Eastman 555, 565, 623 User Manual

etSTMAN

OPERATION,

r

LUBRICATION

AND

CARE

EVERY2HOURS-DAILY

Fill

oil

cups

connecting

To

oil,

foot

rod

until

you

rod

shaft

G.

Use

spout

(furnished

machine).

in

holeinshaft

Do not

drop

and

see

through

can

A-B-C.

rod

pressure

turn

connecting

with

Insert

DO

use

Oil

bearing

small

and

crank

hole

with

spout

NOT

G.

oil.

USE

sewing machine

cutting machine lubrication.

compounded

motor

Eastman

oil.

LUBRICATION

ONCEAWEEK

One

drop

Tubes

at

Turning

at

M

Pulley

Belt

AN

CAUTION

Shaft

Pulleys

EXCESS

oil.Itis

For

oilorat

least

only

to:

K & L

Knob

N

O

AMOUNT

entirely

best

results

a good

ONCE

Remove

and

insert

tube.

amount

qualtothe

a

pea

into

OF

OIL

too light

use specially

grade

of No. 30

A

MONTH

plugatP

grease

Squeeze

about

size

opening.

for

an

e-

of

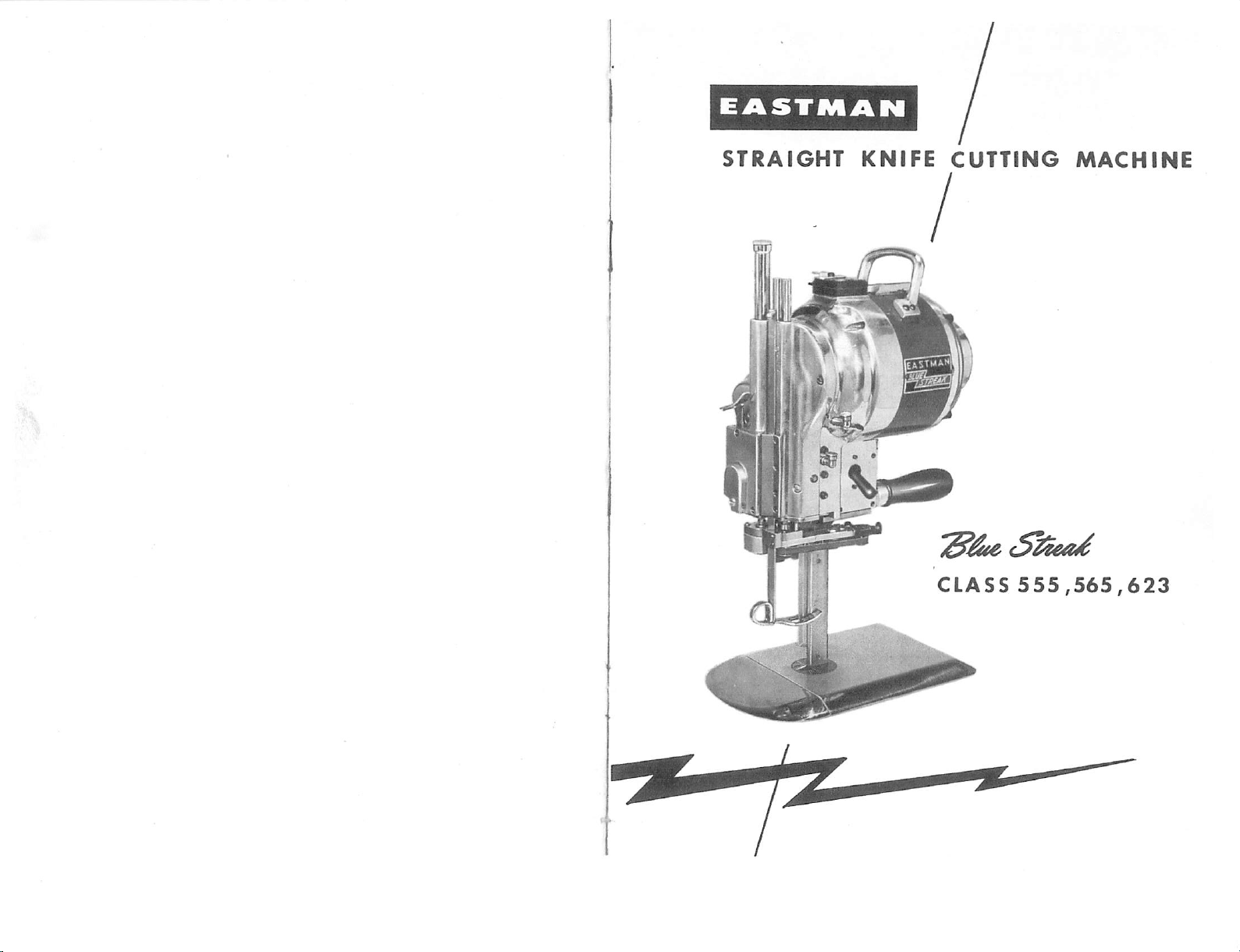

BLUE

STREAK

IN

COLD

WEATHER,

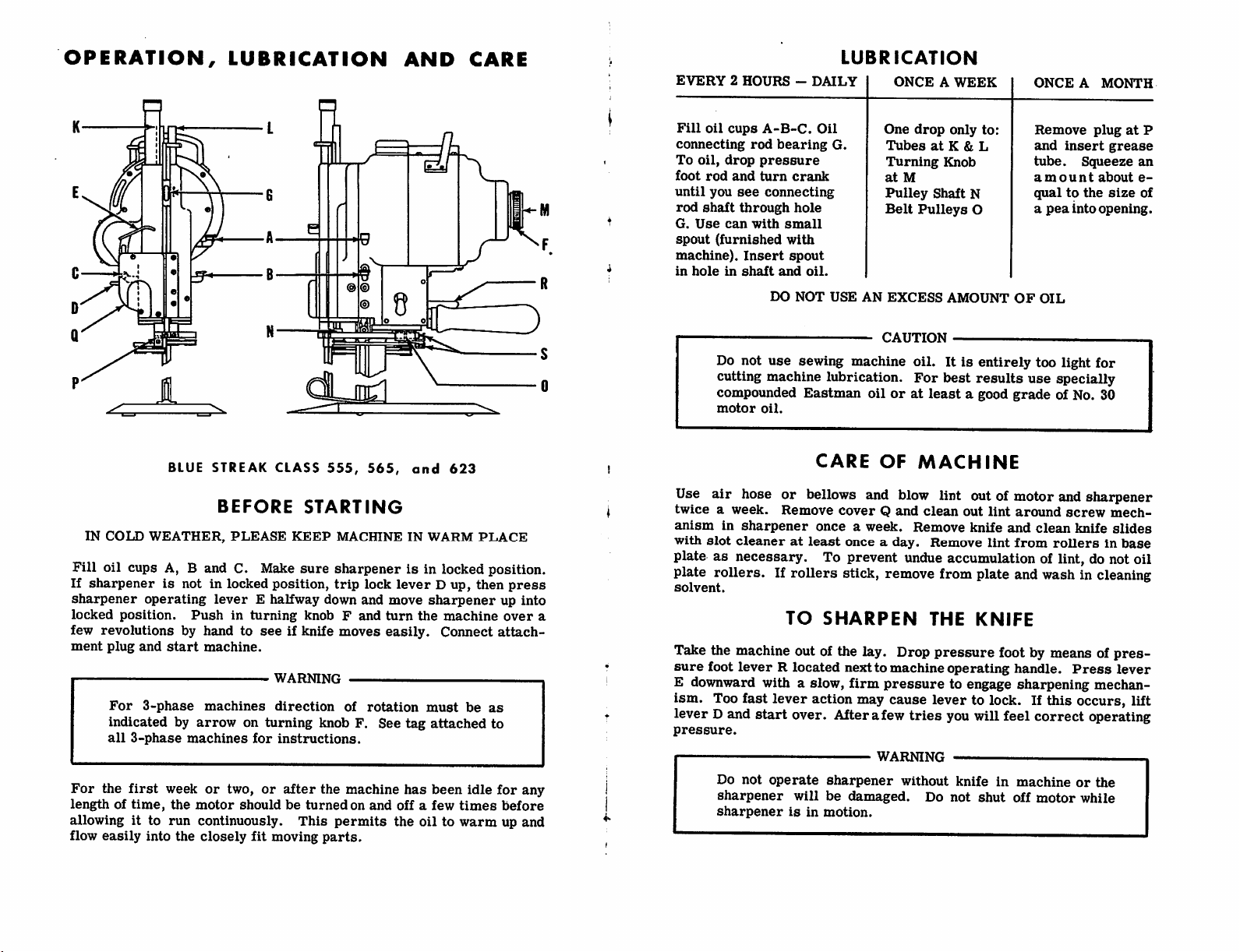

Fill

oil cups A, B and C. Make

If

sharpenerisnot in locked

sharpener

locked

few

ment

operating

position.

