EarthQuake Beaver Owner's Manual

IDENTIFICATION

MODEL IDENTIFICA TION ........................................... 1

WARRANTY................................................................. 2

SAFETY RULES ......................................................... 3

General ..................................................................... 3

Setting Up................................................................. 3

Operating Location.................................................... 4

Safe Wearing Apparel ............................................... 4

Operating Safety....................................................... 5

T ransporting & Storage ............................................. 6

Service & Maintenance............................................. 6

ASSEMBL Y ................................................................. 7

General ..................................................................... 7

T ools Required .......................................................... 7

Hardware Description ................................................ 7

Chipper Cone ............................................................ 7

Handle ...................................................................... 7

Hopper ...................................................................... 8

Discharge Bag .......................................................... 8

Engine Oil................................................................. 8

CONTROLS & MAJOR COMPONENTS ...................... 9

Operating Controls .................................................... 9

Major Components.................................................... 9

OPERA TION.............................................................. 11

Description.............................................................. 11

Site Location........................................................... 11

Checks Before Starting .......................................... 12

Start-up .................................................................. 1 2

Operating Instructions............................................. 12

Material Processing ................................................ 14

Shutting Down ........................................................ 14

Waste Materials Guide............................................ 15

NORMAL CARE ........................................................ 16

Schedule ................................................................ 16

Servicing the Chipper/Shredder............................... 16

ST O RA G E..................................................................18

T emporary Storage.................................................. 18

Long T erm Storage.................................................. 19

TROUBLESHOOTING AND REPAIR ......................... 20

T roubleshooting....................................................... 20

Repair ..................................................................... 21

OPTIONS & ACCESSORIES .................................... 25

P ARTS LISTING........................................................ 26

MODEL IDENTIFICATION

Record your model number , manufacturer number , and

serial number in the space provided for easy reference.

The model and manufacturer numbers can be found on

the unit I.D . plate. Refer to the Engine Owner's Man ual

for location of engine serial number .

If you have a service problem requiring special

assistance and cannot contact a local dealer to help,

call the Customer Service Department at 715-822-2415.

CHIPPER/SHREDDER REFERENCE DA TA

Model Description/Number

M/N (Manufacturer's Number) S/N (Serial Number)

Dealer Name Date Purchased

ENGINE REFERENCE DA TA

Engine Make/Model Engine ID/Serial Number

WARNING

You must read, understand, and comply with all

safety and operating instructions in this manual

before attempting to setup and operate your

rototiller.

Failure to comply with all safety and operating

instructions can result in loss of machine control,

serious personal injury to you and/or bystanders,

and risk of equipment and property damage. The

triangle in the text signifies important cautions or

warnings which must be followed.

NOTICE

Upon start-up and shut down, you may hear the

metal-to-metal sound of the triangular hammers and

J-hammers positioning themselves on the rotor .

is a normal sound.

machine obtains full speed, please contact your dealer

for an inspection of your chipper/shredder .

If this sound continues after the

WARNING

This

Engine exhaust from this product contains

chemicals known, in certain quantities, to cause

cancer, birth defects, or other reproductive harm.

1

WARRANTY

Thank You . . .

for purchasing a Beaver chipper/shredder. We guarantee that this chipper/shredder conforms to

applicable North American safety standards, and have worked to ensure that it will meet your exacting

standards for usability and durability. With proper care, your chipper/shredder will provide many years of

service.

Please take time to read this manual carefully to learn how to operate and service your chipper/

shredder correctly. Failure to do so could result in personal injury or equipment damage. This manual

should be considered a permanent part of your chipper/shredder. Congratulations on your investment in

quality.

TWO YEAR

LIMITED WARRANTY

The Ardisam, Inc., Manufacturing Company warrants this chipper/shredder to be free from defects in material or

workmanship. Conditions of this warranty include:

What is covered under warranty:

For the first year from the date of purchase, Ardisam will furnish 100% par ts and labor to correct any defect

caused by faulty material or workmanship. During the second year of ownership, Ardisam will furnish 100% of the

parts to correct any defect caused by faulty material or workmanship. All repairs made under warranty must have

prior approval from Ardisam, Inc. Items subject to normal wear and tear, such as belts, batteries, tines, shear bolts

and tires, due to the nature of their function are not covered under this warranty. Any unit used in a commercial

application is covered for a period of 90 days after purchase. The engine is covered under a separate warranty

issued by the engine manufacturer as stated in the engine manual.

What is not covered under warranty:

This warranty applies only to products which have not been repaired or altered outside our factory. It covers only

defects resulting from normal use, and does not cover defects arising from misuse, alteration, negligence, or

accident. This warranty applies only to the original purchaser, and is not transferrable.

