Page 1

Page 2

©2007 Dynojet Research, Inc. All Rights Reserved.

Dynojet Data Link Module-OBDII Installation and User Guide

This manual is copyrighted by Dynojet Research, Inc., hereafter referred to as Dynojet,

and all rights are reserved. This manual, as well as the software described in it, is

furnished under license and may only be used or copied in accordance with the terms of

such license. This manual is furnished for informational use only, is subject to change

without notice, and should not be construed as a commitment by Dynojet. Dynojet

assumes no responsibility or liability for any error or inaccuracies that may appear in this

manual. Except as permitted by such license, no part of this manual may be reproduced,

stored in a retrieval system, or transmitted, in any form or by any means, electronic,

mechanical, recording, or otherwise, without the prior written permission of Dynojet.

The Dynojet logo is a trademark of Dynojet Research, Inc.

Any trademarks, trade names, service marks, or service names owned or registered by any

other company and used in this guide are the property of their respective companies.

Dynojet Research, Inc., 2191 Mendenhall Drive, North Las Vegas, Nevada 89081, USA.

Printed in USA.

Part Number: 98100005 Version 04 (09/07)

Page 3

T

ABLE OF

C

ONTENTS

Data Link Module-OBDII

Introduction

Computer Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Conventions Used In This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

DJDLM-OBDII Setup

Installing the DJDLM-OBDII . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Configuring the DJDLM-OBDII . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Troubleshooting Connection Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Dynojet DLM-OBDII Dialog Box—Config Tab

Entering the Vehicle Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Dynojet DLM-OBDII Dialog Box—Channels Tab

Verifying the Supported Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Using Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Enabling Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Using Active Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Dynojet DLM-OBDII Dialog Box—Trouble Codes

DJDLM-OBDII and WinPEP 7

Configuring the MakeRun Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Viewing the Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Appendix A Data Link Module-OBDII Basic Configuration

Introduction

Connecting the DJDLM-OBDII . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Configuration

Accessing the Boot Options Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

Configuring the DJDLM-OBDII as a Stand Alone Wireless Device . . . . . . . .A-5

Configuring the DJDLM-OBDII as a Wireless Client . . . . . . . . . . . . . . . . . .A-6

Configuring the DJDLM-OBDII with a Category 5 Crossover Cable . . . . . .A-8

Configuring the DJDLM-OBDII with a Category 5 Standard Cable . . . . . . .A-8

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Index-i

Data Link Module-OBDII Installation and User Guide

i

Page 4

Page 5

D

ATA

L

INK

M

ODULE

-OBDII

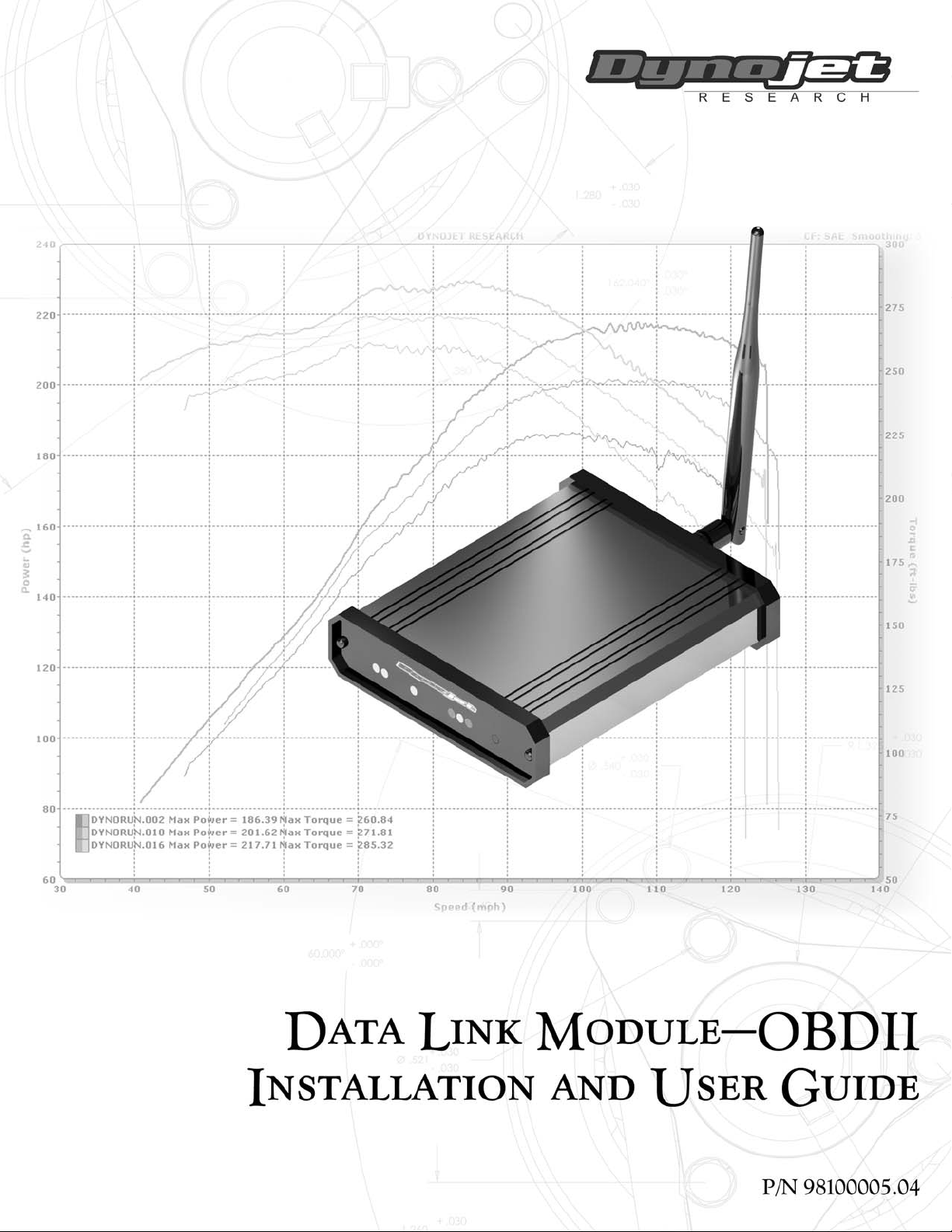

Thank you for purchasing the Dynojet Data Link Module-OBDII (DJDLM-OBDII). The

DJDLM-OBDII allows data, such as spark advance, throttle position, head

temperature, inlet air temperature, and numerous other parameters to be transmitted

from the vehicle’s OBDII compatible Powertrain Control Module (PCM) via the

vehicle’s data port. The WinPEP 7 software lets you easily view, save, and compare this

data using just a few mouse clicks.

