Page 1

Instruction Manual for the Data Recorder Electric Expander

Document Version 3.0

Model # CDR-ECV, CDR-ECV140, CDR-ECV300

Thank you for your purchase! This instruction manual will guide you through the installation and operation of

your Data Recorder Electric Expander. Please read the entire manual carefully before proceeding. If, after you

read the manual (including the Troubleshooting section!!), you have further questions or problems, see the Support

page on http://www.eagletreesystems.com for additional information, or email us at

support@eagletreesystems.com.

If you have purchased a Secondary or Tertiary Electric Expander, allowing up to three Electric Expanders to

be used simultaneously, please refer to the Secondary Expander instructions for additional information, after

reading the instructions below.

WARNING: High Voltages can cause electric shock. Be extremely careful when

working with high voltage packs! Work with High Voltages at your own risk!

Packing List

Your package should include the following: Electric Expander (standard 100 amp, or larger 140 amp or 300 amp sensors), and a

printed version of this manual. Please check your box for printed addenda to this manual which may be included if changes were

made after printing.

How the Electric Expander Works

The Electric Expander is compatible with our Flight Data Recorder V2/Pro, all Seagull systems, Car Data Recorder, and Boat Data

Recorder products. It is not compatible with our original Flight Data Recorder V1 product.

The Electric Expander works with your Data Recorder to

measure motor battery pack voltage and current. The

Expander measures current by means of a tiny,

lightweight hall effects current sensor ring. Battery

pack voltage is measured by the alligator clip attached to

the expander. NOTE: a common ground between your

battery pack and the Recorder is required for the voltage

measurement to work correctly.

Connecting the Electric Expander

to the Recorder

Note: If you have a Secondary or Tertiary Electric

Expander, please refer to the Secondary Expander

instructions for plugging in your Expander to the

Recorder.