This warranty supersedes all other warranties either expressed or implied and all other obligations or liabilities

on our part. Ardisam, Inc., does not assume, and does not authorize any other person to assume f or us , an y

liability in connection with the sale of our products. This guarantee is v oid unless the warr anty card is properly

filled out and returned to Ardisam, Inc., Cumberland, Wisconsin, within two weeks of the purchase date.

ARDISAM

2

SAFETY RULES

GENERAL

The safety alert symbol shown here is used to

alert you to important safety information that

must be read, fully understood, and followed at

when handling, transporting, operating, servicing, or

storing your chipper/shredder unit.

Each safety alert symbol is followed by a "signal word"

that advised you of the relative intensity, or level, of the

hazard the safety alert instructions pertain to.

The following list of signal words is being provided to

help you understand the intensity levels associated with

each signal word used in this manual.

DANGER

The signal word "D ANGER" is used when a serious

injury or fatality will result if the safety instructions

that follow this signal word are not obeyed.

WARNING

The signal word "W ARNING" is used when a serious

injury or fatality could result if the safety

instructions that follow this signal word are not

obeyed.

CAUTION

The signal word "CA UTION" is used when personal

injury, or property or equipment damage could

result if the safety instructions that follow this

signal word are not obeyed.

DANGER

You must read and understand this manual and

all safety instructions and labeling completely,

before attempting to assemble, setup, transport,

operate, service, or install any options or

accessories on this unit.

This chipper/shredder is a powerful machine

designed for chipping of tree limbs and branches

up to 2-1/2” in diameter (3” on 8hp or 10hp model),

and is capable of amputating or causing serious

injury to fingers, hands, feet, and other extremities

if accidental contact with rotating chipper and

shredder blades should occur .

Always keep hands, feet, and other extremities out

of the shredder hopper, chipper cone, and

discharge area, and never wear loose fitting

clothing or jewelry that could get caught on tree

limbs, branches, or rotating parts, and pull your

hands, or other body parts into the rotating chipper/

shredder blades.

all

times

Safe operation of the chipper/shredder unit requires that

all operating and safety instructions be obeyed by

everyone who uses, services, or otherwise handles the

unit.

Although the instructions and warnings appearing in this

manual cover most normal operating conditions,

everyone using the chipper/shredder unit must also

always follow safe work practices while operating,

servicing, or handling the chipper/shredder unit under

any conditions not specifically covered in this manual.

SETTING UP

• Although most assembly has been done at the

factory , your chipper/shredder unit requires minor

assembly and the addition of engine oil before it can

be used. Nev er attempt to start or operate the unit

unless the chipper cone and shredder hopper have

been properly installed and engine oil has been

added.

• Perf orm the required assembly in an area where the

chipper/shredder can be handled comfortably . Nev er

attempt to assemble the unit unless the engine/base

assembly can be held or securely positioned for

assembly needs.

• Use proper hand tools for assembling the chipper/

shredder. Ne ver use tools such as adjustable openend wrenches that can slip off hardware as it’ s being

fastened. Never use toothed gripping pliers which

may damage hardware and make removal difficult.

• Always use only the hardware provided with this unit

for assembly. Never substitute parts, or mix the

proper position of parts during assembly . If a part is

missing, contact your local dealer for an exact

replacement.

• Assemble the unit in the sequence indicated in the

assembly instructions. Make sure all hardware is

properly tightened after assembly is completed and

before starting the unit.

• Make sure all required hardware has been installed.

Never attempt to start or operate the unit unless you

are sure that all required hardware has been used.

• Inspect the shredder hopper and chipper cone for any

debris, loose hardware, or other material that may

have f allen in during unpacking and assembly.

Always disconnect the spark plug wire from the

spark plug, before removing any objects.

• Never fill the fuel tank indoors! Gasoline vapors are

explosive, and can easily travel unnoticed to sources

of ignition, such as pilot lights or open flames on

water heaters, furnaces, stoves, or dryers, sparks

from electric motors and other electrical appliances,

3

SAFETY RULES

or unattended smoking materials. Contact with these

or any other ignition sources will cause an explosion

or fire, serious personal injury , and damage to

property and equipment.

• Never overfill the fuel tank. Fuel may run out of the

tank and contact hot surfaces on the chipper/

shredder motor and ignite, causing a fire and/or risk

of an explosion. Fill fuel tank to 1/2” below bottom of

filler neck only.

• Use only an approved container for fuel and always

handle the container with extreme care. Never smoke

while fueling the chipper/shredder or transporting the

fuel container.

