S25ss

SPRAY-PRO

SPRAY-PRO

EarthWay

R

EarthWay

R

SPRAY-PRO PUSH SPRAYER

ASSEMBLY and OPERATING INSTRUCTIONS

Congratulations on the purchase of this new sprayer from Earthway Products, Inc. Please call us if you have any difculty

with assembly or operation of this sprayer. We can be reached via the telephone at 800-294-0671 or 574-848-7491, Monday

- Friday 9:00am ~ 4:00pm or visit us online at www.earthway.com This sprayer comes with lifetime technical support,

email us at techsupport@earthway.com.

HELPFUL HINTS: READ THE DIRECTIONS BEFORE ASSEMBLY

THIS SPRAYER COMES PARTIALLY ASSEMBLED, REQUIRING YOU TO INSTALL THE WHEELS, HANDLE ASSEMBLY,

SPRAY GUN HOLDER, AND CONTROL ROD. IT SHOULD TAKE APPROXIMATELY 15 MINUTES WITH THE USE OF TWO

7/16” WRENCHES AND 1 PAIR OF PLIERS.

5 Your sprayer is designed to be pushed at three miles per hour, which is a brisk walking speed. Slower or faster speeds

will change the spray patterns and output volumes that you will achieve.

5 Clean your sprayer tank thoroughly after each use. Wash with clean water and push sprayer several feet to evacuate any

residual materials until you see clean water. Do this in a safe area as described in the chemical supplier directions.

5 Gears are permanently lubricated at the factory. Do not open the gearbox or dirt may enter.

5 Check all hose connections regularly to ensure they remain tight.

5 If unit fails to spray on initial use, or leaks from the nozzle, remove the cap from the top of the DCV, wipe off the top of

DCV body to remove any debris, and then replace the cap and tighten.

5 Coat all metal surfaces (inside & outside of chassis) with light oil or silicon spray to help prevent corrosion.

5 When the tank is empty, PULL THE SPRAYER BACKWARD to the designated cleaning or storage area to prevent

damage that can occur with a dry pump.

