Page 1

EARLEX SPRAYSTATION 6900

®

OPERATING INSTRUCTION MANUAL

Thank you for purchasing the Professional Earlex low pressure paint system.

This highly versatile (high volume of air, low pressure painting) system can be

used for a wide variey of applications.

BEFORE USE - PLEASE READ THE MANUAL AND SAFETY INSTRUCTIONS.

Please retain for future reference.

Page 2

• Never under any circumstances aim the Spray Gun at another person or animal. In the event

SAFETY OPERATING INSTRUCTIONS

PLEASE READ BEFORE USE

of injury occurring seek expert medical advice immediately.

• The Spray Gun must only be used with paints and solvents that have a flash point suitable for

spraying. If in doubt, consult the paint or solvent manufacturer’s data.

• Always ensure there is adequate ventilation when spraying.

• NEVER spray near a naked flame, including appliance pilot light.

• NEVER smoke whilst spraying.

• NEVER allow children to operate or play with the Spray Gun.

• Always read the solvent manufacturer’s instructions before use.

• Always disconnect unit from mains supply when filling the paint container.

• Always wear a suitable protective mask when spraying. We would also recommend the use of

gloves, goggles and overalls.

• After each use, thoroughly clean the Spray Gun and grease the Fluid Needle.

• This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless they

have been given supervision or instruction concerning use of the appliance by a person

responsible for their safety.

• Use only genuine manufacturer replacement parts.

• Always disconnect the Spray Station from the mains supply before cleaning the

appliance.

• Warning. The use of any accessory or attachment, other than those recommended in this

instruction manual, may present a risk of personal injury.

• Use the Spray Gun for the job it was designed for only. Mis-use of the Spray Gun will invalidate

the guarantee.

• Wear ear protection.

WARNING: The substances used with this Spray Gun (paints, solvents, etc.) may contain

dangerous, harmful, explosive or corrosive materials. ALWAYS COMPLY WITH THE

SAFETY INSTRUCTIONS ISSUED WITH THIS PRODUCT AND THE MATERIAL BEING USED.

Only use the Spray Station as described in this manual.

TECHNICAL SPECIFICATION:

Wattage: 1100 Watts Container capacity: 1 litre

Voltage: 230 V (50hz) Air hose length: 4.5 m

Air output: 24L/sec Dynamic air pressure: 0.30 bar

Sound pressure level: 96 dB (A)

Maximum viscosity: 250DIN/sec

2

Page 3

Mains Switch

(230V)

Power IN

(IEC Connector)

Circuit Breaker

1

2

3

4

5

6

7

8

9

10

11

12

7

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

(x2)

