Page 1

Page 2

©2010-2011 Dynojet Research, Inc. All Rights Reserved.

#

RECORD

Installation Guide For Model SD12 Scooter Dynamometers.

This manual is copyrighted by Dynojet Research, Inc., hereafter referred to as Dynojet,

and all rights are reserved. This manual is furnished under license and may only be used

or copied in accordance with the terms of such license. This manual is furnished for

informational use only, is subject to change without notice, and should not be construed

as a commitment by Dynojet. Dynojet assumes no responsibility or liability for any error

or inaccuracies that may appear in this manual. Except as permitted by such license, no

part of this manual may be reproduced, stored in a retrieval system, or transmitted, in any

form or by any means, electronic, mechanical, recording, or otherwise, without the prior

written permission of Dynojet.

The Dynojet logo is a trademark of Dynojet Research, Inc.

Any trademarks, trade names, service marks, or service names owned or registered by any

other company and used in this guide are the property of their respective companies.

Dynojet Research, Inc., 2191 Mendenhall Drive, North Las Vegas, Nevada 89081, USA.

Printed in USA.

Part Number: 98200024 Version 3 (05/2011)

Dynamometer Number: ____________________________________________________

Page 3

T

ABLE OF

C

ONTENTS

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Chapter 1 Specifications and Operating Requirements

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Conventions Used In This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Your Dyno Room . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Dynamometer Specifications and Requirements . . . . . . . . . . . . . . . . . . . .1-4

Chassis Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Compressed Air Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Computer Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Forklift Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Phone and Internet Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Tie-Down Straps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Dyno Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Chapter 2 Installation

Unpacking the Dyno . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Unpacking the Dyno . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Removing the Drum from the Crate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Installing the Front Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Routing Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Wiring the Breakout Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Installing the Ramp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Fold and Move the Dyno . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Folding the Dyno . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Moving the Dyno . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Opening the Dyno . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

Compressed Air Pump Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

Stand Alone Blowers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Model SD12 Scooter Dynamometer Installation Guide

i

Page 4

TABLE OF CONTENTS

Chapter 3 Basic Dyno Operation

Loading the Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Connecting the RPM Pickup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

RPM Pickup Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Connecting the Secondary Inductive Pickup . . . . . . . . . . . . . . . . . . . . . . .3-5

Connecting The Primary Inductive Pickup . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Pre-Run Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Before Starting the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Engine Warm Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

After Engine Warm Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Making a Test Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Adjusting the Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Adjusting the Brake Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Index-i

ii

Model SD12 Scooter Dynamometer Installation Guide

Page 5

W

ARNINGS

Disclaimers

Dynojet Research, Inc. (Dynojet) makes no representation or warranties with respect to the contents

hereof and specifically disclaims any implied warranties of merchantability for any particular purpose.

Dynojet reserves the right to revise this publication and to make changes from time to time in the

content hereof without obligation of Dynojet to notify any person of such revision or changes.

Dynojet is not responsible for false operation due to unexpected dynamometer operation such as may

be caused by static, software bugs, hardware failure, etc.

Dynojet is not responsible for damage resulting from improper installation of the dynamometer or

from improper service rendered to the dynamometer. Dynojet is not responsible for damage incurred

due to alteration of the dynamometer or components, use of unapproved parts, or abuse to the

dynamometer.

Do not connect or disconnect cables or components on the dynamometer with the power on.

Always wear protective clothing, ear protection, and eye protection (goggles, safety glasses) when

using and servicing the dynamometer.

Equipment Power Requirements

The dynamometer has specific power requirements. Connecting the dynamometer to the incorrect

voltage will void the dynamometer warranty. Installation may require a licensed electrician.

Potentially Lethal Voltages

Components attached to and within the dynamometer operate with potentially lethal voltages. To

provide the greatest assurance of safety, the AC power cord(s) must be disconnected from the power

source before servicing electrical components or wiring. Disconnect all power cords before servicing

electrical components for the greatest assurance of safety.

Model SD12 Scooter Dynamometer Installation Guide

iii

Page 6

WARN IN GS

Electrostatic Discharge Precautions

Electrostatic Discharge

Electrostatic Discharge (ESD), or static shock, can damage electronic components within the

dynamometer. The damage may occur at the time of an ESD occurrence, or the shock may degrade

the component, resulting in a premature component failure later. To avoid ESD damage, always

practice good ESD control precautions when servicing the dynamometer. Dynojet designs its

dyn amo me ter s to be v er y to ler ant of sta tic sho ck s by the users, but the electronics are vulnerable when

the electronics are exposed. ESD occurs as a result of a difference of potential between two objects

when the two objects touch. Damage occurs as a result of the energy released when the discharge

(touch) occurs. The difference of potential can accumulate by as simple an action as a user moving

across carpet or a seat. If that person’s energy is discharged directly to the electronics, the electronics

can be damaged.

Precautions

To protect against ESD damage, you must eliminate the difference of potential before the electronics

are handled. Touch the chassis of the dynamometer before touching any of the electronics. By touching

the chassis, you discharge any static shocks to the chassis instead of to the electronics.

If you are holding a circuit board or dynamometer component in your hand when you approach the

machine, touch the chassis of the dynamometer with your hand before installing the circuit board or

component.

When handing a circuit board or component to someone, touch that person with your hand first, then

hand them the component.

Always carry circuit boards in anti-static bags when the boards are exposed (removed from the

dynamometer).

Battery Fire and Explosion Hazards

There is a danger of explosion if the battery is incorrectly replaced. Replace only with the same or

equivalent type recommended by the manufacturer. Discard used batteries according to the

manufacturer’s instructions.

Automotive Batteries

In operation, batteries generate and release flammable hydrogen gas. They must always be assumed

to contain this gas which, if ignited by burning cigarette, naked flame or spark, may cause battery

explosion with dispersion of casing fragments and corrosive liquid electrolyte. Carefully follow

manufacturer's instructions for installation and service. Keep away all sources of gas ignition and do

not allow metallic articles to simultaneously contact the negative and positive terminals of a battery.

