

Allow the blade to reach full speed. If the blade is

struggling, the sharpener is still not in the locked

position. If this is the case, turn off the machine and do

the following:

7.1 With your left hand, straddle the front of the sharpener with fingers and thumb.

7.2 Press the bell crank release lever (Figure 2, H) to

disengage the sharpener mechanism from the motor.

7.3 With your right hand, hold the operating handle

and turn on the motor switch. Allow the motor to

gather full speed and then release the release lever.

This automatically returns the sharpener to the locked

position.

Operating Procedure

Safety Considerations

WARNING

CAUTION

Turn the motor on and off a few times before running

the machine continuously . This permits the oil to warm

up and flow easily into the close-fitting moving parts.

Failure to do this may result in damage to your machine.

The machine is now ready for use.

A oil reservoir N pulley shaft

D release lever O belt pulley

E sharpener lever P plug

F turning knob Q cover

H bell crank release lever R pressure foot lever

K tube S sharpener bracket

L tube T knife guard/pressure foot

M oil lifting handle

To prevent serious injury, read and follow these safety

precautions.

Before starting or using your machine:

1. Check that you know and understand the following:

• That proper voltage is supplied to machine.

• How to turn of f the machine in an emergency .

• The meaning of all warning labels on the machine.

• What happens to the machine when you operate the

controls.

• Proper start-up procedures described in Initial Set Up

section.

• What to do in the event of a jam or other unforeseen

situation.

• How to disconnect power from the machine.

If you are not familiar with any of these points, ask your

supervisor or contact an Eastman representative.

2. Check the condition of your machine and working area.

Make sure that:

• There is no visible damage to the machine. Pay p ar-

ticular attention to the blade.

• No maintenance work is currently being performed in

your working area.

• No unnecessary people are in your working area.

• Your working area is clear of debris, spilled liquids,

food, drink, or other obstructions.

• Your clothing, hair, and jewelry cannot snag or be-

come tangled in the machine. Wear appropriate protective equipment as necessary. Remove all rings,

watches, neckties, and other loose objects. Tie up

hair or wear a hair net.

Figure 2. Controls and Adjustments

If you are uncertain about any of these points, do NOT use

the machine.

WARNING

Failure to use all recommended safety measures and

equipment may result in serious personal injury .

Form C-1555

3

EASTMAN

Starting the Machine

If you have had the machine less than one month or if it has

stood idle for any length of time, turn the motor on and off a

few times before running it continuously . This permits the

oil to warm up and flow easily into the close-fitting moving

parts.

CAUTION

Failure to warm up your machine adequately may damage the motor.

Making a Cut

WARNING

Failure to keep hands, arms, and hair away from the knife

area at all times may result in serious personal injury .

1. Bring the machine up to the material spread.

2. Raise the knife guard/pressure foot by depressing the

pressure foot lever (Figure 2, R) and lifting the knife

guard/pressure foot lifting handle (Figure 2, T). Raise

the pressure foot only enough to clear the material being

cut.

3. Turn on the machine, allow the blade to reach full speed,

and enter the fabric.

4. Using the pressure foot lever (Figure 2, R) and the knife

guard/pressure foot lifting handle (Figure 2, T), lower the

pressure foot so that it is slightly above the material

being cut. This will prevent the material from reciprocating.

T urning Off the Machine

When you have finished using your machine:

1. Position the power switch to off.

2. Make sure the knife guard/pressure foot is lowered to the

baseplate by depressing the pressure foot lever (Figure

2, R).

3. Disconnect the attachment plug from the power source.

4. In cold weather, ensure that the machine is kept in a

warm place when not in use.

Routine Maintenance

WARNING

Always unplug the machine before performing maintenance, adjustments, or repairs.

WARNING

After servicing the machine, always make sure the plate

bolt nut is securely fastened (Figure 3, X on page 6)

before resuming cutting operation.

Care of the Machine

To ensure proper operation of your machine, carry out the

following procedures at the intervals indicated. If you use

your machine intensively , consider performing these procedures more often.

