Page 1

INSTALLATION

/ USER’S

GUIDE

THIS GUIDE COVERS THE INSTALLATION AND USE OF THE

TARGET TUNE ACCESSORY FOR DYNOJET POWER VISION

PARTS LIST

1 - Target Tune Module

1 - Installation Guide

3 - 8" Cable Ties

2 - Dual Lock strips

1 - Alcohol Swab

2

2 - O

1 - Y-Adapter Cable *

2 - 18mm O

2 - O

Sensor Bungs *

2

Sensors *

2

Sensor Cables *

Parts shown with an asterisk (*) are

excluded in Target Tune kits that have

a part number ending in “X.” These

kits are intended for users that are

upgrading from PV Auto Tune to PV

Target Tune. These users should

already have these specific parts

installed from the previous PV Auto

Tune kit.

!!! IMPORTANT PLEASE READ FIRST !!!

The Target Tune module requires the use of (2) 18mm O

system doesn’t have bungs pre-installed, bungs will have to be welded into the header

pipes to use this module.

Your bike’s ECM will need to be flashed by the Power Vision with a tune that enables

Target Tune.

SOFTWARE AND OTHER TECHNICAL INFORMATION ARE AVAILABLE ONLINE AT:

WWW.FLASHYOURHARLEY.COM.

