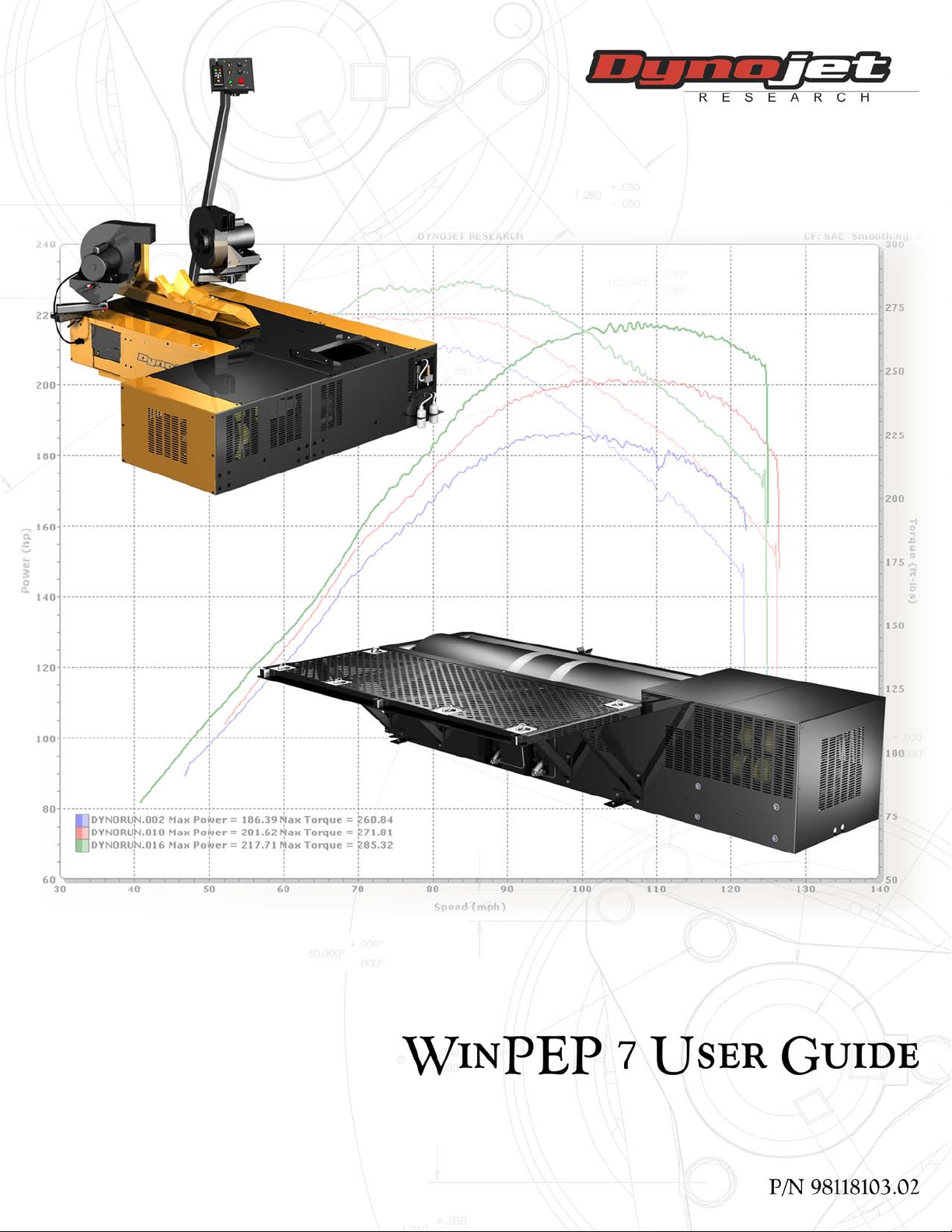

Page 1

Page 2

©2002-2006 Dynojet Research, Inc. All Rights Reserved.

WinPEP 7 User Guide

This manual is copyrighted by Dynojet Research, Inc., hereafter referred to as Dynojet,

and all rights are reserved. This manual, as well as the software described in it, is

furnished under license and may only be used or copied in accordance with the terms of

such license. This manual is furnished for informational use only, is subject to change

without notice, and should not be construed as a commitment by Dynojet. Dynojet

assumes no responsibility or liability for any error or inaccuracies that may appear in this

manual. Except as permitted by such license, no part of this manual may be reproduced,

stored in a retrieval system, or transmitted, in any form or by any means, electronic,

mechanical, recording, or otherwise, without the prior written permission of Dynojet.

The Dynojet logo is a trademark of Dynojet Research, Inc.

Any trademarks, trade names, service marks, or service names owned or registered by any

other company and used in this guide are the property of their respective companies.

Dynojet Research, Inc., 2191 Mendenhall Drive, North Las Vegas, Nevada 89081, USA.

Printed in USA.

Part Number: 98118103 Version 02 (08/2006)

Page 3

T

ABLE OF

C

ONTENTS

Chapter 1 Specifications and Installation

Conventions Used In This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Computer Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

License Agreement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Custom Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Compact Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Dynamic Help Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Removing or Repairing an Installation . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Chapter 2 Dyno and WinPEP Basics

Hardware and Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Dyno Electronics Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

The Pendant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

WinPEP 7 Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Searching the User Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

On-Line Manuals for Your Dyno . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Using the Tutorials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Creating a New Folder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

Dyno Run Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

Mulit Chapter Template March 2006

i

Page 4

TABLE OF CONTENTS

Chapter 3 Getting Started With WinPEP 7

WinPEP’s Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

When a Folder is Selected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Com Port Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Connecting the Dyno Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Troubleshooting the Dyno Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Replacing the Fuses in the Dyno Electronics . . . . . . . . . . . . . . . . . . . . . . .3-13

Loading a Template . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

File Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Search Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Tools Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Display Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

Help Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

Chapter 4 Making A Run

Making a Test Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Making a Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Graphing Negative Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Negative Horsepower Test—Drive Train . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Negative Horsepower Test—Different Brands of Oil . . . . . . . . . . . . . . . . . .4-9

Chapter 5 Graphing A Run

Printing a Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Setting Printer Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Changing the Text Printed At the Top (or Bottom) of the Graph . . . . . . . .5-5

Previewing Print Jobs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

ii

Mulit Chapter Template March 2006

Page 5

Chapter 6 Advanced MakeRun Features

Using Auto Start/Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

Dynojet expansion systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

Supported Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

Exploring the Gauge Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

Adding a Round Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

Adding a Multi Bar Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16

Loading a Template . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-20

Saving a Template . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-20

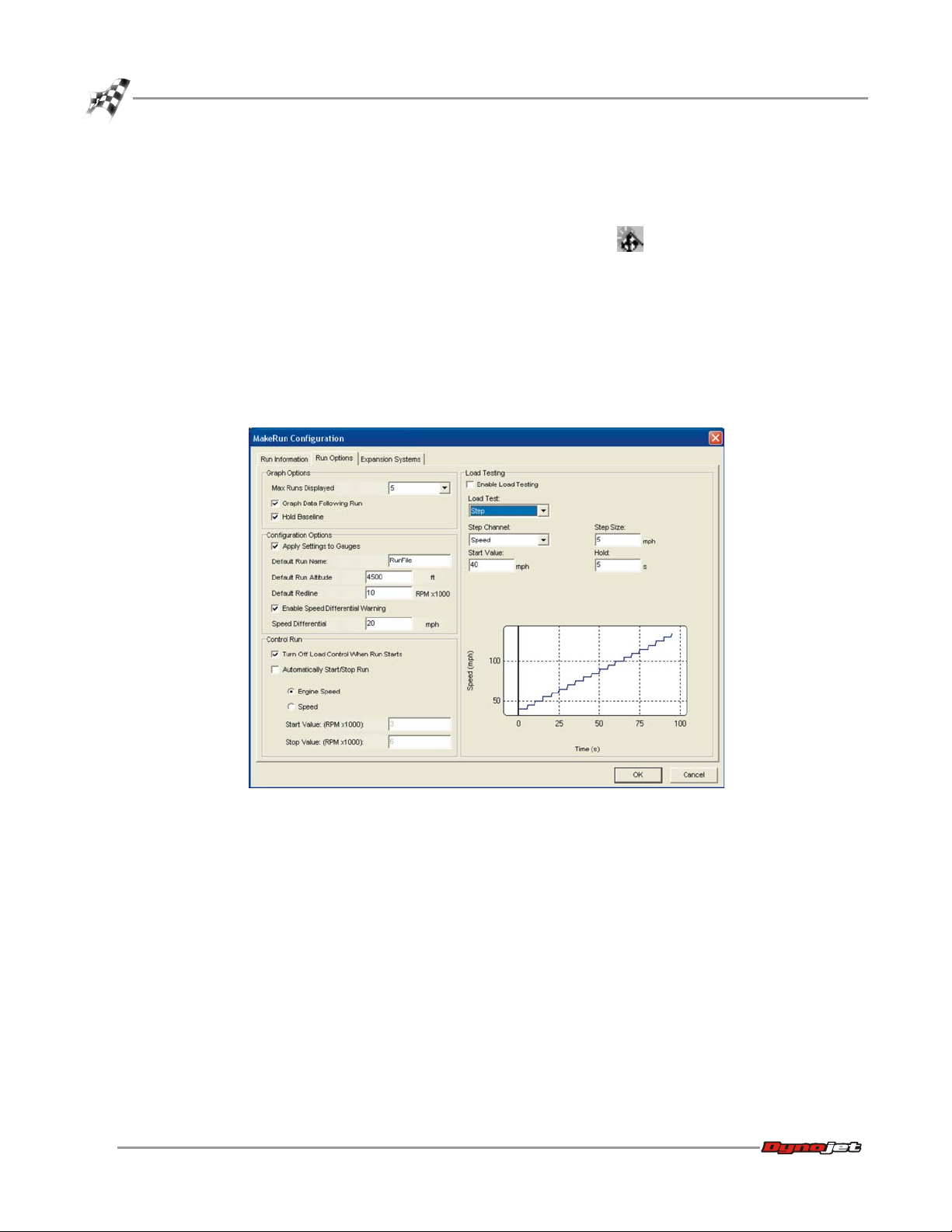

MakeRun Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-23

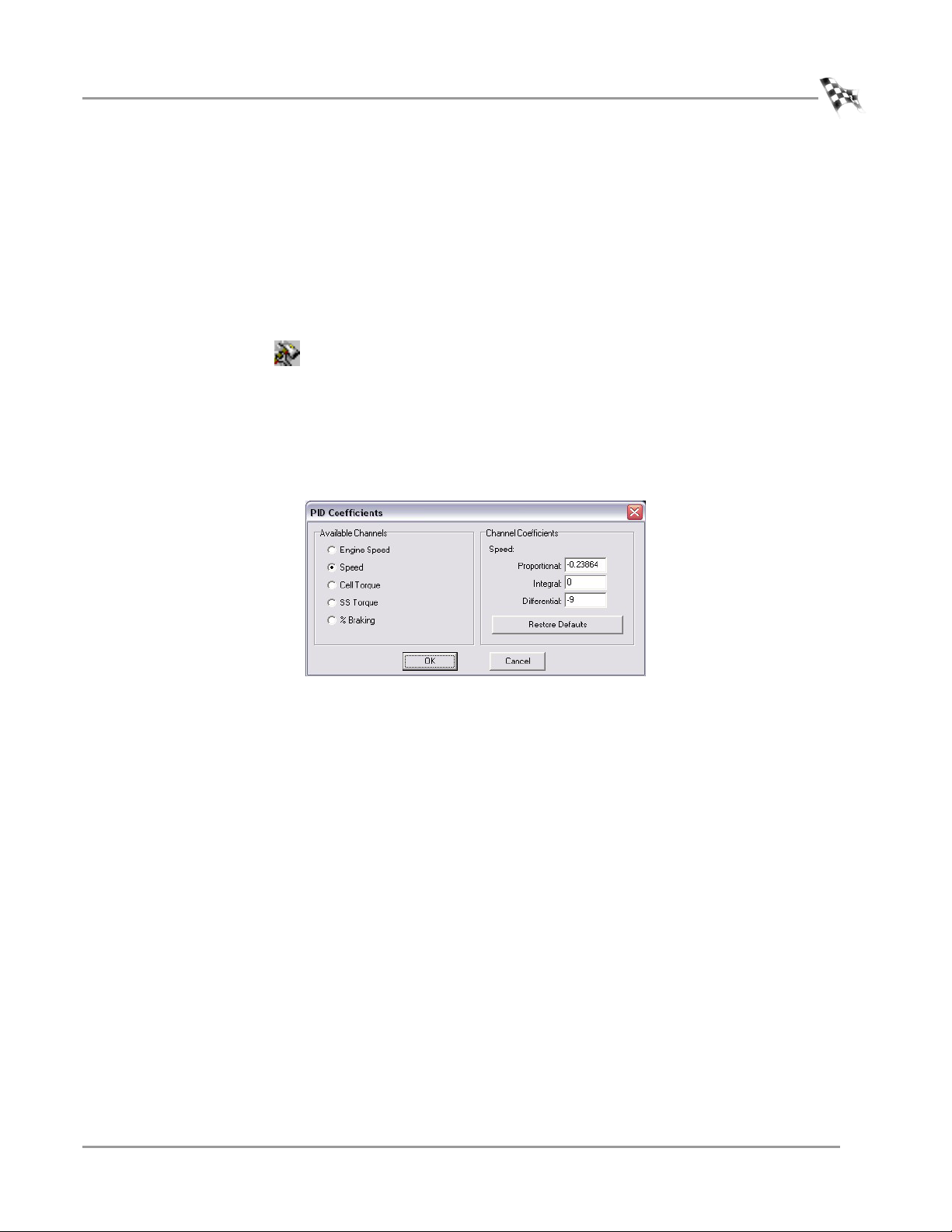

PID Coefficients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-23

Torque Cell Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-24

Analog Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-24

Dyno Electronics Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-25

Edit Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-25

Template Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-25

Gauge Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-26

Dyno Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

TAB LE O F CO NTE NTS

Chapter 7 Advanced Graph Features

Formatting Graphs Using the ListView Shortcut Menu . . . . . . . . . . . . . . . .7-2

Change Line Style . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

Exploring Graph Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-7

Showing All Data Channels for Graphing . . . . . . . . . . . . . . . . . . . . . . . . .7-11

Appendix A Torque Cell Calibration

Appendix B Keyboard Shortcuts

Using MakeRun Screen Keyboard Shortcuts . . . . . . . . . . . . . . . . . . . . . . . .B-2

Using Graph Screen Keyboard Shortcuts . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

Using TreeView Keyboard Shortcuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

Using General Keyboard Shortcuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

Appendix C User License Agreement

For Dynojet Research Software WinPEP 7

Version 1 Mulit Chapter Template March 2006

iii

Page 6

TABLE OF CONTENTS

Appendix D Analog Configuration

Configuring the Analog Channel(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Customizing Sensor Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

Saving and Loading Sensor Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-5

Editing a Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-6

Configuring the Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-8

Appendix E Advanced Breakout Board

Configuring the Advanced Breakout Board . . . . . . . . . . . . . . . . . . . . . . . . E-3

Establishing a Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-4

When the ABOB is Not Connected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-5

Troubleshooting Connection Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-5

Selecting Advanced Brake Controller Braking Configuration . . . . . . . . . . . . E-6

Using Gauges Tied Without Speed Balance . . . . . . . . . . . . . . . . . . . . . . . . E-7

Setting Gauges Tied to Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-8

Selecting Data Channels for Gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-9

Using Templates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-10

Using Load Control with The Advanced Brake Controller . . . . . . . . . . . . . E-11

Appendix F Data Link Module - HD Delphi ECM

Configuring the Data Link Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-2

Establishing a Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-3

Troubleshooting Connection Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-4

Data Link Module Diagnostic Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-5

Saving Diagnostic Codes as a Text File . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-5

Clearing Trouble Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-6

Selecting Data Link Module Data Channels to Use with WinPEP . . . . . . . . . F-7

Save As Default . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-7

Configuring the MakeRun screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-8

Viewing the Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-10

Appendix G DiabloSport Predator

DiabloSport Predator Set Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-2

Configuring DiabloSport Predator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-2

Configuring the MakeRun screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-6

Viewing the Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-8

iv

Mulit Chapter Template March 2006

Page 7

C HAPTER

1

S

PECIFICATIONS AND INSTALLATION

Thank you for purchasing WinPEP 7, Dynojet’s performance evaluation program.

Dynojet’s software and dynamometers will give you the power to get the maximum

performance from the vehicles you evaluate. Whether you are new to the benefits of a

chassis dynamometer or an experienced performance leader, Dynojet provides you

with professional results.

