Page 1

Page 2

©2001-2006 Dynojet Research, Inc. All Rights Reserved.

Tuning Link User Guide

This manual is copyrighted by Dynojet Research, Inc., hereafter referred to as Dynojet,

and all rights are reserved. This manual, as well as the software described in it, is

furnished under license and may only be used or copied in accordance with the terms of

such license. This manual is furnished for informational use only, is subject to change

without notice, and should not be construed as a commitment by Dynojet. Dynojet

assumes no responsibility or liability for any error or inaccuracies that may appear in this

manual. Except as permitted by such license, no part of this manual may be reproduced,

stored in a retrieval system, or transmitted, in any form or by any means, electronic,

mechanical, recording, or otherwise, without the prior written permission of Dynojet.

The Dynojet logo is a trademark of Dynojet Research, Inc.

Any trademarks, trade names, service marks, or service names owned or registered by any

other company and used in this guide are the property of their respective companies.

Dynojet Research, Inc., 2191 Mendenhall Drive, North Las Vegas, Nevada 89081, USA.

Printed in USA.

Part Number: 98128103 Version 02 (08/2006)

Page 3

T

ABLE OF

C

ONTENTS

Chapter 1 Installation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Computer Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Conventions Used In This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Chapter 2 Software Features

Main Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Configuration Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Menu Choices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

File Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Edit Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

View Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Tools Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Commander Port Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Dynamometer Port Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Mode Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

Help Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

Basic Software Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Bike Break-in/Warm Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Steady State Fuel Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Roll-On Fuel Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Index-i

Tuning Link User Guide

i

Page 4

Page 5

C HAPTER

1

I

NSTALLATION

Thank you for purchasing Tuning Link, Dynojet’s Fuel Injection Mapping System.

Tuning Link is an innovative piece of software that allows the automatic fuel curve

optimization of a Power Commander equipped motorcycle.

This document provides instructions for using Tuning Link. This document will walk

you through software installation and program features. To ensure safety and

accuracy in the procedures, perform the procedures as they are described.

Document Part Number: 98128103

Version 2

Last Updated: 08-31-06

This chapter is divided into the following categories:

•Introduction, page 1-2

•Installation, page 1-4

Tuning Link User Guide

1-1

Page 6

CHAPTER 1

Introduction

INTRODUCTION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Tuning Link software interfaces the Power Commander with a Dynojet Load

Control Dynamometer controlling both the Dynamometer and the Power

Commander at the same time.

By utilizing the Dynojet “Real Time” air/fuel ratio monitoring equipment and latest

load control dynamometer technology, Tuning Link monitors the current air/fuel

ratio. At the same time, Tuning Link automatically calculates the correct fuel

adjustment to achieve the user desired air/fuel ratio. Once calculated, Tuning Link

uploads these new fuel values to the Power Commander and saves a copy of the file.

Tuning Link has the ability to map fuel curves in both “static” and “dynamic” modes.

This assures that the generated fuel curves are correct for both steady state cruising as

well as during aggressive on/off throttle movements. This technology allows the dyno

operator to accurately optimize the motorcycle in a very short time, regardless of the

motorcycle’s modifications.

The Tuning Link software operates in three modes:

• Bike Break-in/Warm Up

• Steady State Fuel Mapping

minimum system requirements recommended systems requirements

• Microsoft® Windows 2000/XP • Microsoft® Windows 2000/XP

• Pentium 800 MHz Processor • 2.4 GHz Processor or greater

• 256 MB of available RAM • 256 MB of available RAM or greater

• two COM ports, one USB port • two COM ports, one USB port

• 800x600, 256 color monitor (SVGA) • 1280x1024 256 color monitor (SVGA) or better

• 1.2 gigabyte hard drive • 1.2 gigabyte hard drive

• 30 MB of available hard-disk space • 100 MB of available hard-disk space

• CD ROM and floppy disk drive • CD ROM and floppy disk drive

• printer, if hard copies are needed • printer (preferably HP DeskJet®)

• Roll-On Fuel Mapping

COMPUTER SPECIFICATIONS

You will need to provide a computer system to run the Tuning Link software.

1-2

Tuning Link User Guide

Page 7

INSTALLATION

Introduction

CONVENTIONS USED IN THIS MANUAL

The conventions used in this manual are designed to protect both the user and the

equipment.

example of convention description

The Warning icon indicates potential harm to the

person performing a procedure and/or the

dynamometer equipment.

Bold Highlights items you can select on in the software

interface, including buttons and menus.

!

The arrow indicates a menu choice. For example,

“select

File !Open” means “select the File menu,

then select the

Open choice on the File menu.”

