Page 1

Page 2

©1993-1999 Dynojet Research, Inc. All Rights Reserved.

Installation Guide for Snowmobile Dynamometers.

This manual is copyrighted by Dynojet Research, Inc., hereafter referred to as Dynojet,

and all rights are reserved. This manual, as well as the software described in it, is

furnished under license and may only be used or copied in accordance with the terms of

such license. This manual is furnished for informational use only, is subject to change

without notice, and should not be construed as a commitment by Dynojet. Dynojet

assumes no responsibility or liability for any error or inaccuracies that may appear in this

manual. Except as permitted by such license, no part of this manual may be reproduced,

stored in a retrieval system, or transmitted, in any form or by any means, electronic,

mechanical, recording, or otherwise, without the prior written permission of Dynojet.

The Dynojet logo is a trademark of Dynojet Research, Inc.

Any trademarks, trade names, service marks, or service names owned or registered by any

other company and used in this guide are the property of their respective companies.

Dynojet Research, Inc., 2191 Mendenhall Drive, North Las Vegas, Nevada 89031, USA.

Printed in USA.

Part Number: 98260100 Revision D (11/1999)

Page 3

Document #98260100 1i

Contents

Chapter 1 ..............................................1 - 1

Setup and Maintenance

Uncrating the Dyno ................................................................1 - 1

Dyno Maintenance .................................................................1 - 7

Chapter 2 ..............................................2 - 1

Hardware Installation

DynoWare EX+........................................................................2 - 1

Atmospheric Sensing Module........................................................2 - 1

RPM Module............................................................................2 - 2

Dynamometer Input/Output Module

............................................... 2 -3

CPU Module...................................................................................................2 - 4

Connecting The DynoWare EX+............................................2 - 5

Chapter 3 ..............................................3 - 1

Optional Accessories Installation

Driver Carriage........................................................................3 - 1

Revision D 11/4/1999

Page 4

1ii Document #98260100

Page 5

Document#98260100 1 - 1

Chapter 1

Setup and Maintenance of the Sled Dyno

Uncrating the dyno

Step 1

Look for any external damage to the crate. If any

damage is present contact the carrier and Dynojet.

Step 2

Remove the top of the crate.

Step 3

Remove the sides of the crate.