Document Part Number: 98118103

Version 2

Last Updated: 7-05-06

In this chapter:

Conventions Used In This Manual, page 1-2

Technical Support, page 1-2

Computer Specifications, page 1-3

License Agreement, page 1-3

Registration, page 1-3

Custom Installation, page 1-8

Dynamic Help Files, page 1-9

Removing or Repairing an Installation, page 1-10

WinPEP 7 User Guide

1-1

Page 8

CHAPTER 1

Introduction

INTRODUCTION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Before you begin using WinPEP 7 (Performance Evaluation Program for Windows), be

sure to read this guide for software installation instructions, program features, and

other important information. The Dynojet WinPEP 7 User Guide provides detailed

information about WinPEP 7 features and commands, a theoretical background, and a

hands-on tutorial. This guide is designed to be a reference tool in your everyday work.

CONVENTIONS USED IN THIS MANUAL

The conventions used in this manual are designed to protect both the user and the

equipment.

example of convention description

The Caution icon indicates a potential hazard to the

dynamometer equipment. Follow all procedures

exactly as they are described and use care when

performing all procedures.

The Warning icon indicates potential harm to the

person performing a procedure and/or the

dynamometer equipment.

RECORD

Bold

!

TECHNICAL SUPPORT

For assistance, please contact Dynojet Technical Support at 1-800-992-3525, or write

to Dynojet at 2191 Mendenhall Drive, North Las Vegas, NV 89081.

Visit us on the World Wide Web at www.dynojet.com where Dynojet provides state of

the art technical support, on-line shopping, and press releases about our latest

product lines.

The Record # icon reminds you to record your

#

dynamometer and/or eddy current brake (retarder)

number on the inside cover of this manual.

Highlights items you can select on in the software

interface, including buttons and menus.

The arrow indicates a menu choice. For example,

File !Open” means “select the File menu,

“select

then select the

Open choice on the File menu.”

1-2

WinPEP 7 User Guide

Page 9

SPECIFICATIONS AND INSTALLATION

WINPEP 7 SPECIFICATIONS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Your WinPEP 7 software is dynamometer/drum specific. That means that the precise

drum mass for your individual dynamometer has been calibrated and tied directly to

the WinPEP 7 software that came with your dynamometer. The software will not

record accurate results if it is used with any other dynamometer.

COMPUTER SPECIFICATIONS

You will need to provide a computer system to run the WinPEP software.

WinPEP 7 Specifications

minimum system requirements recommended systems requirements

• Microsoft® Windows 2000/XP • Microsoft® Windows 2000/XP

• Pentium 800 MHz Processor • 2.4 GHz Processor or greater

• 256 MB of available RAM • 256 MB of available RAM or greater

•one

Link

• 800 x 600, 256 color monitor (SVGA) • 1280 x 1024 256 color monitor (SVGA) or better

• 1.2 gigabyte hard drive • 1.2 gigabyte hard drive

• 30 MB of available hard-disk space • 100 MB of available hard-disk space

• CD ROM and floppy disk drive • CD ROM and floppy disk drive

• printer, if hard copies are needed • printer (preferably HP DeskJet®)

COM port, two COM ports for Tuning

• one COM port, two COM ports for Tuning Link

LICENSE AGREEMENT

The user license agreement for WinPEP 7 can be found in Appendix C of this manual.

Please read the User License Agreement carefully and be sure you understand and

accept the terms of the agreement.

REGISTRATION

Registering your software helps Dynojet provide technical support and inform you

about new software developments. To register, go to www.winpep.com.

click here to

register

Figure 1-1: Registering Your Software

Version 2 WinPEP 7 User Guide

1-3

Page 10

CHAPTER 1

WinPEP 7 Installation

WINPEP 7 INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

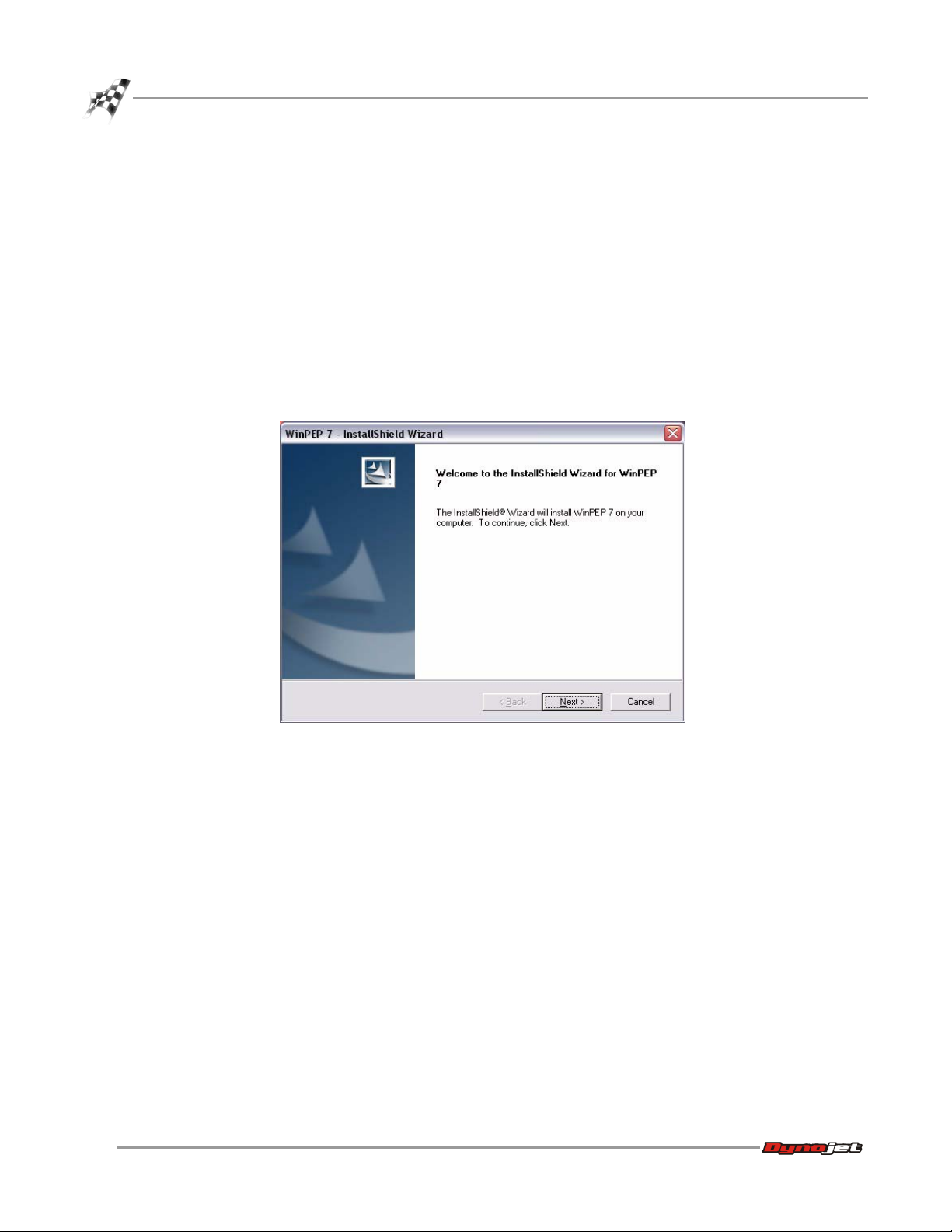

Follow these steps to install WinPEP 7 on your computer.

Note: It is strongly recommended that you exit all other programs before running

this install program.

1 Insert the WinPEP 7 CD in your CD-ROM drive. The launch program will run

automatically showing the InstallShield Wizard, see Figure 1-2.

If auto-run is disabled on your computer, click Start on the Windows® task bar,

and click Run. Type D:\setup.exe, where D is the letter that corresponds to your

CD-ROM drive.

2Click Next to continue.

1-4

WinPEP 7 User Guide

Figure 1-2: InstallShield Wizard Window

Page 11

SPECIFICATIONS AND INSTALLATION

WinPEP 7 Installation

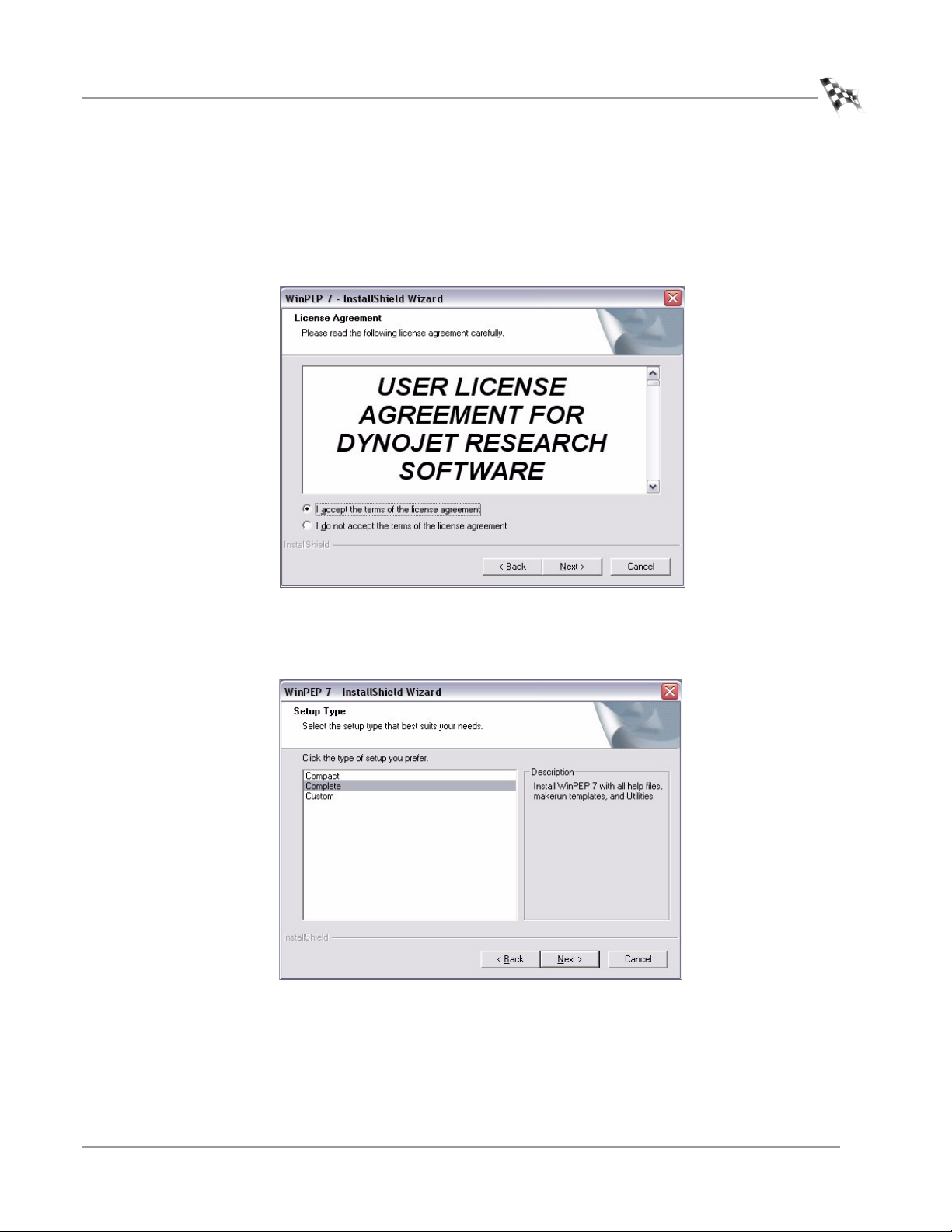

3 Carefully read the WinPEP 7 license agreement and click Next to continue.

To install WinPEP 7, you must accept this agreement. If you choose Cancel, the

InstallShield Wizard will close.

Note: Be sure to read and understand the license agreement. A copy of the

license agreement can be found in Appendix C of this manual.

Figure 1-3: Software License Agreement Window

4 Select the setup type of installation you prefer and click

details on compact and custom installations, see “Custom Installation” on page 1-8.

Figure 1-4: Setup Type Window

Next

to continue. For

Version 2 WinPEP 7 User Guide

1-5

Page 12

CHAPTER 1

WinPEP 7 Installation

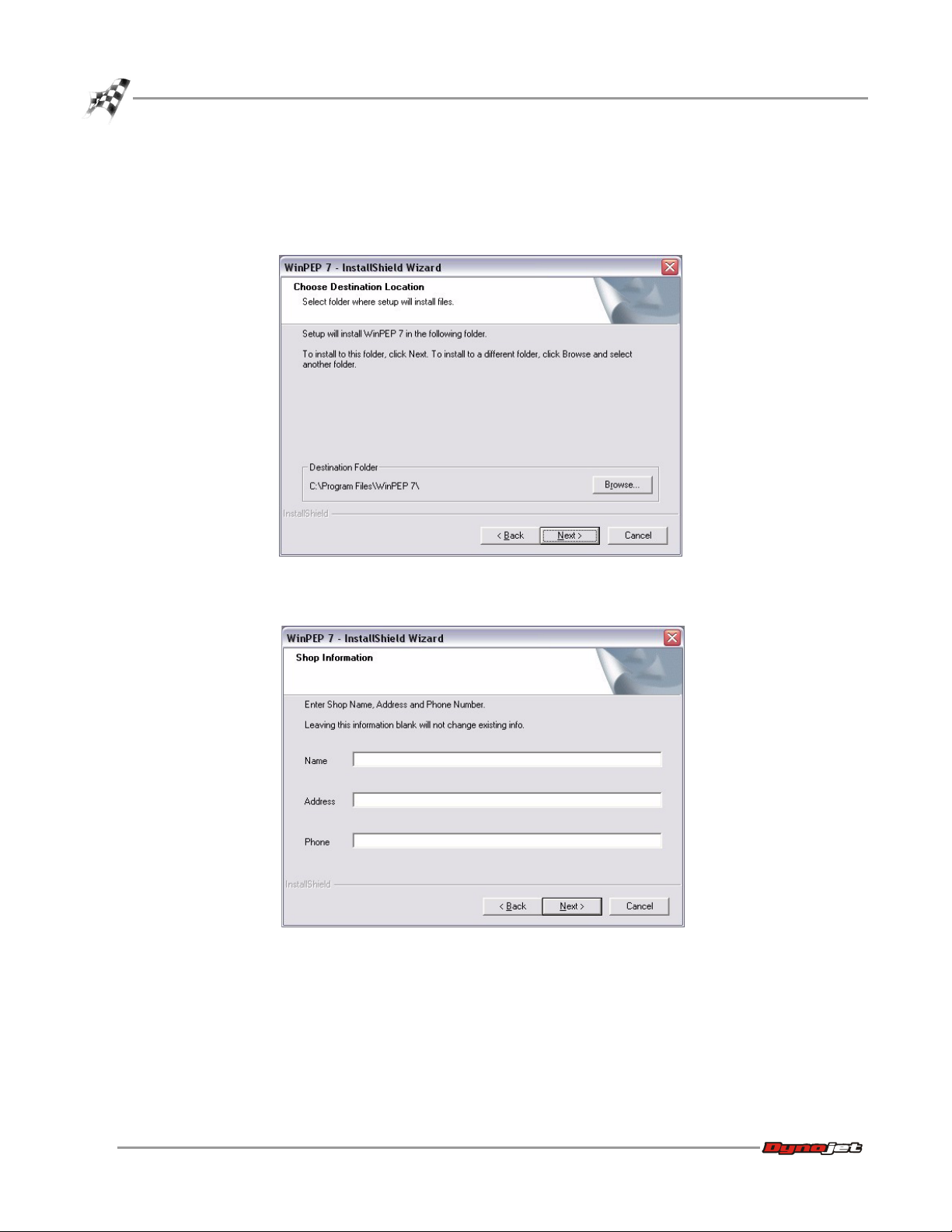

5 Select the location where the WinPEP 7 software will be installed and click Next

to continue.

Note: Dynojet recommends that you do not change the default destination

folder.