Do not allow the positive and negative terminals to short-circuit. The dynamometer chassis is tied to

the negative side of the battery. Do not short between the positive battery terminal or the starter

connections to the chassis. In addition, make sure metal tools such as screw drivers, wrenches, and

torque wrenches do not come in contact with the negative and positive terminals of the battery. Short

circuiting the terminals of the battery can cause burn injuries, damage to the dynamometer, or trigger

explosions.

Charging

Batteries being charged will generate and release flammable hydrogen gas. Charging space should be

ventilated. Keep battery vent caps in position. Prohibit smoking and avoid creation of flames and sparks

nearby.

Wear protective clothing, eye and face protection, when charging or handling batteries.

iv

Model SD12 Scooter Dynamometer Installation Guide

Page 7

WAR NIN GS

Other Potential Hazards

The AC power outlet shall be installed near the equipment and it shall be easily accessible to allow for

disconnect before service.

The dynamometer should be located in a well ventilated area. There is a carbon monoxide hazard with

all internal combustion engines. Engine exhaust contains poisonous carbon monoxide gas. Breathing

it could cause death.

Any dyno room design must incorporate sufficient exhaust extraction.

Always wear proper ear and eye protection when operating the dynamometer.

Never operate the dynamometer with the covers removed.

Never stand behind the dynamometer when in operation.

Never operate the dynamometer when there is excessive vibration or noise. Resolve these problems

before proceeding.

Never fuel the vehicle on the dynamometer unless appropriate safety measures are taken.

Verify brake operation before beginning any dynamometer testing.

Verify the vehicle is properly secured to the dynamometer.

Never operate the blowers without the guards installed.

Exercise care with any dynamometer testing; portions of the dynamometer and vehicle may become

hot.

As with any equipment using electricity and having moving parts, there are potential hazards. To use

this dynamometer safely, the operator should become familiar with the instructions for operation of

the dynamometer and always exercise care when using it.

Do not repair or replace any part of the dynamometer or attempt any servicing unless specifically

recommended in published user-repair instructions that you understand and have the skills to carry

out.

Vers ion 3 Model SD12 Scooter Dynamometer Installation Guide

v

Page 8

Page 9

C HAPTER

S

PECIFICATIONS AND

Thank you for purchasing Dynojet’s Model SD12 Scooter Dynamometer. Dynojet’s

software and dynamometers will give you the power to get the maximum

performance out of vehicles you evaluate. Whether you are new to the benefits of a

chassis dynamometer or an experienced performance leader, the repeatability and

diagnostic tools of WinPEP 7 software and a Dynojet dynamometer will give you the

professional results you are looking for.

This document provides instructions for installing the scooter dynamometer (dyno).

This document will walk you through operating requirements, installation,

accessories, and basic dyno operation. To ensure safety and accuracy in the

procedures, perform the procedures as they are described.

Document Part Number: 98200024

O

PERATING

R

EQUIREMENTS

1

Versio n 3

Last Updated: 05-24-2011

This chapter is divided into the following categories:

•Introduction, page 1-2

• Dynamometer Specifications and Requirements, page 1-4

• Dyno Electronics, page 1-7

Model SD12 Scooter Dynamometer Installation Guide

1-1

Page 10

CHAPTER 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

#

RECORD

Introduction

INTRODUCTION

Before installing your dyno, please take a moment to read this guide for installation

instructions, dyno features, and other important information.

This guide is designed to be a reference tool in your everyday work and includes the

following chapters and information:

SPECIFICATIONS AND OPERATING REQUIREMENTS

This chapter describes the requirements and specifications for the dyno.

INSTALLATION

This chapter describes the procedures for installing the dyno.

BASIC DYNO OPERATION

This chapter describes basic dyno operating procedures.

CONVENTIONS USED IN THIS MANUAL

The conventions used in this manual are designed to protect both the user and the

equipment.

example of convention description

The Caution icon indicates a potential hazard to the

dynamometer equipment. Follow all procedures

exactly as they are described and use care when

performing all procedures.

The Warning icon indicates potential harm to the

person performing a procedure and/or the

dynamometer equipment.

The Record # icon reminds you to record your

dynamometer and/or eddy current brake (retarder)

number on the inside cover of this manual.

Bold Highlights items you can select on in the software

interface, including buttons and menus.

The arrow indicates a menu choice. For example,

“select File

then select the Open choice on the File menu.”

Open” means “select the File menu,

TECHNICAL SUPPORT

For assistance, please contact Dynojet Technical Support at 1-800-992-3525, or write

to Dynojet at 2191 Mendenhall Drive, North Las Vegas, NV 89081.

Visit us on the World Wide Web at www.dynojet.com and www.winpep.com where

Dynojet provides state of the art technical support, on-line shopping, 3D

visualizations, and press releases about our latest product lines.

1-2

Model SD12 Scooter Dynamometer Installation Guide

Page 11

YOUR DYNO ROOM

This section is not meant to imply that a dyno room is essential to repeatable results

on a Dynojet dynamometer. However, a dyno room with an engine cooling intake fan,

exhaust extraction, and noise reduction capabilities can add a new dimension to your

shop.

A proper dyno room design will help to ensure repeatable, accurate runs. A good

dyno room should do the following:

• minimize noise

• provide a controlled environment for testing

• provide a view window (safety glass) for customers

• be designed with safety in mind

Intake Air Fan—After building your dyno room, you will need to supply an intake air

fan. The intake air fan supplies air to cool the bike’s engine while supplying fresh

oxygen for you and your bike to breathe. It is a common misconception that you

cannot tune a bike without a large fan simulating exact road conditions; however, a

good cooling fan is the only requirement for consistent diagnostics and tuning. The

installed fan should be 5200 CFM.

SPECIFICATIONS AND OPERATING REQUIREMENTS

Introduction

Equalizer Box—If the air flow rate coming into the dyno room is greater than the air

flow rate leaving the dyno room, the room will become pressurized. A pressurized

dyno room will make measured power misleading. To compensate, you need an

equalizer box. The equalizer box is a baffled (to reduce noise) vent to the outside of

your dyno room. The size of the equalizer box is dependent on the size of your dyno

room and the size of your fans.