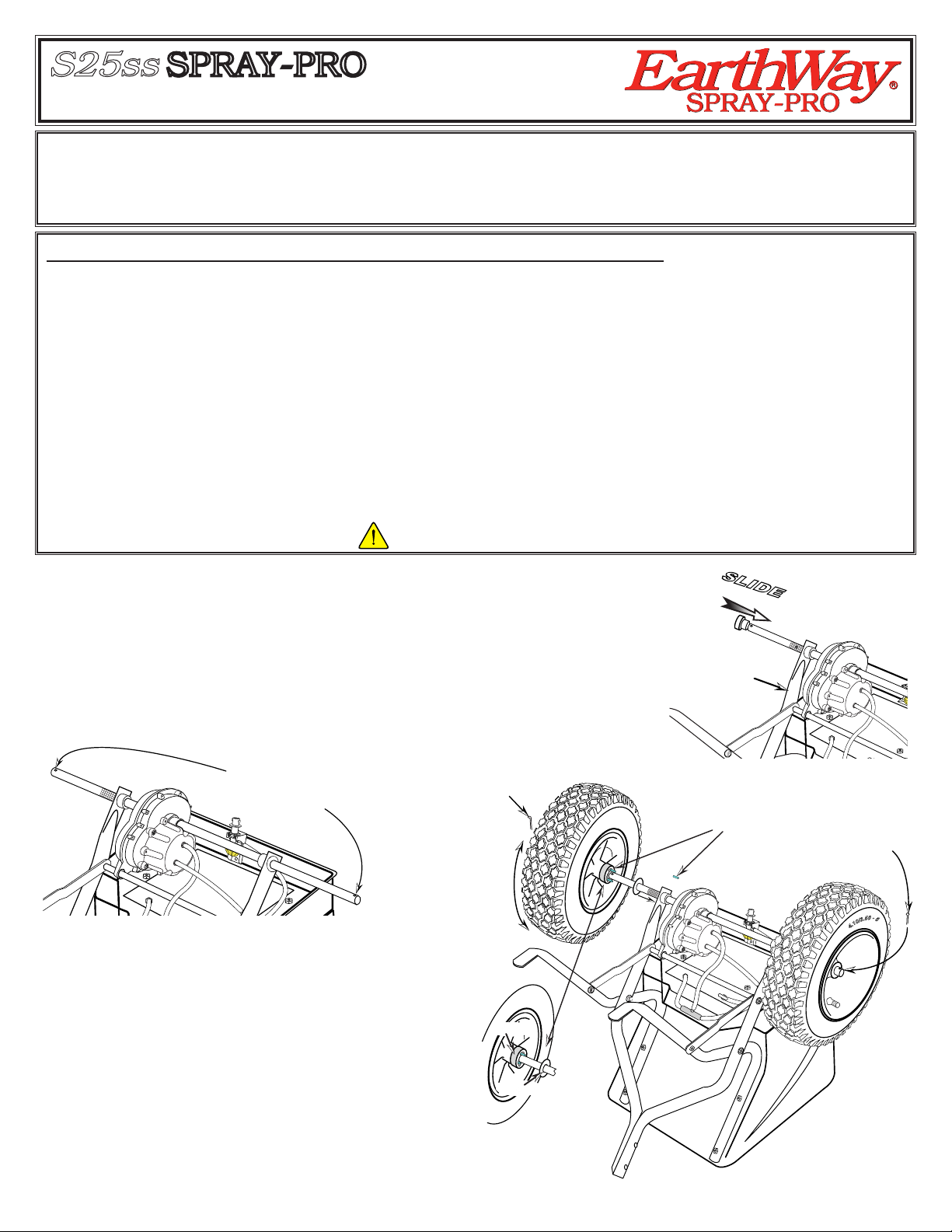

1. Open carton and remove the Handles, Control Rod, Hardware pack, Wheels, and the

S25 from carton.

2. Turn the S25 upside-down on to the tank.

3. Ensure that the Axle Bearings are pushed into the Axle Bushing on both sides as shown

at the right. Install the Coast wheel (this wheel does not have the steel ring on the inside

hub as shown below) on to axle using the cotter pin hole closest to edge of the axle.

Insert 1” cotter pin through the axle and bend with pliers to prevent pin from falling out.

Cotter Pin

Locations

Rotate wheel

4. Install the at washer onto the axle and slide to the lower

handle. Next, position the drive wheel onto the axle 2” and

install the three (3) knurled pins one into each slot located

between the hub and the axle as shown at the right, coat the

knurled pins with WD-40 or a light oil, nish by sliding the

wheel tight against the lower handle. Now insert 1” cotter

pin through axle, bend with pliers to prevent cotter pin from

falling out.

1” Cotter Pin

to help

install pins

Steel Ring

Flat Washer

Drive Wheel

S

L

Axle Bushing

Slide one knurled pin into each slot

in the hub and then spray with WD-40

or a light oil and slide wheel in fully and

I

D

E

Lower

Handle

secure with a cotter pin

1” Cotter Pin

Coast Wheel

NOTE: Included is extra set of Knurled Pins (S25-30003)

which should be saved for future use. These are wear items

and will need to be replaced at some time. Replacements are

available to purchase directly through our Parts department.