2191 Mendenhall Drive North Las Vegas, NV 89081

1-800-992-4993 www.dynojet.com

2

sensors. If your bike’s exhaust

Target Tune Installation - 1

Page 2

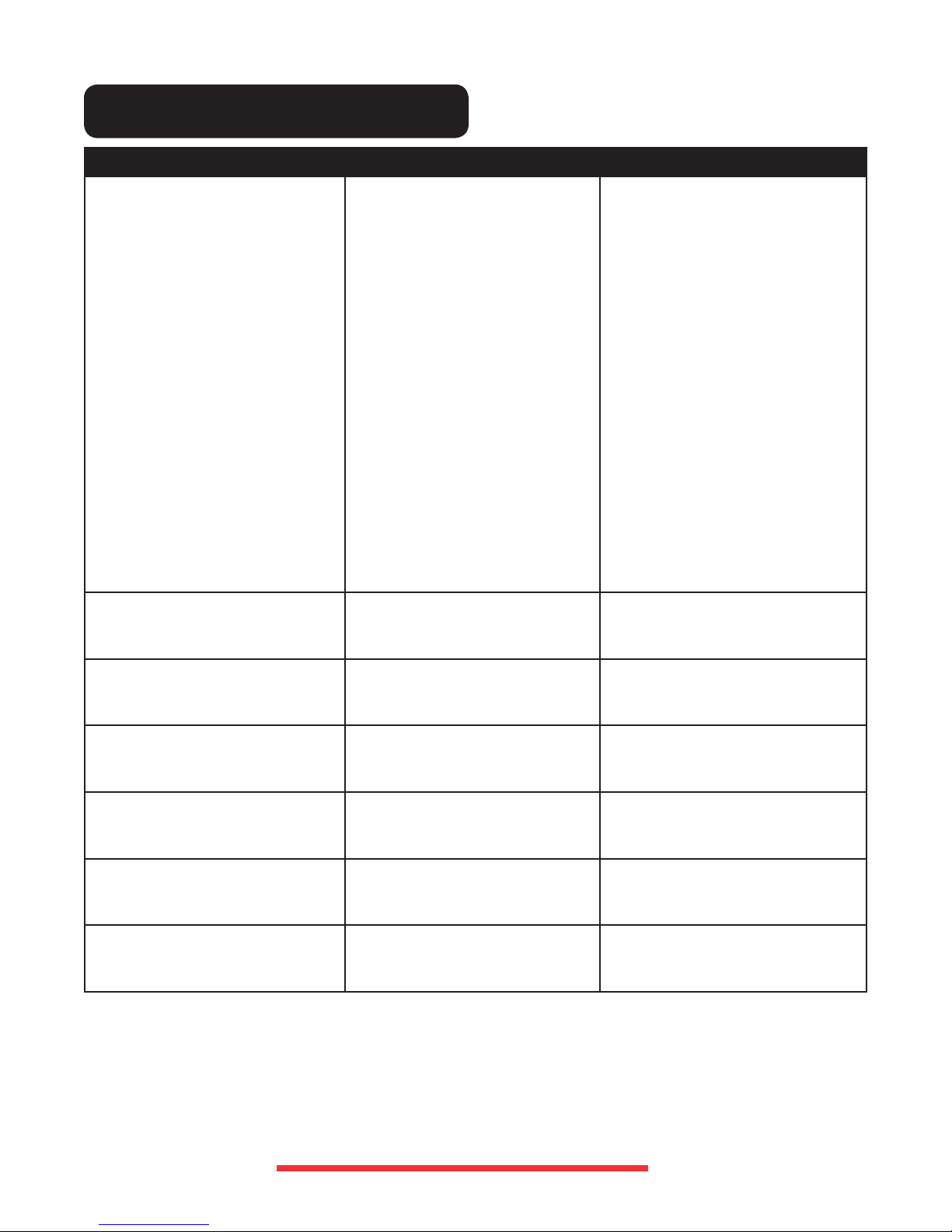

APPLICATION GUIDE

Target Tune Part Number Application Description

2-pin stock O2 connectors

(1 long leg and 1 short leg), 4-pin

diagnostic connector

* 2011 Softail models will require

splicing of the TT module’s power

and ground supply wires; or for

a cleaner install with OEM style

connections a 6-pin Y-adaptor

(PN: 76950389) and a 6-pin to

4-pin adaptor (PN: 76950664)

can be purchased separately.

TT-1 & TT-1X

2007-2011 Softail *

2007-2009 Touring

2008-2011 V-Rod **

2006-2011 Dyna

2007-2013 Sportster

TT-2 & TT-2X 2010-2013 Touring

TT-3 & TT-3X 2012-2015 V-Rod

2012-2015 Softail

TT-4 & TT-4X

2012-2015 Dyna

TT-5 & TT-5X 2014-2015 Touring

TT-6 & TT-6X 2015 Street 500/750

TT-7 & TT-7X 2014-2015 Sportster

** 2008-2011 V-Rod models will

require splicing of the TT module’s

power and ground supply wires; or

for a cleaner install with OEM style

connections a power extension

lead (PN: 76950159) can be

purchased separately.

4-pin stock O2 connectors

(2 short legs), 4-pin diagnostic

connector

4-pin stock O2 connectors

(1 long leg and 1 short leg), 4-pin

diagnostic connector

4-pin stock O2 connectors

(1 long leg and 1 short leg), 6-pin

diagnostic connector

4-pin stock O2 connectors

(2 short legs), 6-pin diagnostic

connector

4-pin stock O2 connectors

(special length), 6-pin diagnostic

connector

4-pin stock O2 connectors

(special length), 6-pin diagnostic

connector

Note: Target Tune kits that have a part number ending in “X” contain Target Tune modules only. There is no

O2 sensor hardware or Y-adapters supplied in these kits. These are intended for users that are upgrading

from PV Auto Tune to PV Target Tune. These users should already have wideband O2 sensor hardware

and Y-adapters installed from the previously installed PV Auto Tune kit.

Dynojet Power Vision

Target Tune Installation - 2

Page 3

PRODUCT OVERVIEW

The Dynojet Target Tune accessory for Power Vision is a product that can add

a new dimension to your Harley-Davidson’s® ECM.

When paired with a Target Tune specific calibration flashed by a Power Vision,

your ECM will run closed loop fuel control based on wideband O2 sensors installed

into the exhaust, rather than the stock narrowband O2 sensors. The Power Vision

delivered calibration changes the coding in the ECM to “understand” the wideband

signal (from Target Tune) and allows the ECM to accurately achieve the target AFR

specified in the commanded air/fuel ratio table of your ECM’s tune. The ECM also

does this at all available engine ranges (not just light throttle cruising speeds).

Dynojet has evolved the OEM closed loop, adaptive fuel control system on your

Harley to meet the needs of performance enthusiasts.

Key Features:

• Allows the factory ECM to interpret and use wideband O2 sensor signals*

• Target fuel table from the calibration / tune is achieved in real time

• Retains OEM closed loop, adaptive fuel control strategy

• Learns and uses VE table corrections as you ride

• Does NOT interfere with dealer diagnostic / service tools

• Includes OEM style connectors to plug into factory O2 harness, either 2-pin

or 4-pin versions

• Fits 2006 and newer Harley Davidson® Bikes**

* Requires Power Vision Target Tune specific calibration

** ECM must be “closed loop capable” and have OEM wiring for O2 sensor circuitry.

Dynojet Power Vision

Target Tune Installation - 3

Page 4

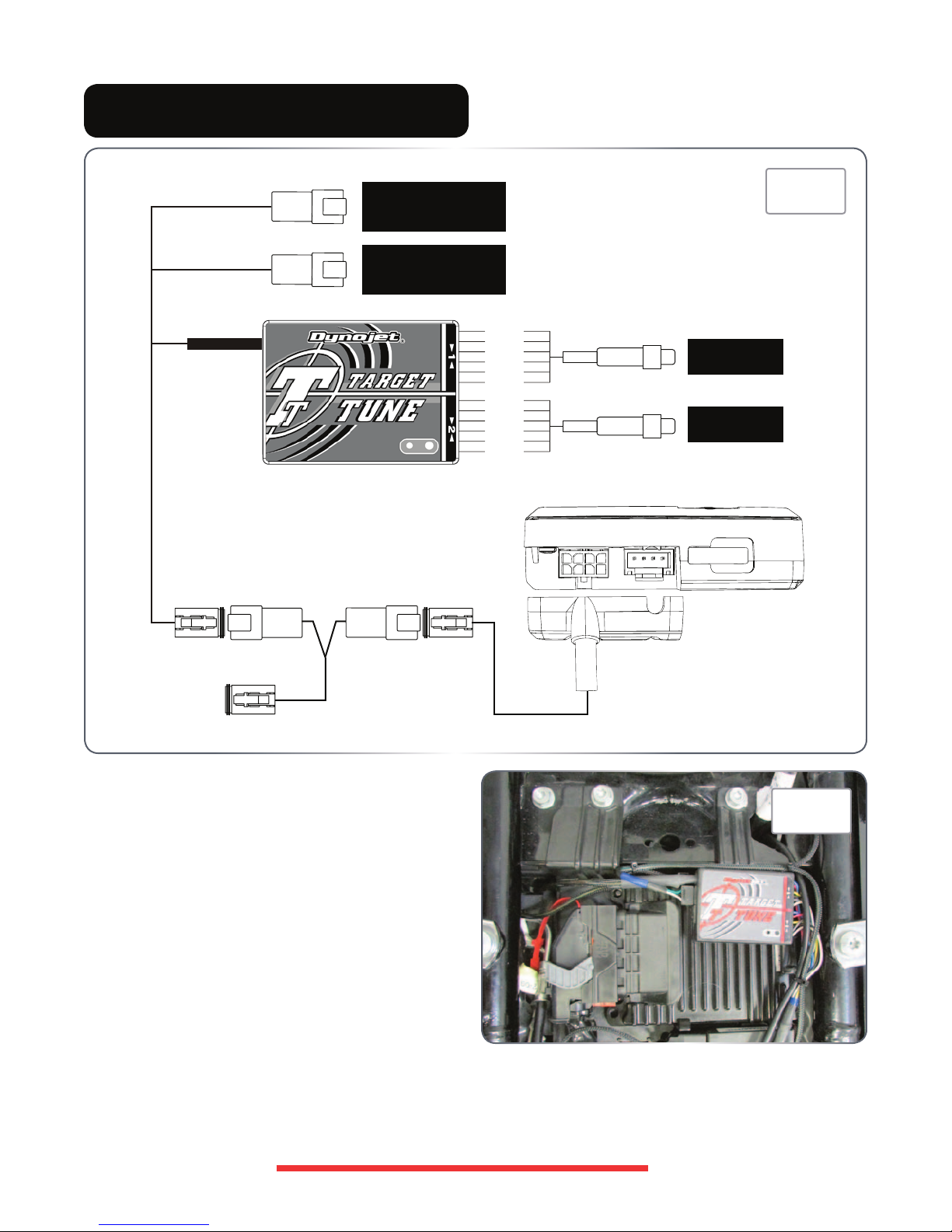

HARDWARE INSTALLATION

YELLOW/ORANGE

YELLOW/GREEN

STOCK O2 CONNECTOR

(FRONT)

STOCK O2 CONNECTOR

(REAR)

BLUE

RED

YELLOW

BLACK

GREY

WHITE

BLUE

RED

YELLOW

BLACK

GREY

WHITE

O2 SENSOR

O2 SENSOR

FIG. A

FRONT

REAR

TO VEHICLE

1. Find a location to mount the Target Tune module

and secure it with the supplied Dual Lock strips.

You can typically find a place under the bike’s

seat or behind a sidecover to mount it. Be sure

to choose a location within the harnesses’ reach

of the diagnostic connector and stock O2 sensor

connectors.

FIG. B

The top of the ECM is typically a good mounting

location for most Touring models (Fig. B).

