Page 1

INSTALLATION GUIDE

www.dynojetwb2.com

Dynojet Research 2191 Mendenhall Drive Suite 105, North Las Vegas NV, 89081 1-800-992-4993

Page 2

©2008 Dynojet Research, Inc. All Rights Reserved.

Wideband 2 Installation Guide

This manual is copyrighted by Dynojet Research, Inc., hereafter referred to as Dynojet,

and all rights are reserved. This manual, as well as the software described in it, is

furnished under license and may only be used or copied in accordance with the terms of

such license. This manual is furnished for informational use only, is subject to change

without notice, and should not be construed as a commitment by Dynojet. Dynojet

assumes no responsibility or liability for any error or inaccuracies that may appear in this

manual. Except as permitted by such license, no part of this manual may be reproduced,

stored in a retrieval system, or transmitted, in any form or by any means, electronic,

mechanical, recording, or otherwise, without the prior written permission of Dynojet.

The Dynojet logo is a trademark of Dynojet Research, Inc.

Any trademarks, trade names, service marks, or service names owned or registered by any

other company and used in this guide are the property of their respective companies.

Dynojet Research, Inc., 2191 Mendenhall Drive, North Las Vegas, Nevada 89081, USA.

Printed in USA.

Part Number: 98200017 Version 03 (10/2008)

Page 3

INSTALLATION

PARTS LIST

WIDEBAND 2 SPECIFICATIONS

ELECTRICAL LAYOUT

REQUIRED CONNECTIONS

Section 1 - Weld Boss and Oxygen Sensor Installation

Section 2 - Wideband 2 Module Installation

Section 3 - Power and Ground Wire Installation

O

PTIONAL CONNECTIONS

Section 4 - Digital Input (RPM) Wire

Section 5 - Analog Input Wire

Section 6 - Data Acquisition Output Wires

Section 7 - Simulated Narrow Band Output Wire

O

PTIONAL ACCESSORY CONNECTIONS

Section 8 - Optional Electrical Gauge In Vehicle Dash Installation

Section 9 - Optional LCD

Section 10 - Optional Data Acquisition/Gauge Harness Installation

S

ENSOR TEST

Section 11 - Sensor Condition Test

PARTS LIST

quantity description

1 Wideband 2 Module

1 Data Acquisition Cable (optional with 15-7011 kit)

1 Bosch LSU 4.2 Wide Band Oxygen Sensor

1 Oxygen Sensor Cable

1 Oxygen Sensor Weld Bung, Plug, and Copper Washer

2 Dynojet CAN-Link Port Seals

3Wire Tap

1Blade Fuse Tap

1Mini Blade Fuse Tap

1Quick Lug

1 Terminal Strip Plug

2Dual Lock Strips

1 Alcohol Swab

3Zip Ties

1 Warranty Registration Card

2Dynojet Decals

98200017.03

Wideband 2 Installation Guide- 1

Page 4

WIDEBAND 2 SPECIFICATIONS

ctio

description specification

Power Requirement 11.5 - 15 VDC, 3A

Dimensions 2.80"w x .56"h x 1.488"d

Range .68 lambda - ambient air

Inputs

Analog 0 - 5 VDC

Digital Square wave, 0 - 12 V nominal (coil (-) tachometer signal)

Outputs

Gauge Driver 0 - 5 VDC analog

Calibrated AFR 0 - 5 VDC analog

Simulated Narrow Band

Expansion Connectivity Dynojet CAN-Link (accessory cable required)