TECHNICAL SUPPORT

For assistance, please contact Dynojet Technical Support at 1-800-992-3525, or write

to Dynojet at 2191 Mendenhall Drive, North Las Vegas, NV 89081.

Visit us on the World Wide Web at www.dynojet.com where Dynojet provides state of

the art technical support, on-line shopping, and press releases about our latest

product lines.

Version 2 Tuning Link User Guide

1-3

Page 8

CHAPTER 1

Installation

INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Use the following instructions to install Tuning Link on your computer.

Note: It is strongly recommended that you exit all other Windows programs

before running this install program.

1 Insert the Tuning Link CD in your CD-ROM drive. The launch program will run

automatically.

If auto-run is disabled, do one of the following:

• Open the CD and double-click Launch.exe.

•Click Start on the Windows® task bar, and click Run. Type D:\Launch.exe,

where D is the letter that corresponds to the CD-ROM drive.

2 Choose one of the following options:

•Click Install Tuning Link to begin installation.

•Click View License Agreement to view the license agreement.

•Click Exit to quit the installation.

1-4

Tuning Link User Guide

Figure 1-1: Launch Interface Window—Install Tuning Link

Page 9

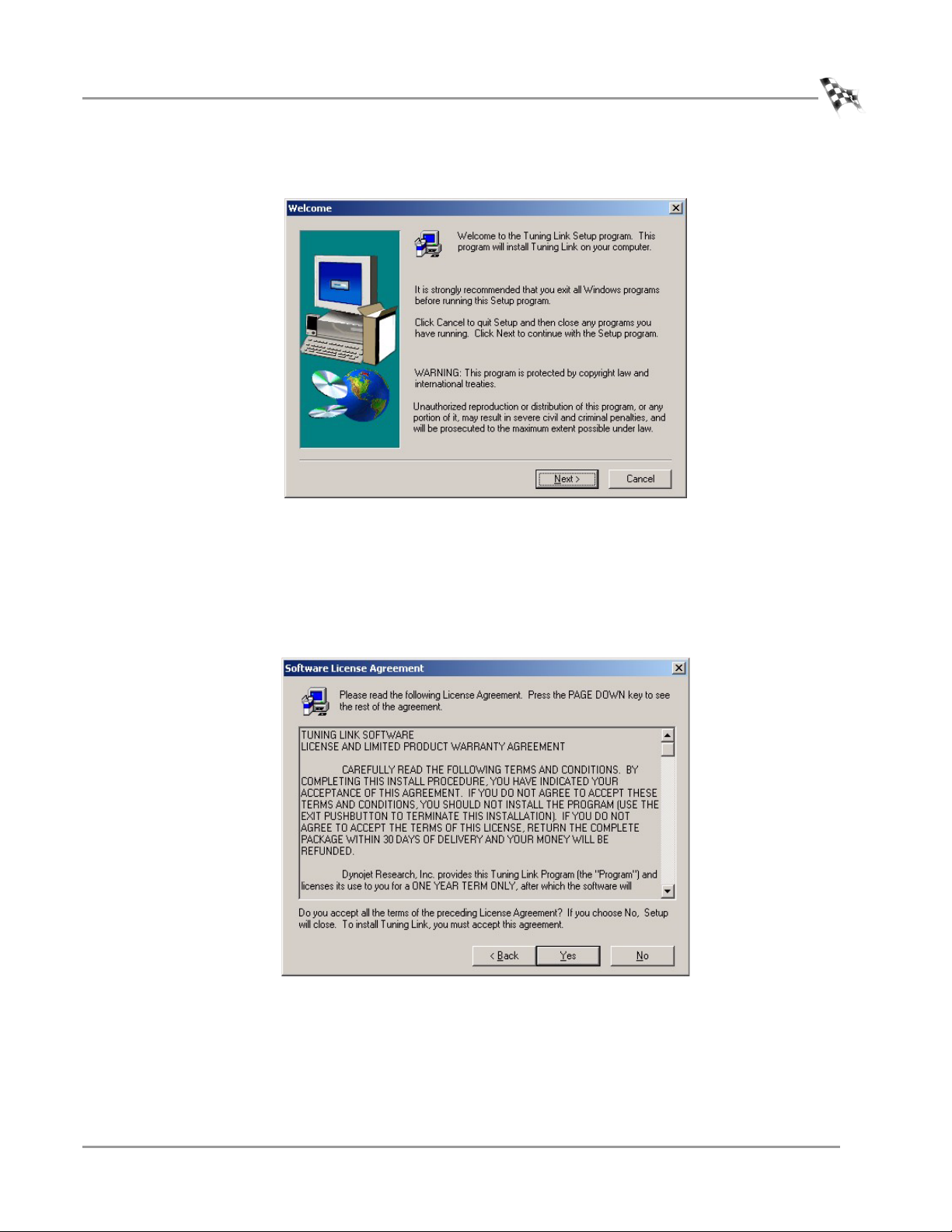

3 Read the Welcome window and click Next to continue.

Figure 1-2: Welcome Window

INSTALLATION

Installation

4 Carefully read the Tuning Link license agreement and click Yes to continue.

To install Tuning Link, you must accept this agreement. If you choose No, Setup

will close.

Note: Be sure to read and understand the license agreement. This license is only

for a one year term.

Figure 1-3: Software License Agreement

Version 2 Tuning Link User Guide

1-5

Page 10

CHAPTER 1

Installation

5 Select the proper dyno configuration file for your load control dyno and click

Next to continue.

The Tuning Link software requires a full WinPEP 6 or WinPEP 7 install.

Removing or renaming your WinPEP directory will cause the Tuning Link

software to function improperly. If you choose to move your WinPEP directory,

you must reinstall the Tuning Link software to ensure proper functionality.

Note: The following window will only appear if Setup finds more than one

configuration file.

