Eastman 548, 562 User Manual

Eastman

Cardinal

MAINTENANCE

INSTRUCTIONS

Class

534,

548,

and

EASTMAN

ARDINAL®

562

Round

Knife

Machines

S

MALL

Parts

PIN

List

The purchaser must instruct all operators

of

the equipment. All standard industrial safety measures

and equipment should be provided to protect the operator.

Operators must be cautioned

equipment can cause bodily injury.

qualified operators to instruct new persons, contact your

Eastman sales representative

factory direct.

.----

--

Read

that

nameplate. All

are

should

control

ing

knife

making a cut

to

being

from

TO

Turn the switch to the on position; if cutter does not start

immediately, return the switch to the

the line

perly and

not attempt to start this unit while it

cut.

---

instructions

voltage

equipped

be

levers

machine.

guard

clear

the

utilized,

the

OPERATE MACHINE

output

is

carefully

and

current

Eastman

with

used

material

equipment.

making full contact, then repeat procedure. Do

sharp

when

and

handles

When

machine

should

be

the

knife

being

the

power

and be sure that the unit

that

or

write

CAUTION ---

before

are

the

machines

blades

this

machine

only

when

is

in

the

should

cut.

When

supply

not

kept

guard

on

improper use

If

you do not have

to

Eastman Machine

starting

motor. Be

same

as

shown

in

this

and

extreme

is

put

into

operating

in

operation

lowered

position. When

be

raised

this

equipment

should

be

off

position. Check

is

plugged

is

in

the material being

the proper use

of

-

----.

sure

stamped

only

disconnected

on

catalogue

caution

use.