The DJDLM-OBDII is great for PCM tuning and maintaining consistency while dyno

testing. No need to guess if the vehicle is too hot, or perhaps if the PCM is retarding

timing. You can even show this information right along side your dyno results using

the WinPEP 7 software.

Dynojet Research is known for its ultra consistent and repeatable line of chassis

dynos, and now with the DJDLM-OBDII you can gather data directly from the vehicle

being tested to achieve even greater consistency. This innovation is just another

example of the professional results you gain using Dynojet products.

Document Part Number: 98100005

Versi o n 4

Last Updated: 09-12-07

Data Link Module-OBDII Installation and User Guide

1

Page 6

DATA LINK MODULE-OBDII

Introduction

INTRODUCTION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Before you begin using WinPEP 7 (Performance Evaluation Program for Windows)

with your DJDLM-OBDII, be sure to read this guide for important system

requirements and installation instructions. Refer to the Dynojet WinPEP 7 User Guide

(P/N 98118103) for detailed information about WinPEP 7 features and commands, a

theoretical background, and a hands-on tutorial.

C

OMPUTER SPECIFICATIONS

You will need to provide a computer system to run the WinPEP software.

minimum system requirements recommended systems requirements

• Microsoft® Windows 2000/XP • Microsoft® Windows 2000/XP

• Pentium 800 MHz Processor • 2.4 GHz Processor or greater

• 256 MB of available RAM • 512 MB of available RAM or greater

• one 9-pin COM port, two 9-pin COM ports for

• USB port for DJDLM-OBDII, additional USB

• 800 x 600, 256 color monitor (SVGA) • 1280 x 1024 256 color monitor (SXGA) or better

• 1.2 gigabyte hard drive • 40 gigabyte hard drive

• 30 MB of available hard-disk space • 100 MB of available hard-disk space

• CD ROM • CD ROM

• printer, if hard copies are needed • printer, if hard copies are needed

• wired or wireless network capability • wireless network capability

Tuning Link

ports may be desired for other accessories

• one 9-pin COM port, two 9-pin COM ports for

Tuning Link

• USB port for DJDLM-OBDII, additional USB ports

may be desired for other accessories

2

Data Link Module-OBDII Installation and User Guide

Page 7

C

ONVENTIONS USED IN THIS MANUAL

The conventions used in this manual are designed to protect both the user and the

equipment.

example of convention description

Bold

!

T

ECHNICAL SUPPORT

For assistance, please contact Dynojet Technical Support at 1-800-992-3525, or write

to Dynojet at 2191 Mendenhall Drive, North Las Vegas, NV 89081.

Visit us on the World Wide Web at www.dynojet.com where Dynojet provides state of

the art technical support, on-line shopping, and information about our latest product

lines.

Highlights items you can select on in the software

interface, including buttons and menus.

The arrow indicates a menu choice. For example,

File !Open”

“select

then select the

Open

DATA LINK MODULE-OBDII

Introduction

means “select the

choice on the

File

File

menu,

menu.”