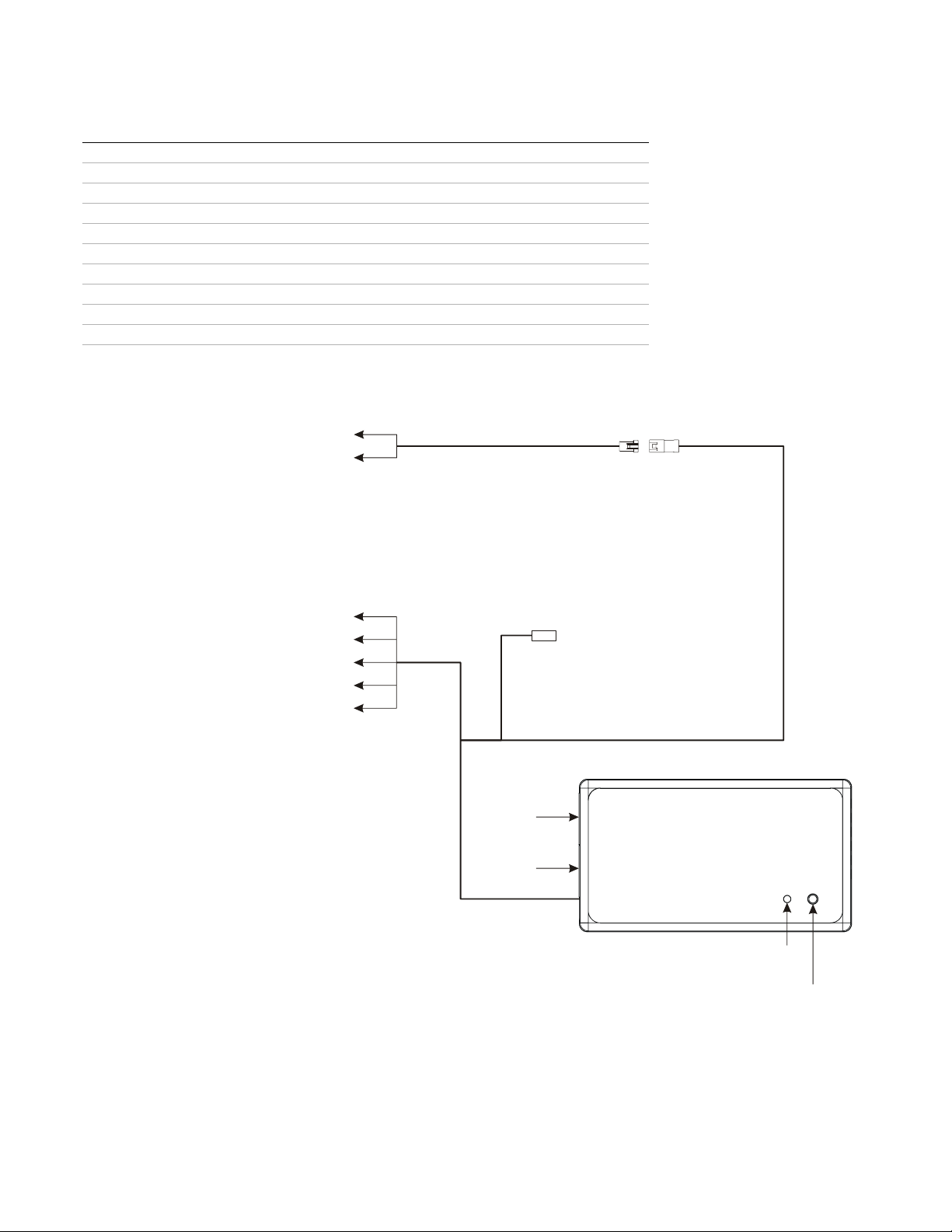

ELECTRICAL LAYOUT

violet - Data Acq. Output Signal (0-5v)

white/violet - To Data Acq. Signal Ground

(optional with 15-7011 kit)

76950114

Data Acquisition Cable

white/blue - RPM

grey - Analog Input (0-5v)

black/white - Digital Ground

red - 12v

black - Ground

CAN

CAN

green - Narrow Band O2 Out

LED

Fun

n Button

98200017.03

Wideband 2 Installation Guide- 2

Page 5

Figure AFigure BFigure C

REQUIRED CONNECTIONS

SECTION 1 - WELD BOSS AND OXYGEN

SENSOR INSTALLATION

INSTALLING THE WELD BOSS—AUTOMOTIVE

1 Find a suitable location to install the included

M18 x 1.5mm weld boss on the exhaust system

as shown in Figure A.

On vehicles equipped with catalytic converters,

Dynojet recommends installing the weld boss

before the converters. Vehicles that do not

utilize catalytic converters are free to install the

boss anywhere in the exhaust, but we

recommend keeping it within thirty inches of

the exhaust port.

Turbocharged vehicles have rather high

exhaust gas temperatures and pressures.

In these applications, it is best to install the

weld boss in the down pipe as far away from

the exhaust turbine as possible.

Note: Never install the sensor in the exhaust

manifold between the cylinder head and the

turbo.

2 Mount the weld boss in a manner that reduces

the risk of moisture contamination on the

sensor. Condensation can build up in the

exhaust pipes and potentially damage the

sensor.

