Page 1

Page 2

©2006 Dynojet Research, Inc. All Rights Reserved.

Spring Applied Air Release (SAAR) Brake Assembly Installation

This manual is copyrighted by Dynojet Research, Inc., hereafter referred to as Dynojet,

and all rights are reserved. This manual, as well as the software described in it, is

furnished under license and may only be used or copied in accordance with the terms of

such license. This manual is furnished for informational use only, is subject to change

without notice, and should not be construed as a commitment by Dynojet. Dynojet

assumes no responsibility or liability for any error or inaccuracies that may appear in this

manual. Except as permitted by such license, no part of this manual may be reproduced,

stored in a retrieval system, or transmitted, in any form or by any means, electronic,

mechanical, recording, or otherwise, without the prior written permission of Dynojet.

The Dynojet logo is a trademark of Dynojet Research, Inc.

Any trademarks, trade names, service marks, or service names owned or registered by any

other company and used in this guide are the property of their respective companies.

Dynojet Research, Inc., 2191 Mendenhall Drive, North Las Vegas, Nevada 89081, USA.

Printed in USA.

Part Number: 98212104 Version 01 (06/06)

Page 3

T

ABLE OF

C

ONTENTS

Spring Applied Air Release (SAAR)

Brake Assembly Installation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

The Hydraulic Brake Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Preparing to Remove the Hydraulic Brake . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Removing the Hydraulic Brake Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installing the SAAR Brake Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installing the Brake Weldment and Brake Shoes . . . . . . . . . . . . . . . . . . . . . 12

Installing the Air Can Mount and Tube . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Installing the Air Can . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Connecting to the Breakout Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Connecting to the Shop Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Fastening the Air Can . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Powering up and Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Four Wheel Drive Dynos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Upgrading the Moveable 224 Dyno . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Connecting the Movement Board and Shop Air . . . . . . . . . . . . . . . . . . . . . 20

Spring Applied Air Release (SAAR) Brake Assembly Installation

i

Page 4

Page 5

S

PRING

This document provides instructions for installing the Spring Applied Air Release

Brake Assembly (P/N 77010008) as an upgrade to model 224 Automotive

Dynamometers (dynos). To ensure safety and accuracy in the procedures, perform

the procedures as they are described.

Document Part Number: 98212104

Version 1

Last Updated: 06-21-06

A

B

RAKE

PPLIED

A

SSEMBLY INSTALLATION

AIR R

ELEASE

(SAAR)

Spring Applied Air Release (SAAR) Brake Assembly Installation

1

Page 6

SPRING APPLIED AIR RELEASE (SAAR) BRAKE ASSEMBLY INSTALLATION

Introduction

INTRODUCTION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Spring Applied Air Release (SAAR) Brake Assembly (P/N 77010008) may be used

to replace the hydraulic brake on model 224 dynamometers. This guide provides

instructions for removing the hydraulic brake and installing the SAAR brake assembly.

The SAAR brake provides braking to the dyno drum through the use of a spring

applied brake mechanism. By default, the brake shoes are pressed against the dyno

drum by the spring mechanism. Air applied to the SAAR brake moves the brake shoes

away from the drum, releasing the brake.

The SAAR brake provides the following advantages over the previous hydraulic brake:

• Vehicles are easier to load since the SAAR brake is applied when the dyno is idle

• The SAAR brake provides braking in the event of a loss of power or an air supply

failure.

• Brake maintenance is reduced as the SAAR brake does not need the filling and

bleeding required for hydraulic brakes.

For more detailed information on the 224 dyno, refer to the Installation Guide for

Model 224 Above Ground Automotive Dynamometers (P/N 98210108) or the

Installation Guide for In Ground Model 224 Automotive Dynamometers (P/N

98210100).

CONVENTIONS USED IN THIS MANUAL

The conventions used in this manual are designed to protect both the user and the

equipment.

example of convention description

The Warning icon indicates potential harm to the

person performing a procedure and/or the

dynamometer equipment.

