Page 1

Page 2

©2015 Dynojet Research, Inc. All Rights Reserved.

Torque Cell Installation Guide for Model 250i/250iP DynoWare RT Dynamometers.

This manual is copyrighted by Dynojet Research, Inc., hereafter referred to as Dynojet,

and all rights are reserved. This manual, and the software described in it, is furnished

under license and may only be used or copied in accordance with the terms of such license.

This manual is furnished for informational use only, is subject to change without notice,

and should not be construed as a commitment by Dynojet. Dynojet assumes no

responsibility or liability for any error or inaccuracies that may appear in this manual.

Except as permitted by such license, no part of this manual may be reproduced, stored in a

retrieval system, or transmitted, in any form or by any means, electronic, mechanical,

recording, or otherwise, without the prior written permission of Dynojet.

The Dynojet logo is a trademark of Dynojet Research, Inc.

Any trademarks, trade names, service marks, or service names owned or registered by any

other company and used in this guide are the property of their respective companies.

Dynojet Research, Inc., 2191 Mendenhall Drive, North Las Vegas, Nevada 89081, USA.

Printed in USA.

Part Number: 98200070 Version 2 (07/2015)

Page 3

T

Chapter 1 Torque Cell Installation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Conventions Used In This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Main Dyno Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Connecting and Disconnecting the Power—Above Ground Dyno . . . . . . . . . . . . 1-3

Connecting and Disconnecting the Power—In Ground Dyno . . . . . . . . . . . . . . . . 1-4

Accessing the Dyno . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Accessing the Dyno—Above Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Accessing the Dyno—In Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Load Cell Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Routing the Load Cell Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Routing the Load Cell Cable—Above Ground Dyno . . . . . . . . . . . . . . . . . . . . . . . 1-12

Routing the Load Cell Cable—In Ground Dyno . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Replacing the Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Replacing the Covers—Above Ground Dyno . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Replacing the Cover—In Ground Dyno . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Chapter 2 Load Cell Calibration

ABLE OF

C

ONTENTS

Load Cell Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Torque Cell Installation Guide for Model 250i/250iP DynoWare RT Dynamometers

i

Page 4

Page 5

C HAPTER 1

The torque cell along with Dynojet Power Core software provides the technician with

the ability to control vehicle RPM or speed at any throttle opening. Through our

exclusive closed-loop software design, the vehicle is automatically held at your predetermined setting. Use the torque cell and Power Core software to measure re al-time

torque, and perform sweep, step and custom load simulation tests.

This document provides instructions for installing the torque cell on a Dynojet

Model 250i/250iP DynoWare RT Motorcycle Dynamometer (dyno) and calibrating

the torque cell using Power Core software. To ensure safety and accuracy in the

procedures, perform the procedures as they are described.

Document Part Number: 98200070

Version 2

Last Updated: 07-01-2015

T

ORQUE

C

ELL INSTALLATION

This chapter is divided into the following categories:

• Introduction, page 1-2

• Main Dyno Power, page 1-3

• Accessing the Dyno, page 1-5

• Load Cell Installation, page 1-9

• Routing the Load Cell Cable, page 1-12

• Replacing the Covers, page 1-14

Torque Cell Installation Guide for Model 250i/250iP DynoWare RT Dynammometers

1-1

Page 6

CHAPTER 1

Introduction

Torque Cell Installation Guide for Model 250i/250iP DynoWare RT Dynammometers

1-2

INTRODUCTION

The torque cell, when added to Dynojet's market leading inertia dynamometer, results

in a complete vehicle performance test. Before installing and calibrating your torque

module, please take a moment to read this guide for installation instructions, features,

and other important information.

CONVENTIONS USED IN THIS MANUAL

The conventions used in this manual are designed to protect both the user and the

equipment.

example of convention description

The Caution icon indicates a potential hazard to the

dynamometer equipment. Follow all procedures

exactly as they are described and use care when

performing all procedures.

The Warning icon indicates potential harm to the

person performing a procedure and/or the

dynamometer equipment.

Bold Highlights items you can select on in the software

interface, including buttons and menus.

TECHNICAL SUPPORT

For assistance, please contact Dynojet Technical Support at 1-800-992-3525, or write

to Dynojet at 2191 Mendenhall Drive, North Las Vegas, NV 89081.

Visit us on the World Wide Web at www.dynojet.com where Dynojet provid es state of

the art technical support, on-line shopping, and press releases about our latest

product lines.