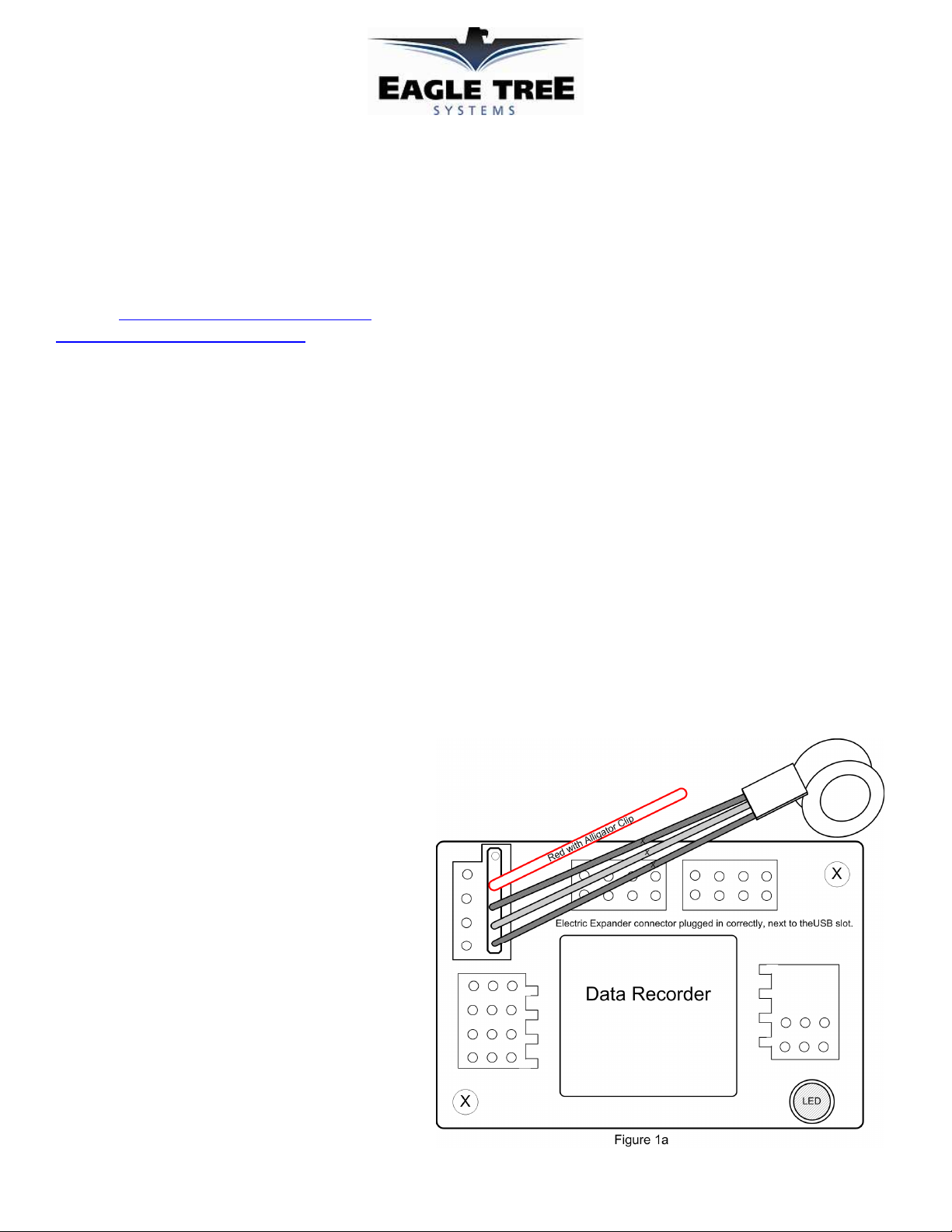

Connect the polarized, 5 pin Electric Expander connector

to the recorder as shown in Figure 1a. NOTE: The plug

is a tight fit – slightly tilting the 5 pin connector back

toward the center of the Recorder can aid installation. If

Copyright © 2003-2010 Eagle Tree Systems, LLC

http://www.eagletreesystems.com

Page 2

Page

2

you still have problems fitting it, you might need to lightly sand the top of the connector (nearest the red wire) with sandpaper, but this

should not be necessary.

EXTREMELY IMPORTANT:

The Electric Expander Connector **MUST** be connected correctly

to your Recorder, or severe damage to the Recorder and other equipment could occur, which will void the

warranty. The Expander connects as shown in Figure 1A, to the right of the USB connector, with the RED wire of

the connector facing UP. If you are uncertain as to how to connect the expander, don’t hesitate to email us at

support@eagletreesystems.com!

Connecting the Electric Expander to Your Battery

To measure current the hall effects current sensor ring can be installed around either the positive or negative wire leading from your

battery to your speed controller. It works through the wire’s insulation, and hence no cutting of the wire is necessary. It can be

installed facing either direction, as it is not polarized.

The alligator clip is for measuring battery pack voltage. It should be attached to an exposed part of the positive (normally red) battery

wire or terminal between the battery and the speed controller. It must be in direct electrical contact with the positive battery wire.

Alternatively, the alligator clip can be removed and soldered to the wire leading to the ESC for a more permanent installation.

If an easily removable installation is desired, one convenient way to do this is to have a removable wire “section” with Deans or other

plugs on either end (male/female). Both the current and voltage leads of the Electric Expander can attach to this wire section (the

alligator clip is normally cut off and the voltage wire soldered), and the section can be removed easily from the model when electric

measurement is not desired.

ESCs with isolation between BEC/Throttle ground and Main Battery Ground

Note that there must be electrical conductivity between the ground wire of your main battery and the Recorder’s internal ground, for

voltage measurement to work correctly. Normally, when the Recorder is connected to your receiver via one or more of the

Recorder’s servo connections, the

ground wire of the ESC’s BEC/Throttle

output results in the correct grounding.

However, some ESCs isolate battery

ground from the ESC/BEC throttle

output ground. The easiest way to tell

if there is ground isolation is, with

everything disconnected from your

ESC, to measure the resistance between

the main battery negative input of the

ESC, and the BEC/Throttle ground

wire. If the resistance is greater than an

ohm or two, there is isolation.