Revision D 11/4/1999

Page 6

1 - 2 Document #98260100

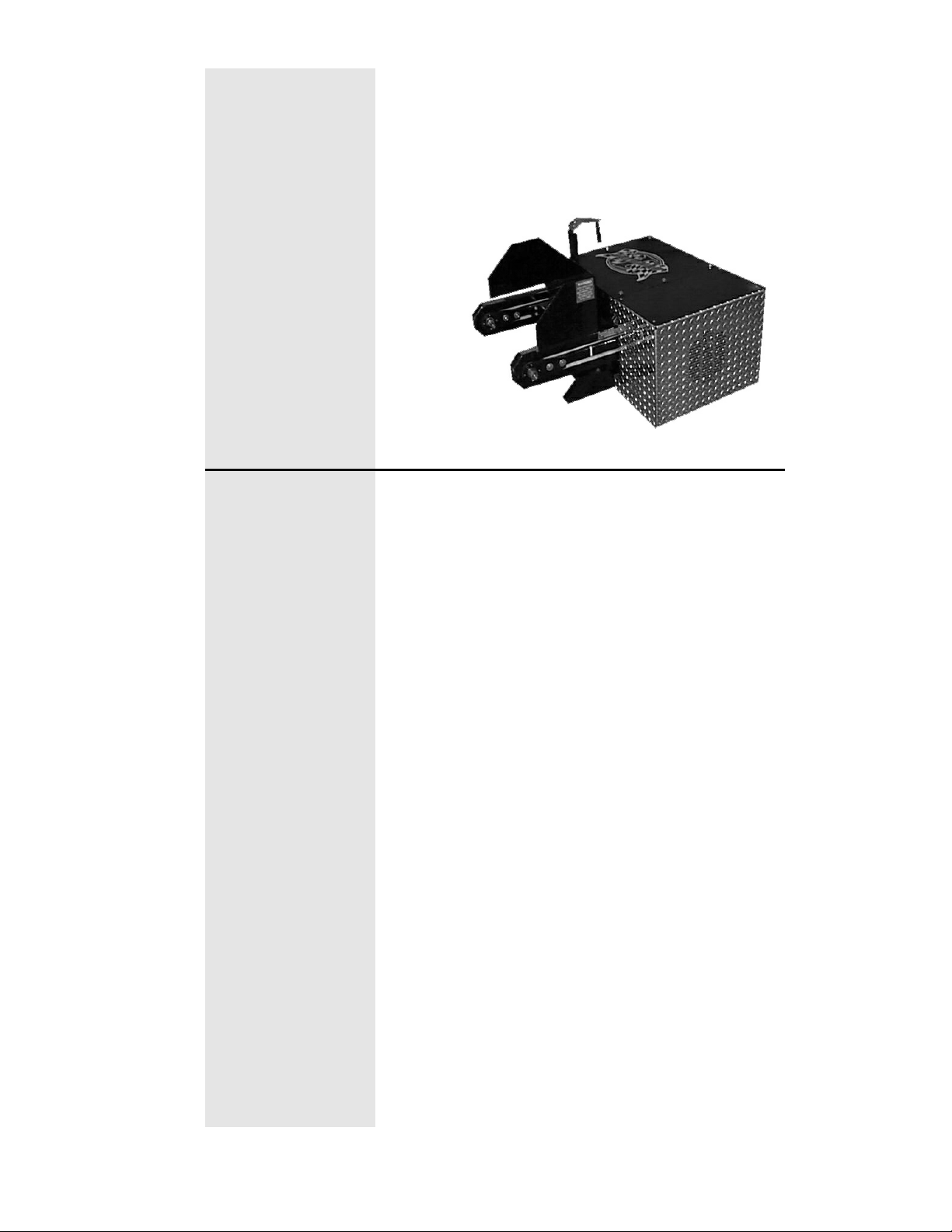

The crate will contain the following.

1 - box containing:

2 - (A) inside driver wheels and hubs

2 - (B) outside driver wheels and hubs

1 - (C) middle spacer

1 - (D) short (red) driver shaft

1 - (E) long (green) driver shaft

2 - (F) short spline shafts

2 - (G) long spline shafts

2 - (H) retainer clips and bolts

4 - (I) inside drive spacers (2 sets)

6 - (J) track tensioning guides (3 sets of 2)

1 - (K) shim pack (6 sets of 2)

1 - (L) track tensioning blocks

1 - (M) Yamaha tensioner

2 - (N) allen head bolts and lock washers

1 - (O) shaft extractor (3 pieces)

1 - (P) Yamaha middle spacer

2 - (Q) Yamaha inside drive spacers

2 - (R) Yamaha suspension adapters

1 - dynamometer guard (not shown)

1 - jack (not shown)

1 - lift handle (not shown)

1 - dynamometer

1 - bolt pack

1 - Brake Cover (not shown)

1 - Lid Extension (not shown)

A

G

B

C

D

E

F

H

M

L

I

K

J

N

O

R

Q

P

Page 7

Document #98260100 1 - 3

Step 4

Remove all components except the dyno and

check the contents.