Use

or

handl-

the

front

enough

is

not

in

pro-

this

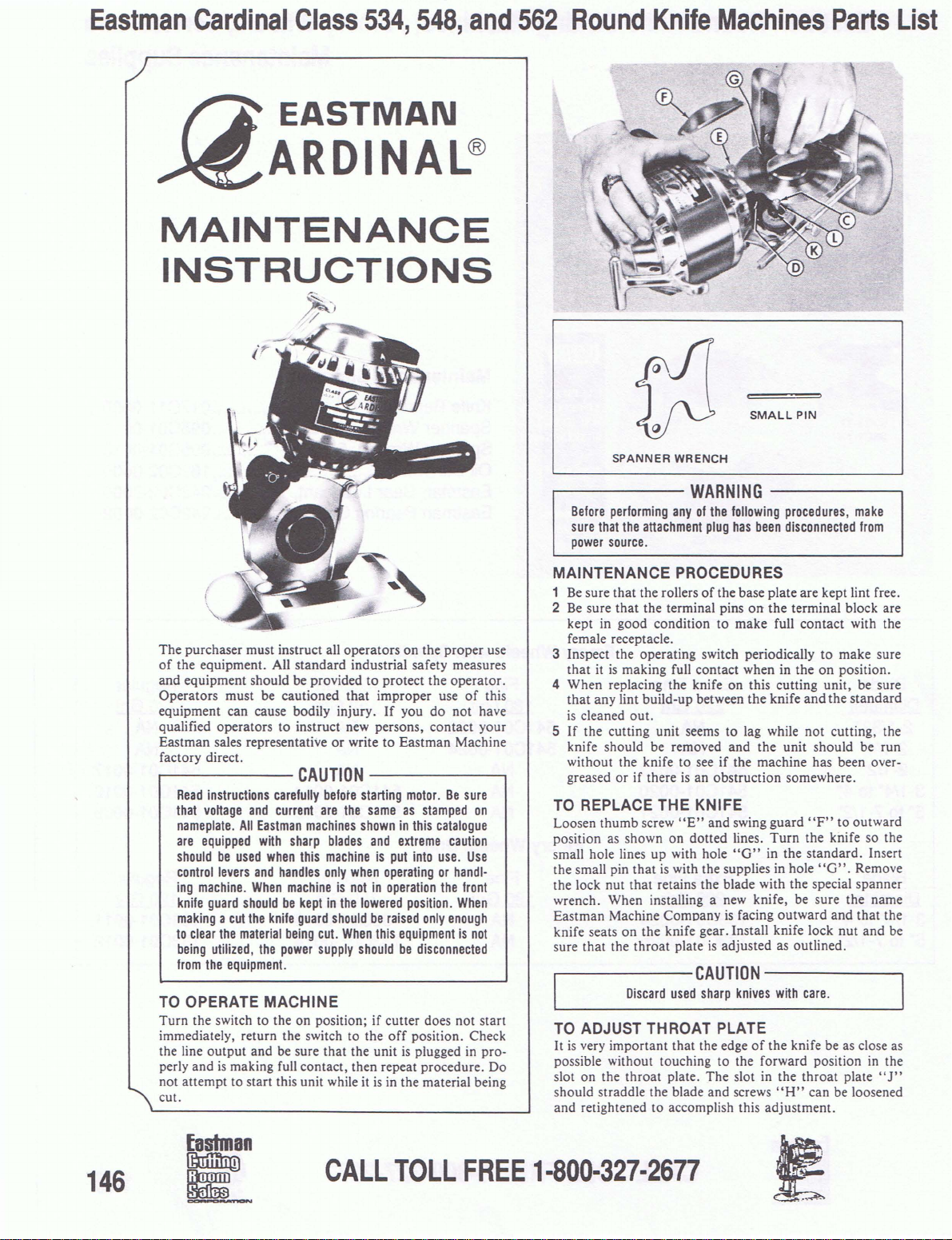

SPANNER

.--------

Be

fore

performing

sure

that

power

MAINTENANCE PROCEDURES

1

Be

2

Be

kept in good condition

female receptacle.

3 Inspect the operating switch periodically

that

4 When replacing the knife on this cutting unit, be sure

that

is

5 If the cutting unit seems to lag while not cutting, the

knife should be removed and the unit should be run

without the knife to see if the machine has been

greased or if there

TO REPLACE THE KNIFE

Loosen thumb screw

position

small hole lines up with hole

the small pin

the lock nut that retains the blade with the special spanner

wrench. When installing a

Eastman Machine Comoany

knife seats

sure

the

source.

sure that the rollers

sure

that

it

is

making full contact when

any lint build-up between

cleaned out.

as

shown on dotted lines.

on

that

the throat plate

.-------

TO

ADJUST THROAT PLATE

It

is

very important that the edge

possible without touching to the forward position

slot

on

should straddle the blade and screws

and retightened to accomplish this adjustment.

the throat plate. The slot

WRENCH

WARNING

any

of

attachment

the terminal pins

that

is

the knife gear. Install knife lock nut

the

plug

of

the base plate are kept lint free.

to

is

an obstruction somewhere.

"E"

and

with the supplies in hole

is

adjusted as outlined.

CAUTION

Discard

used

sharp

-------,

following

has

make full contact with the

swing guard

"G"

new

is

procedures, make

been

disconnected

on

the terminal block are

in

the

on

the

knife

and

"F"

Turn

the knife so the

in the standard. Insert

knife, be sure the name

facing outward

"G".

-----

knives

with

care.

of

the knife be

in

the

throat

"H"

can be loosened

to

make sure

position.

the

standard

to outward

Remove

and

that the

as

close

plate

from

over-

and

in

be

_,

the

"J"

as

fastman

II

146

~=.'

'

=

~

CALL

TOLL

FREE

1-800-327·2677

•

;r.:

Eastman

Cardinal

Class

534,

548,

and

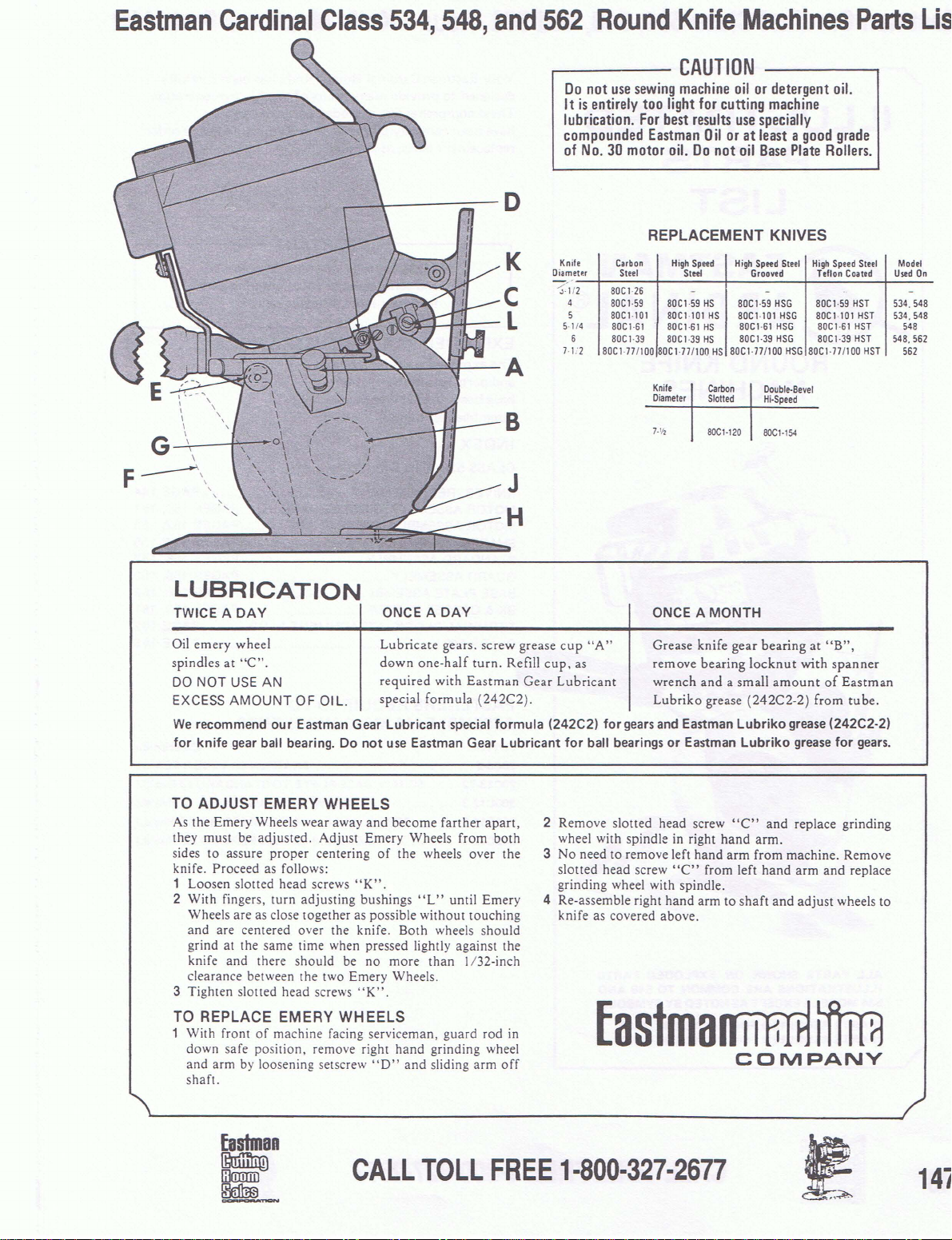

D

K

c

L

A

562

Do

not

It

is

lubrication.

compounded

of

No.

Kni

fe

OiametP.r

'S--1-/

2

4

5

5-1/4

6

7-1.'2

Round

use

sewing

entirely

too

light

For

best

Eastman

30

motor

oil.

REPLACEMENT KNIVES

Carbon

Steel

soc

1-

26

1·

1-61

1

59

·39

SOC1-59

SOC1-101

SOC1-61

SOC 1·39 HS

SOC1

Knife

Diameter

soc

SOC1·101

soc

soc

SOC1-77/100

Knife

Machines

CAUTION

machine

High

St

·77/100

for

results

Oil

Do

not

Speed

..

l

HS

HS

HS

HS

Carbon

Slo"ed

oil

or

cutting

use

or

at

oil

High

Grooved

SOC1·59

SOC1·101

SOC1-61

SOC

SOC1·77/100

detergent

machine

specially

least a good

Base

Plate

Sp

.. d Steel

High

HSG

SOC 1·59

HSG

SOC1-101

HSG

1-39

HSG

HSG

SOC1-77/100

Double-Bevel

Hi-Speed

oil.

grade

Rollers.

Speed

hflon

SOC

1-61

SOC1-39

Parts

Steel

HST

HST

HST

HST

HST

Mod•l

USl!d

534.

534. 54S

54S.

Coated

54S

562

On

54S

562

Lis

G

F

____-'

\

\

\

LUBRICATION

TWICE A

Oil emery wheel

spindles

DO

EXCESS

We

for

TO

As

they must be

sides to assure

knife.

1 Loosen slotted head screws

2 With fingers,

Wheels are

and

grind at the same time when pressed lightl y against the

knife

clearance between the two Emery Wheels.

3 Tighten slotted head screws

TO

1 With front

down safe position, remove right

and arm by loosening setscrew

shaft.

DAY

at

"C".

NOT

USE

AN

AMOUNT

recommend

knife gear ball bearing. Do

OF

OIL.

our

Eastman Gear

ADJUST EMERY WHEELS

the Emery Wheels wear away

adjusted.

and

proper

as

there

Proceed as follows:

are centered over the knife. Both wheels should

Adjust

centering

turn

adjusting bushings

close together as possible without touching

should

REPLACE EMERY WHEELS

of

machine facing serviceman, guard rod in

ONCE A

Lubric2.te gears.

d0wn

required

special

Lubricant

not

use Eastman Gear

and

become farther

Emer

of

''

K''.

be no

more

"K".

" D"

DAY

one-half

y Wheels from both

the wheels over the

"L"

hand

and

turn.

with

Eastman

formula (242C2

special

until Emery

than

I / 32-inch

grinding wheel

sliding

arm

B

J

H

screw

Refill

formula

Lubricant

apart,

off

7-

'h

ONCE A

grease

cup

"A"

cup,

as

Gear

Lubricant

).

(242C2) for gears and Eastman

for

ball bearings

2 Remove slotted head screw

wheel with spindle in right

3

No

need to remove left

slotted head screw

grinding wheel with spindle.

4 Re-assemble right hand

knife as covered above.