revolutions

plug

and

For

3-phase

leverEhalfway

Pushinturning

by hand to

start

machine.

machines

indicatedbyarrow

all

3-phase

For

the

first

lengthoftime,

allowing it to

flow

easily

into

machines

week

or

the

motor

run

continuously.

the

closely

CLASS

BEFORE

PLEASE

555,

STARTING

KEEP

sure

position,

down

knobFand

see

if knife

WARNING

direction

on

turning

for

two,orafter

shouldbeturnedonand

knob F. See

instructions.

the machine

This

fit

moving

parts.

565,

and

623

MACHINEINWARM

PLACE

sharpenerisin locked position.

trip

lock

and

moves

of

rotation

permits

leverDup,

move

sharpener

turn

the

easily.

must

tag

has

offafew

the

oiltowarmupand

machine

Connect

be

attached

been

idle

times

then

as

to

press

up

into

over

attach

for

any

before

Use

air

hose

twiceaweek.

anism

with

in

sharpener

slot

cleaneratleast

CARE

or

bellows and blow lint out of motor and sharpener

Remove

onceaweek.

OF

MACHINE

coverQand

clean

Remove

once a day. Remove

out

knife

lint

lint

around

and

from

clean

screw

mech

knife

slides

rollersinbase

plate as necessary. To prevent undue accumulation of lint, do not oil

plate rollers. If

solvent.

a

rollers

TO

Take the machine out of the lay. Drop

sure

foot

leverRlocated

E downward with a slow,

ism. Too fast

lever D and

pressure.

Do

sharpener

sharpener

not

lever

start

over. After a few

operate

willbedamaged.

isinmotion.

stick, remove from plate and wash in cleaning

SHARPEN

nextto

firm

action may cause

WARNING

sharpener

THE

KNIFE

pressure

machine

operating

pressuretoeng^e

lever

to lock. If

tries

you will feel

without

knifeinmachineorthe

Do

not

shut

foot by means of

handle.

Press

sharpening mechan

this

correct

off

motor

pres

lever

occurs, lift

operating

while

fwr

— \

>

TO

REMOVE

SHARPENER

TO

CHANGE

Push

brackets

S inward to

new belt over front pulley T, then between

and then over

Rough,

ener

a

Coarse, Medium and Fine. When changing from one

belt to another, sharpener shoes U should be adjusted to maintain

uniform

cutting

rear

pulley O. Sharpener belts

edge.

SHARPENER

release

tensionand remove worn

BELTS

sharpener

are

available in 4 grits:

TO

shoe U and knife

ADJUST

SHARPENER

belts.

grit

SHOES

Place

sharp

Press

down to

sharpener

lever E approximately halfway

If

leverEis

(beyond

neutral

neutral position)it will lock

bracket

position

by hand.

NOTE

pressed

and

too

far

the sharpener bracket. To release,

lift

leverDand

Remove

to a

neutral

bracket

move

four

sharpener.

RUBBER

TO

guide

to

hold

original

start

bracket.

position

and

(top)

down

REPLACE

DRIVER

over.

Press

raise

position.

nutsVand

Guide

Bracket

lower

the

down

lever

sharpener

Re

remove

E

Install

emery

to

the

Lower

by

ating

its

mine

shoe

gauge

and

set

illustration.

a

new

belts.

the

bottomofthe

machine

the

sharpener

holding

neutral

the

leverEhalfway

position.

the

correct

setting,

between

the

knife

screw

as

knife

Lower

stroke

turning

sharpener

insert

the

and

shown

and

the

knife

with

knob

by hand,

oper

down

To

deter

sharpener

.010

feeler

set

screw

adjust

in

new

F.

to

the

the

Drive

Pulley

Remove

structions

position

an inch of the squareshafts W

Hold

sharpener

and

square

above.

lower

shaft

from

machine.

