Page 1

Figure

18

Figure

19

—

the

stylus may

damaged. (See Figurel9.)

be

SPECIAL NOTE: The

be

may

assembly

less the

moved to the back side of the

platen.

damaged

is

stylus

if the

pulled

has been

down un-

4. Pull out and down on

at the

assembly

center of the

top

to

expose

the

per spools. (See Figure2o.)

stylus

platen

tab

the

platen

pa-

the

take-up

Align

core with the tabs on the

lower

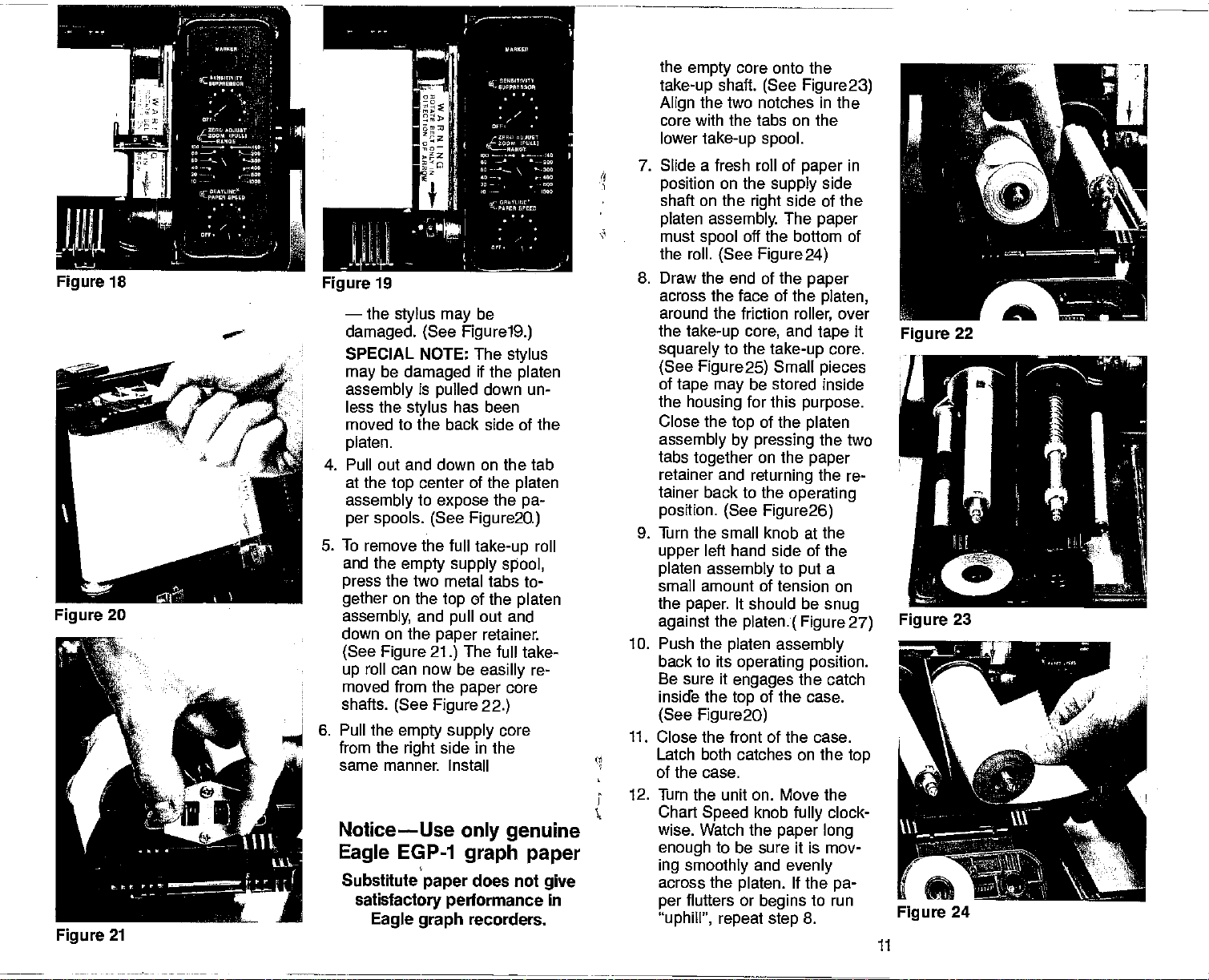

7. Slide a fresh roll of

•

•

position

shaft on the

platen assembly.

must

the roll.

8. Draw the end of the

across the face of the

around the friction

the

take-up

squarely

(See Figure 25)

of

tape may

the

housing

Close the

assembly by pressing

tabs

retainer and

tainer back

position. (See

core onto the

empty

shaft.

(See Figure

the two notches in

take-up spool.

paper

on the

supply

right

side of the

The

off the bottom of

spool

(See Figure 24)

roller,

and

core,

to the

take-up

Small

be stored inside

for this

of the

top

together

on the

returning

to the

operating

Figure26)

23)

the

in

side

paper

paper

platen,

over

it

tape

core.

pieces

purpose.

platen

the two

paper

the re-

9. Turn the small knob at the

5. To remove the full

and the

press

gether

assembly,

down on the

empty supply spool,

the two metal tabs to-

on the

and

(See Figure 21.)

roll can now be

up

moved from the

shafts.

6. Pull the

from the

same manner. Install

(See Figure 22.)

empty supply

right

Notice—Use

Eagle

Substitute

EGP-1

paper

take-up

of the

top

out and

pull

retainer.

paper

The full take-

easilly

paper

side in the

only genuine

graph paper

does not

satisfactory performance

Figure

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

21

Eagle graph

recorders.

platen

core

core

roll

re-

give

in

left hand side of the

upper

platen assembly

small amount of tension on

the

paper.

against

10. Push the

the

platen assembly

back to its

Be sure it

inside the

to

It should be

platen. ( Figure

operating position.

engages

of the case.

top

(See Figure2O)

11. Close the front of the case.

Latch both catches on the

of the case.

12. Turn the unit on. Move the

F

Chart

Speed

wise. Watch the

enough

ing smoothly

across the

flutters or

per

knob

paper long

to be sure it is mov-

and

platen.

begins

"uphill", repeat step

a

put

snug

the catch

clock-

fully

evenly

If the

to run

8.