Grease knife

remove

wrench

Lubriko

~astmaiiTiNR

or

Eastman

"C"

80C1

·120 80C1·154

MONTH

gear

bearing

and

a small

grease (

Lubriko

Lubriko

"C"

hand

hand

arm

from left

arm

to

shaft

COMPANY

bearing

locknut

242C2-2)

arm

from machine. Remove

hand

at

"B",

with

spanner

amount

and

and

of

from

grease (242C2-2)

grease

replace grinding

.

arm

and

adjust

Eastman

tube.

for

gears.

replace

wheels to

lfnT8

CALL

TOLL

FREE

1-800-327·2677

14i

Eastman

Cardinal

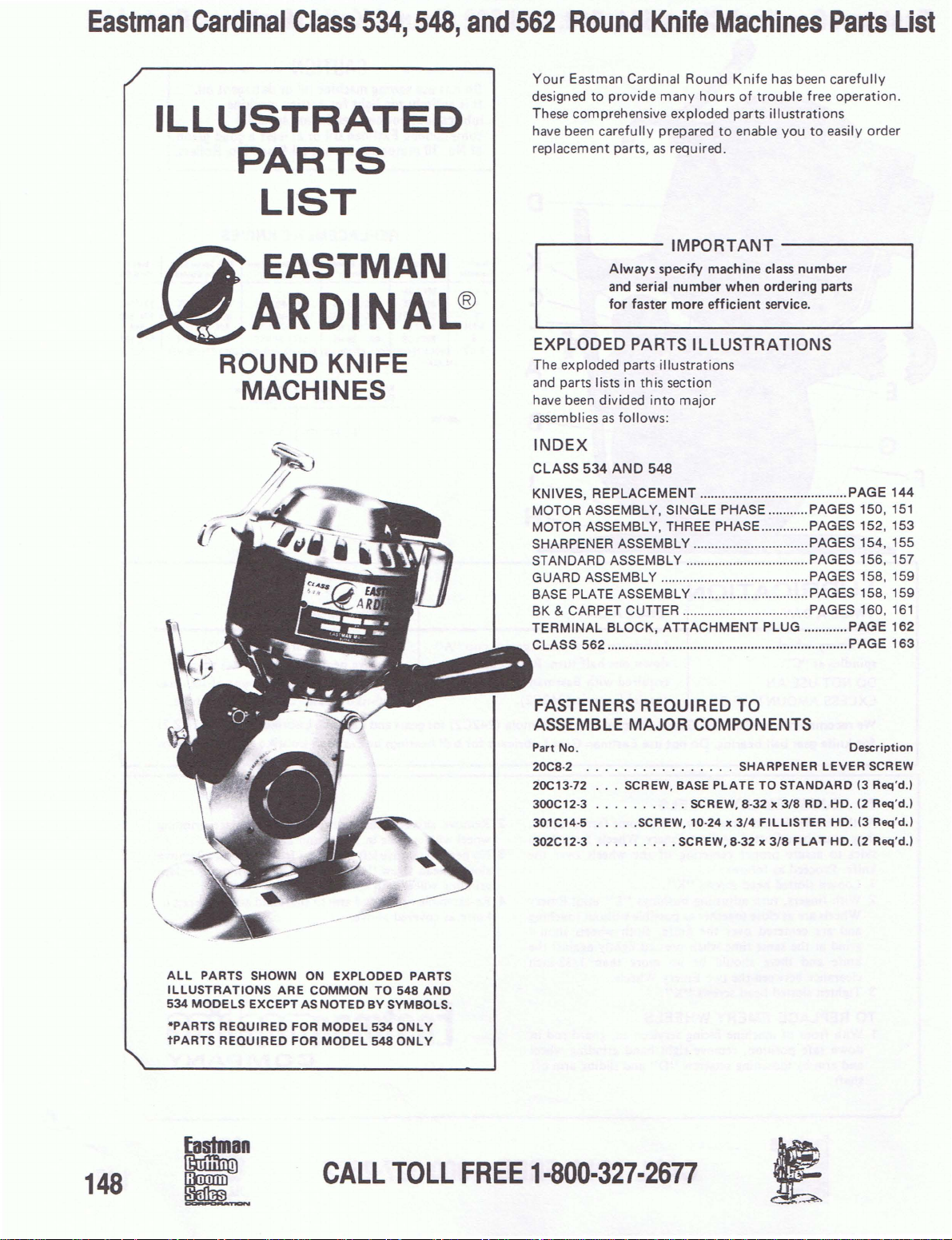

ILLUSTRATED

Class

534, 548,

PARTS

LIST

EASTMAN

ARDINAL®

ROUND KNIFE

MACHINES

and

....

~~~CLASS

562

Round

Your

Eastman Cardinal Round

designed

These comprehensive exploded parts

have been

replacement parts,

to

carefully

provide

Knife

many

hours

prepared

as

required.

Machines

Knife

of

to

enable

has been

trouble

free

illustrations

you

Parts

carefully

operation.

to

easily

order

,..-------IMPORTANT------,

Always specify machine class

and serial number when ordering parts

for faster more efficient service.

number

EXPLODED PARTS ILLUSTRATIONS

The exploded parts

and parts lists in

have been

assemblies

divided

as

this

follows

illustrations

section

into

major

:

INDEX

CLASS 534 AND 548

KNIVES,

MOTOR ASSEMBLY, SINGLE PHASE ........

MOTOR ASSEMBLY, THREE PHASE ............. PAGES 152, 153

SHARPENER

STANDARD

GUARD

BASE PLATE ASSEMBLY ................................ PAGES 158, 159

BK

TERMINAL BLOCK,

REPLACEMENT

ASSEMBLY ................................ PAGES 154, 155

ASSEMBLY ......

ASSEMBLY ......................................... PAGES 158, 159

& CARPET CUTTER ................................... PAGES 160 ,

562 ................................................................... PAGE 163