Press

leverEto

sharpenerbracketuntil

Wwth

wrench.

are

See

neutral

ejqjosed.

Wrench

in

position on shaft should beas closeaspos

sible to

wrench to remove

sharpener

housing. Use spanner

drive

pulley by turning

clockwise as indicated byarrow(pulleyhas

left-hand

thread).

Cut

old

rubber

driver

from pulley. Clean surface of pulley.

Apply

a coat of cement (Pliobondor equiv

alent) to face of pulley. Place oneedgeof

new rubber

ley.

driver

Reassemble

semble

Hold

pulleyinvise

over

sharpener

driver

flanges

pulley on

between flanges ofpul

and

on

machine.

stretch

with

sharpener.

inibber

screwdriver.

Reas

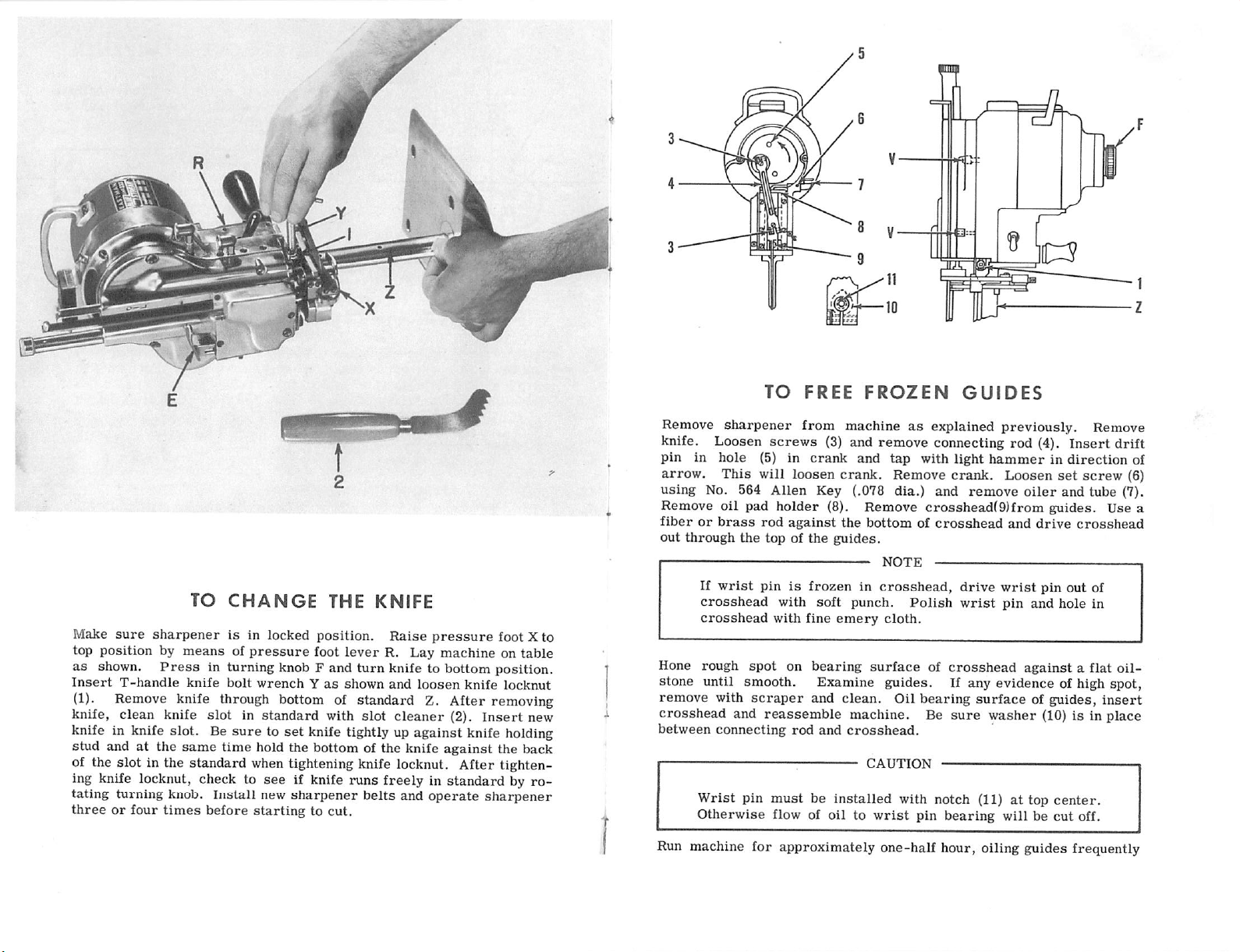

TO

FREE

FROZEN

GUIDES

TO

Make

sure

sharpener

top position by

as shown.