98200017.03

3 Ideally, you should orient the weld boss so the

sensor is between the 9 o'clock and 3 o'clock

position (reading clockwise) as shown in

Figure B. A 10° inclination off the horizontal

plane should be considered a minimum.

Note: Verify you have adequate clearance for

the sensor and wiring harness.

I

NSTALLING THE OXYGEN SENSOR—AUTOMOTIVE

1 Thread the sensor into the weld boss as shown

in Figure C.

Wideband 2 Installation Guide - 3

Page 6

2 Connect the O2 Sensor to the supplied wiring

harness as shown in Figure D.

Figure DFigure EFigure F

3 Find a suitable location to run the wiring to

the Wideband 2 control module as shown in

Figure E.

Note: Verify the wiring is free and clear of

abrasion and heat sources.

98200017.03

4 Route the wiring through a factory grommet as

shown in Figure F.

If you are unable to find a factory grommet to

pass the wiring through, drill a hole large

enough to accommodate the wiring. Make sure

to use a grommet to protect the wiring.

Note: It is very important that the Wideband 2

Sensor is powered up when the vehicle is

running. The sensor may become damaged if

the vehicle is running and the Wideband 2 is

not receiving power. In the event that you do

not have power running to the sensor, remove

the sensor and install the weld boss plug

included in the Wideband 2 kit.

Note: Running the sensor in leaded fuel

applications decreases the service life of the

sensor.

Wideband 2 Installation Guide - 4

Page 7

INSTALLING THE WELD BOSS—MOTORCYCLE

1 Find a suitable location to install the included

M18 x 1.5mm weld boss on the exhaust system

as shown in Figure G.

On vehicles equipped with catalytic converters,

Dynojet recommends installing the weld boss

before the converters. Vehicles that do not

utilize catalytic converters are free to install the

Figure GFigure HFigure I

boss anywhere in the exhaust, but we

recommend keeping it within thirty inches of

the exhaust port.

Turbocharged vehicles have rather high

exhaust gas temperatures and pressures.

In these applications, it is best to install the

weld boss in the down pipe as far away from

the exhaust turbine as possible.

Note: Never install the sensor in the exhaust

manifold between the cylinder head and the

turbo.

2 Mount the weld boss in a manner that reduces

the risk of moisture contamination on the

sensor. Condensation can build up in the

exhaust pipes and potentially damage the

sensor.

98200017.03

3 Ideally, you should orient the weld boss so the

sensor is between the 9 o'clock and 3 o'clock

position (reading clockwise) as shown in

Figure H. A 10° inclination off the horizontal

plane should be considered a minimum.

Note: Verify you have adequate clearance for

the sensor and wiring harness.

I

NSTALLING THE OXYGEN SENSOR—MOTORCYCLE

1 Thread the sensor into the weld boss as shown

in Figure I.

Wideband 2 Installation Guide - 5

Page 8

2 Connect the O2 Sensor to the supplied wiring

harness as shown in Figure J.

3 Route the wiring to the Wideband 2 module.

Use the supplied zip ties to secure the wire

bundle to the motorcycle.

Note: Verify the wiring is free and clear of

abrasion and heat sources.

Note: It is very important that the Wideband 2

Sensor is powered up when the vehicle is

Figure JFigure KFigure L

running. The sensor may become damaged if

the vehicle is running and the Wideband 2 is

not receiving power. In the event that you do

not have power running to the sensor, remove

the sensor and install the weld boss plug

included in the Wideband 2 kit.

Note: Running the sensor in leaded fuel

applications decreases the service life of the

sensor.

SECTION 2 - WIDEBAND 2 MODULE

INSTALLATION

AUTOMOTIVE

1 The module is robust and water resistant and

can be mounted inside the vehicle or under

the hood. Verify the CAN-Link Ports are

accessible for data transfer.

Note: Install the CAN-Link Expansion Port

seals when the ports are not in use.

2 Mount the module using the supplied dual

lock strips or other suitable means as shown in

Figure K.

When using the dual lock strips, please clean

the surfaces thoroughly with the supplied

alcohol swab.

98200017.03

M

OTORCYCLE

1 On most motorcycle applications the best

place to mount the Wideband 2 module is

under the seat or in the tail section of the

motorcycle. Verify the CAN-Link Ports are

accessible for data transfer.

Note: Install the CAN-Link Expansion Port

seals when the ports are not in use.

2 Mount the module using the supplied dual

lock strips or other suitable means as shown in

Figure L.

When using the dual lock strips, please clean

the surfaces thoroughly with the supplied

alcohol swab.

