Page 1

Operator’s Manual

CAUTION ICON R1

READ OM ICON R1

Original Operating Instructions

Manuel de l’utilisateur

Manual del operador

MC43

2-Cycle Cultivator

Motobineuse 2 temps

Cultivador de 2 ciclos

Get parts online at

Pièces détachées en ligne à

Obtenga piezas en línea en

www.GetEarthquake.com

Includes Model:

Inclut le modèle, Incluye el modelo

MC43

P/N: 26478

ECN: 11296

REV1: 10/01/16

© 2016 Ardisam, Inc.

All Rights Reserved

Tous droits réservés

Todos los derechos reservados

Page 2

Operator’s Manual

MC43 2-Cycle Cultivator

INTRODUCTION

Thank you for purchasing a cultivator from Earthquake®. We have worked to ensure that this cultivator meets the highest

standards for usability and durability. With proper care, your cultivator will provide many years of service.

Please read this entire manual before installation and use. Earthquake® reserves the right to change, alter or improve the product

and this document at any time without prior notice.

CONTENTS

Introduction/Content/Registration and Service ............................................................................................................................................................... 2

Warnings and Safety Precautions ....................................................................................................................................................................................... 3-6

Operation Precautions/Maintenance and Storage Precautions ..................................................................................................................................6

Burns and Fires/Safety Decals .............................................................................................................................................................................................. 6-7

Features ...........................................................................................................................................................................................................................................8

Unpacking and Assembly ......................................................................................................................................................................................................... 9

Operation ..................................................................................................................................................................................................................................9-12

Maintenance and Storage ................................................................................................................................................................................................ 12-14

Troubleshooting and Repair ............................................................................................................................................................................................14-15

Illustrated Parts Breakdown.............................................................................................................................................................................................16-20

15073 Border-Edger Kit Installation (Optional Accessory) ..........................................................................................................................................21

DK43 Dethatcher Kit Installation (Optional Accessory) ................................................................................................................................................22

Warranty ........................................................................................................................................................................................................................................23

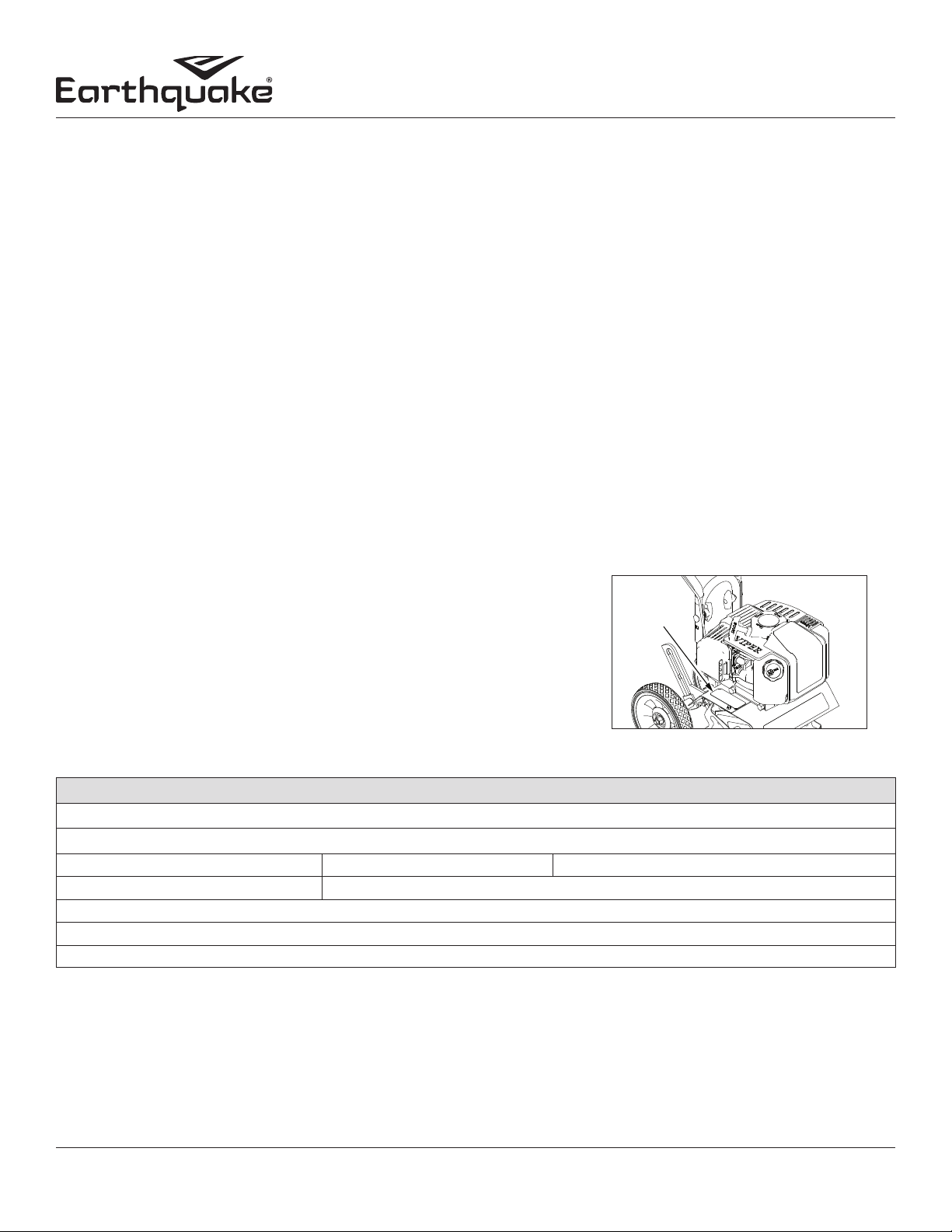

REGISTRATION AND SERVICE

Record the product model number and serial number in the space provided for

easy reference when ordering parts or requesting technical support. Excluding

emissions-related warranty items, the warranty is valid only if the completed

registration is received by Ardisam within 30 days of purchase. (SEE WARRANTY

SECTION FOR MORE INFORMATION) You can register your warranty online by

visiting www.earthquake.com, or by mailing it to: Ardisam Inc, 1160 8th Avenue,

Cumberland, WI 54829. You may also call our Customer Service department at

(800) 345-6007 Mondays through Fridays from 8 a.m. to 5 p.m. CST.

OWNERSHIP RECORDS

Owner’s Name:

Owner’s Address:

City: State/Province: Zip Code/Postal Code:

Model Number: Serial Number:

Date of Purchase:

Notes:

Read and keep this manual for future reference. This manual contains important information on SAFETY, ASSEMBLY, OPERATION,

AND MAINTENANCE. The owner must be certain that all the product information is included with the unit. This information includes

the MANUAL, the REPLACEMENT PARTS and the WARRANTIES. This information must be included to make sure state laws and other

laws are followed. All persons to whom rent/loan this unit must have access to and understand this information. This manual should

remain with the product even if it is resold.

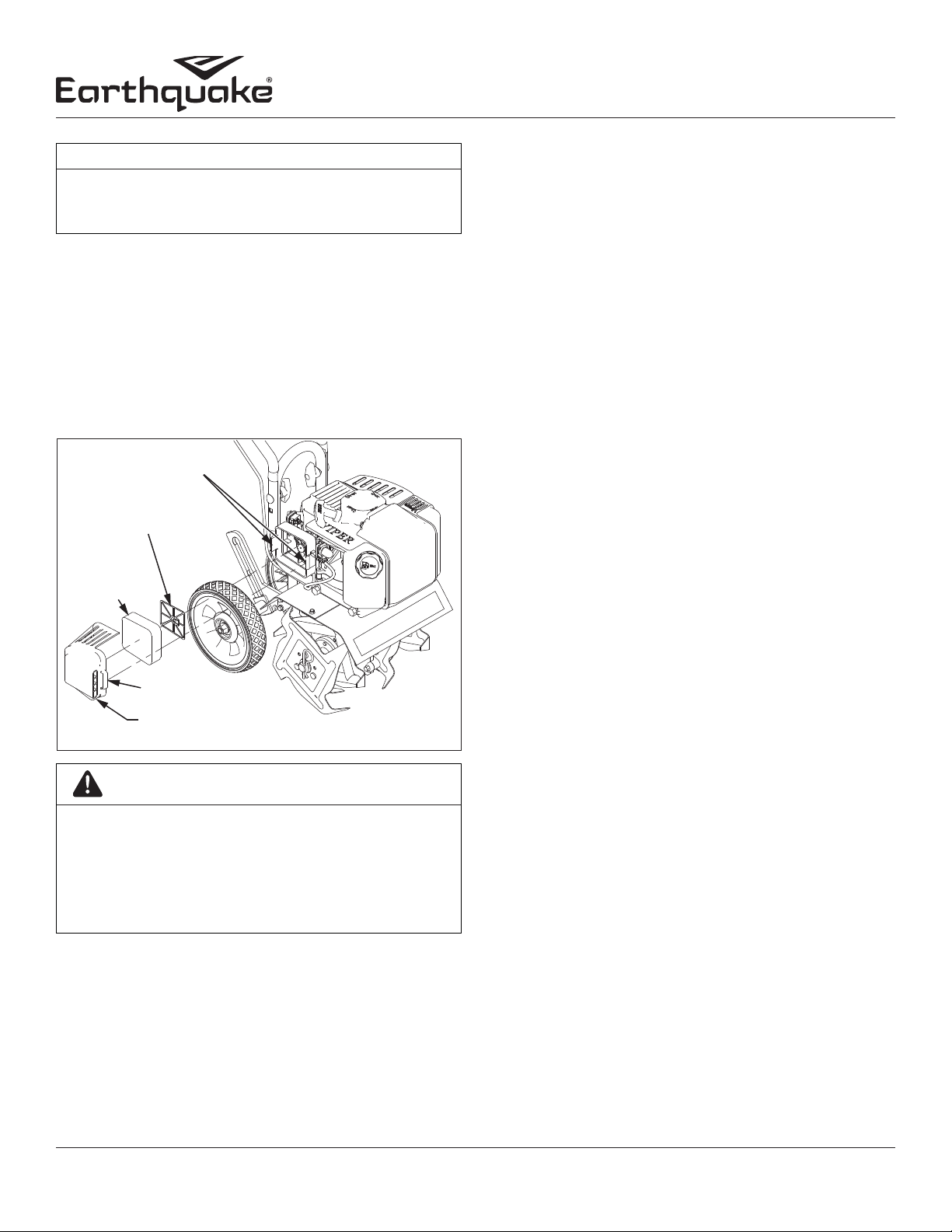

SERIAL

NUMBER

DECAL

2

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Page 3

Operator’s Manual

MC43 2-Cycle Cultivator

WARNINGS AND SAFETY PRECAUTIONS

Owner’s Responsibility

Accurate assembly and safe and eective use of the machine is

the owner’s responsibility.

• Read and follow all safety instructions.

• Carefully follow all assembly instructions.

• Maintain the machine according to directions and

schedule included in this Earthquake operator’s

manual.

• Ensure that anyone who uses the machine is familiar

with all controls and safety precautions.

Special Messages

Your manual contains special messages to bring attention to

potential safety concerns, machine damage as well as helpful

operating and servicing information. Please read all the

information carefully to avoid injury and machine damage.

NOTE: General information is given throughout the

manual that may help the operator in the

operation or service of the machine.

THIS SYMBOL POINTS OUT IMPORTANT

SAFETY INSTRUCTIONS WHICH, IF NOT

FOLLOWED, COULD ENDANGER YOUR

PERSONAL SAFETY. READ AND FOLLOW ALL

INSTRUCTIONS IN THIS MANUAL BEFORE

ATTEMPTING TO OPERATE THIS EQUIPMENT.

NOTICE

NOTICE INDICATES YOUR EQUIPMENT CAN BE

DAMAGED IF THE SAFETY INSTRUCTIONS THAT

FOLLOW THIS SIGNAL WORD ARE NOT OBEYED.

CAUTION

CAUTION INDICATES A HAZARD WHICH, IF NOT

AVOIDED, COULD RESULT IN PERSONAL INJURY

AND/OR PROPERTY DAMAGE.

WARNING

WARNING INDICATES A HAZARD WHICH, IF NOT

AVOIDED, COULD RESULT IN DEATH OR SERIOUS

INJURY AND/OR PROPERTY DAMAGE.

DANGER

DANGER INDICATES A HAZARD WHICH, IF NOT

AVOIDED, WILL CERTAINLY RESULT IN DEATH OR

SERIOUS INJURY AND/OR PROPERTY DAMAGE.

IMPORTANT

IMPORTANT INDICATES HELPFUL INFORMATION

FOR PROPER ASSEMBLY, OPERATION, OR

MAINTENANCE OF YOUR EQUIPMENT.

Before Operating Engine:

Please read this section carefully. Read entire operating and

maintenance instructions for this product. Failure to follow

instructions could result in damage to personal property,

serious injury or death. Operate the machine according to the

safety instructions outlined here and inserted throughout the

text. Anyone who uses this machine must read the instructions

and be familiar with the controls.

Intended Use / Foreseeable Misuse

IMPORTANT: This is a motorized rotary cultivator that works

the soil by means of rotating tines. It is pedestrian-controlled,

but not self-propelled, with a gasoline-fueled internal

combustion engine to power the tines. It shall not be used for

any other purpose.

DANGER

WARNING

CALIFORNIA PROPOSITION 65 WARNING

ENGINE EXHAUST FROM THIS PRODUCT

CONTAINS CHEMICALS KNOWN TO THE STATE OF

CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS,

OR OTHER REPRODUCTIVE HARM.

WARNING

YOU MUST READ, UNDERSTAND AND COMPLY

WITH ALL SAFETY AND OPERATING INSTRUCTIONS

IN THIS MANUAL BEFORE ATTEMPTING TO SETUP

AND OPERATE YOUR MACHINE.

FAILURE TO COMPLY WITH ALL SAFETY AND

OPERATING INSTRUCTIONS CAN RESULT IN LOSS

OF MACHINE CONTROL, SERIOUS PERSONAL

INJURY TO YOU AND/OR BYSTANDERS, AND RISK

OF EQUIPMENT AND PROPERTY DAMAGE. THE

TRIANGLE IN THE TEXT SIGNIFIES IMPORTANT

CAUTIONS OR WARNINGS WHICH MUST BE

FOLLOWED.

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

3

Page 4

Operator’s Manual

MC43 2-Cycle Cultivator

General Safety Rules

• Read, understand, and follow all instructions on the

machine and in the manual(s). Be thoroughly familiar

with the controls and the proper use of the machine

before starting.

• Use this equipment for its intended purpose only.

• Familiarize yourself with all of the safety and

operating decals on this equipment and on any of its

attachments or accessories.

• Do not put hands or feet near or under rotating parts.

• Only allow responsible individuals who are familiar

with the instructions to operate the machine. Do

not allow children to operate this machine. Do not

allow adults to operate the machine without proper

instruction.

• Thoroughly inspect the area where the machine

is to be used and remove all foreign objects. Your

equipment can propel small objects at high speed

causing personal injury or property damage. Stay

away from breakable objects, such as house windows,

automobile, greenhouses, etc.

• Wear appropriate clothing such as a long-sleeved

shirt or jacket. Also wear long trousers or slacks. Do

not wear shorts. Never wear sandals, sneakers, or

open shoes, and never operate the machine with bare

feet.

• Do not wear loose clothing or jewelry. They can get

caught in moving parts. Always keep hands, feet, hair

and loose clothing away from any moving parts on

engine and machine.