• Never store the fuel container or chipper/shredder

indoors where there is a possibility of contact with

any ignition source such as a spark, open flame,

pilot light, heating element, or smoking materials.

• Never attempt to operate a unit indoors or in an

enclosed area. Engine exhaust contains Carbon

Monoxide, an odorless, colorless, and tasteless gas.

If inhaled, Carbon Monoxide can cause dizziness,

nausea, unconsciousness, and if contact is allowed

to continue, brain damage or death.

OPERATING LOCATION

• Always operate the chipper/shredder outdoors only,

on a firm, level, earthen or grassy area where the

unit will be stable and will stay in position. Never

attempt to operate the unit on a slope, or on wet or

slippery surfaces where you could slip and fall

toward the chipper cone or hopper openings.

• Never operate the chipper/shredder on asphalt,

concrete, or other hard or paved surfaces, as

material being ejected out of the discharge chute

could ricochet, causing injury to you or bystanders in

the immediate area.

• Never operate the chipper/shredder where children,

pets, or others who may be unaware of the potential

hazards associated with chipping and shredding

operations could enter the area unexpectedly and be

exposed to these hazards.

• Never operate the chipper/shredder on rocky or

gravel covered surfaces, as this surface debris could

enter the unit and cause extensive damage, or be

ejected out of the machine with sufficient force to

cause a serious injury to you or bystanders.

• Never operate the chipper/shredder in an area where

sparks from the muffler could ignite surrounding

brush or flammable materials. See following Fire

Hazard Warning!

DANGER

SP ARK/FIRE HAZARD

GAS ENGINES MA Y REQUIRE

A SP ARK ARRESTER FOR SAFE OPERA TION

If the engine on this unit is not equipped with a

spark arrester and is to be used on any forest,

brush, or grass-covered unimproved land, a spark

arrester must be added to the muffler before using

the engine on such land. The arrester must be

maintained in effective working order by the

operator. In the State of California, the above is

required by law (Section 4442 of the California

Public Resources Code.) Other states may have

similar laws. Federal laws apply on federal lands.

See your authorized engine service center for

muffler spark arrester options.

SAFE WEARING APPAREL

• Always wear safety goggles to protect your eyes

from flying debris when operating the chipper/

shredder. One pair of safety goggles has been

provided with the unit for your immediate use. All

others in and around the immediate area must also

wear approved safety glasses to protect their eyes

from flying debris.

• Wear hearing protection when the chipper/shredder is

to be used for prolonged periods of time, or whenever

noise reaches an uncomfortable lev el.

• When wearing work gloves, always wear only

properly fitted leather work gloves to protect your

hands from cuts and scratches caused by tree limbs

and branches. Never wear gloves with pull-ties or

straps, as these could get entangled with branches

and draw your hands into the chipper cone or

shredding hopper cutting areas.

• Never w ear loose fitting clothing, hanging jewelry ,

ties, scarves, or other items that could get caught on

tree limbs, branches, or moving parts, and draw y our

body parts into the cutting areas of the chipper cone

and shredder hopper.

• Always tie up long hair and prevent it from hanging

down, where it could become tangled in branches or

get caught in rotating parts and pull you into the

cutting areas.

• Even if you are wearing heavy-duty leather work

gloves, ne v er , e v er place y our hands in the chipper

cone or shredder hopper while the unit is running. If

you must reach in to clear a jam or free up branches,

shut the unit off, disconnect the spark plug wire at

the spark plug, and carefully remove or clear the

jammed material.

4

SAFETY RULES

OPERATING SAFETY

• Always obey the size limitations for tree limbs and

branches stated in the W aste Materials Guide portion

of this manual.

• Never leave the machine running unattended.

Always turn off the engine, wait for the rotor to come

to a complete stop, and disconnect and secure the

spark plug wire before leaving the area. Always

move the unit to a safe storage area when not in use.

• Always maintain secure footing and solid balance

while starting or operating the chipper/shredder.

Never lean directly over the machine.

• Always stand to the side of the chipper cone when

feeding tree limbs and branches into the unit, as tree

limbs, branches, and harder woods may whip around

while being chipped.

• Always keep hands out of the chipper cone and

shredder hopper when feeding materials. Never wrap

fingers tightly around branches as you are feeding

them into the unit, as a sudden inward surge could

pull your hands and arms into the unit.

- Check for loose parts, and loose or missing

hardware, and repair or replace as required.

- Check the oil level in the engine crankcase. See

the engine service manual shipped with your chipper/

shredder for additional information.

