Page 1

EARLEX SPRAY STATION 6900

OPERATING INSTRUCTION MANUAL

Thank youforpurchasingthe professional Earlex low pressurepaintsystem.

Thishighly versatile HVLP(high volume of air,low pressurepainting) system

BEFORE USE– PLEASE READTHE MANUAL ANDSAFETYINSTRUCTIONS.

can be used fora wide variety of applications

Please retain for futurereference

.

Mercid’avoir choisile systèmeprofessionnelde pulvérisationde peinture basse pression

Earlex.Cetappareil est doté dusystème HVLP (haut volume d’air,basse pressionde peinture)

extrêmementpolyvalent dontvous pourrez vous servir pour une grande variétéd’applications.

AVANT TOUTEUTILISATION,VEUILLEZLIRE CE MANUEL ETLESINSTRUCTIONS

Veuillezconserver ce documentafinde leconsulterultérieurement

Gracias por comprar esta unidadprofesional depintura a baja presión Earlex.

Esteversátil aparato HVLP (equipo de pintura de gran caudal deairey baja presión)se

LEA LAS INSTRUCCIONES DE SEGURIDADY FUNCIONAMIENTO ANTES DEUTILIZAR ELAPARATO.

MANUAL DE INSTRUCCIONES

puedeutilizar para una gran variedadde aplicaciones.

Guarde estas instruccionesparafuturas consultas.

MODE D’EMPLOI

RELATIVES ÀLA SÉCURITÉ.

Page 2

The substances used with this spray applicator (paint, thinners etc) may contain hazardous,

SAFETY OPERATING INSTRUCTIONS

PLEASE READ BEFORE USE

PARTS LIST

US

harmful, explosive or corrosive materials.

The spray applicator must only be used with paints and solvents that have a suitable flash point

for spraying. If in doubt, consult the paint or solvent manufacturer's data

Always ensure there is adequate ventilation when spraying.

NEVER spray near an open flame, including an appliance pilot flame.

NEVER smoke when spraying.

Always disconnect the unit from the mains supply cleaning the spray applicator.

Always ensure the sprayarea is safeandfreefrom all debris thatmaypresenta fireortrip hazard.

NEVER, under any circumstances, point the spray gun at another person or animal. In the

event of injury occurring, seek expert medical advice immediately.

NEVER allow children or unauthorised users to operate or play with the spray equipment.

This equipment is for professional use only.

Always read the paint manufacturer's thinning instructions before use.

Always wear the correct protective face mask when spraying. We also recommend wearing

gloves, goggles and overalls.

After every use ensure that you clean the spray gun thoroughly and grease the gland washer.

Use only genuine manufacturer replacement parts.

Only use the spray equipment as detailed in these instructions.

Do not use the air hose or mains cable to pull the HVLP unit.

Check the hoses, hose connectors and mains cable daily. Any worn or damaged parts should

be replaced immediately.

This appliance is recommended for household use only.

This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible

for their safety.

WARNING: The substances used with this Spray Gun (paints, solvents, etc.) may contain

dangerous, harmful, explosive or corrosive materials. ALWAYS COMPLY WITH THE

SAFETY INSTRUCTIONS ISSUED WITH THIS PRODUCT AND THE MATERIAL BEING USED.

Only use the Spray Station as described in this manual.

TECHNICAL SPECIFICATION:

Wattage: 1100 Watts Container capacity: 1 litres

Voltage: 120 V (60hz) Air hose length: 4.5 m

Air output: 22L/sec Dynamic air pressure: 0.30 bar

Sound pressure level: 88 dB (A) Maximum viscosity: 250DIN/sec

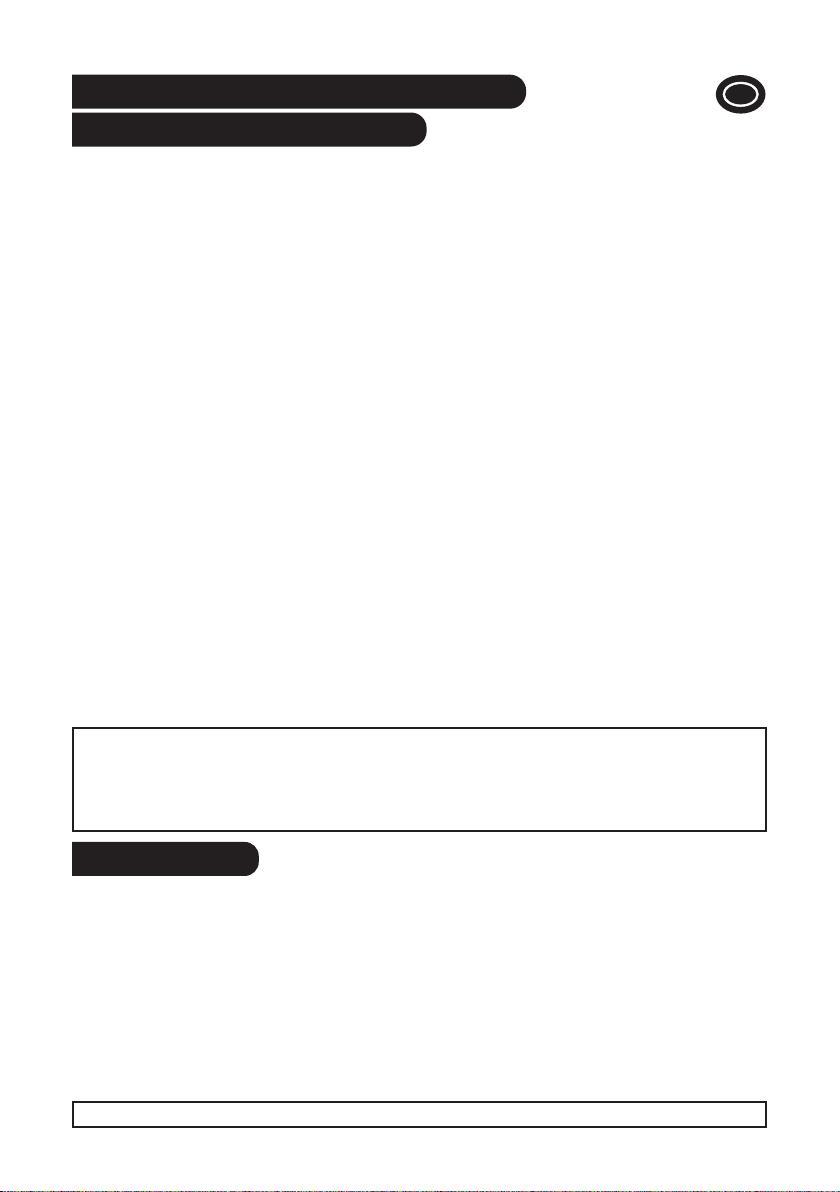

Fig.1

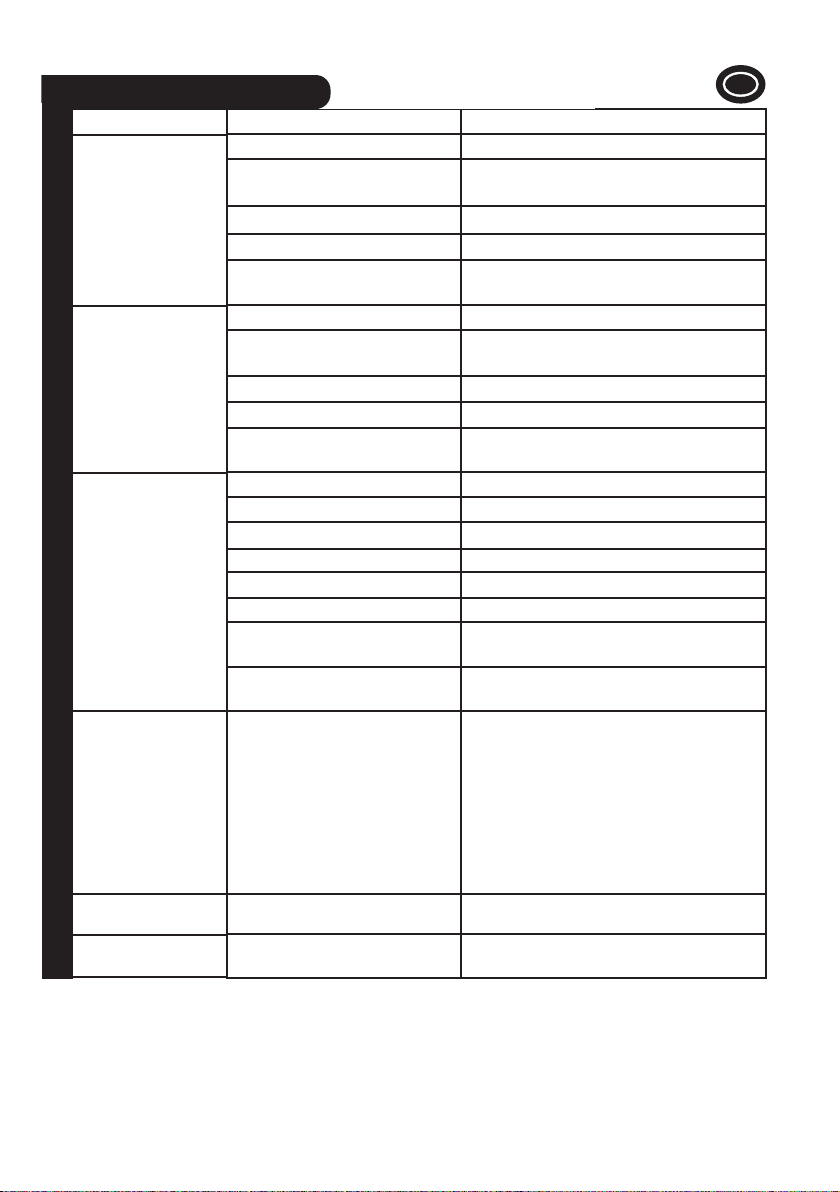

No Description Part No

1. Air Cap Ring L0151

2. Air Cap L0517

3. Air Distributor Plate L0162

4. 0.08” (2.0mm) Fluid Tip L0157

5. Fluid Tip Seal L0159

6. Pivot Screw L0179

7. Washer L0195

8. Main Body Assy L0180

9. 0.08” (2.0mm) Fluid Needle L0166

10. Adaptor L0174

11. Needle Spring L0175

12. Fluid Adjusting Screw L0176

13. Pivot L0178

Optional Accessory to Purchase 30ʼ Hose - N0099

No Description Part No

14. Flexible Tube Air Feed L0182

15. Gland Nut L0173

16. Gland Seal (2 pcs) L0168

17. Trigger L0177

18. Centre Bolt & Pick Up Tube Assy L0183

19. Yoke L0184

20. Clamp Lever L0185

21. Shim L0186

22. Lid Assy L0187

23. Gasket L0188

24. Centre Bolt Nut L0189

25. Paint Container L0190

26. Filter (x2) N0087

27. Air Hose N0212

2

Page 3

Mains Switch

(120V)

Power IN

(IEC Connector)

Circuit Breaker

1

2

3

4

5

6

7

8

9

10

11

12

7

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

(x2)

EXPLODED PARTS VIEW

DIAGRAMS

Fig. 1

US

Fig. 3

Vertical Spray

Fig. 2

Horizontal Spray

3

Round Spray

Fig. 4

Let go of the trigger at the end

of each spray movement to

avoid excessive paint and drips.

Page 4

The concept

INTRODUCTION

PREPARATION

US

A motor feeds out a high volume of air (HV) and enables products to be sprayed at a low pressure

(LP). The product is released from the Fluid Tip of the Spray Gun at a very low pressure (0.18 bar)

and is enclosed in a high volume of air. The Hose feeds the air produced by the motor to the

Spray Gun.

The powerful motor can spray a width range of paint with or without dilution. However, there will

always be some paint which will not be suitable for the Spray Gun. The good quality paint

contains a high percentage of dry particles which make the dilution easier. The users must keep in

mind that low temperatures make the paint thicker, thatʼs why we recommend spraying with the

Spray Gun with a 15 degrees minimum temperature.

• Carefully cover areas which are not to be painted with a plastic cover and protective tape.

• Wear a suitable mask when spraying products (and make sure there is adequate ventilation in

the room when working indoors).

• Clean the surface you are going to paint. As well as being clean, it must also be dry and

smooth.

• Practice first on some old wooden planks to make sure you are holding the Spray Gun correctly.

• We recommend you wear protective clothing

• Stir the paint well using a mixer where possible.

• Make sure there are no solid particles in the paint.

• Many products can be sprayed without being thinned. However, if the application is not good,

thin the product progressively in stages of 5%.

• Most paints can be sprayed by being thinned just a little, e.g. by 5% or 10%.

• Some thick paints such as outer wall paints and certain undercoats will need to be thinned by

20% or 25%.

• Use water to thin a water-based product.

• Use white spirit to thin a solvent-based product.

• Certain manufacturers will indicate on the can whether a specific thinner is to be used.

The viscosity, which is expressed in DIN/sec, is the time it takes for the paint to stop running as a

continuous flow through the viscosity cup (Fig 2). Your Spray Station 6900 comes with a 2.0mm

Fluid Tip and a 2.0 mm Fluid Needle fitted. This applies for products which have a viscosity

between 25 and 50 DIN/sec, i.e., which will take between 25 and 50 seconds to run through the

viscosity cup. Refer to the chapter on cleaning to see how the Fluid Tip and Fluid Needle can be

removed and switched for a smaller/larger Fluid Tip and Fluid Needle

assembly.

• Fill the Paint Container with the product to be sprayed. Stir well (as mentioned above).

• Screw the Paint Container to the base of the Spray Gun and tighten accordingly.

• Unroll the motor unit air hose and attach it to the back of the Spray Gun.

• Unroll the power cable and attach the plug to the mains supply.

• Switch the Spray Station on. This will immediately cause some air to be produced, which is

quite NORMAL. However, none of the product will be sprayed until the Spray Gun trigger

is pulled.

Very important: when spraying for the first time, we recommend that you always leave the motor

to run for 1 to 2 minutes before applying the product. Do not forget that the Fluid Adjusting Screw

controls the quantity of paint sprayed, for instance the more the Paint Adjusting Screw is tightened

the less paint is sprayed.

4

Page 5

3 spray patterns

SPRAYING TECHNIQUE

US

CLEANING INSTRUCTIONS

By slightly loosening the Air Cap Ring (at the front) you can turn the Air Cap a little

(catch locking system) and obtain 3 different spray patterns: (Fig. 3)

Horizontal and Vertical Spray

Vertical and Horizontal for normal sized jobs

Round Spray

Round for small and precise jobs

The most commonly used technique for painting a wall is the ʻcrisscrossʼ technique, i.e. you apply

the product in horizontal lines and then cross over these lines by applying the product in

vertical lines; (Fig. 4)

1) Adjust the Air Cap to obtain a Vertical spray, then pull the Trigger and move your arm across to

the right.

