Page 1

Page 2

©2004 Dynojet Research, Inc. All Rights Reserved.

Flow Meter User Guide

This manual is copyrighted by Dynojet Research, Inc., hereafter referred to as Dynojet,

and all rights are reserved. This manual, as well as the software described in it, is

furnished under license and may only be used or copied in accordance with the terms of

such license. This manual is furnished for informational use only, is subject to change

without notice, and should not be construed as a commitment by Dynojet. Dynojet

assumes no responsibility or liability for any error or inaccuracies that may appear in this

manual. Except as permitted by such license, no part of this manual may be reproduced,

stored in a retrieval system, or transmitted, in any form or by any means, electronic,

mechanical, recording, or otherwise, without the prior written permission of Dynojet.

The Dynojet logo is a trademark of Dynojet Research, Inc.

Any trademarks, trade names, service marks, or service names owned or registered by any

other company and used in this guide are the property of their respective companies.

Dynojet Research, Inc., 2191 Mendenhall Drive, North Las Vegas, Nevada 89081, USA.

Printed in USA.

Part Number: 98129104 Version 01 (12/04)

Page 3

T

ABLE OF

C

ONTENTS

Flow Meter Testing

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Conventions Used In This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Flow Meter Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Assembling the Flow Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Flow Meter Test Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Removing the Pump Head Service Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Checking Test Point One—Overall System Flow . . . . . . . . . . . . . . . . . . . . . . . 7

Checking Test Point Two—Filter Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Checking Test Point Three—Pump Inlet Port, Sensor Side . . . . . . . . . . . . . . . 10

Checking Test Point Four—Left Outflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Checking Test Point Five—Right Outflow . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Interpreting Your Flow Meter Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Replacing the Pump Head Service Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Data Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Flow Meter User Guide

i

Page 4

Page 5

F

LOW

M

ETER

T

ESTING

This document provides instructions for performing flow meter tests on your

air/fuel ratio pump (air pump). To ensure safety and accuracy in the procedures,

perform the procedures as they are described.

Document Part Number: 98129104

Vers ion 1

Last Updated: 12-30-04

Flow Meter User Guide

1

Page 6

FLOW METER

Introduction

INTRODUCTION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flow Meter testing is a valuable troubleshooting tool. Testing with the flow meter will

help you determine if you need to rebuild the air pump. Be sure to read and follow all

warnings found throughout this manual.

For more detailed information on the air pump, refer to the Air Fuel Ratio Module

Installation and User Guide (P/N 98295110).

WARNINGS

The sensor and the copper sample tube are hot. Before touching the sensor or

the sample tube, make sure it has cooled.

The sensor is not covered by a warranty. Be sure to read and understand the Air

Fuel Ratio Module Installation and User manual.

CONVENTIONS USED IN THIS MANUAL

The conventions used in this manual are designed to protect both the user and the

equipment.

example of convention description

The Caution icon indicates a potential hazard to the

dynamometer equipment. Follow all procedures

exactly as they are described and use care when

performing all procedures.

The Warning icon indicates potential harm to the

person performing a procedure and/or the

dynamometer equipment.

TECHNICAL SUPPORT

For assistance, please contact Dynojet Technical Support at 1-800-992-3525, or write

to Dynojet Research at 2191 Mendenhall Drive, North Las Vegas, NV 89081.

Visit us on the World Wide Web at www.dynojet.com where Dynojet provides state of

the art technical support, on-line shopping, 3D visualizations, and press releases

about our latest product line.