Wideband 2 Installation Guide - 6

Page 9

install the wire tap

SECTION 3 - POWER AND GROUND WIRE

INSTALLATION

CONNECTING THE POWER WIRE—AUTOMOTIVE AND

M

OTORCYCLE

Figure MFigure NFigure O

choose a fuse tap based

on fuse type

fuse tap installed on fuse

Connect the red power wire to a 12 volt "Fused Key

On" power source.

This type of power source only has power when

the ignition switch is turned on. A wire tap, along

with two different sizes of blade fuse taps and a

quick lug, is included for easy installation. Refer to

Figure M.

Note: If you are not sure, please refer to a

workshop manual or electrical diagram for

your vehicle or consult a specialist.

C

ONNECTING THE GROUND WIRE—AUTOMOTIVE

Connect the black and the black/white wires to a

good ground location with the eyelets provided.

Refer to Figure N.

When using the Analog Input on the Wideband 2,

you may need to run the black/white wire to the

sensor ground. For example, using the Analog

Input to measure TPS voltage, you would tie the

black/white wire to the TPS sensor ground.

98200017.03

Never connect the black wire to a sensor

ground.

Note: Verify the wiring is free and clear of

abrasion and heat sources.

C

ONNECTING THE GROUND WIRE—MOTORCYCLE

Connect the black and the black/white wires to a

good ground location with the eyelets provided.

Refer to Figure O.

When using the Analog Input on the Wideband 2,

you may need to run the black/white wire to the

sensor ground. For example, using the Analog

Input to measure TPS voltage, you would tie the

black/white wire to the TPS sensor ground.

Note: Consult your motorcycle’s service

manual for more information on wire

definitions and colors.

Never connect the black wire to a sensor

ground.

Note: Verify the wiring is free and clear of

abrasion and heat sources.

Wideband 2 Installation Guide - 7

Page 10

Figure PFigure QFigure R

white/blue - RPM

grey - Analog Input

black/white - Digital Ground

black - Ground

red - 12v

white

grey

black

yellow

red

blue

green - Narrow Band O2 Out

CONNECTING THE O2 SENSOR CABLE

Attach the O2 Sensor wiring harness wires to the

screw terminal as shown in Figure P.

Using the color coded decal on the Wideband

2 module, install the wires into the correct

location. The wires pierce a foam gasket.

Note: Be sure to install the supplied terminal

strip plug when mounting the Wideband 2

under the hood or in an area that may be

exposed to moisture or dirt.

OPTIONAL CONNECTIONS

SECTION 4 - DIGITAL INPUT (RPM) WIRE

There is one digital RPM input channel built into

the Wideband 2.

1 Locate the white/blue wire in the main harness

as shown in Figure Q.

2 Using a supplied wire-tap, connect the

white/blue wire to the negative side of the

ignition coil.

This provides a stable RPM signal without the

need for a special "tach adaptor".

black/white - Digital Ground

98200017.03

white/blue - RPM

grey - Analog Input

red - 12v

black - Ground

green - Narrow Band O2 Out

SECTION 5 - ANALOG INPUT WIRE

There is one analog input channel built into the

Wideband 2.

1 Locate the grey wire in the main harness as

shown in Figure R.

2 Connect the grey wire to a 0-5v "variable

voltage" analog signal.

Most 0-5v type sensors (such as TPS, MAF, or

MAP) have three wires:

•+5 volt reference

• ground

•0 - 5 volt signal

Wideband 2 Installation Guide - 8

Page 11

Data Acquisition

data acq. unit must

be grounded to vehicle

Figure S

+

input

-

Ground

white/blue - RPM

grey - Analog Input

black/white - Digital Ground

black - Ground

violet - Data Acq. Output Signal (0-5v)

white/violet - To Data Acq. Signal Ground

use jumper if data acq.

input (-) is floating

red - 12v

Data Acquisition Cable

green - Narrow Band O2 Out

Wideband 2

76950114

SECTION 6 - DATA ACQUISITION OUTPUT

W

IRES

The Data Acquisition cable is designed to produce

a calibrated lambda/AFR output voltage that ranges

from 0 - 5 volts.

Your data acquisition device, or flash tuner device,

should have a provision in their software to define

the analog input. Enter the following formula:

(Volts * 1.6)+10 = AFR.