• Always wear safety goggles or safety glasses with side

shields when operating the machine to protect your

eyes from foreign objects which can be thrown from

the unit. Always wear a protective hearing device.

• Always wear work gloves and sturdy footwear.

Wear footwear that will improve footing on slippery

surfaces. Leather work shoes or short boots work well

for most people. These will protect the operator’s

ankles and shins from small sticks, splinters, and other

debris.

• It is advisable to wear protective headgear to prevent

the possibility of being struck by small ying particles,

or being struck by low hanging branches, twigs,

or other objects which may be unnoticed by the

operator.

• Do not operate the machine without proper guards or

other safety protective devices in place.

• See manufacturer’s instructions for proper operation

and installation of accessories. Only use accessories

approved by the manufacturer.

• Operate only in daylight or good articial light.

• Do not operate product when fatigued or under the

inuence of alcohol, drugs or other medication which

can cause drowsiness or aect your ability to operate

this machine safely.

• Never operate machine in wet grass. Always be sure of

your footing; keep a rm hold on the handle and walk;

never run.

• Watch for trac when operating near, or when

crossing roads.

• If the equipment should start to vibrate abnormally,

stop the engine (motor), disconnect the spark plug

wire and prevent it from touching the spark plug.

Check immediately for cause. Vibration is generally

a warning of trouble. If the noise or vibrations of the

machine increase, stop immediately and perform an

inspection.

• Never leave the machine unattended when the

engine is running. Remove the wire from the spark

plug.

• Regularly inspect the machine. Make sure parts are

not bent, damaged or loose.

• Temperature of muer and nearby areas may exceed

150° F (65° C). Allow muer and engine areas to cool

before touching. Never pick up or carry the machine

while the engine is running.

• Prolonged exposure to noise and vibration from gasoline

engine-powered equipment should be avoided. Take

intermittent breaks and/or wear ear protection from

engine noise as well as heavy work gloves to reduce

vibration in the hands.

• Keep all screws, nuts and bolts tight.

• Do not transport the machine from one place to

another with the engine running.

• When moving the packaged machine, always do so

with a partner.

• Check local regulations for age restrictions on use of

this machine.

Product-Specic Safety Rules

• Do not cultivate above underground utilities,

including water lines, gas lines, electric cables, or

pipes. Do not operate the machine on terrain/soil with

large rocks and foreign objects which can damage the

equipment.

• After striking a foreign object, stop the engine.

Remove the wire from the spark plug. Inspect the

machine for damage. If damaged, repair before

starting and operating the machine.

• The tines of the cultivator should not rotate when the

engine is idling. If it does rotate when engine is idling,

contact Earthquake for instructions.

• If an object becomes lodged in the tines, turn engine

o, remove the wire from the spark plug and secure,

allow to cool before attempting to remove the foreign

object.

• The clutch will transfer maximum power after about

two hours of normal operation. During this break-in

period clutch slippage may occur. The clutch should

be kept free of oil or other moisture for ecient

operation.

4

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Page 5

Operator’s Manual

MC43 2-Cycle Cultivator

DANGER

ENGINES GIVE OFF CARBON MONOXIDE, AN

ODORLESS, COLORLESS, POISONOUS GAS.

CARBON MONOXIDE MAY BE PRESENT EVEN IF

YOU DO NOT SMELL OR SEE ANY ENGINE EXHAUST.

BREATHING CARBON MONOXIDE CAN CAUSE

NAUSEA, FAINTING OR DEATH, IN ADDITION TO

DROWSINESS, DIZZINESS AND CONFUSION.

IF YOU EXPERIENCE ANY OF THESE SYMPTOMS,

SEEK FRESH AIR AND MEDICAL ATTENTION

IMMEDIATELY.

Engine Safety Precautions

If your product comes with a separate engine manual, be

sure to read and follow all safety and warning precautions

outlined there, in addition to any in this manual.

Preventing Carbon Monoxide Poisoning

• Always start and run engine outdoors. Do not start

or run engine in an enclosed area, even if doors or

windows are open.

• Never try to ventilate engine exhaust indoors. Carbon

monoxide can reach dangerous levels very quickly.

• Never run engine outdoors where exhaust fumes may

be pulled into a building.

• Never run engine outdoors in a poorly ventilated area

where the exhaust fumes may be trapped and not

easily taken away. (Examples include: in a large hole

or areas where hills surround your working area.)

• Never run engine in an enclosed or partially enclosed

area. (Examples include: buildings that are enclosed

on one or more sides, under tents, car ports or

basements.)

• Always run the engine with the exhaust and muer

pointed in the direction away from the operator.

• Never point the exhaust muer towards anyone.

People should always be many feet away from the

operation of the engine and its attachments.

• Do not change the engine governor settings or overspeed the engine.

Gasoline Fires and Handling Fuel Safely

Use extra care in handling gasoline and other fuels. They are

ammable and vapors are explosive.

• When storing extra fuel be sure that it is in an

appropriate container and away from any re hazards.

• Prevent re and explosion caused by static electric

discharge. Use only nonmetal, portable fuel

containers approved by the Underwriter’s Laboratory

(U.L.) or the American Society for Testing & Materials

(ASTM).

• Never remove the fuel cap or add fuel with the engine

running. Stop engine and allow to cool before lling.

• Never drain fuel from engine in an enclosed area.

CAUTION

HOT GASES ARE A NORMAL BYPRODUCT OF A

FUNCTIONING INTERNAL COMBUSTION ENGINE.

FOLLOW ALL SAFETY INSTRUCTIONS TO PREVENT

BURNS AND FIRES.

WARNING

NEVER ALTER OR MODIFY THE ENGINE FROM

THE FACTORY. SERIOUS INJURY OR DEATH MAY

OCCUR IF ENGINE IS MODIFIED OR ALTERED.

WHEN WORKING ON OR REPLACING PARTS FOR

THE ENGINE OR PRODUCT, YOU MUST ALWAYS

FLIP THE ON/OFF SWITCH TO THE OFF POSITION.

• Always ll fuel tank outside in a well ventilated area.

Never ll your fuel tank with fuel indoors. (Examples

include: basement, garage, barn, shed, house, porch,

etc.) Never ll tank near appliances with pilot lights,

heaters, or other ignition sources. If the fuel has to be

drained, this should be done outdoors. The drained

fuel should be stored in a container specically

designed for fuel storage or it should be disposed of

carefully.

• Always wipe up excess (spilled) fuel from engine

before starting. Clean up spilled fuel immediately.

If fuel is spilled, do not start the engine but move

product and fuel container from area. Clean up spilled

fuel and allow to evaporate and dry after wiping and

before starting.

• Allow fuel fumes/vapors to escape from the area

before starting engine.

• Test the fuel cap for proper installation before starting

and using engine.

• Always run the engine with fuel cap properly installed

on the engine.

• Never smoke while relling engine fuel tank.

• Do not store engine with fuel in fuel tank indoors. Fuel

and fuel vapors are highly explosive.

Preparation

• Dress appropriately when operating the cultivator.

Always wear sturdy footwear. Never wear sandals,

sneakers or open shoes, and never operate the

cultivator with bare feet. Do not wear loose clothing

that might get caught in moving parts.

• Carefully inspect the area to be cultivated and

remove all foreign objects. Do not cultivate above

underground water lines, gas lines, electric cables, or

pipes. Do not operate the cultivator in soil with large

rocks and foreign objects which can damage the

equipment.

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

5

Page 6

Operator’s Manual

R

MC43 2-Cycle Cultivator

• Handle fuel with care; it is highly ammable.

a. Use an approved fuel container.

b. Never add fuel to a running engine or hot engine.

c. Fill fuel tank outdoors with extreme care. Never ll

fuel tank indoors.

d. Replace gasoline cap securely and clean up spilled

fuel before restarting.

NOTICE

THE RIGHT AND LEFT SIDES

OF YOUR CULTIVATOR ARE

DETERMINED FROM THE

OPERATING POSITION AS

YOU FACE THE DIRECTION OF

FORWARD TRAVEL.

THE 2CYCLE ENGINE USES A 50:1 RATIO OF GAS:OIL.

DO NOT USE STRAIGHT, UNMIXED GASOLINE OR

ENGINE DAMAGE WILL OCCUR.

L

OPERATION PRECAUTIONS

• Do not operate cultivator under the inuence of

alcohol or drugs.

• Never operate cultivator without guards, covers, and

hoods in place.

• Keep hands, feet, and clothing away from rotating

parts. Keep clear of cultivator tines at all times.

• Tines rotate when cultivator is engaged; tines rotate

when the drive safety control lever is pulled up.

Releasing the drive safety control lever to neutral

stops the tines.

• Use extreme caution when operating on or crossing

gravel drives, walks, or roads. Stay alert for hidden

hazards or trac.

• After striking a foreign object, stop the engine,

remove the wire from the spark plug, thoroughly

inspect the cultivator for any damage, and repair

the damage before restarting and operating the

cultivator.

• If vegetation clogs the tines, stop the engine and

disconnect the spark plug wire before removing

vegetation by hand.

• If the unit should start to vibrate abnormally, stop the

engine and check immediately for the cause. Vibration

is generally a warning of trouble.

• Do not run engine indoors; exhaust fumes are deadly.

• Do not overload the machine capacity by attempting

to till too deep at too fast of a rate.

• Never operate the cultivator without good visibility or

light.

• Take all possible precautions when leaving the

machine unattended. Disengage throttle control,

stop the engine, wait for all moving parts to stop, and

make certain guards and shields are in place.

• When leaving the operating position for any reason:

- shut o the engine.

- wait for all moving parts to stop.

MAINTENANCE AND STORAGE PRECAUTIONS

• Keep machine, attachments and accessories in safe

working condition.

• Check shear bolts, engine mounting bolts and other

bolts at frequent intervals for proper tightness to be

sure the equipment is in safe working condition.

• To prevent accidental starting, always disconnect and

secure the spark plug wire from the spark plug before

performing cultivator maintenance.

• Never run the engine indoors. Exhaust fumes are

deadly.

• Always allow muer to cool before lling the fuel

tank.

• Never store equipment with gasoline in the tank

inside a closed building where fumes may reach an

open ame or spark. Allow the engine to cool before

storing in any building.

• Always refer to the operator’s guide instructions for

important details if the cultivator is to be stored for an

extended period.

BURNS AND FIRES

The muer, muer guard and other parts of the engine become

extremely hot during the operation of the engine. These parts

remain extremely hot after the engine has stopped.

Prevention of Burns and Fires

• Never remove the muer guard from the engine.

• Never touch the muer guard because it is extremely hot

and will cause severe burns.

• Never touch parts of the engine that become hot after

operation.

• Always keep materials and debris away from muer guard

and other hot parts of the engine to avoid res.

Children and bystanders

Tragic accidents can occur if the operator is not alert to the

presence of children and/or bystanders. Never assume that

others will remain where you last saw them.

• Keep the area of operation clear of all persons, especially

small children and pets. Keep children under the watchful

care of a responsible adult.

• Be alert and turn machine o if children enter the area.

• Before and while moving backwards, look behind and down

for small children.

• Never allow children to operate the machine.

• Use extra care when approaching blind corners, shrubs, trees,

or other objects that may obscure vision.

6

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Page 7

Service

• Always stop the engine whenever you leave the equipment,

before cleaning, repairing or inspecting the unit. Engine

should be turned o and cool. Never make adjustments or

repairs with the engine (motor) running. Flip the ON/OFF

switch to the OFF position to prevent accidental starting.

• Always wear eye protection when you make adjustments or

repairs.

• Keep all nuts and bolts tight and keep equipment in good

condition.

• Never tamper with safety devices. Check their proper

operation regularly.

• When servicing or repairing the machine, do not tip the

machine over or up unless specically instructed to do so in

this manual. Service and repair procedures can be done with

the machine in an upright position. Some procedures will be

easier if the machine is lifted on a raised platform or working

surface.

• To reduce re hazard, keep machine free of grass, leaves or

other debris build-up. Clean up oil or fuel spillage. Allow

machine to cool before storing.

• Stop and inspect the equipment if you strike an object.

Repair, if necessary, before restarting.

• Clean and replace safety and instruction decals as necessary.

• Inspect machine before storage. When not in use, ip the

ON/OFF switch to the OFF position and store indoors in a

dry place locked or otherwise inaccessible to children.

• Use only original equipment parts from Earthquake,

including all nuts and bolts.

Operator’s Manual

MC43 2-Cycle Cultivator

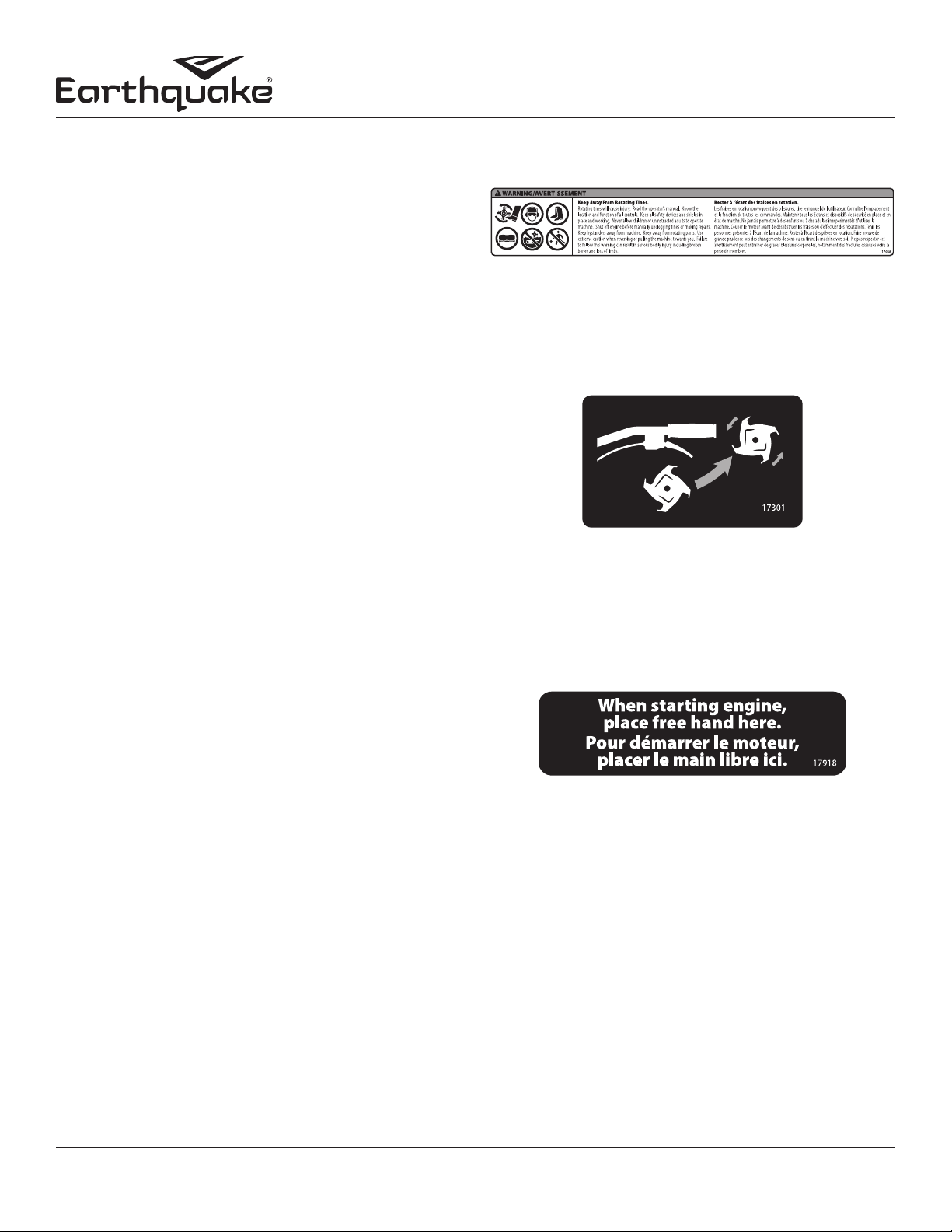

Part No. 17048

Cultivator Warning Decal - Tine Shield

Part No. 17301

Throttle Control Decal - Right Handlebar

SAFETY DECALS

This cultivator has been designed and manufactured to

provide you with the safety and reliability you would expect

from an industry leader in outdoor power equipment

manufacturing.