Exhaust Extraction—An exhaust fan is needed to remove exhaust gasses, especially

carbon monoxide, from the dyno room. Carbon monoxide is potentially lethal to

people if not removed from the room and will affect engine power when mixed with

fresh air. Plans for exhaust extraction (P/N 73429201) are available from Dynojet.

Engine exhaust contains poisonous carbon monoxide gas. Breathing it could

cause death. Operate machine in well ventilated area.

Fire Suppression—Always have adequate fire suppression or fire extinguishers in

your dyno room.

Industrial Noise Control, Inc.—Industrial Noise Control, Inc. offers a zinc-coated

steel room custom built to your specifications. This room meets all dyno room

requirements. The dyno room must be clean and dry with a comfortable room air

temperature above 32 degrees Fahrenheit (0 degrees Celsius), and have some system

of exhaust extraction. For more information on a dyno room, refer to your

Pre-Installation Guide For Model 200i, 250i, 200iP, and 250iP Motorcycle

Dynamometers (P/N 98129103).

Vers ion 3 Model SD12 Scooter Dynamometer Installation Guide

1-3

Page 12

CHAPTER 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dynamometer Specifications and Requirements

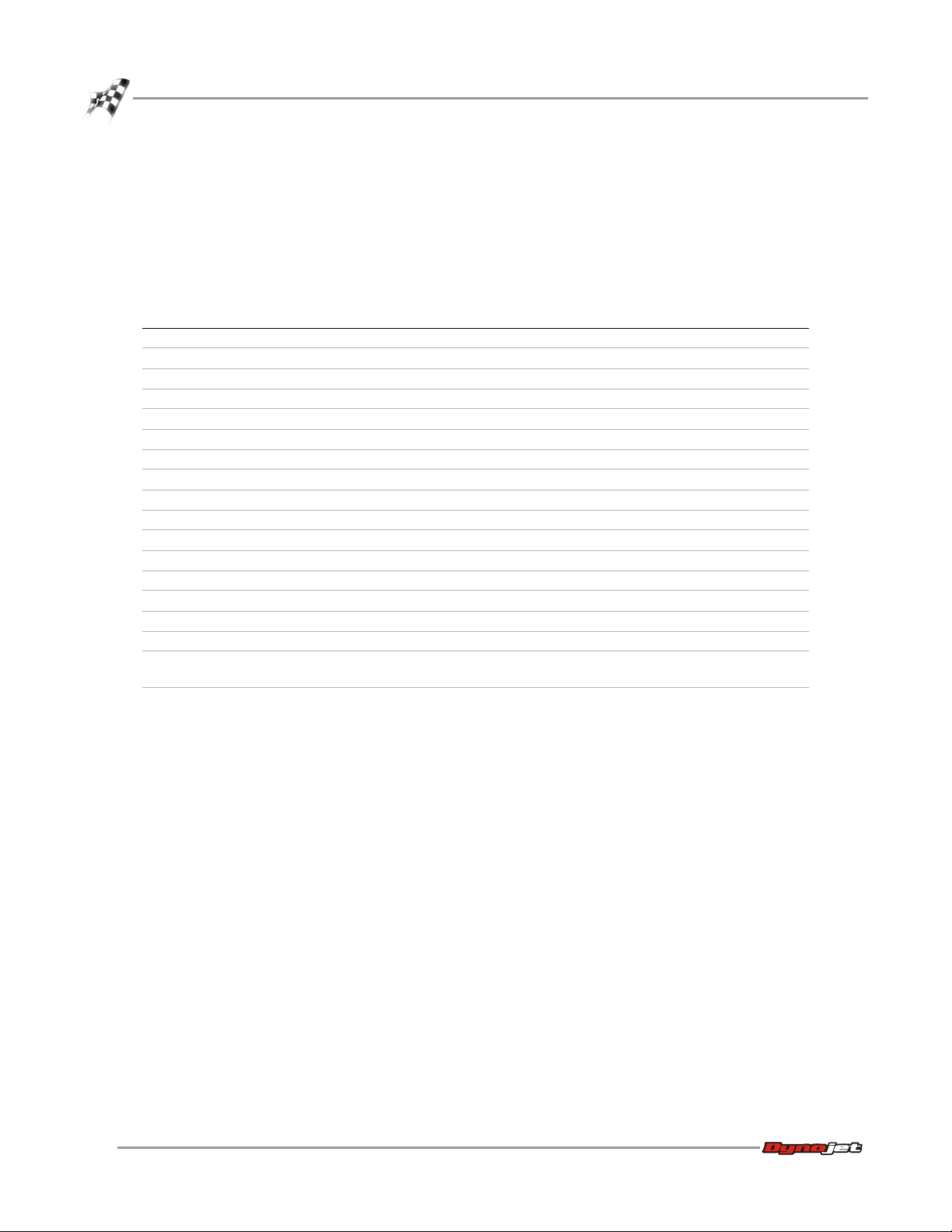

DYNAMOMETER SPECIFICATIONS AND REQUIREMENTS

The following specifications and requirements will help you set up your dyno area

and verify you have the requirements to operate your dyno safely.

CHASSIS SPECIFICATIONS

description specifications

Length

dyno 218.70 cm (86.10 in.)

with ramp 335.92 cm (131.25 in.)

Height

to top of dyno 31.00 cm (12.21 in.)

to top of wheel clamp 61.10 cm (24.05 in.)

Width

of dyno 48.21 cm (18.98 in.)

of dyno with tie-downs 86.36 cm (34.00 in.)

Weight

dyno/crated dyno 272 kg (600 pounds)

Drum

diameter 30.50 cm (12.00 in.)

width 35.56 cm (14.00 in.)

Frame structural steel

Maximum Speed 175 KPH (109 MPH)

Maximum Scooter Length (front of front

wheel to center of rear wheel)

Remote Switches remote software control

188.27 cm (74.125 in.)