Version 4 Data Link Module-OBDII Installation and User Guide

3

Page 8

DATA LINK MODULE-OBDII

DJDLM-OBDII Setup

DJDLM-OBDII SETUP

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

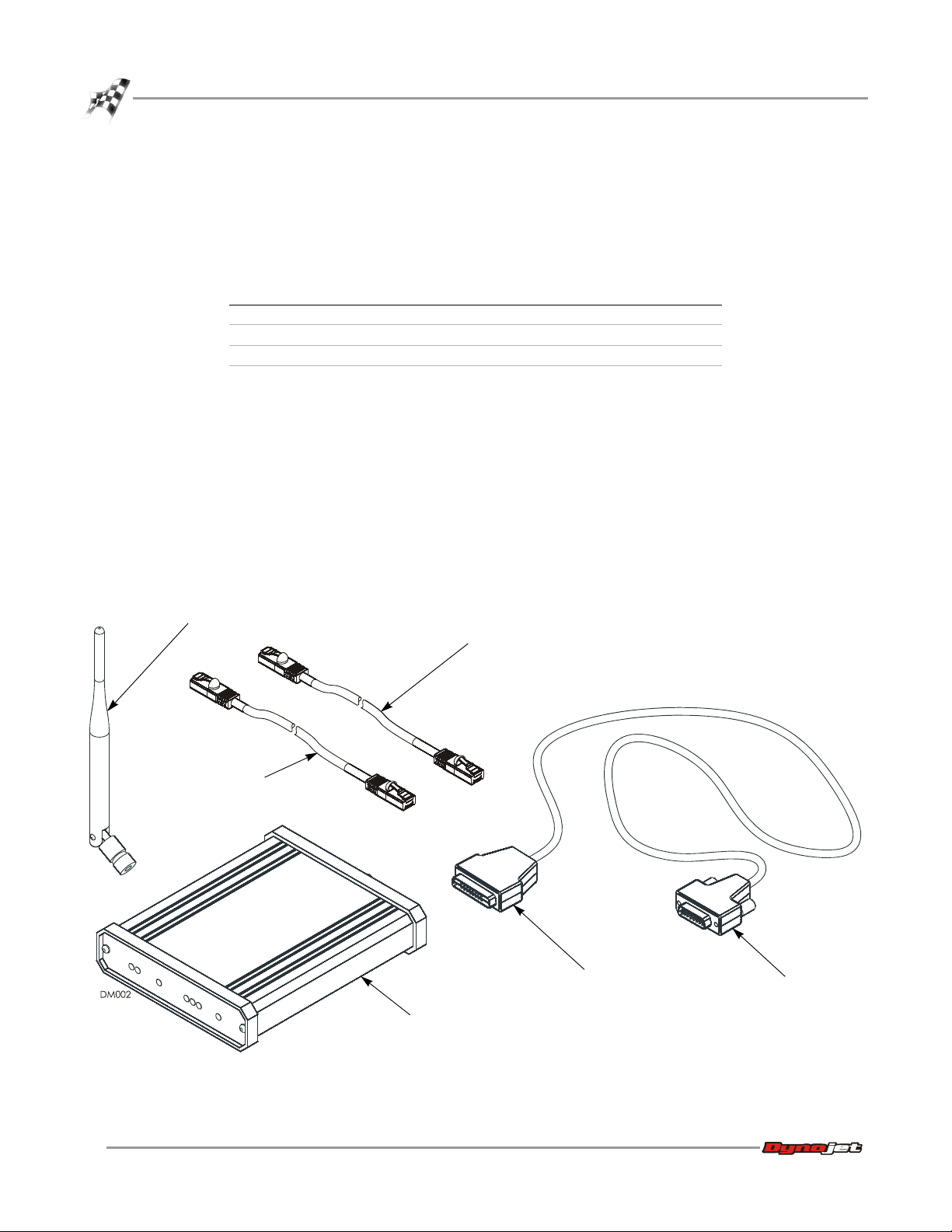

This section provides basic instructions for setting up the DJDLM-OBDII with

WinPEP 7. To ensure safety and accuracy, perform the procedures as they are

described.

part description quantity

DJDLM-OBDII (P/N 76100008) includes the following:

42900000 cat5e patch cable, 15', black 1

42900001 cat5e crossover patch cable, 14', red 1

66100005 OBDII Data Link Module, with antenna and

15-pin cable

I

NSTALLING THE

1 Connect the DJDLM-OBDII to the vehicle’s data port. The data port is usually

2 Connect the DJDLM-OBDII to your computer, where you are running the WinPEP

3 Turn the vehicle’s key to the ON position. The engine may need to be running on

connect antenna for

wireless networks

DJDLM-OBDII

located on the driver’s side underneath the dash.

software, using either the wired or wireless network. Verify that your computer

system has network connectivity with the DJDLM-OBDII.

some vehicles in order to power the DJDLM-OBDII.

use red cat5 crossover cable

to connect to peer to peer

wired network

1

use black standard cat5

cable to connect to a

wired network hub

4

Data Link Module-OBDII Installation and User Guide

connect to

vehicle’s data port

DJDLM-OBDII

module

Figure 1: Installing the DJDLM-OBDII

connect the15-pin

cable to the

DJDLM-OBDII

Page 9

C

ONFIGURING THE

1 Start the WinPEP software by double-clicking the desktop icon or by selecting

Start

When WinPEP starts, the Graph View shows by default.

2Click the MakeRun button on the toolbar or select Display

Screen from the menu choices.

3 Verify your computer is connected to the dyno electronics and the dyno

electronics is powered on. Refer to "Connecting the Dyno Electronics" in your

WinPEP 7 User Guide for more information.

4Click the MakeRun Configuration button .

Note: If You may have more than one DJDLM-OBDII connected to your network

at the same time, a window will pop up. Choose which device you wish to

connect to.