Reading this manual and the safety instructions it contains

will provide you with the necessary basic knowledge to

operate this equipment safely and eectively. We have placed

a safety decal on the cultivator to remind you of some of this

important information while you are operating the unit.

These important safety decals are shown here to help

familiarize you with the location and content of the safety

messages you will see as you perform normal cultivating

operations. Please review these decals now, and if you have

any questions regarding its meaning or how to comply with

these instructions, reread the complete safety instruction text

in this manual.

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Free Hand Safe Starting Location Decal - Left Handlebar

Part No. 17918

7

Page 8

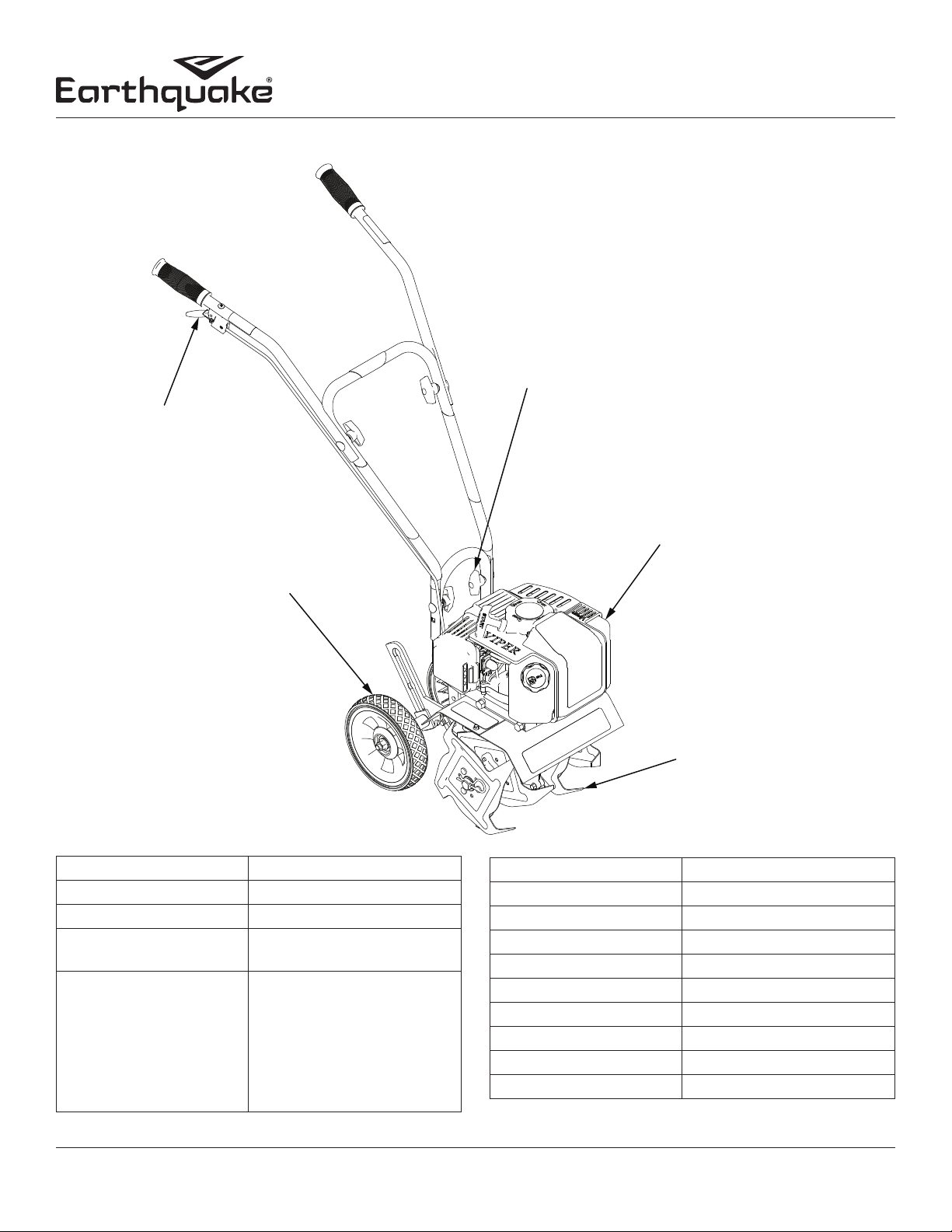

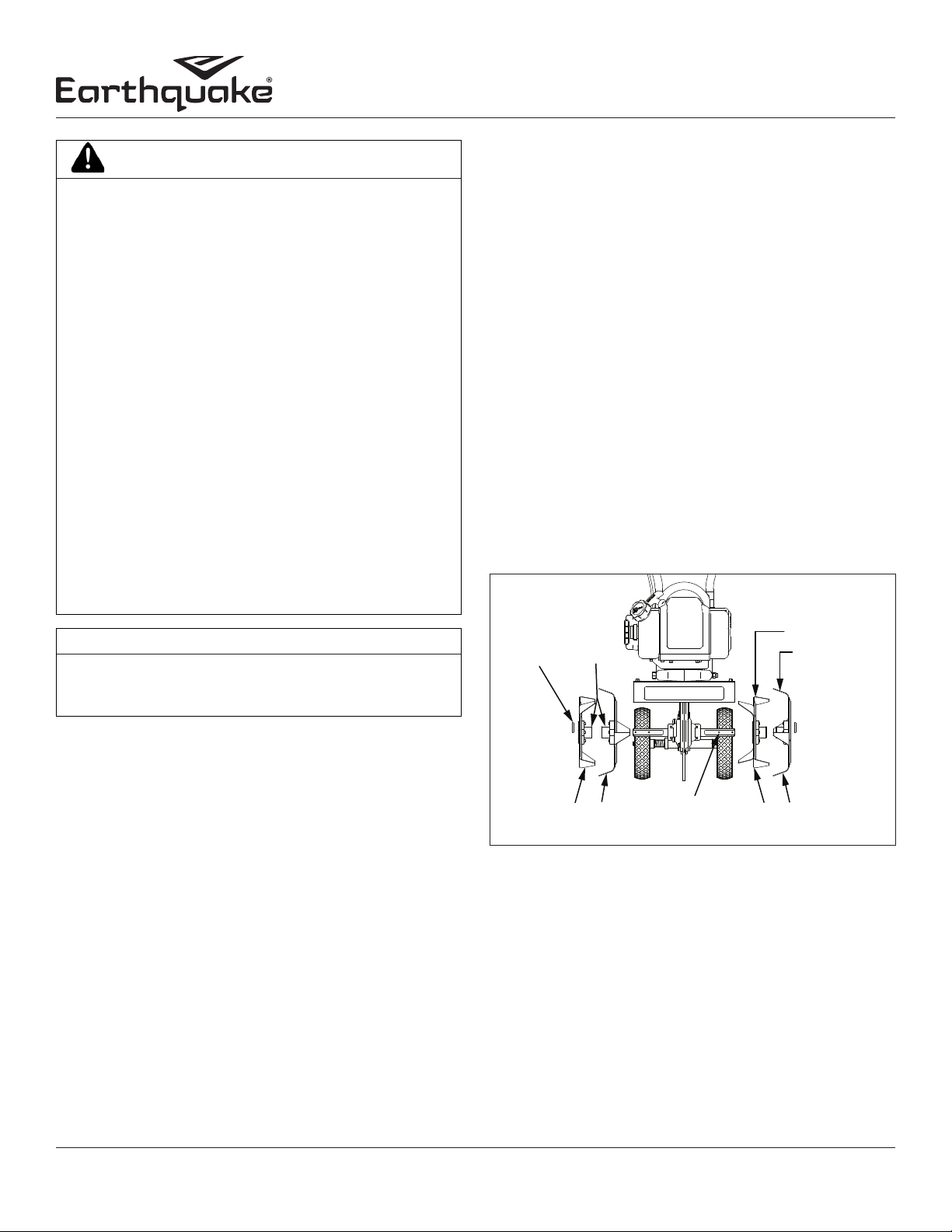

FEATURES

TOOL-LESS REVERSIBLE

THROTTLE

CONTROL

Operator’s Manual

MC43 2-Cycle Cultivator

2 POSITION TOOL-LESS

HANDLEBAR HEIGHT

ADJUSTMENT

LEVER

3 POSITION

TOOL-LESS

WHEEL HEIGHT

ADJUSTMENT

SPECIFICATIONS

ENGINE DISPLACEMENT 43cc

FUEL TANK CAPACITY 36 -oz

OIL/GAS RATIO 50:1 - 2.6 -oz per gallon

OIL TYPE Viper 2-cycle engine oil

(Part number: 16890)

FUEL TYPE Minimum 87 octane gasoline.

NOTE: If using an ethanol

blended fuel, a fuel

stabilizer, mixed

to manufacturer

specications, is

recommended.

SEE THROUGH

FUEL TANK

& REPLACEABLE TINES

SPARK PLUG L7RTC

SPARK PLUG GAP 0.027 inch

TRANSMISSION Bronze gear drive

GEAR RATIO 32:1

TILLING WIDTH 6 inch min. - 10 inch max.

TILLING DEPTH 8 inch max.

TINE SPEED 250 rpm max.

WHEEL SIZE 7.0 inch dia. x 1.375 inch wide

WEIGHT OF UNIT 33 lb

ASSEMBLED SIZE 35 x 18 x 38 inch (L x W x H)

8

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Page 9

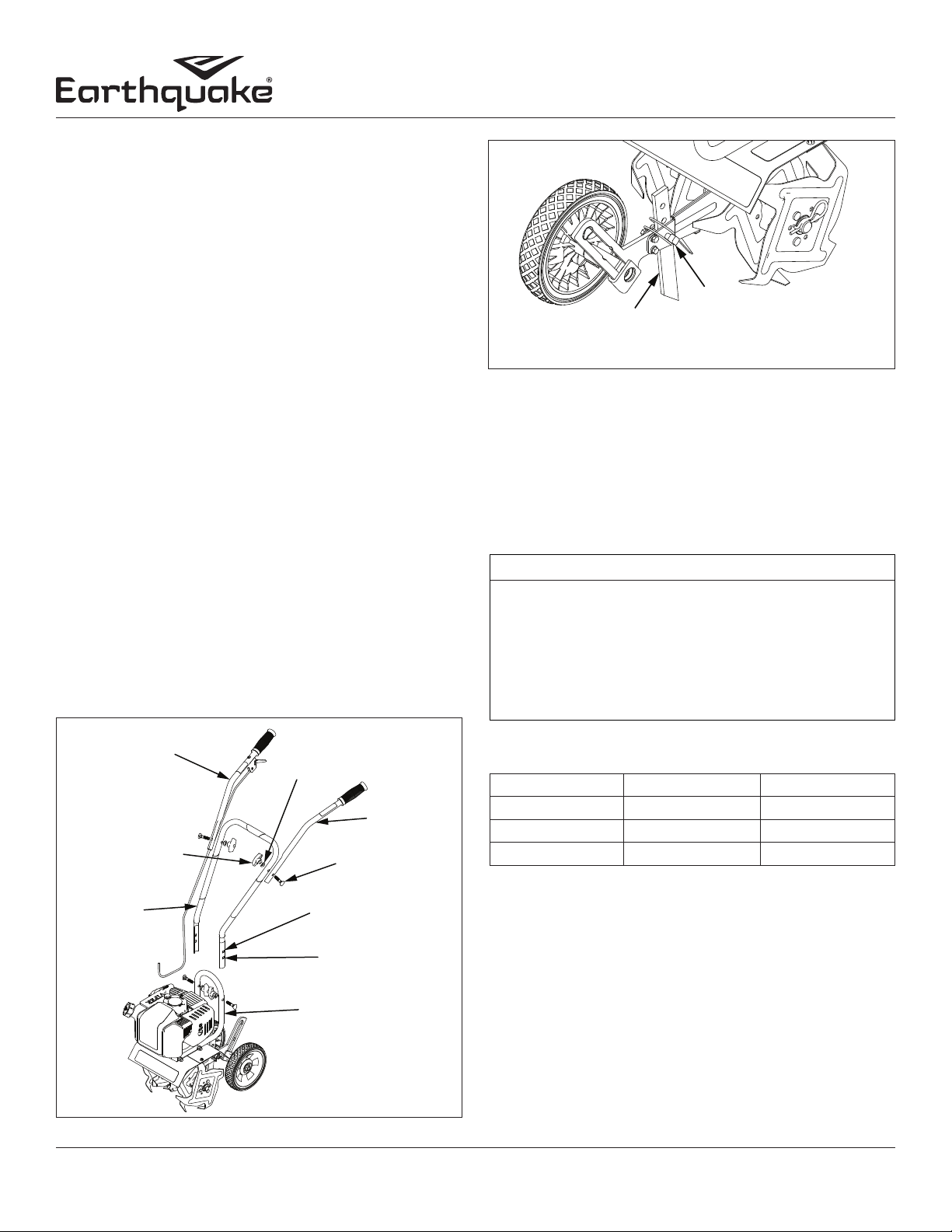

UNPACKING AND ASSEMBLY

UPPER RIGHT

Unpack Cultivator

1. Carefully lift the cultivator out of the box, remove any

packing material and cut any ties holding the handlebar

pieces to the cultivator assembly.

2. Find parts packet. Parts packet contains:

• 4 - T-Handle Nuts (4640)

• 4 - Curved Washers (4641)

• 4 - Saddle Bolts (4642)

Assembly

1. Stand the cultivator assembly upright with tines and

wheels on a level surface. Wheels should be set in the

lowest position. DO NOT place the cultivator on a high

surface where it can fall and cause property damage or

personal injury.

2. Using two T-handle nuts, two saddle bolts, and two

curved washers, attach the middle handlebar to the lower

handlebar that is already connected to the cultivator

assembly. The middle handlebar can be installed in

one of two positions, one high and one low. DO NOT

overtighten the T-handle nuts. SEE FIGURE 1

3. Attach the upper right and left handlebars to the middle

handlebar using the two remaining T-handle nuts, saddle

bolts, and curved washers. SEE FIGURE 1. DO NOT

overtighten the T-handle nuts.

4. The drag stake is shipped with point facing upwards.

Before using, remove lock pin and turn the drag stake

around so the point is directed in the downward position

facing towards the tines. Re-insert lock pin.

SEE FIGURE 2

HANDLEBAR

T-HANDLE NUT

CURVED

WASHER

HANDLEBAR

SADDLE BOLT

UPPER LEFT

Operator’s Manual

MC43 2-Cycle Cultivator

LOCK PIN

DRAG STAKE

(POINT DOWN FOR OPERATION)

FIGURE 2

OPERATION

Operation Tips

1. The clutch will transfer maximum power after about two

hours of normal operation. During this break-in period

clutch slippage may occur. The clutch should be kept free

of oil and other moisture for ecient operation.

2. Cultivate without placing excessive body weight on the

unit. The cultivator operates most eciently with the

weight of the unit itself.