2) When you get to the end of the line, release the Trigger for a moment and then apply the

product in the opposite direction just beneath the line you have sprayed.

3)Proceed in this manner applying the product in Horizontal lines one underneath the other.

4)Next, adjust the Air Cap to obtain a Horizontal spray and apply the product in horizontal lines

over the lines you have just sprayed.

Release the trigger to avoid overspraying which will cause the product to run.

Cross over the horizontal lines (spayed with a Vertical pattern) with vertical lines (sprayed with a

Horizontal pattern). Only the fore arm must move not the wrist.

Flush out the residue paint from the spray gun, as follows:

Remove the paint container (25) from the spray gun.

Pour any residual paint into its original container for future use.

Use a cloth soaked in thinners to wipe out excess paint from the container, the underside of the

lid (22) & the gasket (23).

Pour a small quantity of clean thinners into the container, re-fit the container to the spray gun

and shake the gun lightly.

Now spray all of the thinners through the gun.

Repeat this, each time using clean thinners, until there is no trace of paint in the thinners

being sprayed.

To thoroughly clean the remainder of the spray gun, remove all working parts as per the

exploded spare parts drawing on p.3 as follows.

Loosen and remove Air Cap Ring (1), Air Cap (2) and Air Distributor Plate & Spring (3).

Now unscrew the Adjusting Screw (12) and pull out the Needle (9) and Needle Spring (11).

Use the supplied spanner, to remove the Fluid Tip (4) and Fluid Tip Seal (5).

All of the components above can be immersed in thinners and cleaned using the cleaning kit

supplied with this product. After cleaning your spray gun and before fitting the needle, dip the tip

into some vaseline which will lubricate the gland washers as the needle is inserted.

The external surfaces of the spray gun can be wiped clean with a cloth soaked in thinners.

• NEVER DISPOSE OF PAINTS OR SOLVENTS DOWN THE DRAIN. ALWAYS USE

YOUR LOCAL WASTE COLLECTION SITE.

5

Page 6

PROBLEM

TROUBLESHOOTING

SPRAY GUN

US

The paint drips onto

item being painted

Paint is too thin or

irregular

No paint being

released

Paint leaking from

the Gland Nut (15) in

front of the Trigger

Too much paint in an

area

Pulverisation

CAUSE ACTION REQUIRED

Paint too diluted Add undiluted paint

Paint output too high Reduce the paint output by

Moving too slowly Increase speed of application

Spray Trigger held for too long Release Trigger sooner

Spray Gun too close Increase the distance between the Spray

Paint too diluted Add undiluted paint

Paint output too low Increase the paint output by

Moving too fast Reduce speed of application

Gun clooged Clean the Spray Gun

Gun too far away Move the Spray Gun closer to the work

Paint too thick Add thinner

Fluid Tip clogged Clean the Fluid tip

Pick-up Tube clogged Clean Pick-up Tube (18)

Air Hose split Replace air Hose (27)

Grainy paint Filter the paint

Container almost empty Refil Paint Container

Spray Gun at an angle Check that the Pick-up Tube is

Air inlet blocked Check the condition of the Filter and

Gland Seal (16) not attached or

the wrong way round or not

tight enough.

Over time the Gland Seal (16)

will wear and need adjusting

You move you wrist Move your fore arm instead

Either too much or not enough

paint

adjusting the Fluid Adjusting Screw (12)

Gun and the work surface

adjusting the Fluid Adjusting Screw (12)

surface

pointing towards the paint (18)

clean if necessary (26 x2)

Reattach the Gland Seal (16) and

retighten Gland Nut. (15)

To check the Gland Nut is

correctly fitted you will need a small ad

justable spanner. Pull the Trigger (17)

back and gradually tighten the gland but

by turning it in a clockwise direction until

the needle is not free to move when the

trigger is released

Use the Fluid Adjusting Screw to control

the flow

6

Page 7

PLEASE NOTE: We have done all we can to ensure that when used correctly and in accordance

MAINS CONNECTION

US

with these instructions the spray gun has a long and fault-free life. We accept no responsibility

for damage caused by the use of incorrect or unsuitable substances, paints or liquids which have

not been thinned correctly or which are not suitable for the surfaces to which they are applied,

health hazards arising from a lack of ventilation when working in confined spaces or equipment

which is faulty due to inadequate cleaning of the components after use. If in doubt, test a small

inconspicuous area first. Always read the manufacturerʼs instructions before use. Neither our

guarantee nor the above statement affects your statutory rights.

Your Spray Station has been supplied with a mains lead which is fitted with a plug.

• If the plug is cut off from the mains lead, it must be disposed of safely. NEVER under

any circumstances insert a plug which is cut off from the mains lead into socket.

We declare that the unit: HV6900 conforms to the standard of motor-operated Air

(ANSI/UL 1450. Third Edition dated 07/01/03, with revision through and including 10/17/07);

and Motor-operated Appliances (Household and Commercial) (CAN/CSA-C22.2 NO:68-92)

EARLEX INC. WILL ACCEPT NO RESPONSIBILITY FOR THE USE OF THIS PRODUCT IF

USED FOR ANY OTHER PURPOSES THAN THOSE DETAILED HEREIN

This product is warranted for a period of 24 months against faulty manufacture and materials. It

is not warranted for industrial or rental purposes. This limited warranty does not affect your

statutory rights. Earlex Inc. will accept no responsibility for the use of this product if used for any

Compressions, Vacuum Pumps and Painting Equipment:

Technical Director, Tim Hopper

All rights reserved © 2010

LIMITED WARRANTY

purposes other than detailed herein.

If you require further assistance, please contact our helpline on

Tel: 704 827 7889 Fax: 704 827 7849

Customer Service: Toll Free 888-783-2612

Website: www.earlex.com Email: service@earlex.com

Earlex Inc, 8261 Hwy 73, Suite F, Stanley, N.C. 28164, USA

7

Page 8

Les substances présentes dans ce pulvérisateur (peinture, dissolvant, etc.) peuvent contenir

CONSIGNES DE SÉCURITÉ

VEUILLEZ LIRE CES CONSIGNES AVANT UTILISATION

LISTE DES PIÈCES

des matières dangereuses, nocives, explosives ou corrosives.

Le pulvérisateur ne doit être utilisé qu'avec des peintures et des solvants ayant un point d'éclair

permettant la pulvérisation. En cas de doute, consulter les informations du fabricant de peinture

ou de solvant.

Toujours s'assurer que la pièce est suffisamment ventilée lors de la pulvérisation.

NE JAMAIS pulvériser près d'une flamme y compris une veilleuse.

NE JAMAIS fumer lors de la pulvérisation.

Toujours débrancher l'alimentation secteur de l'appareil lors du remplissage du réservoir de

peinture

Toujours débrancher l'alimentation secteur de l'appareil lors du nettoyage du pistolet.

Toujours s'assurer que la zone de pulvérisation est sûre et qu'il n'y a pas de débris qui

pourraient présenter un danger d'incendie ou de chute.

Dans aucune circonstance, NE JAMAIS pointer le pistolet vers une personne ou un animal.

En cas de blessure, appelez immédiatement un médecin

NE JAMAIS laisser les enfants ou des personnes non autorisées utiliser ou jouer avec

l'appareil de pulvérisation.