Figure 1-5: Choose Destination Location Window

6 Enter your information and click Next to continue.

Figure 1-6: Shop Information Window

1-6

WinPEP 7 User Guide

Page 13

SPECIFICATIONS AND INSTALLATION

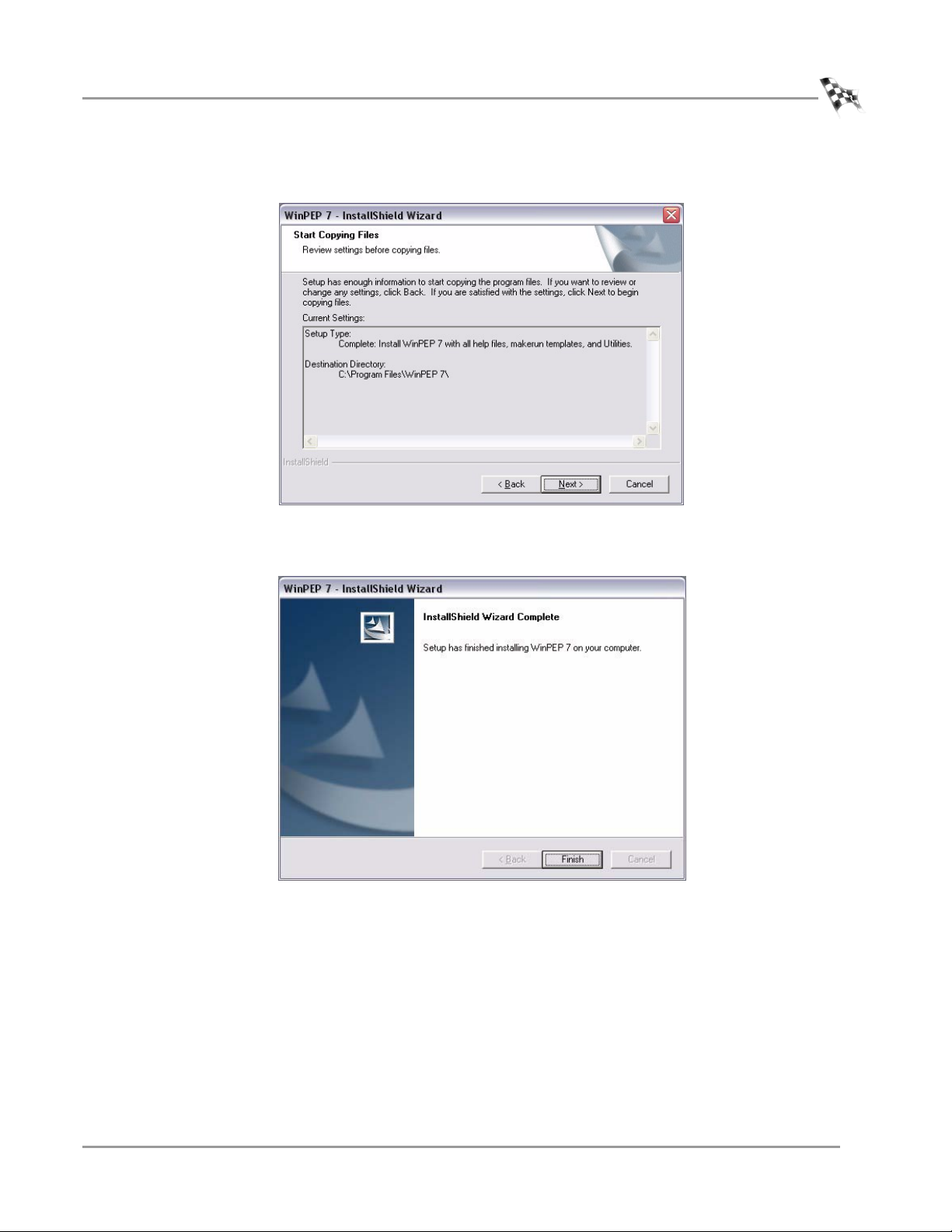

7 Review the settings and click Next to begin copying files.

Figure 1-7: Start Copying Files Window

WinPEP 7 Installation

8Click Finish to complete Setup.

Figure 1-8: InstallShield Wizard Complete Window

The installation is complete. You may now run WinPEP 7 by double-clicking the

program icon installed on your desktop or on your start menu.

Version 2 WinPEP 7 User Guide

1-7

Page 14

CHAPTER 1

WinPEP 7 Installation

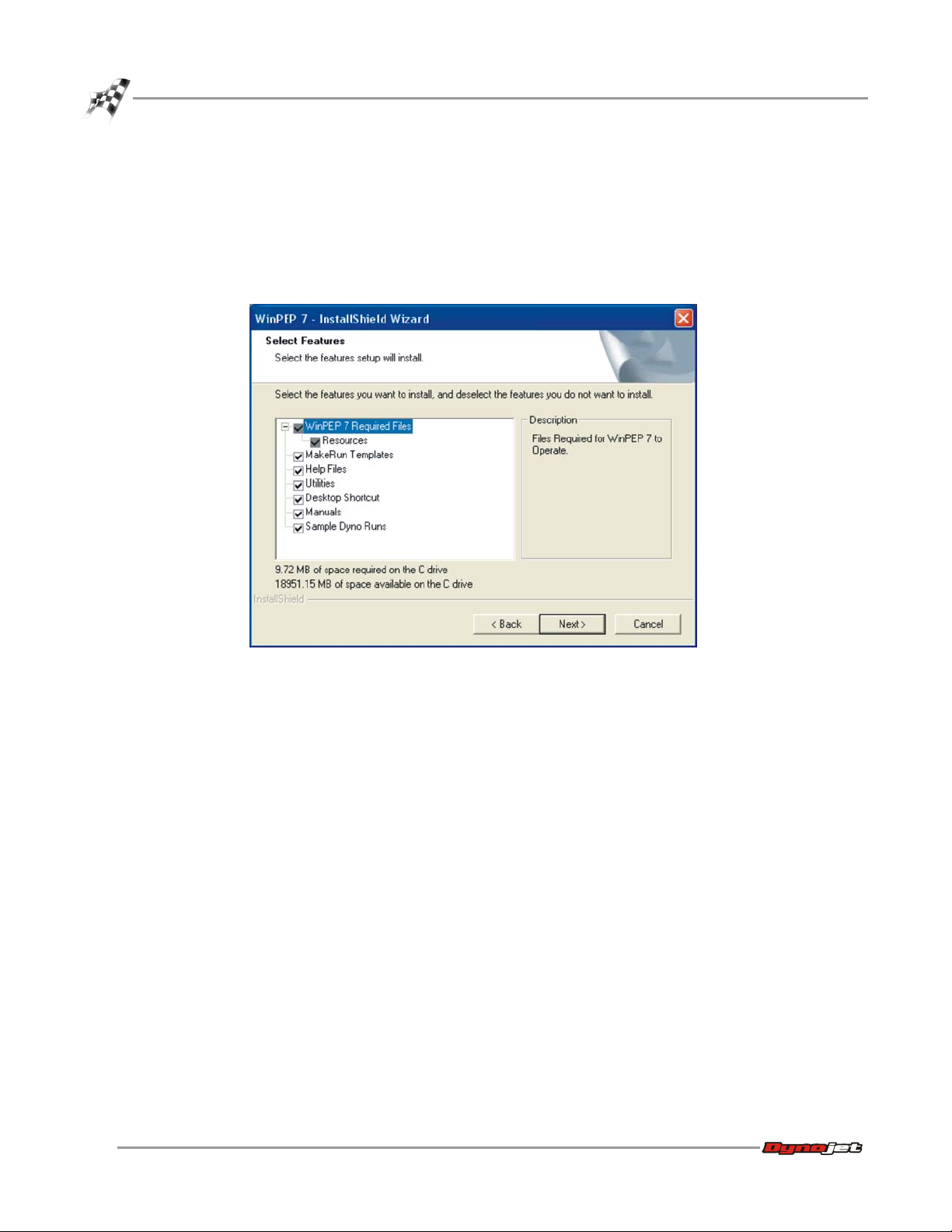

CUSTOM INSTALLATION

If you prefer to select which portions of the software are installed, choose Custom

Install from the InstallShield Wizard Setup Type screen (refer to “Setup Type Window”

on page 1-5). When you select Custom you will see the options shown in Figure 1-9.

Use your mouse to select the features you want to install by selecting their boxes so

that they appear checked.

Figure 1-9: Custom Install from InstallShield Setup Type

COMPACT INSTALLATION

The compact installation does not install the Help Files, Utilities, Desktop Shortcut,

Manuals, or Sample Runs.

1-8

WinPEP 7 User Guide

Page 15

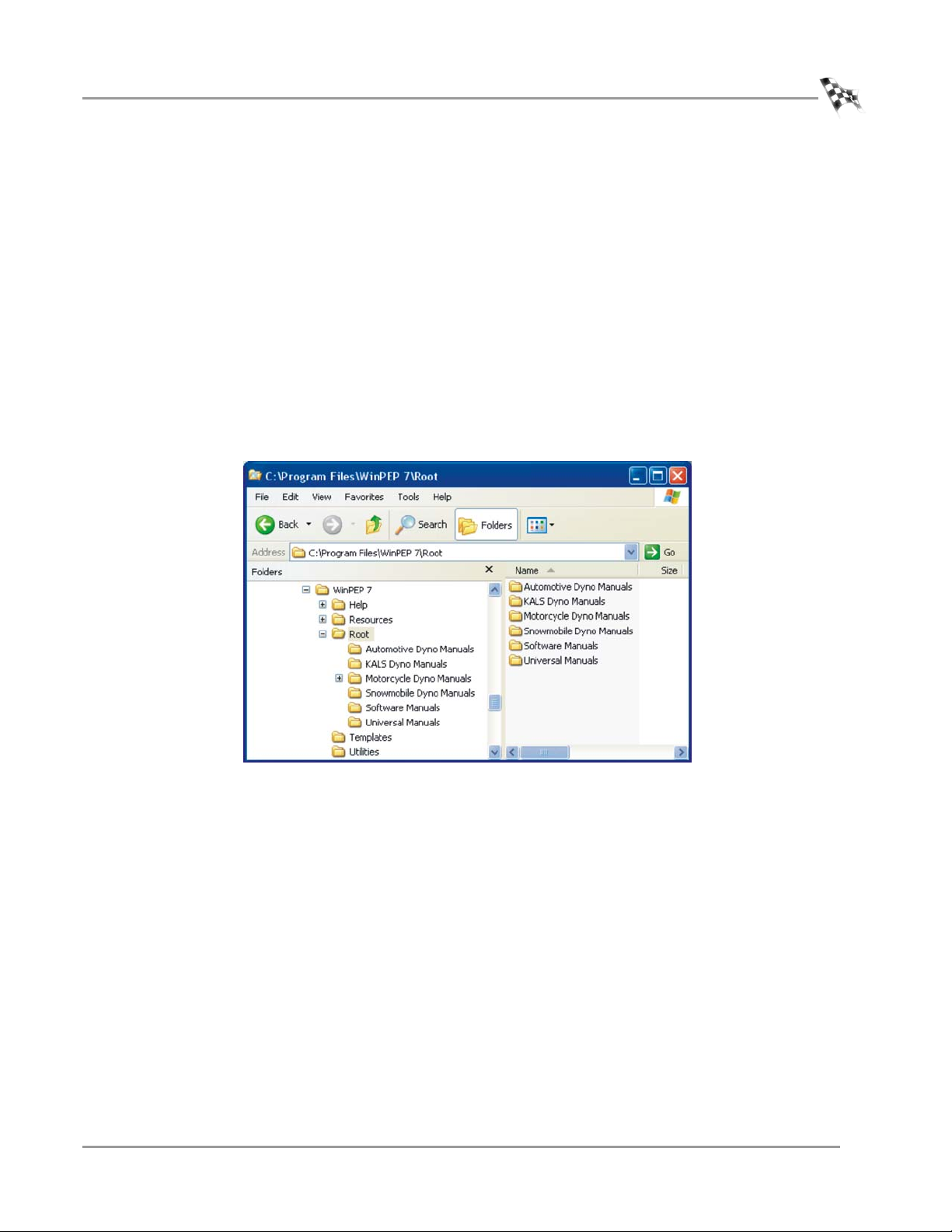

DYNAMIC HELP FILES

When you select the Complete Installation or choose a Custom Installation with the

Manuals feature selected, a subfolder named Root is created within the WinPEP 7

folder. Any legitimate Adobe Portable Document Format (.pdf) file that is copied into

this folder automatically appears listed in your help menu.

When you install WinPEP 7, manuals install that are useful for your type of dyno. For

example, if you are using a motorcycle dyno, when you pick Help

see a listing for Motorcycle Dyno Manuals, but not necessarily for Automotive Dyno

Manuals.

To add your own files to the Manuals list, simply use your desktop My Computer icon

and copy any valid .pdf file into the folder named Root located inside the WinPEP

installation folder.

The directory structure for the help files is shown in Figure 1-10.

SPECIFICATIONS AND INSTALLATION

WinPEP 7 Installation

!

Manuals you will

Figure 1-10: WinPEP 7 Directory Structure for Help Files

Version 2 WinPEP 7 User Guide

1-9

Page 16

CHAPTER 1

WinPEP 7 Installation

REMOVING OR REPAIRING AN INSTALLATION

If you have already installed WinPEP and you launch the setup program from the CDRom, the options to Remove/Repair, Remove Application Only, or Remove All will

appear as shown in Figure 1-11. To remove an installation you can also use the Add or

Remove Programs selection from the Control Panel.

Figure 1-11: Using WinPEP Setup Program to Remove or Repair an Installation

1-10

WinPEP 7 User Guide

Page 17

D

YNO AND

W

IN

PEP B

C HAPTER

2

ASICS

Understanding the theory and layout of your WinPEP software helps you build a solid

foundation upon which you can build advanced skills quickly.

In this chapter:

How Your Dyno Works, page 2-2

Hardware and Software, page 2-2

Theory of Operation, page 2-2

Dyno Electronics, page 2-4

Dyno Electronics Symbols, page 2-5

The Pendant, page 2-6

WinPEP 7 Software Interface, page 2-7

WinPEP 7 Menus, page 2-7

Using WinPEP 7 Help, page 2-8

Searching the User Manual, page 2-9

On-Line Manuals for Your Dyno, page 2-10

Tutorials, page 2-11

WinPEP 7 Dialog Boxes, page 2-12

Setting the User Level, page 2-14

Managing DynoRun Files, page 2-15

Creating a New Folder, page 2-17

Dyno Run Files, page 2-18

WinPEP 7 User Guide

2-1

Page 18

CHAPTER 2

How Your Dyno Works

HOW YOUR DYNO WORKS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dynojet’s inertia dynamometer (dyno) is a measuring device for recording and

displaying power and torque of an engine. Its method of measurement directly

implements the engineering principles of power and torque. Correction factors assist

in the comparison of these measurements under various test conditions, making

computer hardware (your dyno electronics) and software (WinPEP 7) necessary to

obtain, interpret, and display the data.

HARDWARE AND SOFTWARE

The dynamometer electronics acquire data, from the spinning dyno drum, necessary

for power, torque, and correction factor calculations. This includes air temperature,

absolute barometric pressure, humidity, drum timing, and engine RPM.

During a run, the data is stored in the dyno electronics memory.

After a dyno run is finished, data from the dyno electronics, calibration data, and user

notes are saved to a file on the computer’s hard disk. When you use WinPEP to select

a run, the data is loaded from the hard disk into computer memory. Data from up to

twelve runs can be viewed in WinPEP at once.

The information collected can be used for viewing horsepower and torque graphs.

Data can either be viewed as measured (“uncorrected”) or corrected to standard

atmospheric conditions using WinPEP.

THEORY OF OPERATION

POWER

Power, in mechanical terms, is the ability to accomplish a specified amount of work in

a given amount of time. By definition, one horsepower is equal to applying a 550

pound force through a distance of one foot in one second. In everyday terms, it

would take one HP to raise a 550 pound weight up one foot in one second. So to

measure horsepower, we need to know force (in pounds) and velocity (in feet per

second).

Dynojet’s inertia dynamometer measures power just in this way. The dyno calculates

velocity by measuring the time it takes to rotate the heavy steel drum one turn. The

dyno measures force at the surface of the drum by indirectly measuring the drum’s

acceleration. Acceleration is simply the difference in velocity at the surface of the

drum from one revolution to the next. The force applied to the drum is calculated

from acceleration using Newton’s 2nd law, F=MA, (F)orce equals (M)ass times

(A)cceleration.

Power is coupled to the drum by friction developed between the driving tire of the

vehicle and the knurled steel surface on the drum of the dynamometer.

2-2

WinPEP 7 User Guide

TORQUE

When an object rotates around a point, the object’s speed of rotation depends on

both an applied force and the moment arm. The moment arm is the distance from the

Page 19

DYNO AND WINPEP BASICS

How Your Dyno Works

point of rotation to where the force is being applied. Torque is the product of the

force and the moment arm. For example think about trying to spin a drum by

wrapping a rope around the drum and then pulling on the rope. If the rope is

wrapped around a drum of one foot radius and pulled with 550 pounds of force, the

resulting torque is 550 foot-pounds.

The torque on the dyno’s drum can be calculated by multiplying the force applied by

the drum’s radius. However, engine torque is not equal to the dyno’s drum torque

because the gearing through the drive train changes the moment arm. The change in

the moment arm is proportional to the ratio of engine speed to drum speed.

Therefore, tachometer readings are necessary to calculate and display engine torque.

CORRECTION FACTORS

The calculation of horsepower, or the accuracy of a Dynojet dynamometer, is not

dependent on the location or conditions during the measurement. The performance

of the internal combustion engine however, is sensitive to atmospheric conditions,

especially air density and air temperature. To compare power measurements taken at

different times or places, it is necessary to compensate for differing atmospheric

conditions.

Correction Factors are used to compensate for different operating conditions while

measuring engine horsepower. The typical correction factor (CF) is calculated based

on the absolute barometric pressure, air temperature and the water content of the air

used for combustion by the engine under test. The correction factor attempts to

predict the engine horsepower if the engine were tested at sea level under standard

pressure and temperature conditions.

