Page 1

MODELS: ASG100, ASG120

OPERATING INSTRUCTIONS

Thank you for purchasing an Earlex Electric Airless Spray Gun,

this is a highly versatile spray gun and can be used

for a variety of applications.

Please read all these instructions before operating this

product and retain them for future reference.

Earlex Ltd will accept no responsibility for the use of this product if used

for any other purposes than those detailed herein.

Page 2

SAFETY OPERATING INSTRUCTIONS

WARNING: When using the spraygun, basic safety precautions, including

the following, should always be followed to reduce the risk of fire, electric

shock and personal injury.

l Keep work area clean - Cluttered areas and benches

invite injuries.

l Consider work area environment - Do not expose the

spray gun to rain. Do not use the spray gun in damp

or wet locations. Keep work area well lit. Do not use

the spray gun where there is risk to cause fire or

explosion.

l Guard against electric shock - Avoid body contact with

earthed or grounded surfaces (e.g. pipes, radiators,

ranges, refrigerators).

l Keep children away - Do not let visitors touch the tool

or extension cord. All visitors should be kept away

from the work area.

l Store idle tools - When not in use, tools should be

stored in a dry, high or locked place, out of reach of

children.

l Do not force the tool - it will do the job better and

safer at the rate for which it was intended.

l Dress properly - do not wear loose clothing or

jewellery, they can be caught in moving parts. Rubber

gloves and non-skid footwear are recommended when

working outdoors. Wear protective hair covering to

contain long hair.

l Always wear a mask when spraying.

l We recommend the use of eye protection to keep

hazardous vapours out of eyes.

l We recommend the use of ear protectors.

l Do not abuse the cord - Never carry the tool by the

cord or yank it to disconnect it from the socket. Keep

the cord away from heat, oil and sharp edges.

l Do not overreach - Keep proper footing and balance

at all times.

l Always disconnect from mains supply when not in

use, when refilling the paint container and before

cleaning.

l Avoid unintentional starting, do not carry a plugged in

tool with a finger on the switch and ensure the switch

is off when plugging in.

l When tool is used outdoors, use extension cords only

intended for outdoor use.

l It is recommended that a RCD (residual current

device) rated at 30mA is fitted into the mains supply

socket for added protection against electric shock.

l Stay alert - Watch what you are doing. Use common

sense and do not operate tool when you are tired.

l Never under any circumstances aim the nozzle at

another person or animal. In the event of injury

occuring seek expert medical advice immediately.

l Always keep the spray basket nozzle in place during

use. Never allow the spray to come in direct contact

with the skin.

l Always ensure there is adequate ventilation when

spraying.

l Never spray near a source of ignition, e.g. hot

surfaces, sparks, cigarettes, glowing wires & open

flames including appliance pilot flame.

l The spray gun must not be used for spraying

flammable materials below flashpoint 21˚C.

l Always beware of any hazards presented by the

material being sprayed and consult the markings on

the container or the information supplied by the

manufacturer of the material to be sprayed, including

requirements for the use of personal protective

equipment. Do not spray any material where the

hazard is not known.

l The spray gun must not be cleaned with flammable

liquids below flash point 21˚C.

l Check for damaged parts - Before further use of the

tool, a guard or other part that is damaged should be

carefully checked to determine that it will operate

properly and perform its intended function. Check for

alignment of moving parts, free running of moving

parts, breakage of parts, mounting and any other

conditions that may affect its operation. A guard or

other part that is damaged should be properly

repaired or replaced by an authorized service centre

unless otherwise indicated in this instruction manual.

Have defective switches replaced by an authorized

service facility. Do not use the tool if the switch does

not turn it on and off.

l Warning - The use of any accessory or attatchment,

other than those recommended in this instruction

manual, may present a risk of personal injury.

l Maintain tools with care - Follow instructions for

lubrication and changing the accessories, inspect tool

regularly and if damaged, get repaired by an

authorized service centre.

l Have your tool repaired by a qualified person - This

electric tool is in accordance with the relevant safety

requirements. Repairs should only be carried out by

qualified persons using original spare parts, otherwise

this may result in considerable danger to the user.

l Use genuine Earlex parts only

.