5. Begin cutting.

6. When you are not making a cut, or when the machine is

not in use, keep the knife guard/pressure foot lowered to

the baseplate by depressing the pressure foot lever

(Figure 2, R).

7. Turn off the machine when not cutting fabric.

4

Form C-1555

Daily

Remove the knife and clean the knife slides with the slot

cleaner (Figure 7, 2 on page 9) included with machine. To

prevent undue accumulation of lint, do NOT oil the plate

rollers. If the rollers stick, remove them from the plate and

wash them in cleaning solvent.

Twice Weekly

Use an approved air hose or bellows to blow any lint from

around the motor and sharpener.

• Tubes at locations shown as Figure 2, K and L.

• Pulley shaft shown as Figure 2, N.

• Belt pulley shown as Figure 2, O.

WARNING

Failure to wear eye protection when using air hose or

bellows may result in serious eye or facial injuries.

Weekly

Remove the cover (Figure 2, Q) and clean any lint from

around the screw mechanism in the sharpener.

Lubrication

Lubricate your machine according to the following

schedule:

CAUTION

Use only specially compounded Eastman 30-weight, nondetergent oil. Use of sewing machine oil or detergent oil

may result in damage to your machine. Do not oil the

baseplate rollers. Use of an excessive amount of oil

may damage the machine.

Daily

Monthly

1. Carry out the Daily and Weekly lubrication schedules

above.

2. Remove the plug (Figure 2, P) and insert a grease tube.

Squeeze an amount of grease approximately the size of

a pea into the opening.

WARNING

Routinely check the tightness of the operating handle to

ensure a secure connection.

Sharpening the Knife

Sharpen the knife at frequent intervals or whenever you feel

it is not cutting adequately:

1. Take the machine out of the lay.

2. Drop the knife guard/pressure foot using the pressure

foot lever (Figure 2, R on page 3), located next to the

machine operating handle.

1. Place two drops of oil at each of the two locations shown

in Figure 2, M. Use an oil can with a small spout. (A

suitable oil can is furnished with the machine.)

2. Fill the oil reservoir (Figure 2, A) for continuous use. If

you only use the machine intermittently, you can use

less oil.

Weekly

1. Carry out the Daily lubrication schedule above.

2. Apply one drop of oil only to each of the following:

3. Press the sharpener lever (Figure 2, E) downward with

a slow, firm pressure to engage the sharpening mechanism. Too fast a lever action may cause the lever to

lock. If this occurs, lift the release lever (Figure 2, D) and

start over again.

Removing the Sharpener

1. Disconnect the machine from the power source.

2. Using the turning knob (Figure 2, F) raise the blade to top

position.

3. Press the sharpener lever (Figure 3, E on page 6)

approximately halfway down and to the neutral position,

and lower the sharpener by hand.

Form C-1555

5

EASTMAN

WARNING

This machine is equipped with a very sharp knife. Remove the knife when working in this area. Failure to keep

hands, arms, and hair away from the knife area may result

in serious personal injury .

4. Remove the back guide (Figure 3).

5. Press the lever (Figure 3, E) to a neutral position and

raise the sharpener to the top (original) position.

6. Remove the four hold-down nuts (Figure 3, V) and

remove the sharpener.

Note: If you press the sharpener lever (Figure 3, E)

down too far (beyond the neutral position), it will lock

the sharpener bracket. If this occurs, lift the release

lever (Figure 3, D) and start over again.

BACK GUIDE

Replacing the Rubber Driver Pulley

The sharpener is driven by a rubber driver pulley , as shown

in Figure 4. Replace this driver pulley whenever it appears

to be worn or damaged, as follows:

1. Remove the sharpener from the machine (see Remov-

ing the Sharpener on page 5).

2. Press the sharpener lever (Figure 3, E) to a neutral

position and lower the sharpener until an inch of the

square shaft (Figure 4, W) is exposed.

X

D release lever

E sharpener lever

V hold-down nut

X plate bolt nut

Figure 3. Removing the Sharpener

W square shaft

Figure 4. Replacing the Rubber Driver Pulley

3. Hold the square shaft with a wrench. Position the wrench

as close as possible on the shaft to the sharpener

housing.