TECHNICAL SUPPORT

For assistance, please contact Dynojet Technical Support at 1-800-992-3525, or write

to Dynojet Research at 2191 Mendenhall Drive, North Las Vegas, NV 89081.

Visit us on the World Wide Web at www.dynojet.com where Dynojet provides state of

the art technical support, on-line shopping and press releases about our latest

product line.

Do not repair or replace any part of the dynamometer or attempt any servicing

unless specifically recommended in published user-repair instructions that you

understand and have the skills to carry out.

2

Spring Applied Air Release (SAAR) Brake Assembly Installation

Page 7

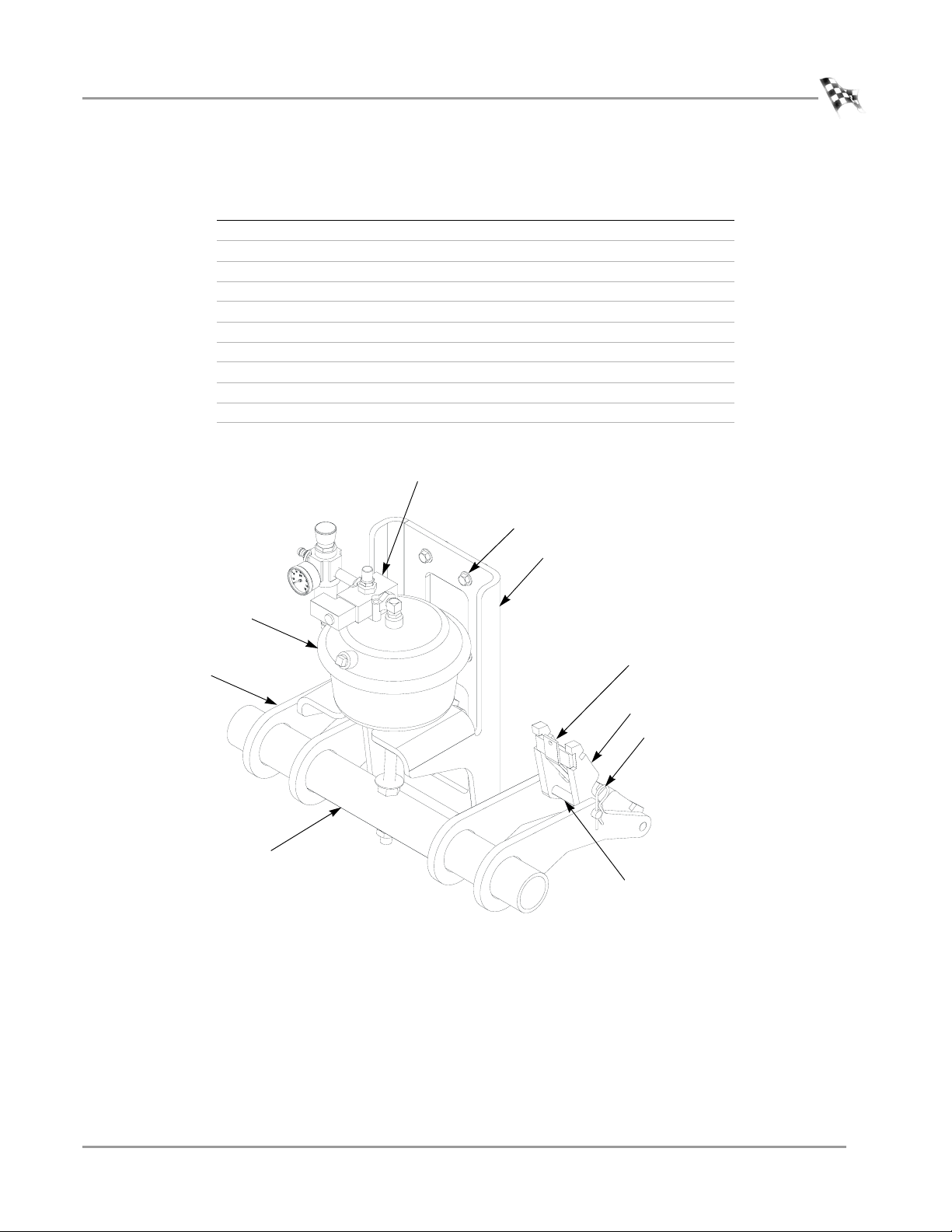

SPRING APPLIED AIR RELEASE (SAAR) BRAKE ASSEMBLY INSTALLATION

77010008 Spring Applied Brake Upgrade, 224

Stock Code Description Quantity

21612112 Mount, Air Can, Upgrade, 224 1

21612400 Brake Arm, 24 4

21612900 Brake Shoe Retainer, 224 2

21612901 Brake Actuating Tube, 224 1

32904080 Hairpin Cotter, 7/16"-3/4" 4

32916144 Clevis Pin, 1/2" x 4-1/2" 2

34761003 Air Canister, Type R30 1

36582471 Bolt, 3/8-16 x 1-1/2", Flange-Hex 4

61312105 Brake Holder Weldment, 224 2

64111005 Brake Solenoid Assembly, 224-2 1

brake solenoid

assembly

3/8-16 x 1-1/2" bolt

Introduction

air canister