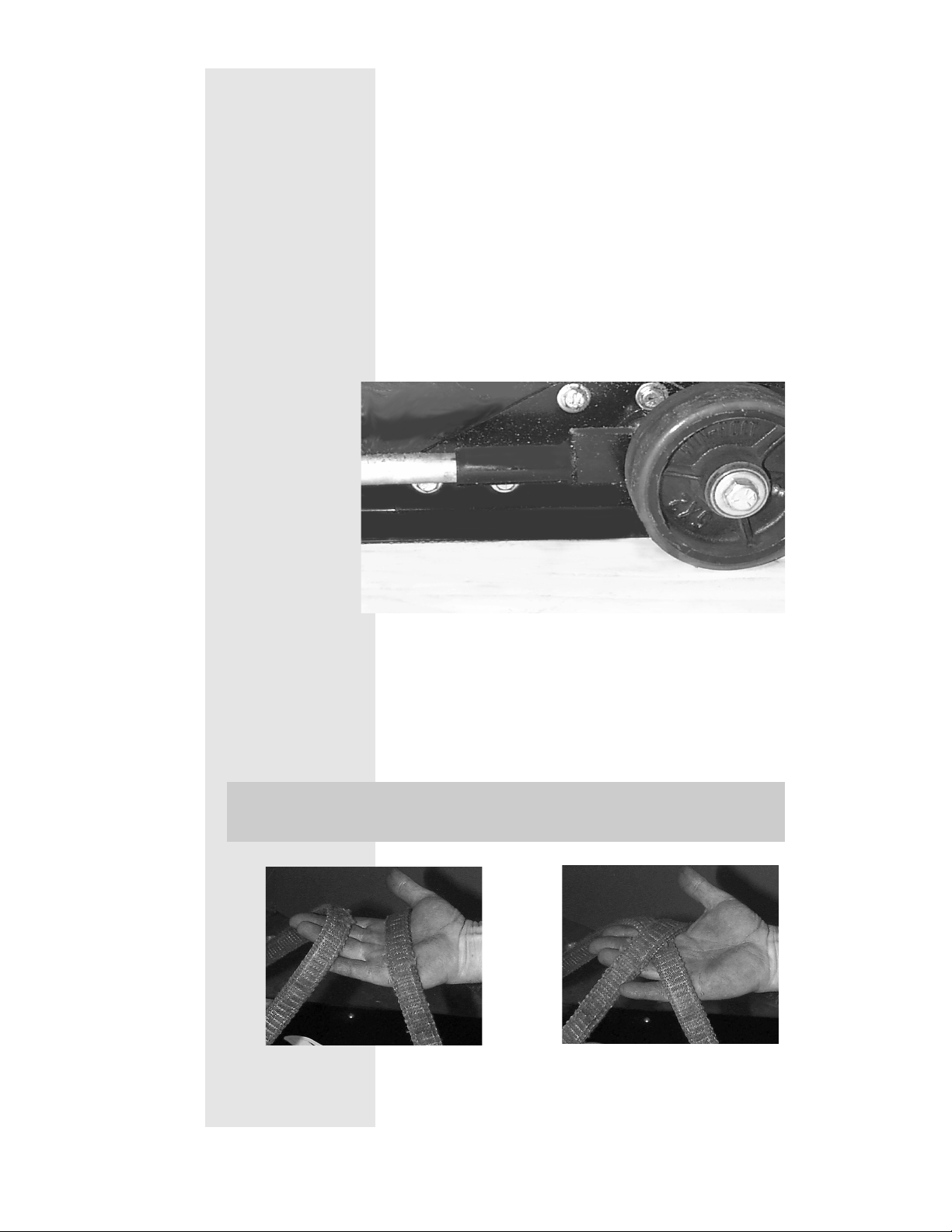

Step 5

Remove bolts holding down the dyno.

Install handle into receivers and secure with 1/4"

bolts. Raise the handle to engage the wheel so the

dyno will roll.

Step 6

To lift the dyno off the crate, use a continuous

loop strap and hook on all four corners of the

main frame (Refer to the picture on the next

page).

Important:

Loop the straps so that they cross at the

top.