Page 7

TORQUE CELL INSTALLATION

Main Dyno Power

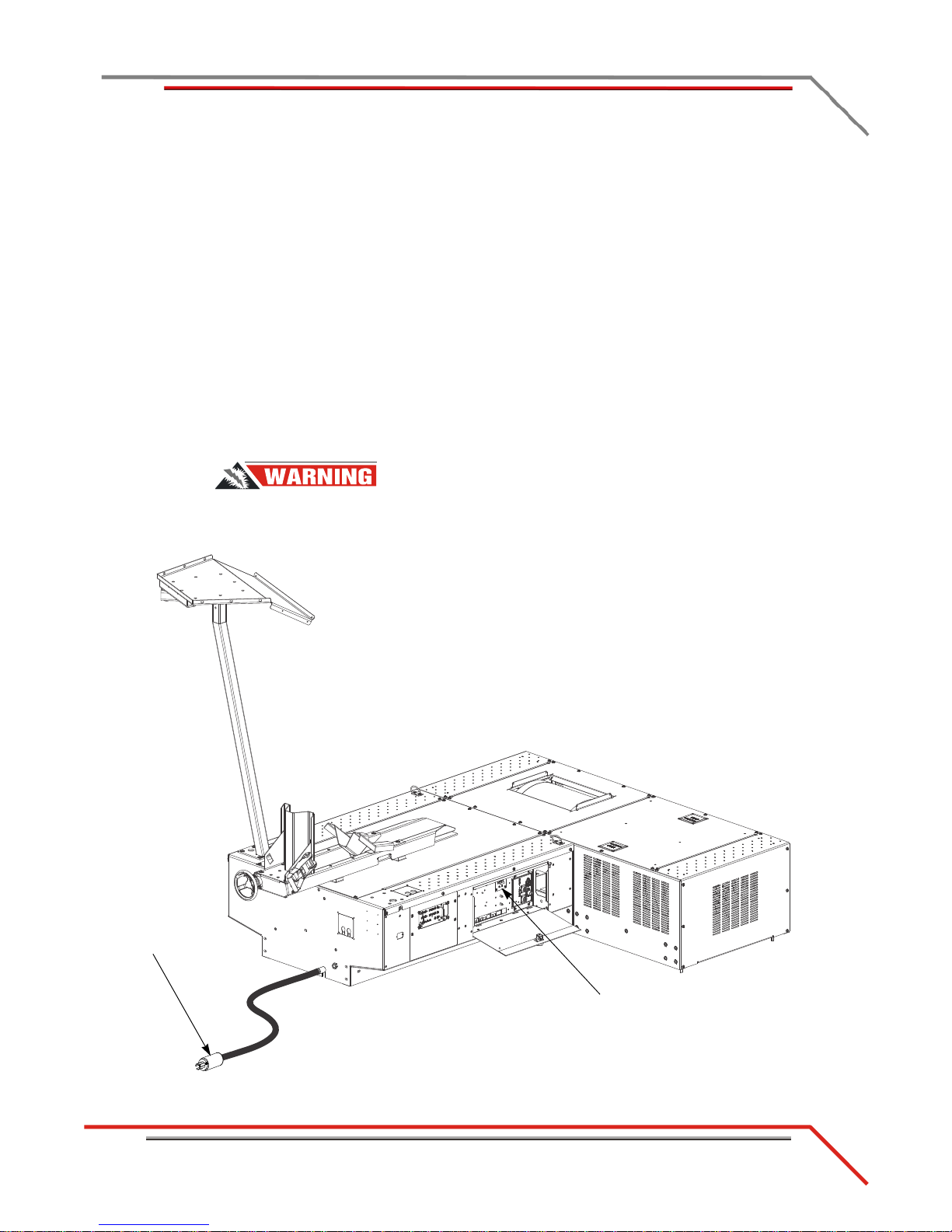

MAIN DYNO POWER

MC153

main breaker

power plug

This section describes how to connect and disconnect the power to both the above

ground and in ground dyno.

CONNECTING AND DISCONNECTING THE POWER—ABOVE GROUND DYNO

Use the following steps to connect and disconnect power to the above ground dyno.

Always turn the power off when connecting and disconnecting cables.

1 Use the main breaker to turn power on and off to the dyno.

The main breaker is located inside the CPI door. When the handle is in the down

position all power into the dyno is turned off.

2 Disconnect the power plug to ensure all power has been removed from the dyno

before performing certain installation procedures.