2

Flow Meter User Guide

Page 7

FLOW METER TESTING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

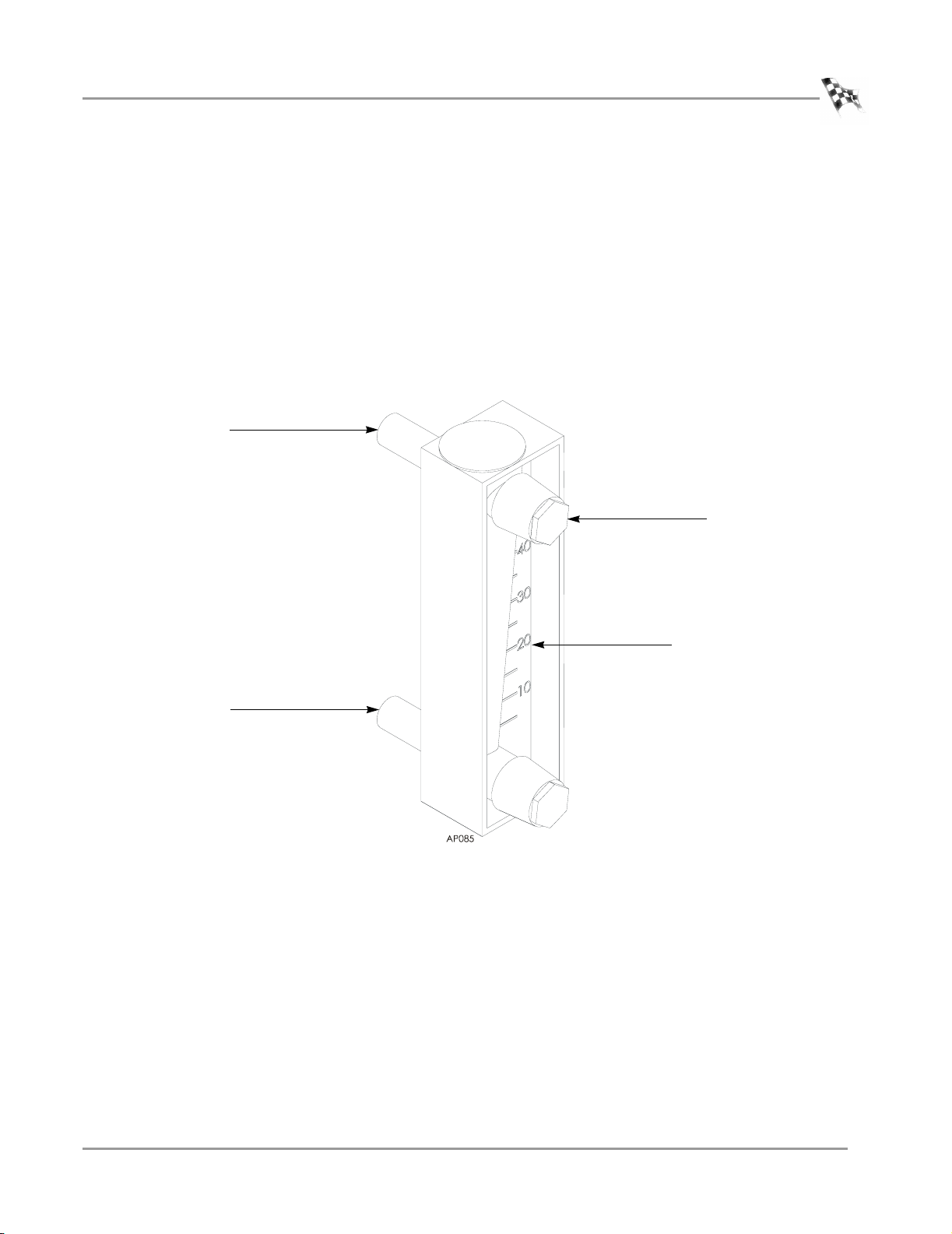

This section describes the five test point procedures using the flow meter to test the

air pump.

• Test Point One—Overall System Flow, page 7

• Test Point Two—Filter Flow, page 8

• Test Point Three—Pump Inlet Port, Sensor Side, page 10

• Test Point Four—Left Outflow, page 12

• Test Point Five—Right Outflow, page 13

top port

USER GUIDE

Flow Meter Testing

plug

bottom port

liters/minute

Figure 1: Flow Meter

Vers ion 1 Flow Meter User Guide

3

Page 8

FLOW METER

Flow Meter Testing

ASSEMBLING THE FLOW METER

Before performing any tests on the air pump you will need to assemble the flow

meter. Everything you need to correctly assemble the flow meter is included with

your flow meter kit (P/N 34803001).

1 Knead the bag containing the o-rings and the lubricant until all three o-rings are

coated.

Note: Be careful not to stretch or tear the o-rings.

2 Place an o-ring on each plug.

3 Secure both plugs to the flow meter using the black circular installation tool.

Note: To secure the plugs, turn the tool counter-clockwise torquing to less than

three inches/pound.

o-ring

plug

4

Flow Meter User Guide

o-ring

plug

Figure 2: Assembling the Flow Meter

Page 9

Flow Meter Testing

FLOW METER TEST POINTS

The following table describes the flow meter readings for a new, rebuilt, or dirty

air pump in liters/minute. Perform all of the tests outlined in this manual and fill

out your results in the data tables on page 16. When you have completed all of the

tests, compare your results with the following table. If the flow meter reading is

equal to or lower than the dirty air pump reading, follow the steps outlined in the

action required column of the table. Pump head rebuild kits (P/N 79190003) are

available from Dynojet. Refer to the Air Fuel Ratio Module Installation and User

Guide (P/N 98295110) for rebuild instructions.