Correct

Incorrect

Page 8

1 - 4 Document #98260100

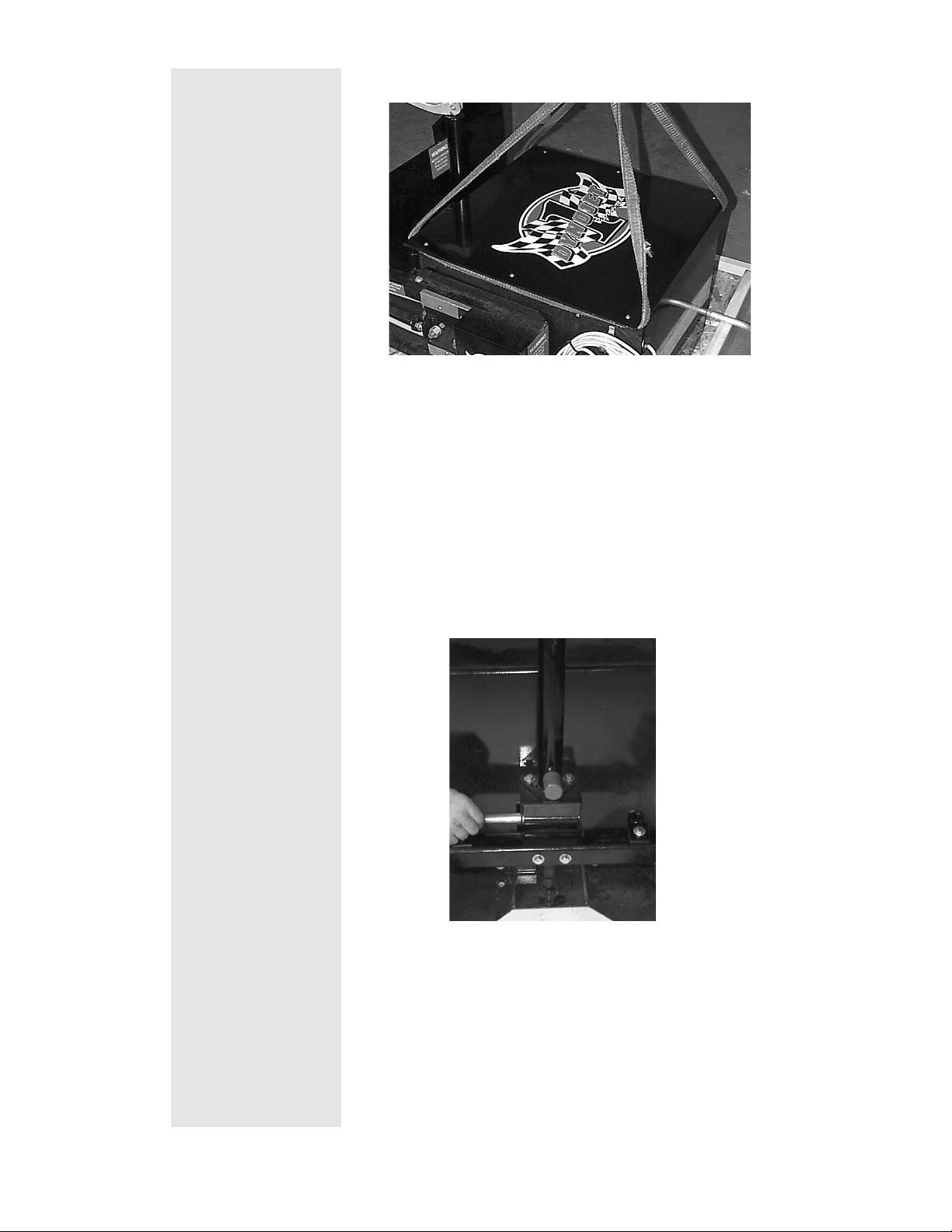

DO NOT LIFT THE DYNO BY THE ARMS !

Step 7

Install the jack with the pin and cotter keys on top

and the 3/8” bolt in the bottom.