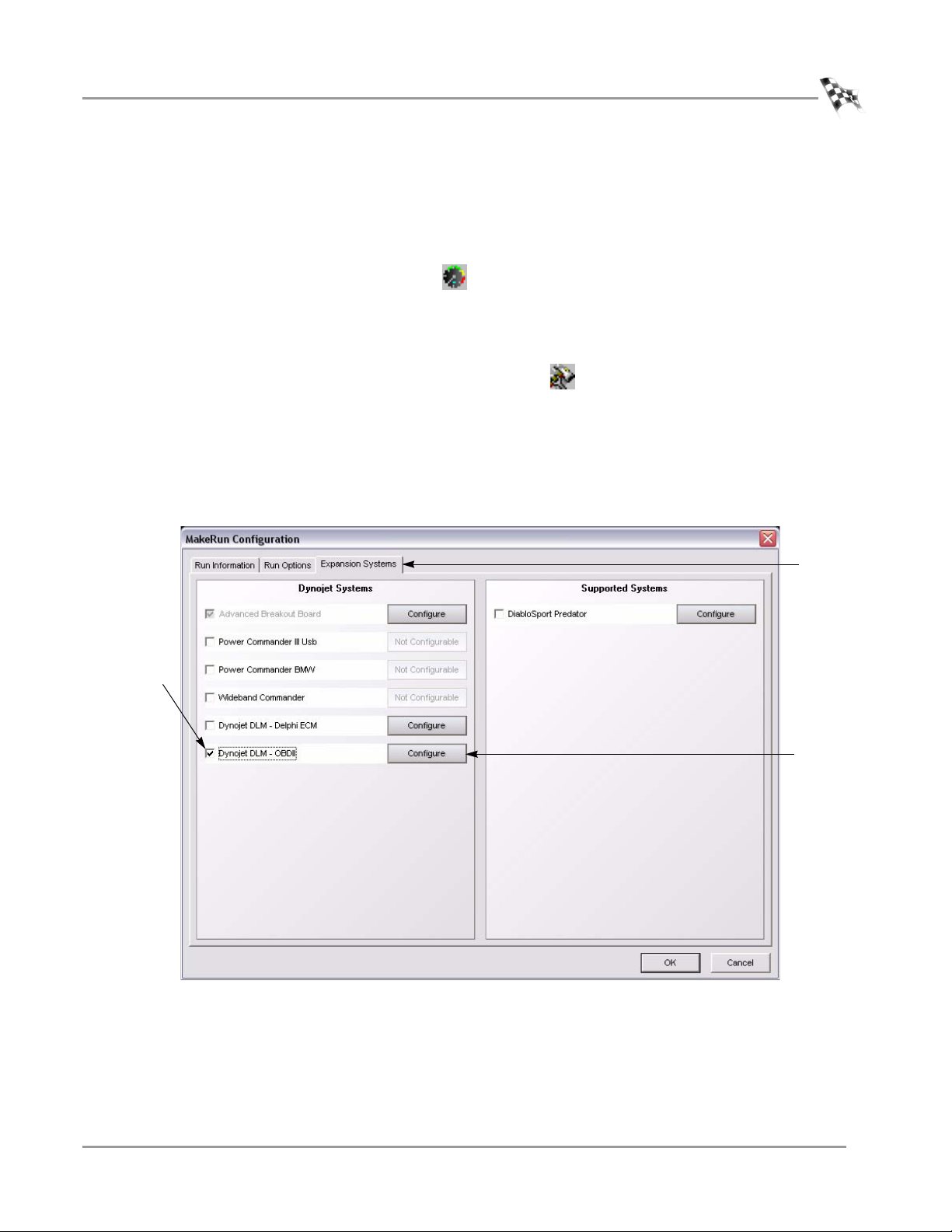

5Click the Expansion Systems tab.

6Select Dynojet DLM-OBDII.

7Click the Configure button.

DJDLM-OBDII

!

All Programs !WinPEP 7 !WinPEP 7.

DATA LINK MODULE-OBDII

DJDLM-OBDII Setup

!

MakeRun

select Dynojet

DLM-OBDII

expansion

systems tab

configure

button

Figure 2: MakeRun Configuration—Expansion Systems

Version 4 Data Link Module-OBDII Installation and User Guide

5

Page 10

DATA LINK MODULE-OBDII

DJDLM-OBDII Setup

DJDLM-OBDII

device is

connected with

your computer

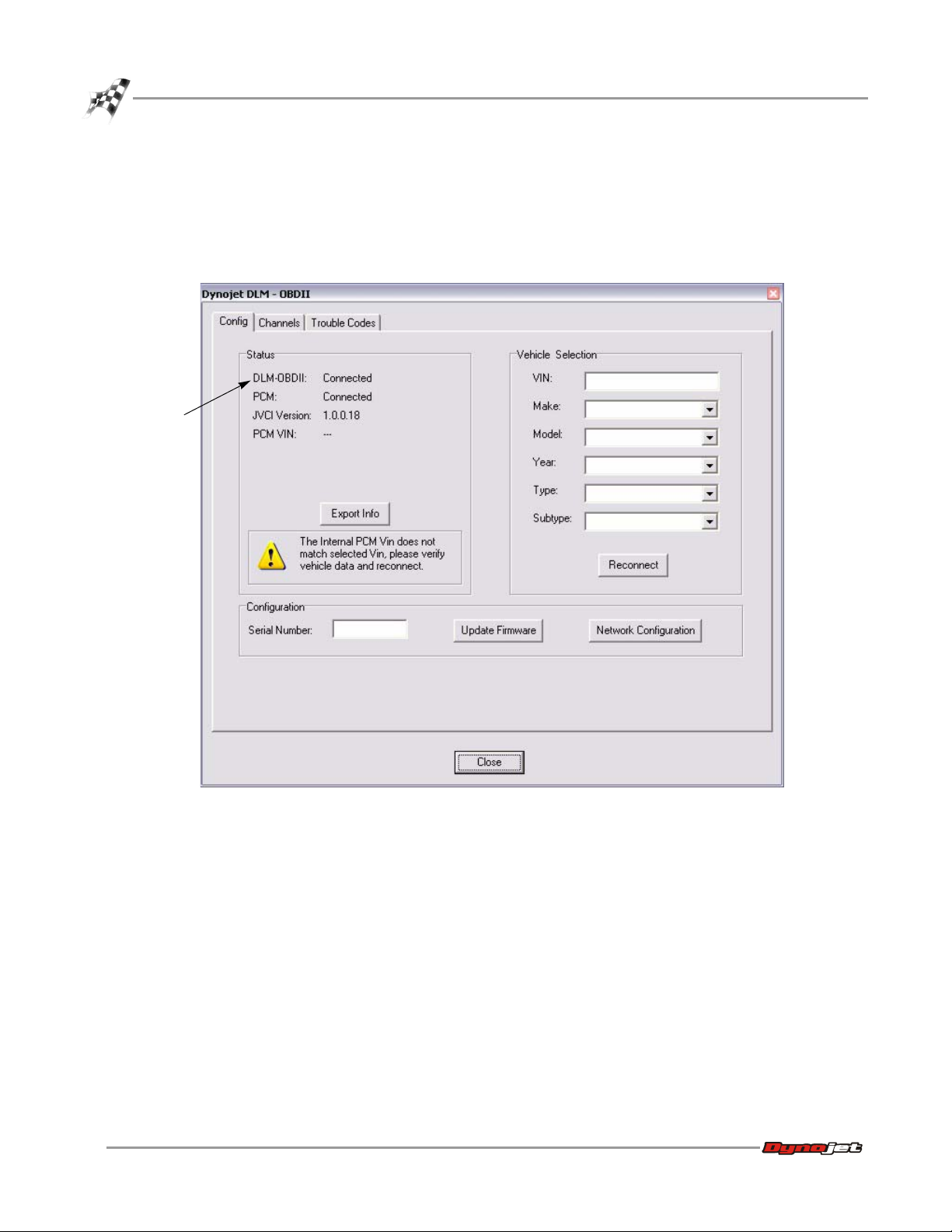

The Dynojet DLM-OBDII dialog box will appear. When the DJDLM-OBDII is

properly connected to your computer system, the Status area will indicate you are

connected.