brake arm

brake actuating tube

air can mount

AB090

Figure 1: Spring Applied Brake Upgrade

brake shoe retainer

brake holder weldment

hairpin cotter

clevis pin

Version 1 Spring Applied Air Release (SAAR) Brake Assembly Installation

3

Page 8

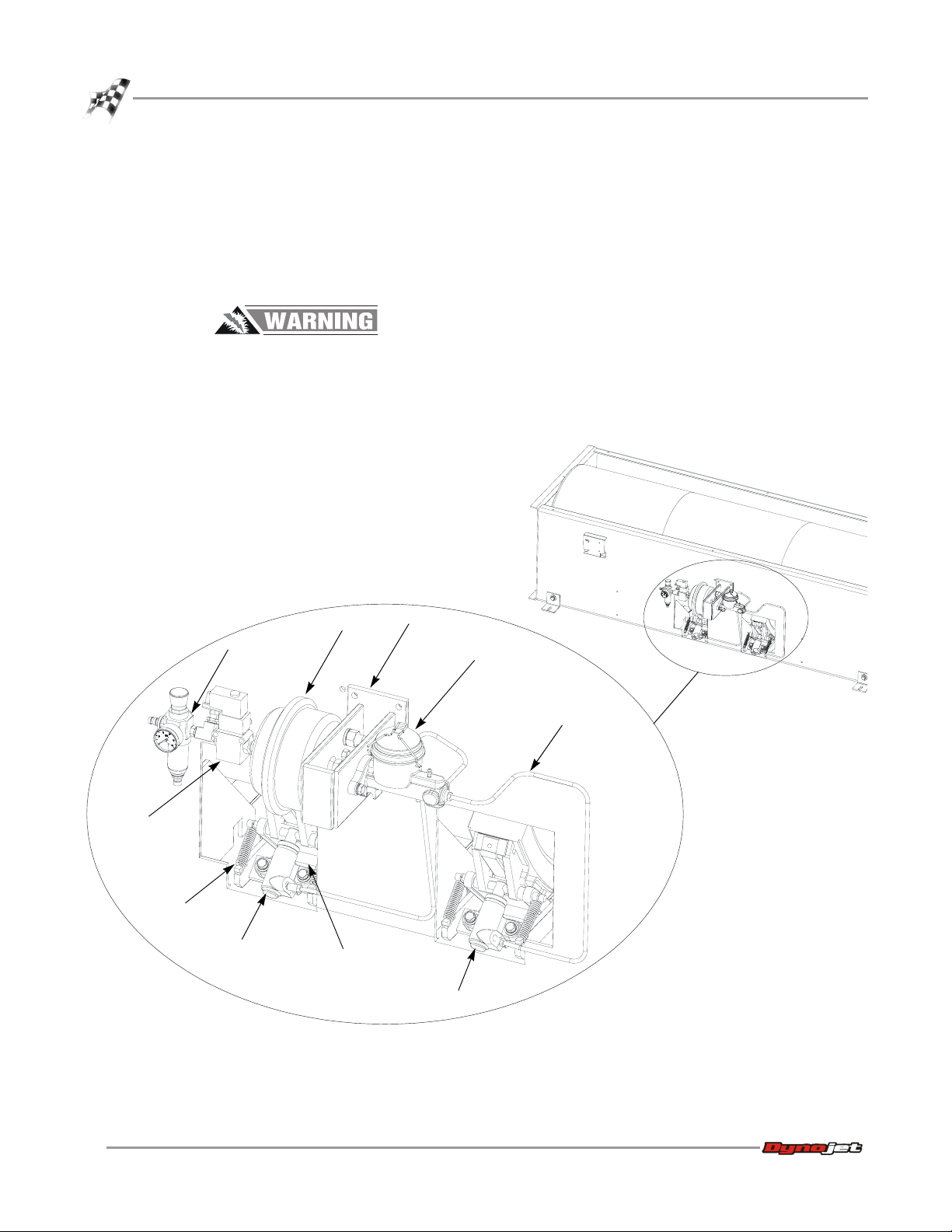

SPRING APPLIED AIR RELEASE (SAAR) BRAKE ASSEMBLY INSTALLATION

The Hydraulic Brake Assembly

THE HYDRAULIC BRAKE ASSEMBLY

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

When upgrading to the SAAR Brake Assembly, you will remove the previously installed

hydraulic braking system shown in Figure 2. In order to minimize your exposure to

the fluid used in the hydraulic brake assembly, you will remove the major portion of

the assembly as one piece.

Follow manufacturer precautions for handling brake fluid used in the

hydraulic braking system. Do not breathe vapors, mist, fume or dust. Do not

get in eyes, on skin or clothing. Wear protective gloves or clothing if exposure

conditions warrant. Wash thoroughly after handling. Launder contaminated

clothing before reuse. Use only with adequate ventilation.

solenoid

assembly

spring

slave cylinder

air pressure

regulator

air can

brake clevis

pin

slave cylinder

mounting

bracket

BR011

master cylinder

hydraulic line