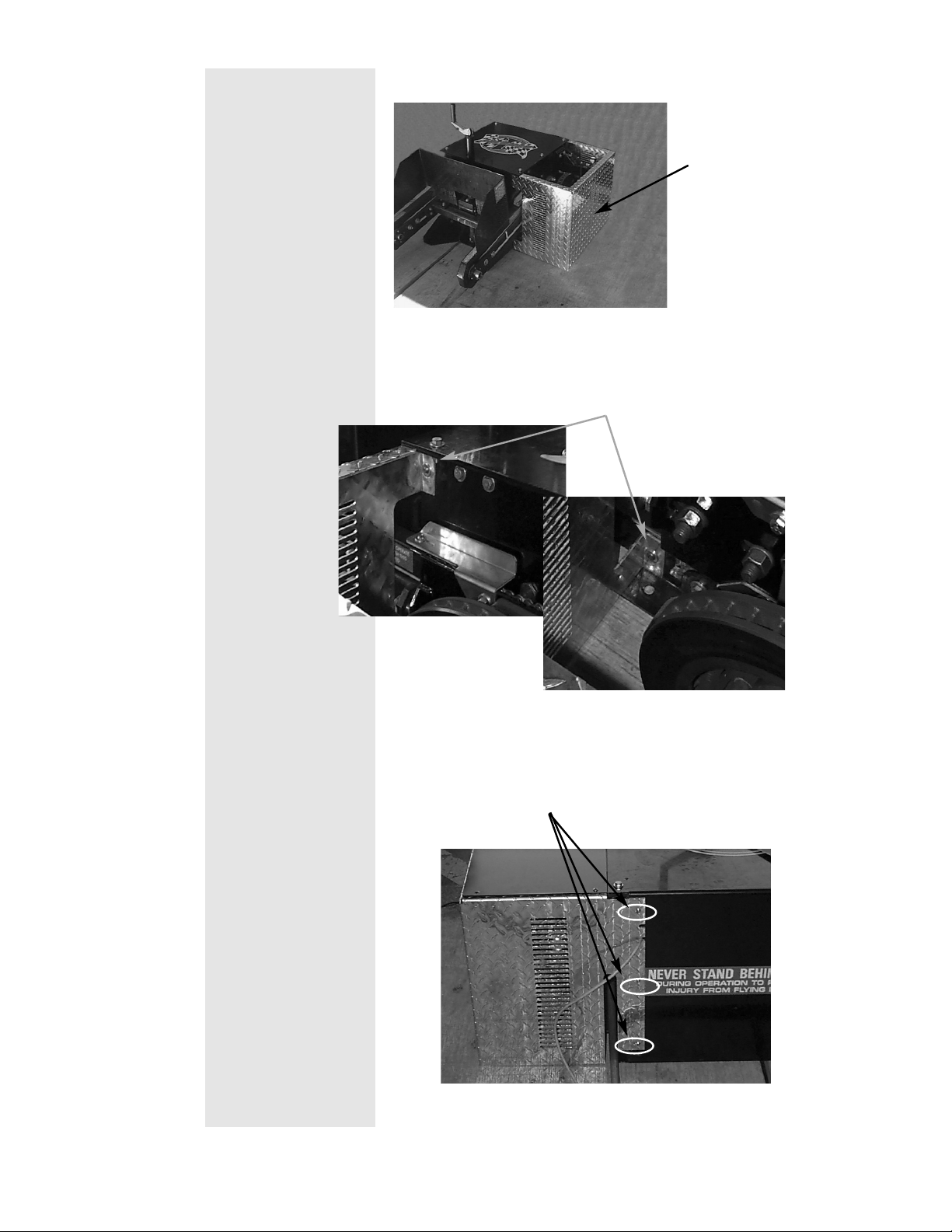

Step 8

Install the brake cover, it attaches with (5) 1/4”

button head screws. Two screws of the front, and

three screws on the rear.

Page 9

Document #98260100 1 - 5

Install the front (2) screws. These screws are

accessed from the inside of the brake cover.

(Leave the Screws Loose)

Install the (3) screws on the back of the Brake

Cover. (Leave the Screws Loose)

Brake

Cover

Page 10

1 - 6 Document #98260100

Step 9

Fit the cover into position and check clearances.

The Lift Handle on the back of the dyno should

move freely without binding.

When everything f its well, you may tighten down

the (5) 1/4” button head screwss

Step 10

Install Lid Extension with (4) 1/4” button head

bolts.

Lid Extension

Page 11

Document #98260100 1 - 7

Dyno Maintenance

The dyno should get a general inspection every 2

weeks depending on the number of runs made.

This inspection should include:

Checking all bolts to ensure they are tight.

Ensure the sprockets and driver assembly is

in good working condition.

Examine the plastic driver wheels to ensure that

they are in good shape and do not show

excessive wear.

The chain guards should be removed and the

chain tension checked every 300 runs. (Refer to

the pictures and the text below)

There is a red arrow on each of the arms. This

is the location at which the chain tension is

checked. Use a pull scale to apply 12 pounds on

the chain pulling the chain up. Measure from

the bottom inside of the chain guide to the top of

a link in the chain. The chain should be 1 3/

16

inches from the bottom of the guide.

Page 12

1 - 8 Document #98260100

The cover should be removed every 300 runs

to ensure the brake is properly adjusted (see

next page) and to check the internal

components for wear.

Use the brake adjustment bolt on the left (shown

below) to adjust the Left side brake pad. Loosen

the lock nut and screw the adjuster bolt in so

that the clearance between the brake pad and

the disk is 0.0500". Tighten the lock nut. Do the

same to the right side. Check the brake fluid

and fill if necessary.

Brake Adjustment Screws

Left Right

Page 13

Document #98226100 Master 2 - 1

Chapter 2

Hardware Installation

DynoWare EX+

The standard dynamometer electronics package is

comprised of 4 interconnected modules:

Atmospheric Sensing Module:

The atmospheric sensing module measures

absolute pressure, air temperature and relative

humidity. These measurements are used by

WinPEP to correct power and torque

measurements to standard atmospheric conditions

according to a DIN, SAE or other formula.

The green LED glows when the atmospheric

sensing module is receiving power.

The flashing amber LED indicates the module

processor is operating properly.