Note: If at any test point, the ball in the flow meter bounces erratically

(+/- 20L/min.) the pump heads need to be rebuilt. Pump head rebuild kits

(P/N 79190003) are available from Dynojet. Refer to the Air Fuel Ratio Module

Installation Guide (P/N 98295110) for rebuild instructions.

new or rebuilt

test point

test point one 35 25 or less rebuild pump heads

test point two 28 25 or less clean or replace filter

test point two—filter

assembly

test point three 28 25 or less rebuild pump heads

test point three—sensor

block assembly

test point four 30 25 or less rebuild pump heads

test point five 30 25 or less rebuild pump heads

pump dirty pump action required

less than 2 greater than 2 clean and tighten filter

housing

less than 2 greater than 2 clean and tighten sensor

USER GUIDE

Vers ion 1 Flow Meter User Guide

5

Page 10

FLOW METER

Flow Meter Testing

REMOVING THE PUMP HEAD SERVICE COVER

You will need to remove the pump head service cover before you can perform certain

tests with the flow meter. It is not necessary to remove the sensor when you remove

the service cover, but exercise extreme caution when handling and working near the

sensor.

The sensor is not covered by a warranty. The sensor is extremely fragile. Use

caution when handling it.

The sensor is hot. Before touching the sensor make sure it has cooled.

1 Remove the four No. 2 phillips head screws securing the pump head service

cover.

2 Remove the cover, gently flipping the cover over the sensor.

sensor

screw

pump head service cover

6

Flow Meter User Guide

Figure 3: Removing the Pump Head Service Cover

Page 11

CHECKING TEST POINT ONE—OVERALL SYSTEM FLOW

The first test point checks the flow into the entire system.

Note: Always keep the flow meter upright when testing.

1 Attach the exhaust inlet hose to the top port of the flow meter.

2Turn the air pump on.

3 Record the flow meter reading in a data table on page 16.

4Turn the air pump off.

USER GUIDE

Flow Meter Testing

exhaust inlet hose

top port

Figure 4: Test Point One—Overall System Flow

Vers ion 1 Flow Meter User Guide

7

Page 12

FLOW METER

Flow Meter Testing

CHECKING TEST POINT TWO—FILTER FLOW

Test point two is comprised of two tests. The first part of this test checks the air flow

in the entire system except for the filter assembly. The second part of this test checks

the filter assembly for leaks.

AIR FLOW

1 Remove the sensor hose from the filter.

2 Attach the end of the sensor hose to the top port of the flow meter.

3 Attach the short hose, included with your flow meter kit, to the bottom port of the

flow meter.

4 Attach the other end of the short hose to the open fitting on the filter bowl.

Note: The sensor hose was attached to this fitting.

5Turn the air pump on.

6 Record the flow meter reading in a data table on page 16.

If the flow between test point one and test point two is significantly different

(>5L/min.) the filter needs to be cleaned or replaced.

7Turn the air pump off.

sensor hose

(included with the flow meter)

8

Flow Meter User Guide

filter fitting

short hose

filter

flow meter

Figure 5: Test Point Two—Air Flow

Page 13

FILTER ASSEMBLY

1 Remove the filter bowl hose from the filter bowl.

2 Plug the filter bowl fitting with your finger.

3 Plug the exhaust inlet hose with your finger.

4Turn the air pump on.

5 Record the flow meter reading in a data table on page 16.

Note: The flow meter reading should be zero. If the flow is more than

two liters/minute the filter bowl has a significant leak.

6Turn the air pump off.

7 If the filter has a leak, clean and tighten all fittings and test again.

8 Remove the short hose from the filter fitting and the flow meter.

9 Attach the sensor hose to the filter.

10 Attach the filter bowl hose to the filter bowl.

USER GUIDE

Flow Meter Testing

sensor hose

exhaust inlet hose

plug with finger

filter bowl fitting

plug with finger

filter bowl hose

Figure 6: Test Point Two—Filter Assembly

Vers ion 1 Flow Meter User Guide

9

Page 14

FLOW METER

Flow Meter Testing

CHECKING TEST POINT THREE—PUMP INLET PORT, SENSOR SIDE

Test point three tests between the sensor block and the inlet port on the pump head.

The first part of test point three checks the flow through the filter and the sensor

block and the second part of test point three checks the sensor and sensor block for

leaks.

FILTER FLOW

1 Remove the pump inlet hose from the pump.

Note: The pump inlet hose is the wider hose inside the air pump.

2 Attach the pump inlet hose to the bottom port of the flow meter.

3 Attach the short hose, included with your flow meter kit, to the top port of the

flow meter.

4 Attach the other end of the short hose to the pump inlet port.

5Turn the air pump on.

6 Record the flow meter reading in a data table on page 16.

7Turn the air pump off.

short hose

top port

bottom port

pump inlet port

pump inlet hose

Figure 7: Test Point Three—Filter Flow

10

Flow Meter User Guide

Page 15

USER GUIDE

Flow Meter Testing

SENSOR BLOCK ASSEMBLY

The sensor is not covered by a warranty. The sensor is extremely fragile. Use

caution when handling it.

The sensor is hot. Before touching the sensor make sure it has cooled.