Toujours lire les instructions du fabricant de solvants avant utilisation.

Toujours porter un masque de protection adapté lors de la pulvérisation. Nous recommandons

également de porter des gants, des lunettes et une combinaison.

Après chaque utilisation, s'assurer de bien nettoyer à fond le pistolet pulvérisateur et lubrifier

les garnitures.

N'utiliser que des pièces de rechange certifiées par le fabricant.

Utiliser l'appareil de pulvérisation uniquement comme décrit dans ce mode d'emploi.

Ne pas utiliser le tuyau ou le câble d'alimentation pour tirer l'unité HVLP.

Vérifier les tuyaux, les raccords de tuyaux et le câble d'alimentation tous les jours. Toutes les

pièces usées ou abîmées doivent immédiatement être remplacées.

Cet appareil nʼa pas été conçu pour être utilisé par des personnes (ou des enfants) ayant des

capacités physiques, sensorielles ou mentales réduites, ou présentant un manque dʼexpérience

et de connaissances, excepté si de telles personnes ont été sous surveillance ou ont reçu

des instructions en rapport avec lʼutilisation de lʼappareil par une personne responsable de

leur sécurité.

AVERTISSEMENT : Les substances utilisées avec ce pistolet de pulvérisation (peintures,

solvants, etc.) peuvent contenir des matières dangereuses, nocives, explosives ou

corrosives. RESPECTEZ TOUJOURS LES CONSIGNES DE SÉCURITÉ FOURNIES AVEC CE

PRODUIT ET AVEC LES MATIÈRES UTILISÉES.

CARACTERISTIQUES TECHNIQUES :

Puissance : 1100 watts Capacité du réservoir : 1 litre

Tension : 120 V (60hz) Longueur du tuyau dʼair : 4.5 m

Débit dʼair : 22 litres/sec Pression dynamique d'air : 0.30 bar

Niveau de pression sonore : 88 dB(A)

Viscosité maximum : 250 DIN/sec (100 DIN/sec pour le réservoir arrière)

Fig.1

N° Description

1. Bague de fixation du chapeau d'air L0151

2. Chapeau d'air L0517

3. Ensemble rondelle d'orientation de l'air L0162

4. Buse de 0,08" (2,03 mm) L0157

5. Joint de la buse L0159

6. Vis de l'axe L0179

7. Joint L0195

8. Ensemble central L0180

9. Aiguille d'injection de 0,08" (2,03 mm) L0166

10. Adaptateur L0174

11. Ressort L0175

12. Vis de réglage L0176

13. Axe L0178

14. Tube d'alimentation en air L0182

N° Description

15. Écrou de presse-étoupe L0173

16. Joint de presse-étoupe (2 pièces) L0168

17. Levier de commande L0177

18. Ensemble tube plongeur & boulon

central L0183

19. Étrier L0184

20. Levier de blocage L0185

21. Cale L0186

22. Ensemble du couvercle L0187

23. Joint statique L0188

24. Écrou central L0189

25. Réservoir de peinture L0190

26. Filtre (x2) N0087

27. Assemblage tuyau N0212

8

Page 9

12

1

2

3

4

5

6

7

8

9

10

11

12

7

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

(x2)

VUE ÉCLATÉE DES PIÈCES DÉTACHÉES

DIAGRAMMES

Fig. 1

Fig. 3

Jet Vertical

Jet Horizontal

Fig. 2

9

Jet Circulaire

Fig. 4

.Relâchez la gâchette à la

fin de chaque mouvement

de pulvérisation pour

éviter les excès de peinture

et la formation de gouttes.

Page 10

Principe

INTRODUCTION

PRÉPARATION

Un moteur génère un haut volume dʼair (HV) et permet de pulvériser la peinture à basse pression

(LP). Un volume d'air important entoure le produit qui sort de la buse du pistolet de pulvérisation

sous une pression très faible (0,18 bar). Lʼair généré par le moteur donc conduit au pistolet de

pulvérisation par le tuyau.Ce puissant moteur de turbine peut appliquer une large gamme de

peintures. Néanmoins, il existera toujours certaines peintures qui ne seront pas compatibles avec

le pistolet de pulvérisation.

Assurez-vous toujours que la peinture que vous achetez peut être diluée. Les peintures de bonne

qualité contiennent, entre autre, un pourcentage élevé de particules sèches permettant une

dilution. Ceci nʼest pas le cas de certains produits dʼentrée de gamme, qui ne sont pas vraiment

adaptés à la dilution. Les utilisateurs doivent également garder à lʼesprit que les basses températures rendent la peinture moins lisse. Nous recommandons donc de pulvériser de la peinture avec

le pistolet à une température d'au moins 15 °C

.

• Protégez bien les zones ne devant pas être peintes à lʼaide dʼune bâche en plastique et

dʼadhésif de masquage.

• Portez un masque adapté (et veillez à ce que la ventilation soit suffisante dans la pièce si

vous travaillez à lʼintérieur).

• Nettoyez la surface à peindre. Celle-ci doit être non seulement propre mais sèche et lisse

• Entraînez-vous au préalable sur de vieilles planches de bois pour vous assurer de la bonne

prise en main du pistolet.

• Nous recommandons de porter des vêtements de protection

• Assurez-vous que la peinture ne comporte pas de particules solides.

• De nombreux produits peuvent être pulvérisés sans être dilués. Toutefois, si lʼapplication

n'est pas bonne, diluez le produit progressivement, par paliers de 5 %.

• La plupart des peintures peuvent être pulvérisées en étant diluées légèrement, par exemple

à 5 % ou 10%.

• Certaines peintures épaisses comme les peintures murales dʼextérieur et certaines

sous-couches devront être diluées à 20 % ou 25 %.

• Utilisez de lʼeau pour diluer les produits à base dʼeau.

• Utilisez un diluant synthétique pour diluer les peintures à base de solvant.

• Certains fabricants indiqueront sur le pot si un diluant spécifique doit être utilisé.

La viscosité, exprimée en DIN/sec, correspond à la durée nécessaire pour que la peinture sʼarrête

de couler en débit continu, en passant dans la coupe de viscosité (Fig 2). Votre station de peinture

6900 est fournie en étant équipée dʼune buse et dʼun pointeau de 2,0 mm. Ceci sʼapplique aux

produits dont la viscosité est comprise entre 20 et 50 DIN/sec, cʼest-à-dire prenant 20 à 50 secondes pour traverser le godet de viscosité. Consultez le chapitre relatif au nettoyage pour savoir

comment retirer la buse et le pointeau, et installer un ensemble buse / pointeau plus petit ou plus

large. Remuez bien.

• Vissez le réservoir sur la base du pistolet et serrez correctement.

• Déroulez le tuyau dʼair de lʼunité moteur et raccordez-le à l'arrière du pistolet.

• Déroulez le cordon dʼalimentation et branchez-le dans la prise secteur.

• Mettez la station de peinture en marche.

• Ceci déclenchera immédiatement la production dʼair, ce qui est NORMAL. Cependant, au

cune pulvérisation de produit nʼaura lieu avant d'avoir appuyé sur la gâchette.

Très important: nous vous recommandons de toujours laisser le moteur tourner pendant 1 à 2

minutes avant d'appliquer la peinture Ne pas oublier que la vise du réglage du débit contrôle la

quantité de produit pulvérise, plus vous la resserrez, plus le débit et faible et inversement plus

vous lʼouvrez plus le débit sera important Veillez à ce que la position du tube plongeur soit cohérente avec la façon dont vous tenez le pistolet Par exemple si vous peignez au sol veillez a ce

que le tube plongeur soit oriente vers le sol.