Absolute barometric pressure is a measure of how hard the air molecules are being

pushed closer to one another. The unit of measurement is typically inches of mercury

(inches Hg). The more pressure, the more molecules there are in a liter of air and the

more air the engine “gobbles up” during the intake stroke. Absolute barometric

pressure is equal to relative barometric pressure only at sea level. Relative barometric

pressure is reported at airports and by weather barometers. A good approximation for

converting relative barometric pressure to absolute barometric pressure is:

AbsHg = RelHg - (Elev/1000)

Where:

AbsHg is Absolute barometric pressure.

RelHg is Relative barometric pressure.

Elev is test location elevation in feet above sea level.

Humidity is the percentage of a volume of air that is occupied by water vapor. Water

vapor displaces oxygen and reduces the amount of combustion air ingested during

the intake stroke.

Air temperature is the temperature of the air entering the intake system of the engine

under test. In some cases this is ambient air temperature, but in other cases the intake

air is significantly heated by the engine and is different than ambient air. Heat tends to

spread air molecules apart. So as temperature increases, there are less molecules in a

liter of air and less air is swallowed during the intake stroke.

Dynojet’s WinPEP 7 software uses the SAE’s latest correction formula (June 1990).

This formula assumes a mechanical efficiency of 85% and is much more accurate than

earlier formulas at extreme conditions.

Version 2 WinPEP 7 User Guide

2-3

Page 20

CHAPTER 2

Dyno Electronics

DYNO ELECTRONICS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

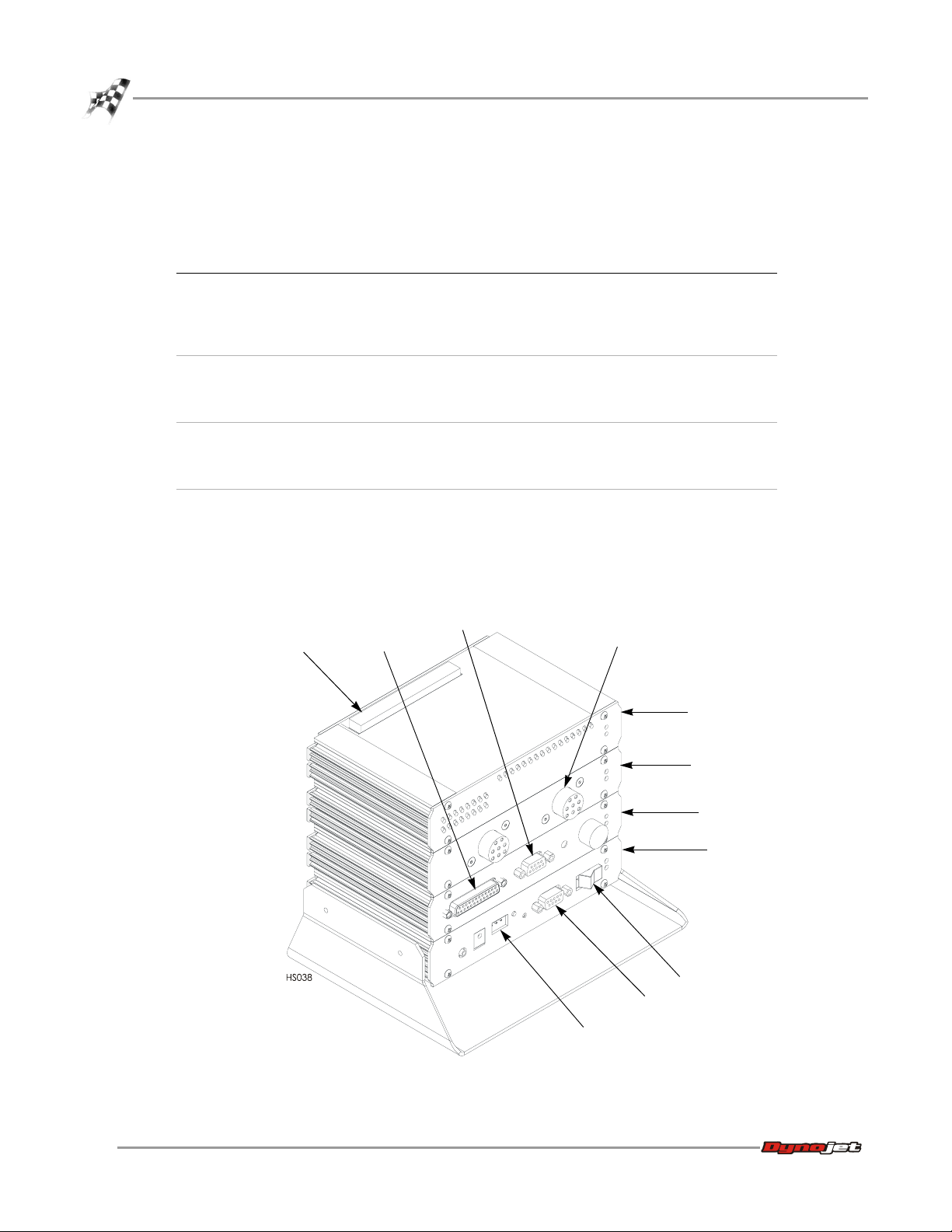

The standard dyno electronics package is comprised of four interconnected modules:

module description

CPU Module Contains a 32-bit processor which acquires data from the

Input/Output Module Sends and receives data from the dyno and the pendant.

RPM Module Receives and processes signals from up to two inductive

Atmospheric Sensing Module Measures absolute pressure, air temperature, and relative

expansion modules and communicates to the main

computer running the WinPEP software. The processor

queries the expansion modules to determine their identity

and capabilities.

This module also contains a buzzer and a light which are

activated when either the vehicle or the dyno speed limit

is approached.

pickups for measurement of engine RPM. Each input has

an automatic gain circuit to compensate for a wide

variance of ignition systems.

humidity. The measurements are used by WinPEP to

correct power and torque measurements to standard

atmospheric conditions according to a DIN, SAE, or other

formula.

system expansion

connector

25-pin socket

9-pin hand

held pendant

inductive pickup

socket

atmospheric

sensing module

RPM module

input/output module

CPU module

power

9-pin RS-232 socket

3-pin power

plug

2-4

WinPEP 7 User Guide

Figure 2-1: Dyno Electronics

Page 21

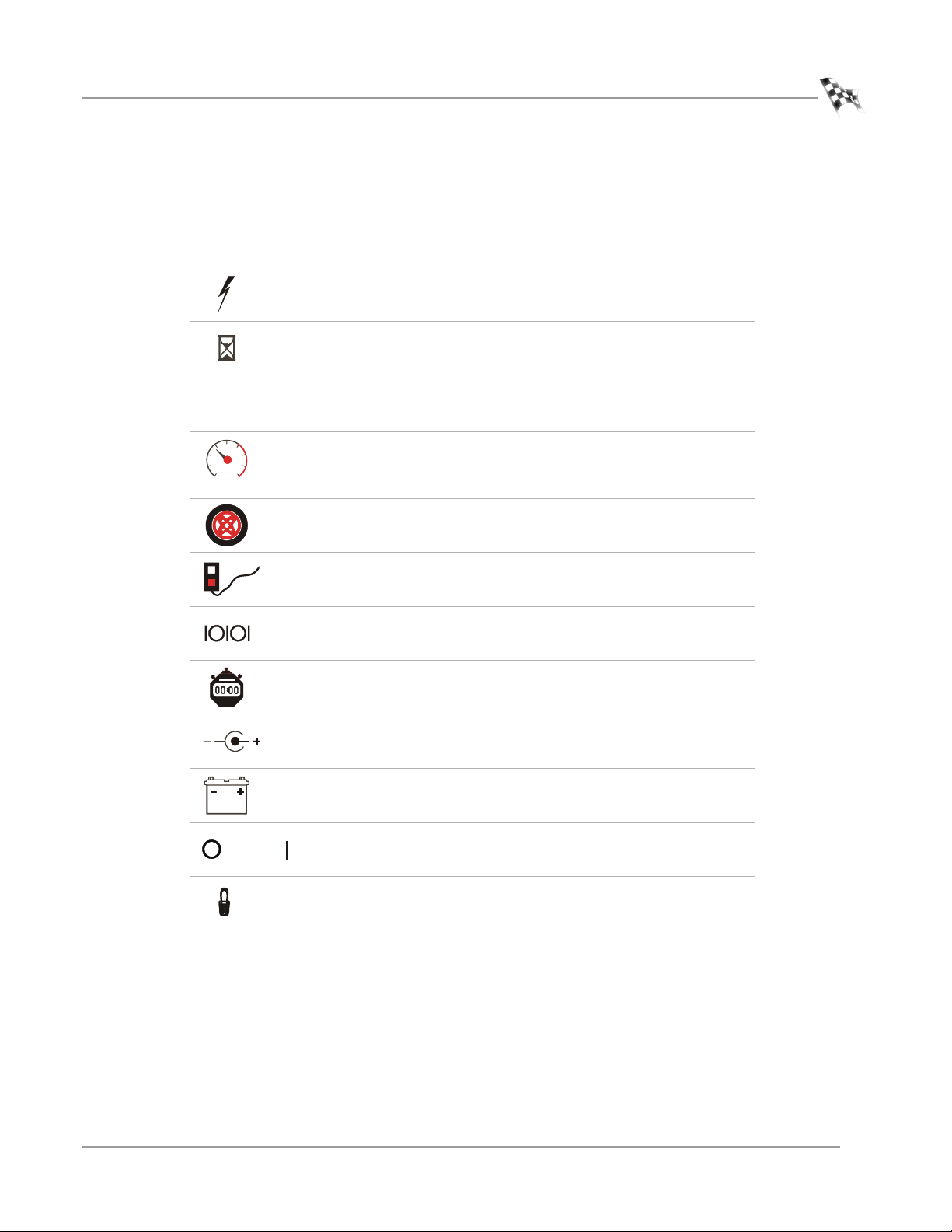

DYNO ELECTRONICS SYMBOLS

Symbols on the dyno electronics modules help you understand their function.

A description of the module symbols and functions follows.

symbol description

DYNO AND WINPEP BASICS

Dyno Electronics

Shows when the module is receiving power.

CPU module: the blue LED is lighted when data from

the modules is being acquired and saved.

Input/Output module: the amber LED flashes

proportionally to the dyno drum rpm.

Atmospheric Sensing module: the flashing amber LED

indicates the module processor is operating properly.

Inputs for both primary and secondary inductive

pickup clips. Either input may be used with a primary

or secondary inductive pickup on a single ended coil.

Both inputs can be used for a wasted spark ignition.

Connects to the 25-pin shielded cable from the

dynamometer.

Connects to the 9-pin pendant cable.

Connects to the 9-pin RS-232 PC serial

communications port.

Connects a synchronization signal to a third party data

acquisition system.

Connects a 12 volt DC power to a third party data

acquisition system.

Connects to a 12 volt DC power supply or battery.

The adjacent LED glows bright green when power is

properly connected.

When this switch is on, power is supplied to all

connected modules.

Amber LED flashes at a steady rate when the power is

on; flashes proportionally to the rpm when an rpm

signal is detected, faster rpm equals faster blinking

rate.

For more information on connecting your dyno electronics, see “Connecting the

Dyno Electronics” on page 3-11.

Version 2 WinPEP 7 User Guide

2-5

Page 22

CHAPTER 2

Dyno Electronics

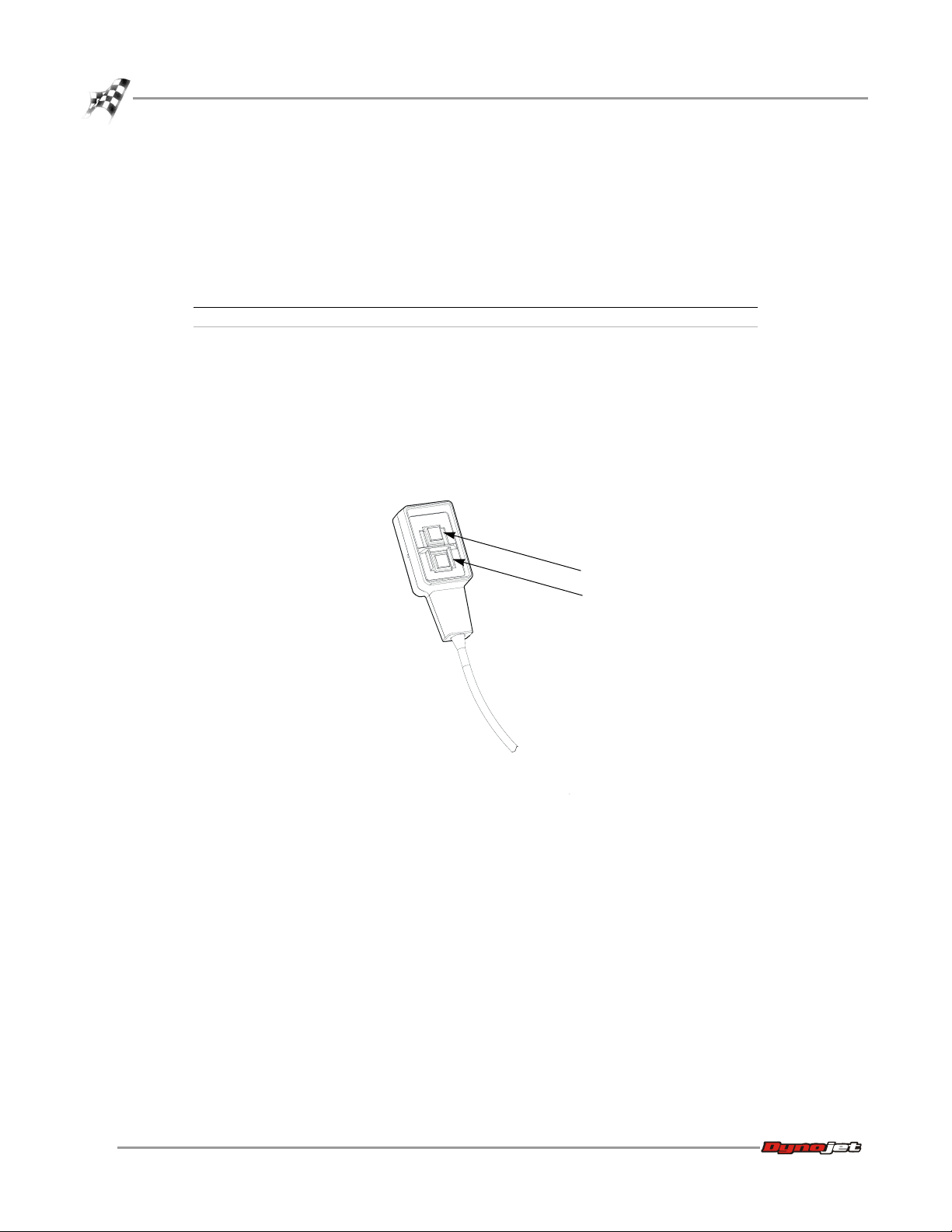

THE PENDANT

press this button to

Red Turn on the emergency brake (apply 100% braking).

Green Move to the next step in the run loop:

The dyno electronics is equipped with a standard two-button pendant that lets you

control sampling and braking from your vehicle. The pendant works with WinPEP 7;

however, many of WinPEP 7’s newest features can only be controlled using the

keyboard or mouse.