27)

top

pa-

11

Page 2

STYLUS

CAUTION

sent

when

REPLACEMENT

—

High voltage

is

in the electronic section

the unit is turned on.'

pre-

1. TURN THE UNIT OFF.

2. Release both catches on the

of the case. Pull

top

down on the

front to

expose

of the case

top

the

out

stylus

and

belt.

(See Figurel8.)

Figure

27

The

3.

wheels located at the

edge

Move the front of the belt

DOWN to

the center of the

4. Hold the

with one

the old

left

edge

from under the tabs on

lus holder.

5. Before

lus,

camparing

by

6. Refer to

the new

correctly

holder. Be sure

in the two slots. If

the

stylus away

it is

move

7. After

won't

the

paper

ure3O,

so that

erted

steel

print

down more

leg

that

8. Close

Latch both catches on the

the case.

of

12 .

belt rides over two

stylus

of the

platen assembly.

position

stylus

finger,

the

platen.

belt

stationary

and remove

stylus by starting

and

moving

installing

be sure it is bent

Figure29to

stylus

the new

it to

Figure

is

positioned

be

under the tabs

it moves

not,

from the

rubbing

freely.

installing,

all,

print

as

bend the

more

against

plate.

all the

it

into the

digs

on until

shown in

pressure

If it still does not

way,

it does

if the

the

the stainless

stylus

way

right leg

bend the left

not so far

(but

paper).

the front of the case.

right

stylus

at its

it out

the

sty-

sty-

properly

28.

sure

on the

freely

bend

edge

down

Fig-

down

is ex-

top

at

Figure

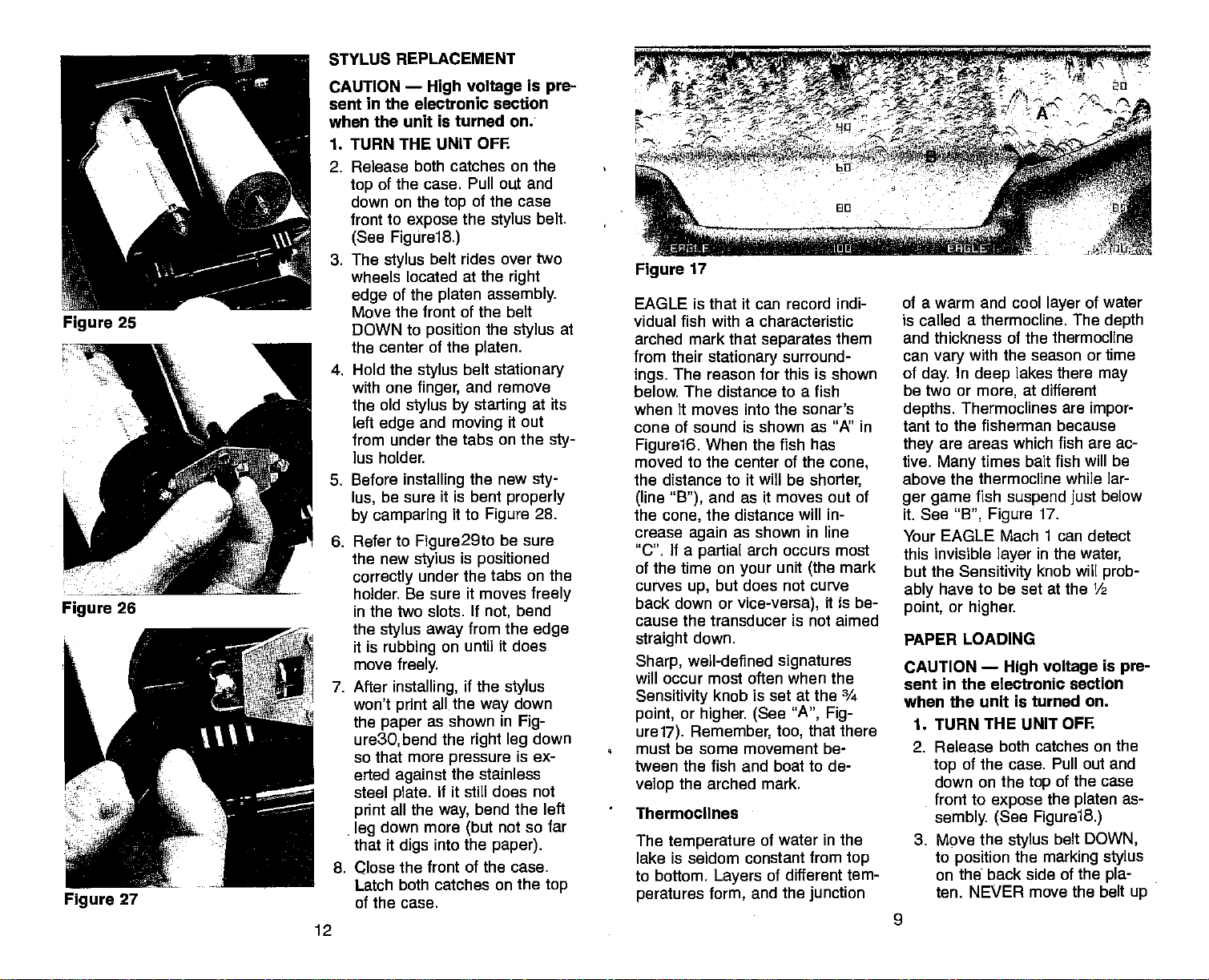

EAGLE is that it can record indi-

vidual fish with a characteristic

arched mark that

from their

ings.

below. The distance to a fish

17

separates

stationary

surround-

them

The reason for this is shown

when it moves into the sonar's

cone of sound is shown

Figurel6.

moved

When the fish has

to the center of the

the distance to it will be

(line "B"),

the

crease

"C". If a

of the time on

curves

back down or

cause the transducer is not aimed

straight

Sharp,

and as it moves

the distance will in-

cone,

as

again

partial

your

but does not curve

up,

vice-versa),

down.

well-defined

shown in line

arch occurs most

as "A" in

cone,

shorter,

out of

unit

(the

it is be-

signatures

mark

will occur most often when the

Sensitivity

point,

urel7).

knob is set at the ¾

or

higher. (See

Remember, too,

"A",

Fig-

that there

must be some movement be-

tween the fish and boat to de-

the arched mark.

velop

Thermoclines

The

temperature

lake is seldom constant from

to bottom.

peratures

form,

of water in the

Layers

and the

of different tem-

top

junction

a warm and cool

of

is called a thermocline. The

layer

of water

depth

and thickness of the thermocline

can

of

be two or

depths.

with the season or time

vary

In

day.

deep

more,

Thermoclines are

lakes there

at different

may

impor-

tant to the fisherman because

are areas which fish are ac-

they

tive.

above the thermocline while lar-

ger game

it. See

Your EAGLE Mach

this invisible

but the

ably

point,

PAPER

CAUTION

times bait fish will be

Many

fish

suspend just

layer

17.