......................................... PAGE 144

...

PAGES 150, 151

.....................

ATTACHMENT

.......

PAGES 156, 157

PLUG ............ PAGE 162

List

161

148

(

\

ALL

PARTS

ILLUSTRATIONS

534

MODELS

•PARTS

tPARTS

SHOWN ON

EXCEPT AS

REQUIRED

REQUIRED

fastman

II

~=,'

'

nrT1CINI

ARE

FOR

FOR

EXPLODED

COMMON

NOTED

MODEL

MODEL

CALL

PARTS

TO

548

BY

SYMBOLS.

534

ONLY

548

ONLY

TOLL

AND

FREE

FASTENERS REQUIRED TO

ASSEMBLE MAJOR COMPONENTS

Part

No.

20C8·2

20C13·12

300C12·3

301C14·5 .

302C12·3

................

...

SCREW, BASE

..........

....

SCREW, 10·24 x

. ....

....

PLATE

SCREW, 8·

SCREW,

SHARPENER

TO

STANDARD

32 x 3/8 RD.

3/4

FILLISTER

8·32 x 3/8

FLAT

1·800·327·2677

!

.

'

Description

LEVER

HD.

HD.

HD.

SCREW

(3 Req'd.)

(2 Req'd .)

(3 Req'd.)

(2 Req'd.)

Eastman

Cardinal

Class

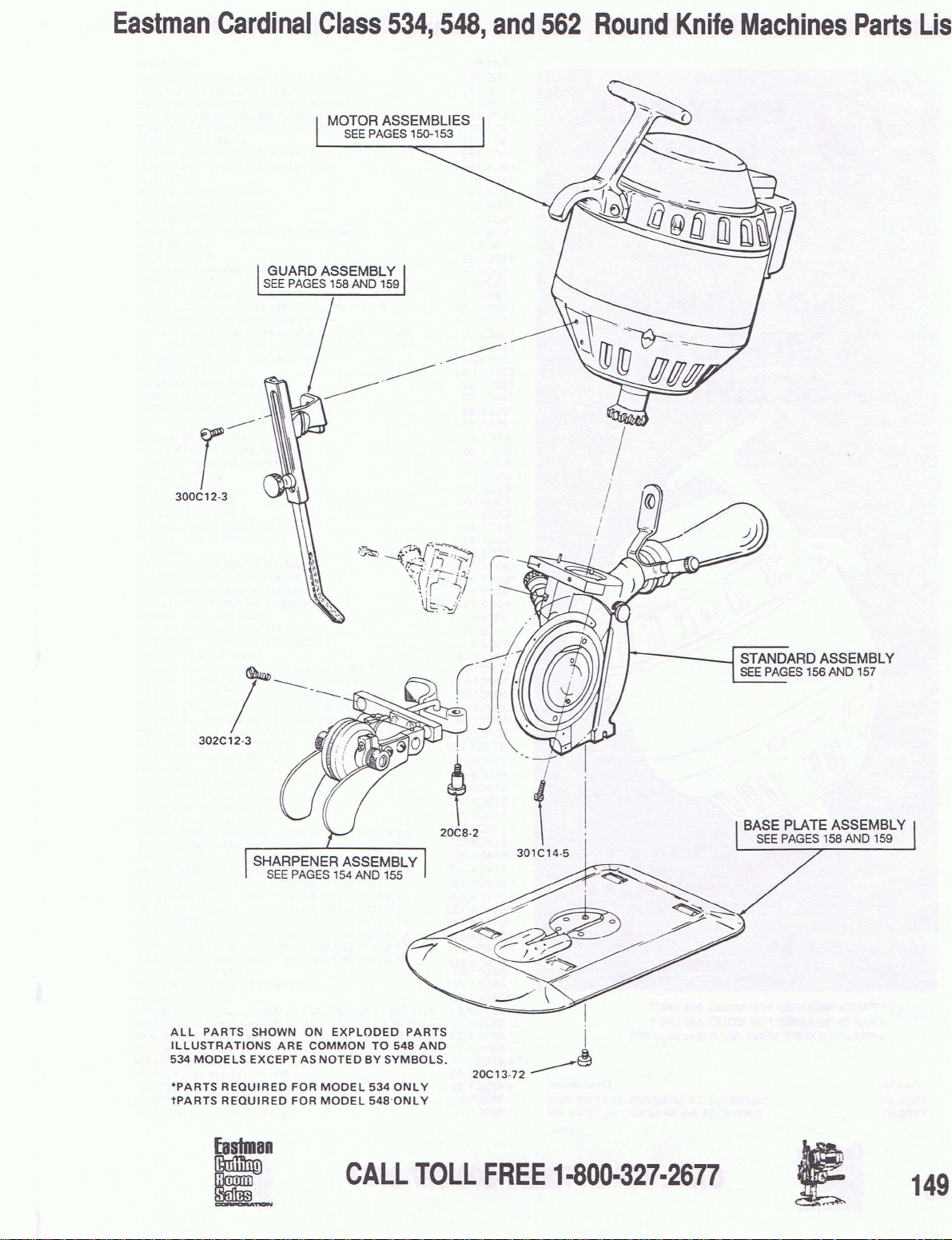

GUARD ASSEMBLY

SEE

PAGES

158

AND

534,548,

159

and

562

Round

Knife

Machines

Parts

Lis

300C12

302C12-3

-3

I

~---_J

STANDARD ASSEMBLY

SEE

PAGES

156

AND

157

ALL

PARTS

ILLUSTRATIONS

534

MODELS

*PARTS

tPARTS

SHOWN

EXCEPT

REQUIRED

REQUIRED

ARE

FOR

FOR

ON

EXPLODED

COMMON

AS

NOTED

MODEL

MODEL

TO

548

BY

SYMBOLS.

534

ONLY

548-0NL

PARTS

AND

Y

fastman

~

=-

CALL

TOLL

FREE

1-800-327·2677

•

lt:

149

Eastman

Cardinal

Class

534,

548,

and

562

Round

Knife

Machines

Parts

List

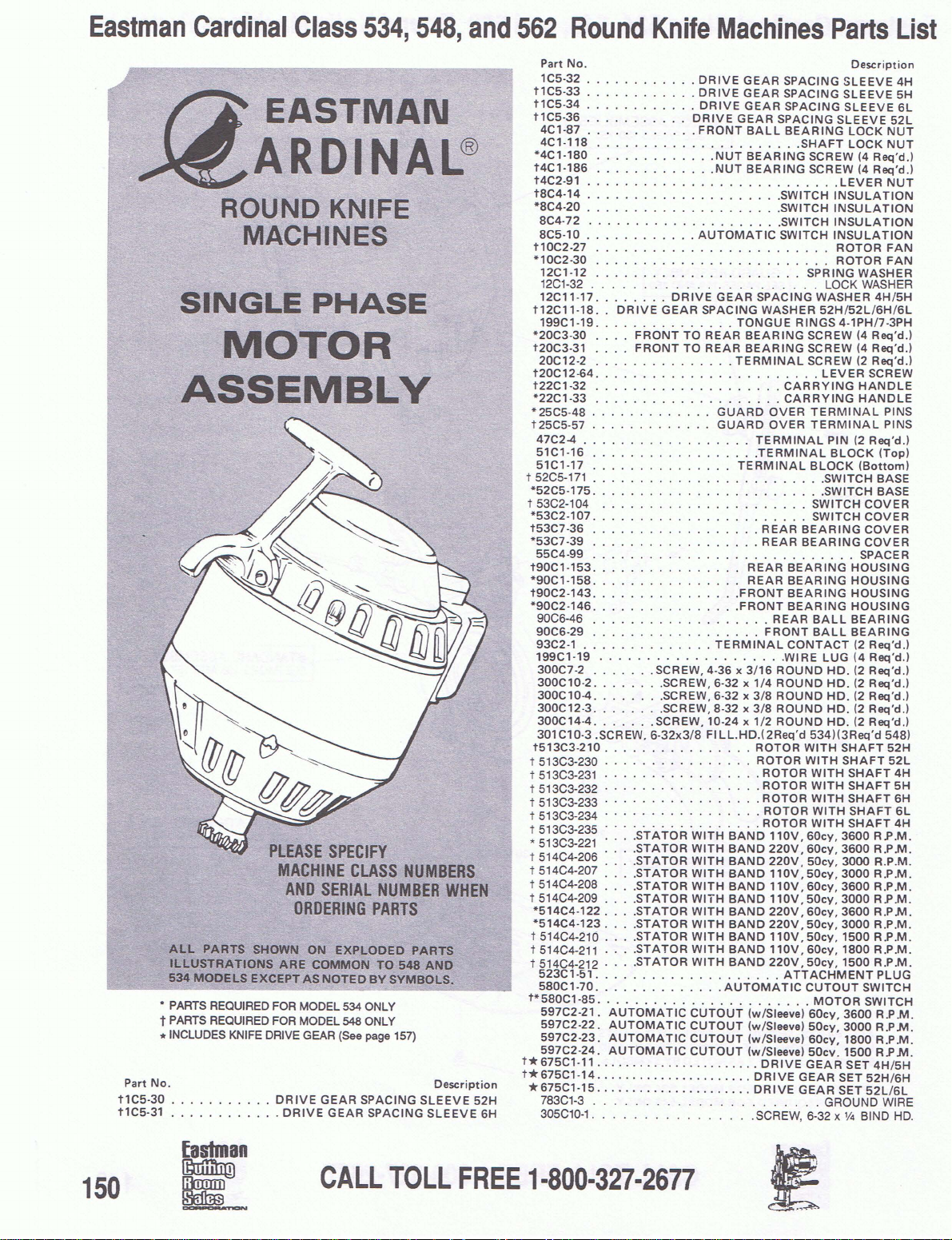

EASTMAN

ARDINAL®

ROUND KNIFE

MACHINES

SINGLE

MOTOR

ASSEMBLY

PLEASE

MACHINE

AND

ORDERING

ALL

PARTS SHOWN ON EXPLODED PARTS

ILLUSTRATIONS

534 MODELS EXCEPT AS NOTED BY SYMBOLS.

• PARTS REQUIRED FOR MODEL 534 ONLY

t PARTS REQUIRED FOR MODEL 548 ONLY

*INCLUDES KNIFE DRIVE

No

.

Part

t1C5-30

t1C5-31 . .... . . . . .