1-6

Tuning Link User Guide

Figure 1-4: Select Dyno Config File

Page 11

INSTALLATION

Installation

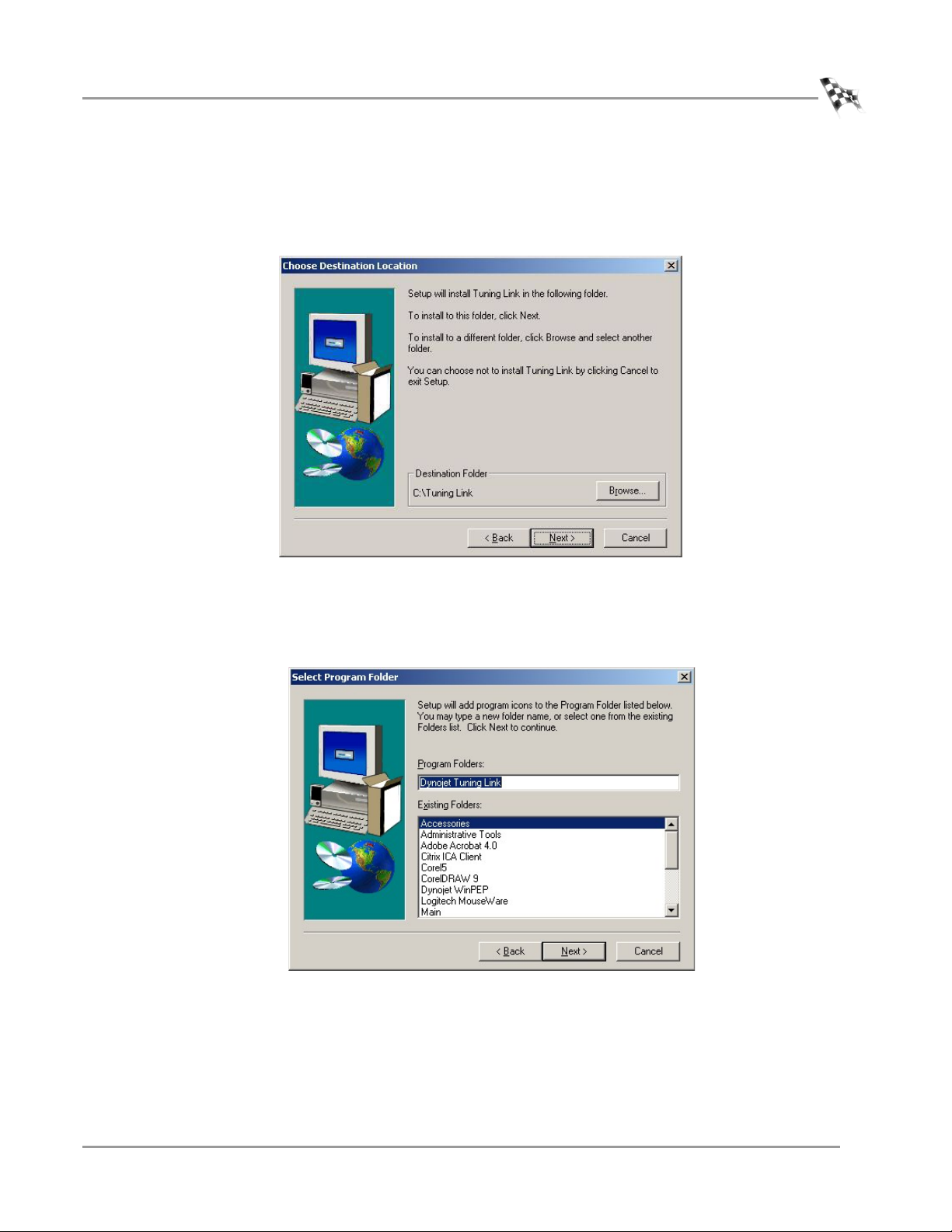

6 Select a location for your Tuning Link software to be installed and click Next to

continue.

Note: Dynojet recommends that you do not change the default destination

folder.

Figure 1-5: Choose Installation Location

7 Setup will automatically add program icons to the Program Folder. You may type

a new folder name or select one from the Existing Folders list. Click Next to

continue.

Figure 1-6: Select Program Folder

Version 2 Tuning Link User Guide

1-7

Page 12

CHAPTER 1

Installation

8 Review your current settings and click Next to continue; Setup will copy the

program files.

Or

Click Back to review or change any settings.

Figure 1-7: Review Current Settings

9Click Finish to complete Setup.

Figure 1-8: Setup Complete

The installation is complete. You may now run Tuning Link by double-clicking the

program icon installed.

Note: The Launch Interface window, Figure 1-1, will still be running; you will

need to exit the window.

1-8

Tuning Link User Guide

Page 13

S

OFTWARE

C HAPTER

2

F

EATURES

This chapter provides information about Tuning Link software features.

This chapter is divided into the following categories:

• Main Window, page 2-2

• Configuration Window, page 2-4

•Menu Choices, page 2-6

• Basic Software Features, page 2-16

Tuning Link User Guide

2-1

Page 14

CHAPTER 2

Main Window

MAIN WINDOW

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

menu choices

actual values

target values

load control

indicator light

shift warning

indicator light

open loop

indicator light

The Main window is shown during each of the three modes of tuning. The RPM,

Throttle Position, and Air/Fuel values will change depending on which tuning mode is

chosen. A description of all window functions and displays follows.

status settings

port status

advanced/basic

status

indicator/warning lights

Figure 2-1: Main Window

Menu Choices—Many of the software features can be accessed from the menu

choices at the top of the Main window; some features are accessed directly from the

current window. For detailed information on the menu choices, refer to “Menu