Components attached to and within the dynamometer operate with

potentially lethal voltages. The power cord must be disconnected from the

power source before servicing electrical components or wiring.

Version 2 Torque Cell Installation Guide for Model 250i/250iP DynoWare RT Dynammometers

Figure 1-1: Main Dyno Power—Above Ground Dyno

1-3

Page 8

CHAPTER 1

Main Dyno Power

Torque Cell Installation Guide for Model 250i/250iP DynoWare RT Dynammometers

1-4

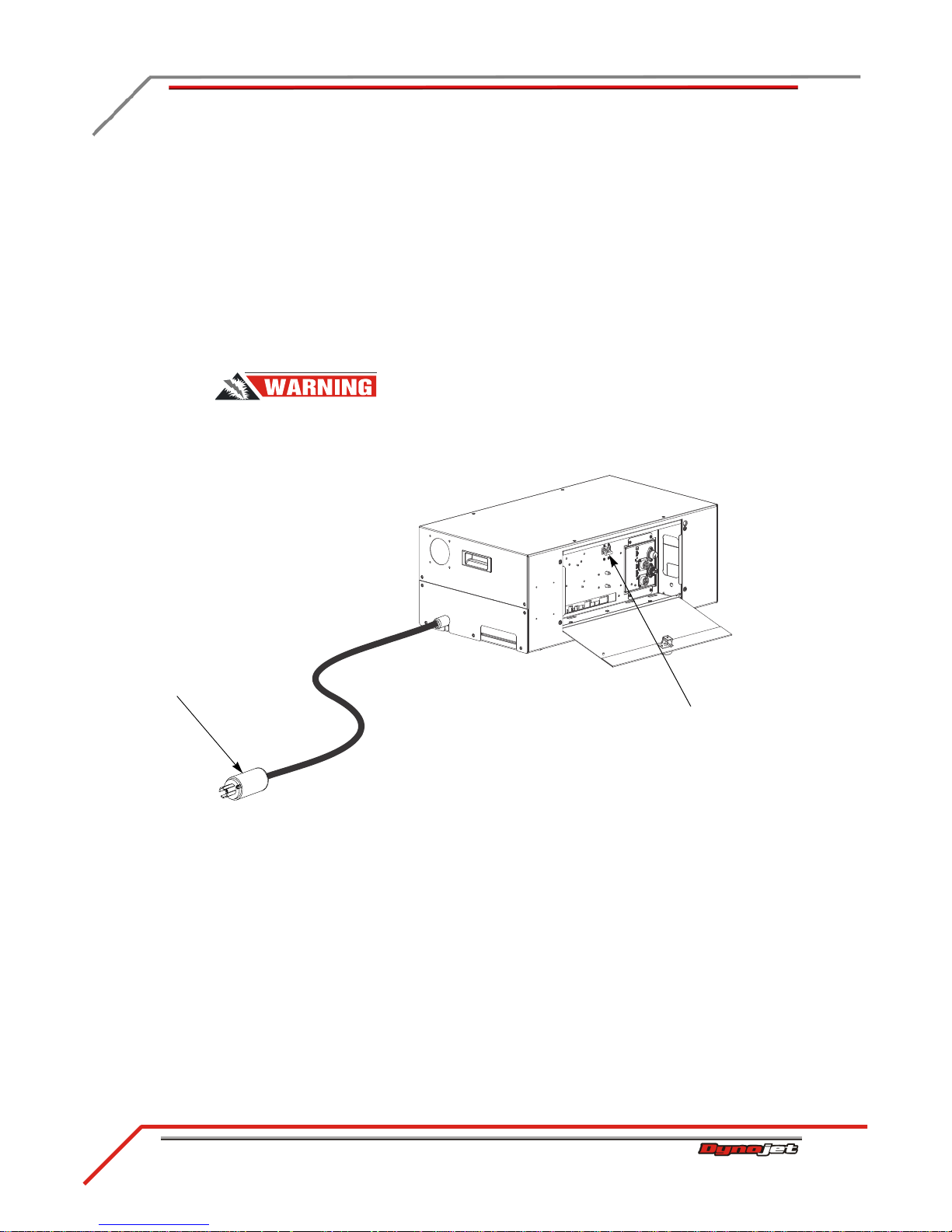

CONNECTING AND DISCONNECTING THE POWER—IN GROUND DYNO

PD231

main breaker

power plug

Use the following steps to connect and disconnect power to the in ground dyno.

Always turn the power off when connecting and disconnecting cables.