.. ..

. .

...

..

..

ARE

DRIVE

DRIVE

PHASE

SPECIFY

CLASS

SERIAL

COMMON TO

GEAR (See page 157)

GEAR

GEAR

NUMBERS

NUMBER

PARTS

548

SPACING

SPACING

WHEN

AND

Description

SLEEVE

SLEEVE

52H

6H

No.

Part

1C5-32 ... . .....

t1C5-33 ...•..

t1C5-34

t1C5-36

*4C1-180

t4C1-186

t4C2-91

t8C4-14

*8C4-20

t10C2-27

* 10C2-30 .... .

t12C11-18

*20C3-30

t20C3-31

t20C12-64

t22C1-32 ... . .... .

*22C1-33

* 25C5-48 .

t25C5

47C24

51C1-

51C1-17 .... . . . . . . . ....

t 52C5-171 .

*52C5

t 53C2-104

*53C2-107

t53C7-36

*53C7-39

55C4-99 ....

t90C1-153

*90C1-158

t90C2-143 ...

*90C2-146 ................

90C6-46

90C6-29 ..... ...

93C2-1 ...

199C1-19 ...

300C7·2

300C10-2 .

300C104

300C12 -3

300C14-4

301C10

t513C3-210

t 513C3-230

t 513C3-231 . . . . . .

t 513C3-232

t 513C3-233 . .

t 513C3-234 ·

t 513C3 23

*

t 514C4-206 . . . .

t 514C4-207 .

t 514C4-208 . . . .

t 514C4-209 .

*514C4-122 ... .

*514C4-123 ....

t 514C4-210

t 514C4-211

t 514C4-212 . . . .

t * 580C1-85

t*

t*675C1-14 ...

*675C1-15

. . .

...

. ...• .

4C1 -

87

. . . .... .

4C1-118

8C4-72 . . ....

8C5-10 .

12C1-12

12C1-32 . . . . . LOCK WASHER

12C11-17

199C1-19 ... . . .... . .

20C12-2 ... . ........

513

523C1-

580C1-70 ....

597C2-21. AUTOMATIC

597C2-22.

597C2-23. AUTOMATIC

597C2-24.

675C1-

783C1-3 . . . . . . . . . . . . . . . GROUND WIRE

305C10-1.

.. ..

. . ....... . . . .

. .

... ...

. .... .

.......

. .

...

...

..

. .

... ...

.........

........

..

DRIVE

....

....

.....

.............

...

-57 ... .

. . . .

16

-175 .

C3'

...

....

..

.. ..

...

..... . . .... . . .

. . . . . . .... . . . .

..................

.........

....

..............

......

.. .. ..........

....

....

.......

. .

....

......

...

. . . . SCREW. 10-24 x