Dynojet Power Vision Target Tune Installation - 4

Page 5

FIG. C

Diag Connector

FIG. D

TT Module

Diag Connector

On many Softail models you can typically find a place

under the seat to store the module (Fig. C). It

could go in the recess at the top of the battery,

on the side of the battery, on the relay bracket, or

even directly on the rear fender.

FIG. E

TT Module

On Sportsters, the left side of the battery is usually

the best location to secure the module (Fig. E).

On Dyna models you can typically fit the Target Tune

module inside the electrical box next to the ECM

(Fig. D).

FIG. F

TT Module

On V-Rod models, the best location to secure the

module is directly under the seat (Fig. F).

2. Install both of the supplied 18mm wideband O2 sensors into the exhaust system. (See “O2 Sensor Bung

Installation” section for guidelines if 18mm x 1.5 bungs need to be welded.)

3. Connect an O2 sensor cable to the front cylinder O2 sensor and route harness along the frame or stock wiring

harnesses going towards the Target Tune module.

4. Connect the other O2 sensor harness to the rear cylinder O2 sensor and route the harness along the frame or

stock wiring harnesses going towards the Target Tune module.

Note: Keep harnesses away from HOT and/or moving parts to prevent damage.

Note: If the supplied cables have different lengths, the longer cable should go to the front cylinder.

5. Connect the front cylinder O2 sensor harness to Target Tune module input #1 per Fig. A.

Connect the rear cylinder O2 sensor harness to Target Tune module input #2 per Fig. A.

Note: The harness can be cut to length if desired.

Note: To make inserting the wires into the module easier, first poke the hole with a paperclip or similar device. Also

tinning the bare wire ends with solder can help.