2

Page 3

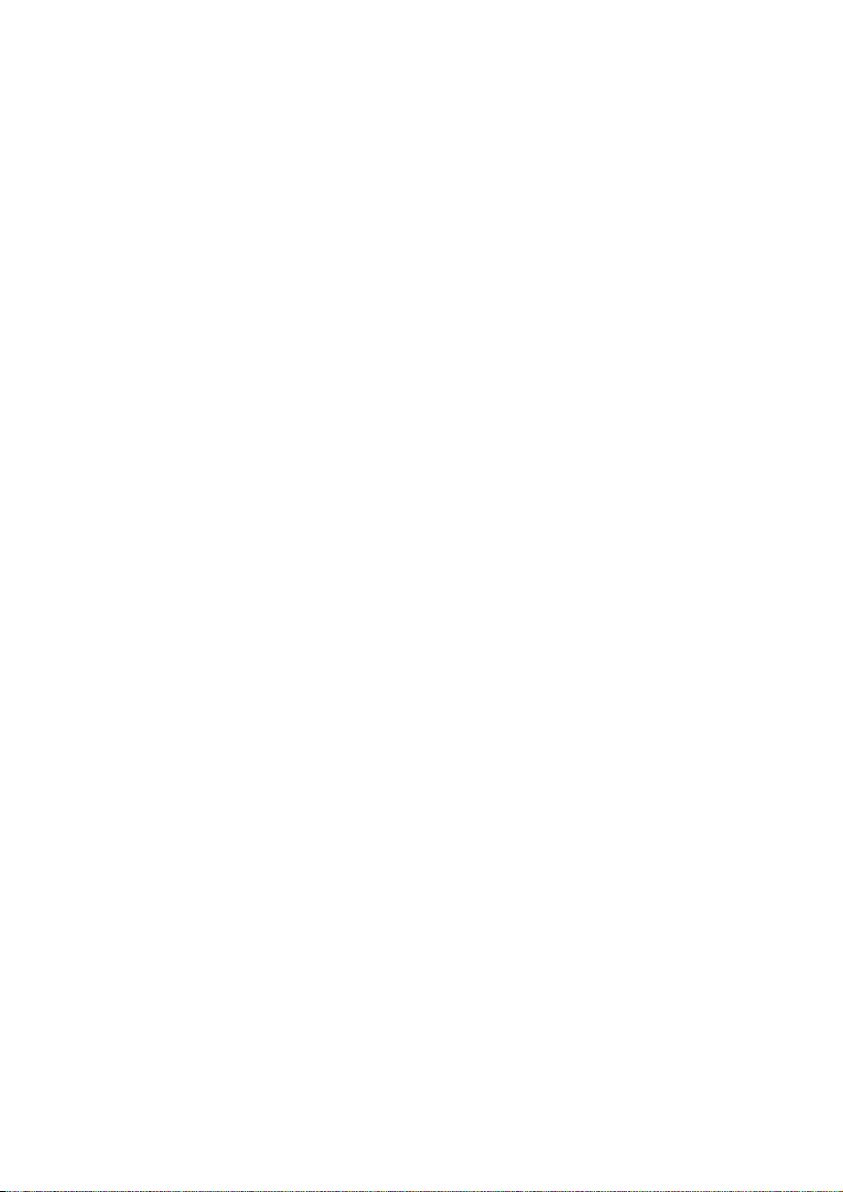

WHAT IS INCLUDED WITH YOUR SPRAY GUN

ASG100 & ASG120 kits include:

l

Spray gun with 1.0mm spray

nozzle (yellow) fitted, for

spraying woodcare treatments.

l

iscosity cup, which enables

V

you to test your paint for

thickness before painting.

l

Flexible Extension (with Swirl

head), can be bent up to 45˚,

to paint horizontal or angled

l

0.6mm general purpose

spray nozzle (black).

surfaces.

l

Replacement atomiser valve.

Atomiser valves wear with use.

See ‘Maintenance and

Repair’.

l

Piston Punch, to help free

l

Bottle of Lubricating Oil

the piston in the unlikely

event of a seizure.

ASG120 kits also include:

l

Remote Pick Up system. For larger jobs, paint can

be fed directly from a can.

See section ‘Remote Pick Up system’.

l

0.8mm spray nozzle

(blue) for spraying

emulsion and other

thick materials.

NOISE AND VIBRATION LEVELS

The following values were measured in accordance with EN50144.

Continuous A-weighted equivalent sound pressure level: 90 dB(A).