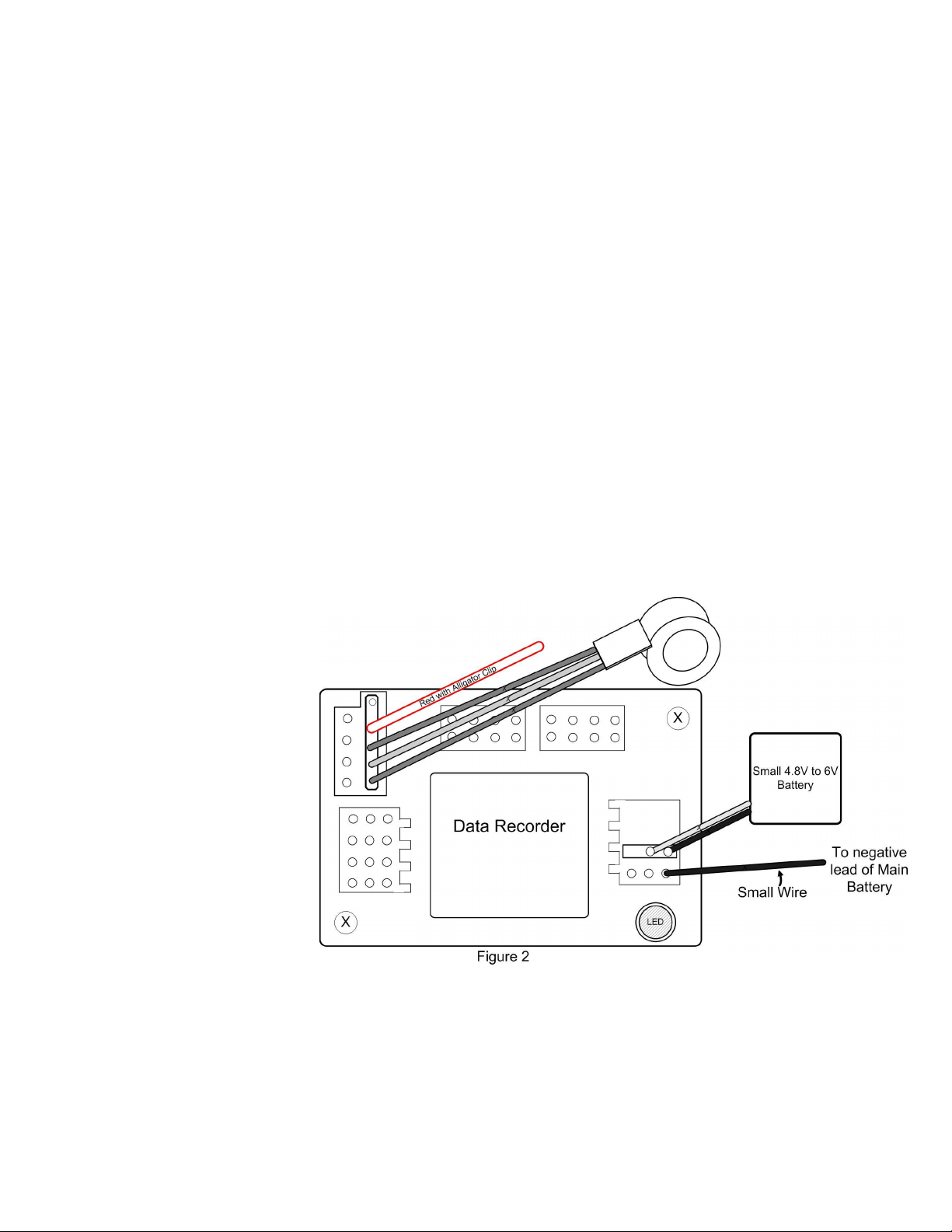

In these cases, for the Recorder to

measure voltage correctly, the

recorder’s ground must be connected to

the ground of the battery to be

measured.

There are two ways to do this:

a) RECOMMENDED: Disconnect all connections between your Receiver (including BEC/Throttle output of the ESC) and

your Recorder, and power the recorder from a separate small battery. Then, connect a small ground wire between one of the

Recorder’s servo ground pins, and the negative lead of the battery being measured, as shown in Figure 2. Note that the

resulting connections should not bypass the ESC’s isolation between the BEC/Throttle ground and the ground of the battery

being measured, since the BEC/Throttle ground is NOT connected to the recorder. Note that servo position logging will

not be possible in this scenario.

b) If you want to continue to power the Recorder from the ESC’s BEC output or the battery you are using to power the

Receiver (and to be able to log servo positions), you will need to leave the servo connections from the Receiver to the