-3 .SCREW .

............

...............

...... -.....

..

..

· · · · ... . . .

5

....

221

- . . . .

...

... STATOR

....

....

51

. .

.. ..

.

.. ..

AUTOMATIC

AUTOMATIC

11 ....

...

. .

. . ....... . . . ..•.

. . . . . .

. . .

DRIVE

....

..

..

. .

..

...

. .

DRIVE

....

. .

..........

. . .

.......

. . ...•... .... . SWITCH

..

. . . .

...

........

. . .

...

. . . .

......

.

....

DRIVE

GEAR

FRONT

FRONT

. . . . .... .

......

.

....•..

...

.

..........

.

· · · . .

..

...

TO

TO

.............

...

...

. . .

...

.....

.........

STATOR

STATOR

STATOR

STATOR

STATOR

STATOR

STATOR

STATOR

STATOR

STATOR

.... ....

......

•.

. . . . . . . .

..

..

. ....

. . .

....

..

SCREW, 4-36 x

SCREW, 6-32 x

..

SCREW, 6-32 x

..

SCREW, 8-32 x

6-32x3/8

..

......

. ••..

......

. . .

....

. .... .

.. ..

....

. . . .......

. . . .

.. ........

...

....

WITH

WITH

WITH

WITH

WITH

WITH

WITH

WITH

WITH

WITH

WITH

CUTOUT

CUTOUT

CUTOUT

CUTOUT

GEAR

DRIVE

GEAR

DRIVE

GEAR

GEAR

FRONT

AUTOMATIC

...

. .

.....

.......

BALL

.

.....

NUT

BEARING

..

NUT

BEARING

.

.....

. ....

. . .

...

. . .

...

...

..

. .

SPACING

....

REAR

REAR

.....

FILL.HD.(2Req'd

..

..

. . .

...

.. ..

....

.... SPRING

GEAR

SPACING

WASHER

TONGUE

BEARING

BEARING

.

..

TERMINAL

. . . . . .

. . . . . . .

GUARD

GUARD

. . .

.....

TERMINAL

.

.

..... ..

. .

......

. . . . . .

..

TERMINAL

TERMINAL

TERMINAL

......

. .

.....

........

........

REAR

REAR

...

.....

. .

REAR

..

REAR

FRONT

FRONT

..

. . .

...

FRONT

. . . . . .

3/16

1/4

3/8

3/8

1/2

...

ROTOR

.

ROTOR

. . .

ROTOR

.... ROTOR

.. ..

ROTOR

. . .

ROTOR

ROTOR

BAND

BAND

BAND

BAND

BAND

BAND

BAND

BAND

BAND