4. Use a spanner wrench to remove the driver pulley

by turning it clockwise as indicated by the arrow in Figure

4.

Note: The pulley has a left-hand thread.

5. Reassemble the new pulley on the sharpener.

6. Reassemble the sharpener on the machine.

6

Form C-1555

Adjusting the Belt Sharpener

Note: You can obtain all the special tools you will require

for adjusting the sharpener by ordering tool kit #820C2.

T

Adjusting Stabilizers for Central Alignment

1. Disengage the attachment plug, if you have not already

done this.

2. Depress the sharpener lever (Figure 2, E on page 3)

halfway and lower the belt carrier to the extreme bottom

position.

3. Loosen the screws (Figure 6, 1) and disengage the back

guide (Figure 6, 6) from contact with the standard.

4. Loosen the screws (Figure 6, 2) and disengage the

stabilizers (Figure 6, 4 and 5).

S

O

U

O rear pulley T front pulley

S slide with pulley U sharpener shoe

Figure 5. Changing the Sharpener Belts

WARNING

Failure to unplug the attachment plug from the power

source before performing maintenance may result in serious personal injury .

Changing Sharpener Belts

1. Push the slide with pulley (Figure 5, S) inward to relieve

tension, then remove the worn belt.

2. Place the new belt over the front pulley (Figure 5, T), then

between the sharpener shoe (Figure 5, U), and then over

the rear pulley (Figure 5, O).

3. Release the slide with pulley.

Note: Sharpener belts are available in four grits: Rough,

Coarse, Medium, and Fine. See Abrasive Belt Grits on

pages 17-18 for ordering information.

1 screw 9 locknut

2 screw 10 clamping arm

3 locknut 11 sharpener shoe

4 stabilizer 12 shoe

5 stabilizer 13 tube

6 back guide 14 spacer

7 pivot screw 15 locknut

8 stop screw

Figure 6. Adjusting the Stabilizers

Form C-1555

7

EASTMAN

5. Remove the locknut (Figure 6, 3).

6. Install gauge C189 on the exposed threaded end of the

pivot screw (Figure 6, 7) and press the end of the gauge

against the side of the standard.

7. Holding this position, engage the opposite stabilizer

(Figure 6, 4) firmly against the side of the standard and

tighten the screws (Figure 6, 2).

8. Remove tool C189 and press the positioned stabilizer

(Figure 6, 4) against the side of the standard. Then

fasten the opposite stabilizer (Figure 6, 5) firmly against

the standard.

9. Re-engage the back guide (Figure 6, 6) in loose contact

with the back of the standard.

Checking the Sharpener Shoes

The shoes should swing in and out freely without excessive

up and down play . If adjustment is necessary, proceed as

follows:

1. Loosen the locknuts (Figure 6, 3) and tighten the screws

(Figure 6, 7) as required.

Checking the Extreme Down Position of the Sharpener

The correct down position is with the tip of the knife at the

center of the belt on the shoe (Figure 6, 12). The belt should

be in the most downward position, and the knife should be

in the most upward position. If the belts are too high, the

bottom point of the knife will not sharpen. If the belts are

too low, the bottom point of the knife will round off excessively. If adjustment is necessary:

1. Raise the belt carrier to the up position.

2. Remove the plastic cap from the tube for the screw

shaft.

3. Insert a pin through the hole in the tube (Figure 6, 13) to

prevent the spacer (Figure 6, 14) from turning. Then

remove the locknut (Figure 6, 15).