If you are unable to connect, refer to “Troubleshooting Connection Errors” on

page 7.

Figure 3: Dynojet DLM-OBDII Dialog Box—Status Connected

6

Data Link Module-OBDII Installation and User Guide

Page 11

T

ROUBLESHOOTING CONNECTION ERRORS

If you are unable to connect to the DJDLM-OBDII and the PCM, use the following

table to troubleshoot your connection.

If you still cannot establish a connection, contact Dynojet Technical Support.

problem try this then this

DJDLM-OBDII:

Disconnected

DJDLM-OBDII:

Disconnected

DJDLM-OBDII:

Disconnected

PCM:

Disconnected

Verify your computer is connecting

to your network through a wired or

wireless network card.

Click Reconnect. Verify the cable is plugged into your

Verify the vehicle power is turned

on; if there is a ready to start switch

verify it is on.

Verify the vehicle power is turned

on; if there is a ready to start switch

verify it is on; start the vehicle if

necessary.

Click Reconnect.

Verify the network cable is making a

connection or the wireless network is

broadcasting.

computer and is making a connection.

Press F5 to reset.

Start the vehicle; some vehicles do not

provide enough power to the DJDLMOBDII unless started.

Check the plug end to the vehicle’s

data port; this occasionally may

appear to “snap” into place, but may

not be making connection.

Press F5 to reset.

DATA LINK MODULE-OBDII

DJDLM-OBDII Setup

Version 4 Data Link Module-OBDII Installation and User Guide

7

Page 12

DATA LINK MODULE-OBDII

Dynojet DLM-OBDII Dialog Box—Config Tab

DYNOJET DLM-OBDII DIALOG BOX—CONFIG TAB

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Dynojet DLM-OBDII dialog box allows sophisticated configuration of your

DJDLM-OBDII. A description of the Config tab functions and displays follows:

Figure 4: Dynojet DJDLM-OBDII Dialog Box—Config Tab

DJDLM-OBDII—displays Connected when the DJDLM-OBDII is connected to your

computer via the network. Displays Disconnected when the DJDLM-OBDII cannot

communicate with your computer. The DJDLM-OBDII must be able to connect to the

8

Data Link Module-OBDII Installation and User Guide

computer before it can connect to the vehicle’s PCM.

PCM—displays Connected when the DJDLM-OBDII is connected to the vehicle’s

PCM. Displays Disconnected when the DJDLM-OBDII cannot communicate with the

PCM.

Page 13

DATA LINK MODULE-OBDII

Dynojet DLM-OBDII Dialog Box—Config Tab

Version—displays the software .dll version used by the DJDLM-OBDII hardware. This

.dll version must be the correct one for your WinPEP software version. If your versions

do not match, contact Dynojet technical support or check for an update on

www.dynojet.com.

PCM Vin—displays the vehicle identification number (VIN) detected from the PCM if

it is available.

Export Info—creates a text file for debugging purposes and may be requested by

technical support.

Serial Number—the serial number for your DJDLM-OBDII identifies it as a unique

device on your computer network. Before selecting Update Firmware or Network

Configuration, specify the serial number of the DJDLM-OBDII to update. Otherwise

the software will find the first available DJDLM-OBDII on the network.

Update Firmware—displays a window used to update your DJDLM-OBDII if

necessary.

Network Configuration—displays a window used to configure your DJDLM-OBDII

to connect to your computer network if necessary. When the DJDLM-OBDII is

properly connecting to your computer system, the Status area will indicate the

DJDLM-OBDII is connected.

VIN—usually the seventeen digit identification number specific to your vehicle; any

text or digits is a valid entry.

Make—use the drop down list to select the vehicle manufacturer, such as Ford or

GMC. You must select Ford or GM to view enhanced channels.

Model—use the drop down list to select the model, such as Mustang, or Bronco.

Year—use the drop down list to select the manufacture year for your vehicle.

Type—when there are variations among the models for a year, the type will be listed

so that you may select it from the drop down list.

Subtype—if further variations (often engine size) exist, the subtype will be listed so

that you may select it from the drop down list.

Note: Because the OBDII standard is used for data from many types of vehicles,

you may be able to retrieve data using your DJDLM-OBDII even when you have

not configured for your specific vehicle. It is generally better to configure for your

vehicle using as much specific information as you have available.

Version 4 Data Link Module-OBDII Installation and User Guide

9

Page 14

DATA LINK MODULE-OBDII

Dynojet DLM-OBDII Dialog Box—Config Tab

E

NTERING THE VEHICLE INFORMATION

1 Enter the vehicle’s VIN number.

2 Using the drop down list, select the vehicle’s make.

Note: You must fill in the vehicle’s make information in order to see enhanced

channels.

3 Using the drop down list, select the vehicle’s model.

4 Using the drop down list, select the vehicle’s year.

5 Using the drop down list, select the vehicle’s type and subtype if applicable.

6Click Reconnect to send the information to the DJDLM-OBDII.

The DJDLM-OBDII will update the list of channels based on the information you

have entered.

10

Data Link Module-OBDII Installation and User Guide

Figure 5: Entering the Vehicle Information

Page 15

DYNOJET DLM-OBDII DIALOG BOX—CHANNELS TAB

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Channels tab displays the available channels and allows you to verify and enable

channels.

V

ERIFYING THE SUPPORTED CHANNELS

To determine whether a channel is supported, the DJDLM-OBDII must communicate

with the vehicle’s PCM. You must verify the channel is supported before you can

enable a channel for use.

1 Click anywhere in the row containing a channel to select a single channel,

Ctrl+click to select multiple channels, or use Ctrl+A to select all channels.