1 can detect

in the

water,

will

knob

"B",

Figure

Sensitivity

have to be set at the 1/2

or

higher.

LOADING

—

High voltage

below

prob-

is

sent in the electronic section

when the unit is turned on.

1. TURN THE UNIT OFF.

2. Release both catches on the

of the case. Pull out and

top

down on the

front to

sembly. (See Figurel8.)

expose

3. Move the

to

position

on the back side of

ten. NEVER move

9

of the case

top

the

belt

stylus

the

marking stylus

platen

DOWN,

the

pla-

the belt

pre-

as-

up

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

Page 3

Figure

28

Figure

29

Figure

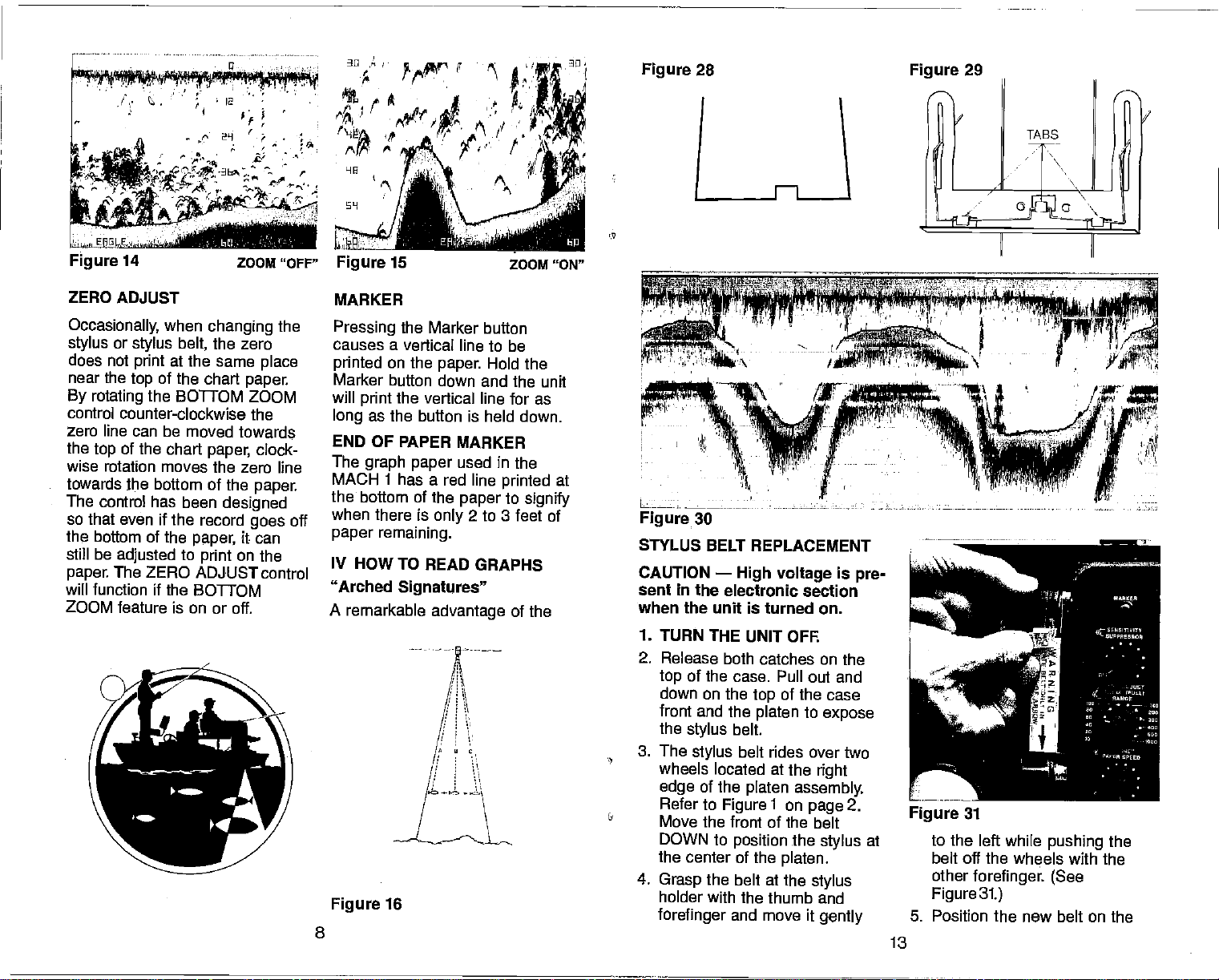

ZERO ADJUST

Occasionally,

stylus

does not

near the

By rotating

control

zero line can be

the

wise rotation

towards

The control

14

when

or

counter-clockwise the

of

top

the

belt,

stylus

at the same

print

of

the chart

top

the

BOTTOM ZOOM

moved towards

the chart

moves the zero line

bottom

has been

so that even if the

the bottom

still be

paper.

will function if

ZOOM feature is on

of the

adjusted

to

The ZERO

the BOTTOM

ZOoM "OFF"

changing

the

the zero

place

paper.

clock-

paper,

of the

paper.

designed

record

it- can

paper,

on the

print

ADJUST control

or off.

goes

off

Figure

MARKER

Pressing

causes

printed

Marker

will

long

END OF PAPER

The

MACH 1

the bottom

when

paper

IV HOW TO READ

"Arched

A remarkable

15

the Marker button

a vertical line to

on the

button down and the unit

print

as the button is held down.

graph paper

there is

remaining.

paper.