1 Use the main breaker to turn power on and off to the dyno.

The main breaker is located inside the CPI door. When the handle is in the down

position all power into the dyno is turned off.

2 Disconnect the power plug to ensure all power has been removed from the dyno

before installing the DynoWare RT electronics.

Components attached to and within the dynamometer operate with

potentially lethal voltages. The power cord must be disconnected from the

power source before servicing electrical components or wiring.

Figure 1-2: Main Dyno Power—In Ground Dyno

Page 9

TORQUE CELL INSTALLATION

Accessing the Dyno

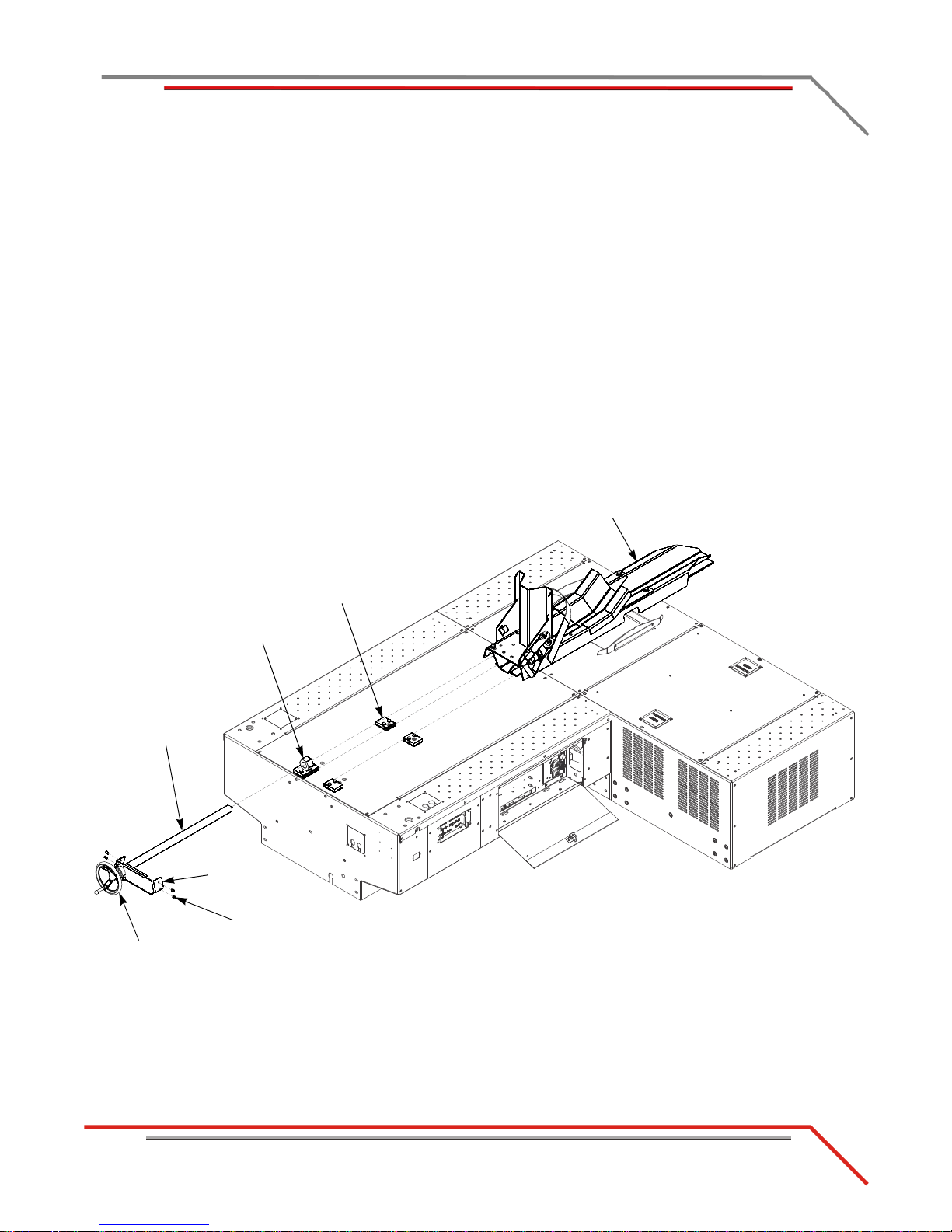

ACCESSING THE DYNO

TC080

hand wheel

carriage screw

screws

carriage clamp

tire carriage

bearing

bracket

nut block

Installing the load cell requires access to the dyno and eddy current brake. This

section will walk you through accessing both the above ground and in ground dyno.