2Click Veri f y to communicate with the PCM to determine whether the channel is

supported.

click a channel

to select it

DATA LINK MODULE-OBDII

Dynojet DLM-OBDII Dialog Box—Channels Tab

Figure 6: Channels Tab—Verifying the Supported Channels

Version 4 Data Link Module-OBDII Installation and User Guide

11

Page 16

DATA LINK MODULE-OBDII

Dynojet DLM-OBDII Dialog Box—Channels Tab

U

SING FILTERS

Use filters to sort and refine the list of displayed channels.

1 Click a column heading to sort using that column. Click and drag a divider to

resize the column.

2 Select a filter from the list. In this example, Supported has been selected.

3 Enter text in the Name Includes/Abrev Includes fields. In this example, Air has

been entered in the Name Includes field.

4Select And to show only channels that meet all of the selected filter criterion.

Select Or to show all of the channels that meet any of the selected filter criterion.

Note: Selecting Enabled and Unsupported using the And button will not show

any channels because there are no channels that can be both unsupported and

enabled.

5Click Apply to update the list using your selections.

The software stores which filters you have selected. They will already be active the

next time you enter the Channels screen.

6Click Clear to clear the filter selections.

click a

column

heading to

sort using

that column

hovering your

mouse over a

truncated

name shows

the full name

channels that

are supported

or have air in

their name

appear listed

click and

drag a

divider to

resize the

column

12

Data Link Module-OBDII Installation and User Guide

Figure 7: Channels Tab—Using Filters

Page 17

channel

enabled

E

NABLING CHANNELS

Enabling is different than verifying channels. Any unsupported channels return to the

disabled state. You cannot enable unsupported channels. Having more than six

generic channels enabled at one time will slow down the incoming data rate. The

lower your data rate, the less precise your data will be.

1 Once a channel or channels have been selected, click Enable.

2Click Close to exit the dialog box.

3Click OK to exit the MakeRun Configuration dialog.

Enabled channels appear with *C_ in front of their abbreviated name in the list of

available WinPEP channels.

The Absolute Throttle Position channel shown below was verified. Since the PCM

has verified that it is able to provide data for this channel it shows as supported. It

has also been enabled for use in WinPEP. *C_TP is now in the list of available Data

Channels, refer to Figure 11.

Note: You cannot enable unsupported channels.

DATA LINK MODULE-OBDII

Dynojet DLM-OBDII Dialog Box—Channels Tab

channel is

supported

Figure 8: Channels Tab—Enabling Channels

Version 4 Data Link Module-OBDII Installation and User Guide

13

Page 18

DATA LINK MODULE-OBDII

Dynojet DLM-OBDII Dialog Box—Channels Tab

U

SING ACTIVE CHANNELS

The Active Channels tab allows you to store your list of channels. Only enabled

channels can be stored for later retrieval.

1Click the Active Channels tab.

2Select Default Path or Current Run Path.

Default Path saves your channel settings in the WinPEP directory. Current Run

Path saves your channel settings in the location you are currently using for your

dyno runs.

Note: Using separate folders within the DynoRuns folder for each vehicle type

allows you to organize and find your dyno runs. Using Current Run Path in

conjunction with organized folders will help you automatically see the channels

you use for the type of vehicle in that folder.

3Click Save to store this list of channels for easy connection in the future.

Note: Selecting Autosave on Exit automatically saves any changes to your active

channels list when you exit the dialog box.

this list has

been filtered

to only include

channels with

rpm in the

name

select to save

your active

channel list

to the default

software

location or to

the current

run location

select to

automatically

save any

changes to

your channel

list on

exiting

Figure 9: Channels Tab—Active Channels

14

Data Link Module-OBDII Installation and User Guide

Page 19

DATA LINK MODULE-OBDII

Dynojet DLM-OBDII Dialog Box—Trouble Codes

DYNOJET DLM-OBDII DIALOG BOX—TROUBLE CODES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The DJDLM-OBDII will only read back codes if the check engine light is on.

1Click Request Codes to display the trouble codes available from the vehicle’s

PCM.

Note: To display trouble codes, the DJDLM-OBDII must be communicating with

the vehicle’s PCM.

2Click Save to save the trouble code information to a text file.

3Click Clear Codes to clear the vehicle’s trouble codes. Always wait a few minutes

after clearing trouble codes before requesting codes again.

Figure 10: Dynojet DLM-OBDII Dialog Box—Trouble Codes

Version 4 Data Link Module-OBDII Installation and User Guide

15

Page 20

DATA LINK MODULE-OBDII

DJDLM-OBDII and WinPEP 7

DJDLM-OBDII AND WINPEP 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Features within WinPEP 7 may use the supported data channels enabled in the

DJDLM-OBDII.

C

ONFIGURING THE MAKERUN SCREEN

The gauges displayed on the MakeRun screen are completely configurable. Editing a

gauge allows live data from the DJDLM-OBDII to be displayed on the MakeRun

screen. Any data from the DJDLM-OBDII will always be recorded when you sample a

run. Dynojet recommends displaying live gauges on the MakeRun screen to help

verify data is streaming from the DJDLM-OBDII to WinPEP 7.

For more detailed information on gauges, refer to the WinPEP 7 User Guide.

1Click the Edit Mode button . You cannot edit gauges unless you are in Edit

Mode.

The gauge toolbar will appear.

2 Choose the style of gauge you would like.

3 Click and drag, holding the mouse button down as you do so, on the MakeRun

screen until the dotted box is the desired size. Release the mouse and the gauge

will appear.

4 Edit the gauge properties.

4a Right click on the gauge and choose Gauge Properties.

The Gauge Property Editor dialog box will appear.

4b Select a Data Channel from the drop down list.

Each type of gauge has a slightly different dialog box, but most share the same

properties. Most channels available are standard channels, but the channels that

are listed with an asterisk are from peripheral devices (Expansion Systems).