the vertical line for

MARKER

used in the

has a red line

of the

paper

2 to 3 feet of

only

GRAPHS

Signatures"

advantage

ZOOM "ON"

be

Hold the

as

printed

to

signify

of the

at

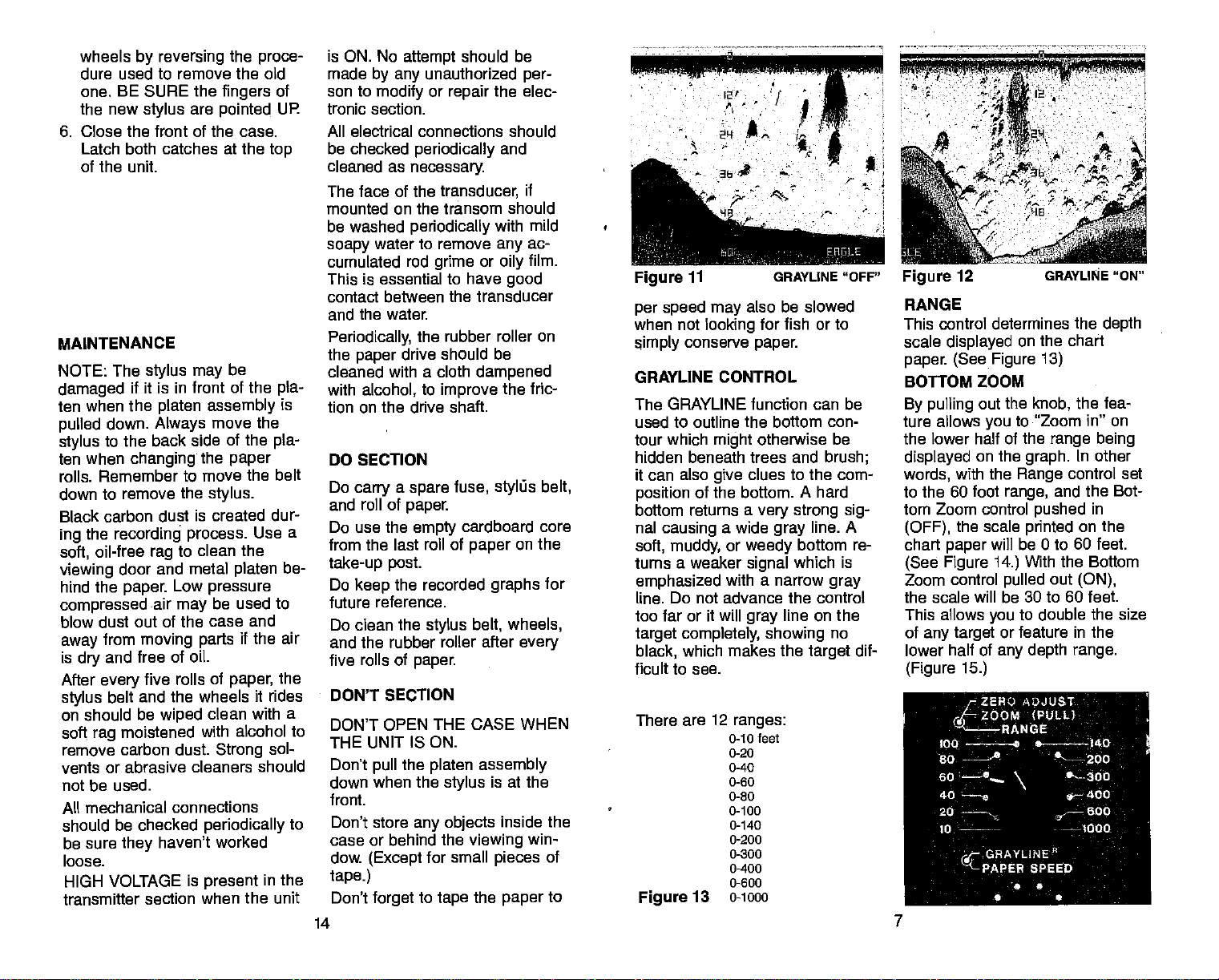

STYLUS BELT REPLACEMENT

CAUTION

sent

when the

—

High voltage

is

in the electronic section

unit is turned on,

pre-

1. TURN THE UNIT OFF.

2. Release both catches

of the case.

top

down on the

front and the

the

stylus

3. The

stylus

wheels located at the

of the

edge

Refer to

Move the front of

DOWN to

top

platen

belt.

belt rides

platen

Figure

position

1 on

the center of the

Figure

4.

16

the belt at

Grasp

holder with the thumb

forefinger

and move it

8

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

on the

Pull out and

of

the case

to

expose

over two

right

assembly.

page

2.

the belt

.the

stylus

platen.

the

stylus

and

gently

at

-I

Figure

31

to the left while

belt off the

other

Figure 31.)

5.

Position the new belt on the

13

wheels with the

forefinger. (See

pushing

the

Page 4

wheels

by reversing

dure used to remove the old

BE

one.

the

Close the front of the case.

6.

Latch

of the

MAINTENANCE

NOTE: The

damaged

ten when the

pulled

stylus

ten when

rolls. Remember

down to remove

Black carbon

the

ing

soft,

viewing

hind the

compressed

blow

away

is

dry

After

stylus

on should be

soft, rag

remove

SURE

new

stylus

both catches at the

unit.

stylus may

if it is in front of the

platen assembly

down.

Always

to the back side of the

changing

the

dust is created dur-

recording process.

oil-free

door and metal

paper.

dust out of the case and

from

and free of oil.

every

belt and the wheels

moistened with alcohol

carbon dust.

to clean the

rag

Low

air

may

moving parts

five rolls of

wiped

vents or abrasive cleaners should

be used.

not

mechanical connections

All

should be checked

sure

be

loose.

HIGH VOLTAGE is

transmitter section when

they

haven't

the

proce-

the

fingers

are

pointed

move the

the

of

UP.

top

be

pla-

is

pla-

paper

to move the belt

stylus.

Use a

platen

pressure

be-

be used to

if the air

the

paper,

it rides

clean with a

to

Strong

periodically

worked

present

sol-

to

the

in

the unit

is ON. No

made

by any

son

to

modify

attempt

should be

unauthorized

or

repair

the elec-

per-

tronic section.