A-weighted sound power level: 103 dB(A)

Vibration level: 12 m/s

2

PLEASE NOTE

We have done all we can to ensure that used correctly and according to these instructions, the Earlex

Electric Airless Spray Gun will give long trouble free service. We accept no responsibility for damage

caused by the use of incorrect or unsuitable substances, paint or fluids which have not been thinned

correctly or are unsuitable for the surfaces to which they are applied, health hazards arising from lack

of ventilation when working in confined spaces, or failure of the equipment due to inadequate cleaning

of components after use.

If in doubt, always test a small inconspicuous area first. Always read the paint manufacturers

instructions first.

Neither our guarantee nor the above statement affect your statutory rights.

3

Page 4

TECHNICAL SPECIFICATION

MODEL ASG100

Power Supply 230V 50Hz ~

Rated Input 100 Watts

Container Capacity 1.0 Itr

Spray Gun weight 2.0 kg

Cable length 2 mtr

MODEL ASG120

Power Supply 230V 50Hz ~

Rated Input 120 Watts

Container Capacity 1.0 Itr

Spray Gun weight 2.0 kg

Cable length 2 mtr

TO OBTAIN THE BEST RESULTS FROM YOUR SPRAY GUN READ THESE

INSTRUCTIONS CAREFULLY BEFORE USE.

ABOUT THE SPRAY GUN

The Spray Gun is a highly versatile electric airless spray gun. It can be used to spray many different

materials including varnishes, wood preservatives, enamel paints, oil based paints & water based

paints.

Airless spraying reduces the mist associated with air spraying & reduces paint loss.

The spray gun can be used for a variety of applications including, fences, sheds, boats, furniture,

radiators, models & louvre doors.

IMPORTANT - SELECTING THE PAINT

Many paints & other materials can be sprayed but some cannot. Always check the manufacturer’s

recommendations before using products with your spray gun.

THE SPRAY GUN MUST NOT BE USED FOR SPRAYING EXTERIOR TEXTURED WALL PAINTS

OR TEXTURED COATINGS. USING THESE MATERIALS WILL CAUSE PREMATURE WEAR ON

THE PISTON & WILL INVALIDATE YOUR GUARANTEE.

PREPARING THE PAINT (OR OTHER SPRAY MEDIUM)

It is most important to follow the paint manufacturer’s recommendations for thinning. Most paints are

supplied ready for brush application & must be diluted for use with the spray gun. If you are in any

doubt about how much to thin the paint, consult the paint manufacturer.

The viscosity cup supplied with your spray gun & the viscosity guide below, can be used to help you

determine the correct thickness of the paint.

The paint, or paint & thinners mixture, must be thoroughly stirred. We do not recommend the use of an

electric stirrer as this can increase the volume of air in the paint, which will reduce the effectiveness of

the spray gun.

VISCOSITY GUIDE

Water based paints 35-45secs

Oil Based paints 15-25secs

Enamel paints 15-25secs

Wood preservatives no dilution

Primers 20-30secs

Varnishes 20-25secs

* These paints cannot be measured in the viscosity cup.

suction tube, thin according to manufacturer’s recommendations and strain to remove any lumps or

particles.

Aluminium paints 15-25secs

Wood stains no dilution

Latex Emulsions *10-20% dilution

Smooth Masonry

Paint (non grit) *5-10% dilution

To spray them, remove the filter from the

4

Page 5

USING THE VISCOSITY CUP

Dip the viscosity cup into the paint (or other medium) to fill it.

Time how long the paint takes to empty from the cup (see fig.1) & refer to the viscosity guide on page

4 to compare the time. Thin the paint further until the recommended time is achieved.

fig.1

PREPARING & USING YOUR SPRAY GUN

SAFETY WARNING!

DO NOT SPRAY FLAMMABLE MATERIALS (FLASH POINT < 21˚C). ALWAYS

SPRAY IN A WELL VENTILATED AREA. NEVER SPRAY NEAR NAKED

FLAMES.

ALWAYS WEAR PROTECTIVE FACE MASK, GOGGLES, GLOVES & EAR PROTECTORS WHEN

USING YOUR SPRAYGUN.

MASK THE AREAS OF THE ITEM THAT YOU DO NOT WANT TO SPRAY & PROTECT ANY

ADJACENT AREAS THAT COULD BE AFFECTED BY

OVERSPRAY.

Before fitting the paint container, turn the spray gun upside down &

put a few drops of lubricating oil down the inlet and outlet spouts.

(see fig.2)

Plug the spray gun into a power socket & run the motor for one or

two seconds to distribute the oil around the cylinder & piston.