1-2012 Pt. # 52230SS PAGE 1

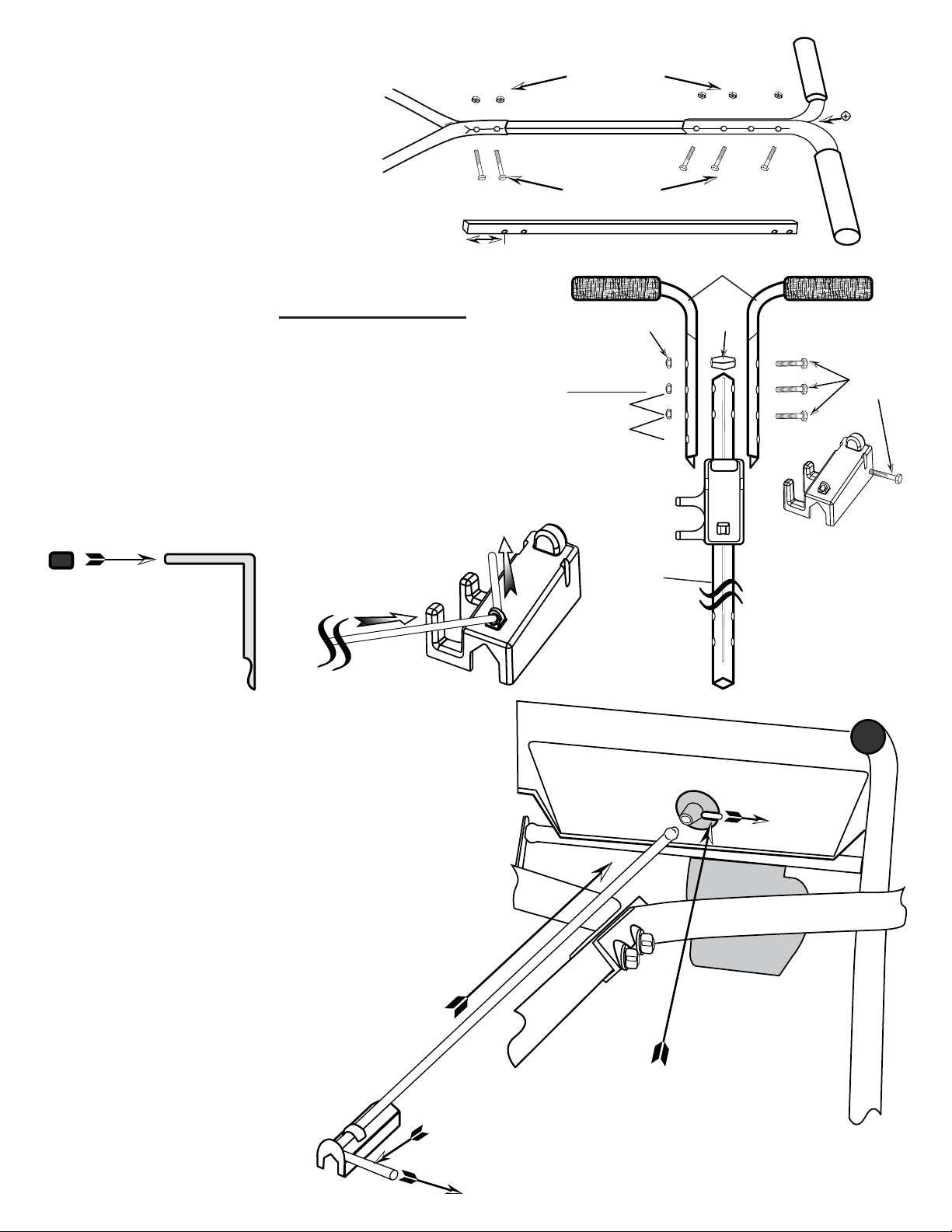

5. Install handle shaft to lower handles as

shown. Using 2” bolts and locknuts.

Make sure that you install the

handle shaft with the long end

facing toward the sprayer.

TIGHTEN BOLTS AND NUTS NOW.

Long End

holes farther

from one end

6. NOTE: Before installing the Gun Holder and Upper Handles to the

Handle Shaft, the Upper Handles have (3) three positions for operators

comfort. If operator chooses the middle or upper positions, please use

the Handle Spacer. Install the Handle Spacer in hole nearest the handle

grips as shown to the right. Insert 2” bolt through Upper Handle, then

through Handle Spacer and then through other Upper Handle, then

secure loosely with ¼-20 locknut. Now install one 2” bolt so that it goes

through the top hole in the handle shaft and secure with ¼-20 locknut.

TIGHTEN BOLTS AND NUTS NOW.

7. Install Control Rod into the Gun Holder as shown below. Next install

black nut protector to the short leg on Control Rod.

36300

1/4-20 Lock Nut

36216

2” HHCS

Handle Shaft

¼-20

Locknuts

POSITIONS

LOWER

UPPER

Upper Handles

Handle

Spacer

12344

Handle

Spacer

¼-20 x 2”

Hex Head Bolt

Nut Protector

8. Next, Install Control Rod into Valve Adapter by pressing onto

the Valve Adapter located at the back of the sprayer skirt, shown

below right. Install the Control Rod by installing attened end

of Control Rod into Valve Adapter, shown below right.