Figure 2: Existing Hydraulic Braking System

4

Spring Applied Air Release (SAAR) Brake Assembly Installation

Page 9

SPRING APPLIED AIR RELEASE (SAAR) BRAKE ASSEMBLY INSTALLATION

PREPARING TO REMOVE THE HYDRAULIC BRAKE

1 Turn off the power and unplug the dyno electronics and observe all applicable

safety procedures.

2 Shut off and release the air pressure to the air pressure regulator.

3 Remove covers as necessary to provide yourself good access to the braking

components. Refer to your dyno manuals, if necessary, to review removing the

covers. You can download copies of the manuals for your dyno from

www.dynojet.com.

4 Disconnect the 3/8-inch air hose from the fitting on the pressure regulator, or cut

off the existing air hose close to the fitting on the pressure regulator.

Note: Leave the air hose with the dyno as you will reconnect it to the new

pressure regulator for the SAAR Brake Assembly.

The Hydraulic Brake Assembly

Version 1 Spring Applied Air Release (SAAR) Brake Assembly Installation

5

Page 10

SPRING APPLIED AIR RELEASE (SAAR) BRAKE ASSEMBLY INSTALLATION

The Hydraulic Brake Assembly

5 On standard dynos the brake control wiring is connected to the breakout board.

The breakout board is located on the dyno as shown in Figure 3.