Insert

(1).

knife,

T-handle

Remove

clean

meansofpressure

Press

in

knife

knife through bottom of standard Z. After removing

knife

slotinstandard

knife in knife slot. Be

stud

and at

of the

slot

the

in the

same

standard

CHANGE

is

in locked position.

turning

bolt

knob F and

wrenchYas

suretoset

time

hold the bottom of the knife

when tightening knife locknut. After tighten

THE

foot

with

lever

turn

shown

slot

KNIFE

Raise

R. Lay

knife to

and

cleaner

pressure

machineontable

bottom

loosen

knife

(2).

Insert

foot X to

position.

locknut

new

knife tightly up against knife holding

against

the

back

ing knife locknut, check to see if knife runs freely in standard by ro

tating turning knob. Install new

threeorfour

times

before

sharpener

startingtocut.

belts

and

operate

sharpener

Remove

knife.

pin

arrow.

using

Remove

fiberorbrass

out

——

Hone

Loosen

in

hole

No. 564

through

If

wrist

crosshead

crosshead

rough

sharpener

This

oil

pad

the

spot

from

machineasexplained previously. Remove

screws

(5) in

will

Allen

holder

rod

topofthe

pinisfrozenincrosshead,

with

with

(3)

and

crank

loosen

crank.

Key (.078 dia.)

(8).

against

on

guides.

soft

fine

bearing

the

punch.

emery

remove

and

tap

with

Remove

connecting

light

crank.

and

Remove

bottomofcrosshead

surface

crosshead(9)from

NOTE

cloth.

———

Polish

of

drive

wrist

crosshead

rod

(4).

hammerindirection

Loosen

remove

and

wrist

pin

set

oiler

and tube (7).

guides.

drive

pin

out of

and

hole

againstaflat

Insert

screw

Use a

crosshead

in

drift

oil

stone until smooth. Examine guides. If any evidence of high spot,

remove

crosshead

between

with

and

connecting

Wrist

pin

Otherwise

scraper

reassemble

rod

^

must

flow of

and

clean.

machine. Be

and

crosshead.

be

installed

oiltowrist

Oil

bearing

sure

CAUTION

with notch (11)attop

pin

bearing

surfaceofguides,

washer

(10) is in place

center.

willbecut

off.

insert

Run machine for approximately one-half hour, oiling guides frequently

of

(6)