All electrical connections should

be

checked

cleaned as

The face of the

mounted on the transom should

be washed

soapy

cumulated rod

This is essential

contact between the

and the

Periodically,

the

paper

cleaned with a cloth

with

alcohol,

tion on

DO SECTION

Do

carry

and roll of

Do use the

periodically

necessary.

transducer,

periodically

water to remove

grime

to have

water.

the rubber roller on

should be

drive

to

a

spare

paper.

empty

improve

the drive shaft.

from the last roll of

take-up post.

Do

future reference.

Do clean the

the recorded

keep

stylus

and the rubber roller after

five rolls of

DON'T SECTION

DON'T OPEN THE CASE WHEN

THE UNIT IS

Don't

down when the

front.

Don't store

pull

the

paper.

ON.

platen assembly

stylus

any objects

case or behind the

tape.)

14

dow.

Don't

(Except

forget

for small

to

tape

and

if

with mild

any

or

oily

good

transducer

dampened

the fric-

fuse,

stylUs

cardboard core

on the

paper

graphs

belt, wheels,

every

is at the

inside the

viewing

pieces

the

paper

ac-

film.

belt,

for

win-

of

to

Q p.r

Figure

per speed may

when not

simply

GRAYLINE CONTROL

The GRAYLINE

used to outline the bottom

tour which

hidden beneath trees and

it can also

position

bottom returns a

nal

soft, muddy,

turns a

emphasized

line. Do not

too far or it will

target completely, showing

black,

ficult to see.

There are

Figure

11 GRAYLINE "OFF"

also be slowed

looking

conserve

for fish or

paper.

function can be

otherwise

might

clues to the com-

give

of the bottom. A hard

very strong sig-

causing

a wide

or

weaker

weedy

signal

with a

advance the control

gray

which makes the

12

ranges:

0-10 feet

0-20

0-40

0-60

0-80

0-100

0-140

0-200

0-300

0-40 0

0-600

0-1000

13

line. A

gray

bottom re-

which is

narrow

line on the

target

r

to

con-

be

brush;

gray

no

dif-

I

Figure

RANGE

12

GRAYLINE "ON"

This control determines the

scale

displayed

paper.

(See Figure 13)

BOTtOM

By pulling

ture allows

the lower half of the

displayed

words,

with the

to the 60 foot

tom Zoom control

(OFF),

chart

(See Figure 14.)

Zoom control

the scale

paper

on the chart

ZOOM

out the

knob,

to "Zoom in" on

you

range being

on the

graph.

Range

range,

pushed

printed

and the Bot-

will be 0 to 60 feet.

With the Bottom

out

pulled

the scale will be 30 to 60 feet.

This allows

of

any target

lower half of

(Figure 15.)

@ERANGE

IOU

—p

60

60

—....

40

---e

20

—

10

r

'<_PAPER SPEED

to double

you

or feature in the

any depth range.

ZERO ADJUST

.

-.

—2O0

r—60O

—1000

GRAYLINER

4 4

0

7

depth

the fea-

In other

control set

in

on the

(ON),

the

size

140

&___300

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

Page 5

sound

weaker it

the

ing

larger signal

is

easier for the receiver to detect

it.

For this

in the MACH 1 automat-

puter

increases the initial

ically

width of the unit as

ranges

operator.

NOTE: Initial

width of the unit when the

pulse

Suppressor

minimum.

RANGE

(feet)

10 110

20

40 -2 0 0

300

400

600-1000

The transmitter

be increased from the initial

at

any

pressor

maximum amount of

RANGE

Figure

added to the initial

pulse

micro-seconds. In

has to

pulse

becomes.

width,

pulse

is transmitted and it

reason,

are selected

time

control clockwise. The

10-100

140-200 0.5 20 2.0 5.0

300-600 0.2 50 1.2 8.3

1000

10

width is

the micro-com-

width is the

pulse

control is turned to

INITIAL TRANSMIT

PULSE WIDTH

(micro-seconds)

pulse

by rotating

(feet)

transmitter

approximately

other

the

travel,

broaden-

By

in

essence,

pulse

deeper

the

by

150

200

300

400

600

width can

point

the

Sup-

width

pulse

APPROXIMATE PAPER SPEED

Minimum

Paper Speed

Inches Hours Inches Hours

Per Mm Per Roll Per Mm Per Roil

1.0 10 3.0 3.3

0.2 50

800

words,

the

feet,

a

is rotated to the maximum clock-

wise

pulse

seconds.

equals

Paper Speed

This knob

the chart

graphs,

depths,

trol

For best

imum.

arches at low

high

being compressed.

speed

when

ter.

appearing

the

ically

the chart

deep

gives

imum

slowed.

The chart

even further

per speed

control is set to 300

range

and the

position,

Suppressor

the transmitter

width would be 1100 micro-

initial

(300

1100

micro-seconds.)

Control

adjusts

paper.

the

For

in shallow to medium

turn the

to at least ¾ when

up

details,

This will show

speed

should be turned down

using

This will

paper speed

turn it

speeds

information from

the unit in

prevent gaps

in the record. In

microcomputer

slow the maximum

paper

water. The chart below

the

points

speed

paper may

control.

will automat-

when

where the max-

the

of

paper

by adjusting

Remember,

Maximum

Paper Speed

0.75 13.3

—

gaps appear

the

if

paper speed

solid record is achieved. The

in the

down until a

pIus

speed

good

up

proper

and

The

deep

operating

be slowed

record,

control

800

detailed

trolling.

to max-

keeps

paper

wa-

from

fact,

speed

is

the

turn

6

of

con-

fish

pa-

if

pa-

of

in

the

take-up

Don't rotate the

Don't use

vents,

TROUBLESHOOTING SECTION

core.

belt

oily

stylus

cloths,

up.

strong

or abrasive cleansers.

sol-

Symptom

On/Off switch is

and

stylus

paper

but the

"ON",

don't move.

What To Do

Check

battery

corrosion.

check connections at

fuse;

for

tightness

and

Symptom

On/Off switch is

but no echoes or bottom

mark,

signal.

"ON",

have zero

What To Do

Be sure the transducer is

plugged

into the unit and the transducer is

in contact with the water.

Symptom

The unit is

"ON",

but

paper

does

not move.

What To Do

Tape paper

to cardboard

spool

on

take-up post.