Disconnect the two wires from the wiring block labeled BRAKE on the Breakout

board, as shown in Figure 3. These two wires connect the brake solenoid. It

should now be disconnected.

Note: If you are installing the upgrade on a four-wheel drive dyno, see “Four

Wheel Drive Dynos” on page 20 for the connections of the brake solenoid to the

movement board.

Never operate the dynamometer when the brake is not functioning.

disconnect

brake

assembly

wiring

breakout

board

AD167

BRAKE

Figure 3: Disconnect the Hydraulic Brake Control Wiring from the Breakout Board

6

Spring Applied Air Release (SAAR) Brake Assembly Installation

Page 11

disconnect air

hose or cut air

hose close to

solenoid

BR012

brake head

SPRING APPLIED AIR RELEASE (SAAR) BRAKE ASSEMBLY INSTALLATION

The Hydraulic Brake Assembly

REMOVING THE HYDRAULIC BRAKE ASSEMBLY

1 Remove the four springs holding the brake head pivot pin to the brake frame rail.

pivot pin

brake frame rail

Figure 4: Remove the Springs

2 Use a large flat blade screw driver or small pry bar to pry the brake shoe retainer

out of the brake holder.

pry the brake shoe retainer

out of the brake holder

remove four

springs

brake

holder

Figure 5: Remove the Brake Shoe Retainer

Version 1 Spring Applied Air Release (SAAR) Brake Assembly Installation

7

Page 12

SPRING APPLIED AIR RELEASE (SAAR) BRAKE ASSEMBLY INSTALLATION

The Hydraulic Brake Assembly

3 Remove the brake shoes from the assembly by sliding them to the outside. Set the

brake shoes aside to be reused with the SAAR Brake Assembly.

BR015

slide brake shoes toward

the outside and remove

cotter

pin

BR020

Figure 6: Remove the Brake Shoes

4 Remove the cotter pin from the brake clevis pin on both brakes.

remove

cotter pin

BR022

BR021

slide brake

clevis pin

Figure 7: Remove the Cotter Pins Holding the Brake Hanger Pivots

8

Spring Applied Air Release (SAAR) Brake Assembly Installation

Page 13

SPRING APPLIED AIR RELEASE (SAAR) BRAKE ASSEMBLY INSTALLATION

The Hydraulic Brake Assembly

5 Slide the brake clevis pin into the square recesses provided. The brake clevis pin

will only slide in one direction. You may need to slide your brake clevis pin

opposite to the direction shown in Figure 8 if your brake clevis pin faces the other

way. After you remove the hydraulic brake assembly, you will reach in to remove

the pivot pins from inside the square recesses.

BR016

slide brake clevis pin into

square recess

Figure 8: Slide the Brake Clevis Pin into the Square Recess

Version 1 Spring Applied Air Release (SAAR) Brake Assembly Installation

9

Page 14

SPRING APPLIED AIR RELEASE (SAAR) BRAKE ASSEMBLY INSTALLATION

The Hydraulic Brake Assembly

6 Remove four lower bolts holding the slave cylinders and brake head assembly to

the brake frame rail.

7 Remove the four bolts holding the master cylinder bracket to the dyno,

supporting the hydraulic brake assembly during the final removal of the bolts.

master cylinder bracket

BR017

remove four

bolts

slave cylinder

slave cylinder

remove bolts and washers

Figure 9: Remove Bolts

10

Spring Applied Air Release (SAAR) Brake Assembly Installation

Page 15

BR018

SPRING APPLIED AIR RELEASE (SAAR) BRAKE ASSEMBLY INSTALLATION

The Hydraulic Brake Assembly

8 The hydraulic brake assembly should now be completely free. Remove it from the

dyno.

9 Extract the brake clevis pins from the square recesses and set them aside.

Note: You will reuse the brake shoes and the two clevis pins. The other parts can

be appropriately discarded.