• Start/stop sampling

•Close Graph

• Close special MakeRun dialog boxes

Click and hold to toggle load control on and off

(available only when load control is supported)

green button

red button

Figure 2-2: Standard Two Button Pendant

2-6

WinPEP 7 User Guide

Page 23

DYNO AND WINPEP BASICS

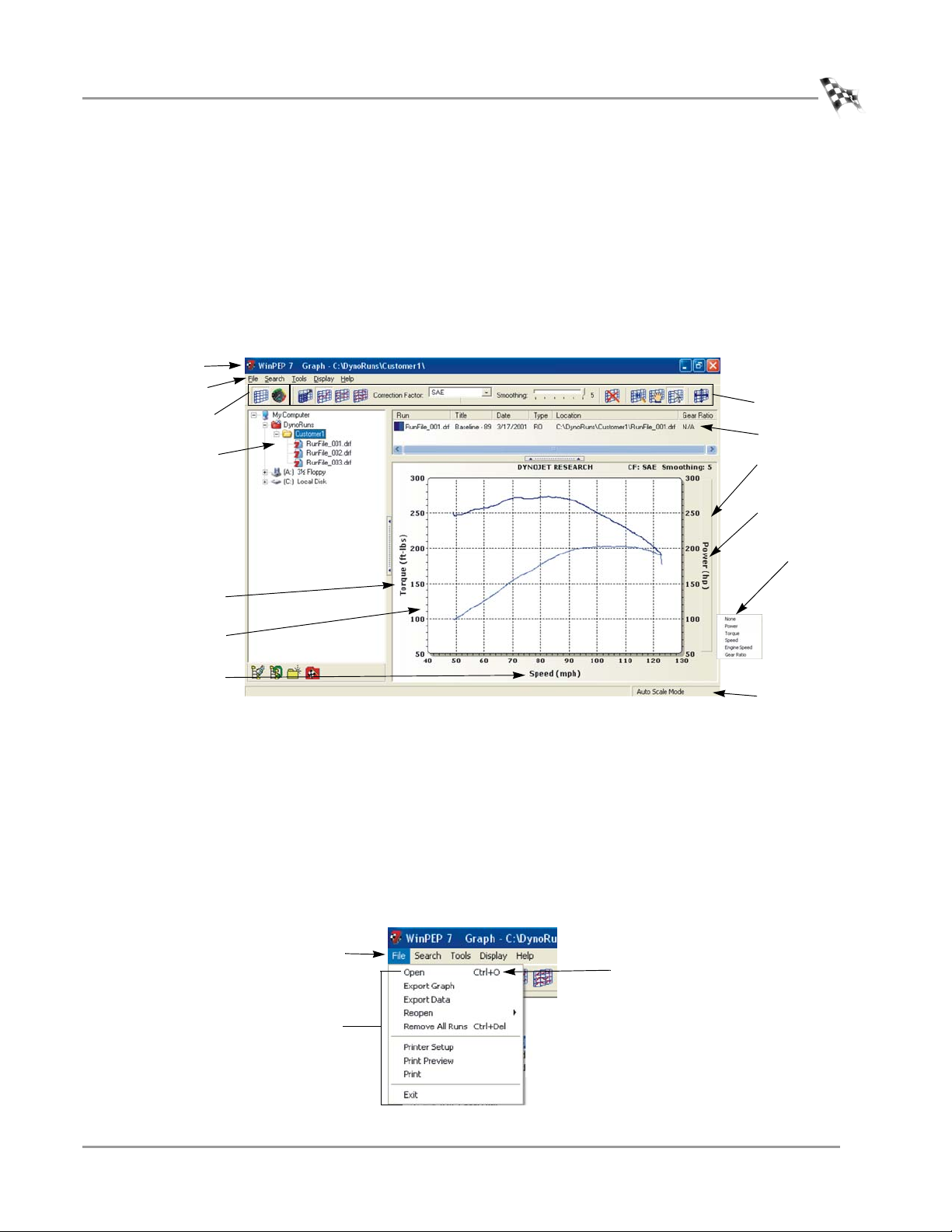

WINPEP 7 SOFTWARE INTERFACE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WinPEP 7 is designed to be user-friendly and intuitive. Once you understand the basic

layout, it will be easy for you to obtain information efficiently. This section provides a

quick look at standard interface controls, as well as features unique to WinPEP 7.

WinPEP 7 menus and dialog boxes conform to Microsoft Windows® conventions—

with a few enhancements. If you are new to Windows®, consult the documentation

resources provided with your computer for complete information about using Windows®.

The Graph screen is displayed by default when WinPEP 7 opens.

title bar

menus

navigation

toolbar

tree view

WinPEP 7 Software Interface

graph toolbar

list view

axis selection

button

axis channel

label

axis channel

label

graph display

axis channel

label

WINPEP 7 MENUS

There are two types of menus available in WinPEP 7. The menu bar, located across the

top of the screen, and pop-up menus that are available when you right click key areas,

such as: the TreeView, Graph Display, and ListView.

The menu bar displays the five menus available in WinPEP 7: File, Search, Tools,

Display, and Help. Each menu contains groups of related commands. Some

commands will be disabled depending on which screen you are currently in. Many

commands have a keyboard shortcut list after their name. You will learn more about

the menu bar in “The WinPEP 7 Menu Bar” on page 3-17.

axis

channels

scale mode display

Figure 2-3: Graph Features

menu choices

keyboard shortcut

commands

Figure 2-4: WinPEP 7 Menus

Version 2 WinPEP 7 User Guide

2-7

Page 24

CHAPTER 2

Using WinPEP 7 Help

USING WINPEP 7 HELP

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

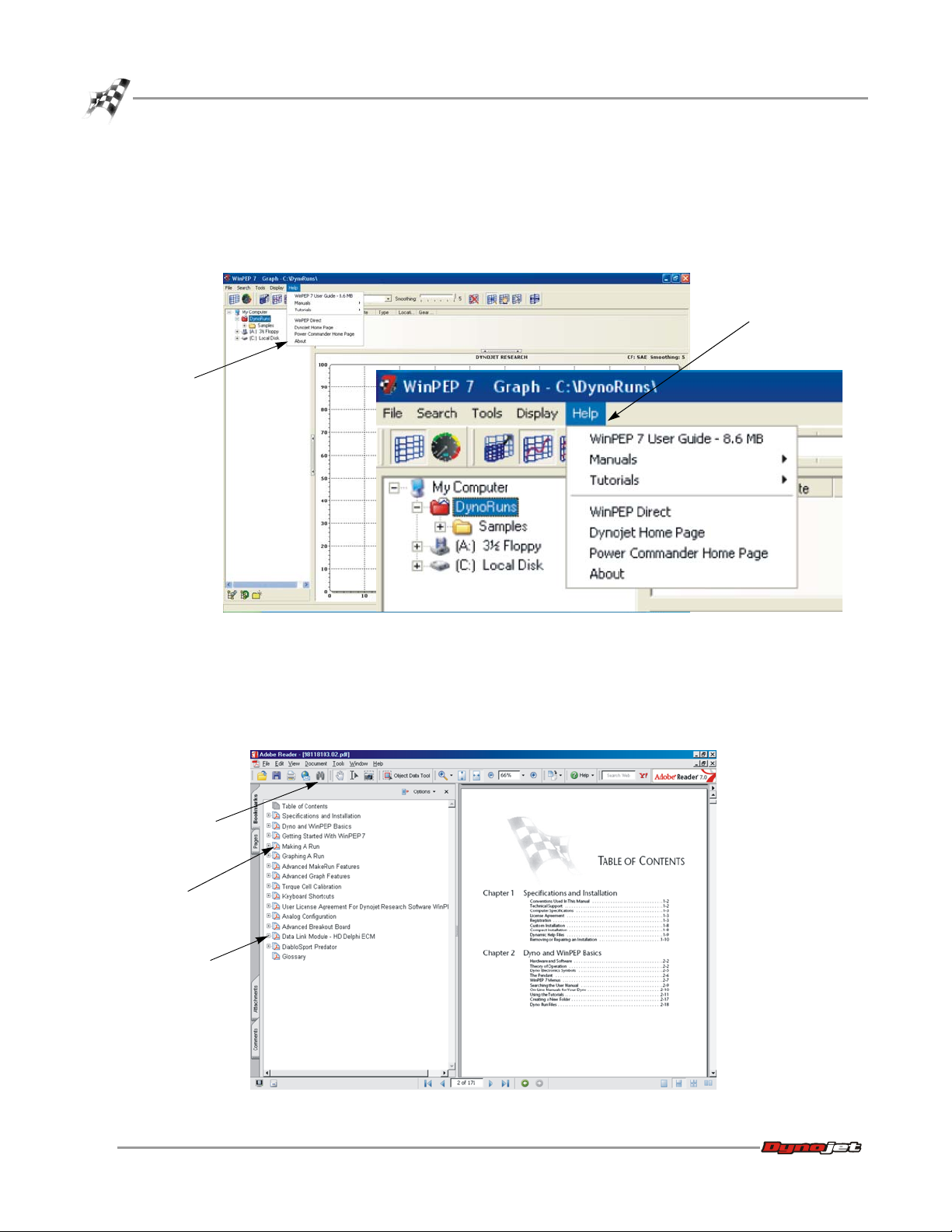

WinPEP 7 includes complete documentation in online Help. From the WinPEP 7

menu bar, choose Help to display the Help menu as shown in Figure 2-5. You can also

visit www.winpep.com to find user manuals and technical support.

help menu

enlarged view

showing help

menu

search icon

click item to

browse file

click plus sign (+)

to expand contents

Figure 2-5: Help Menu

Click Help !WinPEP 7 User Guide to show this user manual as a Public Document

Format (.pdf) file that you can browse and search.

Note: To display the manuals, you must have a program capable of displaying

.pdf files installed. Dynojet recommends Adobe Reader 6.0 or higher.

2-8

WinPEP 7 User Guide

Figure 2-6: On-Line User Manual

Page 25

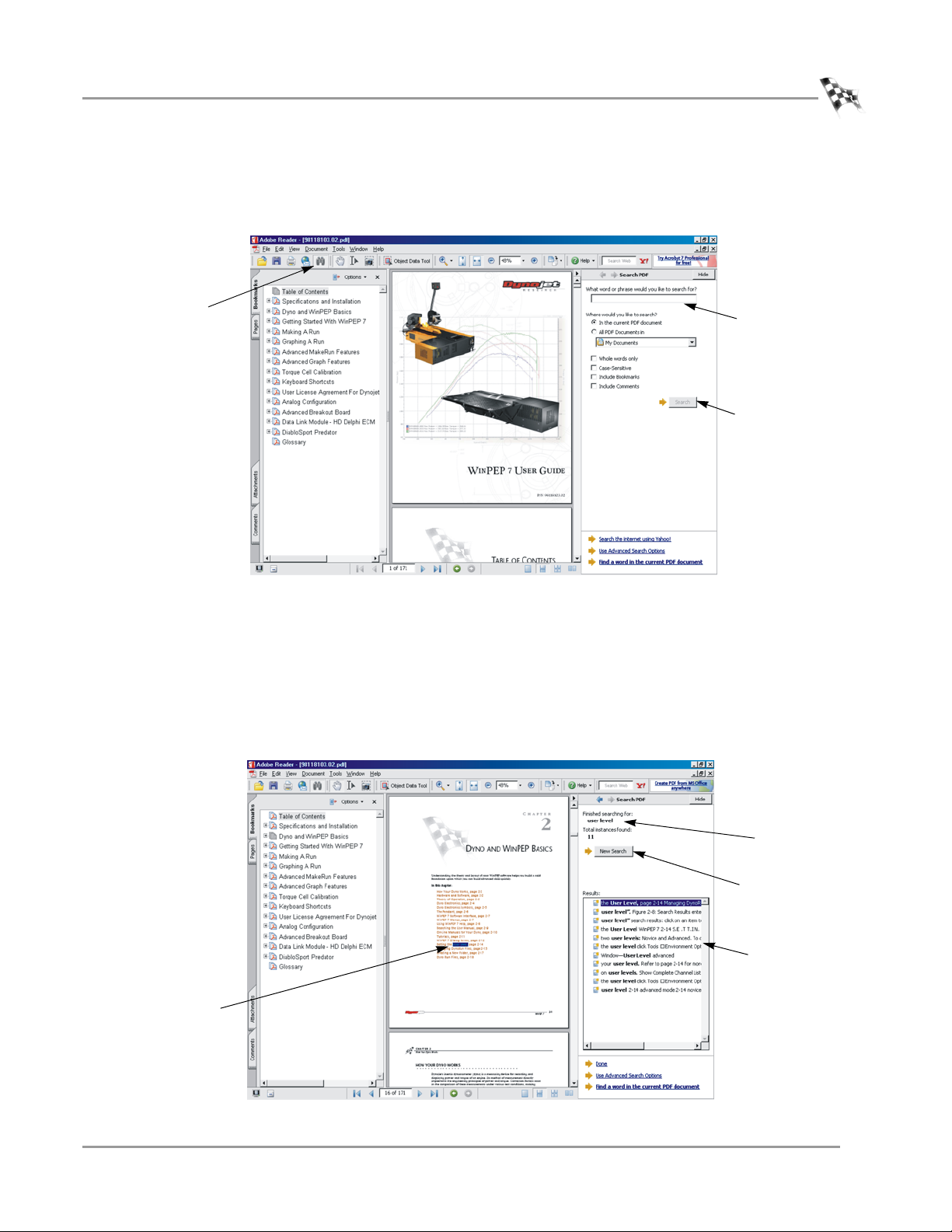

SEARCHING THE USER MANUAL

•Click the Search icon (which looks like a pair of binoculars) to search the on-line

user manual. The search window opens on your screen as shown in Figure 2-7.

DYNO AND WINPEP BASICS

Using WinPEP 7 Help

search icon

enter word or phrase

to search for

click search button

to display results

Figure 2-7: Search the User Manual

• Enter your search in the field below the prompt, “What Word or Phrase Would You

Like to Search For?”

•Click the Search button or press the Enter key. The results of your search will be

displayed as shown in Figure 2-8.

• Click on the items displayed in the right hand column under Results in order to

jump to that section of the manual. Figure 2-8 shows the results when searching for

the phrase “user level”.

search for the

phrase “user level”

new search button

search results: click

on an item to jump

highlighted search

result

Figure 2-8: Search Results

Version 2 WinPEP 7 User Guide

to that section of

the manual

2-9

Page 26

CHAPTER 2

Using WinPEP 7 Help

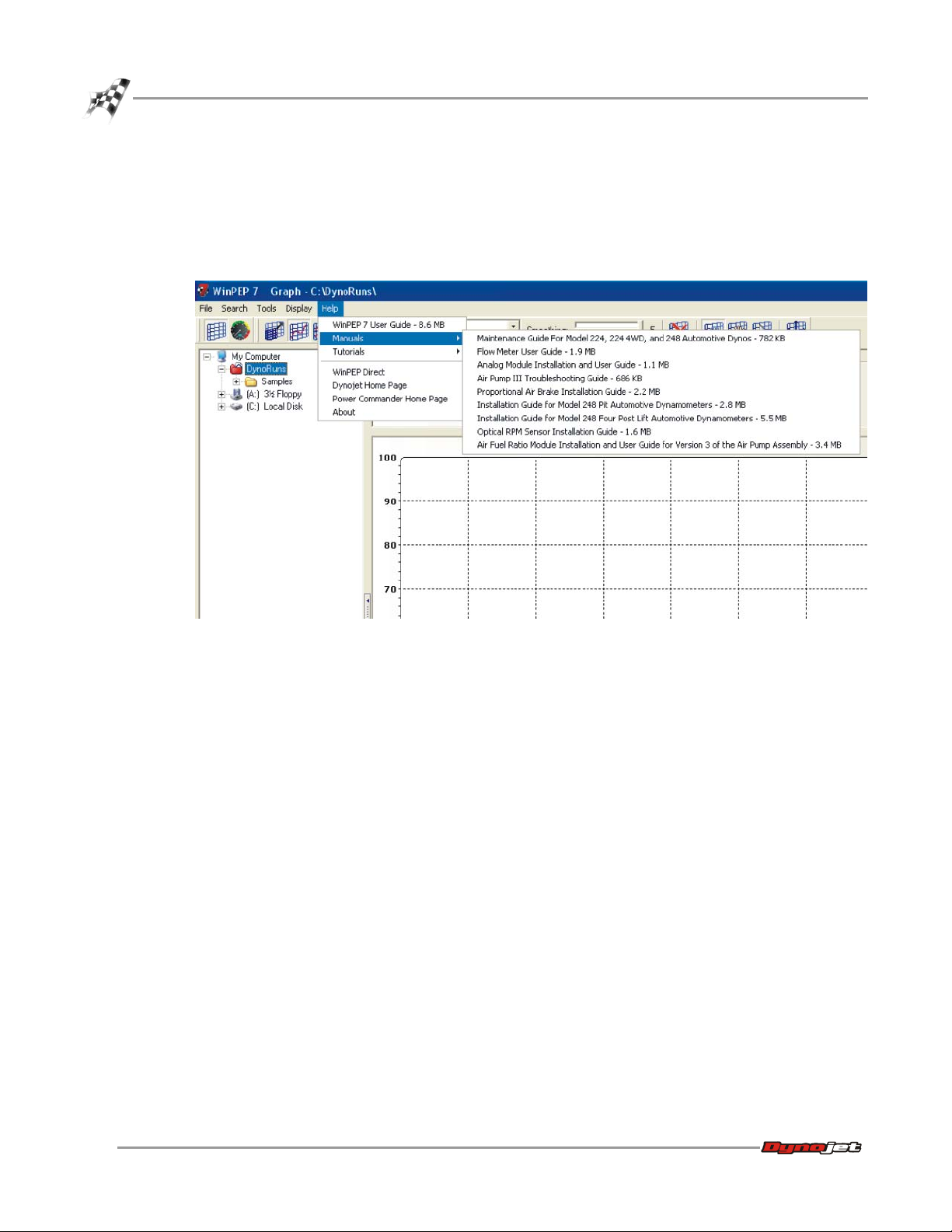

ON-LINE MANUALS FOR YOUR DYNO

On-line manuals are also available as .pdf files by choosing Help !Manuals and

selecting the manual you would like to view. In addition to the manuals provided by

Dynojet, you can also add your own .pdf files to the directory \WinPEP 7\Root in order

to see your own company manuals displayed on the help menu.