1-4

Model SD12 Scooter Dynamometer Installation Guide

Page 13

SPECIFICATIONS AND OPERATING REQUIREMENTS

SD001

335.92 cm

(131.25 in)

48.21 cm

(18.98 in)

61.10 cm

(24.05 in)

31.00 cm

(12.21 in)

86.36 cm

(34.00 in)

218.70 cm

(86.10 in)

SD002

Drum Module

Wheel Clamp

Stand Alone

Blowers Option

(not shown)

Air Pump Option

(not shown)

Front Support

Folding Ramp

Tie-Down

Brake Release

Dynamometer Specifications and Requirements

Figure 1-1: Model SD12 Dyno Dimensions

Figure 1-2: Model SD12 Dyno

Vers ion 3 Model SD12 Scooter Dynamometer Installation Guide

1-5

Page 14

CHAPTER 1

Dynamometer Specifications and Requirements

COMPRESSED AIR REQUIREMENTS

The following requirements are needed for optional compressed air pump assembly:

• Clean and dry air, 100 psi or greater, 5 CFM or better flow

• Fittings to hook your air system to a 3/8-inch inside diameter hose (if no air brake is

present)

• optional air regulator

COMPUTER SPECIFICATIONS

You will need to provide a computer system to run the WinPEP software. WinPEP 7

includes complete documentation in online Help. From the WinPEP 7 menu bar,

choose Help

name and password). Refer to the section on Computer Specifications in the WinPEP

documentation, P/N 98118103, for the specific computer system requirements.

WinPEP 7 Help or visit www.winpep.com (accessible with a valid user

ENVIRONMENTAL REQUIREMENTS

description specifications

Te mp e r at u r e

operating min./max 10°C/50°C (50°F/122°F)

storage min./max 0°C/60°C (32°F/140°F)

Humidity 0 to 95% non condensing

FORKLIFT REQUIREMENTS

You will need to provide equipment capable of lifting a minimum of 454 kg.

(1000 lb.) to lift and move the crated dyno.

You will need to provide a 5/8-inch x 3-foot steel bar to lift the drum off the crate.

PHONE AND INTERNET ACCESS

Dynojet recommends you have a phone close to the dyno to call for assistance in an

emergency. You may also wish to contact Dynojet to troubleshoot your dyno.

Internet access on your computer is desirable for contacting Dynojet and

downloading new information and updates.

TIE-DOWN STRAPS

Dynojet recommends using motorcycle tie-down straps for securing the bike on the

dyno. You will need to provide the tie-down straps.

1-6

Model SD12 Scooter Dynamometer Installation Guide

Page 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DYNO ELECTRONICS

9-pin RS-232 socket

CPU module

atmospheric

sensing module

RPM module

input/output module

9-pin hand

held pendant

3-pin power plug

system expansion

connector

RPM inductive

pickup socket

25-pin socket

power

The standard dyno electronics package is comprised of four interconnected modules:

Atmospheric Sensing Module, RPM Module, Dynamometer Input/Output Module, and

the CPU Module. For more information refer to your WinPEP 7 User Guide

(P/N 98118103).

SPECIFICATIONS AND OPERATING REQUIREMENTS

Dyno Electronics

Figure 1-3: The Dyno Electronics

Vers ion 3 Model SD12 Scooter Dynamometer Installation Guide

1-7

Page 16

Page 17

C HAPTER

2

I

NSTALLATION

This chapter will walk you through unpacking and installing the dynamometer. To

ensure safety and accuracy in the procedures, perform the procedures as they are

described.

This chapter is divided into the following categories:

• Unpacking the Dyno, page 2-2

•Installation, page 2-4

• Fold and Move the Dyno, page 2-10

• Accessories, page 2-13

Model SD12 Scooter Dynamometer Installation Guide

2-1

Page 18

CHAPTER 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

#

RECORD

Unpacking the Dyno

UNPACKING THE DYNO

When you receive your dyno, examine the exterior of the shipping container for any

visible damage. If damage is detected at this stage, contact the shipper or Dynojet

before proceeding with unpacking.

Use the following steps to unload your dyno. You will need to provide equipment

capable of lifting a minimum of 454 kg (1000 pounds) to move the crated dyno into

position in your dyno room. Refer to “Dynamometer Specifications and

Requirements” on page 1-4 for more information.

The following directions describe how to unpack, and install your dyno. Follow the

directions in the order that they are presented.

UNPACKING THE DYNO

1 Move the crated dyno to a clear area near your dyno room.

2 Using a pry bar, or a large flat screwdriver, and a hammer, carefully remove the

top and sides of the crate.

Note: At this point, you will want to inspect the exterior of the dyno for any

indications of damage. Report any damage immediately.

part description part description

Be sure you record the dynamometer number on the inside cover of this

manual.

3 Remove the hardware boxes from the crate.

4 Verify the contents of the hardware boxes and set aside.

drum wheel clamp

P/N 71300003

front support dyno electronics

P/N 76199001

ramp inductive secondary

pickup

P/N DE100-109S

2-2

Model SD12 Scooter Dynamometer Installation Guide

Page 19

INSTALLATION

#

RECORD

SD018

steel bar

shaft hole

Unpacking the Dyno

part description part description

axle shaft (2)

P/N 22100011

inductive primary pickup

clip

P/N DE100-110L

retaining ring, 1/2" (4)

P/N 32800000

screw, 1/4-20 x 5/8”, panhead, torx (2)

P/N 36561045

REMOVING THE DRUM FROM THE CRATE

You will need to provide a 5/8-inch x 3-foot steel bar to lift the drum off the crate and

into position in your dyno room. Lifting the drum will require two people.

Be sure you record the dynamometer number on the inside cover of this

manual.

1 Remove the lag bolts and washers securing the drum to the crate base using a

9/16-inch socket, open or box end wrench.