Copyright © 2003-2010 Eagle Tree Systems, LLC

http://www.eagletreesystems.com

Page 3

Page

3

Recorder connected, AND you will need to connect the small wire between the between one of the Recorder’s servo ground

pins, and the negative lead of the battery being measured, as shown in Figure 2. CAUTION! This configuration causes

the internal ESC isolation to be bypassed. While the vast majority of the customers who have done this with our

equipment have not reported any problems, we have had one report of two different high powered ESC’s which may

have been damaged by performing this connection. Therefore, we strongly recommend contacting the ESC

manufacturer or consulting the ESC manual to ensure that connecting the ground of the ESC’s throttle output and

the main battery ground together will not cause a problem with that particular ESC, before proceeding. Bypassing

the ESC isolation is done at your own risk!

If your ESC has isolation, and you don’t understand how to set up the recorder in this configuration, don’t hesitate to visit the

“Support” page of our website for information about how to contact us with your issue.

Configuring the Expander with the Recorder and the Application

If you have not already done so, install your Data Recorder in your model and set up the Recorder software as described in your

instruction manual.

Zeroing the Current Sensor for First Time Use

Some ESCs, servos, etc., can draw a large constant current when the systems are powered up. Therefore, it is good to set the zero

current reference with your new Electric Expander. To do this, simply connect the Electric Expander to your Recorder, and connect

the Recorder to USB, but make sure there is no current draw through the ring current sensor (don’t connect a battery pack to the ESC).

Then, in the Windows Application, click “Tools, Rezero current sensors” and follow the instructions on that page. Note that this only

needs to be done once, but it’s not a bad idea to do it once a year or so, to account for any slight current sensor drift over time.

Special Instructions for the High Voltage Sensor

If you ordered the High Voltage option with your Recorder, complete the following step:

• Connect the Recorder and click “Advanced, Custom Hardware Options” and click ON the option “My Recorder has the High

Voltage option.” Then, click “OK”.

Special Instructions for 140 Amp and 300 Amp Sensors

If you are using the 300 Amp Sensor, complete the following step:

• Connect the Recorder and click “Advanced, Custom Hardware Options” and click ON the option “I am using the 300 Amp

Current Sensor.” Then, click “OK”.

If you are using the 140 Amp Sensor, complete the following step:

• Connect the Recorder and click “Advanced, Custom Hardware Options” and click ON the option “I am using the 140 Amp

Current Sensor.” Then, click “OK”.

Recorder Logging Setup

If you desire to log current or voltage in the Recorder, connect the Recorder to your PC as described in the Recorder manual, and

under Tools->Choose What to Log, choose Electric Motor Voltage and Electric Motor Current in the Optional Parameters section.

Choose other parameters you want to log as described in the Recorder manual.

To display the new parameters, under Tools->Choose What to Display, choose numeric and/or instrument display of Motor Voltage,

Motor Current, Motor Wattage, and/or cumulative amp-hours.

Seagull Dashboard Setup

If you are using the Seagull Wireless system, choose “Tools, Choose Parameters to Display on the Seagull Dashboard” and select the

desired Dashboard parameters to display, per the Seagull manual.

Playing Back Data after the Run

After your race, download data to your PC as described in the Recorder Manual. If you have selected to log and display motor

voltage, current, and/or RPM, these instruments and/or numerical readouts should appear in the application.

Troubleshooting

Copyright © 2003-2010 Eagle Tree Systems, LLC

http://www.eagletreesystems.com

Page 4

Page

4

Below is a list of problems that may be encountered, and steps to remedy them. If your particular issue is not addressed by the

below, see the Support page on http://eagletreesystems.com or email info@eagletreesystems.com. Include a full description of your

problem, your machine configuration, brands/models of receivers, transmitters and servos, application and Recorder firmware version

if possible (from Help->About in the app) and any other relevant

details.

Issue: I do not see motor voltage and/or current values changing after

using the Expander.

Solution:

• Make sure that you have selected logging of voltage and/or

current in the “Choose What to Log” dialog box under the

Tools menu.

• If voltage measurement is not working, but current is working,

see the “ESC’s with isolation between BEC/Throttle ground

and Main Battery Ground” section above.

• If Current is not working correctly, please verify that the Ring

sensor is correctly installed on the Electric Expander harness.

Please see the figure below.

• Ensure that you have selected motor voltage and/or current in the “Choose What to Display” dialog box under the Tools

menu.