System Expansion Connector

Atmospheric Sensing Module

RPM Module

Dynamometer Input/Output

Module

CPU Module

Revision C 11/16/00

Page 14

2 - 2 Master Document #982261002 - 2 Master Document #98226100

RPM Module:

The RPM module receives and processes signals

from up to 2 inductive pickups for measurement

of engine RPM. Each input has an automatic

gain circuit to compensate for a wide variance of

ignition systems.

The green LED glows when the RPM module is

receiving power.

The amber LED flashes when an RPM signal is

detected. A steady flash rate, proportional to

engine RPM, indicates a good RPM signal.

These connectors are the inputs for both primary

and secondary inductive pickup clips. Either

input may be used with a primary inductive

pickup or a secondary inductive pickup on a

single ended coil. Both inputs can be used for a

wasted spark ignition.

Page 15

Document #98226100 Master 2 - 3Document #98226100 Master 2 - 3

Dynamometer Input/Output Module:

The dynamometer I/O module sends and receives

data from the dynamometer and the hand held

pendant. The module also contains a buzzer and

light which are activated when either the vehicle

or dynamometer speed limit is approached.

The green LED glows when the dynamometer

input/output module is receiving power.

The amber LED flashes proportionally to

dynamometer drum RPM.

This 25-pin receptacle connects to the shielded

cable from the dynamometer.

This 9-pin receptacle connects to the hand held

pendant which houses the button used to

Start/Stop acquiring data. The pendant may also

contain a brake switch.

Page 16

2 - 4 Master Document #982261002 - 4 Master Document #98226100

CPU Module:

The CPU module contains a 32-bit processor

which acquires data from the expansion modules

and communicates to the main computer running

the WinPEP software. The processor queries the

expansion modules to determine their identity

and capabilities.

The green LED glows when the CPU module is

receiving power.

The blue LED is lighted when data from the

modules is being acquired and saved.

One of these connectors is used to communicate

to the main computer. The 9-pin receptacle (left)

connects to the PC’s RS-232 serial

communications port. The 8-pin modular

connector (right) provides communications

according to the RS-422/485 specification.

Page 17

Document #98226100 Master 2 - 5Document #98226100 Master 2 - 5

CPU Module: ..... Continued

This connector provides a synchronization signal

to a 3rd-party data acquisition system.

This connector provides 12 Volt DC power to a

3rd-party data acquisition system.

This connector accepts 12 Volt DC power from a

power supply or battery. The adjacent LED

glows bright green when power is properly

connected.

When this switch is on, power is supplied to all

connected modules.

Connecting the DynoWare EX+

Use the cables that came in the DynoWare

package to make the following connections:

• 9-pin shielded serial cable between the RS-232

connector of the CPU Module and a free COM

(serial communications) port on the PC. A 9pin to 25-pin adapter may be required at the

PC.

• 25-pin shielded cable from the dynamometer to

the Dynamometer Input/Output Module.

• 9-pin connector from the hand held pendant to

the Dynamometer Input/Output Module.

• 3-pin plug from the power supply to the CPU

Module with its flat side facing down.

(Refer to the picture on the next page)

Note:

The DynoWare EX+ stack must be

mounted in your shop so as to be easily

seen while making dyno runs.

Page 18

2 - 6 Master Document #982261002 - 6 Master Document #98226100

Remote Switch

Breakout Board to

DynoWare Cable

Cord from Power Supply

Primary Inductive Pickup Cable

(not shown)

Computer Serial Port Cable

Page 19

Document # 98260100 3-1

Chapter 3

Optional Accessories Installation

Several optional accessories are available for the

Dynojet Dynamometer. Call Dynojet for more

information on these optional accessories.

Optional Accessories

Driver Carriage

This fully adjustable Carriage has several

benefits. First, this option allows a dyno owner to

hook to any conventionally driven snowmobile.

The OEM suspension can be removed and the

Driver Carriage will adjust to fit the stock

mounting holes.

Second, the Driver Carriage offers advantages

when extensive product development is being

done on the dyno. Some tracks are too tight to

install the standard Dynojet Driver Set at the

factory recommended tension. In this case, using

the Dynojet Driver Carriage offers quick and

easy installation to reduce set up times.

Page 20

3-2 Document # 98260100

Contents

(A) - Driver Carriage Frame

(B) - Front Mount Assembly

(C) - Rear Mount Assembly

Driver Carriage Set up

Step 1

The pins on the Driver Carriage frame should be

retracted when you receive it. Fit the Front

Carriage Mount to the front of the frame and

release the pins.