Symptom

Recorder marks are faint or dim.

What To Do

Clean

viewing

stylus;

LI9

ED ER6LE

Figure

check

2H

3b

32

door;

battery

replace

connections.

-

LINES

the

2H

BE

L9

bE

"OFF"

Symptom

Recorded marks are

is torn

paper

by stylus.

very heavy;

What To Do

Bend the

pressure

stylus slightly

on

paper.

VI ADVANCED

OPERATION

to reduce

The EAGLE MACH 1 takes ad-

of the

vantage

power, giving you options

lows it to

of

jority

sportfishing

graph

micro-processor's

that al-

outperform

the vast ma-

recorders in the

field. To use the func-

tions in this section two controls

must be used

urge you

carefully

superior performance

simultaneously.

to read this section

to take

advantage

of

the

EAGLE MACNi.

Lines

When the unit is first turned

lines are

depth

on the

ally

turn the lines

control to 20

switch

control to the 10 feet

'ON",

printed

paper.

off,

feet,

and rotate the

automatic-

If

desire to

you

rotate the

hold the marker

position.

marker switch must be "ON" dur-

the switch from 20 to 10 feet.

ing

The MACH 1 will

stop printing

H

b

L19

----——--—-——---—

ED

Figure

15

33 LINES "ON"

ERDLE

We

of the

on,

range

range

The

the

2H

Sb—

ED

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

Page 6

lines

immediately.

control back to

setting.

To turn the lines back

reverse

the

the

range

control to 10

the marker switch

tate the

feet

on the

control

setting.

Scale

rnge

position.

paper.

to the desired

Turn the

range

your original depth

on,

simply

procedure by turning

hold

feet,

and ro-

"ON",

control to the 20

Lines will be

Return the

printed

range

depth

The numbers that indicate the

or scale

depth

desired. Rotate the

to the 60 feet

marker control

control to the 40 feet

range

tion. The

ger

now

depth setting.

To turn the

rotate the

depth

be

printed.

be turned to the desired

may

depth

range

hold the marker switch

rotate

the

the 60 feet

range

position. Remember,

the marker switch must

the

ing

range

the

depth setting.

period

control is switched. Return

control to the desired

range

be deleted if

may

position,

"ON",

control

range

hold the

and turn the

scale will no lon-

The

range

control

scale back

control to 40

"ON",

control back to

be on dur-

of time that the

posi-

on,

feet,

and

Transmit and Print Alternate

When

using

it

water,

the

erably.

may

paper sped

However,

you may get

dark,

heavy printing

that

is difficult to read. Much de-

MACH 1 in

the

deep

be desirable to slow

down consid-

when

'over

print"

doing

or

so,

very

over an area

tail can be lost due to this.

An available feature is the Trans-

mit

and Print Alternate function

which,

the

stylus

tion instead of

This

2. Prevents the

when

activated,

transmitter and causes the

to

print

every

every

accomplishes

1. Since the

ery

corded information is

squeezed together

small area. This allows

records at slower

speeds. Also,

bers are

they

"wrap

desirable occurrence of

second or third bottom echo

printed

stylus

other

revolution,

spread

are more

around". This is the un-

possibility

on the

or middle of the

triggers

other revolu-

revolution.

three

only prints

the re-

into a

paper

the scale num-

out

more,

legible.

at the

paper

page. Many

things:

ev-

not

very

better

so

of

the

top

times this can interfere with

fish or other

wish to see.

targets

that

you

Suppressor

The

Suppressor

Control

Control is used

to reduce interference from noise.

Noise,

undesired

caused

(such

tem),

turbed water which is called

cavitation noise. In both

the noise could

wanted marks on the

Figure 7). Fortunately,

-- P -

:..çj—TT1:

Advancing

will cause the

these

without

in electronic

signal.

an electrical

by

as the

or

air bubbles in dis-

by

terms,

It can be

engine's ignition sys-

produce

—

—r

- --—-

.-1

Figure

pulses

compared

6

are

—— —________

HO

Iff...!J'1!Ijii —

EQ

---——---————-EHIL

relatively

to real sonar

the

Suppressor

system

unwanted,

reducing

any way.

pression settings,

ord becomes coarse and the

However,

short

the

with

the

is

any

source,

cases,

un-

paper. (See

noise

short in time

signals.

knob

to

reject

pulses

sensitivity

in

high sup-

rec-

graph

to

ability

bottom or from other fish will be

decreased.

Therefore,

sion

the knob

necessary

unwanted noise marks. Most of

separate

the lower the

setting,

setting only

to remove the

the time at low or

no

suppression

However,

to have

noise is not a concern. When us-

Figure

ing

it is

longer

7

a sonar

easier -for the unit to detect

ger pulse coming

bottom or from the fish.

called

"Probability

The

tion".

being

turning

ished because

probability

able to detect

from

fish from the

(See Figure 9).

the better. Advance

suppres-

as far as

erratic,

trolling speeds,

will be needed.

helpful

in

sometimes

widths when

pulse

deeper water,

it is

a lon-

back from the

This is

of Echo Detec-

of the unit

an echo re-

water is dimin-

deep

the further the

- -———-

24

- - -— — — ________-

3b

HR

by

Figure

—---

——— -

34 SCALE "ON"

ERELE

--—--———-

—

Lb

4

bu--

--

16

Figure

35

EAGLE

SCALE "OFF"

PROPER SEllING

Figure

8

SUPPRESSION:

Figure

9

TOO HIGH

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

Page 7

Figure

BASIC

ON-OFF and

SENSITIVITY

Rotate the

wise to turn

sitivity

3

OPERATION

Control

ON/OFF knob clock-

the unit on. The Sen-

knob

works much like the

volume control on a

weaker

signals

will be detected

radio,

that

with

higher

When

when

information

sitivity

water

toms which

echoes,

be

higher.

When

used,

appear.

caused

flecting

ter,

making

bottom

When detailed information

brush

thermocline is

sitivity

proximately

settings

cruising,

just

setting

or over

the

high

a

second bottom

or at other times

simple

is

desired,

can be low. In

soft,

produce

setting

Sensitivity settings

This is normal and is

the

by

returning signal

off the surface of the wa-

a second

and back.

individual fish or the

piles,

desired,

knob should be set

to the ¾

to the illustration below to see

what effect the

has

on the recorded

Recording

"arched"

accomplished

with the

point,

tion

information about this

is,

function of

Sensitivity

or

"Arched

Sensitivity

individual fish with an

signature

at

trolling speeds

higher.