.

remove hydraulic brake

assembly

Figure 10: Remove the Hydraulic Brake Assembly

Version 1 Spring Applied Air Release (SAAR) Brake Assembly Installation

11

Page 16

SPRING APPLIED AIR RELEASE (SAAR) BRAKE ASSEMBLY INSTALLATION

Installing the SAAR Brake Assembly

INSTALLING THE SAAR BRAKE ASSEMBLY

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The following instructions are for installing the Spring Applied Air Brake Assembly on

a 224 above-ground or pit dyno.

In the next steps you will:

• attach the brake holder weldment using the brake clevis pin you removed

from the hydraulic brake assembly

• bolt the mounting bracket to the dyno

• slide the tube into place

• mount the air can assembly

• make the final connections

Note: If you have a 4 wheel drive dyno model 224-248 or 224-224, refer to

additional instructions for “Four Wheel Drive Dynos” on page 20.

INSTALLING THE BRAKE WELDMENT AND BRAKE SHOES

1 Slide the brake clevis pins into the square recesses as shown in Figure 11. Face

the head end of the pivot toward the outside, so that the brake clevis pin is

partially inside the recess and then slide the clevis pin partially into the mounting

bracket. The hole on the end of the brake clevis pin, which is designed to accept

the hairpin cotter, should be pointed toward the center of the dyno. Do not fully

insert the brake clevis pin until after you slide the brake weldment into position

2 Position the brake weldment so that the holes on the arms are aligned to accept

the brake clevis pin.

slide brake clevis

pin into position

BR024

Figure 11: Slide Brake Weldment into Position

12

Spring Applied Air Release (SAAR) Brake Assembly Installation

brake holder weldment

brake arms

Page 17

SPRING APPLIED AIR RELEASE (SAAR) BRAKE ASSEMBLY INSTALLATION

Installing the SAAR Brake Assembly

3 Insert the brake clevis pin through the holes as shown in Figure 12.

4 Install the hairpin cotter.

5 Use the same method to install the remaining brake weldment with arms, pivot,

and hairpin cotter.

head end of

brake clevis pin

BR025

insert

hairpin cotter

brake shoe

Figure 12: Connect the Brake Weldment and Arms using the Brake Clevis Pin

6 Slide the brake shoe into position and thread the brake shoe retainer into

position. (Now is a good time to check for wear and use new brake shoes if

necessary, P/N 33831001.)

brake shoe

retainer

brake shoe

installed

BR031

brake shoe retainer

installed

Figure 13: Install the Brake Shoes

Version 1 Spring Applied Air Release (SAAR) Brake Assembly Installation

13

Page 18

SPRING APPLIED AIR RELEASE (SAAR) BRAKE ASSEMBLY INSTALLATION

Installing the SAAR Brake Assembly

INSTALLING THE AIR CAN MOUNT AND TUBE

1 Install the air can mount using the four 3/8"-16 x 1-1/2" flange bolts provided

BR027

four 3/8"-16 x 1-1/2"

flange bolts

air can mount

air can assembly

Figure 14: Attach the Air Can Mount to the Dyno

14

Spring Applied Air Release (SAAR) Brake Assembly Installation

Page 19

SPRING APPLIED AIR RELEASE (SAAR) BRAKE ASSEMBLY INSTALLATION

Installing the SAAR Brake Assembly

2 Slide the tube through the brake arms.

3 Rotate the tube so that the center hole is oriented vertically.

BR028

slide tube through arms

orienting the hole

vertically

Figure 15: Slide the Tube into Place

Version 1 Spring Applied Air Release (SAAR) Brake Assembly Installation

15

Page 20

SPRING APPLIED AIR RELEASE (SAAR) BRAKE ASSEMBLY INSTALLATION

Installing the SAAR Brake Assembly

INSTALLING THE AIR CAN

1 Thread the pipe fitting which extends from the solenoid subassembly into the

threaded hole on the top of the air can. Apply pipe thread sealer to the fitting if

sealer is not already present.