Make sure you have disconnected the power to the dyno before removing the covers.

Refer to “Main Dyno Power” on page 1-3.

ACCESSING THE DYNO—ABOVE GROUND

You will need to remove the tire carriage, center panel, and eddy current brake top

cover in order to route the load cell cable to the eddy current brake driver.

1 Remove the four screws securing the bearing bracket to the tire carriage and set

aside.

2 Using the hand wheel, or the power carriage, unscrew the bearing brac ket and the

carriage screw and set aside.

3 Remove the tire carriage by sliding the carriage under the carriage clamps toward

the back of the dyno and set aside.

Version 2 Torque Cell Installation Guide for Model 250i/250iP DynoWare RT Dynammometers

Figure 1-3: Remove the Tire Carriage

1-5

Page 10

CHAPTER 1

Accessing the Dyno

Torque Cell Installation Guide for Model 250i/250iP DynoWare RT Dynammometers

1-6

4 Remove the two 5/16-inch bolts and washers securing each of the carriage clamps

TC081

screw

center panel

carriage clamp

washer

bolt

shim

nut block

shim

and shims and set aside.

5 Remove the three carriage clamps and shims and set aside.

6 Remove the two 5/16-inch bolts and washers securing the nut block and shim and

set aside.

7 Remove the nut block and shim and set aside.

8 Remove the six 1/4-20 x 5/8-inch pan head screws securing the center panel to

the dyno carriage and set aside.

9 Remove the center panel and set aside.

Figure 1-4: Remove the Center Panel

Page 11

TORQUE CELL INSTALLATION

Accessing the Dyno

10 Remove the six screws securing the eddy current brake top cover and set aside.

brake top cover

11 Remove the brake top cover and set aside.

Figure 1-5: Remove the Brake Top Cover

Version 2 Torque Cell Installation Guide for Model 250i/250iP DynoWare RT Dynammometers

1-7

Page 12

CHAPTER 1

Accessing the Dyno

Torque Cell Installation Guide for Model 250i/250iP DynoWare RT Dynammometers

1-8

ACCESSING THE DYNO—IN GROUND

PD245

brake cover

You will need to remove the eddy current brake pit cover in order to route the load cell

cable to the eddy current brake driver.

1 Remove the four 3/8-16 x 1/8-inch button-head flange screws securing the eddy

current brake pit cover and set aside.

2 Remove the eddy current brake pit cover and set aside.

Figure 1-6: Remove the Brake Pit Cover

Page 13

TORQUE CELL INSTALLATION

Load Cell Installation

LOAD CELL INSTALLATION

bar

This section describes how to remove the existing bar on the eddy current brake and

install the load cell. Use the following instructions for both the above ground and in

ground dynos.

You will need the following part:

part description

load cell and cable, above ground

P/N 76950573

load cell and cable, in ground

P/N 76950759

1 Verify the main dyno power is disconnected. Refer to“Main Dyno Power” on page

1-3 for more information.

2 Remove the two bolts and nuts securing the existing bar on the eddy current brake

and remove the bar. Set the bolts and nuts aside.

Version 2 Torque Cell Installation Guide for Model 250i/250iP DynoWare RT Dynammometers

Figure 1-7: Remove the Existing Bar

1-9

Page 14

CHAPTER 1

Load Cell Installation

Torque Cell Installation Guide for Model 250i/250iP DynoWare RT Dynammometers

1-10

3 Verify the eyelets on the load cell are spaced the same as the bar removed earlier.

distance must be

the same

eyelet

bar

lock nut

load cell cable

load cell

Adjust the load cell spacing by loosening the lock nut and turning the eyelet.

Figure 1-8: Verify Load Cell Spacing

4 Secure the load cell to the mountin g bracket using t he two bolts and nu ts removed

earlier.