• Double check your connections to ensure that the Recorder is connected correctly to the Electric Expander, and the battery.

•

Ensure that you are operating within the ranges listed in the Specifications section below.

Issue: My Electric Expander seems to be out of calibration. The readings I receive for current and/or voltage are somewhat incorrect

or differ slightly from my favorite meter.

Solutions:

• If you have a “High Voltage” recorder, or a “High Current” (140 or 300 amp) Electric Expander, ensure you have made the

“Custom Hardware Options” settings as described above.

•

If the current sensor appears to be reading incorrectly, make sure you’ve performed the steps in the “Zeroing the Current

Sensor for First Time Use” section above.

•

ADVANCED: If current and/or voltage seem to be reading slightly incorrectly, or you wish to calibrate the readings to a

particular meter you use, click “Tools, Calibrate Pack Voltage and Amperage Readings” in the windows application, and

follow the instructions.

Electric Expander Specifications

Motor Voltage: 0 to 50V (70 volts with High Voltage recorder option)

Motor Current: (standard sensor) 0 to 100 amps, with approximately 50 mA resolution

(140 amp sensor) 0 to 140 amps, with approximately 70 mA resolution

(300 amp sensor) 0 to 300 amps, with approximately 150 mA resolution

Weight: (standard sensor and 140 amp sensor) approximately 0.3 ounces

(300 amp sensor) approximately 1 ounce

Inside Diameter of Sensor Ring: 100 amps: ~5mm

140 amps: ~7mm

300 amps: ~22 mm

Limited Warranty

Eagle Tree Systems, LLC, warrants the Electric Expander to be free from defects in materials and workmanship

for a period of one (1) year from the date of original purchase. This warranty is nontransferable. If your unit

requires warranty service during this period, we will replace or repair it at our option. Shipping cost to us is

your responsibility.

To obtain warranty service, contact us by phone, fax or email to request an RMA number. No returns will be accepted without this

number.

This limited warranty does not cover:

Copyright © 2003-2010 Eagle Tree Systems, LLC

http://www.eagletreesystems.com

Page 5

Page

5

• The Software included with the Data Recorder. See the Software license agreement for more information on Software

restrictions.

• Problems that result from:

o External causes such as accident, abuse, misuse, or problems with electrical power

o Servicing not authorized by us

o Usage that is not in accordance with product instructions

o Failure to follow the product instructions

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY

FROM STATE TO STATE (OR JURISDICTION TO JURISDICTION). OUR RESPONSIBILITY FOR MALFUNCITONS AND

DEFECTS IN HARDWARE IS LIMITED TO REPAIR AND REPLACEMENT AS SET FORTH IN THIS WARRANTY

STATEMENT. ALL EXPRESS AND IMPLIED WARRANTIES FOR THE PRODUCT, INCLUDING, BUT NOT LIMITED TO,

ANY IMPLIED WARRANTIES AND CONDITIONS OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, ARE LIMITED IN TIME TO THE TERM OF THE LIMITED WARRANTY PERIOD AS DESCRIBED ABOVE. NO

WARRANTIES, WHETHER EXPRESS OR IMPLIED, WILL APPLY AFTER THE LIMITED WARRANTY PERIOD HAS

EXPIRED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THIS

LIMITATION MAY NOT APPLY TO YOU.

WE DO NOT ACCEPT LIABILITY BEYOND THE REMEDIES PROVIDED FOR IN THIS LIMITED WARRANTY OR FOR

CONSEQUENTIAL OR INCIDENTAL DAMAGES, INCLUDING, WITHOUT LIMITATION, ANY LIABILTY FOR THIRDPARTY CLAIMS AGAINST YOU FOR DAMAGES, FOR PRODUCTS NOT BEING AVAILABLE FOR USE, OR FOR LOST

DATA OR LOST SOFTWARE. OUR LIABILITY WILL BE NO MORE THAN THE AMOUNT YOU PAID FOR THE PRODUCT

THAT IS THE SUBJECT OF A CLAIM. THIS IS THE MAXIMUM AMOUNT FOR WHICH WE ARE RESPONSIBLE.

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES,

SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Copyright © 2003-2010 Eagle Tree Systems, LLC

http://www.eagletreesystems.com

Loading...

Loading...