Figure 2-9: On-Line Manuals

2-10

WinPEP 7 User Guide

Page 27

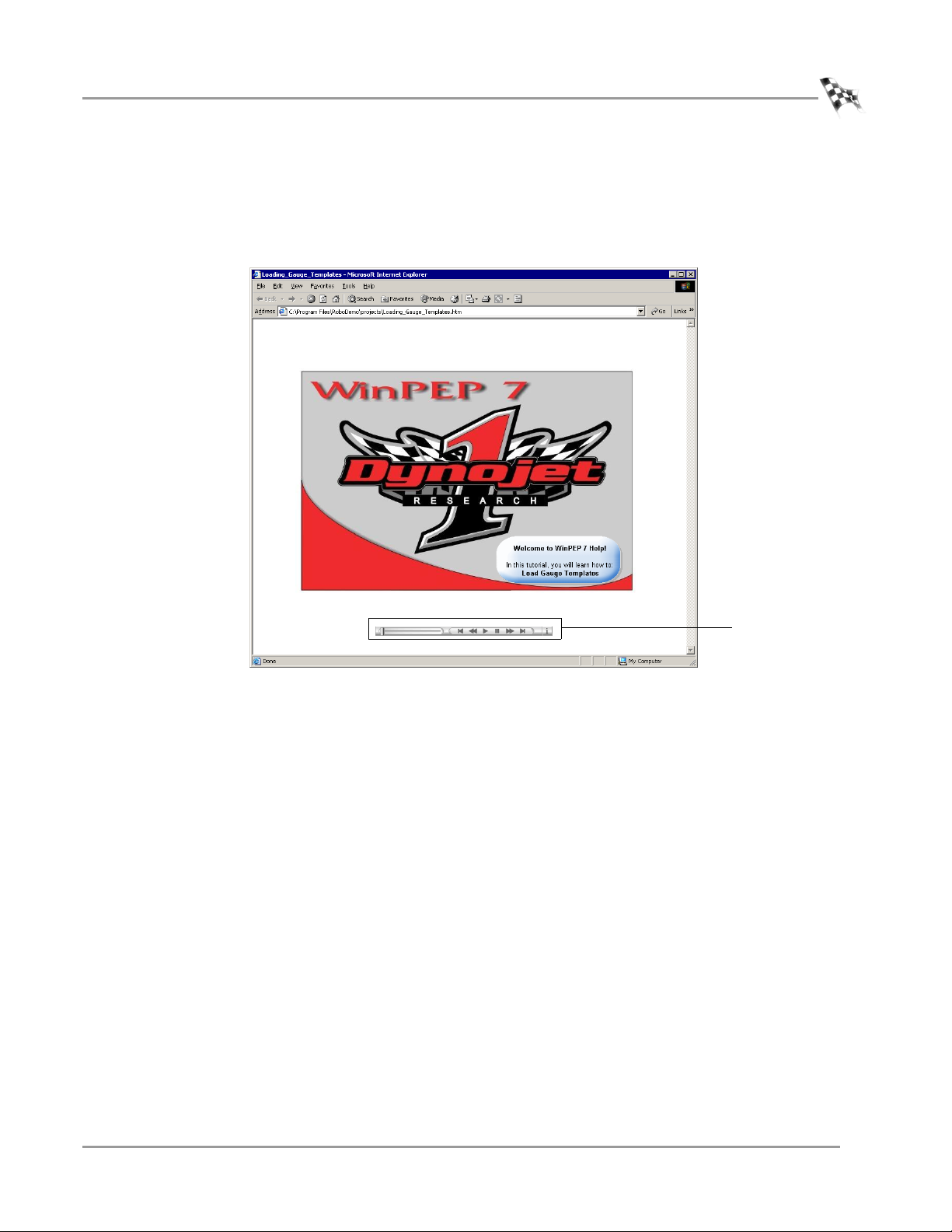

USING THE TUTORIALS

You can watch video tutorials by choosing Help !Tut ori al s and selecting the tutorial

you would like to view. Use the navigation bar in the tutorial to stop, pause, move

forward, or go back at any time during playback.

DYNO AND WINPEP BASICS

Using WinPEP 7 Help

Figure 2-10: Video Tutorial Navigation Bar

navigation bar

Version 2 WinPEP 7 User Guide

2-11

Page 28

CHAPTER 2

WinPEP 7 Dialog Boxes

WINPEP 7 DIALOG BOXES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

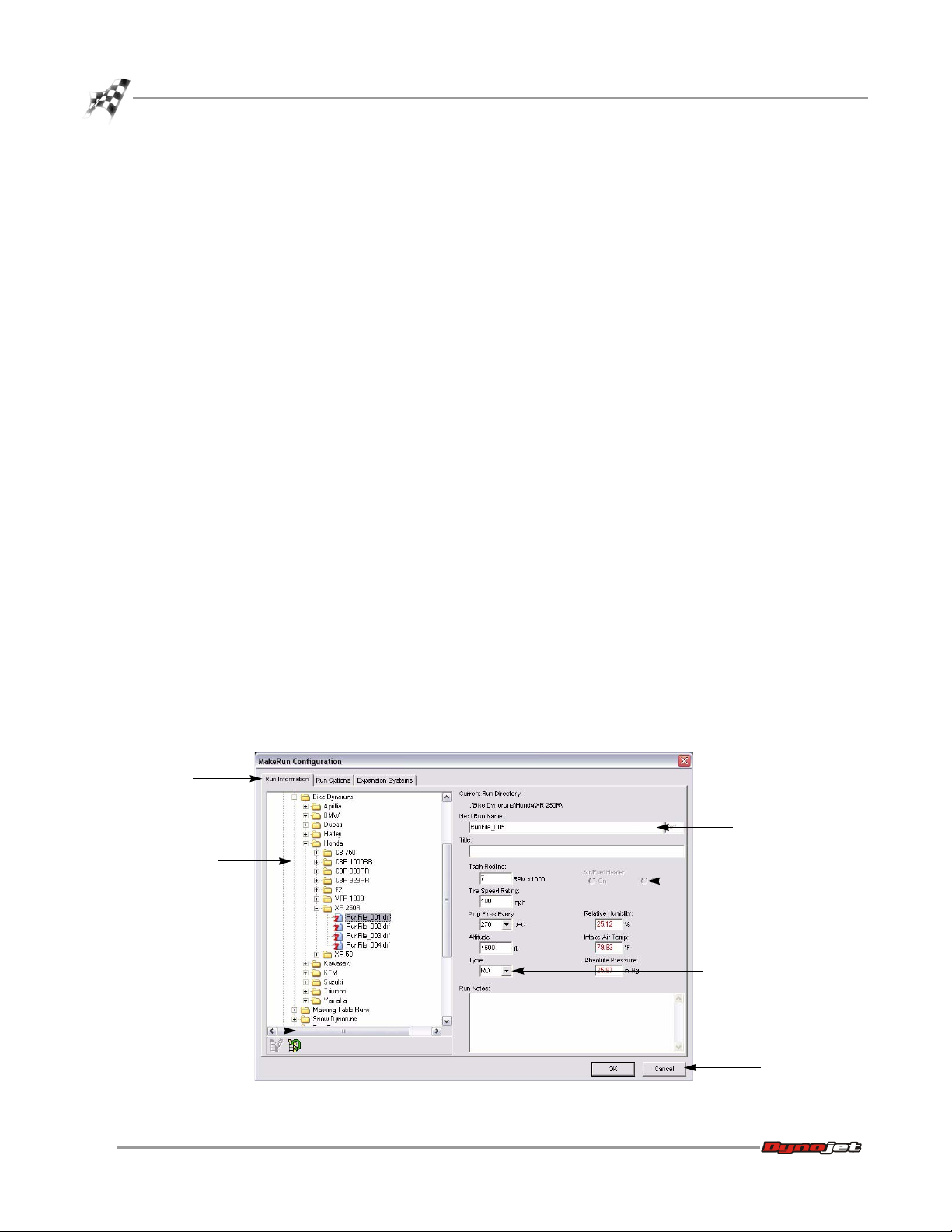

Many menu items display dialog boxes after you select them. An example is shown in

Figure 2-11. The dialog boxes in WinPEP 7 consist primarily of tabs, fields, drop-down

lists, radio (option) buttons, check boxes, and buttons.

Page Tabs—Many dialog boxes provide multiple functions through tabs. By clicking a

tab icon, you can display different sets of controls.

Fields—A field is a rectangular box for entering a specific value or information. For

example, you can enter the run name in the Next Run Name field shown in Figure 2-

11.

You can use the tab key to highlight the next field in a dialog box and shift+tab to

highlight the previous field.

Drop-down Lists—A drop-down list is a small menu within a dialog box. A dropdown list contains various options for you to choose from. Click on the arrow to

reveal the list.

page tab

tree view

Radio (Option) Buttons—A radio button lets you select options or turn options on

and off. Selecting a radio button may activate other controls and may expand a dialog

box to display more controls.

Check Boxes—A check box lets you turn options on and off. Selecting a check box

may activate other controls and may expand a dialog box to display more controls.

Buttons—A button performs an action. If a button has a bold outline, you can press

Enter when in any field of a dialog box to activate the button, rather than clicking the

button with your mouse. A button may also include a drop-down list that lets you

choose a type of action.

field

radio button

drop-down list

scroll bar

2-12

WinPEP 7 User Guide

button

Figure 2-11: WinPEP 7 Dialog Box Features

Page 29

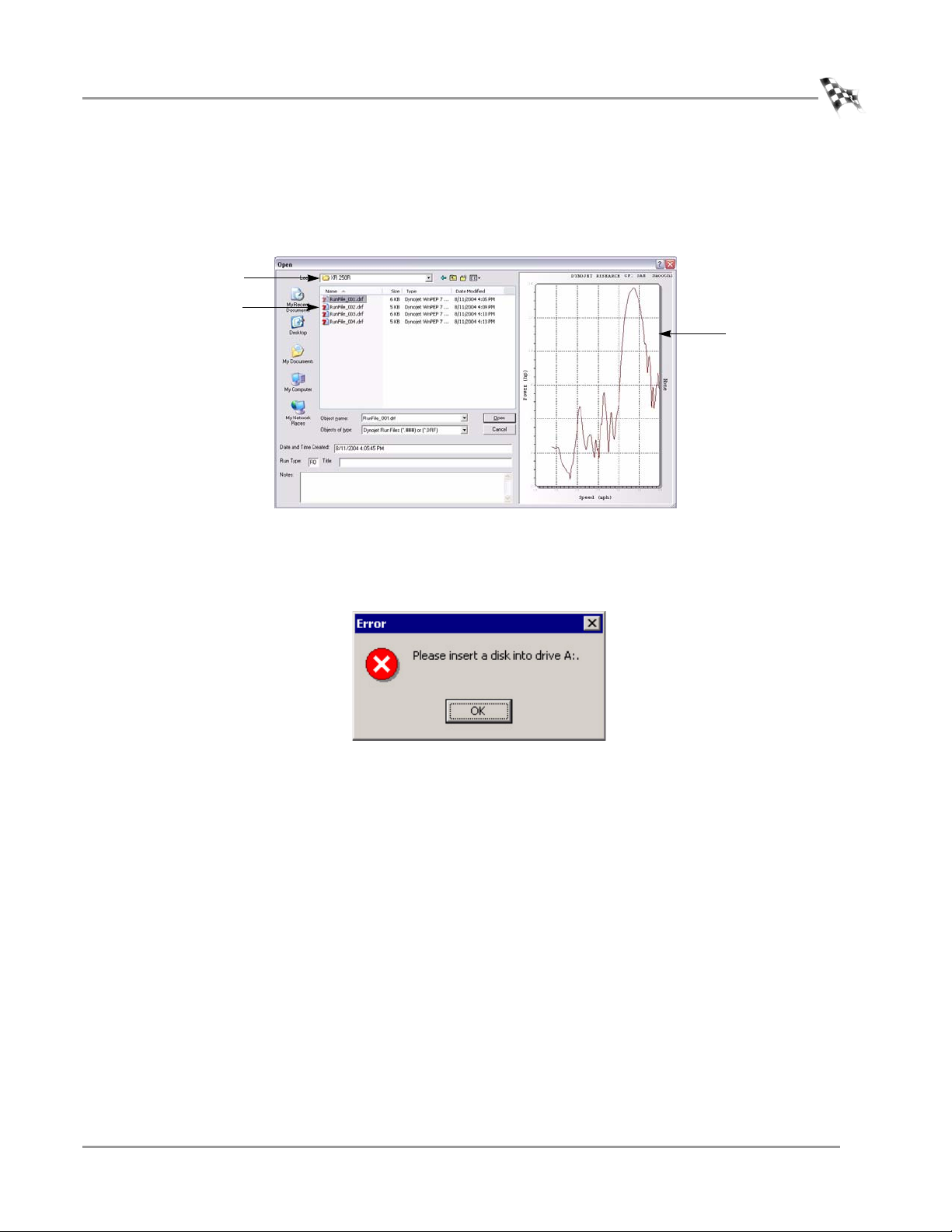

Open, Save As Dialog boxes—These dialog boxes are used to open or save files;

they include standard Windows® controls for navigating through disks and folders so

you can locate files, or choose where you want to save files. WinPEP 7 includes

additional areas for previewing graphs, notes, and titles.

browse directories

locate files

DYNO AND WINPEP BASICS

WinPEP 7 Dialog Boxes

graph preview

Figure 2-12: Open Dialog Box

Warning Dialog Box—A warning dialog box alerts you when there is a problem and

often suggests a solution.

Figure 2-13: Warning Dialog Box

POWER THROUGH KEYBOARD COMMANDS

As you use WinPEP 7, you will develop your own working style. Maybe you will prefer

to use the mouse and menu commands or you may find that you prefer the quick

access to features provided by keyboard commands. A list of keyboard commands is

available in

Version 2 WinPEP 7 User Guide

2-13

Page 30

CHAPTER 2

Setting the User Level

SETTING THE USER LEVEL

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

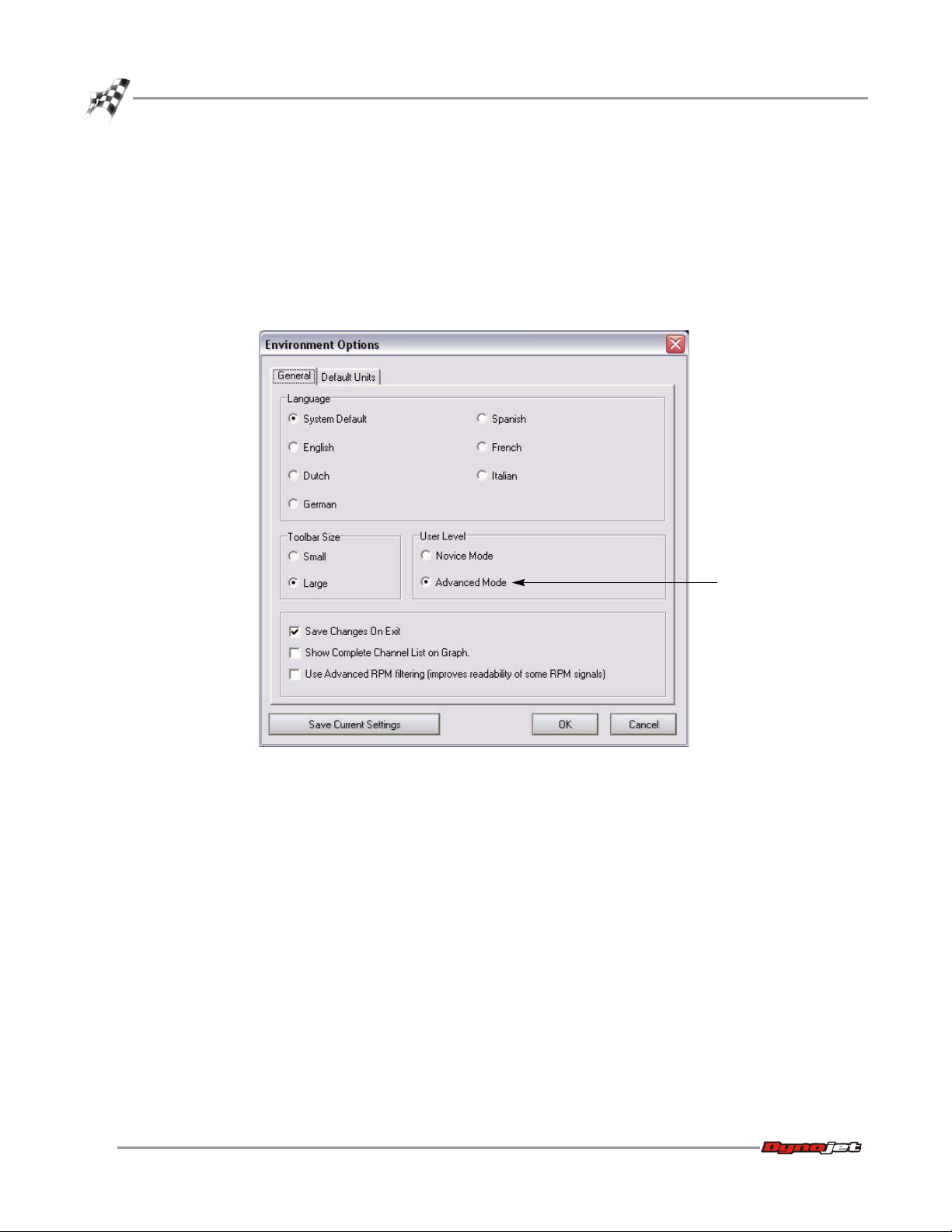

WinPEP 7 lets you work in two user levels: Novice and Advanced. To change the user

level click To ol s

WinPEP 7 defaults to Advanced Mode. Dynojet recommends you use Advanced Mode.