NOTE: Make sure that the ValVe Handle and

the Control rod Handle point in the SAME

DIRECTION.

Finally, install the Gun Holder onto the lowest bolt (closest

to the sprayer TANK) and secure with a 2” bolt and

locknut.

Be sure to position the Gun Holder as show above.

TIGHTEN NOW.

Spray Gun Holder

Handle Shaft

SPRAY TRANSPORT

PAGE 2

VERY IMPORTANT

Control Rod Handle MUST point in the

same direction as the VALVE HANDLE

5-YEAR LIMITED WARRANTY

Earthway Products, Inc. warrants this product free of defects in original workmanship and materials for a period

of 5-years to the end user with the original purchase receipt. If a manufacturing non-conformance is found,

Earthway Products, Inc. at its discretion will repair or replace the part(s) or product at no charge provided the

failure is not the result of incorrect installation, mishandling, misuse, tampering, or normal wear and tear as

determined by Earthway. Earthway at its discretion may require that the part(s) or product be returned along with

the original purchase receipt at owners’ expense for examination and compliance with the terms of this warranty.

Do not return any product without rst receiving authorization from Earthway Products, Inc. To seek remedy

under this warranty, contact Earthway Products, Inc. at 574-848-7491, techsupport@earthway.com or write to

Earthway Products, Inc. P.O. Box 547 Bristol, Indiana 46507 and describe the nature of the manufacturing defect.

SPECIFIC LIMITATIONS: This warranty covers only the part(s) or product; any labor charges associated

with repair or replacement of non-conformances are specically excluded. Due to the corrosive nature of most

fertilizers and ice melt products, Earthway Products, Inc. makes no warranty against and specically excludes

part(s) or product degradation or failure due to corrosion or its effects. Clean and dry your sprayer thoroughly

after each use, as a preventative measure, coat all metal parts (inside and outside of the tubing) with a light oil or

silicon spray.

For Support for your S25, please contact:

nortH ameriCa europe

Earthway Products, Inc.

P.O. Box 547

1009 Maple Street

Bristol, IN 46507

T: 574-848-7491

T: 800-294-0671

E: techsupport@earthway.com

W: www.earthway.com

RUBBER

WASHER

NOZZLE

with

FLAT SIDES

align with

CAP Tabs

CAP Tabs

4

3

2

1

DCV Locking Tabs

CAP in LOCKED

position

CAP in ready to

install position

Nozzle Installation

5 To remove turn Cap from right to left

5 Push Nozzle out of the Cap and remove rubber washer.

5 Install Nozzle aligning the at sides with the Cap tabs and

reinstall rubber washer.

5 To install the assembly, align the Cap slot with DCV locking

tabs and push onto DCV and turn left to right to lock.

DMMP Limited

T: 0845 643 9776

E: info@dmmp.co.uk

W: www.earthway.co.uk

Muggioli Giardinaggio

T: 0422 96 9990

E: info@muggioligiardinaggio.com

W: www.muggioligiardinaggio.com

EuroAmerica

T: +31 (035) 5315696

E: product-management@euroamerica.nl

W: www.euroamerica.nl

PAGE 3

How to use your S25 Sprayer

The S25 SPRAY-PRO sprayer is designed to be simple to use, easy on the operator and provide

years of accurate spraying. The S25 is the latest development from Earthway Products, Inc., a

world leaders in the manufacture of broadcast spreaders, seeding tools, and sprayers.

DO NOT PUSH

FORWARD WITH

TANK EMPTY, PULL

BACKWARD

Calibration

The S25 is supplied with three different nozzle options. The table below shows the characteristics and performance of the supplied nozzle

options at the eight different height setting of the DCV holder. Other Turbo Floodjet® are nozzles available from a TeeJet Dealer if

additional application rates are required. You can download a new Spray Rate Chart at www.earthway.com.

Before use

Before using any liquid products always read thoroughly

the manufacturers product label, to ensure correct

dosage and proper handling of the product being

applied through the applicator. Use the correct Safety

Equipment as directed by the chemical manufacturer.

; Check that the applicator has been thoroughly

cleaned from its previous use and that both the

nozzle outlet and the handgun line (if included)

have been washed through.