• Never attempt to clear clogs from the chipper cone,

shredder hopper or discharge chute while the unit is

running. Always shut the engine off, allow the rotor

to come to a complete stop, and remove the spark

plug wire from the spark plug before removing

excess materials.

• Never fill the fuel tank while the machine is running

or while the engine is hot. An unexpected spill of fuel

could contact a hot surface and ignite, causing fire or

explosion. Turn off the engine, and allow the engine to

cool before attempting refilling.

• Never attempt to perform any maintenance, repairs,

or attachment of accessories while the unit is

running. Always shut the unit off, allow the rotor to

come to a complete stop, and disconnect and secure

the spark plug wire from the spark plug before

beginning these activities.

• Always stand clear of the discharge area to avoid

being struck by ricochets or material being ejected

from the machine.

• Never allow material to build up in the discharge area

or shredding chamber, as this ma y cause new

material being fed into the machine to kick back with

sufficient force to injure you or other bystanders.

• Never allow material to build up around the engine

during chipper/shredder operation. This could result

in a fire or overheating of the engine.

• Never attempt to reposition or move the chipper/

shredder unit while it is running. Doing so could

cause the machine to tip over , and reaching to

steady the unit could result in accidental insertion of

your hands into the chipper cone or shredder hopper

areas.

• Never contin ue to operate the machine if it starts

making unusual noise or vibration. Shut the engine

off immediately, allow the rotor to stop, disconnect

the spark plug wire from the spark plug, and do the

following:

• Never remove guards, deflectors, or warning labels

from the unit. If any of these are found to be

missing, take the unit out of service until the

appropriate repairs can be made. Tag the machine so

others do not mistakenly attempt to use it while

awaiting parts or repairs.

• Always mak e sure that the shredding chamber ,

shredder hopper, and chipper cone are empty bef ore

restarting the unit after it has been idle. Attempting

to start the unit with material in these areas could

cause the engine starting cord to stop suddenly,

injuring your hand and fingers, or toppling the unit

over.

• Never tamper with any engine controls to alter or

increase maximum unit running speed. An over

speeding condition could cause the engine to

overheat, resulting in risk of fire, permanent engine

damage, and voiding of your product w arranty .

• Always comply with the engine manual instructions

for operating and periodic maintenance requirements.

Make sure the oil level is always in the safe zone,

and keep the air filter element clean.

- Inspect the unit for any signs of damage or foreign

material in the chipping or shredding areas.

Remove any solid material that may be preventing

the unit from operating properly .

• Never allow children to operate the machine. Do not

allow adults to operate it without proper instruction.

5

SAFETY RULES

• The unit must be shut off before attaching or

removing the bag. Shut the engine off, wait for all

moving parts to stop, remove and secure the spark

plug wire, then attach or remove the bag.

• Make certain that pieces of metal, rocks, bottles,

cans, or other foreign objects are not accidentally

included when feeding material into the chipper/

shredder.

TRANSPORTING AND STORAGE

• Always use the hopper handle and built-in wheels to

move the chipper/shredder . Never lift the unit using

the fuel tank for support. If the unit must be lifted ,

always use at least two people, and always grip the

unit securely using the front leg and hopper handle.

• If the unit must be tilted for transporting, consult the

engine manual for required preparation. Normally ,

fuel and oil must be drained to prevent dangerous

fuel leakage, and unwanted transfer of the sump oil

into the cylinder head area.

• Always refill the engine with the recommended oil

before attempting to use the unit again after it has

been drained for transportation.

• Only factory authorized service locations should

perform major service and repairs.

• Never attempt to make major repairs on this unit

unless you hav e been properly trained and certified

to work on large capacity chipper/shredder units.

Improper service procedures can result in hazardous

operation, equipment damage, and voiding of

manufacturer’ s warranty .

• Always observe safe refueling and fuel handling

practices when refueling the unit after transportation

or storage.

• Always follow the engine manual instructions for

storage preparations before storing the unit for

prolonged periods.

• Always follow the engine manual instructions for

proper start-up procedures when returning the unit to

service.

SERVICE AND MAINTENANCE

• Before performing any service or repair, shut the

engine off, wait for all moving parts to stop, then

disconnect and secure the spark plug wire.

• Always follow recommended engine and chipper/

shredder procedures when performing required

service and maintenance on the unit.

• Use only factory authorized replacement parts when

making repairs.

• Always comply with recommended factory

specifications on all settings and adjustments.

6

ASSEMBLY

GENERAL

All of the major assembly procedures on your new

Chipper/Shredder were performed at the factory , and

only the items listed in this section need to be taken

care of to make your unit fully operational.