2 Insert the 5/8-inch x 3-foot steel bar into the shaft hole.

3 Using two people, carefully lift the drum off the crate and move into position in

your dyno room.

cable tie, 4” (2)

P/N 197104130

Figure 2-1: Insert the Steel Bar and Lift the Drum off the Crate

Vers ion 3 Model SD12 Scooter Dynamometer Installation Guide

2-3

Page 20

CHAPTER 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SD003

drum

front support

Installation

INSTALLATION

Use the following steps to install the scooter dyno.

You will need the following parts:

•Drum

•Front Support

•Ramp

• 197104130 Cable Tie, 4" (2)

• 22100011 Axle Shaft (2)

• 32800000 Retaining Ring, 1/2" (4)

• 36561045 Screw, 1/4-20 x 5/8", Pan-head, Torx (2)

• 71300003 Wheel Clamp

INSTALLING THE FRONT SUPPORT

1 Place the front support on the drum.

Figure 2-2: Place Front Support on the Drum

2-4

Model SD12 Scooter Dynamometer Installation Guide

Page 21

INSTALLATION

SD004

axle shaft

axle shaft

retaining ring

SD007

wheel clamp

spring

plunger

Installation

2 Install the front support axle shaft.

3 Secure the shaft in place using two retaining rings.

Figure 2-3: Install the Axle Shaft and Retaining Rings

4 Slide the wheel clamp onto the front support.

5 Lift the spring plunger to slide the wheel clamp to a different position. Release

the spring plunger to lock the wheel clamp in the new position.

Note: The wheel clamp may already be installed.

Figure 2-4: Install the Wheel Clamp

Vers ion 3 Model SD12 Scooter Dynamometer Installation Guide

2-5

Page 22

CHAPTER 2

SD023

control lever

control cable

control lever

bracket

cable ties

Installation

6 Route the control cable, lever, and control lever bracket from the drum along the

inside of the front support.

Note: The control cable is coiled up and secured to the drum.

7 Secure the control lever bracket to the inside of the front support using two

1/4-20 x 5/8-inch pan-head torx screws.

8 Secure the control cable to the inside of the front support using two cable ties.

Figure 2-5: Install the Control Lever Bracket and Cable

2-6

Model SD12 Scooter Dynamometer Installation Guide

Page 23

ROUTING CABLES

SD032

breakout board

pickup card cable

pickup card

25-pin computer

cable

1 Route the pickup card cable to the Breakout board.

Note: The pickup card is already installed and is located on the drum.

2 Route the 25-pin RS232 computer cable from the Breakout board to the dyno

electronics CPU Module.

3 Route the 9-pin cable from the RS232 port on the dyno electronics to your

computer.

For more information on wiring the Breakout board, refer to “Wiring the

Breakout Board” on page 2-8. For more information on connecting cables to the

dyno electronics, refer to “Dyno Electronics” on page 1-7.

INSTALLATION

Installation

Figure 2-6: Routing Cables

Vers ion 3 Model SD12 Scooter Dynamometer Installation Guide

2-7

Page 24

CHAPTER 2

25-pin computer cable

pickup card

J1J2

digital brake

Installation

WIRING THE BREAKOUT BOARD

1 Attach the pickup card cable to the Breakout board. The pickup card cable has

four wires which connect to the wiring block labeled DRUM 1.

• Red wire connects to R1 • Black wire connects to B1

• White wire connects to W1 • Ground (shield) wire connects to S1

2 Attach the 25-pin RS232 computer cable to the Breakout board.

3 Verify jumpers J1 and J2 are set for the digital brake as shown in Figure 2-7.

2-8

Model SD12 Scooter Dynamometer Installation Guide

Figure 2-7: Wire the Breakout Board

Page 25

INSTALLING THE RAMP

SD008

retaining ring

axle shaft

ramp

axle shaft

1 Place the ramp on the drum.

2 Install the ramp axle shaft.

3 Secure the shaft in place using two retaining rings.

INSTALLATION

Installation

Figure 2-8: Install the Ramp

Vers ion 3 Model SD12 Scooter Dynamometer Installation Guide

2-9

Page 26

CHAPTER 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SD021

slide wheel clamp to

lock ramp in place

slide wheel

clamp forward

lock front support

in place

raise ramp

Fold and Move the Dyno

FOLD AND MOVE THE DYNO

Use the following instructions to fold and move the scooter dyno.

FOLDING THE DYNO

1 Lift the front support up until it clicks and locks into place.

2 Lift the spring plunger and slide the wheel clamp forward on the front support.

Release the spring plunger to lock the wheel clamp in position.

3 Raise the ramp until it comes in contact with the front support.

4 Lift the spring plunger and slide the wheel clamp until it locks the ramp in place.

Release the spring plunger.

2-10

Model SD12 Scooter Dynamometer Installation Guide

Figure 2-9: Folding the Dyno

Page 27

MOVING THE DYNO

SD020

front support

leg brace

front support

leg brace

1 With the scooter dyno in the folded position, grab the front support leg brace.

2 Tilt the dyno towards you.

3 Roll the dyno to the desired position.

INSTALLATION

Fold and Move the Dyno

Figure 2-10: Moving the Dyno

Vers ion 3 Model SD12 Scooter Dynamometer Installation Guide

2-11

Page 28

CHAPTER 2

SD022

slide wheel

clamp forward

control lever

lower ramp

Fold and Move the Dyno

OPENING THE DYNO

1 Lift the spring plunger and slide the wheel clamp forward. Release the spring

plunger to lock the wheel clamp in position.

2 Lower the ramp to the floor.

3 Squeeze the control lever to release the front support.

4 Lower the front support to the floor.

Figure 2-11: Opening the Dyno

2-12

Model SD12 Scooter Dynamometer Installation Guide

Page 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ACCESSORIES

This section describes the various optional accessories that are available for the

scooter dyno to meet your individual needs. For more information about these

accessories, please contact Dynojet’s Product Specialists at 1-800-992-3525 for pricing

and availability. Complete installation instruction manuals may also be found by

browsing the Manuals folder on your WinPEP installation CD.