Figure 1-9: Install the Load Cell—Above Ground Dyno

Page 15

TORQUE CELL INSTALLATION

Load Cell Installation

Figure 1-10: Install the Load Cell—In Ground Dyno

PD229

install the load cell

(the brake is not

shown for clarity)

Version 2 Torque Cell Installation Guide for Model 250i/250iP DynoWare RT Dynammometers

1-11

Page 16

CHAPTER 1

Routing the Load Cell Cable

Torque Cell Installation Guide for Model 250i/250iP DynoWare RT Dynammometers

1-12

ROUTING THE LOAD CELL CABLE

load cell cable

eddy current brake driver

DynoWare RT

load cell

M158C

air hole in drum

bulkhead

Use the following instructions to identify and route the load cell cable.

cable brief routing description

76950573 load cell and cable—above ground dyno

76950759 load cell and cable—in ground dyno

connects the load cell to the eddy current brake driver

ROUTING THE LOAD CELL CABLE—ABOVE GROUND DYNO

1 Route the load cell cable from the eddy current brake through the air hole in the

drum bulkhead and over to eddy current brake driver.

Make sure the load cell cable is clear of any power cables or hot or rotating objects.

2 Attach the load cell cable to the eddy current brake driver .

3 Secure the load cell cable with a zip tie to the underside of the carriage assembly

bulkhead.

Figure 1-11: Routing the Load Cell Cable—Above Ground Dyno

Page 17

TORQUE CELL INSTALLATION

Routing the Load Cell Cable

ROUTING THE LOAD CELL CABLE—IN GROUND DYNO

load cell

route

communications

cables in designated

conduit

DynoWare RT

main module

eddy current

brake driver

control panel

interface (CPI)

air fuel ratio

module (AFR)

load cell cable

P246

D

1 Open the front panel of the CPI to access the eddy current brake driver.

2 Route the load cell cable from the eddy current brake, through the designated

communications pit conduit, and attach to the eddy current brake driver inside

the CPI.

Note: Be sure to keep the power and communications cables in different pit

conduits.

Version 2 Torque Cell Installation Guide for Model 250i/250iP DynoWare RT Dynammometers