Choices” on page 2-6.

RPM, Throttle Position, and Air/Fuel Actual and Target Values—These values

indicate the actual readings along with the target readings during tuning.

• In Warm Up mode, target throttle position and target air/fuel will have no

values.

• In Steady State mode, throttle position and RPM values will change colors and

all three readings are visible.

• In Roll-on Mode, RPM and air/fuel values are always green.

Note: The tuning mode will always be marked in the Mode menu. Select Mode to

verify the current tuning mode.

previous/next buttons

2-2

Tuning Link User Guide

Page 15

SOFTWARE FEATURES

Main Window

Send Map—sends the entire map to the Power Commander.

Get Map—retrieves the entire map from the Power Commander.

Load File/Save File—will load/save the existing file.

View Notes—will show/hide the notes.

Config—displays the Configuration window. Refer to “Configuration Window” on

page 2-4 for more information.

Load Control Light—indicates the eddy current brake is activated and will apply load

to the vehicle to hold it at the target RPM. Activate the eddy current brake by pressing

the green button on the pendant or by pressing L on the keyboard.

Note: The eddy current brake can be applied at 100% by pressing the red button

on the pendant or by pressing the space bar on the keyboard. This is an

emergency brake feature and will highlight the grid in red.

Shift Warning Light—indicates the eddy current brake is working too hard to

maintain the target RPM; shift the bike to another gear. Refer to “Status Settings” on

page 2-4 for more information.

Open Loop Indicator Light—is used with BMW Power Commander. The indicator

light turns green when the bike goes into open loop.

Note: Tuning Link is not able to adjust the fuel curve while the bike is in closed

loop.

Status Settings—monitors and shows the status of various conditions. A red warning

light will come on when any condition reaches its warning or danger zone. Refer to

“Status Settings” on page 2-4 to set warning and danger values.

Dyno/PCom Port—monitors the port connections. A green indicator light signifies a

working connection; a red indicator light signifies communication has been lost.