COMPRESSED AIR PUMP ASSEMBLY

INSTALLATION

Accessories

Refer to the Compressed Air Air Fuel Ratio Module Installation and User Guide

(P/N 98200006) for proper operating and maintenance procedures. Refer to the Flow

Meter User Guide (P/N 98129104) to test your air pump for accuracy. Failure to follow

proper procedures may result in inaccurate data or damage to the equipment. These

manuals can be found on your WinPEP CD or at www.dynojet.com.

The sensor and the copper sample tube are hot. Before touching the sensor or

the sample tube, make sure it has cooled.

Leaded racing fuels and two-stroke applications will contaminate the sensor

and dramatically shorten its service life.

The sensor is not covered by a warranty. Be sure to read and understand the

Compressed Air Air Fuel Ratio Module Installation and User manual.

Before turning the pump on, verify there is no water in the hose.

Warm up the vehicle before placing the copper sample tube in the exhaust to

avoid drawing excess water through the pump assembly.

Keep the air pump assembly upright. Tipping the pump assembly may result in

damage to the sensor.

Leaks in the system will result in erroneous readings. Verify there are no cracks

or holes in the hose. Verify the sensor is seated properly in the sensor block.

To ensure accurate readings, pump maintenance should be performed every

six months, or sooner, depending on usage. Refer to the Compressed Air Air

Fuel Ratio Module Installation and User Guide for more information.

STAND ALONE BLOWERS

Refer to the High Pressure Blower Installation Guide (P/N 98220105) for proper

installation and operating procedures. These manuals can be found on your WinPEP

CD or at www.dynojet.com.

Vers ion 3 Model SD12 Scooter Dynamometer Installation Guide

2-13

Page 30

Page 31

B

ASIC

D

YNO

C HAPTER

O

PERATION

3

This chapter includes instructions for basic dyno operation. For more detailed

instructions, refer to the WinPEP 7 User Guide. This manual can be found on your

WinPEP CD or at www.dynojet.com.

This chapter is divided into the following categories:

•Loading the Vehicle, page 3-2

• Connecting the RPM Pickup, page 3-4

•Pre-Run Inspection, page 3-7

• Making a Test Run, page 3-9

• Preventative Maintenance, page 3-10

Model SD12 Scooter Dynamometer Installation Guide

3-1

Page 32

CHAPTER 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

slide the

wheel clamp

center drive axle

on dyno drum

wheel clamp

handle

Loading the Vehicle

LOADING THE VEHICLE

Use the following steps to load a vehicle on the dyno.

Risk of injury. Always wear proper eye and ear protection when operating the

dyno.

1 Verify your computer is running.

2 Verify the wheel clamp is at the front of the front support.

Lift the spring plunger to slide the wheel clamp to a different position. Release

the spring plunger to lock the wheel clamp in the new position.

3 Drive the vehicle onto the dyno and align the vehicle straight with the dyno.

4 Stop the vehicle when the drive axle is centered on the drum.

5 When the vehicle is positioned properly on the dyno, shut the engine off.

• If the vehicle has an automatic transmission, apply the parking brake.

• If the vehicle has a manual transmission, place it in gear.

6 Slide the wheel clamp up to the front tire of the vehicle.

Lift the spring plunger to slide the wheel clamp to a different position. Release

the spring plunger to lock the wheel clamp in the new position.

7 Turn the wheel clamp handle until the front tire is held securely in the wheel

clamp.

Figure 3-1: Load the Vehicle

3-2

Model SD12 Scooter Dynamometer Installation Guide

Page 33

8 Extend the tie-down outriggers.

SD002

tie-down

outrigger

spring pin

8a Remove the spring pins.

8b Slide out the tie-down outriggers.

8c Replace the spring pins.

BASIC DYNO OPERATION

Loading the Vehicle

Figure 3-2: Extend the Tie-Down Outriggers

9 Attach two tie-down straps from the tie-downs on the dyno to the frame or

luggage rack of the vehicle.

10 Tighten the tie-down straps evenly making sure the drive wheel remains centered

on the drum.

Never perform a dyno run if the tie-down straps are not in place or they are

damaged.

Figure 3-3: Attach the Tie-Downs

Vers ion 3 Model SD12 Scooter Dynamometer Installation Guide

3-3

Page 34

CHAPTER 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the RPM Pickup

CONNECTING THE RPM PICKUP

Your Dynojet dynamometer includes a primary wire inductive pickup and two

secondary wire inductive pickups. These small “clothespin like” inductive pickups are

used to sense RPM. An RPM pickup is required if you want to view torque graphs.

Generally you will use one secondary wire inductive pickup on a spark plug wire.

Vehicles with wasted spark ignition systems may require two secondary inductive

pickups. On a wasted spark ignition, typically one coil will be connected to two spark

plug wires. Attach one secondary pickup to each of these wires. If the pickups are

connected to two plug wires that do not fire at the same time, an erratic RPM readout

may occur. The primary wire inductive pickup senses RPM pulses from the coil.

Although this pickup location generally works better, it is harder to find the correct

location to connect the RPM pickup.

Note: If a pickup is not being used, disconnect it from the dyno electronics to

prevent any stray pick up of signals.

Inductive pickups are very fragile. The ferrite core can easily be damaged and

is not covered under warranty. Dropping, snapping, vibration, and heat can all

damage the ferrite core.

RPM pickup description

Secondaries (Non- wasted spark system) Use one secondary pickup. Unplug the other pickup from the RPM

Secondaries (Wasted spark ignition

system)

Primary pickup Attach the primary wire pickup to the primary side of the coil. Set

The dyno electronics RPM module contains the electronics that sense the RPM pulses.

An auto-gain circuit looks at only the peak voltage of the vehicle’s spark, ignoring the

lower voltages to help reduce electronic noise problems. Wasted spark ignition

systems will produce a lower voltage level on the exhaust stroke than the

compression stroke. By definition of the auto-gain circuit, lower voltage spark levels

will be ignored, missing every other spark the vehicle would produce.