; Always spray on a day where wind is minimal.

It can be unsafe and inaccurate if spraying is

undertaken in windy conditions.

; Always wear appropriate safety clothing when

the sprayer is being used. Refer to manufacturers

instructions, or contact your supplier of the

product being applied for safety recommendations.

; Make sure the tires are properly inated to 20 psi.

S25 Mark III

DCV

Spray

Se ng

width in

Posi on

Inches

Height

60 1 0.10 97.7 0.11 113.6 0.07 72.7 0.11 105.3 0.12 115.2

58 1.5 0.10 101.1 0.12 117.6 0.08 75.2 0.11 108.9 0.12 119.1

54 2 0.11 108.6 0.13 126.3 0.08 80.8 0.12 117.0 0.13 127.9

50 2.5 0.12 117.3 0.14 136.4 0.09 87.3 0.13 126.4 0.14 138.2

44 3 0.13 133.3 0.15 155.0 0.10 99.2 0.14 143.6 0.16 157.0

43 3.5 0.14 136.4 0.16 158.6 0.10 101.5 0.15 146.9 0.16 160.7

39 4 0.15 150.4 0.17 174.8 0.11 111.9 0.16 162.0 0.18 177.2

36 4.5 0.16 162.9 0.19 189.4 0.12 121.2 0.18 175.5 0.19 191.9

S25 Mark III

DCV

Spray

Se ng

width in

Posi on

Inches

Height

60 1 0.76 0.89 0.57 0.82 0.90

58 1.5 0.79 0.92 0.59 0.85 0.93

54 2 0.85 0.99 0.63 0.91 1.00

50 2.5 0.92 1.07 0.68 0.99 1.08

44 3 1.04 1.21 0.77 1.12 1.23

43 3.5 1.07 1.24 0.79 1.15 1.26

39 4 1.17 1.37 0.87 1.27 1.38

36 4.5 1.27 1.48 0.95 1.37 1.50

Applica on Coverage - OUNCES/SQUARE FOOT OUNCES/1,000 SQUARE FEET

OTHER Turbo Floodjet® Nozzles

#4 White Nozzle Output #7.5 Green Nozzle Output

SPRAY RATE SPRAY RATE SPRAY RATE SPRAY RATE SPRAY RATE

OZ/SQ FT OZ/1K² OZ/SQ FT OZ/1K² OZ/SQ FT OZ/1K² OZ/SQ FT OZ/1K² OZ/SQ FT OZ/1K²

OTHER Turbo Floodjet® Nozzles

#4 White Nozzle Output #7.5 Green Nozzle Output

SPRAY RATE SPRAY RATE SPRAY RATE SPRAY RATE SPRAY RATE

GAL/1000 Square Feet GAL/1000 Square Feet GAL/1000 Square Feet GAL/1000 Square Feet GAL/1000 Square Feet

Applica on Coverage - GALLONS/1,000 SQUARE FEET

FINE SPRAY MEDIUM SPRAY COARSE SPRAY

#3 Gray Nozzle Output #5 Blue Nozzle Output

FINE SPRAY MEDIUM SPRAY COARSE SPRAY

#3 Gray Nozzle Output #5 Blue Nozzle Output

(1K²)

#10 Black Nozzle Output

#10 Black Nozzle Output

How to use ~ Walk behind spraying

Practice before use

It is recommended for rst time users of the machine that the user familiarizes him/her self with

the workings of the sprayer. By simply putting water in the spray tank and spraying it out onto a

dry tarmac surface the operator will very quickly familiarize themselves with the workings of the

machine. Make sure the spray tank is then emptied of water before further use.

Make sure the handlebar is set right for the size of the operator. There are three position options

on the upper handle for different user heights. By having the handle in the correct position for

the individual user it will make pushing the machine simpler and make spray accuracy easier to

achieve.

; Choose the correct nozzle of the three nozzle options that is suitable for the product being

applied. (See calibration chart above)

; Ensure the Spray (ON) / Transport (OFF) lever on the handlebar is in the Transport position.

The Transport position is with the lever over to the right side when standing behind the

handlebars of the machine.