The Front Carriage Mount should be oriented so

that it can touch the stop.

The Front Carriage Mount should not

be able to

swing out in front of the Carriage Frame!

A

BC

Front Carriage

Mount Stop

Page 21

Document # 98260100 3-3

Step 2

Mount the Rear Carriage Mount to the Carriage

Frame with the (6) 3/8” allen head bolts. The

backing plates that the bolts thread into have a

left and right side.

The holes are offset to one side, this

is the side that should be closest to

the outside on the Carriage Frame.

Backing plates

Offset holes

towards outside

Offset holes

towards outside

Note: The Rear Carriage Mount can be mounted

in two different configurations depending

on your snowmobile. See next page for

applications.

Page 22

Application #1

- Polaris

- Y amaha

- Ski Doo / Bombardier

- Arctic Cat

Rear Carriage Mount should oriented so that 4

out of the 6 holes are towards the front of the

carriage. (The triangular braces are facing

towards the Front Carriage Mount)

Application #2

- Fast M-10

- AD Boi vin

- Similar Designs to the above where additional

Front Carriage Mount clearance is needed.

Rear Carriage Mount should oriented so that 4

out of the 6 holes are towards the rear of the

carriage. (The triangular braces are facing

towards the Dynojet Driver Assembly (not

shown))

Step 3

Install the Driver Set in the Carriage Frame. The

process is the same as installing it in the sled’s

suspension rails. Refer to the video on installing

Driver Sets that was supplied with your dyno.

The spacing between the Driver Carriage rails is

8.5”, similar to setting up a Driver Set for a SkiDoo snowmobile.

3-4 Document # 98260100

Note: The spacing on the Driver Set for the

Driver Carriage stays consistent, even

when testing snowmobiles from different

manufacturers.

Page 23

Document # 98260100 3-5

Installing the Driver Carriage

Step 1

Remove the rear suspension as per manufacturers

instructions.

Step 2

Due to the varying widths of tunnels, it will be

necessary to measure the width between the

suspension mounting holes.

Step 3

Using the measurements, you must lengthen or

shorten the adjustable rods on the Driver

Carriage.

Remove the adjustable rods by loosening the set

screw and “popping” them out with a punch. Be

careful that you don’t damage the threads on

the adjustable rods!

Front Carriage

Mount

Set Screw

Page 24

3-6 Document # 98260100

Step 4

Now that you have the adjustable rods removed,

loosen the locking nuts on the rods.

Adjust the length on the rods equally on each

side (front / rear) to reflect the measurements you

took earlier.

Step 5

Reinstall the adjustable rods into the front and

rear Driver Carriage mounts and tighten the set

screw.

Rear Carriage

Mount

Page 25

Document # 98260100 3-7

Step 6

Install the front Driver Carriage mount in the two

most forward (towards engine) holes in the

tunnel.

If there is a clearance issue, you will need to

remove the idler wheels from the Front Carriage

Mount.

Remove the snap rings and remove each idler

wheel. The idler wheels will need to be “pressed”

off.

Note: On some sleds, the Front Carriage Mount

idler wheels may interfere with the

snowmobile’s drivers. You will need to

test fit the Front Carriage Mount to each

sled and check the clearances.

Remove (2)

snap rings, (1)

from each side

Snap Ring

Pliers

Page 26

3-8 Document # 98260100

Step 7

Retract the spring pins in the Driver Carriage,

and then position it in the front mount. Release

the spring pins when you have the holes lined up.

Step 8

Install the rear mount of the Driver Carriage to

the rear mounting holes on the tunnel.