The Prefix *C_ indicates data channels that are available from the DJDLM-OBDII.

Other expansion systems have an asterisk (*) in front of the channel name. Data

channels without an asterisk (*) in front of their names are information from your

dyno.

Data Channel determines which channel the gauge is linked to (such as the

DJDLM-OBDII). The data channels that you selected when you configured your

DJDLM-OBDII are the ones that are available. If you do not see a data channel that

you think should be shown, make sure that it is a supported channel that you

enabled when configuring your device as shown on page 11. Some types of

gauges automatically place the name of the Data Channel selected on the gauge.

Digital gauges do not display the name and will require you to add a label.

Note: You must be connected to the dyno electronics for the list of channels to be

available.

16

Data Link Module-OBDII Installation and User Guide

Page 21

edit mode

button

DATA LINK MODULE-OBDII

DJDLM-OBDII and WinPEP 7

4c Click OK to enter these changes or click Cancel to abort the changes and

return to the MakeRun screen.

data channel

drop down list

Figure 11: Segment Display Property Editor—Data Channels

Version 4 Data Link Module-OBDII Installation and User Guide

17

Page 22

DATA LINK MODULE-OBDII

DJDLM-OBDII and WinPEP 7

V

IEWING THE RESULTS

Data streaming from the PCM during the dyno run is available to be graphed right

along side all of the standard channels such as HP, Trq, AFR, and rpm. This feature will

be instrumental to assist you with troubleshooting, tuning, and maintaining

consistency during dyno testing.

Note: Rpm cannot be graphed on the horizontal axis due to the sampling rate

from the vehicle sensors. WinPEP provides graphing of rpm on the vertical axis.

streaming data

channels

Figure 12: Graph Example

18

Data Link Module-OBDII Installation and User Guide

Page 23

A

PPENDIX

D

ATA

The appendix contains instructions for configuring the Dynojet Data Link ModuleOBDII (DJDLM-OBDII). To ensure safety and accuracy in the procedures, perform the

procedures as they are described.

L

B

ASIC

INK

M

C

ODULE

ONFIGURATION

-OBDII

A

Data Link Module-OBDII Installation and User Guide

A-1

Page 24

APPENDIX A

Introduction

INTRODUCTION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

There are four basic configurations for the Dynojet Data Link Module-OBDII (DJDLMOBDII). Each DJDLM-OBDII ships with the ability to be configured using any of the

four methods described below. Dynojet recommends the DJDLM-OBDII be set up as a

client on your wireless network. If this is not possible, it is recommended to use a

direct connection to your dynamometer PC with a category 5 crossover cable.

Stand Alone Wireless—directly connects to your PC via your PC’s wireless card. This

is the factory default and requires no special configuration. Refer to “Configuring the

DJDLM-OBDII as a Stand Alone Wireless Device” on page A-5 for more information.

Figure A-1: Stand Alone Wireless Configuration

Wireless Client—connects through your wireless network as a node on the wireless

network. Refer to “Configuring the DJDLM-OBDII as a Wireless Client” on page A-6 for

more information.

Figure A-2: Wireless Client Configuration

Category 5 Crossover Cable—directly connects to your PC with a category 5

crossover cable. This is the fastest data transfer option available. No configuration is

needed to the DJDLM-OBDII when using the crossover cable; just plug and play. Refer

to “Configuring the DJDLM-OBDII with a Category 5 Crossover Cable” on page A-8 for

more information.

Figure A-3: Category 5 Crossover Cable Configuration

A-2

Data Link Module-OBDII Installation and User Guide

Page 25

DATA LINK MODULE-OBDII BASIC CONFIGURATION

Introduction

Category 5 Standard Cable—connects to your wired network with a category 5

standard cable. Refer to “Configuring the DJDLM-OBDII with a Category 5 Standard

Cable” on page A-8 for more information.

C

ONNECTING THE

Once unpacked, a direct connection via a crossover cable must be made.

1 Plug the DJDLM-OBDII into a vehicle for a power source. Turn the vehicle’s key to

the ON position. The engine may need to be running on some vehicles in order to

power the DJDLM-OBDII.

2 Connect the crossover cable to the DJDLM-OBDII and to your PC.

3 Turn on the DJDLM-OBDII power.

4 Open Internet Explorer.

5 In the address bar, type 192.168.0.101. Do not type anything else.

6Press Enter.

You will see the following window when successfully connected.

Figure A-4: Category 5 Standard Cable Configuration

DJDLM-OBDII

Figure A-5: DJDLM-OBDII Successfully Connected

Version 4 Data Link Module-OBDII Installation and User Guide

A-3

Page 26

APPENDIX A

Configuration

CONFIGURATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This section describes the four ways to configure the DJDLM-OBDII. Changes made

do not take effect until you save them and reset the DJDLM-OBDII. Dynojet

recommends documenting any changes you make; this will make it easier to undo

incorrect modifications should the DJDLM-OBDII not function properly. Tracking

your changes allows for faster technical support of the DJDLM-OBDII.

A

CCESSING THE BOOT OPTIONS WINDOW

Before you can begin configuration, you must access the Boot Options window.

1 In the address bar type 192.168.0.101/cgi-bin/bootparam.

2Press Enter. This will take you to a password screen.

3Type root in the user name text box. Root is an admin level login.

4Type powerful in the password text box. This password is all lowercase.

A-4

Data Link Module-OBDII Installation and User Guide

Figure A-6: Entering the Password

Page 27

DATA LINK MODULE-OBDII BASIC CONFIGURATION

Configuration

The Boot Options window will appear. You can begin configuring the DJDLM-OBDII.

C

ONFIGURING THE

The stand alone wireless device is the factory default. This is a direct wireless

connection from your dynamometer PC and the DJDLM-OBDII; no configuration is

necessary.