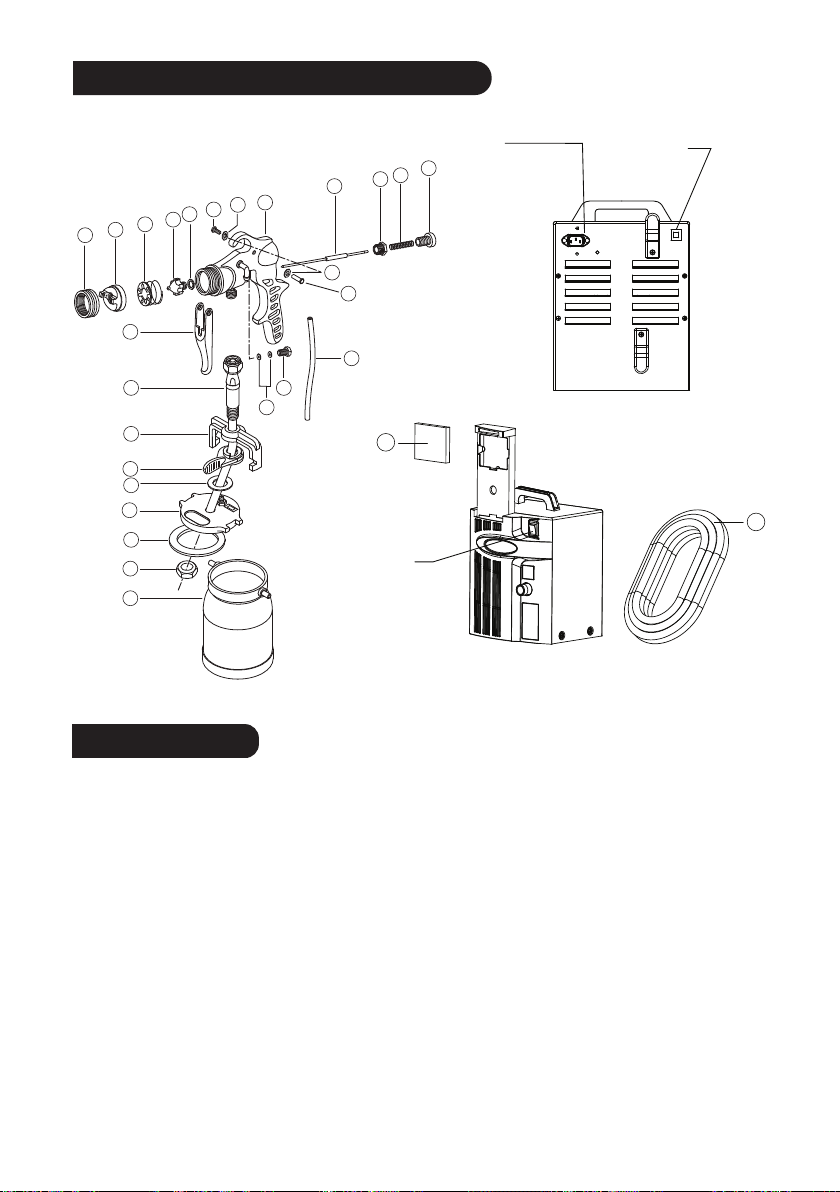

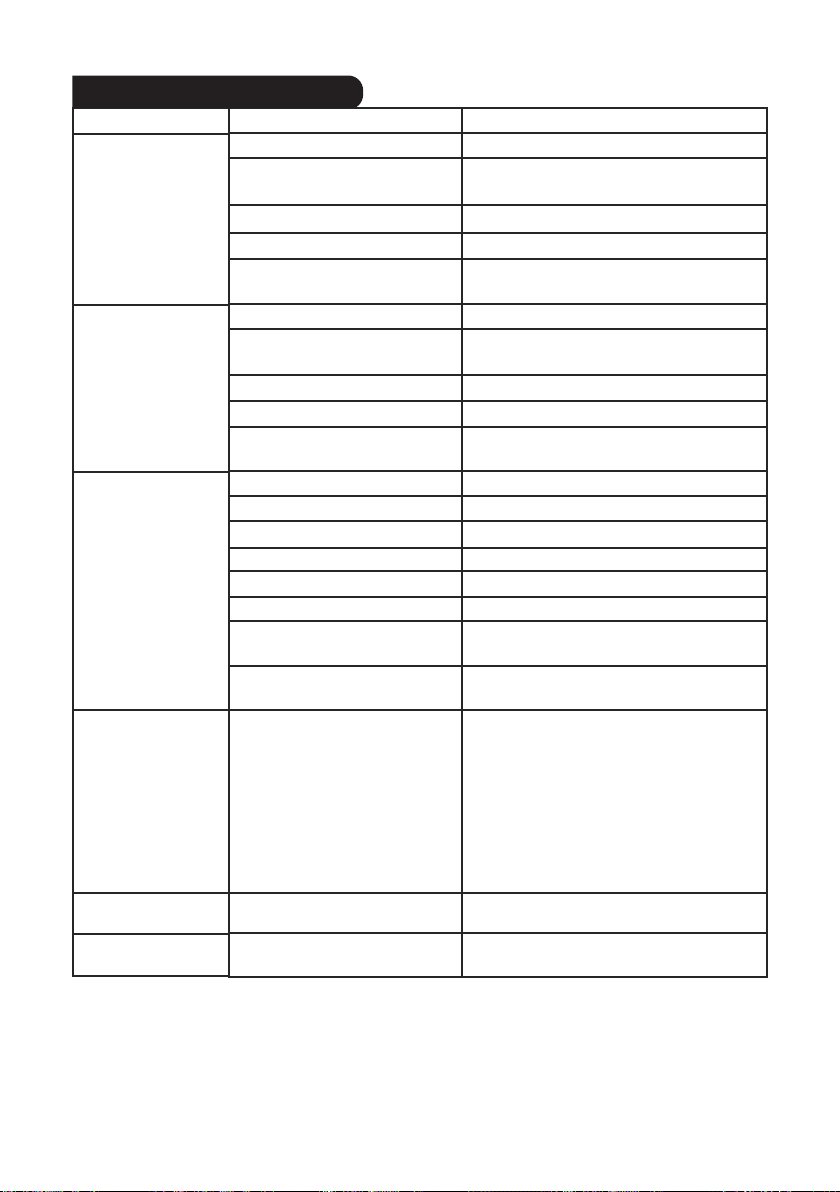

EXPLODED PARTS VIEW

PARTS LIST

No. Description Part No.

1. Air Cap Ring L0151

2. Air Cap N0517

3. Air Direction Plate L0162

4. 2.0mm Fluid Tip L0157

5. Fluid Tip Seal L0159

6. Pivot Screw L0179

7. Washer L0195

8. Main Body Assy L0180

9. 2.0mm Fluid Needle L0166

10. Adaptor L0174

11. Needle Spring L0175

12. Fluid Adjusting Screw L0176

13. Pivot L0178

14. Flexible Tube Air Feed L0182

No. Description Part No.

15. Gland Nut L0173

16. Gland Seal (2 pcs) L0168

17. Trigger L0177

18. Centre Bolt & Pick Up Tube Assy L0183

19. Yoke L0184

20. Clamp Lever L0185

21. Shim L0186

22. Lid Assy L0187

23. Gasket L0188

24. Centre Bolt Nut L0189

25. Paint Container L0190

26. Filter (x2) N0087

27. Air Hose N0259

3

Page 4

The concept

INTRODUCTION

PREPARATION

A motor feeds out a high volume of air (HV) and enables products to be sprayed at a low pressure

(LP). The product is released from the Fluid Tip of the Spray Gun at a very low pressure (0.18 bar)

and is enclosed in a high volume of air. The Hose feeds the air produced by the motor to the

Spray Gun.

The powerful motor can spray a width range of paint with or without dilution. However, there will

always be some paint which will not be suitable for the Spray Gun. The good quality paint

contains a high percentage of dry particles which make the dilution easier. The users must keep in

mind that low temperatures make the paint thicker, that’s why we recommend spraying with the

Spray Gun with a 15 degrees minimum temperature.

• Carefully cover areas which are not to be painted with a plastic cover and protective tape.

• Wear a suitable mask when spraying products (and make sure there is adequate ventilation in

the room when working indoors).

• Clean the surface you are going to paint. As well as being clean, it must also be dry and

smooth.

• Practice first on some old wooden planks to make sure you are holding the Spray Gun correctly.

• We recommend you wear protective clothing

• Stir the paint well using a mixer where possible.

• Make sure there are no solid particles in the paint.

• Many products can be sprayed without being thinned. However, if the application is not good,

thin the product progressively in stages of 5%.

• Most paints can be sprayed by being thinned just a little, e.g. by 5% or 10%.

• Some thick paints such as outer wall paints and certain undercoats will need to be thinned by

20% or 25%.

• Use water to thin a water-based product.

• Use white spirit to thin a solvent-based product.

• Certain manufacturers will indicate on the can whether a specific thinner is to be used.