IMPORTANT

TO OPERATE THE ENGINE, WE RECOMMEND

USING “VIPER” BRAND 2CYCLE OIL PN 16890,

OR EQUIVALENT HIGH QUALITY 2CYCLE OIL

DESIGNED FOR AIRCOOLED 2CYCLE ENGINES, TO

ENSURE THAT THE ENGINE OPERATES CORRECTLY

THROUGHOUT THE LIFE OF THE ENGINE. USE

PREMIUM GASOLINE, LOW/NO ETHANOL BLENDS

RECOMMENDED.

Preparing Engine for Starting

Mixing Fuel and Filling the Fuel Tank

GAS OIL RATIO

1 gallon 2.6 uid-ounces 50:1

2 gallons 5.1 uid-ounces 50:1

5 gallons 13 uid-ounces 50:1

MIDDLE

HANDLEBAR

FIGURE 1

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

LOW POSITION

MOUNT HOLES

HIGH POSITION

MOUNT HOLES

LOWER

HANDLEBAR

NOTE: Engine must be run with a 50:1 Fuel:Oil ratio.

1. Fuel must be mixed in a container outside in a well

ventilated area.

2. Fill certied fuel container 1/4 full of recommended fuel.

3. Add recommended amount of 2-cycle oil.

4. Screw container gas cap on straight and tight.

5. Shake the container to mix fuel and oil.

6. Unscrew gas cap slowly to vent, add the remainder of fuel

requirements.

7. Wipe away any spilled fuel or oil and allow to evaporate

before moving or transporting.

9

Page 10

INNER HOLE

WARNING

DO NOT STORE ENGINE INDOORS WITH FUEL IN

THE TANK. FUEL AND FUEL VAPORS ARE HIGHLY

FLAMMABLE.

NEVER MIX FUEL AND OIL DIRECTLY IN ENGINE

FUEL TANK. USE ONLY NONMETAL, PORTABLE

FUEL CONTAINERS APPROVED BY THE

UNDERWRITER’S LABORATORY U.L. OR THE

AMERICAN SOCIETY FOR TESTING & MATERIALS

ASTM.

AN ADULT MUST ALWAYS HANDLE AND FILL THE

ENGINE WITH FUEL.

ALWAYS HANDLE GAS IN A WELL VENTILATED

AREA, OUTDOORS, AWAY FROM FLAMES OR

SPARKS.

DO NOT START ENGINE IF FUEL IS SPILLED. WIPE

OFF EXCESS FUEL AND ALLOW TO DRY. REMOVE

ENGINE FROM AREA TO AVOID SPARKS.

NEVER RUN ENGINE INDOORS. EXHAUST FUMES

ARE DEADLY.

FAILURE TO FOLLOW THESE WARNINGS CAN

CAUSE DAMAGE TO EQUIPMENT AND INJURY TO

PERSONNEL.

Operator’s Manual

MC43 2-Cycle Cultivator

To Install Tines

1. First slide the inside tines onto each end of the tine shaft.

One inside tine is stamped with a B and the other is

stamped with a C.

2. Slide the outside tine A and tine D onto each end of the

shaft next. The tines should be installed in the correct

order so that they are positioned left to right A, B, C, D,

as viewed from the user’s position on the cultivator. Make

sure that the hub collars on both the right and left pairs

of tines face each other so that there is adequate spacing

between the tine blades.

3. Insert the hairpins into the holes at each end of the tine

shaft to lock the tines into place.

NOTE: Tines can be reversed so the pointed tip of the

tines are directed forward - for more aggressive

digging. In this arrangement, tines are positioned

left to right D, C, B, A as viewed from the user’s

position.

To reduce cultivating width from 10” to 6”, remove

both outer tines and reinsert hairpins through the

two inner holes on the tine shaft to secure both

inner tines in place.

NOTICE

THIS ENGINE USES A FUEL/OIL MIXTURE. DO NOT

RUN ON STRAIGHT GASOLINE ONLY, ENGINE

DAMAGE WILL OCCUR.

Filling Fuel Tank

1. Shut-o engine and allow engine to completely cool

before relling the fuel tank.

2. Move to a well ventilated area, outdoors, away from

ames and sparks.

3. Clean debris from area around the fuel cap.

4. Loosen fuel cap slowly. Place the cap on a clean, dry

surface.

5. Carefully add fuel without spilling.

6. Do not ll gas tank completely full, allow space for fuel to

expand.

7. Immediately replace fuel cap and tighten. Wipe o spilled

fuel and allow to dry before starting engine.

Tine Removal and Installation

To Remove Tines, do as follows: SEE FIGURE 3

1. Remove the hairpins from each end of the tine shaft.

2. Slide the four tines o the shaft.

HAIR

PIN

FIGURE 3

Starting and Stopping the Engine

• Move engine to a well ventilated area, outdoors, to

• Move to an area away from ames or sparks, to avoid

• Remove all debris from air cleaner holes and gas cap

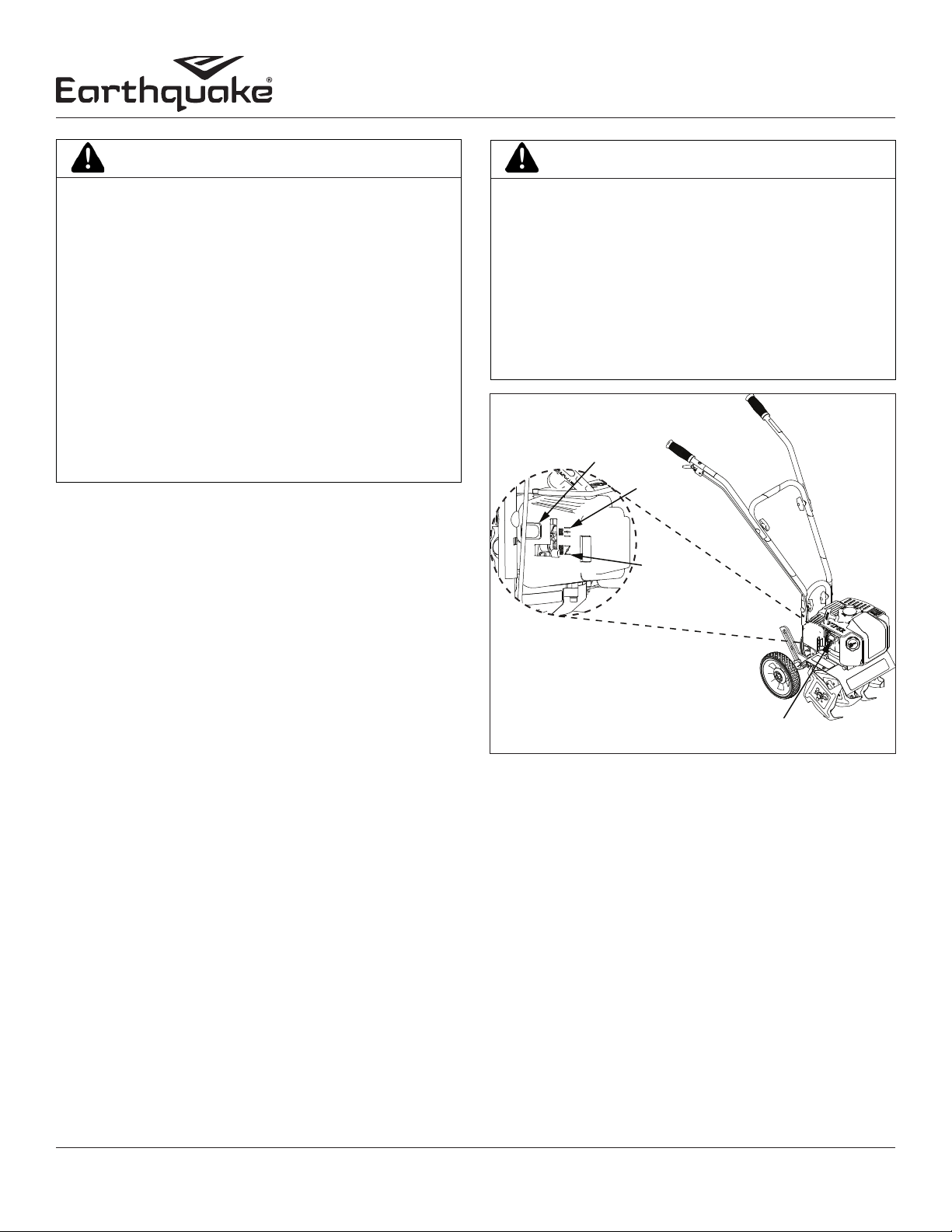

Cold Engine Start (SEE FIGURE 4):

Starting engine for rst time or after engine has cooled o or

after running out of fuel.

1. Prime unit until primer hose is lled with gas.

NOTE: When using the primer bulb, allow the bulb to

HUB

COLLARS

D C

prevent carbon monoxide poisoning.

ignition of vapors if present.

to ensure proper air ow.

return completely to its original position between

pushes.

TINE SHAFT

INNER TINE

OUTER TINE

B A

10

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Page 11

Operator’s Manual

BULB

MC43 2-Cycle Cultivator

WARNING

MAKE SURE THE UNIT IS IN A STABLE POSITION

BEFORE PULLING THE STARTER HANDLE.

WHEN THE UNIT STARTS TO FIRE OR RUN, RETURN

BOTH HANDS TO THE HANDLE BAR POSITION TO

MAINTAIN CONTROL AND STABILITY OF THE UNIT.

STARTER ROPE CAN CAUSE AN UNANTICIPATED

JERK TOWARDS ENGINE. PLEASE FOLLOW

INSTRUCTIONS TO AVOID INJURY.

NEVER LEAVE ENGINE RUNNING WHILE

UNATTENDED. TURN OFF AFTER EVERY USE.

NEVER CARRY CULTIVATOR FROM ONE LOCATION

TO ANOTHER WHILE ENGINE IS RUNNING.

ALWAYS WEAR A PROTECTIVE HEARING DEVICE.

DO NOT START ENGINE IF FUEL IS SPILLED. WIPE

OFF EXCESS FUEL AND ALLOW TO DRY.

2. Move choke lever to CHOKE position.

NOTE: CHOKE position is dened by moving the choke

lever as far to the CHOKE position as possible.

3. Push ON/OFF switch to the ON position.

4. Hold handle bar rmly. Grasp starter handle with other

hand and pull out slowly, until it pulls slightly harder.

Without letting starter handle retract, pull rope with a

rapid full arm stroke. Let it return to its original position

very slowly. Repeat this step every time the starter rope is

pulled until unit res or runs.

NOTE: If engine fails to start after 5-6 pulls, push primer 1

time and pull starter rope again.

5. After engine starts running, move choke lever to HALF

CHOKE position until unit runs smoothly.

NOTE: Half choke is dened when the choke lever is

positioned between CHOKE and RUN.

6. Move choke lever to RUN position and squeeze throttle

to desired speed.

NOTE: Run at full throttle when possible. Do not let unit

idle for extended periods of time.

7. To stop engine, push ON/OFF switch to OFF position.

Hot/Warm Engine Start:

1. Begin with Step 3 of Cold Engine Starting.

2. If engine does not re, refer to Step 1 of Cold Engine

Starting.

Note: If engine fails to start after trying starting

procedures, please contact our customer service

department at 800-345-6007 or e-mail

info@getearthquake.com

WARNING

DO NOT ATTEMPT TO START ENGINE IN THE

FOLLOWING WAYS:

• DO NOT USE STARTING FLUID

• DO NOT SPRAY FLAMMABLE LIQUIDS OR

VAPORS INTO AIR CLEANER, CARBURETOR,

OR SPARK PLUG CHAMBER.

• DO NOT REMOVE SPARK PLUG AND ATTEMPT

TO START ENGINE. FLAMMABLE FUEL CAN

SPRAY OUT AND IGNITE FROM A SPARK FROM

SPARK PLUG.

ON/OFF

SWITCH

RUN

CHOKE

PRIMER

FIGURE 4

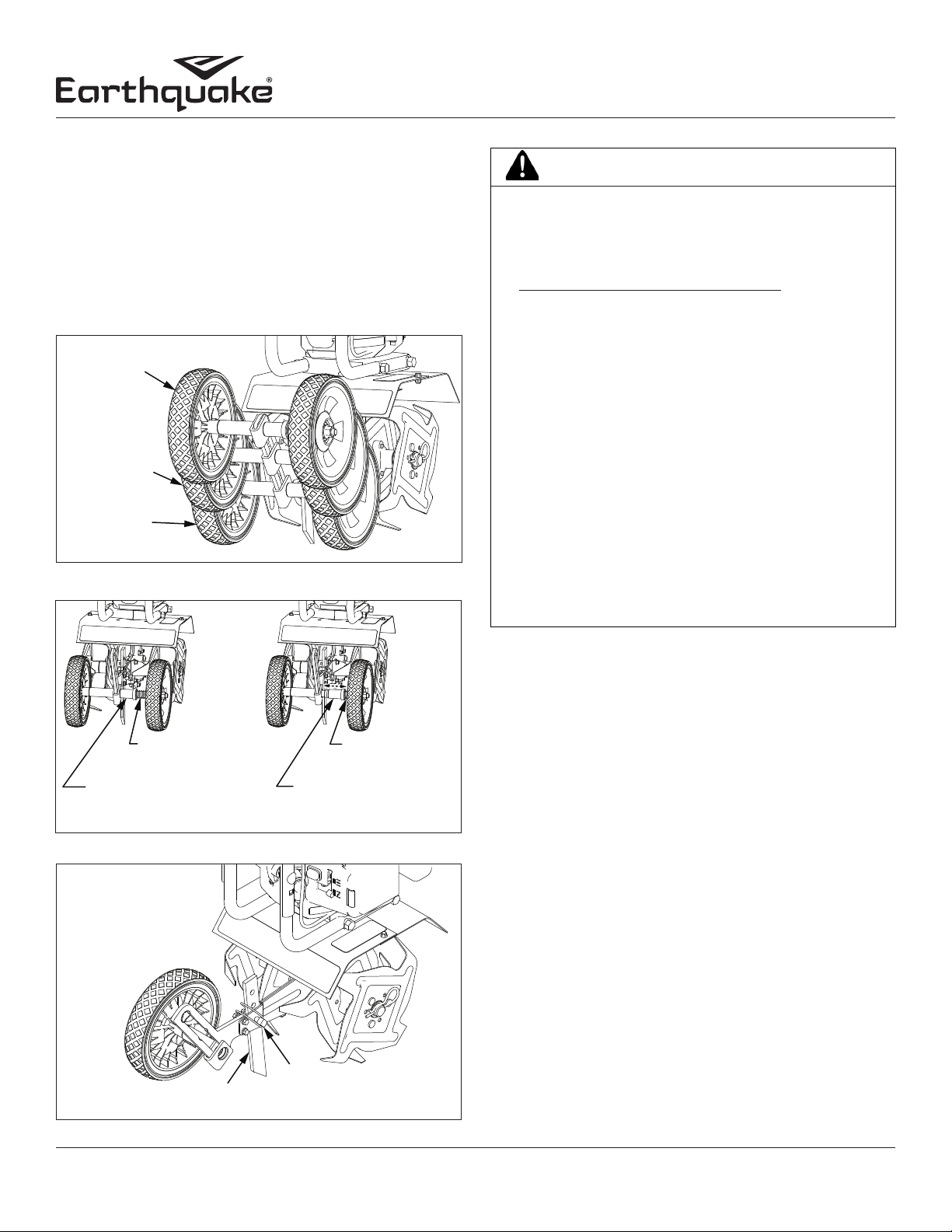

Adjusting Wheels and Drag Stake

The wheels on the cultivator can be adjusted to one of three

positions. The LOW wheel position is used for transporting

the cultivator across a smooth level surface while the engine

is not running. The HIGH and HIGHEST wheel positions are

used when cultivating in soil and help stabilize the unit when

cultivating at dierent depths. SEE FIGURE 5

To Adjust Wheels Up Or Down do as follows:

SEE FIGURES 5 & 6:

1. Pull the locking metal sleeve against the spring, away

from the vertical guide until it releases from one of the

three notched positions in the vertical guide.