If the DJDLM-OBDII does not make a direct wireless connection, click Load Factory

Default Settings as shown in Figure A-7. This will load all defaults and allow for AD

Hoc Wireless communication with your dynamometer PC.

1 Open your PC’s wireless connection manager (usually windows manages

wireless).

If you are not sure how to manage your wireless networks, contact Dynojet

Technical Support or a local IT professional.

2 Scan for available networks. You should see a DLM or OBDII in your list.

3 Select DLM or OBDII from the list. The connection will be completed.

Figure A-7: Boot Options Window

DJDLM-OBDII AS A S

TAND ALONE WIRELESS DEVICE

Version 4 Data Link Module-OBDII Installation and User Guide

A-5

Page 28

APPENDIX A

Configuration

C

ONFIGURING THE

DJDLM-OBDII AS A W

Your wireless network must be running a maximum security of WEP with a 64 bit

encryption. The wireless network can be open or shared, but "WEP security" is the

highest security level available using the 64 bit encryption that the DJDLM-OBDII is

currently configured to understand. If you cannot provide this level of security, or do

not feel safe enough with this level of security, another method of configuring the

DJDLM-OBDII must be used.

1 In the Boot Options window, scroll down to Wireless Network Card.

2Select Client then Server from the Network Type drop down menu.

IRELESS CLIENT

A-6

Data Link Module-OBDII Installation and User Guide

Figure A-8: Scroll Down to Wireless Network Card

Page 29

DATA LINK MODULE-OBDII BASIC CONFIGURATION

Configuration

3 In the ESSID text box, type the wireless network name used in your business. The

ESSID are case sensitive, be sure to match the case of your existing networks

SSID.

4Select Auto from the Mode drop down menu. You can statically define the Mode,

however it is not necessary in most installations.

5 In the Key text box, type your wireless WEP key you have previously assigned to

your wireless network. If you do not have a WEP key on your wireless network, it

is strongly recommended that you use a WEP key.

The key is a hexadecimal key using a ten digit combination of numbers (0-9) and

letters (A-F).

6 Save the changes.

7 Unplug the crossover cable from the DJDLM-OBDII and remove the cable

connecting the DJDLM-OBDII to the vehicle.

8 Wait a few seconds. Reconnect the cable.

The wireless client will negotiate with your wireless network and you can begin

using the DJDLM-OBDII with the WinPEP software.

Figure A-9: Entering the Wireless Network Parameters

Version 4 Data Link Module-OBDII Installation and User Guide

A-7

Page 30

APPENDIX A

Configuration

C

ONFIGURING THE

C

ONFIGURING THE

DJDLM-OBDII

The category 5 crossover cable ships with the DJDLM-OBDII. This is the fastest data

transfer option available. No configuration is needed to the DJDLM-OBDII when

using the crossover cable; just plug and play.

1 Power the DJDLM-OBDII on in the car.

2 Attach the crossover cable to the Ethernet port on the DJDLM-OBDII.

3 Attach the crossover cable from the DJDLM-OBDII to the dynamometer PC’s

Ethernet port.

DJDLM-OBDII

This configuration requires a standard category 5 patch cable and a network jack.

You must have a DHCP server configured on your network to run this option. If you

are not sure what a DHCP server is, contact Dynojet Technical Support or a local IT

professional.

1 In the Boot Options window, scroll down to Built-in Internet.

2Select Client then Server from the Network Type drop down menu.

Once connected to your Ethernet network, the DHCP server will assign the

DJDLM-OBDII an IP address and it will be a network member. The DJDLM-OBDII

will then be visible through the network to WinPEP.

WITH A CATEGORY

WITH A CATEGORY

5 C

ROSSOVER CABLE

5 S

TANDARD CABLE

Figure A-10: Entering the Built-in Ethernet Parameters

A-8

Data Link Module-OBDII Installation and User Guide

Page 31

I

NDEX

A

active channels 1-14

autosave on exit 1-14

current run path 1-14

default path 1-14

antenna 1-4

B

boot options window A-4

C

category 5 crossover cable A-2, A-8

category 5 standard cable A-3, A-8

channels

active 1-14

enabling 1-13

using filters 1-12

verifying supported 1-11

computer specifications 1-2

configuration 1-5

category 5 crossover cable A-8

category 5 standard cable A-8

stand alone wireless A-5

wireless client A-6

configuration dialog box 1-8

configuration types

category 5 crossover cable A-2

category 5 standard cable A-3

stand alone wireless A-2

wireless client A-2

conventions 1-3

crossover cable 1-4

D

data channel 1-16

data link module 1-1, A-2

DJDLM-OBDII 1-1, 1-8, A-2

boot options window A-4

connecting A-3

E

enabling channels 1-13

enhanced channels 1-9

ESSID A-7

expansion systems, configuring 1-5

export info 1-9

F

filters 1-12

I

installation 1-4

K

key A-7

M

make 1-9

MakeRun configuration 1-16

model 1-9

N

network connection 1-9

P

PCM

status 1-8

VIN 1-9

powertrain control module 1-1

R

requesting trouble codes 1-15

rpm 1-18

Data Link Module-OBDII Installation and User Guide

Index-i

Page 32

INDEX

S

serial number 1-9

setup 1-4

software version 1-9

stand alone wireless A-2, A-5

status 1-8

subtype 1-9

T

technical support 1-3

trouble codes 1-15

troubleshooting 1-7

type 1-9

U

update firmware 1-9

V

vehicle identification number 1-9

vehicle information

enhanced channels 1-10

entering 1-10

make 1-10

model 1-10

subtype 1-10

type 1-10

VIN 1-10

year 1-10

verifying supported channels 1-11

version 1-9

viewing graphs 1-18

VIN 1-9

W

WinPEP 7 1-1

wireless client A-2, A-6

Y

year 1-9

Index-ii

Data Link Module-OBDII Installation and User Guide

Page 33

Loading...

Loading...