Fuel Table—The fuel table, or map, lists the RPM values in the left column and

throttle positions in the top row. Adjustments made during tuning will appear in the

corresponding columns and rows. Changes to the Map Setting and Power Mode

Target Air/Fuel Ratio values are made from the Configuration window. Refer to “Map

Settings” on page 2-5 for more information. Use the next and previous buttons

located at the bottom of the map to browse through additional map tables if

applicable.

Version 2 Tuning Link User Guide

2-3

Page 16

CHAPTER 2

Configuration Window

CONFIGURATION WINDOW

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Configuration window allows you to control the status, throttle position, and

map settings for all tuning modes.

Select Too ls

status settings

options drop

down menu

!

Configuration (or click Config in the Main window).

2-4

Tuning Link User Guide

Figure 2-2: Configuration Window

Status Settings—The status settings control each corresponding indicator light in the

status settings section of the Main window.

Status Options—An arrow is placed next to each status label allowing the user to

select a different channel to configure the indicator lights in the Main window.

The selection options available will depend on what is connected to the dyno or

Power Commander (for example: Multi-Function Hub, Analog Module, Torque

Module, or Dynojet Data Link Module). The status options menu is also available

by right-clicking the status settings on the Main window.

Note: Setting the warning and danger values to zero will disable the warning light

on the Main window.

Shift Warning—controls the Shift Warning Light on the Main window.

Page 17

SOFTWARE FEATURES

Configuration Window

Map Settings—controls the target air/fuel ratio (AFR) for all tuning modes. The map

can be separated into three modes as specified by Map Settings in the Configuration

window, refer to Figure 2-2.

Figure 2-3: Configuration Window—Map Settings

Save Roll-on Log Files—saves the roll-on runs as a .dlf file to be viewed in

WinPEP 7.

Enable Advanced Tuning—allows advanced mapping ability. With advanced tuning

enabled, you can tune basic or advanced (individual cylinders).

Throttle Position (TP) Settings—Each row in this table allows you to set the allowed

error between the target and actual throttle positions and the roll-on acceleration for

a roll-on in that throttle position range (RPM/Sec.).

Note: Roll-on Tuning is not allowed at 0% and 2% throttle; these values are not

adjustable.

Max Tire Speed—controls the warning light on the Main window and the warning

flasher on the dyno electronics.

Degrees Per Fire—controls the RPM reading. Degrees Per Fire represents the number

of degrees of crank rotation between RPM pulses.

Correction Factor—adjusts the horsepower reading of the roll-on log files when

viewing them in WinPEP 7.

Roll-on Wait Time—is the number of milliseconds (1000 milliseconds equals one

second) that the software allows the bike to settle before starting a roll-on tuning run.

Max Steady State TP—the upper TP limit that can be tuned using the steady state

mode.

Version 2 Tuning Link User Guide

2-5

Page 18

CHAPTER 2

Menu Choices

MENU CHOICES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The menu choices are accessible from the Main window. A description of all menu

choices and functions follows.

FILE MENU

Select File !New

New Map allows you to type in information specific to that bike and create a new

map to work with along with placing it in the appropriate location.

Select File

These commands allow you to open an existing map, save the current map, or

print the current map.

Select File

EDIT MENU

Select Edit !Copy/Paste

These commands allow you to copy or paste individual cells or the entire current

map.

Select Edit

This command allows you to select all of the current map.

!

Open/Save/Print

!

Exit to exit Tuning Link.

!

Select All

2-6

Tuning Link User Guide

Page 19

VIEW MENU

Select View !Power Commander Info

SOFTWARE FEATURES

Menu Choices

The Power Commander Info window allows you to view all of the power

commander related information.

Figure 2-4: Power Commander Information

power commander information description

serial number the serial number of the power commander

currently being tuned

production date the date the power commander was produced

version firmware version number

fuel revision fuel firmware revision number

mode the mode the power commander is in, basic or

advanced

production notes any production notes stored in the hardware

module information the information relating to each module on the

power commander

Version 2 Tuning Link User Guide

2-7

Page 20

CHAPTER 2

Menu Choices

Select View !Dynamometer Info

The Dynamometer Info window allows you to view the dynamometer related

information.

Figure 2-5: Dynamometer Info

dynamometer information description

dyno serial number the dynamometer serial number

dyno electronics serial number the electronics (CPU module) serial number

version the firmware version number

dyno electronics born on the born on or production date

lease expire date the date the Tuning Link lease will expire

lease time remain the number of days remaining until the Tuning Link

lease expire date

brake setting the jumper setting on the breakout board

number of modules the number of modules in the dyno electronics

modules lists the available modules in the dyno electronics

The Air/Fuel module must be installed in order to

use Tuning Link.