2. Slide the wheel set up or down to the desired position,

and release the locking metal sleeve until it locks into

desired notch in the vertical guide.

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

11

Page 12

To Adjust the Drag Stake do as follows: SEE FIGURE 7

The drag stake is used to help regulate cultivating depth and

control the cultivator from leaping forward during operation.

Resistance to forward motion is greatest when the drag stake

is set in its lowest position allowing for deeper cultivation.

1. Pull the lock pin out of the drag stake mount hole.

2. Position drag stake so the pointed tip is directed

downward.

3. Insert lock pin into the hole that achieves desired depth.

HIGH

POSITION

MIDDLE

POSITION

LOW

POSITION

FIGURE 5

EXPANDED

SPRING

LOCKING METAL SLEEVE

(LOCKED POSITION)

FIGURE 6

LOCKING METAL SLEEVE

(UNLOCKED POSITION)

COMPRESSED

SPRING

Operator’s Manual

MC43 2-Cycle Cultivator

WARNING

PRACTICE SAFETY AT ALL TIMES. ENGINE MUST

BE TURNED OFF AND ALLOWED TO COOL, AND

SPARK PLUG WIRE MUST BE DISCONNECTED

BEFORE ATTEMPTING ANY MAINTENANCE OR

REPAIR.

TO PREVENT ACCIDENTAL STARTING:

ENGINE MUST BE TURNED OFF AND COOL, AND

SPARK PLUG WIRE MUST BE REMOVED FROM

SPARK PLUG BEFORE CHECKING AND ADJUSTING

ENGINE OR EQUIPMENT.

TEMPERATURE OF MUFFLER AND NEARBY AREAS

MAY EXCEED 150° F 65° C. AVOID THESE AREAS.

CHECK CULTIVATOR OFTEN FOR LOOSE NUTS

AND BOLTS. KEEP THESE ITEMS TIGHTENED.

NEVER STORE ENGINE WITH FUEL IN THE TANK

INSIDE A BUILDING. POTENTIAL SPARKS MAY

BE PRESENT FOR IGNITION OF FUEL AND FUEL

VAPORS.

AN ADULT MUST ALWAYS DO MAINTENANCE AND

REPAIR ON ENGINE AND CULTIVATOR.

ENGINE MUST BE SHUTOFF, COOL, AND SPARK

PLUG WIRE REMOVED BEFORE ANY REPAIR OR

MAINTENANCE CAN BE DONE.

MAINTENANCE AND STORAGE

Steps For Working On Equipment (SEE FIGURE 8):

1. Turn engine switch to the OFF position.

2. Disconnect the spark plug wire from the spark plug.

3. Securely place the disconnected spark plug wire away

from the spark plug and any metal parts. This must

always be done or arcing may occur between spark plug

wire and metal parts.

4. Replace or repair the part on the cultivator.

5. Check all parts that were repaired, or removed during

repair, that they are secure and t correctly.

FIGURE 7

12

NOTE: All repair parts must come from the factory. Never

replace parts that are not specically designed for

the cultivator.

6. Reconnect the spark plug wire.

Cultivator Maintenance

1. Keep all screws, nuts, and bolts tight.

2. For cold weather operation, store the unit in a cool

environment. Transferring the unit from a cold to a warm

place can cause the build up of harmful condensation.

LOCK PIN

DRAG STAKE

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Page 13

SPARK PLUG WIRE

FIGURE 8

Engine Maintenance

Please read the maintenance schedule and observe these

recommendations to extend the life of your engine.

Good maintenance is essential for safe, economical, and

trouble-free operation. It will also help reduce air pollution.

To help you properly care for your engine, the following

pages include a maintenance schedule, routine inspection

procedures, and simple maintenance procedures using basic

hand tools. Other service tasks that are more dicult, or

require special tools, are best handled by professionals and

are normally performed by a technician or other qualied

mechanic.

Maintenance, replacement or repair of the emissions control

devices and systems may be performed by any non-road

engine repair establishment or individuals. However, items

must be serviced by an authorized dealer to obtain "no

charge" emissions control service.

The maintenance schedule applies to normal operating

conditions. If you operate your engine under unusual

conditions, such as sustained high-load or high-temperature

operation, or use in unusually wet or dusty conditions, consult

your servicing dealer for recommendations applicable to your

individual needs and use.

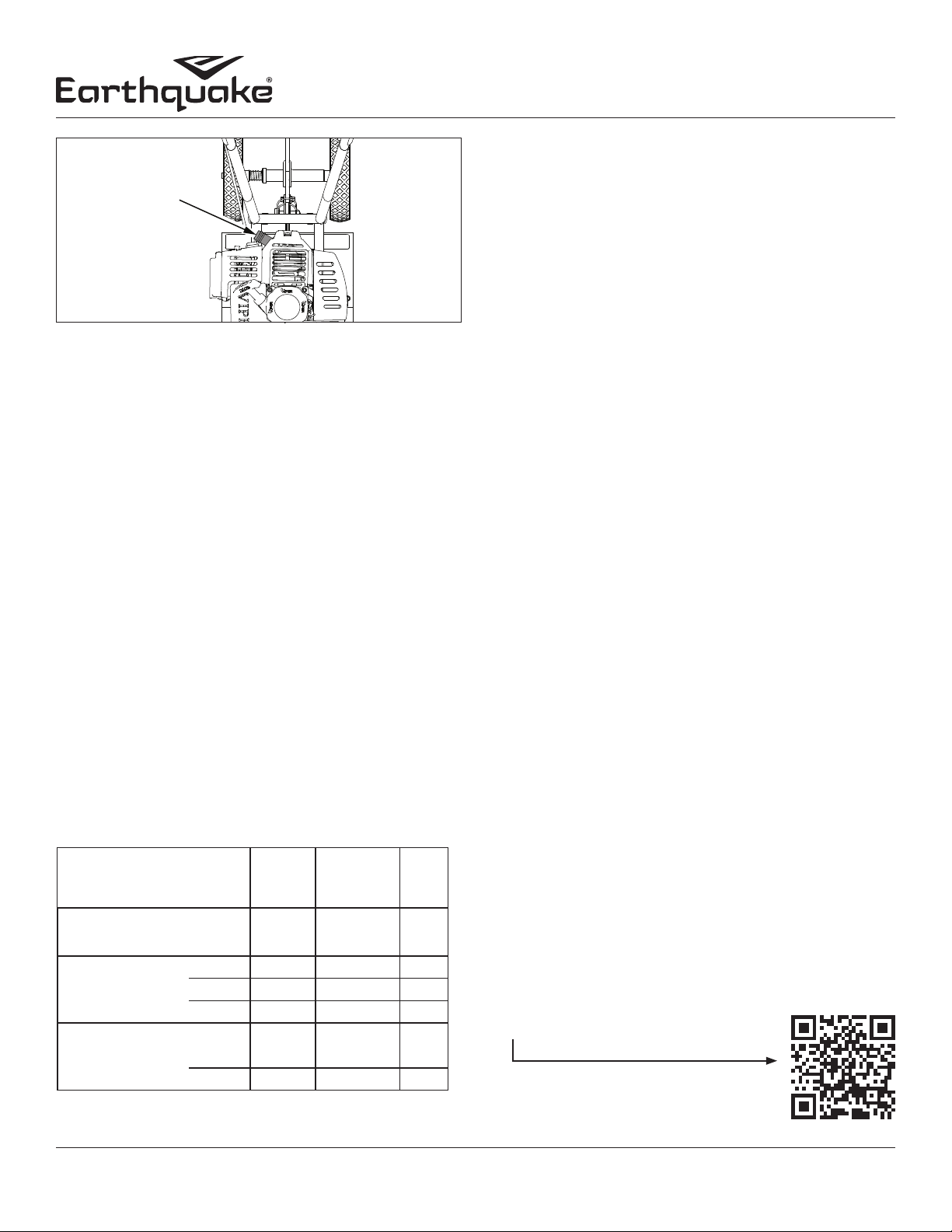

Maintenance Schedule

Every 8

hours

MAINTENANCE ITEM

Clean Engine and

Check Bolts & Nuts

Air Filter Check X

(See Air Filter section)

Spark Plug

(Gap 0.028”)

(See Spark Plug section)

* Service more frequently under dusty conditions

Clean * X

Replace X X

Check/

Adjust

Replace X

(daily)

X

Every 20

hours or

seasonally

X

Each

Year

Operator’s Manual

MC43 2-Cycle Cultivator

Spark Plug

The recommended spark plug is a Torch L7RTC which cross

references to a Champion RCJ6Y.

1. Check spark plug at the beginning of each season.

2. Disconnect the spark plug cap, and clean any debris from

around the spark plug area.

3. Remove spark plug and replace if any of the following

occur; pitted electrodes, burned electrodes, cracked

porcelain, or deposits around electrodes.

4. After analysis, seat spark plug and tighten with spark plug

wrench. Reconnect the spark plug wire.

• Reinstall original spark plug, tighten additional 1/2

turn.

• Installing new spark plug, adjust spark plug gap to

0.027 inch and tighten additional 1/8 – 1/4 turn .

NOTE: A loose spark plug may overheat and damage

engine. An over tightened spark plug may damage

threads in the cylinder head.

Cooling Fins

Cooling ns, air inlets and linkages must be free from any

debris before each use.

Carburetor

Never tamper with factory setting of the carburetor.

Air Filter

Never run engine without air cleaner properly installed. Added

wear and engine failure may occur if air cleaner is not installed

on engine.

Service air cleaner every 3 months or after 20 hours of

operation. Clean lter daily in extremely dusty conditions.

To Replace or Clean Air lter, do as follows:

1. Before removing the air lter cover, move the choke lever

to the CHOKE position.

2. To remove air lter cover, squeeze the latch tabs on both

sides of the cover. SEE FIGURE 9

3. Once the latch tabs are released, remove the air lter

cover by rotating the cover away from the engine.

4. Remove the foam lter element. Replace with a new oiled

foam lter or clean the original foam lter with warm

water and mild soap.

*Scan this QR code with your smartphone

for helpful hints and tips for using your

cultivator. www.getearthquake.com

You may need to get a QR Code® reader from your

smartphone app store. Data rates may apply.

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

13

Page 14

Operator’s Manual

MC43 2-Cycle Cultivator

NOTICE

DO NOT TWIST AIR FILTER WHEN CLEANING, ALWAYS

PRESS. TWISTING OR TOO MUCH FORCE CAN DAMAGE

THE FILTER ELEMENT.

5. After cleaning, thoroughly oil the foam lter with 30 or 40

weight motor oil and squeeze out any excess oil before

reinstalling it. Make sure to press the foam lter evenly

into place over the lter reinforcement plate to ensure

that the foam is fully seated into its sealed position.

6. Replace the air lter cover so that it fully snaps into place

and is secured by the latch tabs. Check that the cover is

securely attached by pulling slightly on the cover. If the

cover doesn’t move when pulled, it is secure.

LATCH

TABS

FILTER

REINFORCEMENT

PLATE

FOAM

FILTER

ELEMENT

LATCH TAB RECEIVER

(BOTH SIDES)

AIR FILTER COVER

FIGURE 9

DANGER

DO NOT SIPHON FUEL BY MOUTH. GASOLINE

IS TOXIC AND CAN CAUSE SERIOUS PERSONAL

INJURY.

NEVER STORE CULTIVATOR WITH FUEL IN THE

FUEL TANK INSIDE AN ENCLOSED AREA OR

BUILDING. FUEL VAPORS CAN COLLECT AND

CAUSE A FIRE.

Transporting Your Cultivator

1. After using the cultivator and before transporting it,

screw the gas cap on (clockwise) tightly. The gas cap will

not leak during transporting if gas cap is tight. Never

transport engine inside an enclosed space within a

vehicle. Fuel or fuel vapors may ignite causing serious

injury or death.

2. If fuel is present in the fuel tank, transport in an open

vehicle in an upright position.

3. If an enclosed vehicle must be used, remove gas into an

approved red fuel container. DO NOT siphon by mouth.

4. Run engine to use up the fuel in the carburetor and fuel

tank. Always run engine in a well ventilated area.

5. Wipe away any spilled fuel from engine and cultivator.

Allow to dry.

6. Ensure gas cap is shut tightly before transporting

cultivator in a vehicle.

Long-Term Storage

If your cultivator will not be used for more than one month,

prepare it for long term storage.

Steps for Long-Term Storage

1. Mix an appropriate amount of fuel stabilizer to fresh

gasoline in the ratio recommended on the stabilizer

packaging. Run the engine for ve minutes to distribute

the stabilizer mixture throughout the fuel system. This

will prevent gum, varnish and corrosion build up in

your fuel system during long-term storage for up to 12

months.

2. Store cultivator in an upright position.

3. Remove all debris from cultivator tines and engine.

TROUBLESHOOTING AND REPAIR

At Earthquake, we build quality and durability into the

design of our products; but no amount of careful design by

us, and careful maintenance by you, can guarantee a repairfree life for your Earthquake Cultivator. Most repairs will be

minor, and easily xed by following the suggestions in the

troubleshooting guide in this section.

The guide will help you pinpoint the causes of common

problems and identify remedies.

For more complicated repairs, you may want to rely on an

authorized service center or Earthquake. Earthquake will make

the necessary repairs if a service center is not available. A parts

breakdown is located toward the end of this manual.

We will always be glad to answer any questions you have, or

help you nd suitable assistance.

Ordering Replacement Parts

Parts can be obtained from an authorized service dealer or

direct from the factory. To order parts visit;

www. getearthquake.com or call 1-800-345-6007.

For other general questions, you can e-mail us at:

info@getearthquake.com.

14

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Page 15

Operator’s Manual

MC43 2-Cycle Cultivator

Please include the following information with your order:

1) Part numbers

2) Part description

3) Quantity

4) Model number and serial number

Spare Parts

Only use approved Earthquake service parts.