The Data Acquisition cable has two wires as shown

in Figure S:

• violet wire is the 0 - 5 volt signal

• white/violet wire connects to the data

acquisition device ground reference

Note: The white/violet wire is not a ground;

however, it needs to be connected to a ground.

It is important the data acquisition device has

its own ground to the vehicle.

Data acquisition device types are varied. Some may

be grounded by connecting to the vehicle's

diagnostic port. If no other ground exists, you

must run a ground wire from the data acquisition

system to the vehicle chassis ground as shown in

Figure S.

white/blue - RPM

grey - Analog Input

black/white - Digital Ground

black - Ground

Figure T

red - 12v

Refer to the data acquisition documentation for

more information.

SECTION 7 - SIMULATED NARROW BAND

OUTPUT WIRE

The Wideband 2 provides a Simulated Narrow

Band Output signal as shown in Figure T.

Contact Dynojet for more details on this feature.

green - Narrow Band O2 Out

98200017.03

Wideband 2 Installation Guide - 9

Page 12

Figure UFigure VFigure W

yellow, warning

orange, dimming

gauge

76950060

Gauge Cable

OPTIONAL ACCESSORY CONNECTIONS

SECTION 8 - ELECTRICAL GAUGE IN VEHICLE

DASH INSTALLATION

A 2 1/16th diameter hole is required for the gauge,

as shown in Figure U, which can be mounted indash or in an aftermarket gauge pod.

The gauge cable must be routed to the Wideband 2

Module and connected to the four pin connector

or to the optional Data Acquisition/Gauge Cable

(P/N 76950118).

When the yellow wire is grounded, as shown in

Figure V, the warning light will turn on and the

alarm will sound. The alarm is selectable with a dip

switch on the back of the gauge.

Apply 12v to the orange wire to dim the

backlighting to nighttime intensity as shown in

Figure V.

Gauge Part Numbers:

part number description

49600000 analog, white face

49600001 analog, black face

49600002 digital, white face

49600003 digital, black face

98200017.03

SECTION 9 - OPTIONAL LCD

Visit www.DynojetWB2.com for more information.

Wideband 2 Installation Guide - 10

Page 13

Data Acquisition

G

S

data acq. unit must

be grounded to vehicle

Figure XFigure Y

+

input

-

Ground

white/blue - RPM

grey - Analog Input

black/white - Digital Ground

black - Ground

violet - Data Acq. Output Signal (0-5v)

white/violet - To Data Acq. Signal Ground

use jumper if data acq.

input (-) is floating

red - 12v

black - Gauge Ground

auge Connector

Data Acquisition/Gauge Cable

green - Narrow Band O2 Out

Wideband 2

76950118

SECTION 10 - OPTIONAL DATA

ACQUISITION/GAUGE HARNESS INSTALLATION

The Data Acquisition/Gauge Cable (P/N 76950118)

allows you to use the data acquisition output and

one of the optional gauges at the same time. Refer

to Figure X.

Note: Before connecting the Data

Acquisition/Gauge cable, be sure to read and

understand “Section 6 - Data Acquisition

Output Wires”.

The Data Acquisition/Gauge cable has three wires

as shown in Figure X:

• violet wire is the 0 - 5 volt signal

• white/violet wire connects to the data

acquisition device ground reference

• black wire is the ground for the gauge

Note: This black wire is the ground for the

gauge and is not a ground coming from the

module. The data acquisition device needs to

have its own ground to the vehicle.

Data acquisition device types are varied. Some may

be grounded by connecting to the vehicle's

diagnostic port. If no other ground exists, you

must run a ground wire from the data acquisition

system to the vehicle chassis ground as shown in

Figure X.

Refer to the data acquisition documentation for

more information.

8000

7000

6000

5000

(in feet)

4000

3000

LEVATION

E

2000

1000

98200017.03

SENSOR TEST

SECTION 11 - SENSOR CONDITION TEST

The Wideband 2 has a built in circuit which allows

you to test the sensor accuracy and condition.

sensor ok

0

LASHE

F

5

0

234

1

7

8

6

9 10

1 Verify the sensor is exposed to clean ambient

air.

2 Verify the Wideband 2 has been on for at least

one minute.

3 Press and hold the function button for three

seconds and release the button.

The LED light will blink rapidly, pause for a

moment, and then begin to flash.

4 Count the number of flashes and refer to the

Sensor Condition Chart as shown in Figure Y.

5 Retest the sensor if there is any question as to

the purity of the air during the test.

Wideband 2 Installation Guide - 11

Loading...

Loading...