TOOLS REQUIRED

• 1/2" Box Wrench or Socket

• 7/16" Box Wrench or Socket

• 1/4" Hex Wrench

• Phillips Screw Driver

• Hex (Allen) Wrench

HARDWARE DESCRIPTION

The hardware pack included with your unit contains the

items listed below . (Additional hardware ma y be involv ed

for other models.)

Description Qty .

• BOLT , He x Head 5/16-18 x 1 1

• BOLT , Hex Head 5/16-18 x 3/4 2

• BOLT , Hex Head 5/16-18 x 1/2 2

• W ASHER, Flat 5/16 4

• LOCKWASHER, 5/16 2

• CAPSCREW, Hex Sock et 1/4-20 x 3/4 6

• NUT , Flange (Whiz-lock) 1/4-20 6

• WASHER, 1/4 4

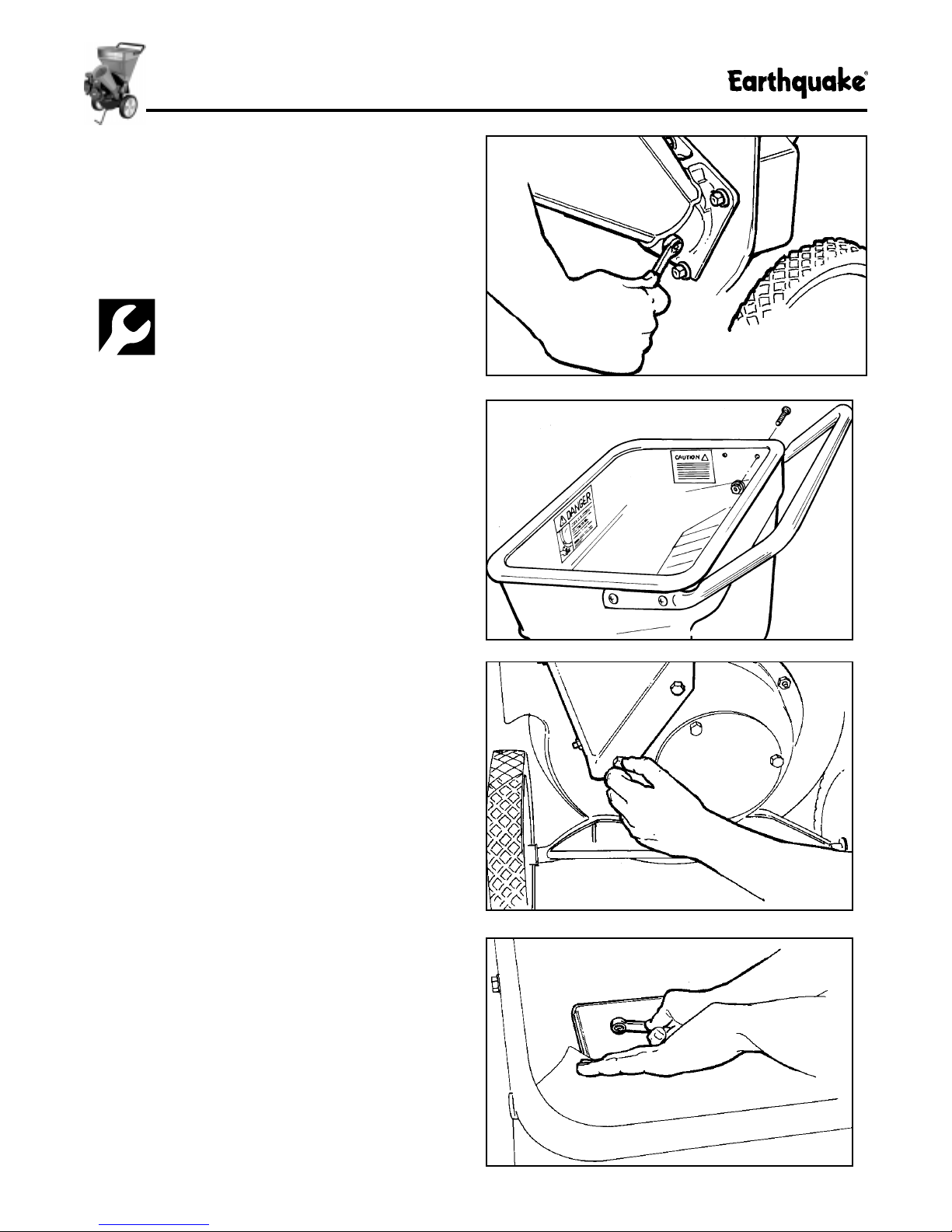

Figure 1. Installing the Chipper Cone

Figure 2. Installing the Hopper Handle

Be sure to clean all hardware threads of paint and debris

before assembling.