; Make sure the tank is clean and there is no chance of remnants or deposits from a previous

spray task being left in the tank.

; With the tank clean ll the tank with the required volume of liquid for the designated spray

task, making sure the product being used is mixed and being applied in accordance with the

manufacturers instructions.

; With the control lever is in the Transport (closed position) the machine can be safely pushed to the area where spraying is to be

carried out.

; Locate the sprayer at the point at which spraying needs to commence. Lift the machine up off the two feet, so the body of the

machine is parallel with the ground (important see drawing on next page). To spray simply roll the control lever (ON/OFF) over to

the left side (SPRAY POSITION), and walk forward at a brisk walking speed 2 to 3 MPH is recommended.

; To stop the spray roll the ON/OFF lever back to the right side (TRANSPORT POSITION). NOTE: When the Spray/Transport

lever is to the right side (TRANSPORT POSITION) and the machine is being pushed, the pump is pumping liquid out of the

tank and circulating it back into the tank. This circulation provides agitation and helps keep liquids that are mixed with water in

suspension while walking the sprayer to and from the area being treated.

For best results keep enough

liquid in the tank to ensure

the pump supply line remains

lled. Hills and rough

ground can create a “wave

effect” in the tank that will

cause the pump to have an

inconsistent spray or to lose

prime. If this occurs, turn the

control lever to TRANSPORT

and push a few feet to

re-establish the prime and

continue from where you

stopped.

PAGE 4

How to use the S25 Sprayer - continued

4

3

2

1

Liter Gallon

25

20

15

10

5

2

6

5

4

3

2

1

S25 SPRAY-PRO

S25 SPRAY-PRO

EarthWay

EarthWay

®

®

Spray width can change

if you lift or lower

the handle.

Position handle to keep

the nozzle parallel

with the surface.

4

3

2

1

25

20

15

10

5

6

5

4

3

2

When Tank is empty, pull the S25 backwards to prevent and damage to the pump.

Technical spray information and how to ensure accuracy

The S25 SPRAY-PRO Mark III has an adjustable height nozzle that offers a spray width

from approximately 3 feet/.9 meters to 5 feet / 1.5 meters.

Spray Width Adjustment

You can adjust the spray width of the S25, which will change the application coverage,

by moving the Adjustable DCV holder up or down. To use, loosen the knob located

on the front of the skirt, and slide the DCV & Nozzle assembly up/down to the desired

spray width or to a position indicated on the Application Chart on the previous page, then

tighten knob.

The SPRAY-PRO Teejet TF nozzles are designed to “feather” at the edges to allow the

second pass to “feather in,” and so provide uniform coverage. The area of “feather” or

overlap, is approximately 15% of the spray width at the edges, for a total of 30% over the

two edges/ends of the spray pattern. To maximize uniform coverage the second pass over the area

should allow for the 15% “feather” or overlap.

1

W

A

ay

U

D

R

N

2

S25

SPRAY-PRO

J

U

S

T

S

2

”

D

E

a

r

t

h

G

RO

Spray Pattern

1X RATE

PATH IS

ONE WAY

Ensure accuracy

It is important that the S25 SPRAY-PRO sprayer is pushed in a

manner that keeps the spray head parallel to the ground at all times, so that the spray

nozzle is constantly kept at the same correct height. Keeping the height of the nozzle

constantly parallel to the ground ensures the nozzle will spray to its stipulated spray

FEATHERED-EDGE

application cover. If the sprayer is pushed at a downward angle and the nozzle tip is

nearer to the ground, the spray width will be reduced and over application will occur. In

the reverse situation of the spray nozzle height being increased by pushing the sprayer at

an upward angle the nozzle fan will be wider, the spray width will becoming inaccurate,

under application will likely occur. To ensure spray width accuracy it is important that

the handlebar height is set right for the individual user, and the operator is aware that the

sprayer is pushed in a manner that keeps the nozzle constantly parallel with the ground.

2X RATE

PATH IS

BOTH WAYS

FEATHERED-EDGE

Keeping the top of the tank parallel with the ground is a good guide.

Most applications will only require

one pass of up/back (1X Rate). When

higher application rates are required a

cross pattern (2X Rate) as shown above

should be used.