Advanced Mode enables all WinPEP 7 features and functions giving you complete

control over the software.

!

Environment Options and click on the General tab.

advanced mode

Figure 2-14: Environment Options Window—User Level

2-14

WinPEP 7 User Guide

Page 31

DYNO AND WINPEP BASICS

MANAGING DYNORUN FILES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The WinPEP 7 software makes it easy to create and store your dyno run files. Icons

located near the bottom of the screen allow you to manage your folders and files, so

that you can easily retrieve your dyno run results.

The default directory C:\DynoRuns is automatically created when you install the

software, unless you selected to have a different default directory created. The default

C:\DynoRuns directory is automatically mapped and shown with a red folder icon as

shown in Figure 2-15. For more information on using the tree view and managing

files, see “TreeView” on page 3-6.

default directory

Managing DynoRun Files

Figure 2-15: TreeView Showing Default Directory

find run file

refresh

new folder

Version 2 WinPEP 7 User Guide

2-15

Page 32

CHAPTER 2

Sample Files

SAMPLE FILES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Samples directory

Sample files that were installed along with your software provide an example of well

organized dyno run files that use folders (also called directories) arranged by the

make and model of the vehicle being dynoed. Using folders makes it easy to find the

information you want and to compare data for different vehicles.

You can double-click on the DynoRuns folder to expand its contents. You should see

the Samples folder listed below the DynoRuns folder as shown in Figure 2-16. To

expand (or shrink) the contents of a folder, double-click on it or pick the adjacent (+)

plus sign.) Figure 2-16 shows a list of folders organized into vehicle makes.

Figure 2-16: Showing the Sample Files

Figure 2-17 shows the contents of the Ford folder expanded. Inside it is a folder for

the Mustang model dynoruns. To display the graph of a dyno run, you can doubleclick on it. Click on the Remove All Runs icon to clear the graph screen.

Remove All Runs

icon

2-16

WinPEP 7 User Guide

Figure 2-17: Graphing a Sample File

Page 33

CREATING A NEW FOLDER

You can use the tree view to create new folders to manage your files. To keep your

files organized, put your new folders inside the DynoRuns folder.

A new folder will appear in the treeview below the DynoRuns folder as shown in

Figure 2-18 when you click the New Folder icon. New folders are created inside the

currently selected folder which is shown highlighted.

new folder

DYNO AND WINPEP BASICS

Sample Files

title bar

Figure 2-18: Creating a New Folder

You can replace the text, “New Folder”, by typing the name you would like to have

appear for your folder, such as your customer’s name or the make of the vehicle being

tested and then pressing the Enter key.

The current folder name appears in the title bar as shown in Figure 2-19 so that you

can tell where your dyno run files will be stored.

Creating separate folders for each customer’s dyno runs within a make and model

structure is a good practice. It lets you find the appropriate runs quickly and also

helps you get the most from WinPEP’s ability to automatically increment the run file

names.

Figure 2-19: Title Bar Showing Current Folder Name.

Version 2 WinPEP 7 User Guide

2-17

Page 34

CHAPTER 2

Sample Files

DYNO RUN FILES

The first file you sample is named runfile_001.drf by default. It is stored in the

C:\DynoRuns folder unless you have changed from the default settings.

Figure 2-20 shows Customer1 as the current folder. The open folder icon appears

next to it inside the C:\DynoRuns folder. The new runs are stored in that folder.

File names automatically increment for each successive run.

dyno run file

Figure 2-20: Dyno runs Stored in the Current Folder

2-18

WinPEP 7 User Guide

Page 35

G

ETTING

S

TARTED

W

ITH

C HAPTER

W

IN

PEP 7

3

This chapter provides the information you need to quickly start using the WinPEP 7

software to view dyno runs and connect and troubleshoot your dyno electronics.

In this chapter:

Using WinPEP 7, page 3-2

Starting WinPEP 7, page 3-2

WinPEP’s Screens, page 3-2

The Graph View Screen, page 3-3

TreeView, page 3-6

ListView, page 3-9

MakeRun and Your Dyno Electronics, page 3-10

Com Port Selection, page 3-10

Connecting the Dyno Electronics, page 3-11

Troubleshooting the Dyno Electronics, page 3-13

Replacing the Fuses, page 3-13

Exploring the MakeRun Screen, page 3-14

Load Template, page 3-16

The WinPEP 7 Menu Bar, page 3-17

File Menu page 3-17

Search Menu, page 3-17

Tools Menu, page 3-18

Display Menu, page 3-19

Help Menu, page 3-20

WinPEP 7 User Guide

3-1

Page 36

CHAPTER 3

Starting WinPEP 7

STARTING WINPEP 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

You can start WInPEP 7 two ways: by double-clicking the desktop icon or by selecting

Start

!

All Programs! WinPEP 7! WinPEP 7.

When WinPEP starts, the Graph View, shown in Figure 3-21 shows by default.

WINPEP’S SCREENS

WinPEP’s two screens are:

•the Graph View screen

• the MakeRun screen.

Icons at the left of the toolbar let you switch from the Graph View screen to the

MakeRun screen.

The Graph View screen is optimized for displaying your dyno runs graphically.

The MakeRun screen lets you connect with your dyno electronics to sample and store

dynoruns. Refer to “Exploring the MakeRun Screen” on page 3-14

Note: The MakeRun screen is only accessible if you are using WinPEP as a dyno

control system. The MakeRun button and the MakeRun screen will not be visible

when the software is used exclusively as a run viewer.

3-2

WinPEP 7 User Guide

Page 37

GETTING STARTED WITH WINPEP 7

Exploring the Graph View Screen

EXPLORING THE GRAPH VIEW SCREEN

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Graph View contains features that can be accessed from the menu choices at the

top of the Graph window, by clicking on the buttons in the toolbar, or by right

clicking to show options.

title bar

menus

navigation

toolbar

tree view

axis channel

label

graph display

graph toolbar

list view

axis selection

button

axis channel

label

axis

channels

axis channel

label

Figure 3-21: The Graph Screen

screen element function

Title bar The area displaying the name of the screen you are

currently working in, the current run directory, and current

run name.

Menu bar The area containing menu options.

Navigation Toolbar A dockable toolbar that contains shortcuts for moving

between the Graph and MakeRun screens.

Graph Toolbar A dockable toolbar that contains shortcuts to many of the

menu commands and commonly used features.

TreeView The area that displays a tree structure for viewing dyno runs

allowing access to the runs from an enhanced Windows

tree format. Right click on the tree to access the tree menu.

The TreeView is only available in Advanced Mode.

ListView The area displaying information about the run(s) currently

graphed including the file name, title, date, type, location,

and average gear ratio.

Graph Display The area in which you view the run data in graph format.

Axis Selection Button Lets you access the axis channels. As you move your cursor

over the axis label, the axis selection button will appear.

Axis Channel Label Displays the current channel being graphed.

Axis Channels A window that contains all the available channels for that

axis. Available channels may differ depending on the dyno

model and configuration.

Scale Mode Display Displays the current scaling mode, auto (default) or

manual.

scale mode display

®

Version 2 WinPEP 7 User Guide

3-3

Page 38

CHAPTER 3

Exploring the Graph Toolbar

EXPLORING THE GRAPH TOOLBAR

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Graph toolbar is a collection of buttons allowing quick access to commonly used

graph features.

graph toolbar

Figure 3-22: Location of the Graph Toolbar

3-4

WinPEP 7 User Guide

Page 39

GETTING STARTED WITH WINPEP 7

A description of the toolbar buttons and functions follows.

press this button to

Fill the entire window with the graph.

Display the graph with two vertical axes (normal).

Display the graph with four vertical axes.

Display the graph with six vertical axes.

The correction factor changes the view of the graph

using either SAE, DIN, EEC, JIS, STD, or Uncorrected

correction factors.

Smoothing lets you to show six different levels of

detail in the graph. Level zero shows the most detail

while level five shows the least detail. Level three is

the default setting.

Remove all currently graphed runs displayed in the

ListView.

Exploring the Graph Toolbar

Change the magnification level in the graph display.

Clicking and dragging on the graph selects a zoom

box.

Clicking and dragging on any axis zooms in and out

on that axis only.

Move the graph around inside the window.

Move the vertical cursor or select runs (do not pan or

zoom).

Restore the graph to default scaling.

Version 2 WinPEP 7 User Guide

3-5

Page 40

CHAPTER 3

TreeView

TREEVIEW

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using a tree structure for viewing dyno runs lets you access your runs from an

enhanced Windows® tree format. The TreeView is only available in Advanced Mode.

tree view

folder

file

Figure 3-1: TreeView

3-6

WinPEP 7 User Guide

Page 41

GETTING STARTED WITH WINPEP 7

TreeView

Right click the file or folder to view the available options. The menu display depends

on whether you have a folder (directory) or a file (run) selected. A description of

these options are listed below. To see a list of keyboard shortcuts, refer to

Appendix B.

right click

on a file

shortcut menu

Figure 3-2: Right Click to Show File Shortcuts

When a File is Selected

• Load Run — places the selected run file(s) into the ListView for graphing.

• Cut/Copy/Paste — cut removes the selected run file(s) and places them on the

clipboard; copy places the selected run file(s) on the clipboard without removing

them; and paste places the clipboard contents into the selected location.

• Delete — deletes the run file.

• Rename — renames the selected run.

• Renumber — automatically renumbers the runs to fill in gaps in the number

sequence.

• Find Run Files — opens the Search dialog box.

• Refresh — forces WinPEP 7 to re-scan the hard drive and update the TreeView.

for files

Version 2 WinPEP 7 User Guide

3-7

Page 42

CHAPTER 3

TreeView

WHEN A FOLDER IS SELECTED

• New Folder — adds a new folder to store runs in. When you test a new make,

model, or customer’s vehicle, you can create a new folder to store these new runs.

• Cut/Copy/Paste — cut removes the selected run file(s) and places them on the

clipboard; copy places the selected run file(s) on the clipboard without removing

them; and paste places the clipboard contents into the selected location.

• Delete — deletes the selected directory and all of the sub folders and files in that

directory.

Note: Deleting a mapped directory (one that appears with a red folder) will not

delete the real directory. When deleting folders inside a mapped directory (ones

that appear yellow), the real directory and files will be deleted. After selecting to

delete the file, if you do indeed intend to delete them, click Yes at the prompt,

“Are you sure you want to remove the folder and move all of its contents to the

recycle bin?” If you wish to restore the deleted files, locate them in the recycle bin

and restore them.

• Rename — renames the selected directory.

• Renumber — automatically renumbers all runs in the currently selected folder(s)

to fill in gaps in the number sequence.

right click

on a folder

• Map Directory — displays a copy of a local or network directory making your run

files easier to find. Use Map Directory for run file directories you use frequently.

shortcut menu

for folders

Figure 3-3: Right Click to Show Folder Shortcuts

3-8

WinPEP 7 User Guide

COMMON TO BOTH

• Sort Runs By — rearranges the files by date or file name (default).

• Display Details — displays the date and time after the run name.

• Recursive Renumbering — if this option is on, selecting Renumber will renumber

all the run files in all the selected directories and their sub directories. The run files

will be automatically renumbered to eliminate gaps in their number sequence.

Page 43

GETTING STARTED WITH WINPEP 7

LISTVIEW

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The ListView displays information about the run(s) currently graphed including the

file name, title, date, type, location, and average gear ratio. Right click the ListView to

view the available options. A description of these options are listed below.

ListView

run information

list view

Figure 3-4: ListView

• View Run Info — lets you view the information stored in the run file. You can only

make changes to the Run Title, Run Type, and Notes.

• Remove Selected Runs — removes the highlighted run(s) from the list of runs

displayed in the ListView.

• Remove All Runs — removes all of the runs displayed in the ListView.

• Change Line Style — lets you change the line style and colors used for graphing a

dyno run. See “Formatting Graphs” on page 7-2 for more details.

Version 2 WinPEP 7 User Guide

3-9

Page 44

CHAPTER 3

MakeRun and Your Dyno Electronics

MAKERUN AND YOUR DYNO ELECTRONICS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The MakeRun screen is only accessible if you are using WinPEP as a dyno control

system. The WinPEP software’s Graph View screen can be used to view your dyno

runs whether or not you have the dyno electronics connected.

THE DATA7.CFG FILE

When you install WinPEP as a dyno control system, a file named Data7.cfg is created

on your computer. (A file named Data7-2.cfg is created if you have two dyno drums.)

This file stores the specific information about your dyno drum. This file must exist in

the correct location on your computer in order for WinPEP to communicate with your

dyno electronics.

Note: You will not see the MakeRun icon on your screen unless you have your

dyno electronics connected to your computer, turned on and functioning

properly, and the Data7.cfg file in the correct location on your computer.

To display the MakeRun screen, click the MakeRun button on the toolbar or select

Display

appear similar to Figure 3-5.

!

MakeRun Screen from the menu choices. The Make Run Screen should

COM PORT SELECTION

The dyno electronics is connected to a communication (com) port on the back of

your computer. There may be several com ports on your computer and in order for

WinPEP 7 to communicate with the dyno electronics, the program must know which

com port is being used. If you know which com port is being used, you can manually

select the port. Make sure you are in the MakeRun screen then select

To ol s

!

MakeRun Options !Dyno Port and choose the com port. If you do not

know the correct port, use the Find Dyno Electronics feature.

3-10

WinPEP 7 User Guide

Page 45

CONNECTING THE DYNO ELECTRONICS

The “Not Connected” message in the MakeRun Status Bar, shown in Figure 3-5,

indicates the computer is not currently communicating with the dyno electronics.

GETTING STARTED WITH WINPEP 7

MakeRun and Your Dyno Electronics

Figure 3-5: MakeRun Screen with the Dyno Electronics Not Connected

Version 2 WinPEP 7 User Guide

3-11

Page 46

CHAPTER 3

MakeRun and Your Dyno Electronics

Use the following steps to verify the dyno electronics is properly connected to your

computer and communicating with WinPEP 7.

1 Verify the dyno electronics is on and connected to your computer.

2 Make sure you are in the MakeRun screen.

3Select Search

WinPEP 7 automatically searches for the dyno electronics.

If WinPEP 7 is unable to find the dyno electronics, a message telling you the dyno

electronics was not found will appear. Verify the dyno electronics is on and

connected to your computer. Have WinPEP 7 search for the dyno electronics

again.

4 In our example, the dyno electronics was found. Click OK.

The message, “Clear Area Behind Dyno!” in the Status Bar indicates WinPEP 7 is

connected and ready to proceed.

!

Find Dyno Electronics.

3-12

WinPEP 7 User Guide

Figure 3-6: Dyno Electronics—Connected

Page 47

TROUBLESHOOTING THE DYNO ELECTRONICS

1Close WinPEP 7.

2 Verify the serial cable is connected to the dyno electronics. Unplug the cable and

plug it back in.

3 Verify the serial cable is connected to the computer. Unplug the cable and plug it

back in.

4 Verify the dyno electronics is on and the green power LEDs on all the modules are

illuminated bright and equally.

Note: A dim green light may indicate a blown fuse. Refer to “Replacing the Fuses

in the Dyno Electronics”.

5 Launch WinPEP 7.

6 Repeat the steps for connecting the dyno electronics.

Note: If you have tried these steps and your dyno electronics is still not

communicating with your computer, verify that the file Data7.cfg exists in your

WinPEP software installation directory.

REPLACING THE FUSES IN THE DYNO ELECTRONICS

GETTING STARTED WITH WINPEP 7

MakeRun and Your Dyno Electronics

The CPU module uses two fuses while the other modules use one fuse.

Hazardous voltage. To avoid risk of electrical shock, disconnect all power to

the dyno electronics.