Dynojet Power Vision

Target Tune Installation - 5

Page 6

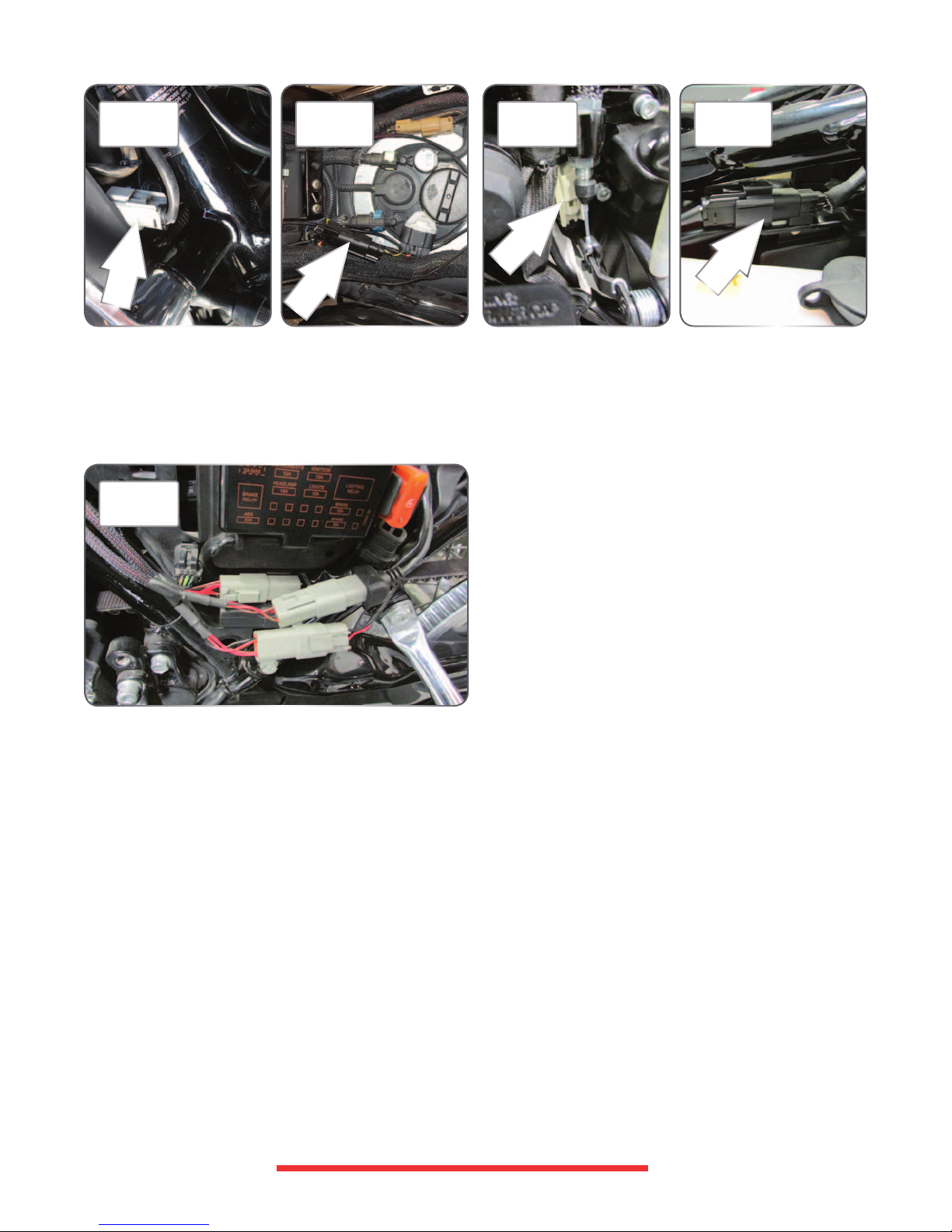

6. Locate and unplug the stock O2 sensor connections.

You can trace the cables from the stock O2 sensors

in the exhaust to these connectors.

7. Plug the connectors from the Target Tune into the

stock O2 sensor connectors (Fig. A).

• Plug the Target Tune lead with the YELLOW/

ORANGE wire into the FRONT cylinder stock O2

connector.

FIG. G

Rear O2

• Plug the Target Tune lead with the YELLOW/GREEN

wire into the REAR cylinder stock O2 connector.

Note: The stock O2 sensors will no longer be

connected to anything and can be removed from the

exhaust if desired, and if you have a way to plug the

holes in the exhaust.

FIG. Ha

FIG. Hb

Front O2

Rear O2

On 2007-2009 Touring models and 2007-2011

Softails the stock O2 connectors for the front

cylinder are found at the front of the engine

near the voltage regulator (Fig. Ha), and the rear

cylinder O2 sensors connectors are found at the

rear of the engine near the oil tank (Fig Hb).

Front O2

On 2010-2015 Touring models the stock O2

connectors are found behind the right-hand side

cover (Fig. G).

FIG. Ja

FIG. Jb

Front O2

Rear O2

On 2012-2015 Softails the stock O2 connectors

for the front cylinder are found at the front of the

engine near the voltage regulator (Fig. Ja), and

the rear cylinder O2 sensor connectors are found

under the seat near the battery (Fig Jb).

FIG. Ka

FIG. Kb

Rear O2

Front O2

On 2006-2015 Dyna models the stock O2

connectors for the front cylinder are found at the

front of the engine near the voltage regulator (Fig.

Ka), and the rear cylinder O2 sensor connectors

are found under the seat (Fig Kb).

Dynojet Power Vision

FIG. La

FIG. Lb

Rear O2

Front O2

On Sportsters the front O2 connection is always at

the front of the engine on the left side near the oil

filter (Fig. La). The rear O2 connection is above

the battery on 2014-2015 models (Fig. Lb) or

just rear of the engine on 2007-2013 models (not

pictured).

Target Tune Installation - 6

Page 7

FIG. Ma

Front O2

FIG. Mb

Rear O2

FIG. Na

Front O2

FIG. Nb

Rear O2

On V-Rods the front O2 connection is always on the

left side of the radiator (Fig. Ma). You may need

to loosen the radiator shroud to gain access to it.

The rear O2 connection is under the seat near the

fuel filler (Fig. Mb).

FIG. O

On Street models (500 and 750), the front O2

connector is located on the right side of the

bike between the swingarm pivot shaft and the

engine case (Fig. Na). The rear O2 connector is

behind the left hand sidecover above the coolant

reservoir (Fig. Nb).

8. Connect the supplied Y-Adaptor to the Diagnostics

port on the motorcycle. (See “Diagnostic Connector

Locations” of the PV Quick Start guide for model

specific diagnostic connector locations.)

9. Route and connect the power lead from the Target

Tune module to one side of the Y-adaptor.

• 2008-2011 V-Rod models will require splicing of the

TT module’s power and ground supply wires; or for a

cleaner install with OEM style connections a power

extension lead (PN: 76950159) can be purchased

separately. If you are splicing the power supply,

the TT’s BLACK wire can go to a constant chassis

ground source such as the frame or the engine case.

The TT’s RED wire will need to go to a key-switched

12v power source.