The following step describes the correct procedure for

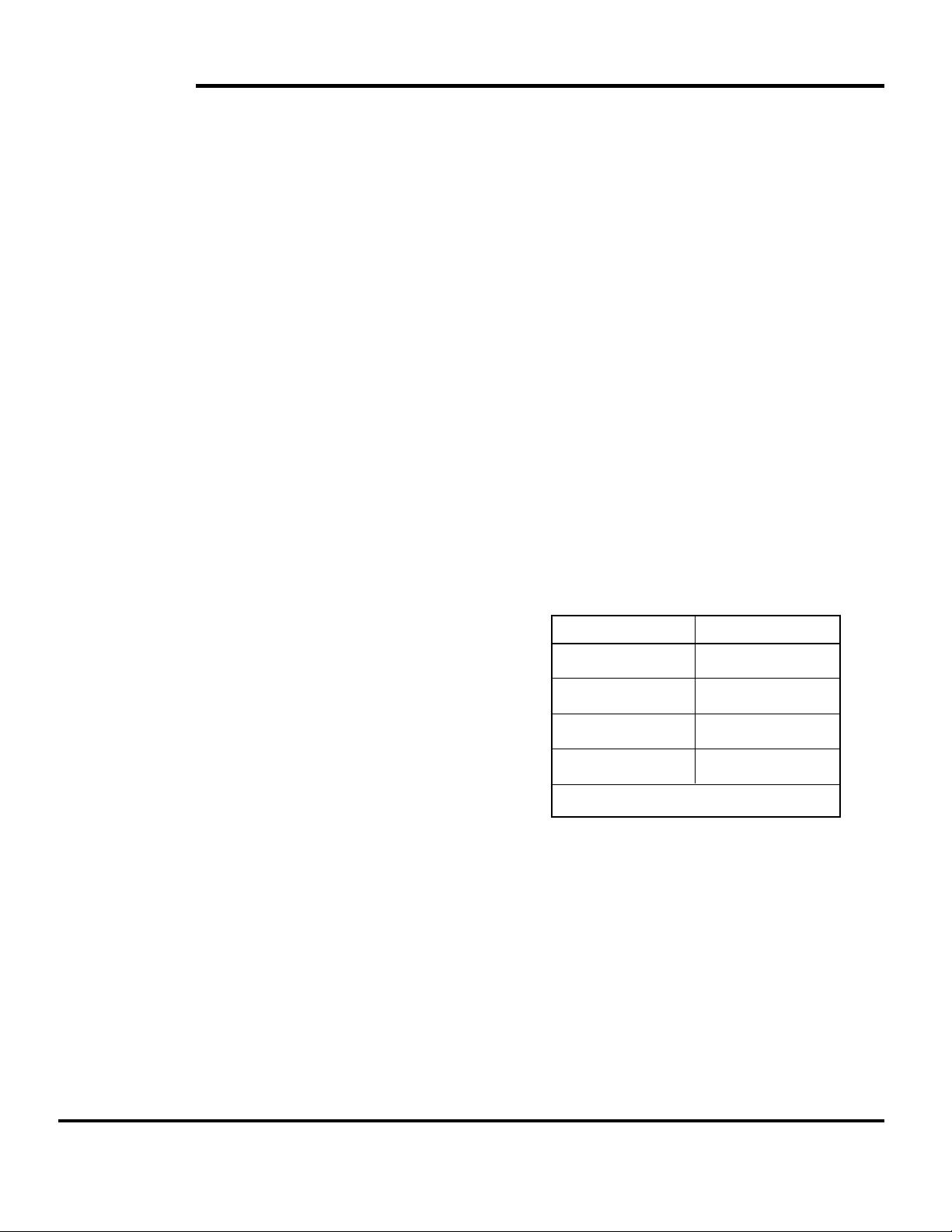

setting spacer adjustment on different stroke machines:

Note: Prior to beginning adjustment, be sure that the

spacer is threaded fully onto screw shaft.

Stroke Turns

2. Check the clamping arm (Figure 6, 10) with the belt

carrier in the most downward position and the knife in the

most upward position. The clamping arm should keep

the sharpener shoe from moving in. If it fails to do so,

the serrations on the clamping arm are worn or the

sharpener shoe (Figure 6, 11) is worn.

3. Replace worn part(s) as necessary.

1-1/8" 11

1-1/4" 9

1-1/2" 13

1-3/4" 8

Note: Each turn = 1/32"

4. Turn the spacer clockwise with wrench C6153 to raise

the bottom position, or turn counter-clockwise to lower

the position.

Note: One turn in either direction adjusts the position

by 1/32".

8

Form C-1555

Loading...

Loading...