Figure 1-12: Routing the Load Cell Cable—In Ground Dyno

1-13

Page 18

CHAPTER 1

Replacing the Covers

Torque Cell Installation Guide for Model 250i/250iP DynoWare RT Dynammometers

1-14

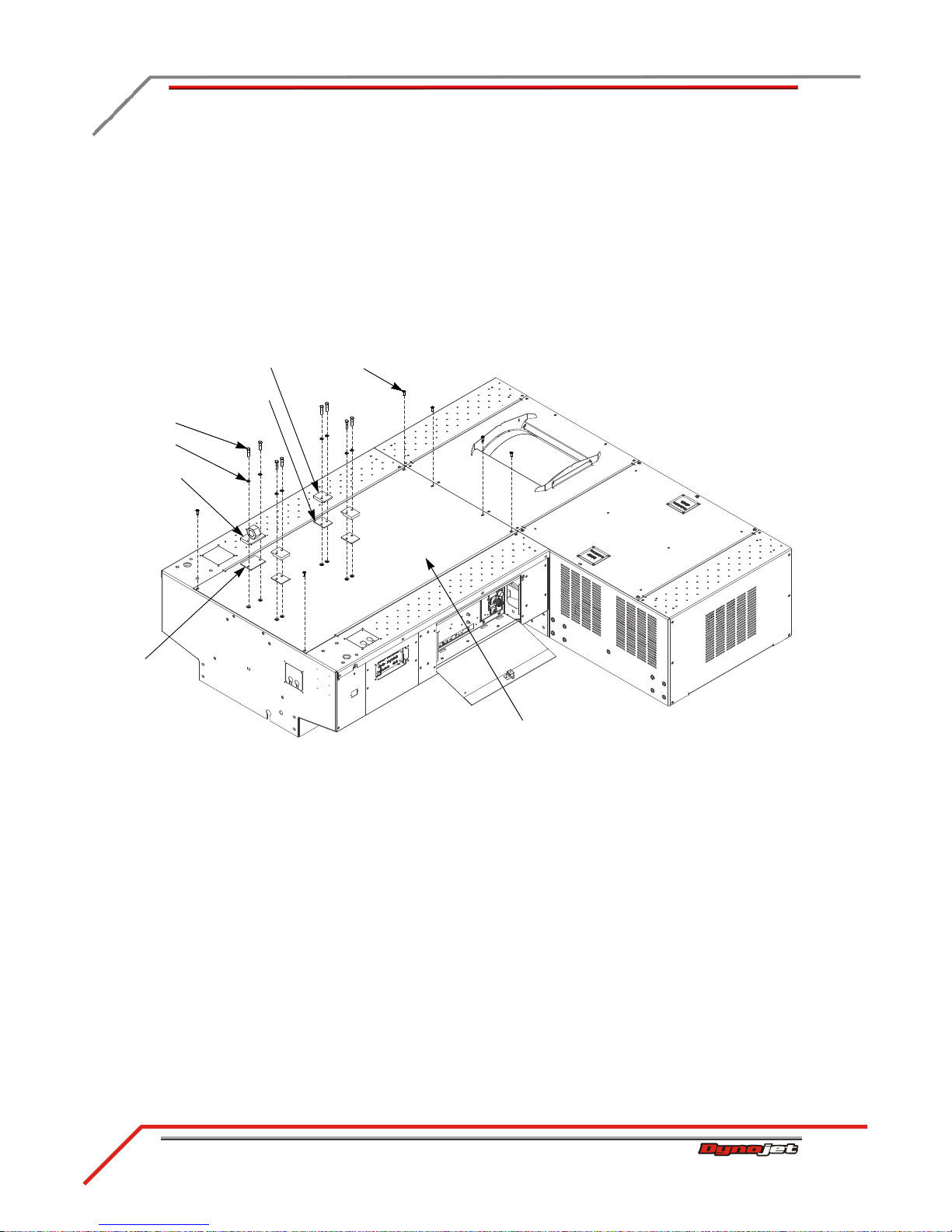

REPLACING THE COVERS

TC081

screw

center panel

carriage clamp

washer

bolt

shim

nut block

shim

Before replacing the covers, verify the load cell is installed and the load cell cable is

routed to the eddy current brake driver.

Before replacing the eddy current brake top cover, be sure to calibrate your load cell.

Refer to “Load Cell Calibration” on page 2-2.

REPLACING THE COVERS—ABOVE GROUND DYNO

1 Secure the center panel to the dyno carriage using the six 1/4-20 x 5/8-inch pan

head screws removed earlier.

2 Secure the nut block and shim using the two 5/16-inch bolts and washers removed

earlier.

3 Secure each carriage clamps and shim using two 5/16-inch bolts and washers

removed earlier,

Figure 1-13: Replace the Center Panel

Page 19

TORQUE CELL INSTALLATION

Replacing the Covers

4 Starting from the back of the dyno, slide the carriage under the carriage clamps.

TC080

hand wheel

carriage screw

screws

carriage clamp

tire carriage

bearing

bracket

nut block

5 Slide the carriage screw, bearing bracket, and the hand wheel t oward the nut block

until the carriage screw is touching the nut block.

6 Using the hand wheel, or the power carriage, screw the carriage through the nut

block and into the screw support bracket.

7 Secure the bearing bracket to the carriage using four screws removed earlier.

Version 2 Torque Cell Installation Guide for Model 250i/250iP DynoWare RT Dynammometers

Figure 1-14: Replace the Tire Carriage

1-15

Page 20

CHAPTER 1

Replacing the Covers

Torque Cell Installation Guide for Model 250i/250iP DynoWare RT Dynammometers

1-16

8 Secure the eddy current brake top cover using the six bolts removed earlier.

EB242

eddy current

brake cover

Note: Before replacing the eddy curren t brake top cove r, be sure to calibrate your

load cell. Refer to “Load Cell Calibration” on page 2-2.

Figure 1-15: Replace the Eddy Current Brake Top Cover

Page 21

TORQUE CELL INSTALLATION

Replacing the Covers

REPLACING THE COVER—IN GROUND DYNO

PD245

brake cover

Before replacing the eddy current brake pit cover, be sure to calibrate your load cell.

Refer to “Load Cell Calibration” on page 2-2.

Secure the eddy current brake pit cover using the four screws removed earlier.

Figure 1-16: Replace the Brake Pit Cover

Version 2 Torque Cell Installation Guide for Model 250i/250iP DynoWare RT Dynammometers

1-17

Page 22

Page 23

C HAPTER 2

This chapter will walk you through calibrating the load cell on both the above ground

and in ground dynos. To ensure safety and accuracy in the procedures, perform the

procedures as they are described.

L

OAD

C

ELL

C

ALIBRATION

Torque Cell Installation Guide for Model 250i/250iP DynoWare RT Dynamometers

2-1

Page 24

CHAPTER 2

Load Cell Calibration

Torque Cell Installation Guide for Model 250i/250iP DynoWare RT Dynamometers

2-2

LOAD CELL CALIBRATION

This section provides instructions for calibrating the load cell. Follow the direct ions on

the screen exactly. Failure to perform the directions accurately will result in improper

torque values.