Page 27

Document # 98260100 3-9

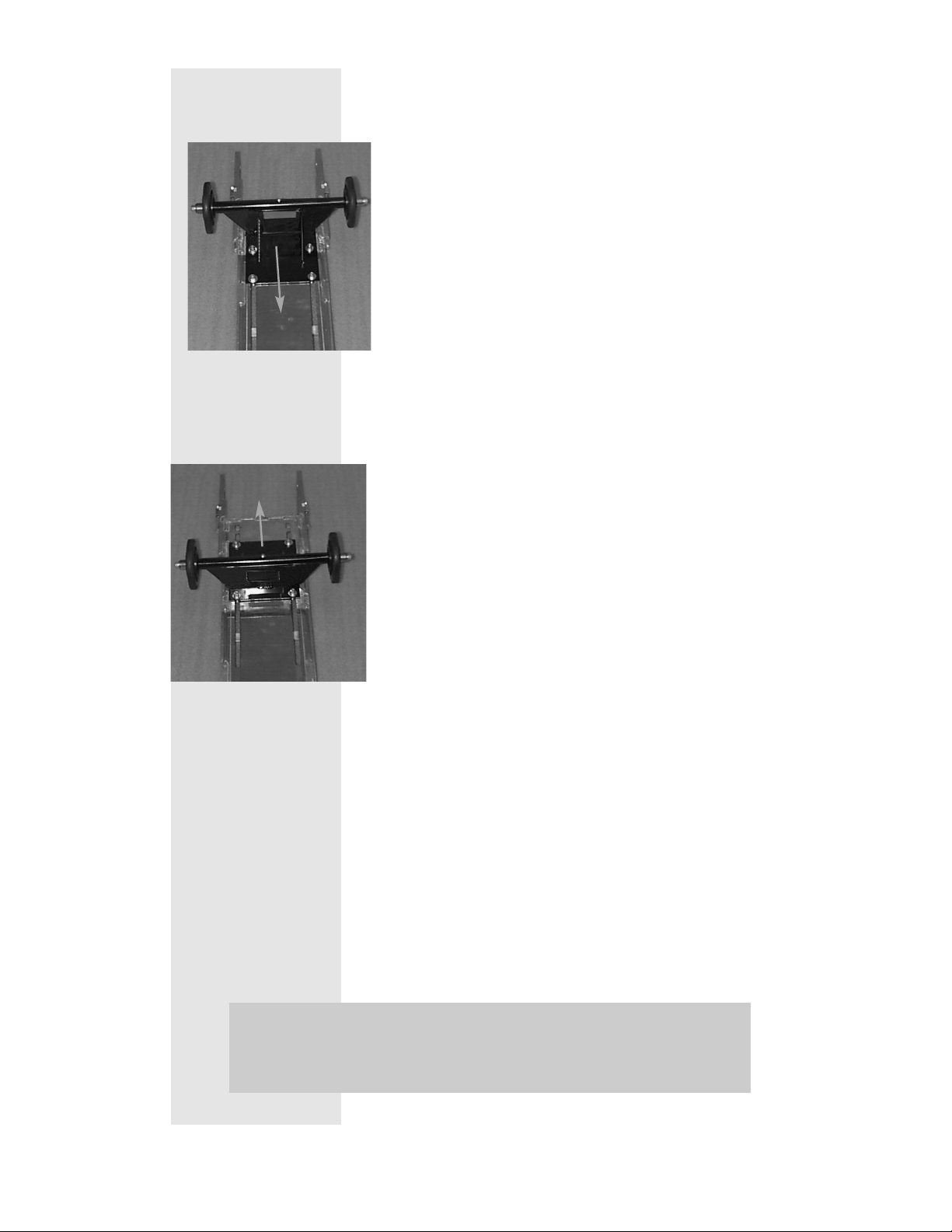

Step 9

The track should be hanging loose at this point,

you will need to pre-tension the track with the

Driver Carriage.

Loosen the bolts that hold the rear mount on the

Driver Carriage.

Loosen (6) Bolts

(3 on each side)

Page 28

3-10 Document # 98260100

Tighten the center adjuster bolt to pre-tension the

track.

Tighten the (6) bolts that hold the rear mount on

the Driver Carriage.

Step 10

The track should now be pre-tensioned, and the

Driver carriage should be secure.

Use the (2) adjuster bolts on the Driver Carriage

and tension the track to manufacturers

specifications.

Note: Do not use the center Driver Carriage

adjuster bolt to tension the track. This

is for rough adjustment purposes only !

Tighten (6) Bolts

(3 on each side)

Page 29

Document # 98260100 3-11

Step 11

Reverse the procedure to remove the Driver

Carriage, and replace the suspension per

manufacturers instructions.

Warning: The Driver Carriage is designed for

dynamometer testing. Never attempt to

ride a snowmobile with the driver

carriage installed!

Warning: Never sit on the snowmobile

when the

Driver Carriage is installed, you will

damage it!

Note:

To maintain years of trouble free service,

clean the Driver Carriage at the end of

each day. Use “anti-seize”on the

channels to ensure smooth operation.

Loading...

Loading...