CHIPPER CONE

1. See Figure 1. P osition the chipper cone assemb ly

base over the three 5/16-18 threaded studs protruding

from the engine plate, and attach using (3) 5/16-18

whiz nuts.

2. Tighten whiz nuts securely using a box or socket

wrench.

HANDLE

1. See Figure 2.Lift the Hopper Handle up until the outer

holes in the handle align with the holes in the

shredder hopper.

2. Secure the Hopper Handle in position using 1/4-20 x

3/4 hex socket screws, and 1/4-20 whiz nuts,

inserting the screws from the outside of the hopper.

3. Tighten all four screws securely.

Figure 3. Attaching Hopper to the Rotor

Figure 4. Installing Hardware Inside Hopper

7

ASSEMBLY

HOPPER

1.See Figure 3. Attach the hopper to the rotor housing,

using care to engage the metal lip of the hopper liner

to the inside of the housing.

2.Secure the hopper to the rotor housing using (2) 5/16

x 1/2 hex head bolts and (2) 5/16 flat washers. Do not

tighten hardware at this time.

3.See Figure 4. F rom the inside of the hopper, install (1)

5/16-18 x 3/4 hex head bolt, 5/16 lockw asher , and

5/16 flat washer into each of the upper and lower

holes of the metal hopper liner. Do not tighten at this

time.

4.Make sure the hopper is properly seated on the rotor

housing, and then tighten all hardware securely .