RPM PICKUP DESCRIPTIONS

module and set the degrees between plug fires to 720° in WinPEP 7.

Use two secondary pickups. Attach one pickup on each spark plug

wire on the same coil and set the degrees between plug fires to 360°

in WinPEP 7.

the degrees between plug fires by taking 720 (four cycle engines) or

360 (two cycle engines) divided by the number of coils. For

example, the number of degrees between plug fires on a four

cylinder four cycle engine with dual coils (where each coil fires two

cylinders) is 720/4 x 2 = 360°.

3-4

Model SD12 Scooter Dynamometer Installation Guide

Page 35

CONNECTING THE SECONDARY INDUCTIVE PICKUP

connect secondary

inductive pickup on

the coil wire

coil

connect secondary inductive

pickup on the coil wires

coil

The secondary inductive pickup cannot be in contact with, or it’s connecting wire be

crossing, other engine electrical wires or stray RF interference may result.

The inductive pickups contain a fragile Ferrite Core that is sensitive to engine

heat and vibration. Do not drop the inductive pickup or snap the pickup

closed. Use extreme care in handling and placement of the pickups.

BASIC DYNO OPERATION

Connecting the RPM Pickup

1 Clip the secondary inductive pickup around one spark plug wire.

Note: On a wasted spark ignition system, two secondary inductive pickup wires

may be needed.

2 Route the inductive pickup cable clear of devices that produce electronic noise

(spark plug wires, coil wire, coil etc.) to the dyno electronics RPM module.

Note: Inductive pickup placement is important. Position the inductive pickup so

that it is not making contact with any other spark plug wires. Separate the spark

plug wire from the spark plug wire bundle for proper operation.

Note: You must ground the vehicle to the dyno for the electronics to function

properly.

Figure 3-4: Connect the Secondary Inductive Pickup

Vers ion 3 Model SD12 Scooter Dynamometer Installation Guide

3-5

Page 36

CHAPTER 3

connect primary

inductive pickup on

the negative side of

the coil

coil

Connecting the RPM Pickup

CONNECTING THE PRIMARY INDUCTIVE PICKUP

The primary inductive pickup cannot be in contact with, or it’s connecting wire be

crossing, other engine electrical wires or stray RF interference may result.

The inductive pickups contain a fragile Ferrite Core that is sensitive to engine

heat and vibration. Do not drop the inductive pickup or snap the pickup

closed. Use extreme care in handling and placement of the pickups.

1 Clip the primary inductive pickup around the wire to the primary side of the coil.

2 Route the primary wire cable clear of devices that produce electronic noise to the

dyno electronics RPM module.

Note: You must ground the vehicle to the dyno for the electronics to function

properly.

3-6

Model SD12 Scooter Dynamometer Installation Guide

Figure 3-5: Connect the Primary Inductive Pickup

Page 37

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRE-RUN INSPECTION

Perform a vehicle inspection before making a run. Check the following:

• Check the radiator coolant (if applicable) and oil levels.

•Check the fuel source.

• Rotate the drum and check for rocks caught in the tire tread that could fly out.

• For scooters equipped with a drive chain, check the chain and the chain master

link. Make sure it is lubricated and adjusted to the proper tension.

• Check the tire pressure and tire speed rating. Improperly inflated tires or

exceeding the maximum speed rating can result in premature wear or severe tire

damage. Make sure the tire has no major deficiencies (cracks in sidewalls, tread life,

etc.).

• Visually inspect the vehicle. Make sure it is in safe running order.

• Make sure ear protection and safety glasses are used when the dyno is being

operated.

• Check the tie-down straps to make sure that they are tight and secured.

BASIC DYNO OPERATION

Pre-Run Inspection

• Check the drive tires to be sure that they are aligned correctly on the

dynamometer’s drums.

• Keep all rotating components clear at all times.

• Only the operator should be near the dyno or the vehicle during the test.

• Never allow any person(s) to stand behind the dyno or vehicle when it is being

operated.

• Perform any other safety inspections appropriate to running your vehicle on the

dyno.

Never allow any person(s) to stand behind the dyno or vehicle when it is being

operated. Only the operator should be near the dyno or the vehicle during the

test.

Vers ion 3 Model SD12 Scooter Dynamometer Installation Guide

3-7

Page 38

CHAPTER 3

Pre-Run Inspection

BEFORE STARTING THE ENGINE

Connect an exhaust hose or hoses (if dual exhaust) on the vehicle, make sure the

hose fits over the tail pipe, is not plugged or kinked and the hose is vented correctly

out of the dyno room.

Engine exhaust contains poisonous carbon monoxide gas. Breathing it could

cause death. Operate machine in well ventilated area.

ENGINE WARM UP

Warm the vehicle’s engine and drivetrain before beginning testing. Consistent engine

temperatures will assure your runs are repeatable.

AFTER ENGINE WARM UP

Always leave the vehicle in neutral (automatic transmission) or in first gear (manual

transmission), with the engine off, and make sure the park brake and the dyno brake

are on when you get off the vehicle on the dyno.

• Fix any fuel, oil, or coolant leaks that may have shown up after engine warm up and

check the carburetor for leaks.

• Any loud or unusual engine noises or excessive exhaust smoke should be resolved

before continuing.

3-8

Model SD12 Scooter Dynamometer Installation Guide

Page 39

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAKING A TEST RUN

Dyno runs provide safe, reliable road testing right in the shop. The dyno allows you to

measure, record, and diagnose performance problems quickly. The dyno combined

with WinPEP 7 produces consistent, easily interpretable power graphs. Use the

following instructions to ensure repeatable and accurate measurements.

1 Verify the vehicle is secured properly.

2 Release the dyno brake by pressing the brake pedal.

3 Slowly accelerate the vehicle to 20 m.p.h.

4 Test the tachometer operation.

4a Rev the engine. The gauges on the computer screen should be moving. If

the tachometer is moving but not registering the correct RPM values, the

number of degrees of revolution of the crank shaft (the plug fires number) is

incorrect.