1

I

list

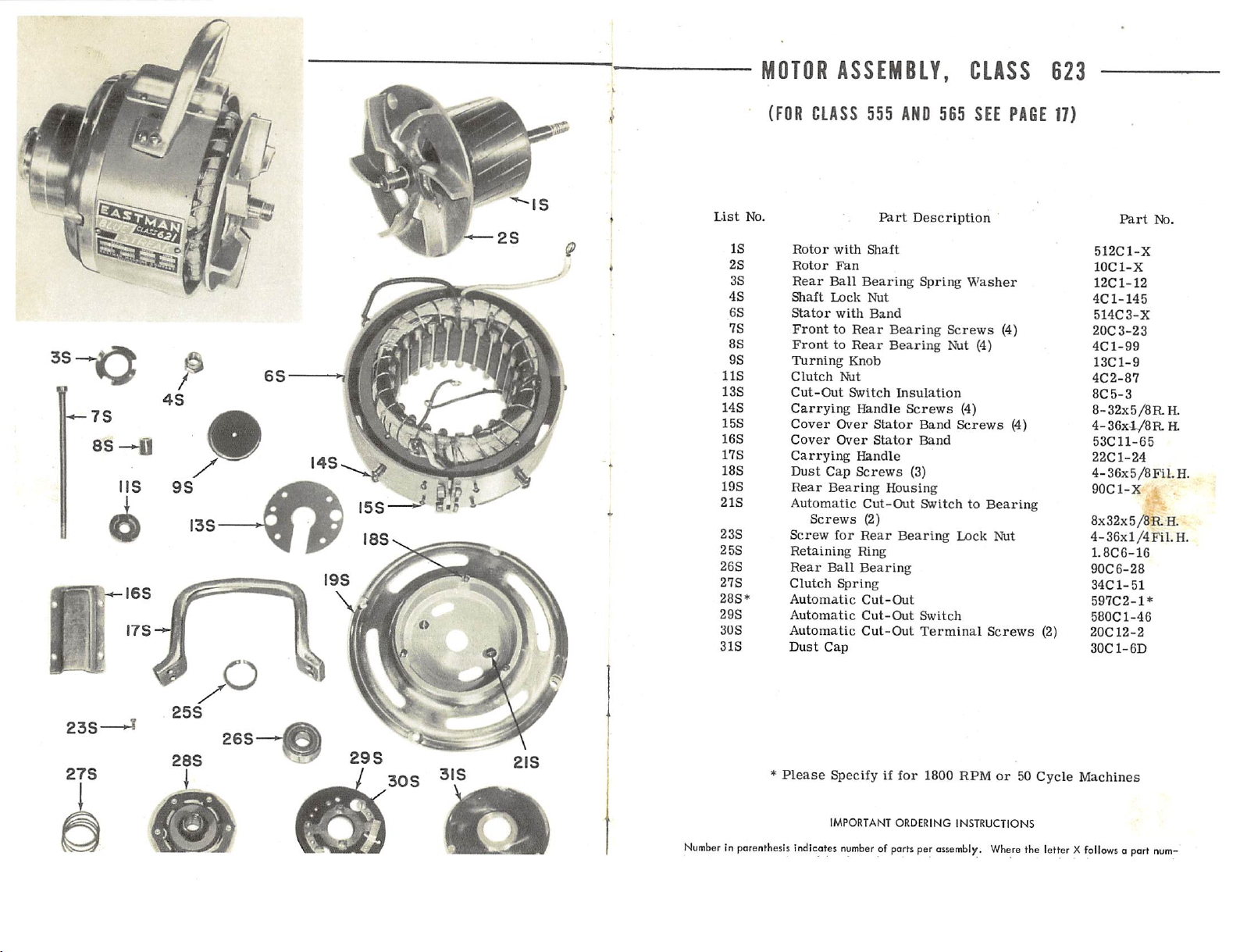

MOTOR

(FOR

No.

ASSEMBLY,

CLASS

555

Part

AND

565

Description

CLASS

SEE

PAGE

623

17)

Part

No.

8s—n

2S

3S

4S

6S

7S

8S

OS

118

13S

148

15S

16S

17S

18S

19S

2

IS

23S

25S

26S

27S

28S*

29S

30S

31S

IS

Rotor

with

Rotor

Fan

Rear

Ball

Bearing

Shaft

Lock

Stater

with

FronttoRear

FronttoRear

Turning

Clutch

Cut-Out

Carrying

Cover

Cover

Carryii^

Dust

Rear

Automatic

Knob

Nut

Switch

Ifendle

Over

Over

Handle

Cap

Screws

Bearing

Cut-Out

Screws

Screw

for

Rear

Retaining

Rear

Clutch

Automatic

Automatic

Automatic

Dust

Ball

Cap

Ring

Bearing

Spring

Cut-Out

Cut-Out

Cut-Out

Shaft

Nut

Band

Stator

Stator

(2)

Sprii^

Bearing

Bearing

Insulation

Screws

Nut (4)

Screws

Band

Band

(3)

Housing

SwitchtoBearing

Bearing

Switch

Terminal

Washer

(4)

Screws

Lock

Screws

Nut

(4)

(4)

(2)

512C1-X

lOCl-X

12C1-12

4C1-145

514C3-X

20C3-23

4C1-99

13C1-9

4C2-87

8C5-3

8-32x5/8RH.

4-36X-L/8RH,

53C11-65

22C1-24

4-36x5/8

90C1-X

FiLH.

;

8x32x5/8Ra

4-36xl/4Fil.H.

1.8C6-16

90C6-28

34C1-51

597C2-1*

580C1-46

20C12-2

30C1-6D

*

Please

NumberInparenthesis

indicotes

Specify If

IMPORTANT

numberofports

for

1800

ORDERING

per

ossembly.

RPMor50

INSTRUCTIONS

Where

Cycle

Machines

the

letterXfollowsaport

num-

Loading...

Loading...