Disconnect the power & push the Suction Tube & Filter firmly into

the inlet spout, which is the longer of the two spouts.

Fill the container with the prepared paint or other medium, which as a precaution should be filtered

through a suitable funnel that has a filter. As an alternative to a filter the paint can be poured through

a nylon stocking or tights. This should ensure there is no contamination of the paint that could block or

damage the spray gun. DO NOT FILL THE CONTAINER BEYOND THE MAXIMUM LEVEL

INDICATED.

Screw the spray gun tightly onto the filled container. Plug the spray gun into a power socket and it is

now ready to be set up.

5

fig.2

Page 6

SETTING UP THE SPRAY GUN FOR OPTIMUM

PERFORMANCE

When setting up the spray gun we recommend that you spray the paint

onto some scrap material, newspaper or cardboard. Purge the air from

the spray gun by running it for a few seconds until the paint comes out of

the gun.

The volume of paint & the spray pattern is controlled using the Output

Control Knob, (see fig. 3) Turn the knob anti-clockwise to increase the

volume of paint sprayed & clockwise to decrease the amount of paint

sprayed.

A good spray pattern is achieved when there is an even amount of paint

in a fine spray throughout the pattern. A poor spray pattern will

concentrate the paint in the centre of the spray & give a blotchy finish.

To get the best spray performance, turn the Output Control Knob fully anticlockwise. Aim the gun at a piece of cardboard, or similar waste material,

& press the switch to start the spray gun. With the spray gun running, turn

the Output Control Knob clockwise until the best spray pattern is achieved.

If you are unable to achieve an even, fine spray you will probably need to

thin the paint further. Follow the thinning procedure as described under

“Preparing the Paint”.

SPRAYING TECHNIQUE

To obtain best results keep the spray gun level & square on to the surface

being sprayed. The gun works best if the nozzle is kept about 25 – 30

cms (10” – 12”) from the surface being sprayed. (See fig. 4) This will result

in consistent, even coverage.

To avoid overlap of the paint & therefore uneven coverage, we

recommend that the spray gun be momentarily turned off whenever you

change direction.

Move the spray gun at an even speed. A fast speed will give a thin coat &

a slow speed will give a thicker coat. Never tilt the spray gun more than

45˚ as this could result in paint getting in to the motor & causing serious

damage.

MAXIMUM

MINIMUM

CONTROL

KNOB

fig.3

HELPFUL HINTS

1) Only apply one coat at a time. If more than one coat is required follow

the paint manufacturers instructions for drying times.

2) If spraying small objects keep the output setting low as this will avoid

excessive use of paint & will minimise overspray.

3) When spraying large areas or objects use a criss-cross pattern either

left to right then up & down or vice-versa. Remember to momentarily

stop spraying as you change direction. This will ensure maximum,

even coverage. (See fig. 5)

4) Do not stop & start spraying while moving the gun in one continuous

direction.

5) To ensure edges are covered begin spraying just outside the area

being sprayed & do not stop until you have just passed the opposite

edge.

6

fig.4

fig.5

Page 7

SPRAY NOZZLE SELECTION

The ASG100 spray gun is supplied with 0.6mm and 1.0mm nozzles, the ASG120 spray gun is also

supplied with a 0.8mm nozzle, these should be used as follows:

1) 0.6mm - This size works best for oil-based materials, stains, sealers, lacquers, water-proofers and

enamels for small application areas.

2) 0.8mm - This is a general purpose nozzle that works best for materials such as emulsions, latex and

thicker type paints.

3) 1.0mm - This nozzle is suitable for spraying woodcare treatments.

If when spraying you find that the spray pattern is small and splattery, and adjusting the output control

knob does not solve the problem, try a different nozzle size before further thinning the material.

USING THE FLEXIBLE EXTENSION TUBE.

Using the Flexible Extension Tube makes the painting of ceilings, floors & all

horizontal surfaces much easier. When fitted, the Flexible Extension Tube is bent

to avoid tilting the spray gun. Tilting the spray gun excessively can cause paint to

leak into the motor, causing serious damage.

TO FIT THE FLEXIBLE EXTENSION TUBE (see fig.6)

1) Unscrew the spray gun nozzle by turning it anti-clockwise. Be sure to leave the valve in place but

check for wear.

2) Screw the end of the extension tube, with the internal thread, tightly onto the spray gun. Leaks may

occur if the flexible extension is loose or if excessive force is used to fit it. e.g. using pliers.