You will need the following parts:

part description part description

weight, 25 pounds (4)

P/N 35430899

1 Verify the dyno is connected to power. Refer to “Main Dyno Power” on page 1-3.

2 Double-click the Power Core program icon.

3Click Dyno Control from the Application Launcher.

4 Verify you are connected to the DynoWare RT main module.

Note: For more information on connecting to the dyno electronics, refer to the

Power Core Quick Start Guide (on your Power Core CD or at www. dynojet.com) or

the Power Core Online Help.

5 From the Configuration ribbon, click Load Cell Calibration .

6 Remove the calibration arm and mass if it is installed.

7 Release the dyno brake. Make sure the drums are free to rotate.

Note: There should not be anything resting on the eddy current brake or the dyno

drum during this procedure.

8Click Next to zero the connected torque cell.

calibration arm assembly

P/N 61319001

Figure 2-1: Zero Calibration Window

Page 25

LOAD CELL CALIBRATION

Load Cell Calibration

9 Using the drop-down arrow, set the index to zero.

bolt pattern closest to

the end of the

calibration arm

bolt pattern near the

center of the

calibration arm

Note: Powersports Dynos have one load cell, leave the index set to zero.

10 Enter the calibration weight. This value is stamped into the calibration arm.

Figure 2-2: Calibration Mass Window

Enter the calibration number stamped near the bolt pattern at the end of the

calibration arm in the Mass box. If you do not have enough room to use the bolt

pattern closest to the end of the calibration arm, use the number stamped near the

bolt pattern in the center of the arm.

Note: Dynojet recommends you secure the calibration arm using the bolt pattern

closest to the end of the arm unless space constraints in your dyno room do not

allow you to.

Figure 2-3: Calibration Arm Number

Version 2 Torque Cell Installation Guide for Model 250i/250iP DynoWare RT Dynamometers

2-3

Page 26

CHAPTER 2

Load Cell Calibration

Torque Cell Installation Guide for Model 250i/250iP DynoWare RT Dynamometers

2-4

11 Install the calibration arm and weights using the bolts at the end of the calibration

T 074M

weights

weight support pin

secure arm to brake by

tightening handle

arm.

Note: If you do not have enough room to use the bolt pattern closest to the end of

the calibration arm, use the bolt pattern in the center of the arm. Refer to Figure

2-6 for above ground dynos and Figure 2-7 for in ground dynos.

11a Secure the calibration arm to the eddy current brake by tightening the bolt

using the handle.

11b Gently place the weights on the calibration arm.

Note: Verify the calibration arm is not contacting the cover.

The calibration weights are very heavy. The weights must be set on the

arm gently or you could damage the load cell.

Figure 2-4: Install the Calibration Arm and Weights Using the Bolt Pattern Closest to the End—Above Ground Dyno

Page 27

LOAD CELL CALIBRATION

Load Cell Calibration

Figure 2-5: Install the Calibration Arm and Weights Using the Bolt Pattern Closest to the End—In Ground Dyno

T076M

weights

weight support pin

secure arm to brake by

tightening handle

Version 2 Torque Cell Installation Guide for Model 250i/250iP DynoWare RT Dynamometers

2-5

Page 28

CHAPTER 2

Load Cell Calibration

Torque Cell Installation Guide for Model 250i/250iP DynoWare RT Dynamometers

2-6

If you do not have enough room to use the bolt pattern closest to the end of the

T075M

weights

weight support pin

secure arm to brake by

tightening handle

calibration arm, use the bolt pattern in the center of the arm as shown in

Figure 2-6 for above ground dynos and for Figure 2-7 in ground dynos.

Figure 2-6: Install the Calibration Arm and Weights Using the Bolt Pattern in the Center—Above Ground Dyno

Page 29

LOAD CELL CALIBRATION

Load Cell Calibration

Figure 2-7: Install the Calibration Arm and Weights Using the Bolt Pattern in the Center—In Ground Dyno

T077M

weights

weight support pin

secure arm to brake by

tightening handle

Version 2 Torque Cell Installation Guide for Model 250i/250iP DynoWare RT Dynamometers

2-7

Page 30

CHAPTER 2

Load Cell Calibration

Torque Cell Installation Guide for Model 250i/250iP DynoWare RT Dynamometers

2-8

12 With the calibration arm and weights secured, click Next to calibrate.

13 Remove the calibration arm and weights and click Finish.

Figure 2-8: Finish Calibration Window

14 Confirm the calibration was successful.

For more information refer to the Power Core Online Help.

Page 31

Loading...

Loading...