2 Align the solenoid assembly so that it is parallel to the two bolts that extend from

the bottom of the air can as shown in Figure 17.

AB093

threaded pipe fitting

solenoid assembly

threaded hole

in air can

3 Remove and set aside the two 5/8" lockwashers and nuts for the air can.

4 Remove and set aside the 5/8" nut from the long threaded rod at the bottom of

5/8" lockwashers

and nuts

air can

Figure 16: Attach the Solenoid Subassembly to the Air Can

the air can.

BR030

align solenoid assembly

with these two studs

5/8" nut

Figure 17: Prepare the Air Can Assembly

16

Spring Applied Air Release (SAAR) Brake Assembly Installation

Page 21

SPRING APPLIED AIR RELEASE (SAAR) BRAKE ASSEMBLY INSTALLATION

Installing the SAAR Brake Assembly

5 While lowering the air can through the hole in the tube, align the air can studs

with the holes in the bracket.

Note: The rod will not extend all of the way through the tube until the electronics

are connected and air pressure is applied to the air can.

6 Loosely attach the air can to the bracket using the two 5/8" nuts and lockwashers

removed earlier.

Keeping the nuts loose will allow for adjustment while extending the air can rod

the remaining distance through the tube. The power and air connections are

necessary to finish connecting the brake assembly.

air can studs

washer and upper nut

will be tightened down

onto tube after lower

nut is fastened

use 5/8" lockwashers

and nuts to attach air

can to bracket

BR029

Figure 18: Install the Air Can

insert air can rod into

hole through tube

Version 1 Spring Applied Air Release (SAAR) Brake Assembly Installation

17

Page 22

SPRING APPLIED AIR RELEASE (SAAR) BRAKE ASSEMBLY INSTALLATION

Installing the SAAR Brake Assembly

CONNECTING TO THE BREAKOUT BOARD

1 Connect the two black wires from the solenoid to the two terminals on the

breakout board labelled BRAKE (one to each terminal).

2 If you have a 4 wheel drive dyno model 224-248 or 224-224, refer to additional

instructions for “Four Wheel Drive Dynos” on page 20.

connect the two black

wires from the brake

solenoid to the

breakout board

CONNECTING TO THE SHOP AIR

BRAKE

Figure 19: Connect the Brake Solenoid Wires to the Breakout Board

1 Connect shop air to the fitting on the brake air can pressure regulator. See

Figure 22 on page 21 if you are installing the brake on a four-wheel drive dyno.

2 Adjust the air pressure by pulling up on the regulator knob and turning

counterclockwise to decrease the pressure to 30 psi (clockwise to increase).

Note: The Spring Applied Brake should be operated at 100 psi, but you will start

with the pressure lower while connecting the air can to aid in lining up the parts.

pull up on regulator

knob and adjust

pressure to 30 psi

0

AB092

18

Spring Applied Air Release (SAAR) Brake Assembly Installation

pressure gauge

should read 30 psi

Figure 20: Adjust the Air Pressure

Page 23

SPRING APPLIED AIR RELEASE (SAAR) BRAKE ASSEMBLY INSTALLATION

FASTENING THE AIR CAN

1 Check to make sure that the area is clear and that the dyno can be operated safely.

2 Power up the dyno electronics.

Keep hands and fingers clear when operating dyno.

3 Use the pendant to turn the brake to the OFF position. This will apply air pressure

to the brake’s air can to extend the rod, allowing you to fit the rod through the

bottom of the hole in the brake actuating tube.

4 Gradually increase the air pressure to 100 psi by pulling up on the regulator knob

and turning it clockwise. As you are doing this, guide the air can rod through the

hole in the brake actuating tube.

5 Torque the upper two nuts fastening the air can to the mounting bracket to

110 ft-lbs.