1 Gently remove the fuse holder from the back of the module.

2 Replace the fuse with a fuse type listed below.

3 Firmly replace the fuse holder in the back of the module.

For continued protection against risk of fire, replace only with a fuse of the

same type and having the same electrical rating.

part number fuse description module used with

54210020 Fuse, 1/4A, 250V, 5mm x 20mm CPU module

54210300 Fuse, 3A, 250V, 5mm x 20mm, FA CPU module

54210100 Fuse, 1 AMP, 250V, 5mm x 20mm I/O module, RPM module, and

Atmospheric Sensing module

Version 2 WinPEP 7 User Guide

3-13

Page 48

CHAPTER 3

Exploring the MakeRun Screen

EXPLORING THE MAKERUN SCREEN

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The MakeRun screen contains features that can be accessed from the menu choices at

the top of the MakeRun window, by clicking on the buttons in the toolbar, and even

through your pendant. A description of the functions and displays follows.

title bar

menu bar

navigation

toolbar

MakeRun toolbar

MakeRun screen

load control

set point edit

indicator lights

sampling timer

status bar

Figure 3-7: MakeRun Features

screen element function

Title bar The area displaying the name of the screen you are

currently working in, the current run directory, and

current run name.

Menu bar The area containing drop down menu options.

Navigation Toolbar A dockable toolbar that contains shortcuts for moving

between the Graph and MakeRun screens.

MakeRun Toolbar A dockable toolbar that contains shortcuts to many of the

menu commands and commonly used features.

MakeRun Screen The area in which you view the template. Templates allow

the user to save and restore specific views. Each view is a

combination of gauges, bars, trend line graphs, LEDs, and

digital displays. Each of these controls is associated with

one or more data channels.

Load Control Set Point Edit The area in which you manually enter the load control set

point. Use the arrows to increase or decrease the set point

by the current step size on the currently selected gauge or

click on the load control value edit field and enter a

specific value.

Edit the current step size (amount of increase/decrease in

the set point value) in the Gauge Property Editor.

3-14

WinPEP 7 User Guide

Page 49

GETTING STARTED WITH WINPEP 7

Exploring the MakeRun Screen

screen element function

Status Bar The area that contains run messages and warnings.

Indicator Lights A set of lights which may be illuminated depending on the

current action. For example, when you are sampling, the

green light is illuminated. Green is Sampling, yellow is

Load Control, and red is Brake.

Sampling Timer The area displaying the duration of the run. The sampling

timer starts when a run is started and stops when the run

is ended.

EXPLORING THE MAKERUN TOOLBAR

The MakeRun toolbar is a collection of buttons allowing quick access to commonly

used MakeRun features. A description of the toolbar buttons and functions follows.

press this button to

Open the MakeRun Configuration dialog box.

Turn on Gauge editing and open the Gauge toolbar.

Automatically start and stop a run.

Enable Load Testing.

Start/stop sampling. This button corresponds to the

green button on your pendant and Enter on your

keyboard.

Start/stop Load Control. This button may be disabled

if your dyno does not support load control. This

button corresponds to the letter L on your keyboard.

Turn on/off the brake. This button corresponds to the

red button on your pendant and the Spacebar on your

keyboard.

Version 2 WinPEP 7 User Guide

3-15

Page 50

CHAPTER 3

Exploring the MakeRun Screen

LOADING A TEMPLATE

You c a n lo ad a template to display gauges you previously saved in a template file. To

learn more about creating your own templates, refer to “Creating and Editing Gauges

(Templates)” on page 6-12. Registered users can also download additional templates

from the internet at http://www.winpep.com/auth/downloads.php. Ask your

salesperson or technician if you need help creating a login name and password.

The following steps describe how to load a template:

1 Make sure you are in the MakeRun screen.

2 Verify you are connected to the dyno electronics. Refer to “Dyno Electronics” on

page 2-4 for more information.

3Select File

3-8.

4 Browse to a directory that contains Gauge Template files (*.tem). WinPEP7

installs with several default templates. The templates are in the WinPEP7 install

directory in a folder called Templates.

5 Select a template and click Open. The gauges saved in that template will appear

on the MakeRun screen.

!

Load Template. An Open dialog box will appear as shown in Figure

3-16

WinPEP 7 User Guide

Figure 3-8: Load Template

Page 51

GETTING STARTED WITH WINPEP 7

THE WINPEP 7 MENU BAR

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The WinPEP 7 menu bar is comprised of the file, search, tools, display and help menus.

FILE MENU

Open—lets you browse to any directory containing run files and select files for

viewing. Open is available only in the Graph screen.

The WinPEP 7 Menu Bar

Export Graph. lets you save an image of the current graph to a file. Export Graph is

available only in the Graph screen. The following image formats are supported:

•JPEG, JPG

•BMP

•EMF

•WMF

Export Data—lets you export the data used to construct the graph to a file or a

printer. Export Data is available only in the Graph screen.

Save Template. lets you save the gauges displayed on the MakeRun screen as a

template. Save Template is available only in the MakeRun screen while in Edit Mode.

Load Template. displays a previously saved template of gauges in the MakeRun

screen. Load Template is available only in the MakeRun screen.

Reopen. displays a list of recently viewed run files. Select any run file to display that

run on the graph. Reopen is available only in the Graph screen.

Remove All Runs. removes all runs currently selected on the graph. Remove All Runs

is available only in the Graph screen.

Printer Setup/Print Preview/Print. These commands are only available in the Graph

screen. These commands may be used to preview, edit, and print simple output of the

graph. Note that the Conditions will always be printed. Be sure to set the paper

orientation to landscape in the printer setup. These commands are available only in

the Graph screen.

Joint Photographic Expert Group

Windows Bitmap

Enhanced Metafile

Windows Metafile

Exit. exits WinPEP 7 from both the MakeRun and Graph screens.

SEARCH MENU

Find Run File. opens the WinPEP Search window. This window lets you search for run

files by name, titles containing certain text, and the advanced search lets you

search by dates. This choice is only available when you are in the Graph screen. It

appears grayed-out when you are in the MakeRun screen.

Find Dyno Electronics. searches the available com ports for the dyno electronics. If

the dyno electronics is found, the correct com port is selected. If the dyno

electronics is not found, an error message will appear. Refer to “Connecting the

Dyno Electronics” on page 3-11 for more information on connecting the dyno

electronics. Find Dyno Electronics is available only in the MakeRun screen.

Version 2 WinPEP 7 User Guide

3-17

Page 52

CHAPTER 3

The WinPEP 7 Menu Bar

TOOLS MENU

Restore All Defaults—restores all settings to default.

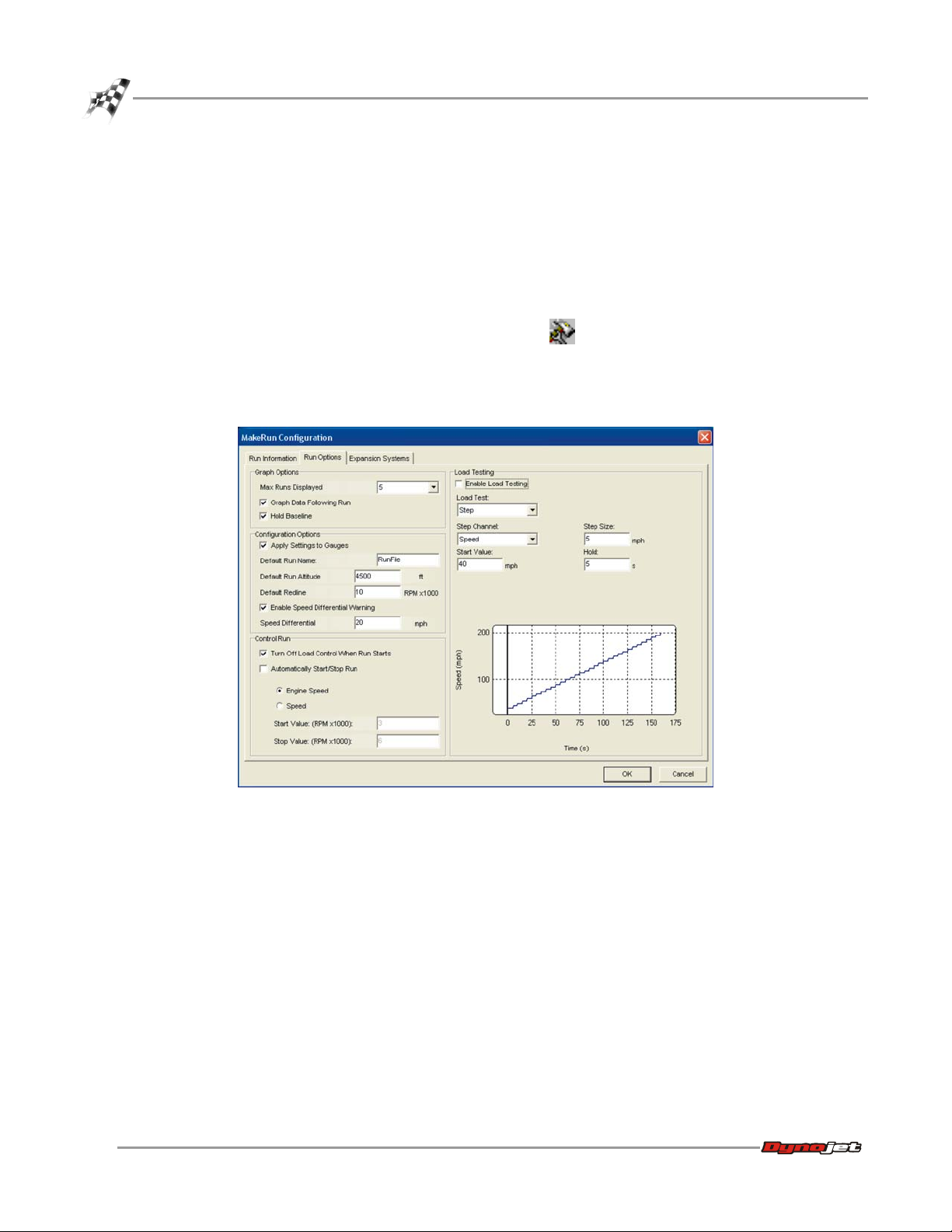

MakeRun Options—the different MakeRun options are discussed below. Many of

these options are covered in greater detail later in this guide.

• MakeRun Configuration — displays the MakeRun Configuration dialog box.

• PID Coefficients — displays the PID Coefficients dialog box.

• Torque Cell Calibration — launches the Torque Cell Calibration Wizard. This

• Analog Configuration — displays the Analog Configuration dialog box. Refer

• Dyno Electronics Information — displays information about the dyno

• Edit Mode — lets you modify and add gauges to the MakeRun screen.

• Te m pla t e O p ti o ns — displays the Template Options dialog box used to

• Gauge Configuration — displays the Gauge Configuration dialog box used to

• Dyno Port — lets you select the com (communications) port used to

wizard displays step by step instructions for calibrating the torque cell. Refer

to Appendix A for more information on calibrating the torque cell.

to Appendix D for more information.

electronics.

configure the gauges on the MakeRun screen.

edit all gauges currently displayed on the MakeRun screen.

communicate with the dyno electronics.

Graph Options—Displays a list of the options available while in the Graph screen.

Refer to page 7-5 for more information.

• Mouse Mode — changes the mouse between point, pan, and zoom mode.

• Cursor Options — determines what will be displayed (run name, channel

name) and what font size along with the intersection values.

• Cursor — turns the vertical cursor on and off. The cursor places a vertical line

on the graph that will display the values where the line intersects the graphed

runs.

• Rescale — resets the scale of the graph to standard.

• UnZoom — returns the viewing area to the previous magnification.

• ReZoom — returns the viewing area to the last unzoom magnification.

• Black & White Mode — removes all colors from the graph to help with

printing and faxing graphs.

• Reset Line Styles — resets the styles of the lines used to graph each run to

their defaults.

• Reset Colors — resets the colors of the lines used to graph each run to their

defaults.

• Force Scaling — forces left and right vertical scales to the same value. Some

graph operations will reset this option.

• Auto Scaling — allows the graph to choose an appropriate scale for the data.

Some graph operations will reset this option.

• Snap to Scale — forces left and right vertical scales to whole numbers. Some

graph operations will reset this option.

3-18

WinPEP 7 User Guide

Page 53

GETTING STARTED WITH WINPEP 7

The WinPEP 7 Menu Bar

• Magnifier Box — magnifies a small area of the graph and displays it in a box.

• Display Negative — When Display Negative is toggled on, all data is

displayed. When off, the data is cut off below zero and only positive data will

be displayed.

• Display — determines what will be displayed on the graph. When printing the

graph, note that the Conditions will always be printed.

• Correction Factor — lets you select the correction factor applied to the data.

• Smoothing — lets you select the level of smoothing to be applied to the data.

• Properties — opens the Graph Options dialog box where you can customize

the graph properties. Refer to page 7-6 for more information.

System Information—Displays information about the computer system.

Drum Information—Displays information about the dynamometer drum(s).

Environment Options—opens the Environment Options dialog box where you can

customize the general WinPEP 7 settings and choose your default units.

• General Tab — lets you change your language, save your current settings,

choose your toolbar size, and choose your user level. Refer to page 2-14 for

more information on user levels.

Show Complete Channel List On Graph — lets you choose to view only the

common channels or all channels. Primarily only applies to 4x4 runs. This

option is applied as runs are added to the graph, any runs already shown on

the graph will not be affected.

Use Advanced RPM Filtering — smooths out RPM signals with minor noise

problems in them. This option is applied as runs are added to the graph, any

runs already shown on the graph will not be affected.

• Default Units Tab — lets you choose a predefined unit setting or you can pick

individual units to suit your specific needs.

DISPLAY MENU

Too l bars—lets you select which toolbars will be displayed.

Graph Screen—lets you navigate to the Graph screen.

MakeRun Screen—lets you navigate to the MakeRun screen.

Version 2 WinPEP 7 User Guide

3-19

Page 54

CHAPTER 3

The WinPEP 7 Menu Bar

HELP MENU

WinPEP 7 User Guide—

the information in this manual and lets you search and browse the help. Adobe Reader

must be installed in order to view the WinPEP 7 User Guide on-line version. You can

download Adobe Reader at

Manuals—Displays a list of the folders and files inside the WinPEP7\Root directory.

Your computer should have Adobe Reader installed in order to view the manuals.

When you install WinPEP 7, the software installs the manuals that are appropriate for

your dyno. If you have a motorcycle dyno, the motorcycle dyno manuals will be

installed. If you have an automobile dyno, the automobile dynos will install

automatically. You can add your own manuals in .pdf file format into the

WinPEP7\Root folder in order to have them display on this list.

Tutorials—displays a list of video tutorials. Click on a tutorial to view the video.

WInPEP Direct—allows registered users to access WinPEP software information and

updates at www.winpep.com on the Internet.

Dynojet Home Page—accesses product information at www.dynojet.com on the

Internet.

Power Commander Home Page—accesses product information at

www.powercommander.com on the Internet.

About—displays version information for WinPEP 7, Data32.dll, Resource.dll, and

Hardware32.dll.

launches WinPEP 7 on-line help. The on-line help contains all

http://www.adobe.com/products/acrobat/readstep2.html

3-20

WinPEP 7 User Guide

Page 55

M

AKING

C HAPTER

4

A R

UN

Dynojet’s advanced engineering delivers the precise horsepower measurements you

need to make quick and accurate evaluations of engine performance and drive train

problems. This chapter describes how to make dyno runs that provide safe, reliable

road testing right in the shop.

In this chapter:

Making a Test Run, page 4-2

Making a Run, page 4-3

Making a Run—Negative Horsepower, page 4-7

Negative Horsepower Test—Drive Train, page 4-8

Negative Horsepower Test—Different Brands of Oil, page 4-9

WinPEP 7 User Guide

4-1

Page 56

CHAPTER 4

Making a Run

MAKING A RUN

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Your Dynojet dynamometer combined with WinPEP 7 produces consistent, easily

interpretable power graphs. Use the following instructions to ensure repeatable and

accurate measurements.

Note: For detailed information on how to load your vehicle on the dyno, connect

the RPM pickups, and make any pre-run inspections, refer to your dynamometer

installation guide.

MAKING A TEST RUN

1 Start WinPEP 7 and go to the MakeRun screen.

2 Verify the vehicle is secured properly.

3 Place the vehicle in a low gear and release the dyno brake using the hand held

pendant.

4 Slowly accelerate the vehicle to 20 m.p.h.

5 Test the tachometer operation.

5a Rev the engine. The gauges on the computer screen should be moving. If

the tachometer is moving but not registering the correct RPM values, the

number of degrees of revolution of the crank shaft (the plug fires number) is

incorrect.

5b Stop the vehicle, return to the MakeRun Configuration dialog box, and enter

the correct value for plug firing order.

6 Press the red brake button to apply 100% braking and slow down the vehicle.

4-2

WinPEP 7 User Guide

Using the vehicle’s rear brake to stop the drum at speeds over 30 m.p.h. can

severely over heat the rear brake parts. Dynojet dynamometers with the

mechanical brake, air brake, or eddy current brake accessory can be used to

slow the vehicle and drum to a full stop at any speed. The vehicle’s brake

should be used in an emergency stop situation only.

7 Shut the engine off and put the vehicle in gear (manual transmission) or neutral

(automatic transmission).

8 Set the vehicle’s parking brake and leave the dyno brake on.

9 Perform a final inspection.

• Verify the drive tire’s alignment on the dyno drums.