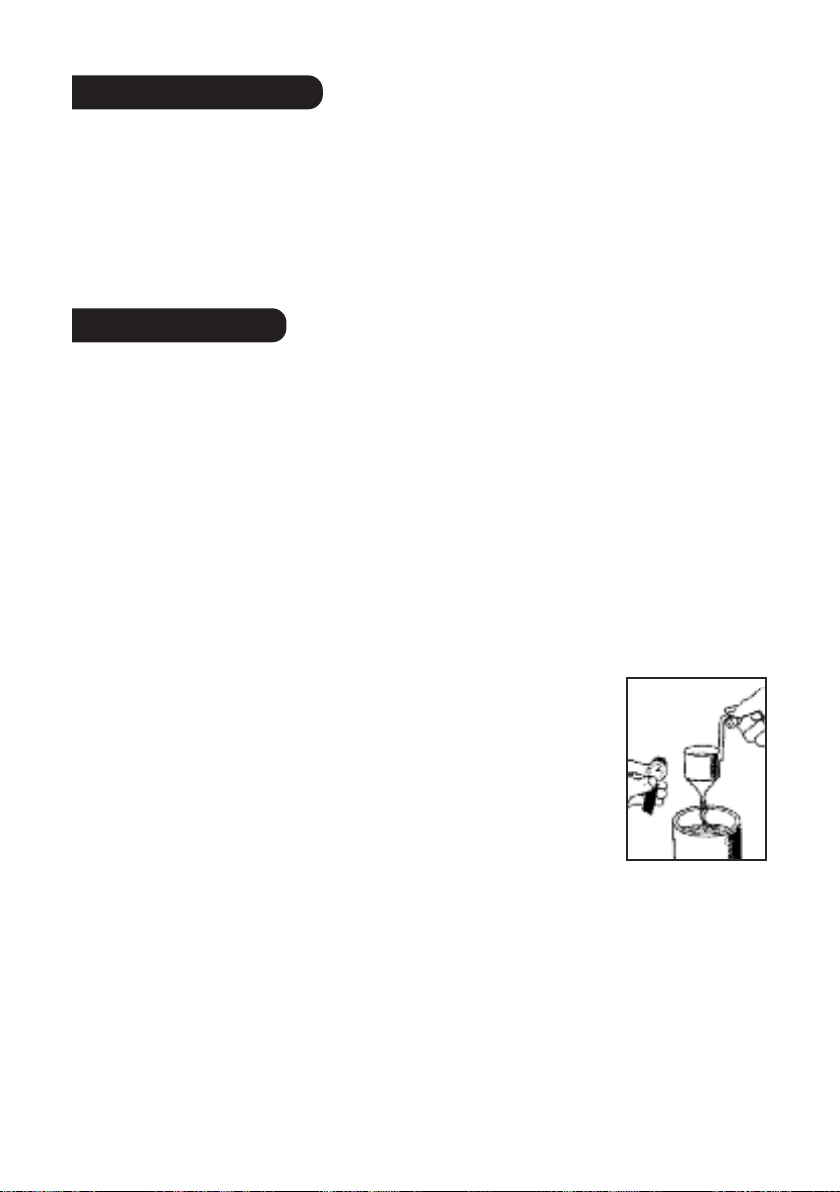

The viscosity, which is expressed in DIN/sec, is the time it takes for the paint

to stop running as a continuous flow through the viscosity cup (Fig 1). Your

Spray Station 6900 comes with a 2.0mm Fluid Tip and a 2.0 mm Fluid Needle

fitted. For the best results with products which are more runny (liquid dyes,

varnishes, runny paints, wood dyes), we recommend that you purchase the

1.5 mm Fluid Tip and Fluid Needle. This applies for products which have a

viscosity between 25 and 50 DIN/sec, i.e., which will take between 25 and 50

seconds to run through the viscosity cup. Refer to the chapter on cleaning to

see how the Fluid Tip and Fluid Needle can be removed and switched for a

smaller/larger Fluid Tip and Fluid Needle assembly.