2-8

Tuning Link User Guide

Page 21

SOFTWARE FEATURES

Menu Choices

Select View !Environment Options

The Environment Options window allows you to control various options such as

language, pendant type, and display units.

Figure 2-6: Environment Options

Version 2 Tuning Link User Guide

2-9

Page 22

CHAPTER 2

Menu Choices

TOOLS MENU

Select Too ls !Configuration

The Configuration window allows you to control the status, throttle position, and

map settings for all tuning modes. Refer to “Configuration Window” on page 2-4

for more information.

Select Too ls

PID Control Parameters are used to control the responsiveness of the eddy

current brake. Use the values specified during your power commander training

course or in the help files.

!

PID Control Parameters

Figure 2-7: PID Control Parameters

Select Too ls !Throttle Position Settings

The Set Throttle Position window allows you to initialize the throttle position

table in the power commander.

1 With the throttle completely closed, click Set TP Closed.

You will see a number change in the box to the left of the button.

2 With the throttle completely open, click Set TP Open.

Note: You may need to set the eddy current brake to hold the engine at a safe

RPM if you are doing this sequence with the bike running.

Figure 2-8: Set Throttle Position

2-10

Tuning Link User Guide

Page 23

SOFTWARE FEATURES

Select Too ls !Map Search

Map Search allows you to search for power commander maps using defined

variables or specific words.

Menu Choices

Figure 2-9: Power Commander Map Search

Select Too ls !Promote Map to Advanced

Promote Map to Advanced promotes a map allowing individual cylinder mapping.

Advanced Tuning will adjust the fuel change for each cylinder.

Note: This type of tuning requires the ability to sample exhaust gas from each

cylinder separately (an O2 sensor in each primary in the header, or equivalent).

Promoting a map only changes the map to an advanced map. To change the mode

of the Power Commander, you must send the map to the Power Commander.

Version 2 Tuning Link User Guide

2-11

Page 24

CHAPTER 2

Menu Choices

Select Too ls !Demote Map to Basic

Demote Map to Basic allows you to demote an advanced map to a basic map. You

will be asked to use values from a single fuel table or the average of all the

advanced map fuel tables.

Demoting a map only changes the map to a basic map. To change the mode of the

Power Commander, you must send the map to the Power Commander.

Figure 2-10: Demote Map to Basic

COMMANDER PORT MENU

Use this menu option to select which communications port the Power Commander

will communicate through.

Select the Commander Port menu and choose a Com Port, the USB port, Auto, or

None.

DYNAMOMETER PORT MENU

Use this menu option to select which communications port the dynamometer will

communicate through.

Select the Dynamometer Port menu and choose a Com Port, Auto, or None.

2-12

Tuning Link User Guide

Page 25

MODE MENU

For detailed information on the mode menu choices, refer to “Basic Software

Features” on page 2-16.

Select Mode

Warm Up mode allows you to bring the dyno, bike, and any other equipment

(air/fuel sensor, etc.) to the proper operating temperature. For detailed

information on warm up mode, refer to “Bike Break-in/Warm Up” on page 2-16.

Select Mode

Steady State Fuel Mapping, or Steady State Tuning, mode allows you to tune

specific portions of the map using the eddy current brake to hold the bike steady

at a particular RPM while you control the throttle position (TP). For detailed

information on steady state tuning, refer to “Steady State Fuel Mapping” on page

2-16.

Select Mode

Roll-On Fuel Mapping, or Roll-On Tuning, allows you to quickly tune the major

portions of the map using similar techniques to the roll-on runs that you are

accustomed to using in WinPEP to measure power and torque. For detailed

information on roll-on tuning, refer to “Roll-On Fuel Mapping” on page 2-17.

!

Bike Break-in/Warm Up

!

Steady State Fuel Mapping

!

Roll-On Fuel Mapping

SOFTWARE FEATURES

Menu Choices

Version 2 Tuning Link User Guide

2-13

Page 26

CHAPTER 2

Menu Choices

HELP MENU

Select Help !About Tuning Link

You may view Tuning Link version numbers from within the Tuning Link

software.

Figure 2-11: About Tuning Link

about tuning link description

Tuning Link version the version of the Tuning Link executable file (main

program version)

Data32.dll version the version of the data manipulation library

Resource.dll version the language/translation library

Power Commander communications

classes

Select Help !View License Agreement

You may view your license agreement from within the Tuning Link software.

the power commander communications library

2-14

Tuning Link User Guide

Figure 2-12: View License Agreement

Page 27

SOFTWARE FEATURES

Select Help !View Tech Bulletins

You may view information regarding specifics on how to tune particular makes

and models. Check www.powercommander.com/centermail.shtml for updates.