10

Page 11

3 formes de pulvérisation

TECHNIQUE DE PULVÉRISATION

NETTOYAGE

En dévissant un peu lʼanneau de réglage (à lʼavant), vous pouvez tourner légèrement le chapeau

dʼair (système de calage des crans) et obtenir 3 formes de pulvérisation différentes: (Fig 3)

Horizontal et Vertical

Horizontal et Vertical pour les travaux classiques

Jet Rond

Pour les travaux de precision

La technique la plus couramment utilisée pour peindre un mur est la technique des « passages

croisés », cʼest-à-dire en appliquant le produit sous forme de lignes horizontales et ensuite en

croisant ces lignes par des passages verticaux; (Fig 4)

1) Réglez le chapeau dʼair de façon à obtenir un jet vertical, puis appuyez sur la gâchette et dé

placez votre bras sur la droite.

2) Lorsque vous arrivez en bout de ligne, relâchez brièvement la gâchette et appliquez ensuite le

produit dans lʼautre sens, juste en dessous de la ligne que vous venez de pulvériser.

3) Procédez de la même manière pour appliquer le produit sous forme de lignes horizontales, les

unes en dessous des autres.

4) Ensuite, réglez le chapeau dʼair pour obtenir un jet horizontal et appliquez le produit en une

succession de lignes horizontales par-dessus celles que vous venez de pulvériser.

Relâchez la gâchette en bout de course pour éviter tout risque de surcharge

et donc de coulure.

Croisez les lignes horizontales (pulvérisation à jet vertical) avec des lignes verticales

(pulvérisation à jet horizontal).

Faites sortir les résidus de peinture du pistolet comme suit:

Retirer le réservoir de peinture (25) du pistolet.

Reversez l'excédent éventuel de peinture dans son pot pour des travaux ultérieurs.

Utilisez un linge imbibé de diluant pour retirer l'excédent de peinture du réservoir, de la face

inférieure du couvercle (22) et du joint (23).

Versez un peu de diluant dans le réservoir, replacez le réservoir sur le pistolet et secouez

légèrement le pistolet.

Pulvérisez maintenant tout le produit diluant dans le pistolet.

Répétez cette opération en utilisant un produit diluant à chaque fois jusqu'à ce qu'aucune trace

de peinture ne soit pulvérisée.

Afin de pulvériser le reste du pistolet, retirer toutes les pièces travaillantes comme montré sur le

schéma décomposé des pièces détachées page 3 comme suit:

Dévisser et retirer l'anneau de chapeau d'air (1), le chapeau d'air (2), le disque d'orientation du

jet et le ressort (3).

Dévisser maintenant la vis de réglage (12) et retirer le pointeau (9) et le ressort du pointeau (11).

Utilisez la clé fournie pour retirer la buse (4) et le joint de la buse (5).

Tous les composants mentionnés ci-dessous peuvent être plongés dans un produit diluant et nettoyés à l'aide du kit de nettoyage fourni avec ce produit. Après avoir nettoyé votre pistolet et avant

de mettre en place le pointeau, plongez le bout dans de la vaseline, ce qui va lubrifier les rondelles

d'écrou de garniture lors de l'insertion du pointeau.

Les surfaces externes du pistolet peuvent être nettoyées avec un linge imbibé de produit diluant.

NE JAMAIS JETER LA PEINTURE OU LES PRODUITS DILUANTS DANS VOS CANALISATIONS.

CONTACTEZ LA MAIRIE DE VOTRE COMMUNE POUR ORGANISER UNE COLLECTE OU POUR

COLLECTE LE PLUS PROCHE.

11

Page 12

PROBLÈME CAUSE ACTION REQUISE

DÉPANNAGE

PISTOLET DE PULVÉRISATION

La peinture goutte

sur lʼobjet peint

La peinture est

trop liquide

ou irrégulière

Pas de

pulvérisation de

peinture

Fuite de peinture

au niveau

de lʼécrou de

presse-étoupe

(15) devant la

gâchette

Application non

uniforme

Application Ou bien trop ou bien pas

Peinture trop diluée Rajoutez de la peinture non diluée

Débit de peinture trop élevé Réduisez le débit de peinture en ajustant la

Mouvement trop lent Augmentez la vitesse

Appui trop long de la gâchette Relâchez la gâchette plus tôt

Pistolet trop près Augmentez la distance entre le pistolet et la

Peinture trop diluée Rajoutez de la peinture non diluée

Débit de peinture trop faible Augmentez le débit de peinture en ajustant

Déplacement trop rapide Réduisez la vitesse d'application

Pistolet obstrué Nettoyez le pistolet

Pistolet trop éloigné Rapprochez le pistolet de la surface à

Peinture trop épaisse Ajoutez du diluant

Buse obstruée Nettoyez la buse

Tube dʼalimentation obstrué Nettoyez le tube dʼalimentation (18)

Tuyau d'air fissuré Remplacez le tuyau d'air (27)

Peinture granuleuse Filtrez la peinture

Réservoir pratiquement vide Remplissez le réservoir

Pistolet de biais Vérifiez que le tube

Arrivée dʼair obstruée Vérifiez l'état du filtre et

Avec le temps, le joint de

presse- étoupe (5) sʼusera

et devra être ajusté

Attachez le joint de

presse-étoupe (5) à nouveau

et resserrez lʼécrou de

presse-étoupe.

Vous bougez votre poignet Seul lʼavant bras doit bouger

assez de peinture

vis de réglage (12)

d'application

surface à pulvériser

la vis de réglage (12)

pulvériser

dʼalimentation est orienté vers la peinture

(14)

nettoyez-le si nécessaire (26 x2)

Attachez le joint de presse-étoupe (5) à

nouveau et resserrez lʼécrou de presseétoupe.(15)

Pour vérifier que lʼécrou de presse-étoupe

est fixé correctement, vous aurez besoin

d'une petite clé réglable.

Tirez la gâchette (17) en arrière et resser

rez lʼécrou progressivement en tournant

dans le sens des aiguilles dʼune montre,

jusquʼà ce que le pointeau ne puisse plus

bouger après avoir relâché la gâchette.

Utilisez la vise de réglage du débit afin

dʼajuster le débit de peinture

12

Page 13

VEUILLEZ NOTER : Nous avons fait tout notre possible pour nous assurer que ce

RACCORDEMENT AU SECTEUR

pistolet pulvérisateur fonctionnera longtemps et sans problèmes, dans le cadre d'une

utilisation conforme à ces instructions. Nous déclinons toute responsabilité en cas de

dommages dus à une utilisation de substances, peintures ou liquides inadaptés ou mauvais,

non dilués correctement ou ne convenant pas aux surfaces sur lesquelles ils sont appliqués, en

cas de danger pour la santé suite au manque d'aération lors de travaux dans un espace confiné,

ou en cas de panne du matériel suite à un mauvais nettoyage des pièces après utilisation. En

cas de doute, faites toujours un test préalable sur une petite zone non visible. Lisez toujours les

instructions du fabricant avant utilisation. Notre garantie et la déclaration ci-dessus nʼaffectent

pas vos droits statutaires.

Votre station de peinture a été fournie avec un cordon dʼalimentation secteur équipé dʼune prise.