• Fill the Paint Container with the product to be sprayed. Stir well (as

• Screw the Paint Container to the base of the Spray Gun and tighten accordingly.

• Unroll the motor unit air hose and attach it to the back of the Spray Gun.

• Unroll the power cable and attach the plug to the mains supply.

• Switch the Spray Station on. This will immediately cause some air to be produced, which is

mentioned above).

quite NORMAL. However, none of the product will be sprayed until the Spray Gun trigger is

pulled.

Fig. 1

Very important: when spraying for the first time, we recommend that you always leave the motor

to run for 1 to 2 minutes before applying the product. Do not forget that the Fluid Adjusting Screw

controls the quantity of paint sprayed, for instance the more the Paint Adjusting Screw is tightened

the less paint is sprayed.

4

Page 5

Fig. 2

SPRAYING TECHNIQUE

Vertical Spray

Horizontal and Vertical Spray

Vertical and Horizontal for normal sized jobs (Fig.2)

Round Spray

Round for small and precise jobs

The most commonly used technique for painting a wall is the ‘crisscross’ technique, i.e. you apply

the product in horizontal lines and then cross over these lines by applying the product in

vertical lines; (Fig. 3)

1) Adjust the Air Cap to obtain a Vertical spray, then pull the Trigger

and move your arm across to the right.

2) When you get to the end of the line, release the Trigger for a

moment and then apply the product in the opposite direction just

beneath the line you have sprayed.

3) Proceed in this manner applying the product in Horizontal lines one

underneath the other.

4) Next, adjust the Air Cap to obtain a Horizontal spray and apply the

product in horizontal lines over the lines you have just sprayed.

Horizontal Spray

Round Spray

Fig. 3

Let go of the trigger at the

end of each spray

movement to avoid

excessive paint and drips

Release the trigger to avoid overspraying which will cause the product to run.

Cross over the horizontal lines (spayed with a Vertical pattern) with vertical lines (sprayed with a

Horizontal pattern). Only the fore arm must move not the wrist.

5

Page 6

Type of paint Cleaning

CLEANING

SPRAY GUN

Water based paint Clean with water

Oiled based paint Clean with white spirit

Removing the Fluid Tip and Fluid Needle assembly (for cleaning or switching to a smaller/larger

diameter).

Flush out the residue paint from the spray gun, as follows:

l

Remove the paint container (25) from the spray gun.

l

Pour any residual paint into its original container for future use.

l

Use a cloth soaked in thinners to wipe out excess paint from the container, the underside of the

lid (22) & the gasket (23).

l

Pour a small quantity of clean thinners into the container, re-fit the container to the spray gun

and shake the gun lightly.

l

Now spray all of the thinners through the gun.

l

Repeat this, each time using clean thinners, until there is no trace of paint in the thinners

being sprayed.

To thoroughly clean the remainder of the spray gun, remove all working parts as per the

exploded spare parts drawing on p.3 as follows.

l

Loosen and remove Air Cap Ring (1), Air Cap (2) and Air Distributor Plate & Spring (3).

l

Now unscrew the Adjusting Screw (12) and pull out the Needle (9) and Needle Spring (11).

l

Use the supplied spanner, to remove the Fluid Tip (4) and Fluid Tip Seal (5).

All of the components above can be immersed in thinners and cleaned using the cleaning kit

supplied with this product. After cleaning your spray gun and before fitting the needle, dip the tip

into some vaseline which will lubricate the gland washers as the needle is inserted.

• NEVER DISPOSE OF PAINTS OR SOLVENTS DOWN THE DRAIN. ALWAYS USE

YOUR LOCAL WASTE COLLECTION SITE.