After use

1. Empty any unused contents out of the spray tank. The S25 SPRAY-PRO tank has been designed

to easily empty and clean. Dispose of the tank contents and all washings in accordance

with the manufacturer’s disposal instructions on the product that has been used.

2. Wash out the tank thoroughly using clean water and or a preparatory tank

cleaner. Make sure that the nozzle and spray gun (if included) are thoroughly

washed as well. To wash through the pipework to the spray nozzle, add

an additional 1/2 gallon or 2 liters of clean water to the tank and wash this

through the nozzle by pushing the sprayer over a safe area for the purpose of

disposal of washings.

3. Empty all water out of the sprayer making sure no water is left in the pump

over winter - do not allow to freeze, unless you have setup the S25 to operate

in freezing temperatures using an Ice Melt or snow pre-treatments.

Maintain the wheel knurled pins regularly by cleaning any debris or dirt

To aid accuracy use a proprietary spray dye indicator which allows the operator

to see where they have sprayed. Contact your local landscape supplier for a

recommendation.

from the Drive Wheel axle area. Keep knurled pins well lubricated to

prevent seizure. An Extra set is included!

PAGE 5

S25 SPRAY-PRO

Earthway Products, Inc.

P.O. Box 547

Bristol, IN 46507

Phone: 800-294-0671

www.earthway.com

9/16" OD. X .257 ID.

Washer Zinc

S25-24506

DCV Mount

S25-70011

Knob

36104

3/16” x 1” Cotter pin

S25-70008

3.5” Drop-In

Tank Filter

S25-19001

90 deg Elbow

1/4 NPT Male to 3/8” barbed

S25-70010

3-Way Valve

Retainer

&

31135

#8 x 1/2 Screw

E

34108

36501

1" Carriage Bolt

4

3

2

#8 x 3/8 Screw

1

ar

31138

S25-70000

DCV Nozzle

Adapter

S25-70003

Nozzle Holder w/gasket

t

h

W

ay

A

S25ss

S25-70001

D

3-way Valve

R

S25 SPRAY-PRO

C

1/2” HHCS

Axle Bushing

SPRAY-PRO Liquid Sprayer ~ Parts List

OPTIONAL

Liter Gallon

25

20

6

5

15

4

10

3

5

2

1

2

S25-19003

Herbie Clamp

36225

12152

S25-60000

Tank w/Cap

Tee 1/4 NPT Male

S25-60001

B

S25-19002

to 3/8” barbed

Skirt

36216

2” HHCS

1-1/4” HHCS

S25-77000 Spray Gun Kit

S25-19105

3/8” Cap for Tee tting

S25-24508

Control to Valve

Adapter

36224

S25-60002

Kelch Cap

36300

1/4-20 Lock Nut

S25-19003

Herbie Clamp

37107

#6-32 x 1" PHPS SS

19132

Tube Plug

36210

1” HHCS

S25-19004

Spray Gun

S25-19000

1/4 NPT Female

to 1/8” adapter

S25- 24507

Gun Holder

70142

Nut Protector

S25-41000

Control Rod

S25-25722-SS

Frame

36300

1/4-20 Lock

Nut

36300

1/4-20 Lock Nut

25223-SS

Handle Shaft

Lower Handle

36216

2” HHCS

25222-SS

12344

Handle Spacer

36300

1/4-20 Lock Nut

60175-SS

Upper Handles w/Grip

36216

2” HHCS

Hoses

S25-19100 (A)

S25-19101 (B)

S25-19102 (C)

S25-19103 (D)

PAGE 6

S25-70138

Drive Wheel

Knurled Pins

S25-30004

Washer

Nozzles

S25-70004 Black

S25-70006 Blue

S25-70012 Gray

S25-30003

Gearcase & Axle Assembly

EXTRA

S25-30003

Knurled Pins

S25-24501

Pump to Tank

B

Pump to 3-way

Valve

A

S25-24600

Pump

S25-24505

Pump Cover

25228

Cross brace

31138

#8 x 3/8 Screw

S25-44292

Frame Brace

12148

Axle Bearing

70138

Wheel

36200

1-1/2” HHCS

36216

2” HHCS

36104

3/16” x 1” Cotter pin

Loading...

Loading...