TROUBLESHOOTING GUIDE

PROBLEM POSSIBLE CAUSE REMEDY/ACTION

Engine will not start 1. Ignition switch o 1. Flip switch to ON position

2. Spark plug wire disconnected 2. Connect spark plug wire to spark plug

3. Out of fuel 3. Refuel

4. Spark plug wet, faulty or improperly

gapped

5. Fuel line hose not positioned in

bottom of gas tank

Engine runs rough, oods

during operation

Engine is hard to start 1. Stale fuel 1. Drain old fuel and replace with fresh fuel. Use fuel

Engine misses or lacks

power

Engine runs, then quits 1. Gas cap not venting 1. Clean or replace gas cap, check vent

Engine revs too high 1. Carburetor out of adjustment 1. Call customer service

Tines turn at idle 1. Idle speed too high 1. Adjust idle speed lower

1. Dirty air lter 1. Clean or replace air lter

2. Choke partially engaged 2. Move choke lever to run position

3. Carburetor out of adjustment 3. Call customer service

2. Spark plug wire loose 2. Make sure spark wire is securely attached to spark

3. Dirty carburetor 3. Clean carburetor, use fuel stabilizer, new gas can

4. Fuel not primed suciently 4. Prime unit 3 more times, then pull recoil handle

1. Clogged fuel lter 1. Clean fuel tank, replace fuel lter

2. Clogged air lter 2. Clean or replace air lter

3. Carburetor out of adjustment or bad 3. Call customer service

4. Spark plug wet, faulty or improperly

gapped

2. Plugged fuel lter 2. Clean or replace fuel lter

3. Carburetor out of adjustment or bad 3. Call customer service

4. Clean, replace or gap spark plug

5. Push fuel line down into fuel in gas tank

stabilizer at end of season or during long term

storage

plug

4. Clean, replace or gap spark plug

2. Broken clutch spring 2. Replace clutch

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

15

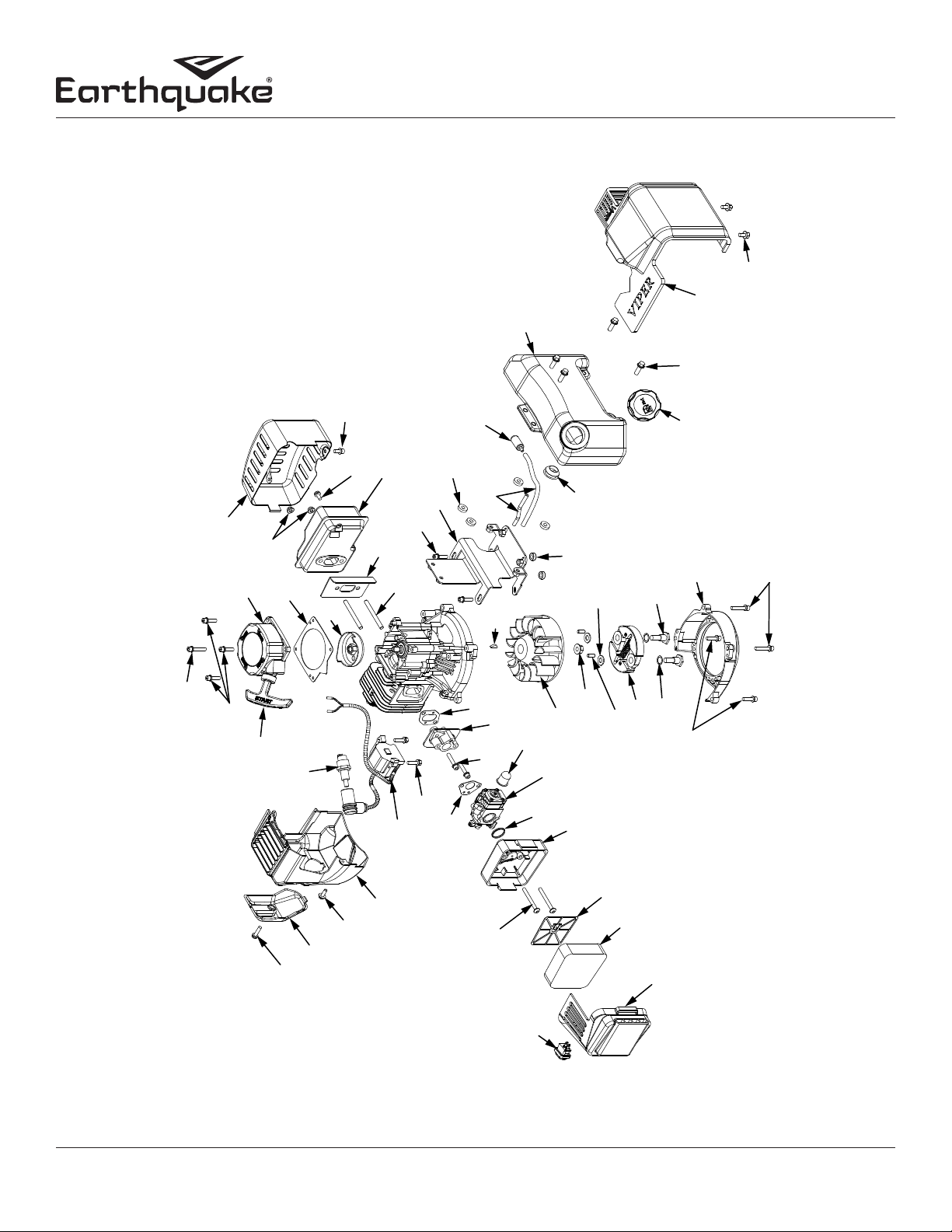

Page 16

Operator’s Manual

13,45

MC43 2-Cycle Cultivator

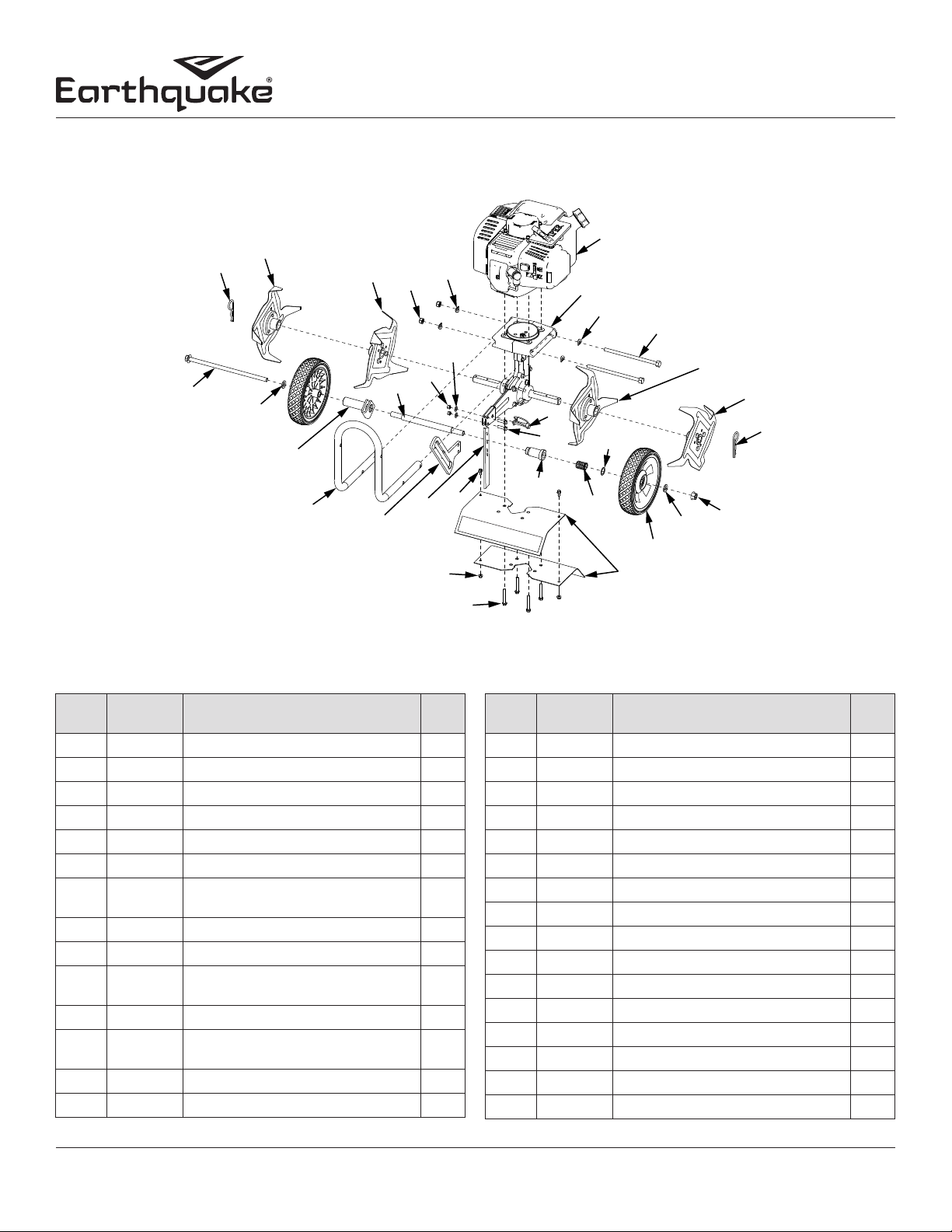

ILLUSTRATED PARTS BREAKDOWN

33,35

35

34,35

27

28

29

Engine Assembly

32,35

35

31,35

30,35

24,36

24

25

24,37,38

24,37

44,45

24

43

24,37

48,49

42

41

24,39 24,40

52

49,51

13

25

26,27

21

23

20

19

18

22

17

9,12,14,53

14,16

14,15

13,14

2,6,9,14,53

45

9,11,53

8,9

9,10

3

2,7

45,46

2,5

47

49

49,50

25,45

2,4

1,2

16

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

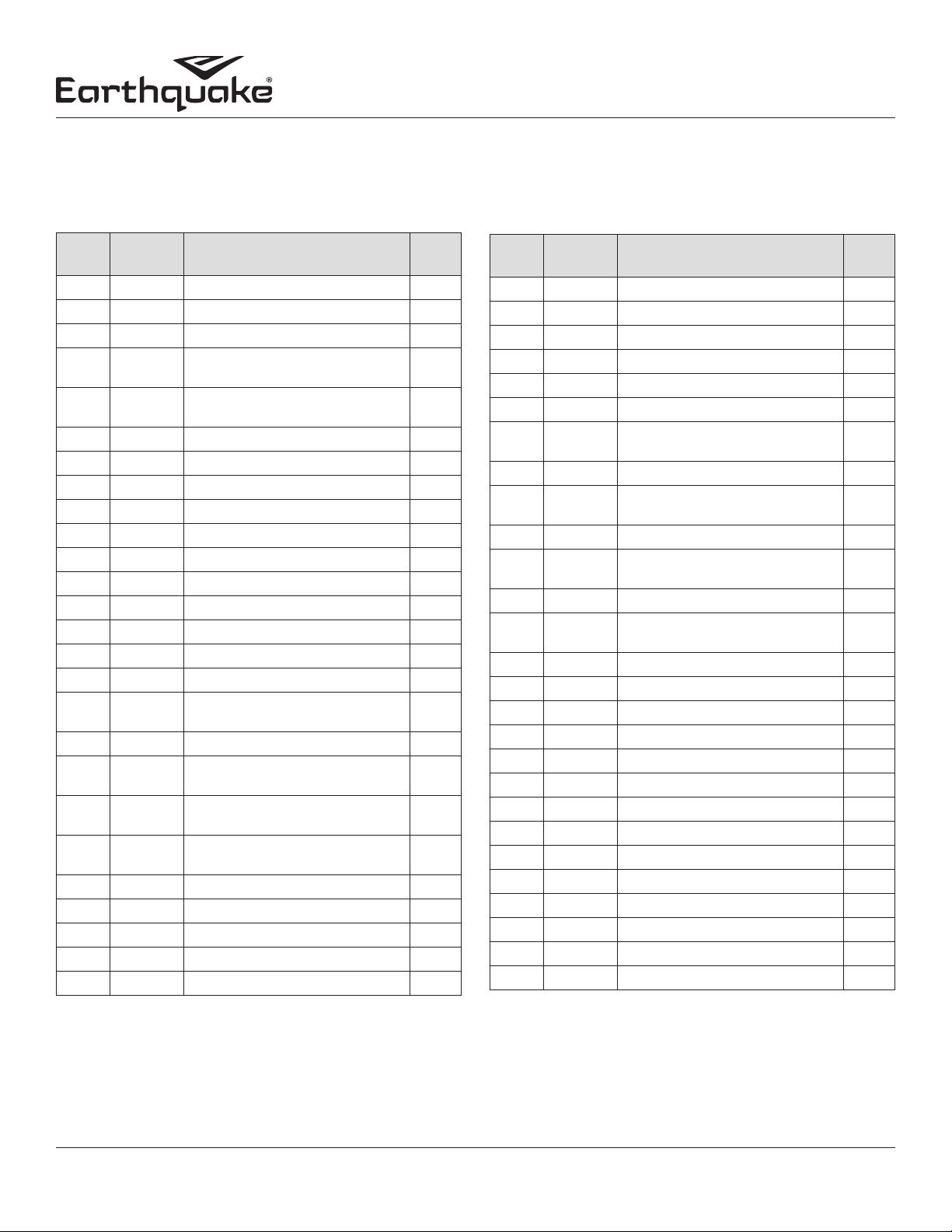

Page 17

Operator’s Manual

MC43 2-Cycle Cultivator

ILLUSTRATED PARTS BREAKDOWN

ITEM

NO.

1 3004158 AIR FILTER COVER 1

2 15230 KIT AIR FILTER ASSEMBLY 1

3 1021 ROCKER SWITCH 1

4 3004156 FOAM ELEMENT AIR FILTER

5 3004157 AIR FILTER REINFORCEMENT

6 15209 BOLT M5 X 52 WITH WASHER 2

7 3004150 AIR FILTER BASE ASSEMBLY 1

8 15261 CARBURETOR 43CC NO TAMP 1

9 11334 KIT CARBURETOR REPLACEMENT 1

10 300481 CARBURETOR O-RING 1

11 3004109 CARBURETOR PRIMER BULB 1

12 300479 CARBURETOR GASKET 1

13 17952 BOLT M5 X 28 WITH WASHER 5

14 11205 KIT INTAKE MANIFOLD 1

15 300478 WINDPIPE INTAKE 1

16 300476 GASKET INTAKE 1

17 300335 BOLT M5 X 20 HEX HEAD WITH

18 300482 ENGINE SHROUD RED 1

19 10887 BOLT M5 X 16 BUTTON HEAD

20 300483 ENGINE SHROUD CAP END

21 300439 BOLT M5 X 20 BUTTON HEAD

22 26579 IGNITION COIL 1

23 35906 SPARK PLUG L7RTC TORCH 1

24 10683 KIT GAS TANK 1

25 17946 BOLT M5 X 20 WITH WASHER 7

26 3004121 RECOIL HANDLE 1

PART

NO.

DESCRIPTION QTY.

BLOCK

FRAME

WASHER

WITH WASHER

BLACK

WITH WASHER

Engine Assembly

ITEM

NO.

27 300430 RECOIL ASSEMBLY 1

28 300429 RECOIL SPACER PLATE 1

29 300491 RECOIL CLUTCH CUP 1

1

1

2

1

1

1

30 300493 STUD M6 X 62 2

31 300475 GASKET MUFFLER HEAT SHIELD 1

32 300471 BOLT M5 X 12 WITH WASHER 1

33 17888 BOLT M5 X 12 SOCKET HEAD

34 300492 NUT M6 X 1 HEX FLANGE 2

35 25977 KIT MUFFLER STRAIGHT

36 11190 SPACER M5 X 4 NYLON 4

37 3004105 KIT FUEL LINE TWO HOLE

38 3004103 FUEL FILTER 1

39 11936 GAS CAP TWO WAY SELF

40 4647 BOLT M6 X 18 HEX FLANGE 4

41 300332 GAS TANK SHROUD BLACK 1

42 300336 BOLT M6 X 10 HEX FLANGE 2

43 11189 SPACER M5 X 5 2

44 300338 KEY WOODRUFF 3 X 5 X 12 1

45 11209 KIT FLYWHEEL 1

46 300337 NUT M8 X 1.25 HEX FLANGE 1

47 300467 DOWEL PIN 5 X 12 2

48 300462 WASHER 15.8 X 8.4 X 1.6 2

49 11235 KIT CLUTCH 1

50 300449 WAVE WASHER 10 X 15 X 0.25 2

51 300450 BOLT M8 X 25 SHOULDER 10 2

52 300487 FLYWHEEL SHROUD 1

53 3004114 KIT CARBURETOR REPAIR 1

PART

NO.