Refer to the sec-

Signatures"

recorder.

your

of the knob.

bottom-contour

the Sen-

deep

muddy

bot-

weak

will have to

are

echo will

re-

to the

trip

about

the Sen-

ap-

Refer

point.

setting

information.

can

usually

knob at the ¾

be

for more

important

n

3. Reduces the

fect. This

lower

frequency units,

though

show

up

graphs.

To use the Transmit and

ternate

control to

function,

down the marker switch

the

range

Now release the marker

Return the

original setting.

now be in the Transmit and

Alternate mode.

marker control must be

RANGE

10-100

140-200

300-600

1000

Figure

By

significant

and Print

36

comparing

function.

reverberation ef-

happens

it does

on

high

mainly

sometimes

frequency

turn the

feet.

100

control to

range

(feet)

Next,

feet.

80

control to

The

MACH 1 will

Remember,

APPROXIMATE PAPER SPEED

Per Mm

(with

this chart with the

amount of

paper

Print Al-

and turn

switch.

"ON" dur-

Inches

Alternate

on

al-

range

hold

your

Print

the

Minimum

Paper

Speed

Per

0.6

0.4

0.2

02

Transmit and

one on

can be saved

the

ing

range

period

control is

of time that

turned from 100 to

80 feet.

To return the MACH

operation, simply

eration

trol to 80

switch

control to

marker

NOTE: A

any

to normal

sensitivity

position

"ON". This

the

by turning

"ON",

switch.

of the

and then

unit,

hold

feet,

rotate the

100

feet,

simple

way

optional

operation

control to the "OFF"

turns off the

erasing

all of the

Paper Speed

Hours

Roll

17

25

50

50

page

by

Inches

Per Mm

2.0

1.2

0.75

015

Print)

6,

you

the Alternate Transmit

using

the

1 to normal

reverse

the

the

range

op-

con-

the marker

range

and release the

to return

features back

is to turn the

turn it back

power

op-

Maximum

Hours

Per

Roll

5.0

8.3

13.3

13.3

can see

that a

to

1

2

2L1

SENSITIVITY: PROPER

Figure

4

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

SETTING

SENSITIVITY: TOO LOW

Figure

4

5

Figure

37

17

Page 8

tional features

grammed

you

scales

only

turn off

in. Just

have turned

and

off,

the scales back

power

that

the lines and the

you

to the unit or

have

you

remember,

wish to turn

don't

on,

pro-

if

you

will have both lines and scales on

—

bfl—--2--

Figure

38 RANGE: 60 FEET

ZOOM: OFF

SENSITIVITY: 1/2

SUPPRESSOR: MINIMUM I

PAPER SPEED: 3/4

GRAYLINE: MINIMUM

when

Turning

again only

method when

feature

features that

normal.

turn the unit back

you

the unit off and then on

works as a

or all of the

on,

p

I

on.

quick

you only

you

RANGE: 60 FEET

ZOOM: ON

SENSITIVITY: 1/2

SUPPRESSOR: MINIMUM

PAPER

GRAYLINE:

have one

optional

wish to return to

SPEED:

3/4

MINIMUM

—

VI

Ad-

This

chapter

operator

use out of

Although

your-

unit,

power

your

it is

and the

you

Depart-

1-800-331-2301.

repre-

may

to

help

be in-

area,

Holes in

happy

Operation.

explain

in

Section

the other features that

described

vanced

will

will enable the serious

the maximum

get

EAGLE.

We

urge you

thoroughly

to read this manual

and familiarize

self with the controls.

this is

easy

of the

front

panel

require

a

to

microcomputer

advanced

very

thanks to the

use,

controls. Should

extra

help, please phone

our Customer Service

ment toll free

Oklahoma residents call collect

918-266-5373. A service

sentative will be

you.

INSTALLATION

Mounting

The

depth

stalled in

provided

the best

—

—

sounder

convenient

any

the unit can be tilted for

viewing angle.

the bracket allow wood screw or

thru bolt

ener

may

of thin

fiberglass panels

the unit.

port

mounting.

be

A wood stiff-

required

on the back

to

sup-

If the desired location is closer

than 18" to a

magnetic compass,

a trial run should be made with

the unit in

that the

compass readings

operation

to be sure

are

not affected.

POWER CONNECTIONS

12 volt DC

to

unit should be

boat's 12 volt DC electrical

tem. The

tached to an

buss,

with electrical

power

power

but if

for the sonar

supplied

cable

accessory

have

you

interference,

cable should be attached

to the

battery.

If a

longer

ordinary

at

any

supply

soldered.

use

connections

in-line fuse holder with fuse is

An

supplied

cable is

#18

lamp

hardware

store.

Splices

If this can't be

type splices. Tape

crimp

with electrical

the EAGLE

with

required,

cord

or electronic

Be certain to install this fuse

holder as close to the

source

as

possible.

This will

tect both the sonar unit and the

power

occurs.

supplied

to the

conductor. The black wire is the

The

cable in the event a short

Crimp

power

in the

power

ground

or

graph

dental

polarity

damage

reversed.

not

operate

is

ity

applied.

connectors are

to attach the fuse holder

cable. The red wire

cable is the

negative

is

will occur if the wires are

However,

until the

conductor.

protected

reversals and

the unit will

from the

sys-

be at-

may

or

power

problems

the

directly

use

available

should be

done,

all

tape.

graph.

power

pro-

positive

from acci-

no

proper polar-

Figure

39 RANGE: 30

SUPPRESSOR:

SENSITIVITY: 3/4

FEET

MINIMUM

18

LINES: OFF

PAPER SPEED: 3/4

ZOOM: ON

GRAYLINE: MINIMUM

Figure

2

Ground

(Negative)

3

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

Page 9

1.