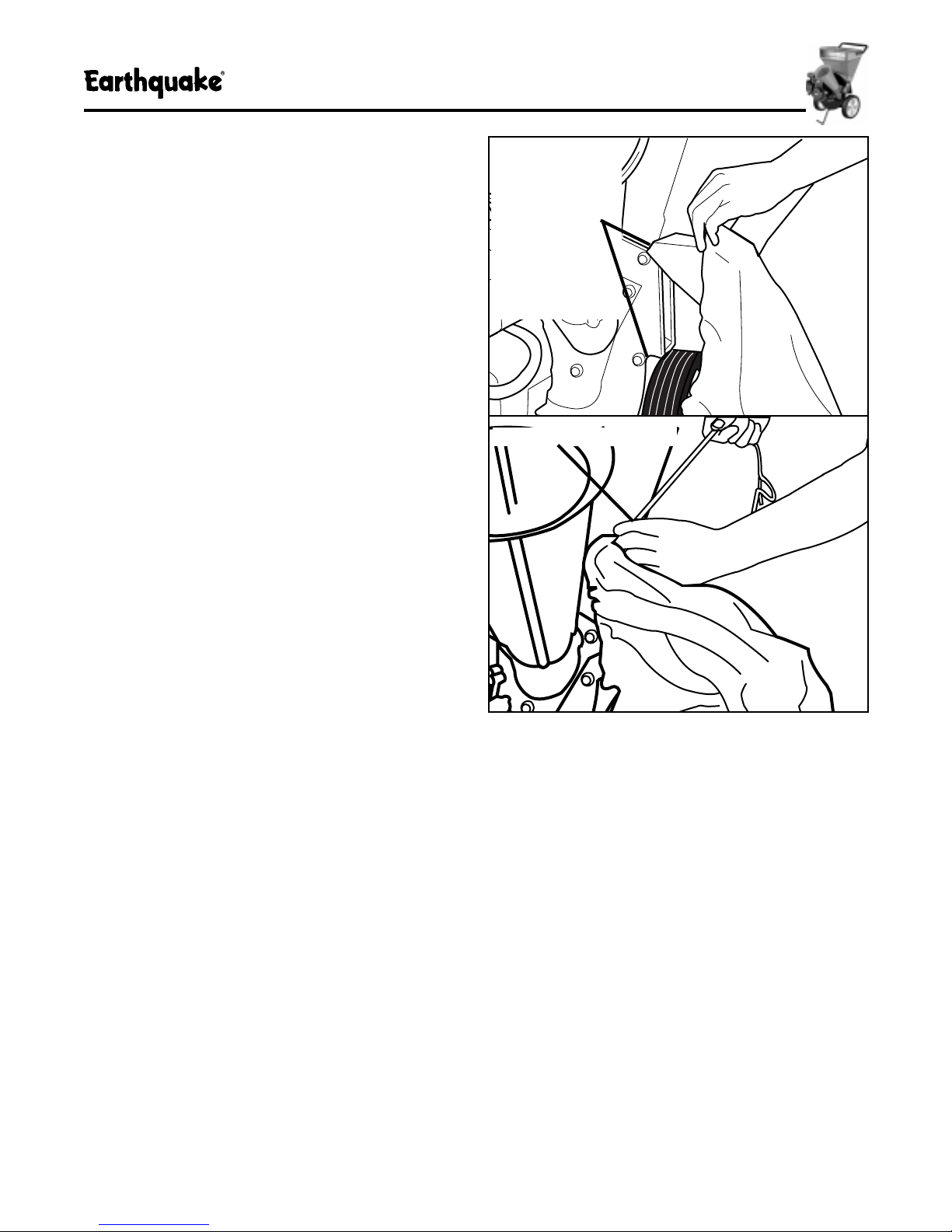

DISCHARGE BAG

Your unit comes equipped with a bag for collecting

debris as it exits the discharge chute.

See Figure 5.

Lift discharge

chute and slide

bag over chute.

Make sure bag

noose fits over

top of discharge

chute and notch

in chute bottom.

Pull drawstring tight

ENGINE OIL

Fill the engine oil sump with the appropriate type of oil

required by that type of engine. See the engine service

manual shipped with your chipper/shredder for additional

information.

Figure 5. Discharge Bag Installation

8

CONTROLS & MAJOR COMPONENTS

OPERATING CONTROLS

Your new chipper/shredder has been designed for both

ease of use and lasting reliability, and features a

simplified control system that required just two operating

controls.

These two operating controls, the Choke and the

Throttle, are conveniently located on the chipper/

shredder engine where they can be easily adjusted to

start and run the unit under a variety of operating

conditions.

Choke

The choke controls the fuel to air ratio, and helps make

cold starts easier by providing a rich, easily ignited fuel

mixture.

Throttle

The throttle controls engine speed, and allows you to

conserve fuel when idling, or to run the unit at maximum

speed for optimal chipping and shredding performance.