4b Stop the vehicle, return to the MakeRun Configuration dialog box, and enter

the correct value for the plug firing order.

5 Step off the brake pedal to apply 100% braking and slow down the vehicle.

BASIC DYNO OPERATION

Making a Test Run

Using the vehicle’s own brakes to slow or stop the drum at speeds over 30

m.p.h. can severely over heat the brake parts. The vehicle’s brakes should be

used in an emergency stop situation only.

6 Shut the engine off and put the vehicle in gear (manual transmission) or apply the

parking brake (automatic transmission).

7 Set the vehicle’s parking brake and leave the dyno brake on.

8 Perform a final inspection.

• Verify the drive tire’s alignment on the dyno drums.

• Make any adjustments to the tie-down straps as needed.

• Perform any other safety checks that you deem appropriate to your particular

situation.

You are now ready to make a high speed run on the dyno. Refer to your WinPep 7

User Guide for more detailed instructions.

Vers ion 3 Model SD12 Scooter Dynamometer Installation Guide

3-9

Page 40

CHAPTER 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SD024

brake stop bolt

Preventative Maintenance

PREVENTATIVE MAINTENANCE

This section contains basic preventative maintenance and troubleshooting

information.

To maintain proper dynamometer operation, Dynojet recommends you make routine

checks of the dyno.

• Drum—keep the drum clean and keep all objects clear of the drum.

• Carriage Slide—keep the carriage slide clean and lightly lubricated.

ADJUSTING THE BRAKE

Use the following instructions to prevent the brake from dragging.

1 Remove any vehicles from the dyno.

2 Push the brake pedal until it stops.

3 Using your hand, turn the drum.

4 Verify the brake is not dragging.

5 If the brake is dragging, adjust the brake.

Using a 7/16 open end wrench, adjust the brake stop bolt until there is no brake

drag.

Note: Adjusting the bolt too loose or too tight can cause brake drag.

Figure 3-6: Adjust the Brake

3-10

Model SD12 Scooter Dynamometer Installation Guide

Page 41

ADJUSTING THE BRAKE TENSION

eyebolt

adjust brake tension here

brake release pedal

Use the following instructions to adjust the brake tension.

1 Locate the eyebolt brake tension adjuster.

2 With the brake release pedal in the up position, turn the 1/4-20 nut on the eyebolt

clockwise to increase the spring tension until the drum can no longer be turned

by hand.

3 Verify the brake releases when the pedal is fully depressed.

Note: The eyebolt can be adjusted until it touches the lever on the release shaft

mechanism. If the eyebolt makes contact when the brake release pedal is fully

depressed, then the eyebolt has been adjusted too far. Back off the eyebolt nut

until it no longer contacts the lever.

BASIC DYNO OPERATION

Preventative Maintenance

Figure 3-7: Adjust the Brake Tension

Vers ion 3 Model SD12 Scooter Dynamometer Installation Guide

3-11

Page 42

Page 43

I

NDEX

A

accessories 1-5

compressed air pump 2-13

stand alone blowers 2-13

air pump assembly 2-13

axle shaft 2-5

B

battery hazards iv

blowers 2-13

brake tension, adjusting 3-11

brake, adjusting 3-10

breakout board

jumpers 2-8

pickup card 2-8

C

cables

pickup card 2-8

RS232 2-8

chassis specifications 1-4

height 1-4

length 1-4

weight 1-4

width 1-4

compressed air 1-6

compressed air pump 2-13

computer specifications 1-6

control cable 2-6

conventions 1-2

CPU module 2-7

crate

remove dyno 2-3

D

dimensions 1-5

disclaimers iii

document part number 1-1

dyno

contents 2-2

height 1-4

installing 2-2

length 1-4

unpacking 2-2

weight 1-4

width 1-4

dyno electronics 1-7

dyno room 1-3

equalizer box 1-3

exhaust extraction 1-3

fire suppression 1-3

intake air fan 1-3

noise control 1-3

E

electrostatic discharge iv

environmental requirements 1-6

equalizer box 1-3

ESD precautions iv

exhaust extraction 1-3

eyebolt 3-11

F

fire suppression 1-3

folding the dyno 2-10

forklift requirements 1-6

front support

axle shaft 2-5

control cable 2-6

installing 2-4

wheel clamp 2-5

Model SD12 Scooter Dynamometer Installation Guide

Index-i

Page 44

INDEX

H

hazards v

height 1-4

I

Industrial Noise Control, Inc. 1-3

inspection 3-7

intake air fan 1-3

J

jumpers 2-8

L

length 1-4

lifting bar 1-6, 2-3

loading the vehicle 3-2

M

maintenance 3-10

making a run 3-9

moving the dyno 2-11

O

opening the dyno 2-12

P

phone, internet access 1-6

pickup card

wiring to breakout board 2-8

pickup card cable 2-7

pre-run inspection 3-7

preventative maintenance 3-10

primary inductive pickup 3-6

S

secondary inductive pickup 3-5

specifications 1-4

stand alone blowers 2-13

T

technical support 1-2

testing

dyno, test run 3-9

tie-down straps 1-6, 3-3

U

unpacking dyno 2-2

using the dyno 3-9

W

warnings iii

weight 1-4

wheel clamp 2-5

width 1-4

wiring breakout board

jumpers 2-8

pickup card cable 2-8

Y

your dyno room 1-3

equalizer box 1-3

exhaust extraction 1-3

fire suppression 1-3

intake air fan 1-3

noise control 1-3

R

ramp 2-9

requirements 1-4

chassis specifications 1-4

compressed air 1-6

computer specifications 1-6

environmental 1-6

forklift 1-6

phone, internet access 1-6

tie-down straps 1-6

routing cables

pickup card 2-7, 2-8

RS232 2-7, 2-8

RPM pickup

connecting 3-4

primary inductive pickup 3-6

secondary inductive pickup 3-5

RS232 cable 2-7

Index-ii

Model SD12 Scooter Dynamometer Installation Guide

Loading...

Loading...