3) Fit a swirl head into the end of the flexible extension tube with the external thread.

4) Screw a nozzle onto the end of the flexible extension tube.

5) Bend the flexible extension to the required angle (45˚ maximum). Do not bend the extention tube

more times than necessary, as repeated bending can cause premature failure.

NOZZLE FLEXIBLE EXTENSION

SWIRL HEAD

ATOMISER VALVE

fig.6

7

Page 8

REMOTE PICK UP SYSTEM - (ASG120 only)

For larger painting tasks, use the Remote Pick Up System. This

enables you to draw paint directly out of a large can instead of using

the paint container supplied with the spray gun, thereby saving

considerable time and making painting an even easier job. When using

the remote pick up system secure the Remote Pick Up Tube to the can

using the Remote Pick Up Clip provided. If working from a ladder, the

can may be carefully hung from a rung on the ladder using a wire hook.

We recommend a maximum continuous spray time of 30 mins, with a

minimum break of 20 mins before spraying again to avoid fatigue.

Assembling the Remote Pick Up System (see fig.7)

l

Unscrew and remove the paint container and remove the Suction

Tube and Filter from the inlet spout. If the spray gun is being used

for the first time, lubricate the piston and cylinder before continuing.

See ‘Preparing and Using your Spray Gun’

l

Push the remote Pick Up Tube (2) firmly over the two spouts of the

cylinder moulding.

l

Fit the Suction Tube and Filter (3) securely to the same side of the Pick Up Tube that is connected

to the inlet spout of the cylinder moulding.

l

Immerse the Suction Tube and Filter into the can of paint and secure the Pick Up Tube to the can

using the Remote Pick Up Tube Clip (1).

l

When using the spray gun with the remote pick up system, only use the gun in the normal upright

position, to allow the residue paint to drain away down the Pick Up Tube.

Priming the Spray Gun

When using the remote pick up system you must remove all the

air by priming the system as follows:-

1. Turn the output control knob fully anticlockwise to the

maximum position.

2. Make certain the spray gun is plugged in.

3. Hold the spray gun below the level of paint to speed the

priming.

4. Aim the spray gun at a piece of cardboard or old newspaper,

squeeze the trigger and hold until all air is out of the system

and material is flowing freely from the nozzle. This should

take about two minutes.

WARNING- When using the Remote Pick Up system the

filter, of the Suction Tube and Filter, must be completely

submerged in the paint at all times. If not completely

submerged, air will be sucked into the system and the

piston may seize. If this happens, the sound of the gun will

change to a low hum and it will quickly become hot. Stop

using immediately. Allow the gun to cool, then clean and

lubricate the gun throughly before re-using.

8

1

2

3

fig.7

Page 9

CLEANING THE REMOTE PICK UP COMPONENTS

<21˚C

Run an appropriate thinners through the tube until it is clean. Disassemble the fittings at both ends

before any remaining paint dries, and thoroughly clean the remote pick up tube, suction tube and filter.

GENERAL CLEANING INSTRUCTIONS

After every use it is essential that you clean the spray gun thoroughly. This will prevent any blockages

occuring and provide consistant performance when you next come to use it.

When you have finished spraying, empty any remaining material out of the paint container and clean it

thoroughly using the thinners used for the last job.

Rinse the spray gun container with the thinners used for the last job and spray through the gun onto

cardboard or newspaper, and follow the instructions below.

REMEMBER - DO NOT USE FLAMMABLE THINNERS

(except white spirit & turpentine substitute)

l

Disconnect the spray gun from the mains power.

l

Remove paint container and pull out the suction tube.

l

Unclip the filter from the suction tube.

l

Unscrew the spray nozzle and remove the atomiser valve, making sure that

the spring is not ‘stretched’ during removal.

l

Unscrew the locking collar and remove cylinder housing from the motor housing, by pulling

forward and down.

l

Remove the piston and spring.

l

Submerge all of the components into a cleaning fluid compatible with the material being sprayed.

l

Clean all parts thoroughly.

l

Lightly oil the piston and slide in and out of the cylinder to distribute the oil over the mating parts.

l

Re-assembly is the reverse of the above.

MAINTENANCE AND REPAIR

Please be aware that certain parts of this spray gun will wear, requiring replacement and that these

parts are not covered by guarantee. These parts include the valve, spray nozzle, piston and spring. The

wear on these parts depends on the abrasiveness of the materials being sprayed. The more abrasive

materials such as latex paint (emulsions) will cause these parts to wear much faster. You would

normally expect to replace an atomiser valve after spraying between 25-45 litres of latex.