6

Page 7

PROBLEM

TROUBLESHOOTING

The paint drips onto

item being painted

Paint is too thin or

irregular

No paint being

released

Paint leaking from

the Gland Nut (15) in

front of the Trigger

Too much paint in an

area

Pulverisation

CAUSE ACTION REQUIRED

Paint too diluted Add undiluted paint

Paint output too high Reduce the paint output by

Moving too slowly Increase speed of application

Spray Trigger held for too long Release Trigger sooner

Spray Gun too close Increase the distance between the Spray

Paint too diluted Add undiluted paint

Paint output too low Increase the paint output by

Moving too fast Reduce speed of application

Gun clooged Clean the Spray Gun

Gun too far away Move the Spray Gun closer to the work

Paint too thick Add thinner

Fluid Tip clogged Clean the Fluid tip

Pick-up Tube clogged Clean Pick-up Tube (18)

Air Hose split Replace air Hose (14)

Grainy paint Filter the paint

Container almost empty Refil Paint Container

Spray Gun at an angle Check that the Pick-up Tube is

Air inlet blocked Check the condition of the Filter and

Gland Seal (16) not attached or

the wrong way round or not

tight enough.

Over time the Gland Seal (16)

will wear and need adjusting

You move you wrist Move your fore arm instead

Either too much or not enough

paint

adjusting the Fluid Adjusting Screw (12)

Gun and the work surface

adjusting the Fluid Adjusting Screw (12)

surface

pointing towards the paint (18)

clean if necessary (26 x2)

Reattach the Gland Seal (16)and

retighten Gland Nut. (15)

To check the Gland Nut is

correctly fitted you will need a small ad

justable spanner. Pull the Trigger

back and gradually tighten the gland but

by turning it in a clockwise direction until

the needle is not free to move when the

trigger is released

Use the Fluid Adjusting Screw to control

the flow

7

Page 8

PLEASE NOTE: We have done all we can to ensure that when used correctly and in accordance

MAINS CONNECTION

with these instructions the spray gun has a long and fault-free life. We accept no responsibility

for damage caused by the use of incorrect or unsuitable substances, paints or liquids which have

not been thinned correctly or which are not suitable for the surfaces to which they are applied,

health hazards arising from a lack of ventilation when working in confined spaces or equipment

which is faulty due to inadequate cleaning of the components after use. If in doubt, test a small

inconspicuous area first. Always read the manufacturer’s instructions before use. Neither our

guarantee nor the above statement affects your statutory rights.

Your SprayStation has been supplied with a mains lead which is fitted with a plug.

• If the plug is cut off from the mains lead, it must be disposed of safely. NEVER under

INFORMATION ON THE DISPOSAL OF WASTE ELECTRICAL &

ELECTRONIC EQUIPMENT KNOWN AS WEEE.

Please do not dispose of tools with your household waste collected by the

council. It is your responsibility to dispose of this type of waste by handing it

over to a special designated collection point for recovery and recycling.

any circumstances insert a plug which is cut off from the mains lead into socket.

Design Registrations: GB 3022947, GB 3022948, FR 06/5463, FR 06/5462,

EU 000608858, US D562,544, US D563,503

EARLEX LTD. WILL ACCEPT NO RESPONSIBILITY FOR THE USE OF THIS PRODUCT IF

This product is guaranteed for a period of 24 months against faulty manufacture or materials. It is

rights. For further information or any user advice, please phone our helpline between 08:30am

and 17:00pm Monday to Thursday and Friday 08:30am to 15:45pm (excluding Bank Holidays), or

USED FOR ANY OTHER PURPOSES THAN THOSE DETAILED HEREIN.

not guaranteed for industrial or hire purposes. This guarantee does not affect your statutory

Opus Park, Moorfield Road, Guildford, Surrey, GU1 1SZ, UK

Tel: +44 (0) 1483 454666. Fax: +44 (0) 1483 454548

Web: www.earlex.com Email: contact@earlex.co.uk

All rights reserved © 2011

GUARANTEE and HELPLINE

visit our website www.earlex.com

Earlex Limited,

© 2011 Earlex Ltd. N0226 08/11

8

Loading...

Loading...