• Si la prise est coupée du cordon dʼalimentation, elle doit être mise au rebut en toute sécurité.

Nʼinsérez JAMAIS, et ce en aucun cas, une prise coupée du cordon dʼalimentation dans

une prise secteur.

Declaramos que la unidad: HV6900 se adecua a the standard of motor-operated Air

(ANSI/UL 1450. Third Edition dated 07/01/03, with revision through and including 10/17/07);

and Motor-operated Appliances (Household and Commercial) (CAN/CSA-C22.2 NO:68-92)

EARLEX INC. NE SAURAIT ÊTRE RESPONSABLE POUR L'UTILISATION DE CE PRODUIT

S'IL EST UTILISÉ POUR D'AUTRES USAGES QUE CEUX DÉCRITS DANS CE MANUEL

Ce produit est garanti pour une période de 24 mois contre les défauts de fabrication ou de

matériaux. Il n'est pas garanti pour une utilisation industrielle ou pour la location. Cette garantie

n'affecte pas vos droits statutaires. Earlex Inc. Ne saurait être responsable pour l'utilisation de ce

produit s'il est utilisé pour d'autres usages que ceux décrits dans ce manuel.

Si vous avez besoin d'une assistance supplémentaire, veuillez contacter notre ligne de service

Compressions, Vacuum Pumps and Painting Equipment:

Tim Hopper, Directeur Technique

Tous Droits Réservés © 2010

GUARANTIE

clients au Tel: 704 827 7889 Fax: 704 827 7849

Service clients: Appel gratuity: 888-783-2612

Site web: www.earlex.com Email: service@earlex.com

Earlex Inc, 8261 Hwy 73, Suite F, Stanley, N.C. 28164, USA

13

Page 14

Las sustancias utilizadas con este aplicador de spray (pintura, disolventes, etc.) pueden

INSTRUCCIONES DE SEGURIDAD

LEA ESTAS INSTRUCCIONES ANTES DE UTILIZAR EL APARATO

LISTADO DE PIEZAS

contener materiales peligrosos, nocivos, explosivos o corrosivos SIGASIEMPRE LAS

El aplicador de spray debe ser utilizado solamente con pinturas y disolventes que tengan un punto

de inflamación adecuado para la pulverización. En caso de duda, consulte la información

proporcionada por el fabricante de la pintura o el disolvente.

Asegúrese siempre de que la habitación tiene una ventilación adecuada cuando aplique el spray.

No pulverice NUNCAcerca de fuego abierto, incluidos dispositivos con llama de encendido.

No fume NUNCAmientras esté pulverizando.

Desconecte siempre la unidad de la red eléctrica cuando rellene el tanque de pintura.

Desconecte siempre la unidad de la red eléctrica cuando limpie el aplicador de spray.

Asegúrese siempre de que el área a pulverizar es segura y está libre de residuos que puedan

provocar riesgo de incendio o tropiezos.

NUNCA, bajo ninguna circunstancia, debe apuntar con la pistola pulverizadora a una persona o

animal. En el caso de que se produzca un accidente con lesiones, acuda a la consulta de un médico

inmediatamente.

No deje NUNCAqueniñoso personasno autorizadas usen o jueguenconel equipo de pulverización.

Lea siempre las instrucciones del fabricante para el rebajado de la pintura antes de utilizarla.

Lleve siempre una mascarilla adecuada cuando efectúe la pulverización. También recomen damos el

uso de guantes, gafas y mono de trabajo.

Después de cada utilización asegúrese de limpiar la pistola pulverizadora a fondo y lubricar las

rondanas.

Use solamente piezas de recambio originales del fabricante.

Use esta unidad solamente del modo detallado en las instrucciones.

No utilice el tubo flexible de vacío o el cable de alimentación de red para arrastrar la unidad HVLP.

Compruebe los tubos, los conectores de los tubos y el cable de alimentación de red a diario.

Cualquier parte desgastada o deteriorada debe ser sustituida de forma inmediata.

Este dispositivo no ha sido diseñado para el uso de personas (niños incluidos) con discapacidad

física, sensorial o intelectual; o que no dispongan de una experiencia o conocimiento suficientes,

salvo que reciban supervisión o formación respecto a su uso, por parte de una persona al

cargo de su seguridad.

ATENCIÓN: Las sustancias que se utilizan con esta pistola de pulverización (pinturas,

disolventes, etc.) pueden contener materiales peligrosos, perjudiciales, explosivos o

corrosivos. CUMPLA SIEMPRE LAS INSTRUCCIONES DE SEGURIDAD QUE ACOMPAÑAN A ESTE

PRODUCTO Y LAS DE LOS MATERIALES QUE UTILICE.

Utilice la unidad exclusivamente como se indica en este manual.

ESPECIFICACIONES TÉCNICAS:

Consumo: 1100 W Capacidad del depósito: 1 litros

Voltaje: 120 V (60hz) Longitud de la manguera del aire: 4.5 m

Caudal de aire: 22 litros / segundo Presión dinámica del aire: 0.30 bar

Nivel de ruido: 88 dB (A)