A worn valve will cause a poor spray pattern and will require replacing. Replacement valves are

available from the Earlex Service Department.

You will need to check the spray nozzles, piston and spring from time to time to check for wear

Replace if necessary.

NEVER DISPOSE OF PAINTS OR SOLVENTS INTO DRAINS. CONTACT

ARRANGE COLLECTION.

O

YOUR LOCAL COUNCIL

T

9

.

Page 10

10

Page 11

PARTS AND ACCESSORIES

15

16

14

8/9/10

17

3/4

13

7

1/2

6

5

11

12

19

20

18

1. ASG100 Main Gun Assembly

(including mains lead) SG435

2. ASG120 Main Gun Assembly

(including mains lead) SG436

3. Cylinder Housing (ASG100) SG453

4. Cylinder Housing (ASG120) SG434

5. Piston Spring SG442

6. Piston

7. Locking Collar SG400

8. Nozzle 1.0mm (yellow)

9. Nozzle 0.6mm (black) SG416

11. Atomiser Valve

SG395

SG414

SG473

12. Suction Tube & Filter SG240

13. Paint Container SG242

14. Flexible Extension SG281

15. Swirl Head SG200

16. Viscosity Cup SG243

17. Lubricating Oil SG244

18. Piston Punch SG318

ASG120 only

Nozzle 0.8mm (blue)

10.

19. Clip for Tube SG431

ube

Remote Pick Up

20.

11

T

SG415

SG432

fig.8

Page 12

MAINS CONNECTION (WARNING-THIS APPLIANCE MUST BE EARTHED)

<21˚C

10

2

0

3

0

4

0

5

0

6

0

7

0

8

0

9

0

<21˚C

<21˚C

If the mains lead is damaged, it must be replaced by the manufacturer or its service agent or a similarly

qualified person in order to avoid a hazard.

our unit may have been supplied with a mains lead that has the plug moulded to it. This type of plug

Y

will have a fuse holder in its base. Please read the following safety instructions before use.

1. If the moulded plug is cut off from the mains lead then the plug must be disposed of safely. It must

NEVER under any circumstances be plugged into a live power socket.

2. NEVER under any circumstances use the appliance without the fuse cover of the 13 amp plug fitted.

This is the little cover fixed into the base of the plug to hold the fuse in place.

3. If you lose the fuse cover then please contact any electrical dealer for a

replacement or ring our helpline.

4. A replacement fuse must be rated at 5amp. The fuse must be manufactured and approved to

BS1362

5. IF IN ANY DOUBT PLEASE CONSULT AN ELECTRICIAN.

WARNING-If you are using an extension lead, it must be rated at a minimum of 6 amps and fully

unwound. Do not operate with a lead rated at less than 6 amps as this will cause premature failure of

the motor and will void your guarantee.

SAFETY WARNING LABEL

One of the labels on the spray gun is a warning label and shows three diagrams. If you are in any doubt

about their meaning, please see the explanation below.

Do not direct the spray gun

at yourself or anyone else.

(Risk of injection)

Do not use your spray gun in

wet weather.

Do not use your spray gun for

spraying flammable materials. i.e

those with a flashpoint less than

21˚C.

GUARANTEE

This product is guaranteed for a period of 24 months against faulty manufacture or materials. It is not

guaranteed for hire purposes. This guarantee does not affect your statutory rights. In the event of any

problem occurring please contact us on our helpline no:

01483-454666

Monday - Friday 08:30 - 18:00 (Except Bank Holidays)

EU Registered Design No 28071

Australian Registered Design No 152436

UK Registered Design No 3009595

Design registration applied for in USA

Copyright & Design Right Reserved ©

EC Declaration of Conformity

We declare that the units

ASG100 &

EN50144-2-7 89/336/EEC, EN61000-3-2 & EN61000-3-3, EN55014-1, EN55014-2

© Earlex Ltd 2004 SG424 03/04

Earlex Ltd., Moorfield Road, Slyfield Industrial Estate, Guildford, Surrey, GU1 1RU.

Tel: 01483-454666 Fax: 01483-454548 email: enquires@earlex.co.uk website: www

ASG120 conform to: 73/23/EEC, EN50144-1,

Tim Hopper-Technical Director

12

.earlex.co.uk

Loading...

Loading...