DESCRIPTION QTY.

1

WITH WASHER

1

EJECTION DPS30

1

GROMMET

1

VENTING

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

17

Page 18

Operator’s Manual

25

MC43 2-Cycle Cultivator

ILLUSTRATED PARTS BREAKDOWN

2

1

10

11

13

14

Hood & Tines Parts Explosion

3

5

4

19

18

16

17

29

26

22

21

20

24

30

(SEE DETAIL BREAKDOWN NEXT PAGE)

6

5

7

8

28

27

11

15

12

23

9

1

ITEM

NO.

PART

NO.

DESCRIPTION QT Y.

1 4652 HAIR PIN, 5/83/4 INCH COTTER 2

2 4601 TINE “A” RIGHT OUTSIDE 1

3 4603 TINE “B” RIGHT INSIDE 1

4 400023 NUT M8 NYLOCK 2

5 4641 WASHER M8 CURVED 4

6 26013 TRANSMISSION ASSEMBLY 1

7 46141 BOLT M8 X 1.25 X 155 HEX

FLANGE

8 4602 TINE “C” LEFT INSIDE 1

9 4604 TINE “D” LEFT OUTSIDE 1

10 4687 BOLT M10 X 1.5 X 231 HEX

FLANGE

11 2431 WASHER M10 NARROW FLAT 2

12 13189 WHEEL 180 X 38 MM DIAMOND

TREAD GREY HUB

13 4678 GUIDE WHEEL TUBE 1

14 15104 HANDLEBAR LOWER 1

ITEM

NO.

PART

NO.

DESCRIPTION QT Y.

15 4629 NUT M10 X 1.5 CENTER LOCK HEX 1

16 4674 WHEEL TUBE 1

17 18039 PIN LOCK 8MM X 40MM 1

18 4650 NUT M6 NYLOCK 2

W1200117

19

WASHER M6 X 13 X 1.75 FLAT 2

20 4673 WHEEL HOLDER 1

2

21 4600 DRAG STAKE 1

22 176 BOLT M5 X 0.8 X 10 HEX FLANGE 2

23 23441 TINE SHIELD 2

24 400020 NUT M5 X 0.8 NYLOCK FLANGE 2

1

25 4625 BOLT M6 X 1.0 X 42 HEX FLANGE 4

26 4684 TUBE WHEEL LOCK 1

2

27 4685 SPRING WHEEL LOCK 1

28 13230 WASHER 21 X 16 X 1 MM 1

29 46142 BOLT M6 X 1.0 X 15 HEX FLANGE 2

30 23433 ENGINE MC43 VIPER 1

18

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Page 19

Operator’s Manual

MC43 2-Cycle Cultivator

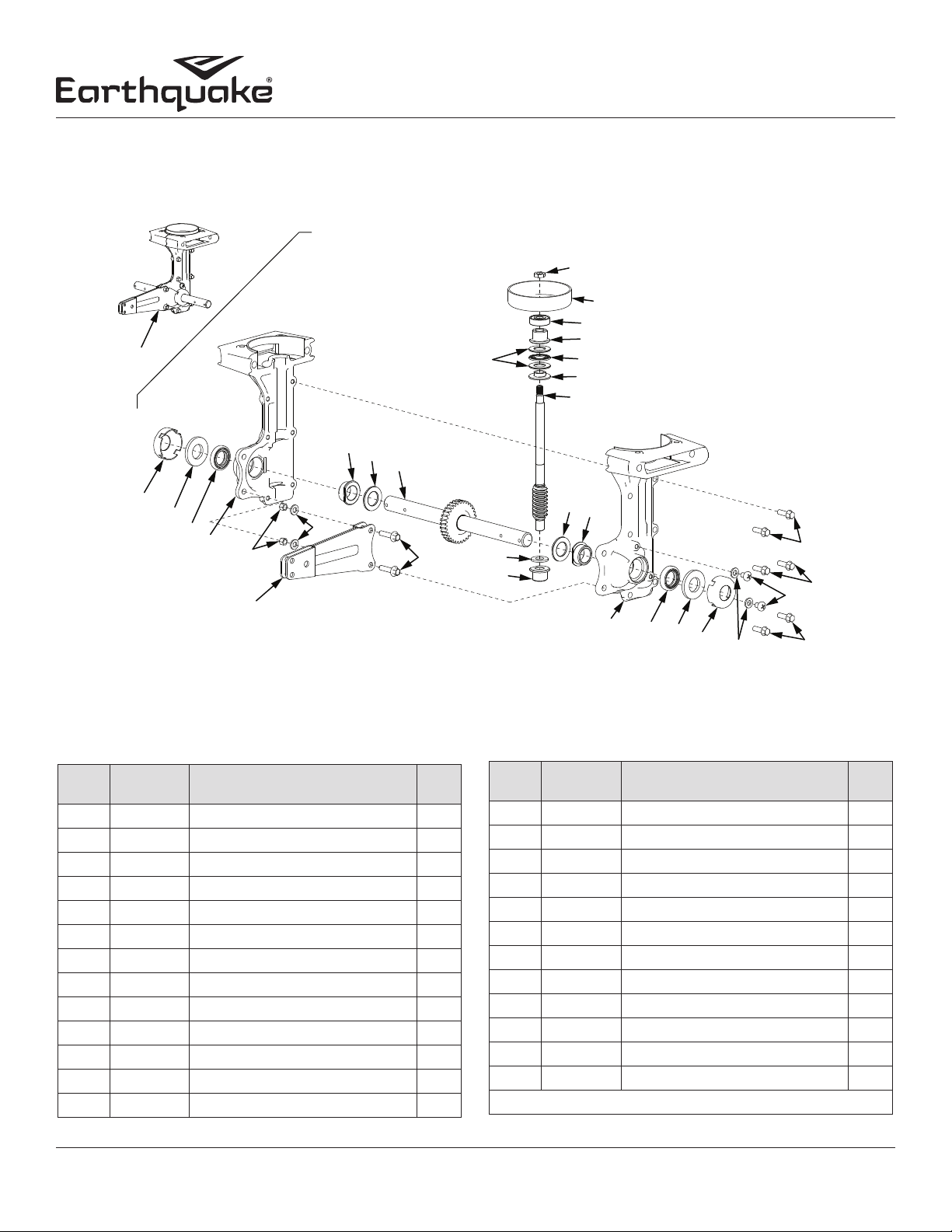

ILLUSTRATED PARTS BREAKDOWN

1

10

2

3

4

5

6

8

7

Transmission Parts Explosion

17, 25

11

12

9

13

14

21

15

11

20

19

14

18, 25

16

10

22

23

23

24

4

3

2

7

23

ITEM

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

PART NO. DESCRIPTION Q TY.

NO.

1 26013 TRANSMISSION ASSEMBLY 1

2 46144 DUST CAP 2

3 4606 FIBER WASHER 2

4 4646 TINE SHAFT SEAL 2

5* TRANSMISSION CASTING LEFT 1

6 4650 NUT M6 NYLOCK 2

7 W1200117 WASHER M6 X 12 X 1 MM 4

8 4633 WHEEL & DRAG STAKE MOUNT 1

9 13600 BOLT M6 X 1.0 X 25 HEX FLANGE 2

10 25159 TINE SHAFT BUSHING STEEL 2

11 4610 TINE SHAFT SHIM 2

12 4651 GEAR AND TINE SHAFT ASSY 1

13 4616 BUSHING SPACER 1

ITEM

* PURCHASE TRANSMISSION ASSEMBLY 26013

PART NO. DESCRIPTION Q TY.

NO.

14 4614 DRIVE SHAFT BUSHING BRONZE 2

15 21953 DRIVE SHAFT 1

16 4617 THRUST BEARING REDUCER 1

17 4618 THRUST WASHER 2

18 4619 THRUST BEARING CAGE 1

19 4623 BALL BEARING 9 X 26 X 8 MM 1

20 300414 CLUTCH DRUM 1

21 4620 JAM NUT M8 1

22* TRANSMISSION CASTING RIGHT 1

23 4647 BOLT M6 X 1.0 X 18 HEX FLANGE 6

24 13447 BOLT M6 X 1.0 X 8 PHILLIPS 2

25 4615 KIT THRUST BEARING SET 1

19

Page 20

Operator’s Manual

MC43 2-Cycle Cultivator

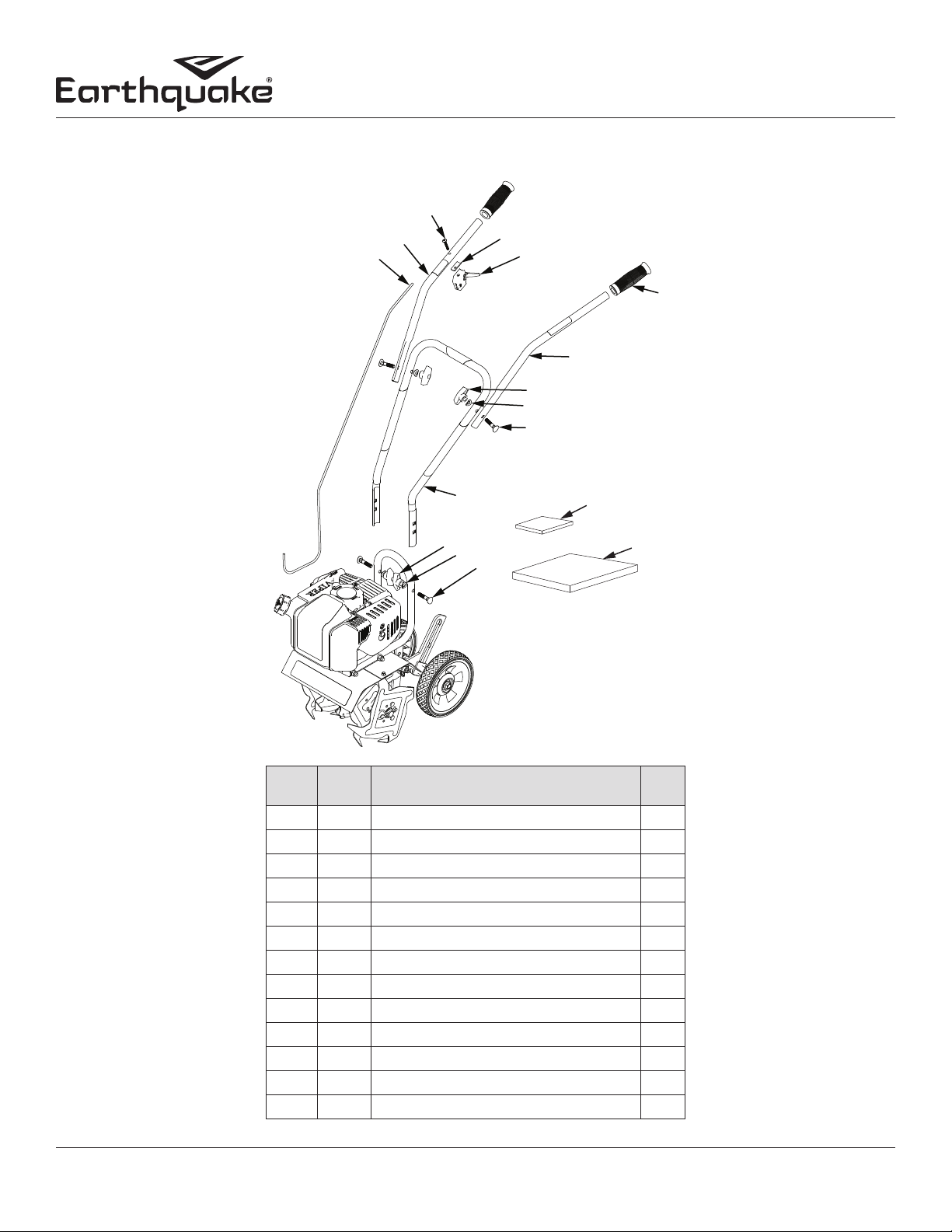

ILLUSTRATED PARTS BREAKDOWN

Handlebar Parts Explosion

1

11

9

4

5

8

9

10

10

2

3

8

6

7

12

13

20

ITEM

PART

NO.

1 4814 BOLT 1024 X 11/4 PHILLIPS 1

2 23442 HANDLEBAR UPPER RIGHT 1

3 14645 THROTTLE CABLE 1

4 12633 RUBBER PAD 1

5 4809 TRIGGER ASSEMBLY SHORT THROW 1

6 4639 HANDLEBAR GRIP 2

7 23443 HANDLEBAR UPPER LEFT 1

8 4640 THANDLE NUT 4

9 4641 CURVED WASHER 4

10 4642 SADDLE BOLT 4

11 4693 HANDLEBAR MIDDLE 1

12 12621 HANDLEBAR PARTS PACKET 1

13 23434 MANUAL PARTS BAG 1

DESCRIPTION QTY.

NO.

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Page 21

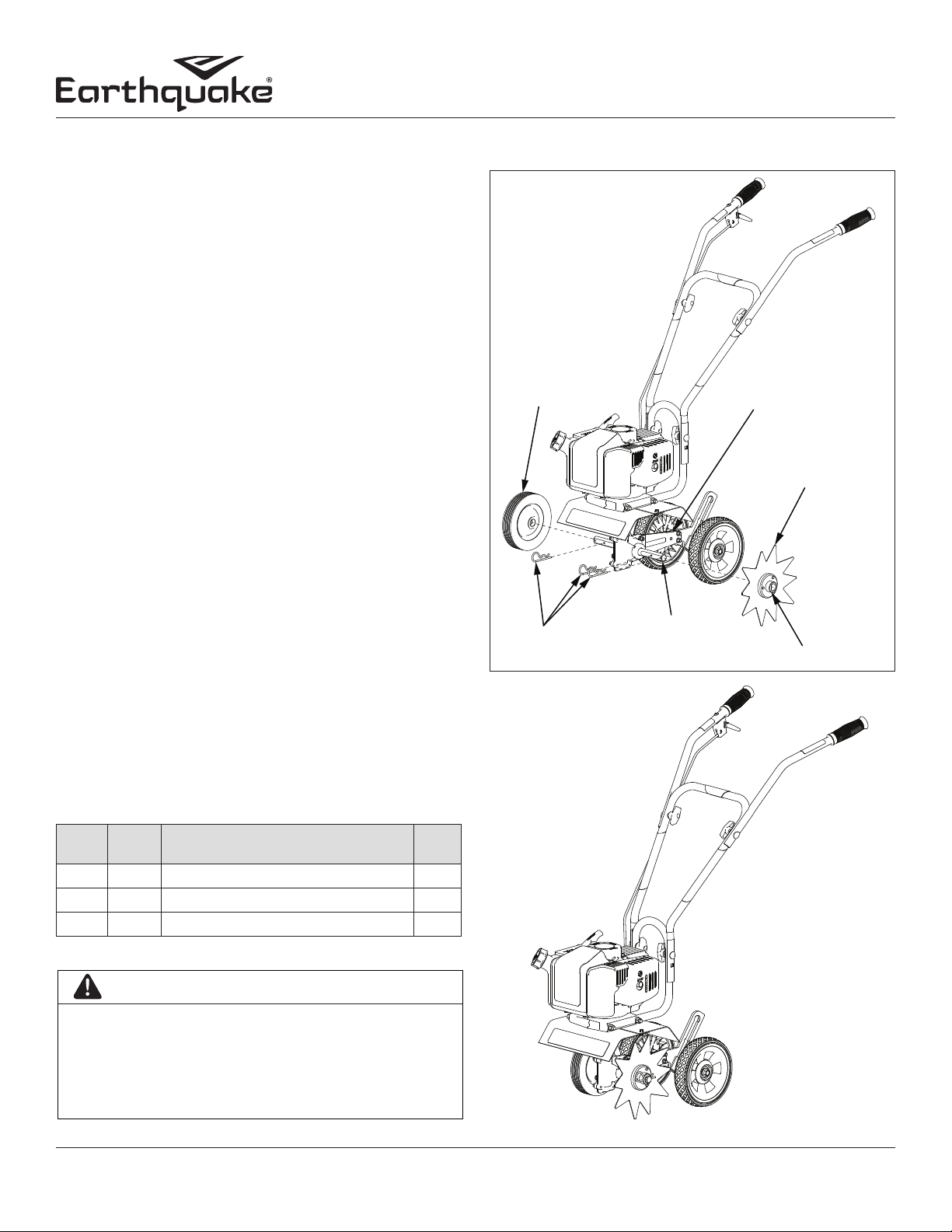

15073 BORDEREDGER KIT INSTALLATION OPTIONAL ACCESSORY

The Border-Edger Kit is a useful tool for making clean cuts in

the lawn along the borders of gardens, ower beds, walkways,

and driveways for a well manicured look. To install the BorderEdger Kit, do the following:

INSTALLATION

1. Make sure the cultivator is not running by turning the ON/

OFF switch to the OFF position.