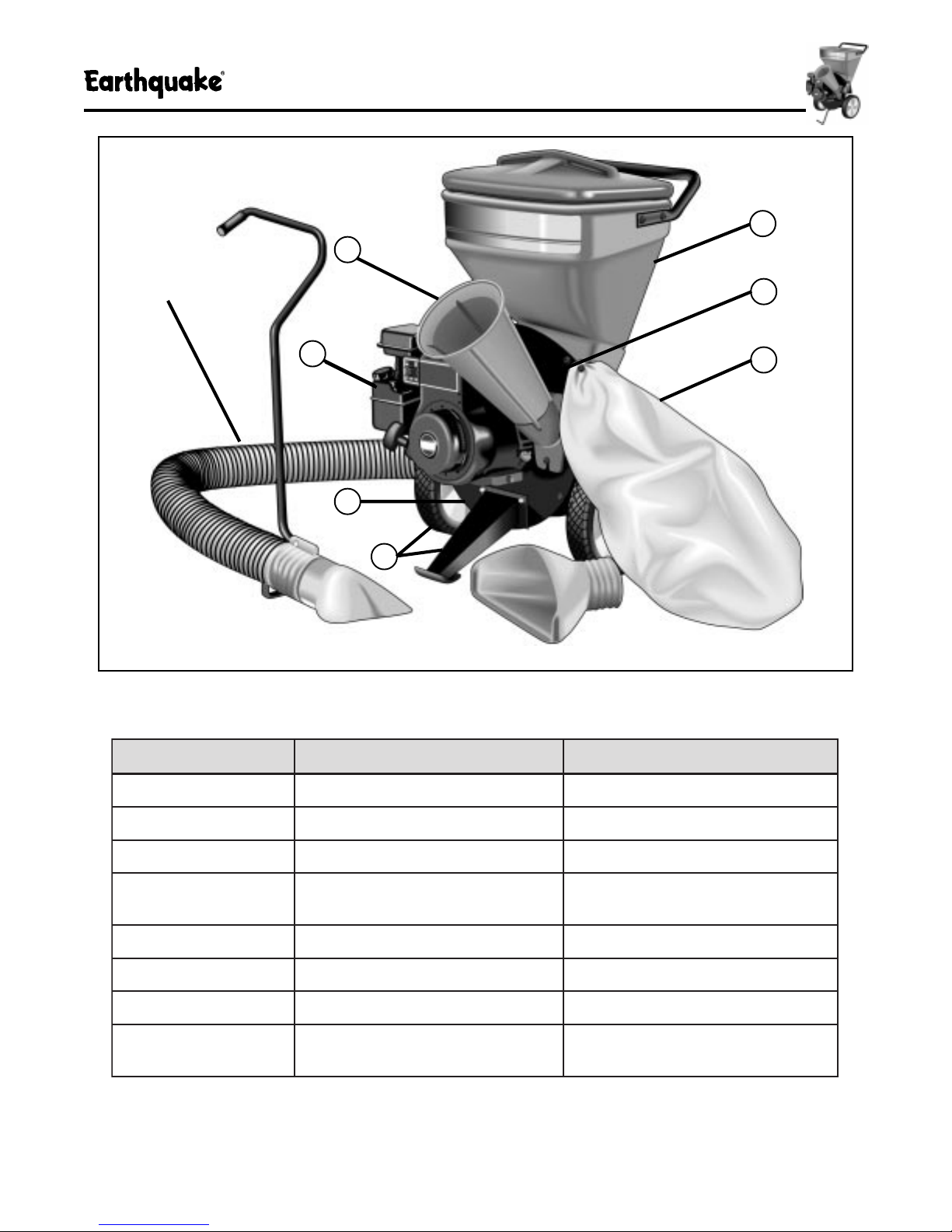

MAJOR COMPONENTS

C. Bag

The two-bushel bag is standard equipment and attaches

in seconds for direct, one-step bagging.

D. The Support Leg and Wheels

The sturdy support leg and wide-track wheels give your

chipper/shredder a stable, three-point stance, allowing

solid positioning on virtually all surfaces. The large

wheel diameter and durable rubber tread design make

transporting the unit easy, and the low center of gravity

helps prevent tipping while moving over bumpy or

uneven terrain.

E. Fan/Rotor Housing

This housing assembly contains the chipper knives and

shredding hammers that process the materials you’ll be

chipping and shredding

F. Engine

The rugged, four-cycle, air cooled engine provides all

the power necessary to readily chip or shred a wide

variety of materials. See the engine service manual

shipped with your chipper/shredder for additional

information.

The major components of your chipper/shredder are:

• Shredder Hopper • Engine

• Discharge Chute • Chipper Cone

• Bag Shredding Hammers

• The Support Leg & Wheels • Chipper Knives

• Fan/Rotor Housing

Each of these major components serves a specific

function on the chipper/shredder. Please take a moment

and familiarize yourself with the name, location, and

function of these components so that you will better

understand the safety and operating instructions

provided in this manual. See Figure 6.

A. Shredder Hopper

The durable, low-profile design of the shredder hopper

makes shredding convenient, yet holds a full size load

of material for maximum processing capability.

B. Discharge Chute

The discharge chute ejects the material out of the

chipper/shredder, delivering processed materials to a

specific area. The pivoting deflector shield directs debris

down, while allowing soft materials to be ejected freely

from the machine.

G. Chipper Cone

The rugged chipper cone helps guide tree limbs and

branches directly into the chipper knives, and it’s unique

angled mounting helps pull the material in quickly for

aggressive chipping action.

Shredding Hammers (Not Shown)

The unique design of the patented free-swinging,

triangular shredding hammers and “J” hammers helps

pull material into the shredding chamber, and increases

volume-reduction efficiency more than most other

brands.

The revolutionary design of these triangular hammers

also provides 300% more shredding power than conventional fixed rectangular hammers, and since they can be

rotated, their six different usable cutting edges help

extend service life dramatically.

Chipper Knives (Not Shown)

Our chipper/shredder line also features high quality,

precision-tempered, solid steel chipper knives, which

can be sharpened again and again to extend their useful

life for many seasons to come.

9

CONTROLS & MAJOR COMPONENTS

G

A

Optional Vacuum Kit

F

Figure 6. Component Locations

MODEL SPECIFICATIONS

B

C

E

D

SNOITACIFICEPSSNOITACIFICEPS

SNOITACIFICEPSSNOITACIFICEPS

SNOITACIFICEPS

rewopesroHph6&ph5.5ph01&ph8

yticapaCgnippihC"2/12"3

sevinKgnippihC2 2

sremmaHgnidderhSralugnairT-2

yticapaCredderhSgnoL"81x"2/1gnoL"81x"2/1

oitaRnoitcudeRetsaW1:02otpU1:02otpU

thgieWetamixorppA.sbl79.sbl911

tnempiuqElanoitpOtiKcaV

sremmaHJ-2

raBwoT&,dnEmuucaV,yarTfaeL/w

10

ralugnairT-2

sremmaHJ-2

tiKcaV

raBwoT&,dnEmuucaV,yarTfaeL/w

Loading...

Loading...