Dynojet Power Vision

• 2011 Softail models will require splicing of the

TT module’s power and ground supply wires; or

for a cleaner install with OEM style connections a

6-pin Y-adapter, PN: 76950389, and a 6-pin to

4-pin adaptor, PN: 76950664, can be purchased

separately. If you are splicing the power supply,

the TT’s BLACK wire can go to a constant chassis

ground source such as the frame or the engine case.

The TT’s RED wire will need to go to a key-switched

12v power source.

10. Connect the Power Vision cable to the other side of

the Y-adaptor (Fig. O).

11. Tie up and secure any loose sections of the wiring

with the supplied zip-ties and verify wiring is free and

clear of abrasion and heat sources.

Target Tune Installation - 7

Page 8

O2 SENSOR BUNG INSTALLATION

1. Find a suitable location to install the included

M18 x 1.5mm bungs on the exhaust system.

Note: Suitable locations may vary depending on

exhaust system. (See Fig. A and B)

2. Mount the bungs in a manner that reduces the

risk of moisture contamination to the sensor, as

condensation can build up in the exhaust system.

Ideally, the sensor should be between the 10

o’clock and 2 o’clock position on the pipe. A 10°

incline of the sensor above the horizon line should

be considered a minimum. (See Fig. C)

3. Mark the pipe where bungs will be mounted.

FIG. A

REAR Location

FIG. B

Note: Adequate room will be needed for the sensor

body and wiring.

4. Remove the exhaust system.

5. Drilling and welding of the exhaust system should

be done by an experienced welder/fabricator.

6. Reinstall the exhaust system.

O2 SENSOR CONDITION TEST

The Target Tune kit has a built in function

which allows you to test the sensor accuracy

and condition.

1. Remove the sensors from the exhaust system and

hold in ambient air.

2. Verify the Target Tune kit has been powered up for

at least 1 minute and has a solid light.

3. Press and hold the function button on the front

of the Target Tune kit for 3 seconds to initiate the

test on sensor #1 and release the button once the

light begins to blink rapidly.

FRONT Location

FIG. C

4. The LED light will blink rapidly, pause for a

moment, and then begin to flash a series of long

blinks before going back to solid. (You may get

zero blinks before going completely solid, which

would indicate a perfect condition if at or near

sea-level.)

5. Count the number of long blinks and refer

to the chart.

6. Initiate the test a second time to get results for

sensor #2.

7. Retest the sensors if there is any question as to

the purity of the air during the test.

Dynojet Power Vision

Target Tune Installation - 8

Page 9

PROGRAMMING THE ECM

Target Tune requires a special calibration to be flashed to your ECM in order to function

properly. You will need to send an e-mail request to targettune@dynojet.com. Calibrations

submitted to make the Target Tune function properly can be:

• Copy of original or current tune

• Custom tunes

• Pre-configured tunes from Dynojet

The original tune that is being modified to work with Target Tune should be as optimal as

possible for the engine and modifications that you are using. This means if you have a very

unique or radical engine build, you may need to have a more optimal starting point tune

developed by other means before Target Tune can work effectively. This might be a tune

developed by a professional dyno tuner, a tune custom made by Dynojet staff, or a tune

developed by Auto-tune Basic or Auto-tune Pro methods.

Note: The Target Tune module can be used in place of the Auto-tune module when using the

Auto-tune Pro feature; but does require an additional CAN link cable that is sold separately

(PN: 76950427) and calibration changes.

If you’d like to use the tune that’s currently flashed to your ECM please follow these steps in

order to read it from your ECM:

1. Plug the Power Vision into the bike’s diagnostic port.

2. Turn the bike to the ON position (key ON, Run/Stop switch to “Run”, engine stalled).

3. Go to Vehicle Tools on the Power Vision.

4. Select Read ECM. Follow the prompts to read the ECM.

5. Turn the key OFF.

6. Remove the Power Vision and bring it to a computer with Dynojet WinPV software installed.

7. Connect a USB cable to the Power Vision.

8. After the Power Vision boots up and says “PC Link Mode Active,” launch the WinPV software.

9. On the menu bar, go to “Power Vision”, and choose “Diagnostic Test functions > Get ECM

Data from PV”.

10. Look for the “.stk” file (something like this…..10-FB4-JHMKORL.stk ).

11. Select the file and save it to your Personal Computer for safe keeping. (WinPV may have

already done this for you.)

12. E-mail the original .stk file to targettune@dynojet.com.

Note: The latest instructions and software pertaining to Target Tune, please visit:

http://www.dynojet.com/powervision

Dynojet Power Vision

Target Tune Installation - 9

Loading...

Loading...