1 With the flow meter still attached, remove the sensor hose from the filter.

2 Plug the sensor hose with your finger.

3Turn the air pump on.

4 Record the flow meter reading in a data table on page 16.

Note: The flow meter reading should be zero. If the flow is more than

two liters/minute the sensor has a significant leak.

5Turn the air pump off.

6 If the sensor is leaking, remove the sensor and clean all threads. Clean and

tighten all fittings. Reinstall the sensor and test again.

7 Attach the pump inlet hose to the pump inlet port.

8 Attach the sensor hose to the filter.

sensor

sensor hose

plug with finger

Figure 8: Test Point Three—Sensor Block Assembly

Vers ion 1 Flow Meter User Guide

11

Page 16

FLOW METER

Flow Meter Testing

CHECKING TEST POINT FOUR—LEFT OUTFLOW

Testing the outflow allows you to determine the efficiency of the left pump head.

1 Remove the left outflow hose from the left outflow catch bottle.

2 Attach the left outflow hose to the bottom port of the flow meter.

3Turn the air pump on.

4 Record the flow meter reading in a data table on page 16.

If the flow meter reading is below the testing range, rebuild the pump head.

Pump head rebuild kits (P/N 79190003) are available from Dynojet.

Note: Dynojet recommends rebuilding both pump heads at the same time.

5Turn the air pump off.

6 Replace the left outflow hose into the left outflow catch bottle.

outflow hose

bottom port

left side of air pump

looking from the bottle

side

right side of air pump

looking from the

bottle side

catch bottle

12

Flow Meter User Guide

Figure 9: Test Point Four—Left Outflow

Page 17

CHECKING TEST POINT FIVE—RIGHT OUTFLOW

Testing the outflow allows you to determine the efficiency of the right pump head.

1 Remove the right outflow hose from the right outflow catch bottle.

2 Attach the right outflow hose to the bottom port of the flow meter.

3Turn the air pump on.

4 Record the flow meter reading in a data table on page 16.

If the flow meter reading is below the testing range, rebuild the pump head.

Pump head rebuild kits (P/N 79190003) are available from Dynojet.

Note: Dynojet recommends rebuilding both pump heads at the same time.

5Turn the air pump off.

6 Replace the right outflow hose into the right outflow catch bottle.

left side of air pump

looking from the

bottle side

USER GUIDE

Flow Meter Testing

right side of air pump

looking from the

bottle side

catch bottle

outflow hose

bottom port

Figure 10: Test Point Five—Right Outflow

Vers ion 1 Flow Meter User Guide

13

Page 18

FLOW METER

Flow Meter Testing

INTERPRETING YOUR FLOW METER RESULTS

The results from the flow meter tests indicate what maintenance needs to be

performed on the air pump. Refer to the following table to evaluate the test results. If

the flow meter reading is equal to or lower than the dirty air pump reading, follow the

steps outlined in the action required column of the table. Pump head rebuild kits (P/N

79190003) are available from Dynojet. Refer to the Air Fuel Ratio Module Installation

Guide (P/N 98295110) for rebuild instructions.

Note: Before replacing the pump head service cover be sure to perform any

necessary maintenance procedures.

new or rebuilt

test point

test point one 35 25 or less rebuild pump heads

test point two 28 25 or less clean or replace filter

test point two—filter

assembly

test point three 28 25 or less rebuild pump heads

test point three—sensor

block assembly

test point four 30 25 or less rebuild pump heads

test point five 30 25 or less rebuild pump heads

pump dirty pump action required

less than 2 greater than 2 clean and tighten filter

housing

less than 2 greater than 2 clean and tighten sensor

14

Flow Meter User Guide

Page 19

REPLACING THE PUMP HEAD SERVICE COVER

Before replacing the pump head service cover be sure to perform any necessary

maintenance procedures.

The sensor is not covered by a warranty. The sensor is extremely fragile. Use

caution when handling it.

The sensor is hot. Before touching the sensor make sure it has cooled.

1 Carefully flip the pump head service cover back over the sensor.

2 Secure the pump head service cover using the four No. 2 phillips head screws

removed earlier.

USER GUIDE

Flow Meter Testing

screw

pump head

service cover

sensor

Figure 11: Replacing the Pump Head Service Cover

Vers ion 1 Flow Meter User Guide

15

Page 20

FLOW METER

Flow Meter Testing

DATA TABLES

Use these tables to keep a record of your flow meter readings. Compare your results

with the table on page 14.

test point flow meter readings

1

2(a)

2(b)

3(a)

3(b)

4

5

test point flow meter readings

1

2(a)

2(b)

3(a)

3(b)

4

5

16

Flow Meter User Guide

test point flow meter readings

1

2(a)

2(b)

3(a)

3(b)

4

5

Page 21

Page 22

Loading...

Loading...