Viscosidad máxima: 250 segundos DIN

Fig.1

Nº Descripción Pieza Nº

1. Anillo del soporte de boquilla de aire L0151

2. Soporte de boquilla de aire L0517

3. Ensamblaje de placa de dirección

de aire L0162

4. Boquilla de fluido (2,0 mm) 0,08” L0157

5. Sello de la boquilla de fluido L0159

6. Tornillo de pivote L0179

7. Arandela L0195

8. Ensamblaje del cuerpo principal L0180

9. Aguja de fluido (2.0 mm) 0,08” L0166

10. Adaptador L0174

11. Muelle L0175

12. Tornillo de ajuste L0176

13. Pivote L0178

14. Tubo de alimentación de aire L0182

Nº Descripción Pieza Nº

15. Tuerca del prensaestopast L0173

16. Rondana (2 piezas) L0168

17. Palanca de control L0177

18. Ensamblaje de tubo recogedor y

perno de centrado L0183

19. Horquilla L0184

20. Palanca de fijación L0185

21. Calce L0186

22. Ensamblaje de la tapa L0187

23. Junta L0188

24. Tuerca del perno de centrado L0189

25. Contenedor de pintura L0190

26. Medio filtrante N0087

27. Cable de alimentación N0212

14

Page 15

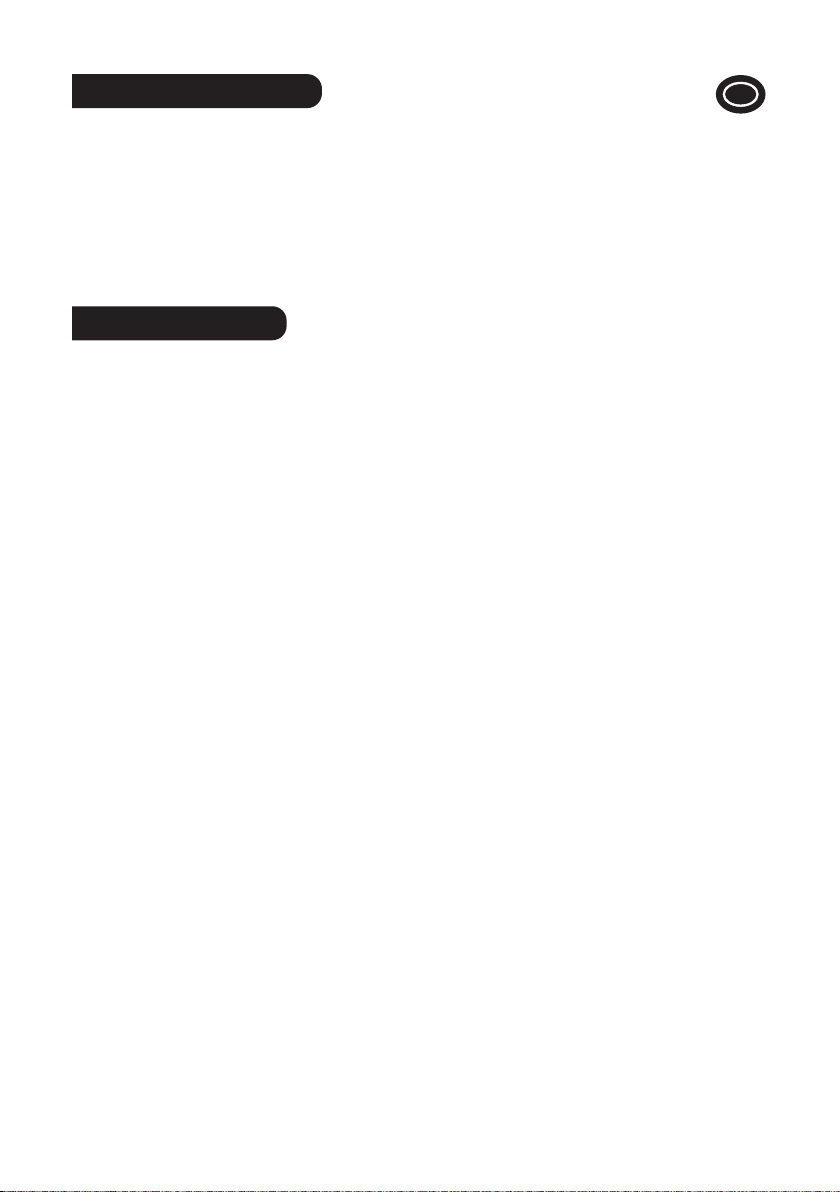

Interruptor

principal

(120V)

Energía adentro

(Conectador IEC)

Disyuntor

1

2

3

4

5

6

7

8

9

10

11

12

7

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

(x2)

DIAGRAMA DE DESPIECE

DIAGRAMAS

Fig. 1

Fig. 2

Fig. 3

Chorro vertical

Chorro Horizontal

15

Chorro circular

Fig. 4

Suelte el gatillo al final de cada

movimiento de pulverización

para evitar el exceso de pintura

y los goteos

Page 16

Concepto

INTRODUCCIÓN

PREPARACIÓN

Un motor impulsa un gran caudal de aire (HV) que proyecta el producto que se va a pulverizar a

baja presión (LP). El producto sale por la boquilla de fluido de la pistola de pulverización a muy

baja presión (0,18 bar), envuelto en un gran caudal de aire. La manguera conduce el aire

producido por el motor hasta la pistola de pulverización.

El potente motor puede pulverizar una amplia gama de pinturas, con o sin diluyentes. Sin embargo, siempre habrá alguna pintura que no resulte adecuada para la pistola. Las pinturas de

buena calidad contienen un alto porcentaje de partículas secas que facilitan su dilución. El

usuario debe tener en cuenta que las bajas temperaturas espesan la pintura, por lo que le recomendamos que utilice la pistola de pulverización a una temperatura mínima de 15 ºC.

• Cubra cuidadosamente con plástico y cinta protectora las superficies que no desee pintar.

• Utilice una máscara apropiada cuando pulverice productos con base de disolvente (y si

trabaja en interiores, asegúrese de que la ventilación sea la adecuada).

• Limpie la superficie que vaya a pintar. Además de limpia, tiene que estar seca y lisa.

• Haga pruebas sobre alguna plancha vieja de madera para asegurarse de que utiliza

correctamente la pistola de pulverización.

• Le recomendamos que utilice ropa protectora.

• Bata la pintura, si es posible con un mezclador.

• Asegúrese de que no queden grumos en la pintura.

• Muchos productos se pueden pulverizar sin diluir. Sin embargo, si al aplicarlo el producto no

queda bien, pruebe a diluirlo progresivamente añadiendo un 5 % de diluyente cada vez.

• La mayoría de las pinturas se pueden pulverizar a poco que se diluyan (por ejemplo, entre un

5 % y un 10 %).

• Algunas pinturas espesas, como las de exteriores o algunas pinturas de base, necesitan

diluirse entre un 20 % y un 25 %.

• Utilice agua para diluir los productos acrílicos.

• Utilice aguarrás para diluir las pinturas sintéticas (con base de disolvente).

• Algunos fabricantes indican en sus productos si se debe utilizar algún diluyente en concreto.

La viscosidad, que se expresa en segundos DIN, es el tiempo que tarda la pintura en dejar de

salir del vaso de viscosidad como un chorro continuo (Fig 2). La unidad 6900 trae instalada una

boquilla de fluido y una aguja de 2,0 mm. Esto afecta a los productos con una viscosidad de entre

25 y 50 segundos DIN, es decir, que tarden entre 25 y 50 segundos, en atravesar el vaso de

viscosidad. Consulte el apartado de limpieza para saber cómo quitar la boquilla de fluido y la

aguja y sustituirlas por un conjunto mayor o menor de boquilla de fluido y aguja. Llene el depósito

con el producto que vaya a pulverizar.

• Bátalo bien (según se indica anteriormente).

• Sujete el depósito a la base de la unidad con los tornillos y apriételos pertinentemente.

• Desenrolle la manguera del aire del motor y conéctela a la parte posterior de la pistola de

pulverización.

• Desenrolle el cable de alimentación y enchufe la clavija a una toma de corriente.

• Ponga en marcha la unidad. Es normal que se produzca inmediatamente un poco de aire. Sin

embargo, no se pulverizará nada de producto hasta que se presione el gatillo.

Muy importante: Cuando vaya a pulverizar por primera vez, le recomendamos que siempre deje

funcionar el motor durante 1 o 2 minutos antes de empezar a aplicar el producto.

No se olvide de que el tornillo regulador de fluido controla la cantidad de pintura pulverizada.

Por ejemplo, cuanto más apretado esté el tornillo, menos pintura se pulveriza.

16

Page 17

TÉCNICA DE PULVERIZACIÓN

INSTRUCCIONES DE LIMPIEZA

Tres patrones de pulverización

Si afloja levemente el regulador del capuchón del aire (en la parte delantera), podrá girar un poco

el capuchón (sistema de anclaje por pasos) y disponer de tres patrones de pulverización distintos:

(Fig. 3)

Horizontal o Vertical

Trabajos normales con el patrón horizontal o vertical

Precisos

Trabajos pequeños y precisos

La técnica más habitual para pintar una pared es el «entrecruzado», que consiste en aplicar el

producto en franjas horizontales y luego repetir la operación con franjas verticales; (Fig 4)

1) Ajuste el capuchón del aire a la posición de pulverización vertical. Pulse el gatillo y mueva el

brazo de izquierda a derecha.

2) Cuando llegue al borde de la superficie, suelte el gatillo un momento y luego aplique el

producto en dirección contraria, justo por debajo de la franja que acabe de pintar.

3) Siga aplicando el producto en líneas horizontales, cada una justo por debajo de la anterior.

4) A continuación, ajuste el capuchón del aire en posición de pulverización horizontal y aplique el

producto en franjas horizontales sobre las que acabe de pintar.