2. Remove the hairpins from both sides of the tine shaft.

3. Remove the cultivating tines from the shaft.

4. Remove the drag stake and lock pin from the unit.

5. Store the tines and save the (2) hairpins; they will be used on

the Border-Edger Kit.

6. Slide the border-edger tine onto either side of the tine

shaft. Make sure that the hub collar of the border-edger tine

faces outward, away from the transmission of the cultivator.

SEE FIGURE 10

7. Take the (2) hairpins saved in Step 4 and insert them through

the inner and outer holes in the tine shaft on each side of the

border-edger tine to secure the tine blade in place on the

shaft. SEE FIGURE 10

8. Slide the border-edger wheel onto the opposite side of the

tine shaft as far as it will go.

9. Insert the remaining (1) hairpin, that came with the kit,

through the inner hole to secure the wheel. SEE FIGURE 10

10. Set the cultivator wheels to the HIGHEST (top) position.

SEE FIGURE 5 (PAGE 12)

BORDER-EDGER

WHEEL

HAIR PIN

FIGURE 10

TINE SHAFT

Operator’s Manual

MC43 2-Cycle Cultivator

DRAG STAKE

REMOVED

BORDER-EDGER

TINE

HUB COLLAR

PARTS BREAKDOWN

ITEM

NO.

PART

1 15009 BORDEREDGER TINE 1

2 46131 BORDER-EDGER WHEEL 1

3 46134 HAIRPIN 1

DESCRIPTION QTY.

NO.

CAUTION

BE AWARE THAT THE CULTIVATOR COULD

UNEXPECTEDLY BOUNCE UPWARD, OR JUMP

FORWARD IF THE TINE STRIKES CONCRETE,

PAVEMENT, OR OTHER HARD SURFACES OR HARD

OBSTACLES BURIED UNDER GROUND.

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

21

Page 22

Operator’s Manual

BOLT

MC43 2-Cycle Cultivator

DK43 DETHATCHER KIT INSTALLATION

OPTIONAL ACCESSORY

The Dethatcher Kit is very eective for lifting away the excessive

matted layers of thatch that can prevent moisture, oxygen and

nutrients from penetrating the soil and can harbor disease and

insects. Use in Spring, Summer, and Fall to bring life and color

back to your lawn.

1. Turn the ON/OFF switch to the OFF position. Remove the

cultivating tines or other working tools and the drag stake.

2. Unscrew mount bolts/nuts that connect the wheel bracket

to the drag stake mount and set wheel bracket aside. SEE

FIGURE11

3. Slide dethatcher shield over the unit’s tine shield from the rear of

the unit and secure using bolts and nuts. SEE FIGURES 11 & 12

4. Secure the lower part of the dethatcher shield to the drag stake

mount using the lock pin. SEE FIGURE 11 & 12

5. Install wheel extension plate (4676) using additional bolts

(46142) and nuts (4650). Make sure wheel extension is facing

the correct direction. (The side, with the two holes ush to the

edge, connects to the drag stake mount) SEE FIGURE 11

a. Attach the wheel extension to the drag stake mount

with mount bolts and nuts from unit.

b. Attach the wheel bracket to the wheel extension with

bolts and nuts included with the Dethatcher Kit.

6. Slide the Left and Right Dethatcher Assemblies onto the tine

shaft making sure the Right Assembly is installed on the right

side and Left Assembly is installed on the left side as dened

from the user’s position. SEE FIGURE 13

7. Secure dethatcher assemblies using the two hairpins (46134)

from the Dethatcher Kit through the inner holes of the tine

shaft. SEE FIGURE 13

NOTE: The drag stake must NOT be used when using the

dethatcher kit.

WASHER

ITEM

NO.

FIGURE 12

DETHATCHER

ASSEMBLY

FIGURE 13

PART

1 46134 HAIR PIN 2

2 4647 BOLT M6 X 1.0 X18 HEX FLANGE 2

3 4650 NUT M6 NYLOCK 2

4 4676 EXTENSION PLATE DETHATCHER 1

5 4707 DETHATCHER ASSEMBLY LEFT 1

6 4708 DETHATCHER ASSEMBLY RIGHT 1

7 4710 DETHATCHER SHIELD 1

RIGHT

DESCRIPTION QTY.

NO.

SHIELD SECURED

WITH LOCKPIN AND

TINE SHIELD BOLTS

HAIR PIN

TINE

SHAFT

LEFT

DETHATCHER

ASSEMBLY

EXTENSION

NUT

(4650)

WHEEL

BRACKET

ASSEMBLY

FIGURE 11

22

PLATE

NUT

BOLT

(4647)

LOCK

PIN

NUT

BOLT

DETHATCHER

SHIELD

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Page 23

Operator’s Manual

MC43 2-Cycle Cultivator

WARRANTY TERMS AND CONDITIONS

Ardisam, Inc. (Ardisam) warrants this cultivator under a ve-year limited warranty to be free from defects in the

material or workmanship or both for a period not exceeding sixty consecutive months from the date of original

purchase by the rst retail consumer or rst commercial end user. This warranty does not apply to the engine

mounted on the product. “Consumer use,” means personal recreational use by a retail consumer. “Commercial

use,” or “commercial application“ means all other uses, including use for commercial, income producing or rental

purposes. Once a product has experienced commercial use, it shall thereafter be considered as a commercial

use product for the purpose of this warranty. This warranty applies to the original owner that provides a proof of

purchase. This warranty is not transferable. The warranty period begins on the date of purchase by the rst retail

consumer or commercial end user, and continues for the sixty month consecutive period thereafter. Any unit used

in a commercial application is covered for a period of 90 days after purchase by the rst commercial end user.

For the warranty to be valid, the product must be registered online within 30 days of purchase, or the warranty

card must be lled out and received by Ardisam within 30 days of purchase. Ardisam shall not be obligated for

transportation charges that result from repair or replacement under the terms of this warranty. Transportation

charges are the sole responsibility of the purchaser.

This warranty excludes tines due to normal wear, wear items such as wheels, grips and cables, routine

maintenance items such as lter elements, o-rings, seals, lubricants, and tune-ups, rotating parts, accessory parts

such as hiller furrowers, edger kits, and dethatcher kits, running the cultivator on straight gasoline or with a

fuel:oil ratio other than 50:1. Negligent use such as using the cultivator for a purpose other than for which it was

designed and manufactured, continued use of cultivator after sudden change in vibration, using the cultivator

in violation of local codes, ordinances and good trade practices voids this warranty. *These warranties apply only

to products which have not been subjected to negligent use, abuse, misuse, overload, improper installation,

alteration, accident, acts of God (or other events beyond Ardisam’s control) lightning, vandalism, unauthorized

parts, or if repairs have been performed at a non-authorized service facility. These warranties shall not cover

damage from normal wear and tear, normal maintenance parts and services, or improper installation, operation,

storage, or maintenance; nor operating the equipment above recommended maximums as stated in this manual

and the accompanying engine manual.

This limited warranty applies to defects in the material or workmanship of the product only. There is no other

express warranty. Implied warranties, including those of merchantability and tness for a particular purpose,

are limited to one year from purchase, or to the extent permitted by law. All other implied warranties are

excluded. Liability for incidental or consequential damages are excluded to the extent exclusion is permitted by

law. Ardisam does not assume, and does not authorize any other person to assume for Ardisam, any liability in

connection with the sale of Ardisam products. To be at “No Charge,” warranty work must be sent directly to

and performed by Ardisam or an Ardisam Authorized Warranty Service Facility. To obtain warranty service

and/or replacement instructions, contact the Ardisam Customer Service Department at 800-345-6007. If you

choose to ship your product to Ardisam for warranty repair, you must rst have prior approval from Ardisam

by calling the Ardisam Customer Service Department for a return material authorization number (RMA#).

Under these circumstances, all items must be shipped prepaid. Ardisam will, in its discretion, at no charge,

repair or replace any defective part to which this warranty applies. Ardisam retains the right to change models,

specications and price without notice. Ardisam shall not be obligated to ship any repair or replacement product

to any location outside of the United States of America or Canada. Some states and countries do not allow the

limitations on how long an implied warranty lasts, or the exclusion or limitation of incidental or consequential

damages, so the above limitation may not apply to you. This warranty gives you specic legal rights, and you may

also have other rights which vary from state to state and country to country.

23

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Page 24

Manuel de l’utilisateur

Motobineuse 2 temps MC43

INTRODUCTION

Merci d’avoir acheté une motobineuse Earthquake®. Nous nous sommes attachés à ce que cette motobineuse réponde aux plus hautes normes

d’utilisation et de durabilité. Moyennant des soins corrects, elle orira de nombreuses années de service able.

Lire ce manuel en entier avant installation et utilisation. Earthquake® se réserve le droit de changer, modier ou améliorer ce produit et cette

documentation à tout moment sans préavis.

SOMMAIRE

Introduction / Sommaire / Enregistrement et service après-vente .....................................................................................................................................................24

Avertissements et mesures de précaution ..............................................................................................................................................................................................25-28

Précautions d’utilisation / Précautions d’entretien et d’entreposage ................................................................................................................................................. 28

Brûlures et feux / Autocollants de sécurité .............................................................................................................................................................................................28-29

Caractéristiques ...................................................................................................................................................................................................................................................... 30

Déballage et assemblage .................................................................................................................................................................................................................................... 31

Utilisation ............................................................................................................................................................................................................................................................31-34

Entretien et entreposage ...............................................................................................................................................................................................................................34-36

Dépannage et réparation ..............................................................................................................................................................................................................................36-37

Illustration des pièces détachées ...............................................................................................................................................................................................................38-42

Installation du nécessaire coupe-bordure 15073 (accessoire en option) .......................................................................................................................................... 43

Installation du nécessaire scaricateur DK43 (accessoire en option) ..................................................................................................................................................44

Garantie ..................................................................................................................................................................................................................................................................... 45

ENREGISTREMENT ET SERVICE APRÈSVENTE

Consigner le numéro de modèle et le numéro de série du produit dans l’espace prévu

pour y accéder facilement lors des commandes de pièces détachées ou des demandes

d’assistance technique. À l’exception des articles couverts par la garantie sur le contrôle

des émissions, la garantie est valable uniquement si l’enregistrement dûment rempli est

reçu par Ardisam dans les 30 jours après l’achat (POUR PLUS DE RENSEIGNEMENTS, VOIR

LA SECTION SUR LA GARANTIE). L’enregistrement de la garantie peut se faire en ligne à

www.earthquake.com ou par courrier à: Ardisam Inc, 1160 8th Avenue, Cumberland,

WI 54829. Il est aussi possible d’appeler notre Service après-vente au (800) 345-6007 du

lundi au vendredi de 8h00 à 17h00 HNC.

RENSEIGNEMENTS SUR LE PROPRIÉTAIRE

Nom du propriétaire:

Adresse du propriétaire:

Ville : État/Province: Code postal:

Numéro de modèle: Numéro de série:

Date d’achat:

Notes:

Lire ce manuel et le conserver pour toute consultation ultérieure. Ce manuel contient des renseignements importants sur la SÉCURITÉ,

l’ASSEMBLAGE, l’UTILISATION et l’ENTRETIEN. Le client doit s’assurer que toute la documentation sur le produit est fournie avec l’appareil. Cette

documentation comprend le MANUEL, la liste des PIÈCES DE RECHANGE et les GARANTIES. Cette documentation doit être fournie en vertu de la

réglementation en vigueur. Toutes les personnes à qui cette machine est louée/prêtée doivent avoir accès à ces informations et les comprendre.

Le présent manuel doit rester avec le produit, notamment s’il est revendu.

AUTOCOLLANT

DE NUMÉRO

DE SÉRIE

24

Voir les pièces détachées en ligne à www.getearthquake.com ou composer le 800-345-6007 L-V 8-17

Page 25

Manuel de l’utilisateur

Motobineuse 2 temps MC43

AVERTISSEMENTS ET MESURES DE PRÉCAUTION

Responsabilité du propriétaire

L’assemblage correct et l’utilisation sûre et ecace de la machine

relèvent de la responsabilité de l’utilisateur.

• Lire et respecter toutes les instructions de sécurité.

• Suivre avec attention toutes les instructions d’assemblage.

• Entretenir la machine conformément aux instructions

et au calendrier gurant dans le manuel de l’utilisateur

Earthquake.

• S’assurer que quiconque utilise la machine est bien

familiarisé avec toutes les commandes et mesures de

précaution.

Messages spéciaux

Ce manuel contient des messages spéciaux attirant l’attention sur des

problèmes de sécurité et dommages potentiels à la machine, ainsi

que des informations utiles sur l’utilisation et l’entretien. Veiller à lire

toutes ces informations avec attention pour éviter les blessures et les

dommages à la machine.

REMARQUE: Des informations générales sont fournies à

travers ce manuel pouvant aider l’opérateur dans

l’utilisation ou l’entretien de la machine.

CE SYMBOLE SIGNALE DES INSTRUCTIONS DE

SÉCURITÉ IMPORTANTES QUI DOIVENT ÊTRE

RESPECTÉES POUR NE PAS METTRE EN DANGER

LA SÉCURITÉ DES PERSONNES. LIRE ET RESPECTER

TOUTES LES INSTRUCTIONS DU MANUEL

AVANT DE TENTER DE FAIRE FONCTIONNER CET

APPAREIL.

Avant de faire fonctionner le moteur :

Veiller à lire cette section avec attention. Lire l’ensemble

des instructions d’utilisation et d’entretien de ce produit. Tout

manquement à respecter ces instructions peut entraîner des dégâts

matériels, des blessures graves ou la mort. Utiliser la machine

conformément aux instructions de sécurité fournies ici et tout au long

du manuel. Quiconque utilise cette machine doit lire les instructions

et être familiarisé avec les commandes.

Emploi prévu / Emploi détourné prévisible

IMPORTANT: Ceci est une motobineuse rotative motorisée qui

travaille le sol au moyen de fraises en rotation. Elle est conçue

pour un utilisateur à pied, mais non autotractée, avec un moteur à

combustion interne à essence pour entraîner les fraises. Elle ne doit

être utilisée à aucune autre n.

AVIS

AVIS INDIQUE QUE LE MATÉRIEL PEUT ÊTRE

ENDOMMAGÉ SI LES INSTRUCTIONS DE SÉCURITÉ