Menu Choices

Figure 2-13: View Tech Bulletins

Version 2 Tuning Link User Guide

2-15

Page 28

CHAPTER 2

Basic Software Features

BASIC SOFTWARE FEATURES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Tuning Link software operates in three different modes; these modes are

available only when load control is turned on. Each mode is described below.

BIKE BREAK-IN/WARM UP

Select Mode !Bike Break-in/Warm Up

Warm Up mode allows you to bring the dyno, bike, and any other equipment (air/fuel

sensor, etc.) to the proper operating temperature. The brake is active in this mode

and may be used to load the bike until it reaches operating temperature. Warm Up

mode is critical since many bikes will operate differently when they are too cold.

While in this mode, the software will not attempt to make any fuel changes.

Note: If you tune the bike when it is too cold, the bike may not run properly once

it has reached operating temperature.

STEADY STATE FUEL MAPPING

Select Mode !Steady State Fuel Mapping

config window—max

steady state TP value

Steady State Fuel Mapping, or Steady State Tuning, mode allows you to tune specific

portions of the map using the eddy current brake to hold the bike steady at a

particular RPM while you control the throttle position (TP). Steady State Tuning mode

is particularly useful for tuning cruise modes to achieve optimum fuel mileage. This

mode is also used to fix problem areas in the low RPM ranges that occur on modified

high-revving sport bikes.

While in Steady State Tuning mode, you can expect to see one of the following

behaviors. These behaviors allow different styles of tuning but will achieve similar

results.

• When the Max Steady State TP is set to a value higher than the current TP value, the

software will tune the current cell and move to the cell directly to the right of the

current cell and continue tuning horizontally across each row. After tuning the last

cell at the end of the row (Current TP equals Max Steady State TP), the software

will move to the first cell of the next row.

tune current cell

2-16

Tuning Link User Guide

tuning will continue

horizontally across each row

Figure 2-14: Steady State Tuning—Max Steady State TP Set Higher Than Current TP

Page 29

SOFTWARE FEATURES

Basic Software Features

• When the Max Steady State TP is set to zero, or any value smaller than the current

cell, the software will tune the current cell and move to the cell directly below the

current cell and continue moving vertically down each column.

config window—max

steady state TP value

set to zero

Figure 2-15: Steady State Tuning—Max Steady State TP Set To Zero

tune current cell

tuning will continue vertically

down each column

ROLL-ON FUEL MAPPING

Select Mode !Roll-On Fuel Mapping

Roll-On Fuel Mapping, or Roll-On Tuning, allows you to quickly tune the major

portions of the map using similar techniques to the roll-on runs that you are

accustomed to using in WinPEP to measure power and torque. This type of tuning

closely simulates driving conditions and tunes an entire RPM range at any throttle

position.

1 Set the starting point of the roll-on by clicking on the appropriate cell in the grid.

The software will hold the bike’s RPM just slightly below your start point. Once

your TP matches the target TP, the software will wait for a short time (to allow the

state of the bike to settle) and then allow the bike to accelerate at the rate you set

in the Configuration window.

acceleration values set in

the configuration window

Figure 2-16: Roll-On Tuning—Set Acceleration Values

Version 2 Tuning Link User Guide

2-17

Page 30

CHAPTER 2

Basic Software Features

If you allow the TP value outside the allowed error for that Target TP, the run will

end and the software will return the bike’s RPM to the start point you selected.

Upon completion of the run, an air/fuel ratio (AFR) vs. RPM graph will appear in

the window. The following is an example of a typical first run AFR graph.

Figure 2-17: Roll-On Tuning—First Run AFR Graph

2 To make changes to the graph, press Enter or click on the graph. You will see the

software change some of or all of the values in the column you are tuning.

changed values

Figure 2-18: Roll-On Tuning—Changes To The Fuel Map

2-18

Tuning Link User Guide

Page 31

SOFTWARE FEATURES

Basic Software Features

3 Repeat these steps until you reach an end graph result similar to the graph shown

below.

Figure 2-19: Roll-On Tuning—Final AFR Graph

4 To keep the graph the same and make no further changes to your map, press Esc

to end the tuning on this column.

Note: You may tune any TP from 5% to 100%; however, 0% and 2% cannot be

tuned using Roll-On Tuning.