Suelte el gatillo para evitar la dispersión del producto y los goterones.

Cubra las franjas horizontales (pulverizadas con el atrón vertical) con franjas verticales

(pulverizadas con el patrónhorizontal). Mueva sólo el antebrazo, no la muñeca.

Limpie los residuos de pintura de la pistola pulverizadora del modo siguiente:

Retire el contenedor de pintura (25) de la pistola pulverizadora.

Vierta todo el residuo de pintura en su contenedor original para utilizarlo en el futuro

Use un paño empapado en diluyente para eliminar el exceso de pintura del contenedor, la cara

inferior de la tapa (22) y l a junta (23).

Vierta una pequeña cantidad de diluyente limpio en el contenedor, vuelva a ajustar el contene

dor a la pistola pulverizadora y agite suavemente la pistola

Pulverice todo el diluyente con le pistola

Repita esta operación, usando cada vez diluyente limpio, hasta que no quede ningún rastro de

pintura en el diluyente que se está pulverizando

Para limpiar a fondo la resta de la pistola pulverizadora, saque todas las partes operantes, de

acuerdo con el esquema de piezas de recambio de la p. 3, del siguiente modo:

Afloje y saque el anillo del soporte de la boquilla de aire (1),el soporte de la boquilla de aire (2)

y el muelle y la placa del distribuidor de aire (3).

Desatornille el tornillo de ajuste (12) y saque la aguja (9) así como el muelle de la aguja(11).

Use la llave de tornillos suministrada para sacar la boquilla de fluido (4) y el sello de la boquilla

de fluido (5).

Todos los componentes mencionados arriba pueden ser sumergidos en diluyentes y limpiados

mediante el kit de limpieza suministrado con este producto. Después de limpiar la pistola

pulverizadora y antes de colocar la aguja, sumerja la boquilla en vaselina, lo que lubricará las

arandelas del prensaestopas al insertar la aguja.

Las superficies externas de la pistola pulverizadora pueden ser limpiadas con un paño empapado

en diluyente.

NO TIRE NUNCA POR EL DESAGÜE PINTURA O DISOLVENTE . PÓNGASE EN CONTACTO

CON EL AYUNTAMIENTO LOCAL PARA ORGANIZAR SU RECOGIDA O PARA SABER LA

UBICACIÓN DEL VERTEDERO DE RESIDUOS REGISTRADO MÁS CERCANO.

17

Page 18

PROBLEMA

RESOLUCIÓN DE PROBLEMAS

PISTOLA PULVERIZADORA

La pintura gotea

en la superficie

que se está

pintando

La capa de pintura

es demasiado fina

o irregular

No sale pintura

Fugas de pintura

por la tuerca del

prensaestopas

(15) por delante

del gatillo

Demasiada pin

tura en una zona

Pulverización

CAUSA SOLUCIÓN

Pintura demasiado diluida Añada pintura sin diluir

Sale demasiada pintura Reduzca la salida de pintura con

Se está moviendo usted demasiado

despacio

Gatillo pulsado demasiado tiempo Suelte antes el gatillo

Pistola demasiado cerca de la superficie Póngase más lejos de la

Pintura demasiado diluida Añada pintura sin diluir

Sale poca pintura Aumente la salida de pintura con

Se está moviendo usted demasiado

deprisa

Pistola obstruida Limpie la pistola

Pistola demasiado lejos de la

superficie

Pintura demasiado espesa Añada diluyente

Boquilla de fluido obstruida Limpie la boquilla de fluido

Manguera de producto obstruida Limpie la manguera de producto

Manguera de aire agrietada Cambie la manguera del aire

Pintura con grumos Filtre la pintura

Depósito casi vacío Rellene el depósito

Pistola en ángulo incorrecto Compruebe que la manguera

Entrada de aire bloqueada Compruebe el estado del filtro y

Junta del prensaestopas (5) no sujeta,

mal colocada o sin apretar lo suficiente.

A lo largo del tiempo la junta del pren

saestopas (5) se desgasta y necesita rea

justes

Está moviendo usted la muñeca Mueva sólo el antebrazo

O demasiada o demasiado poca pintura Ajuste el caudal con el tornillo

el tornillo regulador (12)

Pinte más deprisa

superficie

el tornillo regulador (12)

Pinte más despacio

Póngase más cerca de la

superficie

del aire apunta hacia la pintura

(18)

límpielo si es preciso (26 x2)

Recoloquelajuntadel

prensaestopas(5)y reapriete la

tuerca.Paracomprobarquela

tuerca delprensaestopasestá bien

colocada necesitaráuna llave in

glesa pequeña. Retireelgatillo(17)

y apriete gradualmentela tuerca del

prensaestopasgirándolade

izquierdaa derecha hasta quela

aguja nose puedamover cuando

se suelte el gatillo.

regulador de fluido

18

Page 19

ATENCIÓN: Si sigue las instrucciones de uso y utiliza el producto correctamente, la

CONEXIÓN A LA RED ELÉCTRICA

pistola de pulverización funcionará sin problemas durante mucho tiempo. No nos

hacemos responsables de los daños causados por el uso de sustancias incorrectas o

inadecuadas, pinturas o fluidos mal diluidos o inadecuados para las superficies en que se

aplican, riesgos para la salud deriva dos de una ventilación insuficiente al trabajar en espacios

reducidos o fallos del equipo debidos a una limpieza inadecuada o insuficiente de sus

componentes tras su uso. En caso de duda, haga primero una prueba sobre un área pequeña y

poco visible. Antes de nada, lea las instrucciones del fabricante de la pintura. Ni nuestra garantía

ni las estipulaciones anteriores afectan a sus derechos legales.

La unidad se suministra con un cable de alimentación que lleva una clavija.

• Si la clavija se desprende del cable, debe tirar el cable por seguridad. NO introduzca NUNCA

en un enchufe, bajo ningún concepto, una clavija cortada del cable de alimentación.

Declaramos que la unidad: HV6900 se adecua a the standard of motor-operated Air

(ANSI/UL 1450. Third Edition dated 07/01/03, with revision through and including 10/17/07);

and Motor-operated Appliances (Household and Commercial) (CAN/CSA-C22.2 NO:68-92)

EARLEX INC. NO SE HARÁ RESPONSABLE DEL USO DE ESTE PRODUCTO PARA

PROPÓSITOS DIFERENTES A LOS DETALLADOS EN LAS PRESENTES INSTRUCCIONES.

Este producto está garantizado durante un periodo de 24 meses contra materiales defectuosos

o defectos de fabricación. No se garantiza si se hace un uso industrial o se alquila. La garantía

no afecta sus derechos estatutarios. Earlex Inc. no se responsabilizará del uso de este pro-

ducto si se usa para propósitos diferentes a los detallados en las presentes instrucciones.

Si necesita ayuda, contacte con nuestro servicio de atención al cliente en el

Servicio de atención al cliente: Línea gratuita de atención al cliente 888-783-2612

Compressions, Vacuum Pumps and Painting Equipment:

Tim Hopper - Director Técnico

Copyright y derechos de diseño reservados © 2010

GARANTÍA

Tel. 704 827 7889 Fax: 704 827 7849

Sitio Web: www.earlex.com Email: service@earlex.com

Earlex Inc, 8261 Hwy 73, Suite F, Stanley, N.C. 28164, USA

19

Page 20

© 2010 Earlex Ltd. N0227 08/10

Loading...

Loading...