INTRODUCTION

Small boat sonar

routinely

depth,

and locate fish. The

MACH 1 recorder

yond

these

such as schools of

and

vidual fish closer than six inches

apart,

features combine to make the

MACH 1 a

corder for

industry.

used to measure water

examine

the

ordinary

objects, plus many

plankton,

and much more. These

today's sportfishing

systems

bottom

goes

in

baitfish,

thermoclines,

superior graph

are

contours,

Eagle

far be-

displaying

more

algae

indi-

re-

2. HOW IT WORKS

When the unit is turned

electronically regulated

drives a

at the

paper.

tached to the belt. When the

lus is at the

small mark is made. This is called

the zero

surface of the water. The

continues to move down the

of the

pulse

ter,

tected,

mark on the

the

lightweight

right edge

The

marking stylus

top

mark,

while the sound

paper

is

traveling through

and when an echo is de-

the

stylus

paper.

which reflected the

object

belt located

of the

of the

and

represents

makes another

The

an

on,

motor

rqcording

is at-

sty-

a

paper

stylus

edge

the wa-

depth

the

of

echo can be read

its location on

paring

the

paper.

A

constant

the

treated so that the

scale

depth

speed

paper graph. (The paper

it to leave a

mark.)

the

mark will be made

stylus,

small amount before the next rev-

olution. Each mark will blend into

the one

ite

made,

Due to the

this unit

operation

into two sections. The first

Section

eration" and covers

that is

use

During

belt,

stylus

but the

before,

'picture"

one

tiny

many

has,

section of this manual

is entitled "Basic

III,

absolutely necessary

EAGLE in a wide

your

of situations. It will tell

use the basic controls

sitivity, Suppressor, Paper Speed,

GRAYLINE,

a

few

special

tion will be

situations.

have mastered the basic

tion of the EAGLE MACH

described in Section

wish to

adequate

However,

some of the features

try

in feet

the

printed

com-

by

paper

on the

motor drives

is

will burn

stylus

permanent

one revolution of

a

very

paper

so that a

of the

black

narrow

the flexible

by

will move a

compos-

will be

target

mark at a time.

features that

we have

everything

split

the

part,

Op-

to

variety

how to

you

—

Sen-

Range,

Marker,

functions. This sec-

plus

for most

once

you

opera-

as

1,

Ill,

you may

to

a

Figure

2H

-'

Figure

1:::

40

Mi

p

A3

-.

HO

41

r

-

RANGE:

ZOOM: OFF

SENSITIVITY:

RANGE: 60 FEET

ZOOM: OFF

SENSITIVITY: 3/4

60 FEET

314

1,

SUPPRESSOR: MINIMUM

LINES: ON

PAPER SPEED: 3/4

GRAYLINE: MINIMUM.

2

tA

SUPPRESSOR: MINIMUM

LINES: OFF

PAPER SPEED: MAXIMUM

GRAYLINE: MINIMUM

PULLEY

DRIVE

STYLUS

DRIVE

BELT

STYLUS

Figure

Figure

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

2

PULLEY

42 RANGE:

SENSITIVITY: MAXIMUM

SUPPRESSOR: MINIMUM

80

FEET

19

ZOOM: OFF

PAPER SPEED:

LINES: OFF

GRAYLINE:

MINIMUM

MAXIMUM

Page 10

INDEX

I?

Figure

43

Operating Frequency

Pulse Width

(Duration

Operating Voltage

Operating

Output

Weight

Dimensions Width-i

Power 1600

-

- ic

of

&

RANGE: 60

SENSITIVITY: 3/4

SUPPRESSOR:

Pulse)

Current 0.7 to

LJLI A

P

!t&!i

FEET

SPECIFICATIONS

. . 192 kHZ

accuracy

110-1 400 us

Minimum: 10 volts D.C.

Maximum: 15 volts D.C.

density

(200

L.±

MINIMUM

(192,000

is within

(ADJUSTABLE)

1.8

amps depending

and

output power.

watts

typical peak

watts

RMS)

7 lbs. 14 oz

21/it,

PAPER SPEED: MAXIMUM

LINES: OFF

ZOOM: OFF

GRAYLINE: MINIMUM

cycles per second);

0.6

percent.

on

to

peak.

Height-9",

Depth-65/s"

printing

Introduction

How It Works

Installation

Basic

Operation

Suppressor

Paper Speed

GRAYLINE®

Bottom Zoom

Range

Marker

End Of

How To Read

Paper Loading

Paper

Graphs

Stylus Replacement

Belt

Stylus

Do's and Dont's

Troubleshooting

Advanced

Scale

Specifications

Service

Replacement

Operation

Information

2

2

3

4

5

6

7

7

7

8

8

8

9

12

12

14

15

15

16

20

20

NOTICE

Periodically

Face with

move

Oil and dirt on the

duce

vent

sounding.

wash the Transducer

and

soap

oil film that

any

face will re-

or

sensitivity

may

water to re-

collect.

may

even

pre-

NOTE: This sonar uses LPG -605 Chart

Paper.

20

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

Page 11

HOW TO OBTAIN

Electronics will

Eagle

Eagle parts

write us at the address below before

to save

do have to return the unit for

problem

testing

If

you

If

you

should

the

you

and

live out of the state of

live in the state of

inconvenience of

that

you

repair

provide quick

ever

you

are

of

your depth

Mail to: EAGLE ELECTRONICS

require

service,

having

with the unit. This will assist us in the

P.O. BOX 669

CATOOSA,

Oklahoma,

Oklahoma,

sending

sounder.

SCHEMATIC DIAGRAM & PARTS LIST

Should

sounder,

promptly.

EAGLE.

desire a schematic and

you

send

Please be sure and

to the address above and it will be mailed to

$1.00

us the model and serial number of

give

SERVICE

and efficient service with

it. If

sending

please

call collect 918-266-5373.

parts

do

you

require service,

in the unit. We

the unit back for

enclose a letter

OKLAHOMA 74015

call 1-800-331-2301.

list for

your

repairs.

EAGLE

maybe

genuine

call or

If

stating

depth

your

able

you

the

you

@

Copyright

1963 Lowrance

Electronics,

Inc.

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

Page 12

EAGLE

INSTALLATION

JJLJ jjJ

GRAPH RECORDER

AND OPERATION

flT

MANUAL

dAn

I

flA fi

/

•

MADAINUS A

EAGLE ELECTRONICS

LIThO USA

988-0095-01

A Divsion at

U

Lawrence

P0. BOX

Electronics. Inc

669, CATOOSA,

OKLA. 74015

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

Loading...

Loading...