BAND

BAND

AUTOMATIC

..

. . ......

(w/Sieeve)

(w/Sieeve)

(w/Sieeve)

(w/Sieeve)

.. ..

DRIVE

DRIVE

DRIVE

..

. SCREW, 6-32 x Y4 BIND

SPACING

SPACING

SPACING

SPACING

BEARING

SHAFT

. SWITCH

. SWITCH

SWITCH

...

. ....

RINGS

CARRYING

CARRYING

OVER

OVER

.

.

...

. SWITCH

BEARING

BEARING

BEARING

BEARING

BEARING

BEARING

REAR

CONTACT

.WIRE

ROUND

ROUND

ROUND HD. (2 Req'd.)

ROUND HD. (2 Req'd.)

ROUND

110V, 60cy,

220V, 60cy,

220V, 50cy,

110V, 50cy, 3000

110V,

110V,50cy,

220V, 60cy,

220V, 50cy,

110V,

110V,60cy,

220V,

ATTACHMENT

GEAR

GEAR

Description

SLEEVE

SLEEVE

SLEEVE

SLEEVE

LOCK

LOCK

SCREW (4 Req'd .)

SCREW (4 Req'd .)

...

LEVER

INSULATION

INSULATION

INSULATION

INSULATION

..

ROTOR

ROTOR

WASHER

WASHER

52H/52L/6H/6L

4-1PH/7-3PH

SCREW (4 Req'd.)

SCREW (4 Req'd.)

SCREW

WITH

WITH

60cy,

50cy,

50cy,

CUTOUT

60cy,

50cy,

60cy,

50cv.

GEAR

(2

LEVER

HANDLE

HANDLE

TERMINAL

TERMINAL

PIN

(2

BLOCK

BLOCK

534)(3Req'd

(Bottom)

..

SWITCH BASE

SWITCH BASE

SWITCH

. .... SPACER

BALL

BALL

WITH

WITH

WITH

WITH

WITH

MOTOR

LUG

HD.

HD.

HD.

SHAFT

SHAFT

3600

3600

3000

3600

3000 RP.

3600

3000

1500 RP.

1800

1500

3600

3000

1800

1500

SET

SET

SET

COVER

COVER

COVER

COVER

HOUSING

HOUSING

HOUSING

HOUSING

BEARING

BEARING

(2 Req'd.)

(4

(2 Req'd.)

(2 Req'd.)

(2 Req 'd.)

SHAFT

SHAFT

SHAFT

SHAFT

SHAFT

SWITCH

SWITCH

52H/6H

52L/6L

4H

5H

6L

52L

NUT

NUT

NUT

FAN

FAN

4H/5H

Req'

d.)

SCREW

PINS

PINS

Req'd.)

(Top)

Req'd

548)

52H

52L

4H

5H

6H

6L

4H

RP.M

R.P.M.

R.P.

M.

R.P.

M.

R.P.M.

M.

R.P M .

R.P.

M.

M.

R.P.M.

R.P.M.

PLUG

R.P.M.

R.PM

R.P.M.

RPM

4H/5H

HD.

.)

.

.

.

fastman

~

150

m

~

CALL

TOLL

FREE

1·800-327-2677

~·

;r:

Loading...

Loading...