6 Adjust the nut on the bottom of the air can rod until the brake shoes are

6mm/.25" away from the dyno drum.

7 Tighten the upper nut on the air can rod down onto the brake actuating tube to

sandwich the tube between the two nuts.

8 Torque the lower nut to 110 ft-lbs.

Installing the SAAR Brake Assembly

Your brake should now be completely installed

.

connect the two black

wires from the brake

solenoid to the

breakout board

connect to shop air

Figure 21: Apply Air Pressure to Extend Air Can Rod into Brake Actuating Tube

POWERING UP AND TESTING

torque nuts to

110 ft-lbs

air can rod

upper nut

BR032

torque lower nut

to 110 ft-lbs

1 Verify that the pressure gauge on the Spring Applied Air Brake shows 100 psi.

2 Use the pendant to turn the brake ON.

3 Ensure that the brake shoes are making contact with the dyno’s drum and that the

drum will not rotate.

Adjust the brake if necessary using the nuts on the air can rod.

Version 1 Spring Applied Air Release (SAAR) Brake Assembly Installation

19

Page 24

SPRING APPLIED AIR RELEASE (SAAR) BRAKE ASSEMBLY INSTALLATION

Four Wheel Drive Dynos

FOUR WHEEL DRIVE DYNOS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The instructions in the following sections describe the differences for installing the

SAAR Brake Assembly on four-wheel drive dynos. The SAAR Brake Assembly may be

used to upgrade the braking on 224-248 model and 224-224 four-wheel drive dynos.

The 224-248 dyno has a stationary 248 dyno and a moveable 224 dyno. When

upgrading this model, you will leave the existing air applied brake on the stationary

248 dyno and only upgrade the moveable 224 dyno.

The model 224-224 dyno uses a stationary 224 dyno along with a moveable 224 dyno

that can be positioned to accommodate for the wheelbase of the vehicle being

tested.When upgrading a model 224-224, both 224 dynos must have the SAAR Brake

Assembly upgrade. To upgrade the stationary dyno, follow the directions in the

previous sections of the manual.

UPGRADING THE MOVEABLE 224 DYNO

Moveable 224 dynos use a control box containing the dyno movement board and

other movement components. The wiring to the brake solenoid is connected to the

movement board in the control box and not the breakout board, as in the standard

installation instructions.

In general, when installing a SAAR brake on a moveable 224 dyno, follow the

instructions in the manual, except when disconnecting and connecting the brake

control wiring and air. Use the steps that follow to connect the brake wiring to the

movement board and to connect the air supply to the SAAR brake.

CONNECTING THE MOVEMENT BOARD AND SHOP AIR

The movement board is located inside the control box as shown in Figure 22.

1 Disconnect one black wire and one white wire from the movement board

terminals labelled BRK2 that connect the existing brake solenoid.

2 Route the wires for the new brake solenoid through the opening in the control

box and connect the two black wires to the terminals labelled BRK 2 on the

movement board. (Connect one to each terminal, the order does not matter as

the solenoid will operate correctly with either polarity.)

3 Connect the air hose to the solenoid, replacing the hose if necessary.

4 Continue the installation with step #2, “Connecting to the Shop Air” on page 18.

20

Spring Applied Air Release (SAAR) Brake Assembly Installation

Page 25

SPRING APPLIED AIR RELEASE (SAAR) BRAKE ASSEMBLY INSTALLATION

Four Wheel Drive Dynos

control box

connect air

hose to

solenoid,

replace hose

if needed

BR033

IN BRK 1BRK 2

OUTRAIL

connect the two black wires

from the brake solenoid to

the terminals labelled

BRK 2 on movement board

+12V GND OUTINCOMBRK IN

movement board

-- PRES SW

Figure 22: Connect from Solenoid to the Movement Board in the Control Box

Version 1 Spring Applied Air Release (SAAR) Brake Assembly Installation

21

Page 26

Page 27

Loading...

Loading...