Version 2 Tuning Link User Guide

2-19

Page 32

Page 33

I

NDEX

A

about tuning link 2-14

actual values

air/fuel 2-2

RPM 2-2

throttle position 2-2

AFR vs. RPM graph 2-18

air/fuel

actual values 2-2

target values 2-2

B

basic software features 2-16–2-19

bike break-in/warm up 2-16

roll-on fuel mapping 2-17

steady state fuel mapping 2-16

bike break-in 2-13, 2-16

brake setting 2-8

C

commander port menu 2-12

computer specifications 1-2

config 2-3

configuration 2-10

configuration window 2-4–2-5

correction factor 2-5

degrees per fire 2-5

enable advanced tuning 2-5

map settings 2-5

max steady state tp 2-5

max tire speed 2-5

roll-on wait time 2-5

save roll-on log files 2-5

shift warning 2-4

status options 2-4

status settings 2-4

throttle position settings 2-5

conventions 1-3

correction factor 2-5

D

degrees per fire 2-5

demote map to basic 2-12

document part number 1-1

dynamometer info

brake setting 2-8

dyno electronics born on 2-8

dyno electronics serial number 2-8

dyno serial number 2-8

lease expire date 2-8

lease time remain 2-8

modules 2-8

number of modules 2-8

version 2-8

dynamometer port menu 2-12

dyno config file 1-6

dyno electronics born on 2-8

dyno electronics serial number 2-8

dyno port 2-3

dyno serial number 2-8

E

edit menu 2-6

copy 2-6

paste 2-6

select all 2-6

enable advanced tuning 2-5

F

file menu 2-6

exit 2-6

new 2-6

open 2-6

print 2-6

save 2-6

fuel revision 2-7

fuel table 2-3

G

get map 2-3

Tuning Link User Guide

Index-i

Page 34

INDEX

H

help menu 2-14

about tuning link 2-14

view license agreement 2-14

view tech bulletins 2-15

I

installation 1-4

L

lease expire date 2-8

lease time remain 2-8

load control light 2-3

load file 2-3

M

main window 2-2–2-3

air/fuel 2-2

config 2-3

dyno port 2-3

fuel table 2-3

get map 2-3

load control light 2-3

load file 2-3

map 2-3

menu choices 2-2

open loop light 2-3

pcom port 2-3

RPM 2-2

save file 2-3

send map 2-3

set throttle position 2-11

shift warning light 2-3

status section 2-3

target values 2-2

throttle position 2-2

view notes 2-3

map 2-3

map search 2-11

map settings 2-5

max steady state tp 2-5, 2-16

max tire speed 2-5

menu choices 2-6–2-15

commander port 2-12

dynamometer port 2-12

edit menu 2-6

file menu 2-6

help menu 2-14

mode menu 2-13

tools menu 2-10

view menu 2-7

mode 2-7

mode menu 2-13

bike break-in/warm up 2-13

roll-on fuel mapping 2-13

steady state fuel mapping 2-13

module information 2-7

modules 2-8

N

number of modules 2-8

O

open loop light 2-3

P

pcom port 2-3

PID control parameters 2-10

power commander info

fuel revision 2-7

mode 2-7

module information 2-7

production date 2-7

production notes 2-7

serial number 2-7

version 2-7

production date 2-7

production notes 2-7

promote map to advanced 2-11

R

roll-on fuel mapping 2-13

roll-on tuning 2-17

roll-on wait time 2-5

RPM

actual values 2-2

target values 2-2

S

save file 2-3

save roll-on log files 2-5

send map 2-3

serial number 2-7

set throttle position 2-11

shift warning 2-4

shift warning light 2-3

status options 2-4

status section 2-3

status settings 2-4

status options 2-4

steady state fuel mapping 2-13, 2-16

steady state tuning 2-16

Index-ii

Tuning Link User Guide

Page 35

T

target values

air/fuel 2-2

RPM 2-2

throttle position 2-2

technical support 1-3

throttle position

actual values 2-2

target values 2-2

throttle position settings 2-5, 2-10

tools menu 2-10

configuration 2-10

demote map to basic 2-12

map search 2-11

PID control parameters 2-10

promote map to advanced 2-11

throttle position settings 2-10

V

version

dynamometer 2-8

power commander 2-7

view license agreement 2-14

view menu 2-7

dynamometer info 2-8

environment options 2-9

power commander info 2-7

view notes 2-3

view tech bulletins 2-15

W

warm up 2-13, 2-16

Version 2 Tuning Link User Guide

Index-iii

Page 36

Loading...

Loading...